Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.113 n.8 Johannesburg Jan. 2013

CONFERENCE

Low-cement chrome-oxide-free castable for use in ironmaking rotary kilns

D. Tsweleng

Evraz Highveld Steel & Vanadium Limited

ABSTRACT

In the Evraz Highveld production process, iron ore is prereduced in rotary kilns prior to charging into submerged arc furnaces (SAFs). Owing to the highly aggressive slags that are formed within the combustion zones of these kilns, chrome-oxide-containing low-cement castables have been used for some years in the kiln lining. Due to concerns around the potentially harmful effects should Cr(V1) be present in the spent linings, Highveld and its suppliers of kiln castables devoted time to developing alternative chrome-free lining materials. Such materials needed to be cost-effective and ensure good performance and improved kiln availability. This paper discusses all the parameters surrounding this development..

Keywords: Low-cement castable, chrome-oxide free, chrome (VI), titaniferous magnetite ore, rotary kiln, submerged arc furnace, open slag bath furnace, Evraz Highveld Steel & Vanadium Limited.

History of Evraz Highveld

Evraz Highveld was established in 1957 by Mineral Engineering of Colorado to produce 1.4 million kilograms of vanadium pentoxide a year through a leaching method. In 1959 Anglo American plc acquired two thirds of the shares in Mineral Engineering. A year later the name was changed to Highveld Development Company Ltd, and by then an investigation was under way to establish the viability of processing titaniferous magnetite ore for the production of liquid pig iron and vanadium-bearing slag.

In 1964 a decision was made to build an integrated iron and steelmaking plant. A year later the name changed to Highveld Steel and Vanadium Corporation Limited. By 1966 Highveld was a global leader in vanadium production. Between 1976 and1978, Highveld acquired Transalloys - a manufacturer of manganese alloys and Rand Carbide - a manufacturer of ferrosilicon and char.

In 1991 the group expanded its activities into stainless steel, acquiring Middleburg Steel and Alloys Limited in partnership with Samancor Chrome Limited and forming the Columbus Joint Venture, which commenced in 1995.

Highveld established a wholly owned subsidiary, Hochvanadium Holding, in 1998, based in Austria for the purpose of processing and selling vanadium products.

In 2006 Highveld was bought by Evraz, the world's largest vertically integrated steel and mining business, and Credit Suisse. In 2008 Evraz bought the rest of the shares from Credit Suisse and all other assets of Highveld were sold.

Evraz produces about 17 Mt of crude steel per annum, making it the 15th largest steel producer in the world. Evraz has a number of steel, vanadium, iron ore, coal mining, and processing operations in Russia, Ukraine, USA, Canada, Czech Republic, and South Africa. The company name was changed in 2010 to Evraz Highveld Steel & Vanadium Limited during a rebranding initiative which is in line with the company global strategy.

Mapochs Mine

Approximately 50 per cent of the world's reserves of vanadium ore can be found in South Africa and in particular as part of the Bushveld Igneous Complex, where they occur in titanomagnetite seams and plugs of the Upper Zone. The richest deposits are found at the base of the Upper Zone in the Main Seam (Rohrmann, 1985).

As part of its South African operations, Evraz operates a magnetite ore mine at Mapochs. The mine, which is an opencast operation, is situated to the north of the village of Roossenekal and was first commissioned in 1967. At Mapochs Mine, the Main Seam outcrops and provides the bulk of the ore that is ultimately used at Highveld Steel.

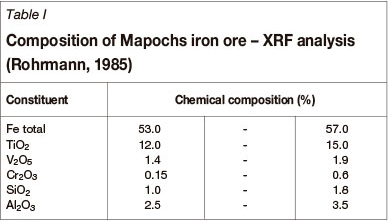

The typical ore composition is as follows (Table I):

Iron- and steelmaking at Evraz Highveld

The Evraz Highveld operation at Witbank consists of iron-and steelmaking activities

The ironmaking plant produces prereduced iron in direct reduction (DR) rotary kilns, which is used as feedstock in the submerged arc furnaces (SAFs) and open slag bath (OSB) furnaces, which were recently converted from SAFs.

