Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of the Southern African Institute of Mining and Metallurgy

versión On-line ISSN 2411-9717

versión impresa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 no.8 Johannesburg ene. 2012

JOURNAL PAPER

Trial of the BX conical-ended borehole overcoring stress measurement technique

H. OgasawaraI, II; H. KatoIII; G. HofmannIV; P. de BruinV

IIJST-JICA, Science and Technology Research Partnership/or Sustainable Development (SATREPS)

IIRitsumeikan University, Japan

IIIAkema Boring Ltd, Japan

IVAnglogold Ashanti, South Africa

VMoab KhotsongMine, South Africa

SYNOPSIS

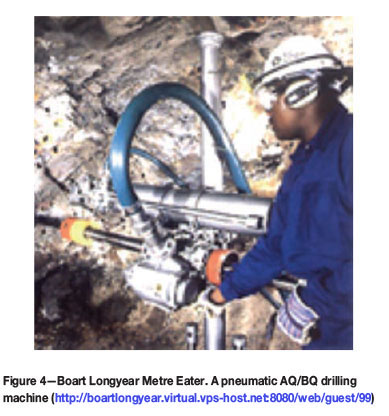

Information on rock stress is important for safe mining in seismically active ground. On a major gold mine, a few tens of crews are continuously conducting geological drilling with small pneumatic machines. However, stress measurements are not often carried out in South African deep-level gold mines. One of the reasons is the drilling diameter that overcoring requires, which is much larger than the diameters used in regular geological drilling, e.g. Boart Longyear Metre Eater, which drills AQ or BQ holes. Larger diameter holes result in slower drilling advance, more load in transportation and handling at sites, and higher cost.

In order to enable overcoring in BX size (60 mm diameter), we modified the compact conical-ended borehole overcoring (CCBO) technique that has been suggested by International Society for Rock Mechanics (ISRM) and was originally designed for NX drilling (76 mm diameter). With a single overcoring, the 3-D stress tensor can be determined. We tested this modified method at a depth of about 3 km at Moab Khotsong mine in South Africa. We worked with drilling crew who usually work at geological drilling with the Metre Eater. In January 2011, we tried using regular geological drilling tools (a sequence of a normal BX bit, reamer, and rod) without success. In August and September 2011, introducing stabilizers and thin BX bits, we succeeded. We could complete a cycle of procedures necessary for an overcoring, including shaping the borehole-end conically, glueing a 16-element strain cell, and overcoring, within 2.5 hours. Only 10 cm overcoring is needed, which increases the chance of successful overcoring in heavily fractured conditions. This modified method is suitable for up-dip holes to depths of 10-15 m from tunnels, and has the potential to be widely used at the initial stage of geological exploration drilling at many localities.

Keywords: stress measurement, borehole overcoring.

Introduction

In South Africa, gold mining is proceeding to ever-greater depths, and also being conducted to remove remnants, both of which involve higher seismic risks. The more in situ stress data is available, the better the seismic hazards can be assessed with the aid of stress modelling software. However, as reported by Gay (1975), or more recently by Wesseloo and Stacey (2006), very little data has been published for each gold mining district in South Africa, although there is more unpublished data. In the data, there is significant scatter in the k-ratios, which does not easily constrain the stress field in the areas of concern. If regular geological drilling equipment can be adapted for overcoring, this would create more opportunities to obtain in situ stress data.

One of the popular methods of in situ stress measurement in South Africa is the CSIRO HI technique (suggested by ISRM; Kim and Franklin, 1987), a version of the South African CSIR triaxial strain cell method initially proposed by Leeman and Hayes (1966). However, as Stacy and Wesseloo (2002) point out, it requires:

(a) high-quality diamond core drilling

(b) associated equipment, facilities, and devices, often using larger diameter bits, and a special device for centring of the pilot hole

(c) good quality of rock (intact overcores at least 300 mm long)

(d) laboratory testing for elastic properties.

The above can cause higher costs and result in fewer measurements.

Here we introduce an overcoring technique in BX holes (60 mm diameter). As will be detailed, we successfully carried out test work in a South African gold mine that solved the first three problems listed above.

