Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Acta Structilia

On-line version ISSN 2415-0487

Print version ISSN 1023-0564

Acta structilia (Online) vol.30 n.2 Bloemfontein 2023

http://dx.doi.org/10.38140/as.v30i2.7326

REVIEW ARTICLE

Artificial Intelligence technology applications in building construction productivity: a systematic literature review

Oluseyi AdebowaleI; Justus AgumbaII

IResearch Fellow, Department of Building Sciences, Tshwane University of Technology, Pretoria, South Africa. Email: <adebowaleoluseyi@gmail.com>, ORCID: https://orcid.org/0000-0003-1381-5658

IIDepartment of Building Sciences, Tshwane University of Technology, Pretoria, South Africa. Email: <AgumbaJN@tut.ac.za>, ORCID: https://orcid.org/0000-0003-1077-1186

ABSTRACT

Artificial Intelligence (AI) holds the potential to revolutionise the construction industry, by enhancing productivity and addressing the challenges posed by a skills shortage. Historically resistant to technological innovation, the construction sector lags behind other industries that have embraced innovative technologies to boost productivity. This study investigates AI technologies that can be used to improve construction productivity, as well as the barriers impeding the widespread adoption of AI in the construction sector. The research adheres to the Preferred Reporting Items for Systematic Reviews and Meta-Analysis (PRISMA) guidelines. A systematic review of scholarly journal articles and conference papers sourced from the Scopus database was conducted, employing relevant screening criteria to select the most pertinent sources aligned with the research objectives. Although AI applications in building construction are still emerging, AI technologies have been successfully deployed in various aspects of building construction. These include floor slab construction, steelwork, safety and risk management, materials management, and labour handling in multi-story buildings. The adoption of AI in the construction sector faces several challenges, including technical complexities, managerial and organisational barriers, economic justifications, and a shortage of AI-proficient talent. Drawing insights from this study, construction stakeholders can make informed decisions regarding AI investments and their specific areas of application within building construction.

Keywords: Artificial intelligence, building construction, productivity, systematic literature review, technology

ABSTRAK

Kunsmatige Intelligensie (KI) het die potensiaal om die konstruksiebedryf te revolusioneer deur produktiwiteit te verbeter en die uitdagings aan te spreek wat deur 'n tekort aan vaardighede ervaar word. Histories het die konstruksiesektor weerstand gebied teen tegnologiese innovasie en is agter ander nywerhede wat innoverende tegnologieë aangeneem het om produktiwiteit te bevorder. Hierdie studie ondersoek kunsmatige intelligensie-tegnologieë wat gebruik kan word om konstruksieproduktiwiteit te verbeter. Dit ondersoek ook die struikelblokke wat die wydverspreide aanvaarding van KI in die konstruksiesektor belemmer. Die navorsing voldoen aan die Voorkeurverslag-items vir sistematiese resensies en meta-analise (PRISMA)-riglyne. 'n Sistematiese oorsig van vaktydskrifartikels en konferensiereferate afkomstig van die Scopus-databasis is uitgevoer, met die gebruik van relevante siftingskriteria om die mees pertinente bronne te kies wat in lyn is met die navorsingsdoelwitte. Alhoewel KI-toepassings in geboukonstruksie steeds ontwikkel, is KI-tegnologieë suksesvol in verskeie aspekte van geboukonstruksie ontplooi. Dit sluit in vloerbladkonstruksie, staalwerk, veiligheids- en risikobestuur, materiaalbestuur en arbeidshantering in meerverdiepinggeboue. Die aanvaarding van KI in die konstruksiesektor staar verskeie uitdagings in die gesig, insluitend tegniese kompleksiteite, bestuurs- en organisatoriese hindernisse, ekonomiese regverdigings, en 'n tekort aan KI-vaardige talent. Uit hierdie studie kan konstruksiebelanghebbendes ingeligte besluite neem rakende KI-beleggings en hul spesifieke toepassingsgebiede binne geboukonstruksie.

1. INTRODUCTION

Due to the growing knowledge of the significant contribution of the construction industry to a thriving economy, productivity growth is becoming more important to the industry's stakeholders and policymakers (Sidorova et al., 2021: 95; Fadejeva & Melihovs, 2010: 64). The volume of investigation on understanding productivity gives rise to different perspectives, resulting in a wide range of propositions. The significance of the construction sector to economic performance continues to resonate in construction literature (Palikhe, Kim & Kim, 2019: 429; Karimi, Taylor & Goodrum, 2017: 370). There is a growing awareness that productivity growth is at the centre of improving the sector's contribution to gross domestic product (GDP), which has engendered considerable academic inventions in the form of investigations into measures to improve construction productivity (Jalal & Shaor, 2019: 389). There are serious concerns regarding the current state of construction productivity, especially compared to other economy-dependent industries (Sidorova et al., 2021: 93). This triggers a plethora of research in developing (Agrawal & Halder, 2020: 569; Hiyassat, Hiyari & Sweis, 2016: 138) and developed (Karimi et al., 2017: 368; Durdyev & Mbachu, 2011: 18) countries. Most of the current productivity research investigated critical factors that hinder construction productivity growth. Some researchers leveraged the established critical productivity influencing factors to develop system dynamics that could engender productivity growth (Jalal & Shaor, 2019: 385; Palikhe et al., 2019: 427; Nasirzadeh & Nojedehi, 2013: 903). Some studies argue for the need to use models to predict labour productivity, in order to enhance managerial decisions (Tsehayae & Fayek, 2016: 203; Jang et al., 2011: 92). Mlybari (2020: 207) adopted computing techniques to predict construction labour productivity (CLP). Arising from these studies and many others are contributions to improve construction productivity. However, the global construction industry's productivity has remained unsatisfactory for decades (Thomas & Sudhakumar, 2013: 109). A recent study in ten European countries and in the United States reported the top-performing industries in terms of total factor productivity growth (Sidorova et al., 2021: 95). While telecoms, agriculture, and manufacturing record total factor productivity growth, construction has a negative total factor productivity growth.

Traditional construction methods no longer deliver competitive results, necessitating the need for advanced technological tools to meet the sector's productivity demands (Yang et al., 2019: 8). The construction sector is one of the least digitised industries, and there is an age-long culture of resistance to change (Young, Panthi & Noor, 2021: 306; Chen, Ho & Su, 2020: 115; Oleinik et al., 2019: 4). It is against this background that the European Union (EU) proposes a gradual transition of the industry from traditional to digital construction, by combining Building Information Modeling (BIM) with other digital technologies (Locatelli et al., 2021: 18; Delgado et al., 2019: 9). Insufficient digital expertise and low technology acceptance have been partly associated with the industry's resistance to change (Mostafa & Hegazy, 2021: 12; Wei, Zhang & Li, 2019: 7; Yan et al., 2019: 4; Yu et al., 2019: 7; Nikas, Poulymenakou & Kriaris, 2007: 634). Due to the benefits technology offers, the construction sector has recently begun to adopt innovative practices such as BIM and artificial intelligence (AI) to address its long-standing productivity issue. AI has the potential to improve construction operations (Abioye et al., 2021: 12; Chien et al., 2020: 2731). It has been used in other industries to address various challenges to support decision-making for real-world problems (Rao et al., 2022: 283). For example, in the manufacturing industry, the advent of the fourth industrial revolution (Industry 4.0) is geared toward automation, data-driven technologies, and the application of advanced AI techniques. This has resulted in significant process improvements, cost efficiencies, reduced production times, and improved safety, and contributes to the sustained improvement in the performance of organisations. This suggests the need for the construction sector to consolidate its effort to promote innovations such as AI in the delivery of construction projects.

Different scholars have offered several construction productivity improvement interventions, including the development of qualitative and qualitative models (Tsehayae & Fayek, 2016: 203; Jang et al., 2011: 92); systems dynamic (Palikhe et al., 2019: 427); causal layered analysis (Adebowale & Agumba, 2023b: 1-24), as well as BIM and other smart technologies (Abioye et al., 2021: 1; Chien et al., 2020: 2730). Considerable improvement has been recorded in the field of construction productivity, due to recommendations arising from these studies. Although AI is being increasingly applied in prefabricated construction (Chang & Zhao, 2020: 7706; Wang & Lian, 2020: 1-4; Smirnova, 2018: 1991); safety and risk management (Locatelli et al., 2021: 1-33; Liu & Tian, 2019: 764-771; Lee & Yi, 2017: 1-15; Zou, Kiviniemi & Jones, 2017: 66-76), as well as project monitoring (Chen et al., 2020: 1-9; Wang & Cheng, 2020: 162), limited studies investigate AI technologies in building construction. Such studies could create awareness with respect to productivity-dependent AI technologies, which has theoretical implications for further investigation. Awareness of productivity-dependent AI technologies in building construction could foster synergy between academics and industry practitioners in terms of taking the research outcome to the next level that can facilitate implementation. While the existing studies have made significant contributions to the field of AI in construction, AI for improving productivity in the building sector is still evasive. The objectives of this study are twofold. First, to investigate AI technologies that can be leveraged to improve productivity in building construction and, secondly, to identify major challenges currently hindering the adoption of AI technologies in the construction sector. These objectives are achieved through a systematic literature review that presents scientific evidence from AI technologies applicable to building construction.

