Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.113 n.7 Johannesburg Jan. 2013

GENERAL PAPERS

A potential method of containing rockburst damage and enhancing safety using a sacrificial layer

T.R. StaceyI; E. RojasII

ISchool of Mining Engineering, University of the Witwatersrand, South Africa

IIDivision El Teniente, Codelco, Chile

ABSTRACT

Rockbursts continue to be a scourge in the mining industry, being responsible for accidents and damage to mining excavations. Although the problem has been present for more than a century, and although much research has been carried out, a solution is still elusive. Determination of, firstly, the demand on the support system imposed in the rockburst and, secondly, the capacity of the support system, cannot be carried out with any confidence, and therefore rockburst support cannot be designed using a conventional design approach. In contrast with the conventional approach, observations of rockburst damage in a mine have revealed a possible alternative approach to rockburst support - sacrificial support. It was observed, in rockburst events, that a support system consisting of concrete panels restrained by grouted cables was destroyed, and the concrete panels were ejected. However, the rock behind the panels remained apparently undamaged and in place. This behaviour reignited the concept of sacrificial support, conceived more than 20 years ago, and which is described in this paper. The remedial solution implemented on the mine, involving cables wrapped over the panels and retained by grouting into boreholes, has been subjected to rockburst loading and has confirmed the validity of the sacrificial support concept.

The concept of sacrificial support may be controversial, but is deliberately presented here with the aim of generating discussions and contributions, and with the ultimate aim of improving safety and reducing rockburst damage in mines.

Keywords: rockburst, seismicity, seismic waves, rock support, support design.

Introduction

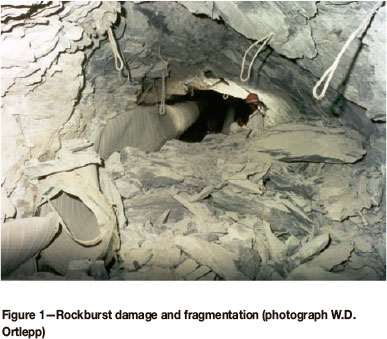

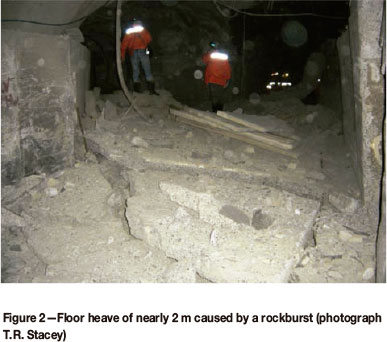

Rockbursts are very violent events that are a great safety hazard and often leave excavations severely damaged. The manifestation of a rockburst is usually rock ejected from the walls of the excavation. The ejected rock is commonly fairly finely fragmented, as illustrated in Figure 1. If concrete is involved in the construction of the excavation, this may be massively moved, as illustrated in Figure 2. Failure of rock support elements is often observed, with containment support (wire mesh, shotcrete) often pulling over tendon supports, leaving them exposed and protruding out of the rock walls, as shown in Figure 3.

Mining and tunnelling operations may also be severely affected by rockburst damage. Clean-up, rehabilitation, and re-supporting of damaged excavations may be hazardous and will incur direct costs, often far in excess of the cost of creating and supporting the original excavation. In addition, there will be many indirect costs, including:

Costs associated with accidents

Costs associated with work stoppages

The cost of loss of production in operations directly affected by the damage

The costs of loss of production in areas more remote from the damage, owing to loss of access such as blockages of tunnels, damage to roadways, damage to ventilation, etc.

The cost due to reassignment of crews

The cost associated with loss of ore

Costs that are difficult to quantify -public perception, reduction of mining company share price, reduced worker morale, labour unrest, etc.

Therefore, if rockburst damage can be reduced or prevented, both direct and indirect costs associated with the damage will be minimized. In determining the value that would be represented by the installation of the 'appropriate' rockburst support, all direct and indirect costs should be taken into account. Recent research by Rwodzi (2010) has shown that, in mining operations, indirect costs far outweigh direct costs in the overall evaluation of consequences, with loss of production usually being the major contributor to costs. The direct costs of rock support components and their installation are usually a small fraction of the overall consequential cost.

