Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.114 no.10 Johannesburg Out. 2014

6TH SOUTHERN AFRICAN ROCK ENGINEERING SYMPOSIUM

Management of the Nkomati Mine crusher slope failure

R. ArmstrongI; K. MoletsaneII

ISRK Consulting

IINkomati Nickel Mine

SYNOPSIS

Due to limited available level ground, Nkomati Nickel Mine cut a weathered rock slope at the base of a mountain spur in order to create a platform for construction of the primary crusher plant and run-of-mine stockpiles. As space is limited around the mining area, ore processing at Nkomati is based on a high reliability of flow of material through the crusher plant, with minimal usage of other and larger designed stockpiles. Evidently, any crusher plant shutdown will render the mine as a whole unproductive and put excessive strain on the medium- to long-term large ore stockpiles, the deposition rates for which are restricted by founding material consolidation requirements.

At the onset of the 2012 rainy season, movement was identified on the slope monitoring system and cracks developed on the slope. After a minor failure on the crusher slope an assessment of the slope stability was conducted and a slope management plan recommended, which included deployment of real-time monitoring. An evaluation of the conditions leading to instability was conducted and the likely causes for the failure identified. A full evaluation of the slope monitoring, rainfall, and mining conditions was undertaken and movement triggers were determined. This paper describes the events leading to the development of the failure and the evaluation of the monitoring data to determine a management plan for the failure that allowed for minimal shutdowns of the primary crusher.

Keywords: slope stability, slope management, slope monitoring.

Introduction

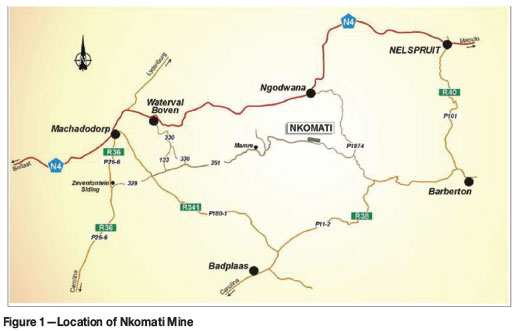

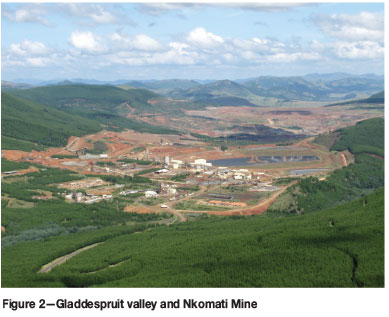

Nkomati Mine is a joint venture between African Rainbow Minerals ARM (50%) and Norilsk Africa (50%), who jointly manage the mine and project. It is situated between Badplaas and Nelspruit in the Mpumalanga Province of South Africa, approximately 300 km east of Johannesburg (Figure 1). The nickel deposit is situated in a steep-sided valley with limited flat ground for mining infrastructure development, as illustrated in Figure 2.

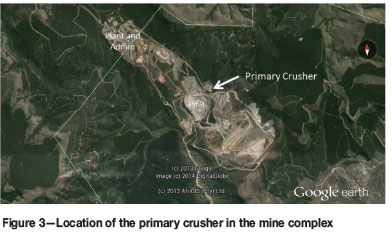

Due to limited available level ground, a weathered rock slope was cut at the base of a mountain spur in order to create a flat platform for construction of the primary crusher plant and run-of-mine stockpiles (Figure 3). As space is limited around the mining area, ore processing at Nkomati is based on a high reliability of flow of material through the crusher plant, with minimal usage of other and larger designed stockpiles. Evidently, any crusher plant shutdown will render the mine as a whole unproductive and put excessive strain on the medium- to long-term large ore stockpiles, the deposition rates for which are restricted by founding material consolidation requirements.

Historic slope performance

In early 2010 a small toe failure and cracks developed on the slope above the primary crusher. A review of the design was undertaken, which included detailed mapping of the geology and laboratory testing by means of of Gradings and Atterburg Limit tests (Dlokweni and Terbrugge, 2010). The analysis of the slope indicated that the slope stability was sensitive to groundwater and slope angle, even at the relatively flat design angles of 23°. Three recommendations were made: to flatten the slope to 19°, backfill the slope with compacted waste material, or dewater the slope and manage the risk. Following consideration of the benefits and costs associated with each option, it was recommended that the slope should remain unchanged and that survey monitoring, depressurization, and groundwater monitoring systems be installed.