2. LITERATURE REVIEW

2.1 Construction productivity

Efforts to understand the concept of productivity have led to different perspectives on the meaning of productivity. A single definition of productivity is yet to be established, as the concept is usually based on the unique project control systems relevant to each organisation (Nasir et al., 2014: 597). The Organization for European Economic Cooperation (OECC) later introduced a formal definition of productivity and defined productivity as a quotient obtained by dividing the output by one of the factors of production (Jarkas & Bitar, 2012: 816). The American Association of Cost Engineers added their contribution, by expressing productivity as a relative measure of production efficiency against an established benchmark that accounts for tasks performed against a previously established standard (Nasirzadeh & Nojedehi, 2013: 907). The manufacturing sector has widely expressed productivity as the ratio of output to input, broadly consistent with the typical definition in many industries, including construction. This study evaluated productivity performance on contractors' ability to deliver construction projects within the constraints of cost, quality, and time defined in the project documents. Studies have reported that many construction projects are not delivered within these objectives (Raykar & Ghadge, 2016: 24). The study sought to establish possible AI technologies that can be deployed in building construction to improve both the performance of these project objectives and, ultimately, construction project productivity.

Many issues have been identified as the major causes of poor productivity in different countries. Delay in responding to requests for information was a major barrier to site productivity in Kuwait, Bahrain, and Oman (Jarkas, 2015: 97; Jarkas, Al Balushi & Raveendranath, 2015: 336; Jarkas & Bitar, 2012: 816). A similar finding was obtained in a study by Dai and Goodrum (2011: 693) in the United States. The study reported late response to drawing related information as one of the significant challenges contributing to low productivity on construction job sites. Challenges associated with workers' supervision have been predominantly reported in most of the studies, suggesting that supervision is a major issue preventing productivity growth. Developed and developing countries are confronted with the problem of job supervision on job sites. In Australia, poor supervision was reportedly a major barrier to productivity growth (Loosemore, 2014: 253); United States (Dai & Goodrum, 2011: 692); New Zealand (Durdyev & Mbachu, 2011: 22); Turkey (Kazaz, Manisali & Ulubeyli, 2008; 98); United Kingdom (Chan & Kaka, 2007: 574), and Canada (Hanna & Heale, 1994: 665). Similarly, developing countries such as Nigeria (Afolabi et al., 2018: 687); Uganda (Alinaitwe, Mwakali & Hansson, 2007: 176), and Thailand (Makulsawatudom, Emsley & Sinthawanarong, 2004: 6) are reportedly affected by inadequate supervision. Skill shortage is also a major challenge to construction productivity. The problem of skilled labour is critical to construction productivity as an inadequately skilled workforce confronts countries such as Bahrain, Kuwait, and Yemen (Alaghbari, Al-Sakkaf & Sultan, 2019; 91; Jarkas, 2015: 108; Jarkas & Bitar, 2012: 820). Studies in Singapore (Hwang, Zhu & Ming, 2017: 12), Nigeria (Odesola & Idoro, 2014: 107), Spain (Robles et al., 2014: 1018), New Zealand (Durdyev & Mbachu, 2011: 33), and Uganda (Alinaitwe et al., 2007: 176) have also reported poor productivity arising from the problem of skills for construction project delivery.

The current poor productivity in construction is a serious concern for construction stakeholders (Cai et al., 2020: 6; Poh, Ubeynarayana & Goh, 2018: 378). The industry's productivity is reportedly lower than most of the industries (Yang et al., 2019: 6). The McKinsey Global Institute (2017: 1) reported that labour productivity in construction has grown at only 1% annually over the past two decades, which is much lower than manufacturing. Out of nineteen construction projects, eleven are behind schedule, and fourteen are over budget (Omran, Abdalrahman & Pakir, 2012: 63). Performance has become more of a concern, given the industry's contribution to micro- and macroeconomic performance (Adebowale & Agumba, 2023a; Adebowale, 2014: 45). Improving global construction productivity has an upside potential of $1.6 trillion, equivalent to a 2% global GDP increase (Barbosa, Woetzel & Mischke, 2017: 5). A steady increase in productivity in construction is now an essential aspect of project delivery (Buitrago et al., 2016: 8). The industry's relatively conservative stance on adopting data-driven technology innovations has been cited as a pivotal contributor to slow growth (Busta, 2016: 1). In high-rise construction, there are even more concerns about the risks associated with the vertical transport of workers, materials and equipment, and the assembly of heavy objects, particularly in steel structures (Cai et al., 2018: 309).

The United Nations (UN) population estimates assume that the world population is expected to grow from 7.97 billion in 2022 to roughly 8.5 billion in 2030, and 9.7 billion in 2050 (United Nations, 2019). The need for the construction of high-rise buildings will continue to increase with population growth and the scarcity of land for construction projects. Construction difficulties increase with increasing building height, which is one of the productivity barriers in the building construction sector. This contributes to the growing advocacy of advanced technologies that promote safe working conditions which, ultimately, increase productivity performance (Cai et al., 2020: 6). For the industry to meet its current and future needs for sustainable building infrastructure, adopting innovative technologies for construction operations is more critical than ever (Gharbia et al., 2020: 12). As the construction sector has enormous potential, the industry must recognise the potential of innovative technologies (Hosseini et al., 2018: 237; Kim, Soibelman & Grobler, 2008: 558). There is a significant opportunity for the industry to realise its potential and adopt new technological solutions to unlock higher productivity and transfer performance results to the broader economy (Fang et al., 2018: 62; Choi et al., 2020: 8).

2.2 Artificial intelligence technologies beneficial to building construction

2.2.1 Optimisation

Prefabrication methods are increasingly used to improve productivity in construction (Chen et al., 2020: 8). An effective decision support tool was developed for project members to evaluate design methods for concrete buildings in the early prefabrication design stages. The decision tool effectively solves various problems of the whole project life cycle (Zavadskas et al., 2012: 516). Decision support is divided into strategic and tactical levels (Chen et al., 2019: 317). The strategic layer assesses prefabrication feasibility against a concise list of pre-fab attributes such as project characteristics, site conditions, market attributes, and local regulations. The tactical level assesses the extent to which components should be prefabricated for a given project based on sustainable performance attributes, assuming the outcome of the previous strategic level is to proceed with prefabrication (Smirnova, 2018: 1993).

Mathematical models have been adopted to optimise construction operations, by determining the total time required for residential building construction using prefabricated elements (Oleinik et al., 2019: 4). Considering substructure and superstructure, the average number of prefabricated elements erected per day was 22-23 elements. An optimisation model for safety in prefabricated construction has been achieved (Chang & Zhao, 2020: 7706). Essential influencing factors and prefabricated construction safety accident trees were established. The scheduling problem of prefabricated buildings from the time/robustness trade-off optimisation perspective was studied (Wang & Lian, 2020: 4). A bi-objective multi-mode resource-constrained project scheduling model and a non-dominated genetic algorithm were developed. The model and algorithm can guide construction managers to make informed decisions and invest resources economically.

Due to the complexity and responsibility associated with high-rise buildings, designers need more time to develop, analyse, and compare many design options. A computer application that significantly increases designers' productivity and reduces design complexity was developed (Vasilkin, 2018: 5). High-rise projects involve many simultaneous activities that must be carried out on different floors above ground (Yazdi et al., 2019: 8). Completed floors are typically used for material storage to provide usable space to support construction activities. Frequent vertical material movements cause delays, while overtime can mean additional site work with correspondingly reduced productivity. A binary mixed-integer linear programming was formulated to optimise the use of material storage cells on lower completed floors (Huang & Wong, 2019: 14). This would minimise the overall material handling and transport costs, considering both horizontal and vertical movement paths. Delays in delivering materials and labourers to work floors were addressed through the optimisation of flexible lift processes in high-rise buildings (Yazdi et al., 2019: 8). A holistic model, which identifies the optimum operational plan for the lift systems, was developed. A computer tool has been used to calculate and verify the loads on slabs and shores (Buitrago et al., 2016: 7). This was needed, in order to obtain optimal construction processes for multi-storey buildings with in situ castings. Exact and heuristic methods were used to search for optimal solutions. The exact method was suitable for buildings with fewer than four floors; heuristic methods can be applied to obtain the optimal processes in buildings with more than four floors.

2.2.2 Automation and robotics

Automation and robotics can be considered old and new to the construction field. The early research in the field can be traced back to the 1970s and 1980s, and the technology has been used to improve construction productivity since the late quarter of the 20th century (Yang et al., 2019: 8; Paulson & Boyd, 1985: 9362). Over the past decades, industrial robots have helped open up new application areas of robotics in on-site building construction (Bilal & Oyedele, 2020: 12). Automation and robotics have contributed to improving safety and productivity in construction (Vaha et al., 2013: 169). Robotic systems are suitable for performing dangerous and repetitive construction operations (Yang et al., 2019: 8). Robot-based automation systems' high accuracy and repeatability resulted in high-quality performance and improved productivity compared to labourers (Jung, Chu & Hong, 2013: 71). Automation and robotics technology has the potential to improve construction productivity and solve challenges related to labour shortage and safety risks, especially in high-rise buildings (Cai et al., 2018: 7). The systems are designed to stabilise the construction process and improve productivity in high-rise buildings, by establishing a comfortable working environment (Cai et al., 2018: 310).