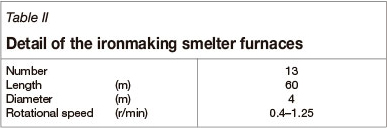

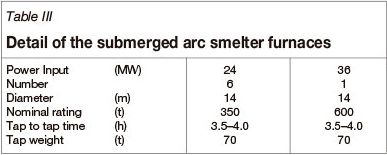

Details of the production units used in the ironmaking activities are shown in Tables II and III

Advantage offered by the OSB furnace compared to the SAF are (Steinberg, Geyser, and Nell, 2011):

The ability to use cheaper coal

Reduction in coal consumption

Reduction in power consumption

Reduction in electrode power consumption.

Hot metal tapped from the arc furnaces is initially treated in a shaking ladle process to separate the vanadium-rich slag before transferring the metal into a standard basic oxygen furnace (BOF) steelmaking process.

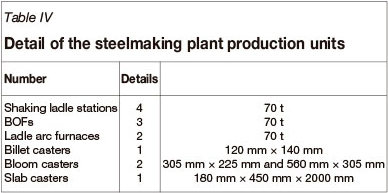

The details of the production units in the steelmaking plant are shown in Table IV.

Downstream facilities include two pusher and two walking beam furnaces at both mills. Billets and blooms are rolled in the structural mill and slabs are rolled into coil and plate according to the specifications.

The direct reduction rotary kiln process

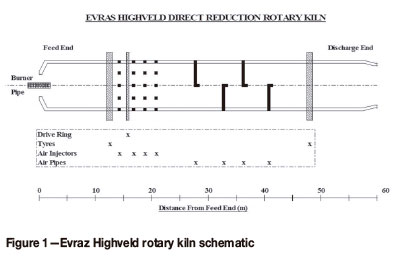

The direct reduction (DR) rotary kilns, a schematic of which is shown in Figure 1, are for the prereduction of the titani-ferous iron ore. The overall effect of the prereduction, with hot feed fed to the electric smelting furnaces, is to reduce electrical energy consumption and to increase smelting rates.

Firing is with pulverized coal and is co-current, with the feed of iron ore, coal, and fluxes (dolomite and silica) being introduced at the burner end.

Fans mounted on the kiln shell introduce additional combustion air through air injectors near the inlet end and through air pipes located along the length of the kiln.

Temperature is controlled at less than 1140°C, but inspection of the kiln lining during shutdowns and of the slag characteristics during simulated slag testing suggest that in the injector area temperatures may be as high as 1450°C in the kiln burden. This results in liquid slagging conditions.

The first section of the kiln is for preheating, with progressive reduction taking place towards the discharge end. The degree of prereduction is 50% to 70%. The hot prereduced iron is discharged at a temperature of about 1100°C into kiln hoppers and transferred batchwise to hot charge ships. These are then transported to the feed hoppers of the smelting furnaces.

Wear factors and requirements for kiln lining materials

There are four main wear mechanisms in the Highveld Evraz direct reduction kilns.

Abrasion

As the particle size of the iron ore and fluxes fed to the kilns is 30 mm and the production rate is 32 t/h, the refractory lining is subjected to severe impact and rubbing/sliding abrasion along the full length of the kiln (Parry, 2013).

Liquid slag attack

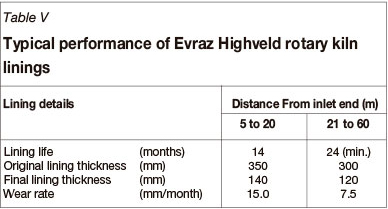

The length of the pulverized fuel flame is estimated at 15 m and additional combustion of coal volatiles takes place within the kiln burden in the air injector zone situated between 14 m and 20 m from the kiln inlet end. As a result, the thermal load on the refractory lining is high during the full 360° rotation of the kiln, and examination of the lining surface and polished sections of samples has shown that the lining is subjected both to slag corrosion and abrasion (Parry, 2013). The effect of the slag attack on the performance of the refractory lining is summarized in Table V.