An automated survey monitoring system was installed and piezometer holes were drilled. Survey monitoring has been ongoing; however, as the piezometer holes were dry on drilling, the piezometers were not installed and no further dewatering measures were taken. No further records related to groundwater monitoring were available at the time of this study.

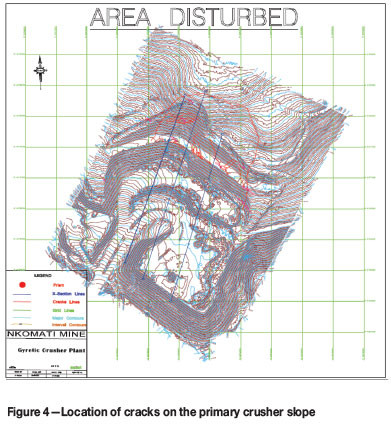

Cracks were observed early in the rainy season of 2012 high up on the slope together with an increase in displacement measured on the survey monitoring system (Figure 4). This prompted a review of the slope instability and the requirement of a management plan that would ensure the safety of the personnel working at the primary crusher area, and also prevent unnecessary downtime for the crusher. Leading up to the review, the mine redeployed the open pit slope stability radar to augment the total station monitoring and dumped a waste rock buttress at the toe of the failure.

Geology

Nkomati Mine is located within the Uitkomst Complex, which is intruded into the lower Transvaal Supergroup. The mafic magma intruded vertically into the Transvaal host rocks and formed into what has been described as an 'anvil-shaped' body.

The lower levels of the valley expose basement granite, followed by Black Reef Formation (the base of the Transvaal Supergroup) through to the Timeball Hill formation higher up. The Transvaal sediments have been intruded by discontinuous diabase sills. Geological investigations were undertaken involving mapping the slope (Dlokweni and Terbrugge, 2010) and interrogation of historic borehole cores and logs. These indicated that the slope consists of an unweathered to slightly weathered dolomite bedrock, including chert horizons along the bedding, capped by a completely weathered diabase sill. Depth of weathering was uncertain over the extent of the slope; however, the cores drilled approximately halfway up the slope indicated that the base of weathering was at 22–35 m.

Slope monitoring

Following the recommendations in the 2010 review, Nkomati installed an Optron robotic total station to the south-east of the slope together with 15 reflective prisms which were measured several times a day (Figure 5). Measurements taken in the early (pre-sunrise) morning were used for regular surveillance of the slope. Following the detection of slope movement, the Groundprobe slope stability radar was redeployed from the open pit and stationed to the south-west of the slope to supply pseudo-real time slope monitoring.

Groundwater and rainfall

Nkomati is in a summer rainfall area. The first rainfall in the 2012 season occurred in September with occasional showers, but the rains started in earnest during November. It is important to note that when the piezometers holes were drilled following the 2010 recommendations and found to be dry, it was during the dry winter months, following which there is no groundwater information. On inspection of the site in December 2012 after the initiation of the slope failure, it was found that one of the old piezometers holes (located between CP23 and CP7 in Figure 5) contained standing water. Several weeks later (January 2013), the hole was dry. This indicates that the groundwater on the crusher slope is meteoric. During the rainy season groundwater builds up along the weathered/bedrock surface. Due to the low permeability of the weathered rock at the base of the slope the water egress is slower than ingress, allowing for a pore pressure build-up that will dissipate with time.

Slope failure triggers

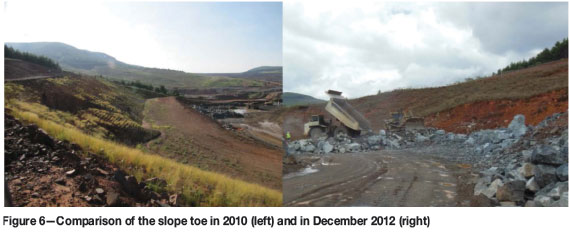

Observations of the slope indicated that degradation of the toe had occurred resulting in undercutting of the slope. At the time of inspection (December 2012), waste rock was in the process of being dumped at the slope toe in an attempt to buttress the failure. Figure 6 shows a comparison of the toe of the slope in 2010 (left) and December 2012 (right). Based on the height of the TR100 dump truck the slope was undercut by 5 m (vertically) above the buttress. The undercutting of the toe resulted in an increase of the overall slope angle from 23° to 25°, the 2° increase being well within the sensitivity of the slope as determined in the 2010 report.