Mining is progressing to greater depths in many countries in the world - currently in excess of 4 km and being planned to depths of 5 km in South Africa; effectively at a depth of about 1.5 km in Chile; numerous deep operations in Canada and the USA; and high stress conditions in Western Australia owing to the high horizontal stress field. Many civil engineering tunnels are now being driven under very significant covers, exceeding 2 km. With correspondingly higher stress levels at these extreme depths, it is unlikely that the occurrence of rockbursts can be expected to decline in the future. More attention therefore needs to be given to the containment of rockburst damage.

Design of rock support for rockburst conditions

In a conventional design process (Bieniawski, 1992), the input data required to be able to carry out the design of rock support would require a thorough understanding of the mechanisms of loading, the mechanisms of rock and rock mass failure that the support is being designed to combat, and the mechanisms of action of the support components, and their interactions in the support system. If this information is known, it is usually possible to determine the demands imposed on the support components, and the capacities of the support components and support systems, and this data can then be used to design the required support. The engineering design process conventionally makes use of the concepts of stress and strength. However, in dynamic loading situations it has been found that these concepts are inappropriate for rock support design, and an energy-based design method is more satisfactory. In this regard, the early work of Ortlepp (1992) is considered to be most apposite. He presented an energy-based design rationale, with an application of the design principle focused on rockbolt elements. In this work, he concluded,'... it has been possible to establish some very important design principles. The more important are:

It is neither practicable or economically possible to contain severe rockburst damage by increasing the strength of the tunnel support

Designed yieldability or compliance is essential to prevent support components being broken by rockbursts

The ejection velocity imposed on the rock walls by the seismic wave is probably the single most important determinant of damage intensity in a tunnel...

Energy considerations rather than stress and strength calculations should form the basis of the design of a tunnel support system and its elements.

'Additionally .... some observations were made which are thought to be possibly of crucial importance in the area of design of rockburst support for tunnels.

Ejection velocities of the order of 10 m/s and possibly higher can result from seismic events of moderate magnitude

Such velocities will cause severe damage in tunnels reinforced with conventional active support even if they are heavily supported

Using the energy approach, yielding support systems based on presently available components, can be designed to withstand these velocities and so contain the damage that would otherwise occur as a result of even very large seismic events.'

The energy involved in a rockburst ejection event can be calculated from the kinetic energy equation and depends on the mass of rock ejected and on the square of the velocity of ejection. It has been observed that, typically, approximately a metre thickness of rock is ejected. If the density of the rock is 3000 kg/m3, and the ejection velocity is 10 m/s, the energy of the event is then 150 kJ/m2. To put this value in context, the capacity of a common rockbolt is in the range of 5 to 10 kJ. Therefore, based on strength concepts, between 15 and 30 bolts per square metre of rock surface would be required to provide the energy absorption capacity to contain this rockburst ejection. This is clearly unrealistic.

To determine the demand for support design calculations requires the expected ejection velocity and the mass of ejection to be quantified. Back-analyses of observations of rockburst damage do provide definitive data on ejection velocities. The cast floor concrete that can be observed in Figure 2 is estimated to have been moved upwards in a rockburst event by about 2 m, based on the fact that the individual on the left is about 1.6 m tall and could easily touch the roof of the tunnel. The original tunnel height was about 4.5 m, hence the estimate of about 2 m of upward movement. Nothing is known concerning the source of the small block of concrete that can be seen perched on top of the concrete wall - if it was ejected from the floor in the rockburst event, the ejection height could have been greater than 2 m. If it is assumed that the concrete was thrown upwards, a simple calculation using Newton's laws and the 2 m height indicates that the ejection velocity must have been near to 6 m/s. The value of the deceleration would probably have been greater than the gravitational value owing to interaction resistance between the concrete and the rock in the sidewalls, and the implication is that the ejection velocity could have been even higher, perhaps as much as 9 m/s.

Another interesting case is illustrated in Figures 4 and 5, showing upwards ejection of rock from the sidewall of a 4 m high tunnel.

Simple back-analysis of the ejection velocity of this rock gives a value of near 8 m/s. Owing to the 'bent' geometry of the rockbolts, they are likely to have enhanced the deceleration, and hence the actual ejection velocity could have been about 10 m/s.