Robotic technologies are increasingly used in high-rise buildings (Chu et al., 2013: 52). Robotic automation of steel beam assembly was achieved by developing a robotic beam-assembly system. The system consists of a robotic bolting device performing beam-assembly work. A robotic transport mechanism, which transports the robotic bolting device to target bolting positions around a building under construction, was achieved (Jung et al., 2013: 68). Climbing robots with considerations for locomotive and adhesion mechanisms are used in construction (Chu et al., 2010: 639). Despite its benefits, the construction sector has witnessed low practical implementation of automation and robotics. Determining the key development priorities for automation and robotics technologies in high-rise buildings is essential to improve implementation (Cai et al., 2018: 309). The priorities should include prefabricated component assembly, facade construction and maintenance, quality inspection, safety control of work performed at high elevations, construction equipment, and steel works.

An autonomous mobile robotic solution for building task execution was achieved, using onboard sensing (Gawel et al., 2019: 2304). The system is based on the comprehensive integration of software solutions on a mobile platform to extract tasks from building plans. Automated bricklaying in building construction has been demonstrated (Shutin, Malakhov & Marfin, 2018: 3). The system improved bricklaying accuracy and productivity in building construction. A networked robotic camera system can automatically monitor construction details and allows remote human experts to zoom in on features as construction proceeds (Song et al., 2005: 174). The system helps archive the construction process timely and reduces travel costs. Digital building models in building designs can provide extensive semantic and geometric knowledge of buildings (Follini et al., 2020: 8).

2.2.3 Machine learning

Machine learning (ML) is a sub-field of AI, where a computer observes a given data set and generates a model based on the input data to solve problems (Baduge et al., 2022: 18). ML is different from traditional programming. In traditional programming, rules are coded in a computer language without explicit learning from the data. By contrast, ML uses data to generate predictive models, which are then used for predictions with unseen data (Baduge et al., 2022: 9). ML has been used for health and safety monitoring (Oyedele et al., 2021; Poh et al., 2018: 377). Despite its success in other fields, it has yet to be widely used in construction (Cai et al., 2020: 9). ML has been used to develop leading indicators that classify construction sites following their safety risk in construction projects (Poh et al., 2018: 384). Frequent electrical injuries in construction were considered, in order to develop machine-learning algorithms to quantify and model the causes of injuries (Oyedele et al., 2021: 8). ML has also been used to predict production time, using real-time radio frequency identification data in industrialised building construction (Mohsen, Mohamed & Al-Hussein, 2022: 3). The production cycle time in industrial building construction was estimated. A mean absolute percentage error and correlation coefficient of 11% and 0.80 was achieved between the actual and predicted values. An algorithm based on ML was used to build engineering safety risk assessment and early warning mechanisms (Liu & Tian, 2019: 769). A safety evaluation index system was established for the construction sites of common accidents, and the analytic hierarchy process determined the index weight.

2.2.4 Natural language processing

Natural language processing (NPL) has been applied to overcome documentation issues in building construction (Locatelli et al., 2021: 12). It aims to represent human language through a formal and machine-readable language (Young et al., 2018: 307). The AI solution has the potential to enhance information flow, thus supporting effective and efficient management of construction projects (Di Giuda et al., 2020: 99). The application of NPL is prevalent in construction safety and risk management (Locatelli et al., 2021: 19). The system has been used to analyse the uncertainty of bidding documents in terms of predicting risks during the bidding process of construction projects (Lee & Yi, 2017: 8; Zou et al., 2017: 69). It is also useful in both analysing construction site accidents, preventing the recurrence of similar accidents, and enhancing scientific risk control plans (Baker, Hallowell & Tixier, 2020: 9; Tixier et al., 2017: 42).

2.2.5 Image-based analysis

Computer vision and image-based learning techniques are recently considered to allow computers to automatically analyse images and videos (Yan et al., 2019: 6). Researchers have investigated advanced image-based methods in construction with potential applications to improve workers' safety, monitor activities progress, and assess structural damages (Mostafa & Hegazy, 2021: 12). Most of the research efforts were geared toward workers' detection and tracking to identify major safety concerns such as the absence of hard hats, safety harnesses, and awkward postures (Wei et al., 2019: 6; Yan et al., 2019: 9; Yu et al., 2019: 12). Besides its health and safety benefits, image-based analysis has great potential to monitor the progress of activities on construction sites (Deng et al., 2020: 10; Luo et al., 2020: 13; Kazemian et al., 2019: 96) and assess damages in building components (Chen et al., 2020: 9; Wang & Cheng, 2020: 171).

2.3 Challenges of implementing artificial intelligence technologies in building construction

Although the practical needs of AI in construction keep rising, the on-site application of AI technologies still needs to be improved (Delgado et al., 2019: 6). Its limited application results from, among other things, construction environments and the peculiarity of the construction operation. A few studies have reported some of the critical challenges of AI adoption in construction. Insufficient development of prototypes and managerial barriers have been identified as some of the challenges (Warszawski & Navon, 1998: 38). Most of the construction tasks require mobility but the construction environments are highly unorganised. Many challenges for robotic systems characterise the construction environment. Among these, the most relevant is the unstructured space subject to weather conditions, the very rough tolerance of operation, and the collaboration with workers not used to robotic systems (Follini et al., 2020: 12). While some of the AI innovations have overcome the barrier of the construction environment, most of the systems have yet to overcome this barrier for their full application on construction projects.

Construction sites are usually remote and need more power, telecommunications, and internet connectivity (Louis & Dunston, 2018: 326). Sometimes, even construction activities lead to interruptions in power and internet connectivity. This poses a serious problem in using AI tools on construction sites whose operation relies mainly on good internet connectivity and power supply (for example, robots and site monitoring systems) (Abioye et al., 2021: 13). Managerial barriers relate to construction managers being highly conservative about innovations (Delgado et al., 2019: 9). Construction is a risky industry, and managers are reluctant to add another risk factor to those already inherent in their work (Warszawski & Navon, 1998: 41). Unlike sectors such as manufacturing, construction sites are unique and different and require AI that can learn and adapt fast to wide-ranging construction projects (Zhao et al., 2022: 14). The uncertainty associated with the usability of AI technologies in different construction projects or sites contributes to the resistance of construction organisations (Delgado et al., 2019: 10). This is connected with economic justification for such technology in some specialised construction projects. Thorough testing must establish their adaptability and suitability for different projects, in order to convince construction contractors and businesses to adopt AI technologies (Zhao et al., 2022: 16).

The problem of economic justification for AI solutions has been long-lasting. The benefits of AI-driven solutions in the construction industry are indisputable. However, contractors' initial and maintenance costs to invest in such AI solutions are usually very high (Cai et al., 2020: 9). This may be unaffordable for the majority of subcontractors and small firms that constitute the bulk of the construction industry (Abioye et al., 2021: 10). There is resistance to AI solution adoption, partly because there is no hard evidence that adoption will genuinely represent a cost reduction in the delivery of construction projects (Delgado et al., 2019: 11), considering the low profit and high risk that characterise some construction projects. Besides, the high cost clients have to incur could contribute to low infrastructure spending (Delgado et al., 2019: 11). Therefore, construction firms and the public sector are usually careful to determine the cost savings and return on investment of AI technologies, in order to establish whether to invest or not. As AI technologies become more accepted and prevalent in construction, prices are expected to drop, making them affordable for smaller construction organisations (Adebowale & Agumba, 2022: 17).

Due to the global shortage of AI engineers with the requisite skills to spearhead serious developments across industries (Technology Review Insights, 2018), it is challenging to get AI engineers with experience in the construction sector to build custom solutions targeted at solving industry-specific problems. Winfield and Jirotka (2018: 13) reported the challenge of public trust. Establishing and maintaining public trust in AI technologies depends on inclusive, transparent, and agile governance. When there is a breach of public trust, the use of AI solutions could lead to an unfair advantage for some construction organisations. Public trust is required for the system to be regulated, in order to avoid accidents and eventualities that may slow the progress of construction operations with attendant cost implications (Winfield & Jirotka, 2018: 13).