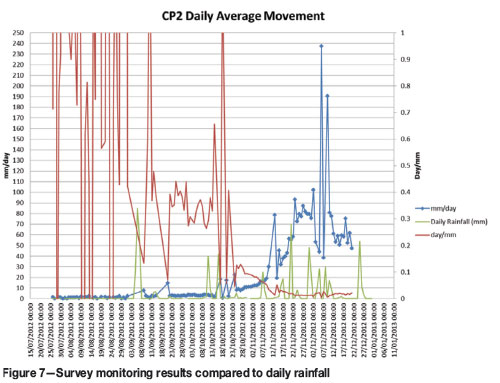

A comparison of the survey monitoring results and measured rainfall is presented as Figure 7. It is evident that the movement of the slope is related to major rainfall events.

The combination of the in situ groundwater and the over-steepening of the slope is considered to be the driving factor for the slope instability.

Remedial action and failure management plan

Observations of rainfall and slope monitoring records indicate that there is a significant increase in slope movement following large rainfall events. It was recommended that any rainfall event greater than 20 mm should be considered a 'trigger' event and monitoring data should be reviewed and the area evacuated if necessary.

The inverse velocity technique (Rose and Hungr, 2007) was also recommended as a tool for analysing monitoring. Since the velocity of movement becomes asymptotic as failure is approached, it stands to reason that the inverse of the velocity will trend to zero. Using this method, the inverse velocity graph can be extrapolated to an estimated time of failure. It is important to note that the method leads to an estimation, and the techniques used to extrapolate the inverse velocity trend can affect the predicted failure time. A daily average velocity and inverse velocity graph for CP2 is presented in Figure 7. The accelerations in the velocity graph can be linked to rainfall events up to two days prior to the spike. Furthermore, these accelerations can be correlated with a decrease in the inverse velocity. It should be noted that at the time of the site visit the inverse velocity had a slight upward trend. It is assumed this reduction in velocity (and increase in inverse velocity) is related to the dumping of the buttress at the slope toe.

Proposal for future remediation

Following the above assessment, a stability investigation was undertaken to determine the risk to the primary crusher from further instability. This programme is currently underway, and has involved the installation of inclinometers into the slope to determine the depth of the failure surface, testing undisturbed soil samples to define the material properties, geophysical tests to determine the depth of the weathered surface, back-analysing the slope to determine the overall strength parameters, and an exercise to design a long-term remedial measure to mitigate the risk to the primary crusher.

Conclusions

Following the review of the slope failure at Nkomati, the following conclusions can be drawn:

► The failure initiated following the undercutting of the slope and the onset of the rainy season

► The failure responded to buttressing the toe by a reduction in slope movement

► Piezometers are required to determine the actual pore pressure that builds up during the rainy season

► Rainfall events greater than 20 mm were considered trigger events for slope movement

► Following the remedial measures taken by the mine and management of the failure, the primary crusher is able to operate under the failure until permanent mitigation measures can be put in place.

Acknowledgements

The authors would like to thank Nkomati Mine for the permission to publish the results of this study.

References

Dlokweni, T. and Terbrugge, P.J. 2010. Review of the stability of the Nkomati Primary Crusher Slope. Report no. 413130. SRK Consulting, Johannesburg, South Africa. [ Links ]

Rose, N.D. and Hungr, O. 2007. Forecasting potential rock slope failure in open pit mines using the inverse-velocity method. International Journal of Rock Mechanics and Mining Sciences, vol. 44, no. 2. pp. 308-320. [ Links ]

This paper was first presented at the, 6th Southern African Rock Engineering Symposium SARES 2014, 12–14 May 2014, Misty Hills Country Hotel and Conference Centre, Cradle of Humankind, Muldersdrift.