McGarr (1997) referred to '... numerous observations, in nearby damaged tunnels ... imply wall-rock velocities of the order of 10 m/s and greater'. Ortlepp (1993) also dealt with high ground displacement velocities associated with rockburst damage and calculated possible ejection velocities: in one case involving a lump of concrete with a size of 0.2 to 0.3 m, the velocity calculated was 8 m/s; in another case, the calculated velocity for a small fragment exceeded 50 m/s. He concluded, '... will highlight paradoxes such as, importantly, how the relatively low PPV generated in the rock mass does not reconcile with the high velocity displacements of the wall rock that has so often been observed to break rock support tendons and produce other phenomena ...' The use of PPV, determined from seismic data, has been suggested as a basis for the determination of ejection velocities (for example Kaiser et al., 1996). To determine the expected ejection velocities for design (for the highest energy level conditions), Kaiser et al. (1996) recommended the following:

'Examine the seismicity records at the mine to establish the spatial and temporal distributions of seismic events

Choose a location of a design event

Select a design magnitude for the seismic event

Select appropriate scaling law parameters for predicting the peak particle velocity ... and hence, the ejection velocity.'

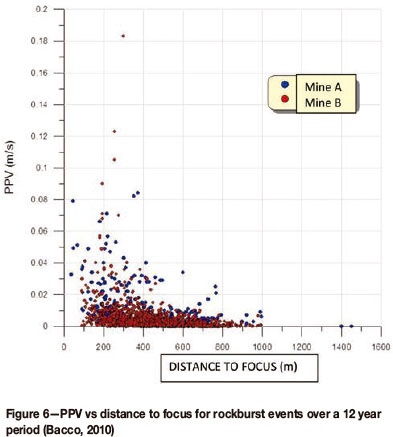

Essentially the same process is suggested in a more recent publication (Kaiser and Cai, 2012). However, back-analysis of ejection velocities from observations of rockburst damage has shown that ejection velocity predictions, based on peak particle velocities determined from seismic data can be unrealistically low (Bacco, 2010). Large PPV amplification factors are required to bring the predicted value to the level of the velocities back-analysed from the 'real' data. For example, from back-analyses of about 60 events in mining operations, which occurred over a 12 year period, ejection velocities were determined (Bacco, 2010). These backanalyses took into account the likely trajectory of the ejected material and the distance of throw. The information for these evaluations was contained in documented reports on each rockburst event. Source locations and PPV data were provided by experienced seismologists, based on records from an ISS seismic monitoring system. Figure 6 shows this PPV data, all associated with rockburst damage, for seismic events with a magnitude greater than 1.5. Amplification factors determined for six selected events ranged between 8 and 52, with an average value of 32.

Alternative explanations for the amplifications have been given by several researchers. Linkov and Durrheim (1998) consider wave amplification as a phenomenon of energy release due to softening. The implication of this mechanism is that it applies to stressed rock conditions. Thus it might be an explanation in certain cases of stressed rock surrounding excavations, but it cannot explain the ejection behaviour observed in Figure 2, in which the unstressed concrete is ejected. Linkov and Durrheim (1998) also refer to the proposition suggested by McGarr (1997), in which buckling of stressed rock slabs on the boundary of an excavation is considered as an amplification mechanism. Again, this mechanism refers to stressed rock conditions, and therefore would not be an explanation for the behaviour observed in Figure 2, or in Figures 4 and 5, in which the direction of ejection does not correspond with what could be expected in buckling behaviour. Similarly, these alternative explanations for increased amplification factors do not apply to the situations in Figures 7, 9, and 11, which appear later in the paper.

Cichowicz et al. (2000) determined amplifications by measurements in mines. They found that the peak ground motion 'is up to five-fold greater on the skin of the hangingwall than 6.5 m in the solid rock.' With regard to this conclusion, however, it is important to note that this could be an underestimate of the amplification that would occur in 02 actual rockburst events. Rockbursts are 'extreme' events, in which circumstances monitoring equipment is likely to be destroyed, and therefore such 'extreme' PPV data will probably never be measured in the field with monitoring instruments installed on the surface of an excavation. Maximum amplifications are therefore likely to be greater than those determined from non-extreme conditions.

Hildyard (2007) concluded, '... the damage potential from an event near an excavation cannot be readily inferred from aspects such as moment, magnitude and the proximity to the source centre, as this ignores the effect of free surfaces [the excavation] and fracturing.'

The implication of the above brief review of some relevant literature is that the wave propagation and interaction processes involved within the rock mass in the generation of ejection velocities are not well understood. Equally, with regard to the mass of rock involved in the ejection, estimates may be made, but confident quantification is likely to be elusive. Therefore, for design purposes the demand is effectively unknown.

