Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.119 n.12 Johannesburg Dec. 2019

http://dx.doi.org/10.17159/2411-9717/725/2020

GENERAL PAPERS

Spider webs and rockburst support — Have rock engineers something to learn from spiders?

T.R. Stacey

School of Mining Engineering, University of the Witwatersrand, South Africa

SYNOPSIS

Spider webs must be able to absorb the energy of impacting insects, and similarly, rock support must absorb the energy of ejected rock in rockbursts. A consideration of the properties of spider webs shows that spider silks (threads) are extremely strong, typically three times as strong as common steel. Spiders also construct their webs with yielding mechanisms to enhance their energy-absorbing capability. In this paper, the techniques employed in web construction are compared with those used in rock support in excavations prone to rockbursting. It is shown that the design of rockburst support could benefit from some of the capabilities used by spiders in the construction of their webs.

Keywords: rockbursts, ground support, energy absorption, dynamic loading.

Introduction

A chance viewing on a television news clip of a wasp impacting a spider web sparked the thought, 'On a small scale, this is a spider's experience of a rockburst - the web representing the rockburst support, absorbing the energy involved and containing the deformation and potential damage from the impact'. This then posed the question, 'Can we learn anything from the structure of spider webs, and the properties of the threads, that could be of benefit in the conceptualization and design of rock support, to ensure stability of underground excavations subject to the dynamic loading experienced in rockbursting conditions?'

There is abundant literature describing the structure of spider webs and the properties of spider silks. In this paper, some of this literature will be considered, to evaluate its relevance to the subject of rockburst support. Webs must be able to withstand buffeting by wind as well as impacts by small and large insects, and even small birds.

One of the most important functions of rockburst support is to contribute to the reduction of the rockburst hazard in underground openings, and to the provision of safe working conditions. In addition to this, it is important that all of the potential consequences of a rockburst are taken into account. This includes the financial consequences, the largest contributor in a mining environment usually being the cost of loss of production (Moganedi and Stacey, 2019). The spider web is of critical importance to the spider - if the web is not capable of capturing prey, or if its integrity cannot be sustained under impacts from large insects or the wind, the spider may starve. The time, direction, and magnitude of such impacts cannot be predicted. Similarly, the time, magnitude, and direction of rockburst ejections cannot be predicted.

Spider web structure

There are many types of spider webs, and Vollrath (1988) has given a very useful summary of this information. In this paper the focus will be on two-dimensional webs such as the orb web from the garden cross spider, Araneus diadematus (Vollrath, 1992). Such a web is illustrated in Figure 1.

Different types of spider silk threads are used in the construction of the web. Some of these are identified in Figure 1, and are described briefly below, with their corresponding properties.

> Anchor threads, frame threads, and radial threads: these non-sticky threads are described as dragline silk. According to Brookes, Young, and Vollrath (2008), they have great tensile strength, up to 3 GPa, with extension to failure of up to 35%. Vollrath, Porter, and Holland (2011) quote somewhat lower values - a strength of the order of 1.5 GPa and strain to failure of about 20%. Nevertheless, dragline silk far outperforms structural steel, which typically has an ultimate tensile strength of about 500 MPa, and chromium-vanadium steel, with a strength of about 900 MPa.

> During web construction, the spider uses an auxiliary spiral to retain the radial threads in place prior to 'constructing' the capture area.

> The 'wet and soft sticky spiral' threads (Vollrath, 2000) constitute the capture area. These threads have enormous energy-absorbing capabilities, and their structure in the web allows extensibility of up to 500%. The tensile strength of these threads is of the order of 1.4 GPa, comparable with the dragline silk. However, the capture silk threads are thinner, and therefore have less force absorption capacity than the dragline threads. As stated by Peters (1995), 'The gluey capture threads of orb-weaving spiders consist of two axial fibres surrounded by an adhesive glue'.

> Vollrath (1992, 1995) states that aqueous droplets, consisting of water and hygroscopic compounds, form a coating that covers the threads, and that the fibres are drawn into the droplets in the form of a 'mini-windlass'. This allows the capture silk to have enormous extensibility, but also to remain taut, no matter how much the thread is contracted. The gluey coating also prevents the threads from drying out and becoming brittle.