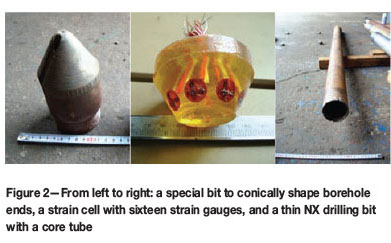

Compact conical-ended borehole overcoring technique (CCBO) and its implementation in Japan

The CCBO technique was first proposed by Kobayashi et al. (1987), who placed 12 strain gauges in a 56 mm diameter holes by overcoring. Sakaguchi et al. (1992) attempted to improve the accuracy of the technique, proposing a cell with 16 or 24 strain gauges. The method was then suggested by ISRM (Sugawara and Obara, 1999). As illustrated in Figure 1 and shown in Figure 2, the technique is designed for NX (76 mm diameter) overcoring of strain gauges glued on a conically shaped borehole end. With a single overcoring of 16 or 24 strain gauges, a 3-D stress tensor can be determined. In sub-horizontal holes, two men can carry out CCBO in good working conditions. If the workable hours are long enough, three or four overcorings can be carried out in a single shift in Japanese mines.

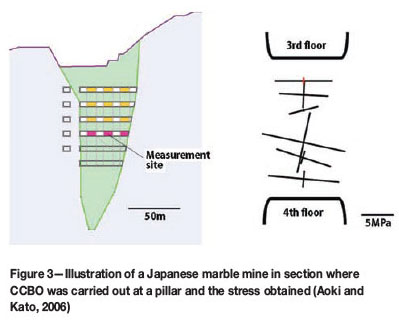

Figure 3 schematically illustrates an example case at a mine and the stress measurement results (Aoki and Kato, 2006). At the mine, pilot drillings followed by ten overcorings as well as hydrofracturing tests were carried out within two weeks. It was demonstrated that CCBO is a straightforward way to obtain stress data, particularly if the mining configuration is too complex to model stress. In another mine, the technology was transferred to a geologist, who has carried out tens of overcorings at eleven sites. At each site a few overcoring were completed in three days. The geologist assembled strain cells himself, which reduced the cost significantly.

An application at a South African gold mine

Typical South African geological pneumatic drilling

In the larger gold mines in South Africa with thousands of employees, tens of crews are continually conducting exploration drilling. A small pneumatic drilling machine (Figure 4) is the most commonly used for AX or BX geological exploration drilling from a small cubbies underground, often located in the footwall drives of thin tabular reefs. The drilling operation is very simple: the rotation speed, generally much faster than those for the drilling machines shown in Figure 1, is driven by compressed air and adjusted by a lever; but only three advance rates can be selected with respect to rotation, and the weight on the bit cannot be controlled. High-quality and accurate geotechnical drilling is therefore not easy. Rods of NX or larger size cannot be accommodated directly through the spindle. Because of vibration of thinner rods in the hole and the higher rotation rate, NX drilling is always much more difficult than AX or BX drilling with the machine.

CCBO technique in BX size

Because of the relative difficulty of NX drilling with Metre Eater in South African gold mines, we designed self-similar, smaller tools for BX overcoring. We kept the aspect ratio of the location of the 16 strain gauges with respect to the strain cell so that we can use the same strain coefficients as those published by Sugawara and Obara (1999, Table 2).

We prepared the tools for overcoring in up-dip holes 10-20 m long. After conically shaping the borehole end, we carefully cleaned the end-surface and checked if it was dry. We applied cyanoacrylate instant gel adhesive (e.g. Loctite® Super Glue Gel) to the strain cell and held the cell onto the end for about 10 minuets. We needed only 10 cm overcoring, which significantly increases a chance of successful overcoring in the rock mass in poor condition.

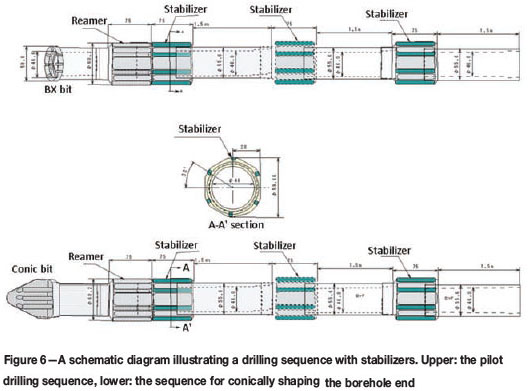

At the Moab Khotsong gold mine, South Africa, we had an opportunity to try a BX CCBO technique. In the first attempt in January 2011, we used a standard drilling system - i.e. BX rod, BX reamer, and BX standard bit (Figure 5, right). There was no dog-earing, core-discing, or bad ground in the pilot hole. However, overcoring could not be conducted although we attempted three times. That was because rotation rate was not controlled to sufficiently suppress the vibration of the rods or the bit; the hole was not drilled straight enough for overcoring, and therefore the strain cell easily became detached when the bit passed the cell.