With regard to the capacity of a support system, theoretical capacities of support components can be calculated, and actual capacities can be measured in laboratory and field tests (Hadjigeorgiou and Potvin, 2007). However, the capacities of support systems, which involve interactions with the rock mass and between the components in the system, are not known. No satisfactory testing of such systems appears to have been carried out to provide measured performance data. Confidence in theoretical calculations of such system capacities, if carried out, would be very low. It is likely that capacities of a particular support system would vary, depending on direction of loading, and form of loading.

Stacey (2011) concluded, '... under dynamic (rockburst) loading conditions, neither the capacity of rock support systems, nor whether a rockburst will occur, and if it does, what demand will be imposed by the rockburst, are known. Therefore, with regard to a conventional design process for rock support, neither of the two essential parameters required to enable a robust rock support design to be carried out, namely, the demand and the capacity, are known. This is a clear case of design indeterminacy, and it is therefore impossible to determine the required support using the classical engineering design approach' (emphasis added).

It is questionable, therefore, whether any support systems for rockburst conditions are, or can be, satisfactorily designed in the sense of conventional engineering design.

An alternative support design concept - sacrificial support

The consideration of what can be considered to be a controversial approach to support design was conceived some time ago when a patent application was registered (Stacey, 1991), with a provisional specification. This development was not pursued for want of proof testing. The idea was revived in 2007 as a research proposal (Stacey, 2007), and again more recently, as a result of observations of rockburst damage in a mine. These recent observations of damage resulting from rockburst events have indicated some intriguing behaviour, as described below.

Rockburst damage case number 1

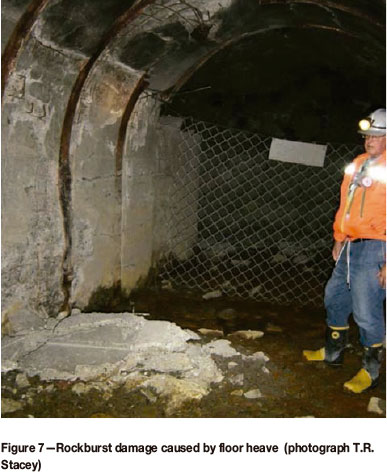

In Figure 7 an area of clean concrete can be seen in the floor. During the rockburst event, this concrete was clearly heaved upwards, causing significant loading on the steel arch. The thrust along the arch has caused it to fail in the roof, with associated damage to the concrete in the roof. However, in the photograph it can be seen that neither of the adjacent arches show any signs of distress. They are each about 1 m from the damaged arch, and their bases are surrounded by mud and water, not clean concrete.

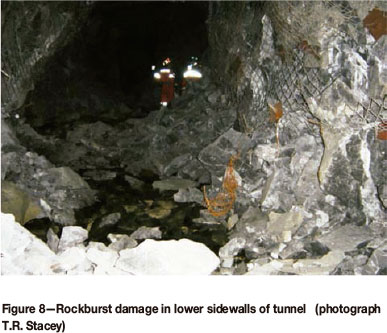

Rockburst damage case number 2

In Figure 8, significant ejection of rock from both lower sidewalls of the tunnel can be seen, and this ejection has caused damage to the installed rockbolt and wire mesh support. In the central floor of the tunnel, however, where water is present, the behaviour has apparently been different, since there appears to have been no heave, nor ejection of rock.

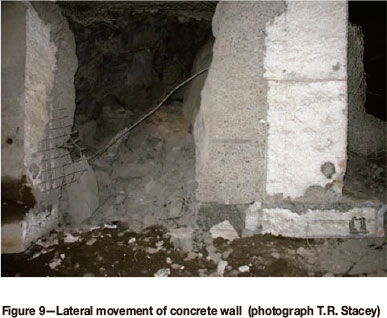

Rockburst damage case number 3

The photograph in Figure 9 shows a concrete wall some 1 m thick that was moved laterally by about 3 m during a rockburst event. The wall was constructed by casting concrete against the rock sidewall and it was 'tied' to the rock by rockbolts and cables. Rockbolts and cables were broken during the event, as can be seen in Figure 10. However, the rock surface was undamaged, as can also be seen in this photograph.