3. RESEARCH METHODOLOGY

3.1 Research design

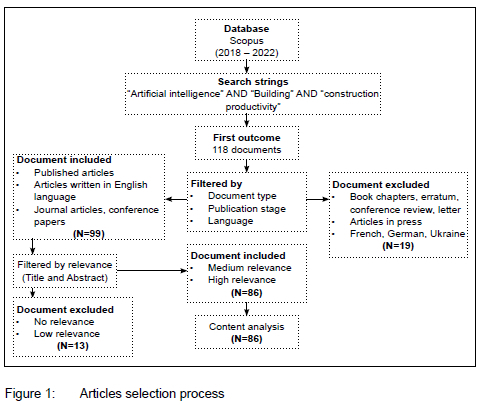

A systematic literature search was carried out in this study. The review included a scientific research approach that assesses, summarises, and presents the research results. Several studies have used systematic literature review to study different areas of construction, including augmented reality (Adebowale & Agumba, 2022: 1-17); robotic technologies (Gharbia et al., 2020: 1-15), and lean construction (Babalola, Ibem & Ezema, 2019: 34-43). The authors have made diverse contributions to their research areas. This study used the Scopus database for article selection. The database was chosen because it covers a broader range of scientific publications than other databases (Babalola et al., 2019: 39). Scopus is said to be the largest research literature citation database, containing publications from various journals and conferences in many fields of study (Abioye et al., 2021: 8). Figure 1 depicts the systematic literature review process employed for this study. This systematic literature review adhered to the preferred reporting items for systematic reviews and meta-analyses framework for retrieving relevant literature from the Scopus database. The figure illustrates a step-by-step research process, offering a comprehensive account of the approach taken.

3.2 Article search

The database was explored on 11 August 2022, to extract publications relevant to the study. The search keywords used include "artificial intelligence" AND "building" AND "construction productivity". The search yielded AI articles that consider productivity in the building sector. The documents extracted were journal articles, conference papers, book chapters, erratum, conference reviews, and letters. The database produced 118 documents.

3.3 Articles screening

It was necessary to select publications with more substantive information and empirical evidence. Book chapters, erratum, conference reviews, and letters were excluded from the list, while journal articles and conference papers were retained. Journal articles and conference papers contain more information than other scholarly literature (Hosseini et al., 2018: 239). Although book chapters, erratum, and conference reviews can provide empirical evidence, most of the articles in these sources would have been published as journals or conference articles (Babalola et al., 2019: 40); hence, the sources were eliminated. After the initial screening, 109 articles were found to be satisfactory. Articles in languages other than English and articles in the press were subsequently eliminated. Article abstracts were read to determine which articles were relevant to the research objective. The inclusion and exclusion criteria used by Babalola et al. (2019: 38) were adapted to choose articles following their relevance to the research goal.

The rating scale consisted of 0 for no relevance, 1 for little relevance, 2 for medium relevance, and 3 for high relevance. The relevance of the articles was determined by analysing their methods and results. Thirteen articles, including Guyot et al. (2019: 6680-6720), GhaffarianHoseini et al. (2017: 935-949), as well as Lee, Kim and Kim (2016: 1-14) were eliminated. The 86 articles that met the screening criteria were reviewed, by examining their abstracts, discussions, and conclusions. The articles' contents were reviewed to determine AI technologies relative to productivity in building construction.

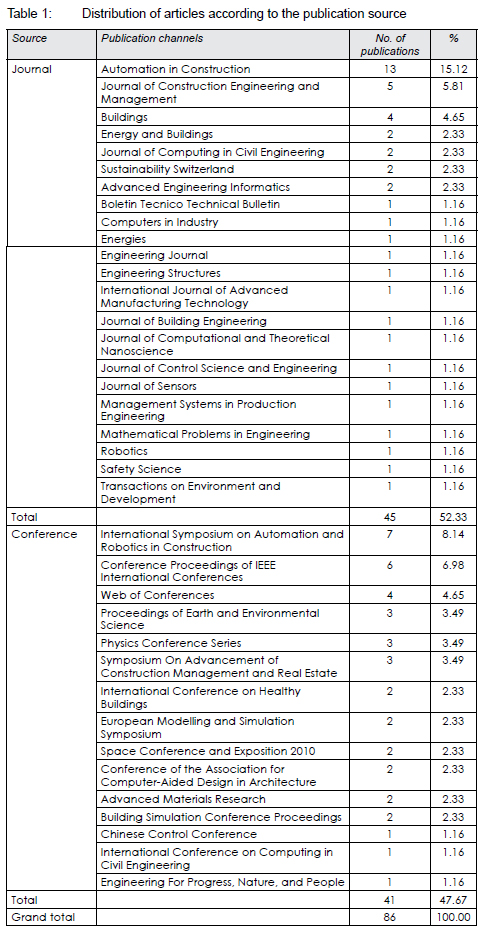

3.4 Publication channels

Table 1 presents the summary of selected research articles by publication source. The table shows that Automation in Construction, International Symposium on Automation and Robotics in Construction, Conference Proceedings of IEEE International Conferences, Journal of Construction Engineering and Management, Buildings, and Web of Conferences have the highest number of articles, accounting for 45.35% of the total number of selected publications. In general, 52.33% of the articles (45 out of 86) were published in scientific journals, while 41 articles, representing 47.67% (41 out of 86), were published at conferences. The publications are spread across 33 countries and regions. China (25), the United States (17), Hong Kong (7), and South Korea (6) have 55 publications, constituting approximately 64% of the total publications in the 33 countries and regions.

4. DISCUSSION OF THE FINDINGS

4.1 Artificial intelligence technologies in building construction

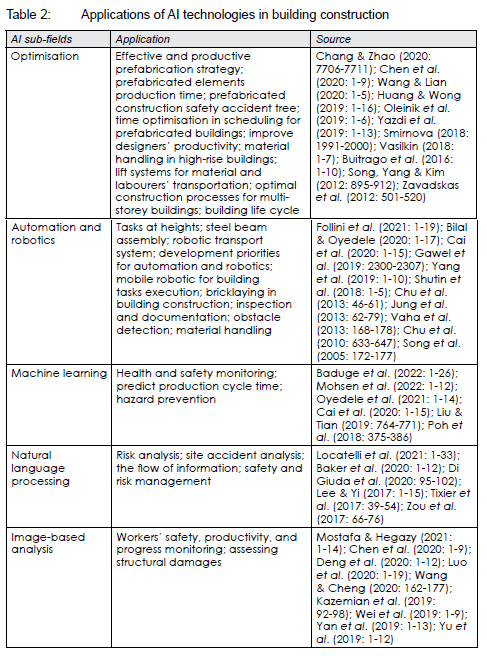

The application of AI has ushered in a transformative era for the construction sector. One of the central themes in contemporary construction is the optimisation of operations in multi-storey buildings. AI systems have proven instrumental in streamlining various aspects such as transportation, loading, and unloading. These optimisations extend to intricate processes such as material storage and supply in high-rise structures. By harnessing the power of AI, construction teams can achieve substantial cost savings and efficiency gains. The optimisation of storage cell utilisation represents a key advancement. These cells can be strategically placed on any floor, allowing material requests to originate from all levels. AI-driven algorithms fine-tune the positioning of storage cells to minimise work times and costs for material deliveries (Buitrago et al., 2016: 10). Notably, this optimisation has the potential to mitigate overtime costs, by reducing transportation times and vertical travel distances within the building. It is worth mentioning that the optimal design of lift systems in multi-storey buildings is a significant contributor to minimising vertical travel time, incorporating characteristics and constraints specific to each project (Yazdi et al., 2019: 13). Table 2 presents some of the applications of AI in building construction.

Modern prefabricated building construction is characterised by its rapid and efficient structural systems and shortened production-to-deployment timelines. However, the management codes governing prefabricated buildings require further development in many countries, in order to prevent frequent accidents during construction (Song et al., 2022: 22). Efforts are underway to mitigate these safety concerns through a combination of optimisations, daily safety management investments, safety education, and improved construction sanitation measures. Optimisation techniques are invaluable in managing the increasing complexity of building projects, enabling engineers to synthesise multiple design options. Structural and parametric optimisation methods play a vital role in delivering tasks that meet engineers' requirements (Song et al., 2022: 22). It is important to acknowledge that ineffective feedback mechanisms can hinder engineers' ability to synthesise structures. However, structural and parametric optimisation effectively reduces building design complexity, promoting constructability.

The adoption of robotic technologies in construction represents a paradigm shift in addressing industry challenges. While organised environments in the automobile and manufacturing industries favour robots, the construction sector grapples with diverse and less structured tasks, necessitating manual labour. However, the urgency to counteract the shrinking labour force and the ageing of skilled workers has driven recent efforts to develop robotic construction systems (Cai et al., 2020: 12; Gawel et al., 2019: 2304). These robotic systems promise increased safety and productivity, particularly in high-risk tasks such as steel beam assembly. Robots are poised to replace ironworkers in this context, offering both enhanced safety and time efficiency (Cai et al., 2020: 12). Autonomous mobile robotic solutions are also emerging as powerful tools for task execution. They can automatically derive construction tasks from 3D building models, localise operations using sensors, and dynamically navigate around obstacles (Gawel et al., 2019: 2304). However, it is crucial to acknowledge the substantial initial investments required for the procurement of automation and robotics technologies in construction organisations (Adebowale & Agumba, 2022: 12). The promise lies in their potential to yield substantial returns by boosting productivity and reducing construction costs. Climbing robots represent a specialised category of construction robotics with the unique ability to navigate complex 2D and 3D environments, including walls, ceilings, roofs, and geometric structures (Chu et al., 2010: 642). These robots are engineered to replace human workers in high-risk tasks within hazardous environments, effectively eliminating the need for costly scaffolding and staffing expenses. The design criteria for climbing robots centre on equipping them with locomotive and adhesion mechanisms tailored to specific environmental demands, allowing them to adapt and operate seamlessly.