The significance of liquid slagging conditions is shown by the wear rate, which in the 5-20 m section of the kilns is double that in the rest of the kiln.

Mechanical stress

During operation the refractory lining cycles from compression to tension on each rotation of the kiln. This results from slight misalignment, kiln warpage, ovality at the tyres, and sag between tyre stations (Parry, 2013).

Carbon monoxide gas attack

In DR kilns carbon monoxide (CO) concentrations are high, reducing any free iron oxides in the refractory lining material to metallic Fe. This reduced iron oxide and any metallic originally present catalyses the Boudouard auto-oxidation reaction (Equation [1]) and carbon is precipitated in the pores around high-iron sites (Parry, 2013).

2CO = C + CO2 [1]

Progressive deposition of carbon results in tensile stresses within the refractory and eventual cracking. The reaction takes place between 450°C and 650°C, and if these isotherms are well behind the hot face, loss of the working face due to the pressure behind will be experienced.

It is important that the bricks and monolithic materials used in reduction furnaces contain as little iron as possible and that the iron that is present has reacted with silica, alumina, or some of the other oxides in the product to form stable compounds (Parry, 2013).

During the initial development of castables for DR kilns, carbon monoxide resistance testing to ASTM C 288 was used extensively until the parameters affecting monoxide resistance were understood.

Key attributes required for kiln lining refractories

To summarize the previous sections, the key attributes for lining materials in the Evraz Highveld direct reduction rotary kilns are:

Mechanical strength

Abrasion resistance

Resistance to the slag formed in the first 20 m of the kiln

Carbon monoxide resistance.

History of rotary kiln lining materials (Parry, 2010)

Over the 45 years since the commissioning of the Evraz Highveld plant, the operating and repair philosophy on the rotary kilns has changed many times, depending on the demand for steel and available plant capacity. The two extreme philosophies were maximum life regardless of lining cost with repairs done as and when required, and planned relines at defined interval using the most cost-effective material giving the required life. In the following discussion it is therefore not possible to directly relate the series of products developed to the lining performance.

Underlying both of these philosophies, the general drive was to increase lining life in a cost-effective manner.

The Evraz Highveld kilns were initially lined with bricks. A move to castables was then made, as the loss of a single brick dislocated the whole ring.

1968 60% alumina bricks were used to reline the whole kiln

1978 Standard castable with abrasion resistant natural corundum aggregate was used. The castable failed prematurely

1983 Low-cement castable based on natural corundum was used, but insufficient tonnages were required at the time

1984 Low-cement andalusite-based castable was used, but failed prematurely in the burning zone

1984 Low-cement chrome-oxide-containing andalusite castable was used. Performance improved, but kiln availability could not be predicted

1998 A trial with tabular alumina was very successful, with one sixth of the wear rate compared to low-cement andalusite with chrome. However, tabular alumina was not cost-effective

1999 Low-cement 60% alumina pumpable was used, but collapsed after commissioning. The pumping technology was neither well established nor understood

2003 Low-cement chrome-oxide-containing bauxite in the burning zone and low cement chrome-oxide containing andalusite in the rest of the kiln were used successfully

2012 Low-cement, high-strength chrome-oxide-free bauxite was used in the burning zone and low-cement, high-strength chrome-oxide-free andalusite in the rest of the kiln. The results are satisfactory.

Table VI shows the five main classes of lining materials used in the DR rotary kilns since commissioning - one brick and four classes of castables.