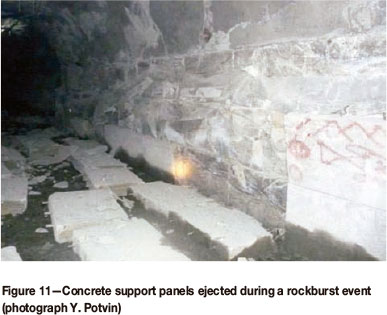

Rockburst damage case number 4

The tunnel support system shown in Figure 11 consists of concrete panels, each panel being retained against the rock surface by fully-grouted cables. After a rockburst it was found that panels had been ejected from the sidewalls, an example of which can be seen in the photograph, causing significant damage to the support system. However, the rock surfaces that were behind the failed panels were not displaced and appeared undamaged.

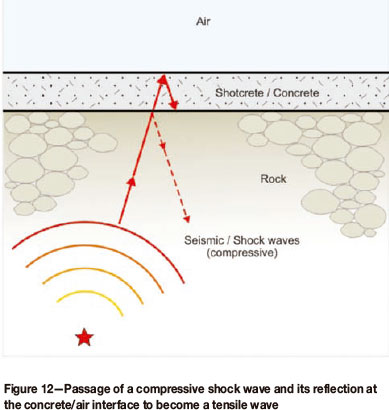

A possible mechanism of behaviour of sacrificial support

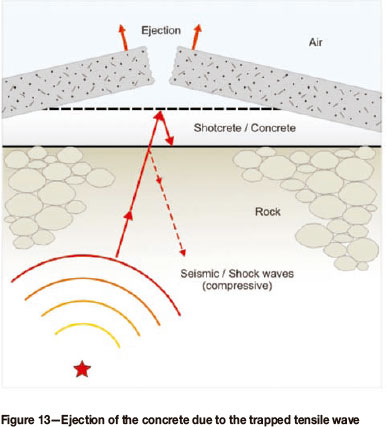

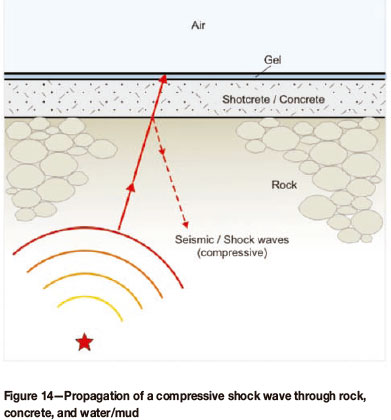

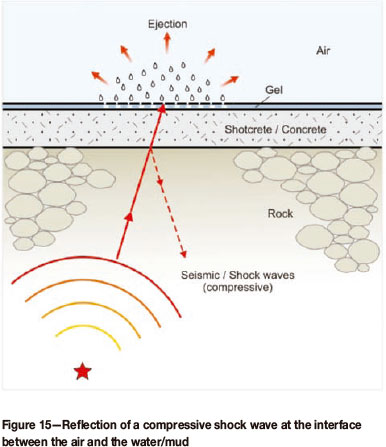

It is suggested that the possible mechanism of behaviour in all of the intriguing examples described above could be that of a tensile wave trap effect, as indicated in the cartoons in Figures 12-15. The concept of a wave trap is well known in the blasting community (for example, Hino, 1959; Starfield, 1967; van Heerden, 1969; Miklautsch, 2002; Grasedieck, 2004), and Hino's material is particularly relevant to the rockburst mechanism described below.

Figure 12 illustrates the propagation of a seismic compressive shock wave from its source location towards a rock surface covered with a layer of concrete. The wave passes through the rock/concrete contact (with possible minor reflection at this interface, as shown, owing to the stiffness difference) and then reflects at the concrete/air interface, since air cannot sustain the passage of compressive waves. On reflection, the compressive wave is converted into a tensile wave, which then travels back down to the concrete/rock contact. Since this contact has no tensile strength, the tensile wave is trapped in the concrete layer and the concrete is ejected as indicated in Figure 13. This leaves the rock surface undamaged. However, much damage would be observed in the excavation owing to the heaved concrete. This behaviour is manifested in the rockburst damage illustrated in Figures 2, 7, 9, and 11.

Similar wave trapping could occur when mud and water are present - this situation is represented in Figures 14 and 15. The compressive wave travels through the rock, concrete, and water/mud (indicated as 'gel'), all of which materials can sustain the propagation of such compressive waves. At the interface between the air and the water/mud, the wave is reflected, becoming tensile, and, since water/mud cannot sustain tensile stresses, the wave is trapped and dissipated as a spray of water and mud, leaving the concrete and rock undamaged.