> One or two 'random', overarching long threads have been noticed crossing webs, but not in contact with the web. Whether these are intentionally present to provide 'backup' support to the web in the event of a large impact or for another purpose, or whether they are actually random, is not known. However, their overarching presence is mentioned here because they are considered to be relevant with regard to rockburst support, as will be described later in this paper.

A different structure facilitating energy absorption is used in web construction by the recluse spider: 'In summary, the recluse spider uses an extraordinary spinneret choreography to spin its [unique ribbon-like] silk into loops at a rate of 10-15 loops per second [bonded at the base of the loop]. The resulting looped strand ... facilitates the formation of [these] strong sacrificial bonds at the ribbon-to-ribbon contact area that do not produce defects upon bond release. The sacrificial loop junctions and hidden loop length effectively introduce pseudo-ductility into the fibre's tensile response... Thus, the recluse's unique spinning process and resulting looped ribbon inspire the design of uniaxial metamaterials with tunable and predictable tensile behaviour and superior toughness' (Koebley, Vollrath, and Schniepp, 2017). This specialized web structure is also of direct relevance to rockburst support.

The spider web literature does not appear to deal with the nature and strength of the web anchor points. Presumably this is because webs do not suffer from anchor failure, i.e. the anchor points are more than strong enough to prevent failure in the event of typical insect impacts.

There is abundant reference in the literature regarding the containment of energy by spider webs during insect impacts and struggles, and wind buffets.

The nature of rockburst impacts on rock support

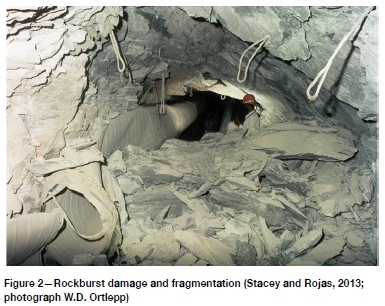

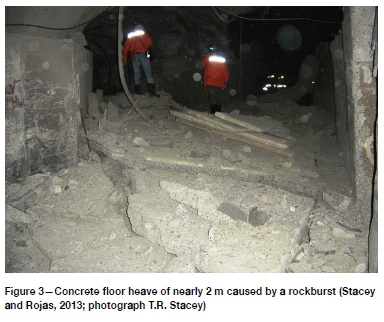

A rockburst involves the 'explosive' ejection of a volume of rock from the surface of excavations (Ortlepp, 1997). Particularly violent events are caused by the reflection of seismic waves at the boundaries of excavations (Hildyard, 2007; Daenhke, 1997; Stacey and Rojas, 2013). Rockbursts may involve the failure and ejection of highly stressed rock from the surface of excavations, but may also involve the ejection of relatively unstressed rock. They may also involve ejection of concrete placed as a roadway surface in tunnels or used for support of walls of excavations. The ejections may occur at significant velocities (Ortlepp, 1993; McGarr, 1997), commonly up to 10 m/s (Stacey, 2011). Examples of rockburst ejections are shown in Figures 2 and 3 (Stacey and Rojas, 2013).

The energy involved in the rockburst event is determined by the mass of the ejected rock material and its velocity of ejection (Ortlepp, 1992). To contain the rockburst damage, this energy must be absorbed by the rock support system. Unfortunately, the design of rockburst support is problematic since neither the demand on the support (volume/mass of ejection, ejection velocity, direction of ejection) nor the capacity of the support system (interaction of support components, and capacities of each component under the interacting forces) are known with sufficient confidence (Stacey, 2011). A conventional approach to design is therefore not possible. Similarly for spider webs, the direction, magnitude, and velocity of impacts are not known.

Typical rockburst support systems consist of some or all of the following components.

> Rockbolts: yielding rockbolts to ensure retention of other support elements with no bolt failure. Numerous types of yielding bolts are now commercially available, for example Li (2010), Ortlepp, Bornmann, and Erasmus (2001).

> Shotcrete: nowadays this is commonly fibre-reinforced. This assists in limiting relative movements of rock blocks and loosening of the rock mass. In some cases, thin spray-on liner material (TSL) is applied as an alternative support, or in addition to shotcrete, fulfilling the same function.

> Wire mesh: the purpose of wire mesh, in conjunction with the rockbolts, is to contain the rock mass and limit the extent of deformation in a rockburst event. Wire mesh may also be used to reinforce shotcrete, although the behaviour of the mesh may be less flexible in such cases.