60% Al2O3 brick

From start-up in 1968 to early 1982, 60% alumina (andalusite) bricks were used. As increasing problems were experienced with the stability of the linings and loss of complete rings of brickwork, the refractories suppliers were requested to examine the use of castables (Parry, 2010).

The first castable installed in early 1982 was a first-generation low-cement product of the type recently developed in Europe by Lafarge, called Phlox. At the time the technology of the materials and their installation requirements were poorly understood, as were the wear mechanisms in the kilns, and the trial was unsuccessful. The inadequacy of selecting materials based only on standard laboratory chemical and physical properties was recognized, and simulative testing was introduced (Parry, 2013). These simulative test techniques are discussed in detail later.

Standard castable

During 1982 a test sample of a standard castable, which is defined as a castable containing between 20% and 30% calcium aluminate cement, was trialled. To protect the low-strength matrix (see Table VI) the aggregate was a coarsegrained natural corundum. Performance was inferior to 60% alumina brick (Parry, 2010).

Low-cement castable

In 1983 true and reliable low-cement castable technology became available in South Africa and an andalusite-based product was evaluated for suitability and installed. Mechanical strength of the material was superior to a 60% alumina brick and performance was only slightly inferior to 60% alumina brick (Parry, 2012).

Low-cement castable with chrome oxide addition (Parry, 2012)

Synthetic chemically pure pigment-grade green chrome oxide (Cr2O3) had historically been used as an additive to aluminosilicate brick and monolithics, both to enhance thermal spalling resistance and decrease penetration and attack by slags, particularly those high in FeO. The optimum level of addition is 9% to 10%, but as the price is approximately 25 times the price of andalusite and 12 times the price of bauxite, cost-effective levels of addition are in the range 1.5% to 5%.

In 1984 an andalusite-based chrome-oxide-containing low-cement castable was installed, as simulative testing indicated reduced slag wear as shown in Table VI. This was confirmed in service and the product was the standard until 1994. Many materials were evaluated and trialled, but were either unsuccessful or not cost-effective. For example a tabular alumina-based chrome oxide product gave one sixth of the wear in service, but was prohibitively expensive. Pumpable products offered major installation advantages and initially showed promise, but ultimately did not give the performance.

In 2003 the aggregate was changed from andalusite to bauxite and the maximum particle size increased to 19 mm. Slag wear was significantly reduced and abrasion resistance was later shown to have also been reduced. The product became the standard in the high-wear area from the inlet end to 20 m into the kiln.

Development of a high-strength chrome-oxide-free material

Chrome oxide in chromite ore and in green chrome oxide is in trivalent form (Cr2O3), insoluble, and does not pose a health or disposal risk. Pigment-grade Cr2O3 is, for example, used in green paints and in roof tiles. In service, however, under oxidizing conditions and in the presence of alkali or alkali earth oxides, hexavalent chrome oxide (CrO3) can be formed. Hexavalent chrome oxide is soluble and presents both a health and an environmental hazard.

Although conditions in the rotary kilns are reducing and irregular tests on used lining samples over the years had indicated that hexavalent chrome levels were below the specified environmental maximum - the occupational exposure in South Africa is 0.05 mg/m3 and landfill limit 30 g/ha/m of Cr(VI) (International Chromium Development Association, 2007) - Evraz Highveld requested that suppliers develop a suitable chrome-oxide-free refractory castable kiln lining material.

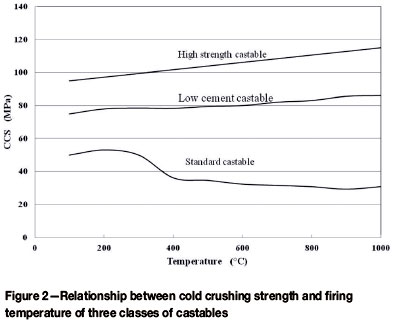

The major wear factors in the rotary kilns are slag erosion and abrasion, so in order to compensate for the removal of chrome oxide, mechanical strength and abrasion resistance had to be significantly improved. Mechanical strength of the new high strength material is shown in Figure 2 compared with those of a standard and a low-cement castable.