BIM integration plays a pivotal role in the deployment of collaborative robotics in construction. BIM leverages sensors to detect unforeseen obstacles within the unstructured construction site environment (Song et al., 2022: 22). As sensor technologies advance and BIM becomes more widespread, new possibilities emerge throughout the building's life cycle. The expanding use of BIM holds the potential to redefine adaptability and efficiency within the construction industry, promising safer and more streamlined operations.

Machine learning stands as a game-changer for the construction industry, offering precise prediction of production cycle times. This capability was demonstrated in a panellised wall manufacturing shop, where real-time loading conditions and panel properties were used to forecast production times (Mohsen et al., 2022: 8). Accurate predictions empower managers to make sound decisions regarding resource scheduling and capacity planning. Predictable production schedules are invaluable for mitigating delays and adapting to unexpected interruptions in factory production, benefiting industrialised building construction.

AI technologies, especially distributed computing and cloud security management, introduce an early warning mechanism for assessing construction site security (Liu & Tian, 2019: 767). These systems judge the overall safety status based on information feedback, aiding in hazard recognition. However, challenges exist in the practical adoption of these systems, due to complicated set-up requirements and information-transfer limitations.

NLP enhances information flow and management within construction projects. Its applications extend to safety enhancement, risk prediction during the bidding process, and accident prevention during project deliveries (Liu & Tian, 2019: 767). Furthermore, the development of computer vision and image-based learning techniques allows computers to autonomously analyse images and videos. This technology enables researchers to tackle complex issues such as assessing workers' postures to prevent work-related musculoskeletal disorders.

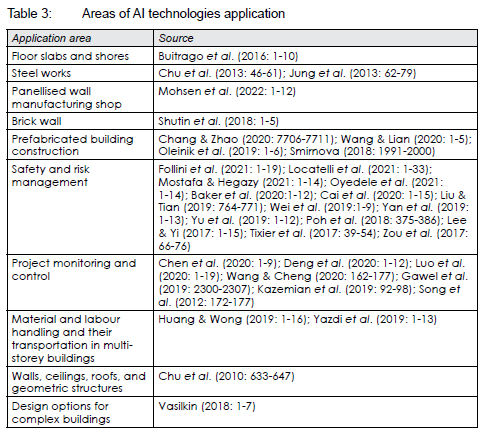

The AI sub-fields discussed, in this instance, find diverse applications in various facets of building construction, ranging from floor slabs and shores to steel works, safety and risk management, as well as material and labour handling in multi-storey buildings. (See Table 3 for a summary of AI sub-fields and their applications in building construction.) The integration of AI technologies into building construction holds immense promise for the industry. These technologies address long-standing challenges, while opening doors to new opportunities for productivity improvement in building construction. Despite hurdles and complexities, the progress made thus far underscores the transformative potential of AI, paving the way for safer, more efficient, and technologically advanced building processes. As AI continues to evolve, it will undoubtedly play an increasingly pivotal role in shaping the construction sector's future.

4.2 Challenges of implementing artificial intelligence technologies in building construction

The implementation of AI technologies in the construction industry presents several complex challenges, as highlighted in the reviewed literature. These challenges are multifaceted, encompassing technical, logistical, economic, and societal aspects. This section discusses these challenges and their implications for the effective integration of AI in building construction.

4.2.1 Technical challenges

One of the fundamental technical challenges in applying AI to construction lies in the unique nature of construction environments. Construction sites are dynamic, unstructured spaces that are susceptible to adverse weather conditions. The construction operations often involve collaboration with human workers who may not be accustomed to working alongside AI-driven systems. As noted by Follini et al. (2020: 12), these factors pose significant challenges for the deployment of robotic systems and other AI-driven technologies. While some advancements have been made to adapt AI to these conditions, it is clear that many AI systems have yet to fully overcome these barriers. This raises questions about the adaptability and robustness of AI technologies in real-world construction settings (Follini et al., 2020: 18). In addition, the need for reliable power, telecommunications, and internet connectivity on remote construction sites cannot be overstated. AI tools such as robots and monitoring systems heavily rely on these resources. The intermittent interruptions in power and connectivity, as highlighted by Abioye et al. (2021: 13), pose a significant obstacle to the seamless operation of AI technologies on construction sites. Overcoming this challenge requires innovative solutions to ensure that AI systems can function effectively even in resource-constrained environments.

4.2.2 Managerial and organisational barriers

The existing literature also sheds light on the managerial and organisational barriers that impede the adoption of AI technologies in construction. Construction managers, as described by Delgado et al. (2019: 9), tend to be conservative when it comes to embracing technological innovations. This conservatism is driven by the inherent risks associated with the construction industry (Locatelli et al., 2021: 22), where even minor errors can lead to costly delays and overruns. Therefore, construction managers are often hesitant to introduce additional uncertainties through the integration of AI. Also noteworthy is the variability and uniqueness of construction projects, which require AI systems that can adapt rapidly. Zhao et al. (2022: 14) emphasised the importance of AI technologies that can learn and adjust to diverse construction contexts. The uncertainty surrounding the usability of AI technologies in different projects contributes to the resistance within construction organisations, making it crucial to establish the adaptability and suitability of these technologies through rigorous testing.

4.2.3 Economic justification

Economic considerations play a pivotal role in the adoption of AI solutions in construction. While the benefits of AI-driven solutions are undeniable, the initial and maintenance costs associated with implementing these technologies can be prohibitively high, particularly for small subcontractors and firms (Cai et al., 2020: 9). There is a pressing need for compelling evidence that AI adoption will genuinely lead to cost reductions in construction project delivery, considering the industry's slim profit margins and high-risk nature. It should be noted that, as AI technologies become more accepted and prevalent in construction, prices are expected to decrease, making them more accessible to smaller construction organisations (Adebowale & Agumba, 2022: 12). This transition toward affordability could potentially drive wider adoption, but the construction industry must carefully assess the cost savings and return on investment associated with AI technologies.

4.2.4 Skills shortage and public trust

A crucial challenge mentioned in the literature is the shortage of AI engineers with expertise in the construction sector (Technology Review Insights, 2018). This skills gap hampers the development of custom AI solutions tailored to address industry-specific problems. Bridging this gap will require targeted efforts to train AI professionals in the nuances of construction, facilitating the creation of specialised solutions. Maintaining public trust in AI technologies is another paramount concern, as highlighted by Winfield and Jirotka (2018: 13). Public trust is essential for transparent and responsible AI governance, particularly in an industry such as construction, where safety and fairness are critical. A breach of public trust could not only lead to unfair advantages for some construction organisations, but also hinder the progress of construction operations with potentially severe cost implications.

The challenges of implementing AI technologies in building construction are intricate and multifaceted, and existing studies have identified some of these challenges. Technical hurdles, managerial conservatism, economic considerations, skills shortages, and public trust are all integral aspects that require thoughtful and strategic solutions. Addressing these challenges will be pivotal in unlocking the full potential of AI to enhance productivity in building construction.

5. SUMMARY OF THE FINDINGS

The global construction industry faces many challenges, of which low productivity is one of the leading challenges. The construction sector's productivity has been compared to productivity in other industries, and several researchers have reported that most of the industries are ahead of construction in terms of productivity growth. Many industries with high productivity performance are quick to leverage advanced technologies, while the construction sector has age-long resistance to adopting new technologies. Reports indicate the industry's resistance to advanced technology adoption as one of the factors responsible for its inefficiency. Construction stakeholders have repeatedly cited the nature of the construction environment as the leading factor responsible for the industry's aversion to innovations. The stakeholders have recently begun to clamour for the need to overcome the factors that make the sector not favourably disposed to take advantage of advanced technologies.

Consequently, research on AI's potential to improve construction operations efficiency has continued to grow. The application of AI technologies is gradually increasing; its relevance is further strengthened by other emerging trends such as BIM, IoT, quantum computing, augmented reality, cybersecurity, and blockchain. Most of the existing studies focus on the entire construction sector, while a few have focused on the building arm of the industry. The research projects that examined AI applications in the building sector conducted field experiments on specific applications and developed models and algorithms that construction organisations can leverage. The building sector contributes significantly to the construction sector's total output. Therefore, improved operational efficiency in the sector would translate to a substantial impact on the construction sector. This study systematically reviews existing studies to evolve a comprehensive view of AI applications in building construction. The AI sub-fields that have the potential to improve efficiency in building construction are reported. These include optimisation, automation and robotics, machine learning, natural language processing, and image-based learning. The study identified applications of these fields of AI. Aspects of building construction, where AI technologies have been used, include floor slabs and shores, steelworks, safety and risk management, material, and labour handling in multi-storey buildings. The AI research and development experts could draw on the evidence about aspects of construction where AI technologies have been implemented. This would increase information on the potential of AI technologies and further provide guidelines on efforts to enhance the application of AI technologies for future building construction.