> Connecting elements: faceplates, and retaining nuts on the rockbolts, ensure that the mesh/shotcrete and rock mass is contained. To achieve this it is essential that no failure of the plate or nut occurs.

> Straps: these may be 'heavy' mesh straps or special tendon straps. They are placed over the wire mesh and shotcrete, and under the faceplate. They provide substantial additional containment and, owing to their greater stiffness than wire mesh, effectively reduce the extent of 'free' span between adjacent rockbolts. They also improve load transfer between rockbolts and mesh/shotcrete, and enhance the integrity of the connection between retainment and containment support components.

> Wire rope lacing: lacing serves the same purpose as straps. Lacing is usually continuous over much greater lengths than adjacent rockbolts.

> Additional shotcrete: this may be sprayed over the other support to minimize damage to the support by mechanized equipment.

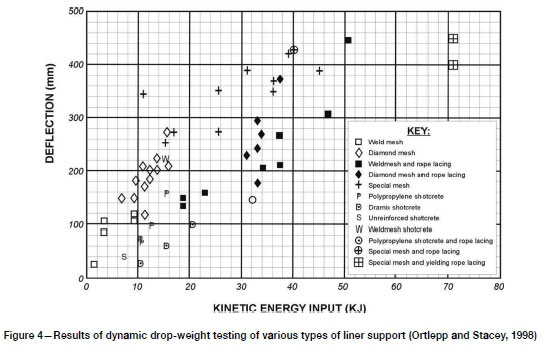

Dynamic, drop-weight testing of support has been carried out (Ortlepp and Stacey, 1998; Hadjigeorgiou and Potvin, 2007) to evaluate the capacities of a range of support systems, and results are summarized in Figure 4 in terms of the input energy imposed by the drop weight.

An interesting interpretation of these results and those of other researchers, in terms of energy absorption instead of kinetic energy absorption, was provided by Potvin, Wesseloo, and Heal (2010).

Correlation between the functions of spider webs and rockburst support systems

As indicated above, rockburst support systems consist of retainment and containment elements, and the connecting elements between the two. The retainment elements are rockbolts and cables that are usually grouted into boreholes in the rock; the containment elements include shotcrete, thin spray-on liners, wire mesh, straps, and wire rope lacing.

Retainment elements

As mentioned above, the spider web literature does not appear to deal with the nature and strength of the web anchor points. This is perhaps indicative that webs do not suffer from anchor failure, implying that the anchor points are more than strong enough to prevent failure in the event of typical insect impacts. In contrast with this, failure of rockbolts and cables, the rockburst support equivalents, commonly occurs in rockburst events (for example, Stacey and Rojas, 2013; Ortlepp, 1997; Jager and Ryder, 1999).

Containment elements

The containment elements of a spider web include the frame threads and the radial threads, both types being extremely strong and with good extensibility. These properties ensure that the web can withstand impacts and wind buffeting without failing. The third containment element of a web is the sticky spiral, whose threads are strong and coated with a gluey liquid to capture prey. In addition, the sticky spiral has an extensibility mechanism in its thread/liquid coating that allows considerable extension without failure, enhancing the energy absorption capacity of the web (Vollrath, 1992). The result of the combination of these extremely high strength non-sticky and sticky spiral threads is an exceptionally strong mesh of threads, with the capability of absorbing significant impact energy. The sticky spiral provides the additional benefit of 'binding' the impacting prey with thread and gluey liquid, ensuring that the prey is captured.

In rockburst support, the most common containment elements are shotcrete and wire mesh. One of the functions of shotcrete is to inhibit the relative movement of rock blocks, and therefore assist in limiting loosening of the rock mass around the periphery of excavations. Shotcrete is commonly reinforced with plastic or steel fibres to improve its tensile strength and toughness. However, shotcrete, even if reinforced, is relatively weak and has little tensile strength. The use of TSLs, which usually have much greater tensile strengths than shotcrete, as well as much greater tensile extensibility, can assist in overcoming the shotcrete limitations. Laboratory studies have shown that a TSL coating can improve the performance of shotcrete significantly (Mpunzi et al., 2015).