To confirm the assumed relationship between mechanical strength and abrasion, resistance abrasion testing to ASTM C 704 was included as a test method during the development. Some of the materials used historically were also tested. Erosion loss on the new high-strength product was 4.2 cm3 compared to 5.0 cm3 on the low-cement castable, as shown in Table VI (Parry, 2013).

Although it was not an objective of the project, surprisingly slag resistance was also improved. The material was installed in August 2012 and to date is performing well.

Simulative testing

As noted earlier, selection of lining materials based on standard laboratory chemical and physical properties (data sheet properties) was found to be inadequate and simulative tests were introduced.

In situ evaluation - slag and abrasion resistance (Parry, 2013)

The first method used was to prepare samples of the trial materials in the form of conical plugs with a hot face dimension of 400 mm. These were placed in position during installation and could be withdrawn for inspection and then reinserted from the outside of the kiln.

Promising products were then further evaluated in panels, not less than one third and preferably one half on the kiln circumference. Using the plug technique a large number of products ranging through basic, ultra-low cement, cement-free, and silica-free, to chemically bonded castables were screened. Most were either unsuccessful or presented installation or heat-up problems.

The limit that the plug technique placed on ongoing development was the time taken to obtain a result. The plug has to be in place for at least half of the expected lining life to show meaningful relative wear. An accelerated evaluation technique was required.

Dynamic slag testing (Parry. 2010)

As it become apparent that slagging was a significant wear mechanism in the first 20 m of the rotary kilns, laboratory slag testing was introduced in order to estimate the expected degree of wear on trial materials.

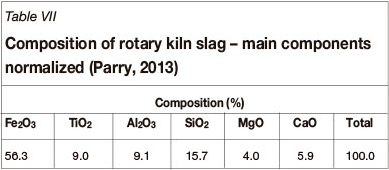

Until May 2004 synthetic slags composed of kiln feed materials and coal ash were used. Subsequently, actual slag removed from the kilns was used. The normalized mean composition of the main components of three samples analysed over the period May 2004 to April 2011 is shown in Table VII.

The state of the oxidation of the iron is not known, and the phase composition of the slag has not been determined.

Microscopic examination in polished section of samples from the kiln has shown attack on the lining materials by CaO and SiO2 with the formation of anorthite (CaO.Al2O3.2 SiO2). Hercynite (FeO.Al2O3) and fayalite (2FeO.SiO2) have also been observed, indicating that even in the preheat section of the kiln some FeO is present. The role of TiO2 has not been investigated.

Static slag pot testing is a useful and simple technique for the rapid initial evaluation of a large number of samples, but the results must be carefully interpreted considering both the limitations of the test and the chemical compositions of the refractory sample and slag.

Limitations of the test are:

No temperature gradient across the sample

No simulation of thermal shock

No flow of slag in contact with the refractory surface

No fresh slag

The slag may quickly become saturated with refractory oxides.

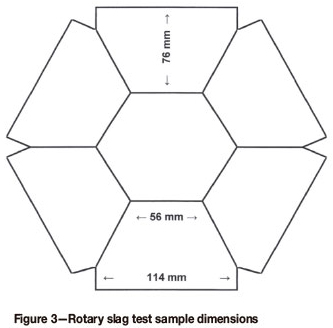

The rotary slag test method is described in ASTM C 774 -75. Refractory specimens are cut from a 230 x 114 x 76 mm sample, assembled as a hexagonal cartridge, and installed in the test furnace as shown in Figures 3 and 4. To reduce possible interactions between adjacent samples, the test piece hot face dimension was 56 mm rather than the ASTM dimension of 44 mm.

As the test gives the relative resistance of refractory materials against slag erosion, a standard reference sample must be included to allow comparison of different runs. If the materials being evaluated are likely to give very different wear rates, then two samples of each should be included to minimize the effect of a high-wear sample on those adjacent to it.