Due to the nature of construction environments and other peculiarities in construction, managerial barrier, power, and internet issues, initial and maintenance costs, as well as uncertainty associated with return on investment are some of the challenges that limit the adoption of AI technologies. These challenges must be overcome, in order to increase the adoption of AI solutions and increasingly derive their benefits. Industry/ academic engagements are required to create awareness of Al's potential to improve efficiency in the construction sector. Besides, through research, evidence-based justification on the economic value of investing in AI technologies should be provided to construction organisations. This should quantify the short- and long-term cost implications of AI technologies adoption against traditional construction methods. Scholars give more prominence to optimisation, automation, and robotics. Although more research efforts are required in these sub-fields of AI, researchers should further intensify efforts in applications of ML, NLP, and image-based analysis, which have recorded minimum publications. Subsequent studies should also consider the efficiency and cost implication of AI technologies in building construction. Besides, future research should consider other AI sub-fields, which include automated planning and scheduling and knowledge-based systems, to determine how their applications can be leveraged to improve efficiency in construction. The articles reviewed in this study are limited to the Scopus database, which constitutes a limitation to the study. Future research should investigate additional databases to gain a broader understanding of the subject matter.

6. CONCLUSION

The global business environment, including the construction industry, is constantly evolving and becoming increasingly competitive. There is a growing recognition that productivity is essential to competitiveness in any sector. Unfortunately, the construction sector has an age-long record of poor productivity, which can be partly attributed to its resistance to adopting innovative technologies to improve production efficiency. This study investigated the transformative potential of AI technologies to enhance productivity in building construction. Due to the potential benefits that AI adoption presents, the study emphasised the urgent need for the construction sector to overcome its historical resistance to technology and embrace innovation. The study identified AI applications that are beneficial to building construction, including optimization, automation, robotics, machine learning, natural language processing, and image-based analysis. These applications are useful for key facets of construction, ranging from floor slabs to safety management. However, the wider implementation of these applications has been hindered by factors such as technical complexities, managerial conservatism, economic considerations, skills shortages, and public trust issues. Addressing these challenges is essential to fully harness AI's transformative potential to improve productivity in building construction. This study recommends collaboration between industry and academia as one of the key measures to promote AI adoption and provide evidence-based economic justifications for its implementation. Future research should explore AI's applications and cost implications in greater depth, especially in underexplored sub-fields such as natural language processing and image-based analysis.

REFERENCES

Abioye, S.O., Oyedele, L.O., Akanbi, L., Ajayi, A., Delgado, J.M.D., Bilal, M., Akinade, O.O. & Ahmed, A. 2021. Artificial intelligence in the construction industry: A review of present status, opportunities and future challenges. Journal of Building Engineering, 44(3), 1-13. DOI: 10.1016/j.jobe.2021.103299 [ Links ]

Adebowale, O.J. 2014. Framework for effective management of the construction workforce towards enhancement of labour efficiency during the building production process in South Africa. Unpublished Masters dissertation, Cape Peninsula University of Technology. [ Links ]

Adebowale, O.J. & Agumba, J.N. 2022. Applications of augmented reality for construction productivity improvement: A systematic review. Smart and Sustainable Built Environment, pp. 1-17. DOI: 10.1108/SASBE-06-2022-0128 [ Links ]

Adebowale, O.J. & Agumba, J.N. 2023a. A meta-analysis of factors affecting construction labour productivity in the Middle East. Journal of Construction in Developing Countries, 28(1), pp. 193-220. https://doi.org/10.21315/jcdc-12-21-0192 [ Links ]

Adebowale, O.J. & Agumba, J.N. 2023b. Construction SMEs labour productivity: Causal layered analysis. Journal of Engineering, Design and Technology, pp. 1-24. DOI: 10.1108/JEDT-11-2022-0583 [ Links ]

Afolabi, A.O., Ojelabi, R.A., Omuh, I.O., Tunji-Olayeni, P.F. & Adeyemi, M. 2018. Critical success factors influencing productivity of construction artisans in the building industry. International Journal of Mechanical Engineering and Technology (IJMET), 9(8), pp. 858-867. [ Links ]

Agrawal, A. & Halder, S. 2020. Identifying factors affecting construction labour productivity in India and measures to improve productivity. Asian Journal of Civil Engineering, 21(4), pp. 569-579. https://doi.org/10.1007/s42107-019-00212-3 [ Links ]

Alaghbari, W., Al-Sakkaf, A.A. & Sultan, B. 2019. Factors affecting construction labour productivity in Yemen. International Journal of Construction Management, 19(1), pp. 79-91. https://doi.org/10.1080/15623599.2017.1382091 [ Links ]

Alinaitwe, H.M., Mwakali, J.A. & Hansson, B. 2007. Factors affecting the productivity of building craftsmen: Studies of Uganda. Journal of Civil Engineering and Management, 13(3), pp. 169-176. https://doi.org/10.3846/13923730.2007.9636434 [ Links ]

Babalola, O., Ibem, E.O. & Ezema, I.C. 2019. Implementation of lean practices in the construction industry: A systematic review. Building and Environment, 148(2), pp. 34-43. DOI: 10.1016/j.buildenv.2018.10.051 [ Links ]

Baduge, S.K., Thilakarathna, S., Perera, J.S., Arashpour, M., Sharafi, P., Teodosio, B., Shringi, A. & Mendis, P. 2022. Artificial intelligence and smart vision for building and construction 4.0: Machine and deep learning methods and applications. Automation in Construction, 141(7), pp. 1-26. DOI: 10.1016/j.autcon.2022.104440 [ Links ]

Baker, H., Hallowell, M.R. & Tixier, A.J.P. 2020. AI-based prediction of independent construction safety outcomes from universal attributes. Automation in Construction, 118(12), pp. 1-12. DOI: 10.1016/j.autcon.2020.103146 [ Links ]

Barbosa, F., Woetzel, J. & Mischke, J. 2017. Reinventing construction: A route of higher productivity. Brussels: McKinsey Global Institute. [ Links ]

Bilal, M. & Oyedele, L.O. 2020. Guidelines for applied machine learning in construction Industry: A case of profit margins estimation. Advanced Engineering Informatics, 43(9), pp. 1-17. DOI: 10.1016/j.aei.2019.101013 [ Links ]

Buitrago, M., Adam, J.M., Alvarado, Y.A., Moragues, J.J., Gasch, I. & Calderón, P.A. 2016. Designing construction processes in buildings by heuristic optimization. Engineering Structures, 111(14), pp. 1-10. DOI: 10.1016/j.engstruct.2015.12.009 [ Links ]

Busta, H. 2016. KPMG report: Construction industry slow to adopt new technology. Construction Dive. [Online]. Available at: <https://www.constructiondive.com/news/kpmg-report-construction-industry-slow-to-adopt-new-technology/426268/> [Accessed: 2 August 2022]. [ Links ]

Cai, S., Ma, Z., Skibniewski, M.J., Bao, S. & Wang, H. 2020. Construction automation and robotics for high-rise buildings: Development priorities and key challenges. Journal of Construction Engineering and Management, 146(8), pp. 1-15. DOI: 10.1061/(ASCE)CO.1943-7862.0001891 [ Links ]

Cai, S., Ma, Z., Skibniewski, M., Guo, J. & Yun, L. 2018. Application of automation and robotics technology in high-rise building construction: An overview. In: Proceedings of the 35th International Symposium on Automation and Robotics in Construction, 20-25 July, Berlin, Germany: IAARC, pp. 309-316. https://doi.org/10.22260/ISARC2018/0044 [ Links ]

Chan, P.W. & Kaka, A. 2007. Productivity improvements: Understand the workforce perceptions of productivity first. Personnel Review, 36(4), pp. 564-584. https://doi.org/10.1108/00483480710752803 [ Links ]

Chang, C. & Zhao, T. 2020. Optimization model for safety investment of prefabricated building construction. In: Proceedings of the 39th Chinese Control Conference (CCC), 27-29 July, Shenyang, China: IEEE, pp. 7706-7711. https://doi.org/10.23919/CCC50068.2020.9188946 [ Links ]

Chen, C., Huy, D.T., Tiong, L.K., Chen, I.M. & Cai, Y. 2019. Optimal facility layout planning for AGV-based modular prefabricated manufacturing system. Automation in Construction, 98(3), pp. 310-321. DOI: 10.1016/j.autcon.2018.08.008 [ Links ]

Chen, I.H., Ho, S.C. & Su, M.B. 2020. Computer vision application programming for settlement monitoring in a drainage tunnel. Automation in Construction, 110(11), article number 103011, pp. 1-9. DOI: 10.1016/j. autcon.2019.103011 [ Links ]

Chien, C.F., Dauzere-Peres, S., Huh, W.T., Jang, Y.J. & Morrison, J.R. 2020. Artificial intelligence in manufacturing and logistics systems: Algorithms, applications, and case studies. International Journal of Production Research, 58(9), pp. 2730-2731. DOI: 10.1080/00207543.2020.1752488 [ Links ]

Choi, J., Gu, B., Chin, S. & Lee, J.S. 2020. Machine learning predictive model based on national data for fatal accidents of construction workers. Automation in Construction, 110(7), article number 102974, pp. 1-14. https://doi.org/10.1016/j.autcon.2019.102974 [ Links ]