The absence of rockburst damage where the floor was covered with mud in Figure 7, and in Figure 8 where the central floor area was under water, could be explained by this behaviour.

The wave trap mechanism of rockburst damage was recognized in the patent application of Stacey (1991), and the means for inhibiting rockbursts was described as 'a method which includes the step of coating the free surface of a tunnel, shaft, stope or the like, with a thin layer of a substance which has a low tensile strength ...': and 'The method of coating or applying the substance in a thin layer to the free surface may include spraying, squirting, pouring, spreading, or by affixing or securing the substance ...'; and 'The substance may comprise grease, tailings with an appropriate binder, or the like, or may consist of thin paving tiles or bricks placed in contact with the free surface ...'. With regard to the last type of 'substance', further information was provided: 'Under the force of a reflected tensile wave ... the tiles will be ejected ... and consequently they must be sufficiently small so as not to present a hazard to life when ejected', and '... a working platform may be placed over the substance applied to the free surface . In order for the substance to be effective ... the platform must be clear of the substance.' Finally, 'The method and means ... for inhibiting rockbursts do not replace any support systems but are to be used in addition to such support systems.'

It is clear from the above, that the 'substance' was seen as a sacrificial layer that would be ejected in the rockburst, leaving the rock surface unaffected by the rockburst.

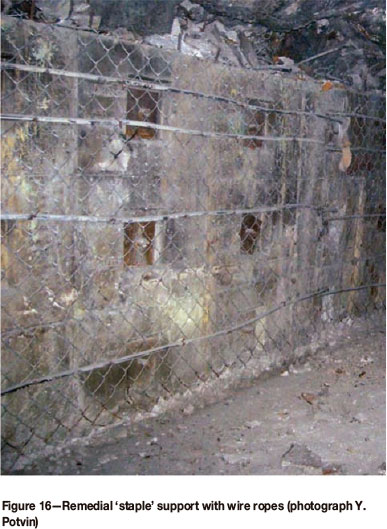

Confirmation of the validity of the sacrificial support mechanism in rockburst events

The concrete panel support shown in Figure 11, a satisfactory design in static conditions, could be considered to be an inappropriate support system for dynamic, rockburst conditions. Concrete panels retained by fully-grouted cables represent a rigid support system. Such a rigid system is contrary to the commonly understood rockburst design requirement of compliant, yielding support systems that can absorb energy during deformation, but at the same time maintain their load-carrying capability. However, what may be considered an inappropriate rockburst support design has provided a rock support method that may be considered a most elegant solution to counter the rockburst problem and contain the associated damage. It has provided an excellent opportunity not only to observe the behaviour (ejection of the concrete panels), but also to observe the implementation of a remedial solution. This remedial solution had to be implemented at short notice to ensure safe, stable working areas. The solution was to install steel wire ropes, wrapping over the panels, with the ends of the ropes being grouted into boreholes drilled through the panels. This remedial support design is illustrated in Figure 16. The photograph shows the support prior to its being sprayed with shotcrete to provide protection against damage by mechanized equipment. Owing to the geometry of the remedial support ropes, they are colloquially referred to as 'staples'. Such staples provide the containment support to the panels, preventing them from being 'thrown off in a rockburst event. They need to be loose enough to perform in a secondary mode - to catch the ejected panels, but not to be part of the primary support system.

The performance of this new, remedied, support system under rockburst loading has already been tested in practice, since such support has been subjected to actual rockbursts in the mine. Under such conditions it has proven to be capable of preventing ejection of the concrete panels, hence proving itself as a successful support system for rockburst conditions. The panels represent sacrificial support components, and their ejection, which would be the observable rockburst damage, is prevented by the staples in their secondary support capacity. Most importantly, the rock is left apparently undamaged, therefore ensuring that the rock mass retains its coherence and that the excavation maintains its stable state. The magnitudes of seismic events to which this support system have been exposed are in the same range as the events that caused the ejection of panels prior to the remedial support.