The rotating furnace is heated and charged with fresh slag at regular intervals to ensure that the chemical composition of the liquid slag remains close to the original composition. The test is run until significant differential wear on the specimens can be easily seen. At a test temperature of 1580°C to 1590°C total run time is 12 to 15 hours with DR kiln slag.

After removal from the furnace the samples are sectioned longitudinally as shown in Figure 5 and the erosion and depth of penetration measured. XRD and microscopy can be carried out if required.

Compared with pot testing, rotary testing has the following advantages:

There is a temperature gradient across the sample

Thermal cycling can be included

There is flow of slag across the face of the refractory

Slag composition remains close to original

The test can be run until there is significant differential wear.

A disadvantage is that atmosphere cannot be closely controlled, but this is compensated for by the regular addition of fresh slag.

Abrasion/erosion resistance testing (Schacht, 2004)

A correlation between abrasion resistance and mechanical strength has long been assumed, but confirmation of the behaviour of both matrix and aggregate became critical during the development of a chrome-oxide-free material.

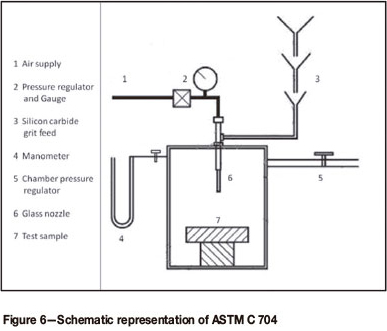

ASTM C704, 'Abrasion Resistance of Refractory Materials at Room Temperature', which has been used for decades in the petrochemical industry, was chosen for evaluation of Evraz Highveld rotary kiln materials.

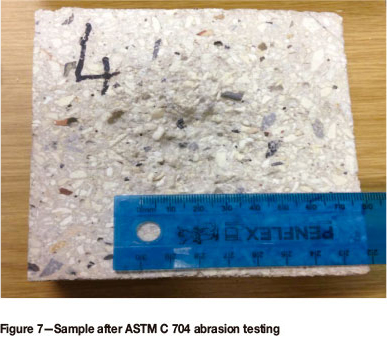

A schematic of the test apparatus layout is shown in Figure 6. A test sample 115 mm x 115 mm x 25 mm is subjected to a stream of compressed air containing silicon carbide particles. After completion of the test the sample volume loss is determined and the abrasion resistance is expressed as a volume loss in cubic centimetres.

The specified impingement angle of 90° was used, which indicates the resistance of both the matrix and aggregate to impact abrasion. A photograph of a sample after testing is shown in Figure 7. The higher wear of the matrix relative to the aggregate is clearly shown. If the impingement angle is decreased, the degree to which the aggregate protects the matrix against sliding/rubbing abrasion is increasingly shown.

The abrasion test results given in Table VI show that the newly developed high-strength castable has better abrasion resistance than the standard material used in the Evraz Highveld rotary kilns, and confirm the relationship between mechanical strength and abrasion resistance.

Carbon monoxide resistance testing

As noted previously, testing to ASTM C 288 was used extensively during the initial development of castables for DR kilns, but is now not done regularly as the requirements for preventing carbon monoxide attack are well understood

Plant trial results

The performance of the low-cement chrome-oxide-free castable was expected to be almost the same or slightly higher than that of low-cement castable with green chrome-oxide, given the mechanical properties and simulative test results as indicated in Table VI. In June 2012 kiln number 1 was installed with the low-cement chrome-oxide-free castable as a trial. As indicated in Table V, the minimum life of low-cement chrome-oxide-containing castable in the burning zone is 14 months, and 24 months in the intermediate to the discharge end.