Chu, B., Jung, K., Han, C.S. & Hong, D. 2010. A survey of climbing robots: Locomotion and adhesion. International Journal of Precision Engineering and Manufacturing, 11(4), pp. 633-647. DOI: 10.1007/s12541-010-0075-3 [ Links ]

Chu, B., Jung, K., Lim, M.T. & Hong, D. 2013. Robot-based construction automation: An application to steel beam assembly (Part I). Automation in Construction, 32(4), pp. 46-61. DOI: 10.1016/j.autcon.2012.12.016 [ Links ]

Dai, J. & Goodrum, P.M. 2011. Differences in perspectives regarding labor productivity between Spanish- and English-speaking craft workers. Journal of Construction Engineering and Management, 137(9), pp. 689-697. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000329 [ Links ]

Delgado, J.M.D., Oyedele, L., Ajayi, A., Akanbi, L., Akinade, O., Bilal, M. & Owolabi, H. 2019. Robotics and automated systems in construction: Understanding industry-specific challenges for adoption. Journal of Building Engineering, 26(7), article number 100868, pp. 1-11. DOI: 10.1016/j.jobe.2019.100868 [ Links ]

Deng, H., Hong, H., Luo, D., Deng, Y. & Su, C. 2020. Automatic indoor construction process monitoring for tiles based on BIM and computer vision. Journal of Construction Engineering and Management, 146(1), article number 1744, pp. 1-12. DOI: 10.1061/(ASCE)CO.1943-7862.0001744 [ Links ]

Di Giuda, G.M., Locatelli, M., Schievano, M., Pellegrini, L., Pattini, G., Giana, P.E. & Seghezzi, E. 2020. Natural language processing for information and project management. In: Daniotti, B. (Ed.). Digital transformation of the design, construction and management processes of the built environment. Cham, Switzerland: Springer, pp. 95-102. https://doi.org/10.1007/978-3-030-33570-0_9 [ Links ]

Durdyev, S. & Mbachu, J. 2011. On-site labour productivity of New Zealand construction industry: Key constraints and improvement measures. Construction Economics and Building, 11(3), pp. 18-33. https://doi.org/10.5130/AJCEB.v11i3.2120 [ Links ]

Fadejeva, L. & Melihovs, A. 2010. Measuring total factor productivity and variable factor utilisation: Sector approach, the case of Latvia. Eastern European Economics, 48(5), pp. 63-101. https://doi.org/10.2753/EEE0012-8775480504 [ Links ]

Fang, Q., Li, H., Luo, X., Ding, L., Rose, T.M., An, W. & Yu, Y. 2018. A deep learning-based method for detecting non-certified work on construction sites. Advanced Engineering Informatics, 35(5), pp. 56-68. DOI: 10.1016/j.aei.2018.01.001 [ Links ]

Follini, C., Magnago, V., Freitag, K., Terzer, M., Marcher, C., Riedl, M., Giusti, A. & Matt, D.T. 2020. BIM-integrated collaborative robotics for application in building construction and maintenance. Robotics, 10(1), article number 2, pp. 1-19. DOI: 10.3390/robotics10010002 [ Links ]

Gawel, A., Blum, H., Pankert, J., Krämer, K., Bartolomei, L., Ercan, S., Farshidian, F., Chli, M., Gramazio, F., Siegwart, R. & Hutter, M. 2019. A fully-integrated sensing and control system for high-accuracy mobile robotic building construction. IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), 4-8 November, Macau, China, pp. 2300-2307. https://doi.org/10.1109/IROS40897.2019.8967733 [ Links ]

GhaffarianHoseini, A., Zhang, T., Nwadigo, O., GhaffarianHoseini, A., Naismith, N., Tookey, J. & Raahemifar, K. 2017. Application of nD BIM Integrated Knowledge-based Building Management System (BIM-IKBMS) for inspecting post-construction energy efficiency. Renewable and Sustainable Energy Reviews, 72(3), pp. 935-949. DOI: 10.1016/j.rser.2016.12.061 [ Links ]

Gharbia, M., Chang-Richards, A., Lu, Y., Zhong, R.Y. & Li, H. 2020. Robotic technologies for on-site building construction: A systematic review. Journal of Building Engineering, 32(2), pp. 1-15. DOI: 10.1016/j.jobe.2020.101584 [ Links ]

Guyot, D., Giraud, F., Simon, F., Corgier, D., Marvillet, C. & Tremeac, B. 2019. Overview of the use of artificial neural networks for energy-related applications in the building sector. International Journal of Energy Research, 43(13), pp. 6680-6720. DOI: 10.1002/er.4706 [ Links ]

Hanna, A.S. & Heale, D.G. 1994. Factors affecting construction productivity: Newfoundland versus rest of Canada. Canadian Journal of Civil Engineering, 21(4), pp. 663-673. https://doi.org/10.1139/l94-066 [ Links ]

Hiyassat, M.A., Hiyari, M.A. & Sweis, G.J. 2016. Factors affecting construction labour productivity: A case study of Jordan. International Journal of Construction Management, 16(2), pp. 138-149. https://doi.org/10.1080/15623599.2016.1142266 [ Links ]

Hosseini, M.R., Martek, I., Zavadskas, E.K., Aibinu, A.A., Arashpour, M. & Chileshe, N. 2018. Critical evaluation of off-site construction research: A scientometric analysis. Automation in Construction, 87(6), pp. 235-247. DOI: 10.1016/j.autcon.2017.12.002 [ Links ]

Huang, C. & Wong, C.K. 2019. Optimization of vertical elevator movements and material storage locations for high-rise building construction with overtime cost effects. Journal of Computing in Civil Engineering, 33(1), 1-16. https://doi.org/10.1061/(ASCE)CP.1943-5487.0000794 [ Links ]

Hwang, B.G., Zhu, L. & Ming, J.T.T. 2017. Factors affecting productivity in green building construction projects: The case of Singapore. Journal of Management in Engineering, 33(3), pp. 1-12. https://doi.org/10.1061/(ASCE)ME.1943-5479.0000499 [ Links ]

Jalal, M.P. & Shoar, S. 2019. A hybrid framework to model factors affecting construction labour productivity. Journal of Financial Management of Property and Construction, 24(3), pp. 385-409. DOI: 10.1108/JFMPC-10-2018-0061 [ Links ]

Jang, H., Kim, K., Kim, J. & Kim, J. 2011. Labour productivity model for reinforced concrete construction projects. Construction Innovation, 11(1), pp. 92-113. DOI: 10.1108/14714171111104655 [ Links ]

Jarkas, A.M. 2015. Factors influencing labour productivity in Bahrain's construction industry. International Journal of Construction Management, 15(1), pp. 94-108. https://doi.org/10.1080/15623599.2015.1012143 [ Links ]

Jarkas, A.M. & Bitar, C.G. 2012. Factors affecting construction labour productivity in Kuwait. Journal of Construction Engineering and Management, 38(7), pp. 811-820. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000501 [ Links ]

Jarkas, A.M., Al Balushi, R.A. & Raveendranath, P.K. 2015. Determinants of construction labour productivity in Oman. International Journal of Construction Management, 15(4), pp. 332-344. https://doi.org/10.1080/15623599.2015.1094849 [ Links ]

Jung, K., Chu, B. & Hong, D. 2013. Robot-based construction automation: An application to steel beam assembly (Part II). Automation in Construction, 32(2), pp. 62-79. DOI: 10.1016/j.autcon.2012.12.011 [ Links ]

Karimi, H., Taylor, T.R. & Goodrum, P.M. 2017. Analysis of the impact of craft labour availability on North American construction project productivity and schedule performance. Construction Management and Economics, 35(6), pp. 368-380. https://doi.org/10.1080/01446193.2017.1294257 [ Links ]

Kazaz, A., Manisali, E. & Ulubeyli, S. 2008. Effect of basic motivational factors on construction workforce productivity in Turkey. Journal of Civil Engineering and Management, 14(2), pp. 95-106. https://doi.org/10.3846/1392-3730.2008.14.4 [ Links ]

Kazemian, A., Yuan, X., Davtalab, O. & Khoshnevis, B. 2019. Computer vision for real-time extrusion quality monitoring and control in robotic construction. Automation in Construction, 101(8), pp. 92-98. DOI: 10.1016/j.autcon.2019.01.022 [ Links ]

Kim, H., Soibelman, L. & Grobler, F. 2008. Factor selection for delay analysis using knowledge discovery in databases. Automation in Construction, 17(5), pp. 550-560. https://doi.org/10.1016/j.autcon.2007.10.001 [ Links ]

Lee, J. & Yi, J.S. 2017. Predicting project's uncertainty risk in the bidding process by integrating unstructured text data and structured numerical data using text mining. Applied Sciences, 17(11), article 1141, pp. 1-15. https://doi.org/10.3390/app7111141 [ Links ]

Lee, D., Kim, S. & Kim, S. 2016. Development of hybrid model for estimating construction waste for multifamily residential buildings using artificial neural networks and ant colony optimization. Sustainability, 8(9), article number 870, pp. 1-14. DOI: 10.3390/su8090870 [ Links ]