Discussion

Perhaps more important to the field of rock engineering than the physical success of the remedied rockburst support system is the fact that its implementation in the mine has provided the opportunity to prove the concept of a sacrificial rockburst support system. This is a serendipitous case in which truly valuable knowledge has been learned from the original support design, elegant for static conditions but perhaps inappropriate under dynamic loading. In the future, the design of the remedied support system needs to be reviewed to convert it from a remediated design to a complete, innovative, optimized design. For example, it may be appropriate to provide slots in the concrete panels to accommodate the 'staples', and the staples should be in the form of yielding bolts or cables (for example, Ortlepp and Erasmus, 2005) to ensure that staple failure does not take place. The system should also be beneficial in the design of roadways and floors to prevent rockburst damage, such as the extensive heave of concrete that is frequently observed, as shown in Figure 2. To the authors' knowledge, floor support is not installed routinely in any mine in the world to combat rockburst conditions. Modular panels, containing engineered slots to accommodate yielding cables, placed in the floor could provide a satisfactory running surface. The cables could be anchored in boreholes drilled steeply into the lower sidewalls. The cables from each side could be joined using a yielding coupling such as that designed by Ortlepp and Erasmus (2005), and again accommodated in an engineered slot in the panels. This is simply a more elegant version of the floor support contemplated in the provisional patent specification of Stacey (1991).

The implementation of sacrificial support should not imply that it replaces other rock support (this was also specifically recognized in the patent application (Stacey, 1991)). Its benefits are likely to be improved safety and reduced (possibly prevented) damage, but these benefits might not accrue in all situations. Therefore, recognized rockburst support systems, with high yield capabilities, should continue to be used to provide the required protection against rockburst damage.

The concept of sacrificial support may be controversial, but is deliberately presented here with the aim of generating discussions and contributions, and with the ultimate aim of improving safety and reducing rockburst damage in mines. It is hoped that practitioners who have made similar (or contrary) observations to those described above will make this information known. Although the sacrificial support concept has been proven by observations of behaviour in a mine, there remain several research questions, the answers to which will assist in the extension of the concept to much more general application:

Is there a minimum thickness for the sacrificial support layer?

What are the effects of different stiffnesses of sacrificial support - would a soft gel sprayed onto the rock surface be effective?

Is the concept restricted to compressive wave reflections or, phrasing the question alternatively, how well will it work with other types of waves, and wave interactions?

The wave trap mechanism has been suggested as a possible explanation for the observed behaviour, but are there other possible explanations? For example, research carried out by Mureithi and Fowkes (2007) indicates that when water is present in cracks (fractures, joints) in the rock, suction forces can be large in the event of a rockburst, thus inhibiting rockburst damage.

Research is planned, using both physical testing and analysis with numerical codes, to investigate these questions.

Conclusions

Observations of the performance of a rockburst support system in a mine subjected to actual rockbursts has proved that the concept of a sacrificial support system can be successful as a means of minimizing or preventing rockburst damage. It has been suggested that a possible mechanism of action of the sacrificial support is that of a tensile wave trap, which has the effect of protecting the rock, or concrete, beneath it from being damaged in a rockburst.

The main benefit that is likely to accrue from the implementation of the sacrificial support concept is reduced excavation damage. Associated with this will be improved safety and, very significantly, major economic benefits due to fewer occurrences of damage requiring rehabilitation and causing disruptions to production.

Investigation of the mechanisms involved in the behaviour, and of the scope for its application in practice, will require further research.

Acknowledgements

Division El Teniente, Codelco Chile, including the New Mine Level Project, is thanked for permission to publish this paper, and to include the photographs and data from the mine.

The work by the first author is based on the research supported in part by the National Research Foundation of South Africa (Grant specific unique reference number (UID) 85971). The Grantholder acknowledges that opinions, findings, and conclusions or recommendations expressed in any publication generated by the NRF-supported research are those of the author(s), and that the NRF accepts no liability whatsoever in this regard.

The referees of the paper are thanked for critical comments and suggestions, which have led to considerable improvement of the paper.