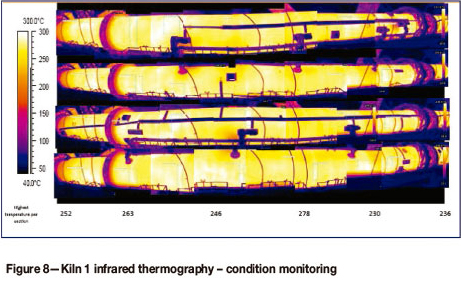

Kiln number 1 is currently 12 months in operation and there has never been any reason to doubt the integrity of the refractories inside; therefore no drill patterns were obtained during this campaign. Kiln availability is of the utmost importance in the ironmaking division, therefore a thermal scan is done intermittently to determine kiln reliability. The optimal shell temperature is about 325°C during operation, and shell temperature increases as the refractory lining decreases. Strangely, although kiln 1 is reaching the end of the burning zone refractory as indicated in Table V, its average temperature is 300°C, which signals positive results.

Figure 8 shows the thermal scan that was done on kiln 1 at 12 months.

Conclusion

Over the past 12 months, Evraz Highveld together with its kiln refractories suppliers has been working towards finding alternative kiln refractory materials that are harmless to people and the environment should chrome (VI) be present in the spent refractories.

Under the current poor market situation, the products had to be cost-effective, give good performance, and ensure kiln availability as kilns are critical in the production path of Evraz Highveld.

Although kiln 1, which was relined with low-cement chrome-oxide-free high-strength castable, has not yet reached end of its refractory life, the results are satisfactory at this point, since the objective - to find a low-cement chrome-oxide-free castable that is cost-effective, that would yield high abrasion resistance, better resistance to slag attack, high mechanical strength, and resistance to attack by CO gas - was achieved through laboratory results, and the plant trial is proving positive so far. The low shell temperature could be a result of an insulating property that was not part of the original design, but would yield great benefits by eliminating shell warping, misalignment, and reducing energy consumption.

Implementation of high-strength castables that are chrome-oxide free is therefore strongly recommended for use at the Evraz Highveld Steel and Vanadium kilns, given the benefits.

Acknowledgement

I would like to express my sincere gratitude to all that gave their support, making it possible to complete this paper. To Vereeniging Refractories (Pty) Ltd and Vesuvius SA, your commitment in assisting us find alternatives is highly appreciated.

I am deeply indebted to Mr R.A. Parry whose help, knowledge, experience, selflessness, and encouragement helped me through the project and made it possible to complete this report.

References

International Chromium Development Association. 2007. Health Safety and Environment Guideline for Chromium. [ Links ]

Parry, R.A. 2010. Product development process for smelter refractories. A text book and practical perspective. Refractories 2010, Misty Hills, Cradle of Humankind, South Africa, 16-17 March 2010. Southern African Institute of Mining and Metallurgy. [ Links ]

Parry, R. 2012. Refractories for the cement industry. Vereeniging Refractories (Pty) Ltd, South Africa. [ Links ]

Parry R.A. 2013. General notes on castable properties and service performance. TSR1879. Vereeniging Refractories (Pty) Ltd, South Africa. [ Links ]

Rohrmann, B. 1985. Vanadium in South Africa. Metal Review Series 2. Journal of the South African Institute of Mining and Metallurgy, vol 85, no. 5. pp. 141-150. [ Links ]

Schacht, C.A. 2004. Refractories Handbook. Taylor & Francis, USA. [ Links ]

Steinberg, W.S., Geyser, W., and Nell, J. 2011. The history and development of pyrometallurgical processes at Evraz Highveld & Vanadium. Journal of the Southern African institute of Mining and Metallurgy. vol. 10. pp. 65-76. [ Links ]

© The Southern African Institute of Mining and Metallurgy, 2013. ISSN 2225-6253.

This paper was first presented at the, Refractories 2013 Conference, 23-24 April 2013, Misty Hills Country Hotel and Conference Centre, Cradle of Humankind, Muldersdrift, South Africa.