The strands of the wire mesh component may be considered to correspond with the mesh of web threads in the spider web. The stickiness, which would assist in confining the rock blocks and preventing loosening of the rock mass, is missing, however.

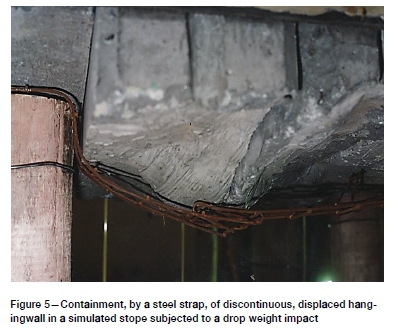

Additional containment elements sometimes used in rockburst support are straps and wire rope lacing. They provide substantial additional containment support and limit the extent of unsupported rock between adjacent rockbolts. As stated above, they also improve the bearing capacity load transfer between wire mesh and shotcrete containment support and the retaining rockbolts. Wire rope lacing could also be likened to a certain extent to the very strong, non-sticky radial dragline threads and frame threads in the spider web. The beneficial effect of straps and wire rope lacing in terms of energy capacity is evident from the drop weight testing results shown in Figures 4. An example of the capability of straps is illustrated in Figure 5, in a drop weight test on a supported, simulated discontinuous stope hangingwall.

The reader's attention is drawn to the two results representing 'special mesh and yielding rope lacing' located at the top right corner in Figure 4. The yielding rope lacing referred to included loops in the wire rope, confined by a friction clamp. This clamp allowed the rope to pull the loop out against the frictional resistance, providing extra toughness in the support, and greater energy absorption capability, performance, which can be seen in Figure 4. This is a direct parallel with the recluse spider's loop system described above. An alternative type of yielding system in wire rope is described by Ortlepp and Erasmus (2005).

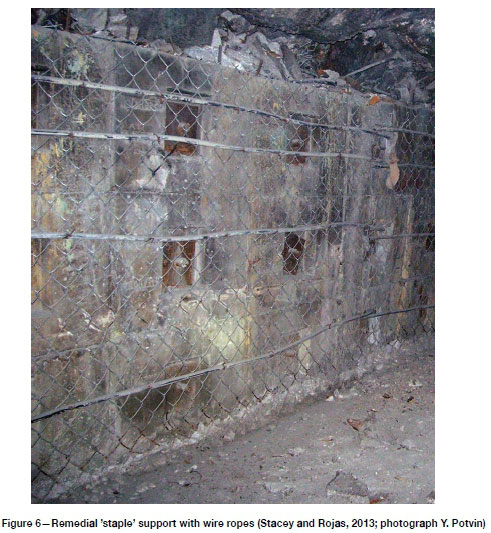

The overarching threads sometimes observed crossing webs, referred to above, also have a parallel in rockburst support. Stacey and Rojas (2013) described failures of rock support as a result of rockbursting. In this case, the installed support consisted of reinforced concrete panels retained against the rock surface by tensioned cables grouted into boreholes in the rock mass. In the rockburst, panels were ejected and cables were broken. The ejection of the panels represented a hazardous situation, which required an immediate remedy. This remedy was to install wire mesh and long wire ropes over the panels, the ends of the ropes being grouted into boreholes, as shown in Figure 6. These ropes, referred to as 'staples', could then 'catch' any ejected panels.

This remedial support system subsequently experienced a rockburst and performed satisfactorily. It is speculated that the overarching threads to the spider web, referred to earlier, may serve a similar purpose to the 'staples' as backup support.

Connecting elements

In rockburst support systems the connecting elements between the retainment and containment support components are commonly faceplates and nuts. Failure of either of these components is almost certain to lead to failure of the support system, and therefore the inability to limit the rockburst damage. Figure 7 shows failure of mesh at a rockbolt/faceplate location, and the consequent lack of retention of the mesh. Such a failure demonstrates the value of the load transfer enhancement provided by straps and wire rope lacing.

It is essential therefore that the connecting components do not fail. Thick steel plates and double-length nuts have been used in attempts to preclude failure. Plates must also not have sharp edges, since this could actually contribute to guillotining failure of the mesh.