References

Bacco, M. 2010. Analisis de estallidos de roca. Powerpoint presentation, El Teniente Mine. [ Links ]

Bieniawski, Z.T. 1992. Principles of engineering design for rock mechanics. Rock Mechanics, Proceedings Of the 33rd US Symposium on Rock Mechanics. Tillerson. J.R and Wawersik, W.R (eds). Balkema, Rotterdam. pp. 1031-1040. [ Links ]

Cichowicz, A., Milev, A.M., and Durrheim, R.J. 2000. Rock mass behaviour under seismic loading in a deep mine environment: implications for stope support. Journal of the Southern African Institute of Mining and Metallurgy, vol. 100. pp. 121-128. [ Links ]

Grasedieck, A. 2004. Die natürliche bruchcharakteristik (NBC) von Gesteinen in der Sprengtechnik. PhD dissertation, Montanuniversität Leoben. 162 pp. [ Links ]

Hadjigeorgiou, J. and Potvin, Y. 2007. Overview of dynamic testing of ground support. Deep Mining 07. Potvin, Y. (ed.). Australian Centre for Geomechanics, Perth. pp. 349-371. [ Links ]

Hildyard, M.W. 2007. Wave interaction with underground openings in fractured rock. Rock Mechanics and Rock Engineering, vol. 50. pp. 531-561. [ Links ]

Hino, K. 1959. Theory and practice of blasting. Nippon Kayaku Co. Ltd., Tokyo. 169 pp. [ Links ]

Kaiser, P.K. and Cai, Ming. 2012. Design of rock support system under rockburst condition. Journal of Rock Mechanics and Geotechnical Engineering, vol. 4, no. 3. pp. 215-227. [ Links ]

Kaiser, P.K., McCreath, D.R., and Tannant, D.D. 1996. Canadian Rockburst Support Handbook: Volume 2: Rockburst Support, Canadian Rockburst Research Program 1990-1995. Canadian Mining Industry Research Organization (CAMIRO), Sudbury, Ontario. [ Links ]

Linkov, A.M. and Durrheim, R.J. 1998. Velocity amplification considered as a phenomenon of elastic energy release due to softening. Mechanics of Jointed and Faulted Rock, Balkema, Rotterdam. pp. 243-248. [ Links ]

McGarr, A. 1997. A mechanism for high wall-rock velocities in rockbursts. Pure and Applied Geophysics, vol. 150. pp. 381-391. [ Links ]

Miklautsch, A. 2002. Experimental behaviour of the blast fragmentation of rocks and concrete. Dissertation, Montanuniversitat Leoben. 160 pp. [ Links ]

Mureithi, E. and Fowkes, N. 2007. Rockburst and mud. Proceedings of the Mathematics in Industry Study Group (MISG), University of the witwatersrand. pp. 27-39. [ Links ]

Ortlepp, W.D. 1992. The design of support for the containment of rockburst damage in tunnels. Rock Support in Mining and Underground Construction. Kaiser, P.K. and McCreath, D.R. (eds.). Balkema, Rotterdam. pp. 593-609. [ Links ]

Ortlepp, W.D. 1993. High ground displacement velocities associated with rockburst damage. Rockburst and Seismicity in Mines. Proceedings of the 3rd International Symposium on Rockbursts and Seismicity in Mines, Kingston, Ontario, Canada, 16-18 August 1993. Young, P.R. (ed.). Balkema, Rotterdam. pp. 101-106. [ Links ]

Ortlepp, W.D. and Erasmus, P.N. 2005. A simple yielding element for steel reinforcement in earthquake-resistant structures. Proceedings of the 6th Asia-Pacific Conference on Shock & Impact Loads on Structures, Perth, Australia. pp. 435-444. [ Links ]

Rwodzi, L. 2010. Rockfall risk: quantification of the consequences of rockfalls. MSc Eng. dissertation, University of the Witwatersrand. [ Links ]

Stacey, T.R. 1991. Method of and means for inhibiting rockbursts. Patent Application, Provisional Specification, registered through Adams and Adams, Patent Attorneys, Pretoria. [ Links ]

Stacey, T.R. 2007. Minimizing the effects of rockbursts? Research proposal, Mathematics in Industry Study Group, University of the Witwatersrand. [ Links ]

Stacey, T.R. 2011. Support of excavations subjected to dynamic (rockburst) loading. Proceedings of the 12th International Congress If the International Society of Rock Mechanics, Beijing. CRC Press/Balkema. pp. 137-145. [ Links ]

Starfield, A.M. 1967. Strain wave theory in rock blasting. Failure and Breakage of Rock. AIME, New York. Ch. 23, pp. 538-548. [ Links ]

Van Heerden, W.L. 1969. A study of pre-splitting by means of an ultra high speed camera. Report MEG778, Council for Scientific and Industrial Research (CSIR), Pretoria, South Africa. [ Links ]

Paper received Jul. 2012

Revised paper received Mar. 2013

© The Southern African Institute of Mining and Metallurgy, 2013.