Liu, H. & Tian, G. 2019. Building engineering safety risk assessment and early warning mechanism construction based on distributed machine learning algorithm. Safety Science, 120, pp. 764-771. https://doi.org/10.1016/j.ssci.2019.08.022 [ Links ]

Locatelli, M., Seghezzi, E., Pellegrini, L., Tagliabue, L.C. & Di Giuda, G.M. 2021. Exploring natural language processing in construction and integration with Building Information Modelling: A scientometric analysis. Buildings, 11(12), article 583, pp. 1-33. DOI: 10.3390/buildings11120583 [ Links ]

Loosemore, M. 2014. Improving construction productivity: A subcontractor's perspective. Engineering, Construction and Architectural Management, 21(3), pp. 245-260. https://doi.org/10.1108/ECAM-05-2013-0043 [ Links ]

Louis, J. & Dunston, P.S. 2018. Integrating loT into operational workflows for real-time and automated decision-making in repetitive construction operations. Automation in Construction, 94(7), pp. 317-327. DOI: 10.1016/j.autcon.2018.07.005 [ Links ]

Luo, H., Wang, M., Wong, P.K.Y. & Cheng, J.C. 2020. Full body pose estimation of construction equipment using computer vision and deep learning techniques. Automation in Construction, 110(12), article 103016, pp. 1-19. DOI: 10.1016/j.autcon.2019.103016 [ Links ]

Makulsawatudom, A., Emsley, M. & Sinthawanarong, K. 2004. Critical factors influencing construction productivity in Thailand. The Journal of KMITNB, 14(3), pp. 1-6. [ Links ]

McKinsey Global Institute. 2017. Reinventing construction: A route to higher productivity. McKinsey company. [Online]. Available at: <http://www.mckinsey.com/industries/capital-projects-and-infrastructure/our-insights/reinventing-construction-through-a-productivityrevolution [Accessed: 31 August 2022]. [ Links ]

Mlybari, E.A. 2020. Application of soft computing techniques to predict construction labour productivity in Saudi Arabia. International Journal, 19(71), pp. 203-210. https://doi.org/10.21660/2020.71.31349 [ Links ]

Mohsen, O., Mohamed, Y. & Al-Hussein, M. 2022. A machine learning approach to predict production time using real-time RFID data in industrialized building construction. Advanced Engineering Informatics, 52(5), article 101631, pp. 1-12. https://doi.org/10.1016/j.aei.2022.101631 [ Links ]

Mostafa, K. & Hegazy, T. 2021. Review of image-based analysis and applications in construction. Automation in Construction, 122(9), article 103516, pp. 1-14. DOI: 10.1016/j.autcon.2020.103516 [ Links ]

Nasir, H., Ahmed, H., Haas, C. & Goodrum, P.M. 2014. An analysis of construction productivity differences between Canada and the United States. Construction Management and Economics, 32(6), pp. 595-607. DOI: 10.1080/01446193.2013.848995 [ Links ]

Nasirzadeh, F. & Nojedehi, P. 2013. Dynamic modeling of labour productivity in construction projects. International Journal of Project Management, 31(6), pp. 903-911. https://doi.org/10.1016/j.ijproman.2012.11.003 [ Links ]

Nikas, A., Poulymenakou, A. & Kriaris, P. 2007. Investigating antecedents and drivers affecting the adoption of collaboration technologies in the construction industry. Automation in Construction, 16(5), pp. 632-641. DOI: 10.1016/j.autcon.2006.10.003 [ Links ]

Odesola, I.A. & Idoro, G.I.O. 2014. Influence of labour-related factors on construction labour productivity in the south-south geo-political zone of Nigeria. Journal of Construction in Developing Countries, 19(1), pp. 93-107. [ Links ]

Oleinik, P., Kuzmina, T., Shvedov, S., Shesterikov, Y. & Pavlov, I. 2019. Optimization of parameters for the construction of prefabricated residential buildings. Web of Conferences, 110, article 3007, pp. 1-6. DOI: 10.1051/e3sconf/201911001060 [ Links ]

Omran, A., Abdalrahman, S. & Pakir, A.K. 2012. Project performance in Sudan construction industry: A case study. Global Journal of Accounting and Economic Research, 1(1), pp. 55-78. [ Links ]

Oyedele, A., Ajayi, A., Oyedele, L.O., Delgado, J.M.D., Akanbi, L., Akinade, O., Owolabi, H. & Bilal, M. 2021. Deep learning and boosted trees for injuries prediction in power infrastructure projects. Applied Soft Computing, 110(5), article 107587, pp. 1-14. DOI: 10.1016/j.asoc.2021.107587 [ Links ]

Palikhe, S., Kim, S. & Kim, J.J. 2019. Critical success factors and dynamic modelling of construction labour productivity. International Journal of Civil Engineering, 17(3), pp. 427-442. https://doi.org/10.1007/s40999-018-0282-3 [ Links ]

Paulson, B.C. Jr. & Boyd C. 1985. Automation and robotics for construction. Journal of Construction Engineering and Management, 11(3), pp. 190-207. DOI: 10.1061/(ASCE)0733-9364(1985)111:3(190) [ Links ]

Poh, C.Q., Ubeynarayana, C.U. & Goh, Y.M. 2018. Safety leading indicators for construction sites: A machine learning approach. Automation in Construction, 93(9), pp. 375-386. DOI: 10.1016/j.autcon.2018.03.022 [ Links ]

Rao, T.V.N., Gaddam, A., Kurni, M. & Saritha, K. 2022. Reliance on artificial intelligence, machine learning and deep learning in the era of industry 4.0. In: Islam, S. (Ed.). Smart healthcare system design: Security and privacy aspects. Hoboken, USA: Wiley, 281-299. doi.org/10.1002/9781119792253.ch12 [ Links ]

Raykar, P. & Ghadge, A.N. 2016. Analyzing the critical factors influencing the time overrun and cost overrun in construction project. International Journal of Engineering Research, 5(1), pp. 21-25. DOI: 10.17950/ijer/v5i1/006 [ Links ]

Robles, G., Stifi, A., Ponz-Tienda, J.L. & Gentes, S. 2014. Labor productivity in the construction industry: Factors influencing the Spanish construction labour productivity. International Journal of Civil Structure Construction Architecture Engineering, 8(10), pp. 1009-1018. [ Links ]

Shutin, D., Malakhov, A. & Marfin, K. 2018. Applying automated and robotic means in construction as a factor for providing constructive safety of buildings and structures. Web of Conferences, 251(5), article 3005, pp. 1-5. https://doi.org/10.1051/matecconf/201825103005 [ Links ]

Sidorova, E.Y., Nikulin, N.N., Vikhrova, N.O. & Ershova, V.Y. 2021. Labour productivity in the metallurgical industries of Russian Federation and the USA in 2010-2018. CIS Iron and Steel Review - Economics and Finance, 21(3), pp. 92-97. DOI: 10.17580/cisisr.2021.01.16 [ Links ]

Smirnova, O.M. 2018. Technology of increase of nanoscale pores volume in protective cement matrix. International Journal of Civil Engineering and Technology, 9(10), pp. 1991-2000. [ Links ]

Song, D., Hu, Q., Qin, N. & Goldberg, K. 2005. Automating inspection and documentation of remote building construction using a robotic camera. International Conference on Automation Science and Engineering, 1-2 September, Edmonton, Canada: IEEE, pp. 172-177. [ Links ]

Song, S., Yang, J. & Kim, N. 2012. Development of a BIM-based structural framework optimization and simulation system for building construction. Computers in Industry, 63(9), pp. 895-912. DOI: 10.1016/j.compind.2012.08.013 [ Links ]

Song, Y., Wang, J., Liu, D. & Guo, F. 2022. Study of occupational safety risks in prefabricated building hoisting construction based on HFACS-PH and SEM. International Journal of Environmental Research and Public Health, 19(3), pp. 1-24. DOI: 10.3390/ijerph19031550 [ Links ]

Technology Review Insights. 2018. The growing impact of AI on business. [Online]. Available at: <https://rebrand.ly/69oofvt> [Accessed: 2 August 2022]. [ Links ]

Thomas, A.V. & Sudhakumar, J. 2013. Critical analysis of the key factors affecting construction labour productivity - An Indian perspective. International Journal of Construction Management, 13(4), pp. 103-125. https://doi.org/10.1080/15623599.2013.10878231 [ Links ]

Tixier, A.J.P., Hallowell, M.R., Rajagopalan, B. & Bowman, D. 2017. Construction safety clash detection: Identifying safety incompatibilities among fundamental attributes using data mining. Automation in Construction, 74(1), pp. 39-54. https://doi.org/10.1016/j.autcon.2016.11.001 [ Links ]

Tsehayae, A.A. & Fayek, A.R. 2016. System model for analysing construction labour productivity. Construction Innovation, 16(2), pp. 203-228. DOI: 10.1108/CI-07-2015-0040 [ Links ]

United Nations Department of Economic and Social Affairs, World Population Prospects. 2019. Highlights. United Nations, New York. doi.org/10.18356/13bf5476-en [ Links ]