There is no direct spider web equivalent to the connection components. However, it could be argued that the connections between the various threads in the web have similar importance. As for the attachment points, there appears to be no focus in the spider web literature on the structure of these connections. However, Hesselberg and Vollrath (2012) describe the connection between a radial thread and a non-sticky spiral thread, which shows numerous twists of the two threads over the length of connection. This would be very effective in preventing failure at the connection, and is partially equivalent to the looping of wire rope lacing around a rockbolt beneath the faceplate in a rockburst support system. It is not known whether a twisted connection is present between the radial and sticky spiral threads of a web. However, failure of the web at these connections does not appear to occur.

Conclusions regarding rockburst support recommendations influenced by the consideration of spider webs

The following is a hierarchy of recommendations for support of excavations in rockbursting conditions, taking into account the properties of spider webs, as summarized in this paper:

> Retainment support must not fail, therefore proven, yielding rockbolts with high-capacity connecting arrangements must be installed, e.g. with bolt threads that are not the weak link, and with nuts that will not fail.

> Containment support must consist of the following elements.

• A sprayed liner to bind the rock blocks together and limit rock mass loosening (shotcrete, which is commonly used, and/or a TSL - the TSL may provide a greater degree of 'stickiness' than shotcrete, although nothing approaching that provided by the sticky spiral in spider webs)

• Extremely strong mesh with unbreakable links' (for example, the chain link mesh made with very high-strength wires by Geobrugg) that will have flexibility as a mesh, and provide maximum resistance to failure

• Straps/lacing to enhance the capacity of the containment (in drop weight testing, lacing improved energy absorption by up to six times), and to ensure the integrity of the rockbolt/mesh connections.

> Connections between retainment and containment support that will not fail, e.g. faceplates without sharp edges and with substantial capacity, and equivalent nuts.

> Surface protection that is able to protect the support from damage but thin enough to prevent shotcrete 'rain' in a rockburst.

> Sacrificial support and retention ropes should be considered. Such support systems could be particularly applicable for support of the floors of excavations (Rizwan and Stacey, 2015).

> Finally, financial evaluations of the cost of the support installed, and the cost of consequences in the event of a rockburst being experienced.

This hierarchy should, however, not be considered as rigid, since it may be necessary to cycle back to earlier steps during the support decision process.

Acknowledgements

The provision of a list of publications of the Oxford Silk Group by Professor Fritz Vollrath is gratefully acknowledged. This information considerably facilitated the preparation of this paper.

References

Brookes, v.L., Young, R.J., and vollrath, F. 2008. Deformation micromechanics of spider silk. Journal of Material Science, vol. 43. pp. 3728-3732. [ Links ]

Daehnke, A. 1997. Stress wave and fracture propagation in rock. PhD thesis, Vienna University of Technology. [ Links ]

Hadjigeorgiou, J. and Potvin, Y. 2007. Overview of dynamic testing of ground support. Proceedings of Deep Mining 07. Potvin, Y. (ed.). Australian Centre for Geomechanics, Perth. pp 349-371. [ Links ]

Hesselberg, T. and Vollrath, F. 2012. The mechanical properties of the non-sticky spiral in Nephila orb webs (Araneae, Nephilidae). Journal of Experimental Biology, vol. 215. pp. 3362-3369. [ Links ]

Hildyard, M.W. 2007. Wave interaction with underground openings in fractured rock. Rock Mechanics and Rock Engineering, vol. 50. pp. 531-561. [ Links ]

Jager, A.J. and Ryder, J.A. (eds).(1999. A Handbook on Rock Engineering Practice for Tabular Hard Rock Mines. Safety in Mines Research Advisory Committee, Johannesburg, South Africa. 371 pp. [ Links ]

Koebley, S.R., Vollrath, F., and Schniepp, H.C. 2017. Toughness enhancing metastructure in the recluse spider's looped ribbon silk. Materials Horizons, vol. 4. pp. 377-382. [ Links ]

Li, C.C. 2010. A new energy-absorbing bolt for rock support in high stress rock masses. International Journal of Rock Mechanics and Mining Sciences, vol. 47, no. 3. pp. 396-404. [ Links ]

McGarr, A. 1997. A mechanism for high wall-rock velocities in rockbursts. Pure and Applied Geophysics, vol 150. pp. 381-391. [ Links ]

Moganedi, K.A. and stacey, T.R. 2019. Value creation as an approach to the management and control of rockburst damage in tunnels. Tunnelling and Underground Space Technology, vol 83. pp. 545-551. [ Links ]

Mpunzi, P., Masethe, R., Rizwan, M., and Stacey, T.R. 2015. Enhancement of the tensile strengths of rock and shotcrete by thin spray-on liners. Tunnelling and Underground Space Technology, vol. 49, June. pp. 369-375. [ Links ]

Ortlepp, W.D. 1992. Invited lecture: The design of support for the containment of rockburst damage in tunnels. Rock Support in Mining and Underground Construction. Kaiser, P.K and McCreath, D. (eds)., Balkema, Rotterdam. pp. 593-609. [ Links ]

Ortlepp, W.D. 1993. High ground displacement velocities associated with rockburst damage. Rockbursts and Seismicity in Mines. Young, R.P. (ed). Balkema, Rotterdam. pp. 101-106. [ Links ]

Ortlepp, W.D. 1997. Rock Fracture and Rockbursts - An Illustrative Study. South African Institute of Mining and Metallurgy, Johannesburg. 255 pp. [ Links ]

Ortlepp, W.D., Bornmann, J.J., and Erasmus, P.N. 2001. The Durabar - a yieldable support tendon - design rationale and laboratory results. Proceedings of Rockbursts and Seismicity in Mines - RaSiM 5. South African Institute of Mining and Metallurgy, Johannesburg. pp. 263-266. [ Links ]

Ortlepp, W.D. and Erasmus, P.N. 2005. A simple yielding element for steel reinforcement in earthquake-resistant structures. Proceedings of the 6th Asia-Pacific Conference on Shock & Impact Loads on Structures, Perth, Australia, 7-9 December. CI Premier, Singapore. pp. 435-444. [ Links ]

Ortlepp, W.D. and Stacey, T.R. 1998. Performance of tunnel support under large deformation static and dynamic loading. Tunnelling and Underground Space Technology, vol. 13, no.1. pp. 15-21. [ Links ]

Peters, H.M. (1995) Ultrastructure of orb spider's gluey capture threads. Naturwissenschaften, vol. 82. pp. 380-382. [ Links ]

Potvin, Y., Wesseloo, J., and Heal, D. 2010. An interpretation of ground support capacity submitted to dynamic loading. Proceedings of the 5th International Seminar on Deep and High Stress Mining, Santiago, Chile. Van Sint Jan, M. and Potvin, Y. (eds), Australian Centre for Geomechanics, Perth. pp. 251-272. [ Links ]

Rizwan, M. and Stacey, T.R. 2015. Conceptual support systems to limit damage to tunnel floors in rockbursting environments. Proceedings of the 13th International Congress of the International. Society for Rock Mechanics. Montreal, Canada. International Society for Rock Mechanics, Lisbon. Paper no. 264. [ Links ]

Stacey, T.R. 2011. Support of excavations subjected to dynamic (rockburst) loading. Proceedings of the 12 th International Congress of the International. Society for Rock Mechanics, Beijing. CRC Press/Balkema. pp. 137-145. [ Links ]

Stacey, T.R. and Rojas, E. 2013. A potential method of containing rockburst damage and enhancing safety using a sacrificial layer. Journal of the Southern African Institute of Mining and Metallurgy, vol 113, July 2013. pp. 565-573. [ Links ]

Vollrath, F. 1988. Untangling the spider's web. Trends in Ecology & Evolution, vol. 3. pp. 331-335. [ Links ]

Vollrath, F. 1992. Spider webs and silks. Scientific American, vol. 266, no. 3. pp 70-77. [ Links ]

Vollrath, F. 1995. Elastic properties of spider's capture silk. A reply to Schneider. Naturwissenschaften, vol. 82. pp. 379-380. [ Links ]

Vollrath, F. 2000. Strength and structure of spider's silks. Reviews in Molecular Biotechnology, vol. 74. pp. 67-83. [ Links ]

Vollrath, F., Porter, D., and Holland, C. 2011. There are many more lessons still to be learned from spider silks. Soft Matter, vol. 7. pp. 9595-9600. [ Links ]

Correspondence:

Correspondence:

T.R. Stacey

Email: Thomas.stacey@wits.ac.za

Received: 23 Apr. 2019

Revised: 9 Jul. 2019

Accepted: 11 Nov. 2019

Published: December 2019