To address the problem, in August 2010, we introduced a thinner BX drilling bit (Figure 5 left) to decrease a chance that the bit could contact the cell and a drilling sequence with stabilizers (Figure 6) to suppress the vibration of rods and to obtain a straighter hole.

The procedures from 2 to 5 in Figure 1 were successfully completed within 2.5 hours on 6 and 7 September. At the Moab Khotsong mine, using the shift boss cage, work at the site was limited to only 3 hours because of the distant access (main shaft, sub-shaft, carriage). However, we could complete a cycle of overcoring within a single shift.

CCBO stress measurement at Moab Khotsong gold mine

Results of stress measurement by the BX CCBO technique

We chose a measurement site on 98 level 103 line (at a depth of about 3 km from surface), where there was little mining activity, for our trial in August and September 2011. The site was also situated in the middle of the Japanese dense array of AE sensors, sensitive strain meters, tilt meters, and fault-transmitted wave monitoring system (e.g. Ogasawara et al., 2009 and Durrheim et al., 2012) as well as mine's accelerometers array to monitor the instability of the De Hoek fault, which is situated several tens of metres below the reef.

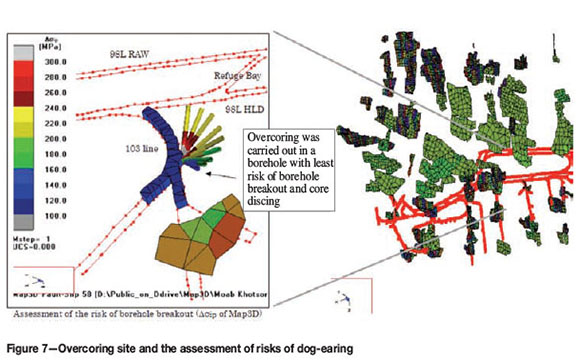

Our CCBO procedure requires a dry up-hole. In order to assess the risk of dog-earing, we input the stress parameters of Hofmann and Scheepers (2010) into the Moab Khotsong model in Map3d, a boundary-element stress modelling software package (Wiles, 2012). Their stress parameters were constrained, compared with moment tensor inversion of M3 and M4 seismic events (Hofmann and Scheepers, 2010) and dog-earing (Lachenicht, 2000) at the Great Noligwa mine, contiguous with the Moab Khotsong mine. A hole with minimum risk of dog-earing was thus obtained, as shown in Figure 7. With the modelled stress, we also checked out that the risk of core discing was minimal, based on the criteria proposed by Matsuki et al. (2004).

A 13 m long pilot hole was drilled. Scoping the hole with a borehole camera confirmed that, except for the initial several meters with slight dog-earing, the hole was in homogeneous quartzite in good condition, which was also confirmed by the drilled core. Figure 8 shows an example of strain change during the overcoring at a depth of 14 m. It can be seen that the strain was successfully relieved (Figure 8, left). The strain field (blue and red lines in Figure 8, right) calculated from the inverted stress agrees well with the strain relieved by overcoring (circles and squares in Figure 8, right). The regression was successful with acceptable confidence because

where F0: test statistics; MSR: mean square of regression; MSE: mean square of residual; F0,01 6; 9: F-value for a probability of 1 per cent and the degrees of freedoms for our case. This suggests that the rock mass responded elastically.

Figure 9 shows the principal stresses in the two overcorings on 6 and 7 September 2011. Because of theft of the recording paper, the roll angle could not be measured on 6 September 2011. Therefore, the roll angle was searched so that the observed strain relief agreed with the strain field shown by the blue and red lines in Figure 8 (right). The stress field thus estimated agreed well in magnitudes and directions with those on 7 September 2011 (Figure 9). It is important to note that the measured maximum principal stress was not normal to the reef plane, whereas Hofmann and Scheepers (2010) assumed in their Map3D model that the maximum principal stress was normal to the reef plane.

Problems to address

Technical problems

Measured vertical stress was about 20 per cent smaller than the overburden stress if we assume a Young's modulus of 70 GPa and Poisson's ratio of 0.20. Because of poor management of core by the drilling company, our core was mixed up with other cores, thus it was not possible to carry out a laboratory test. Additional drilling will provide cores for laboratory testing to check if the Young's modulus is larger than 70 GPa.

As discussed in detail in Sakaguchi et al. (1992), the strain coefficients of the cell will be somewhat different from those published by Sugawara and Obara (1999), because the lengths of strain gauges are finite. However, Sakaguchi (personal communication) suggested to us that this factor cannot be large.

Drilling operators in South African gold mines are not well equipped with tools that handle rods or overcoring tools easily. The introduction of a small portable winch will enable overcoring to be carried out much more easily and with fewer personnel.

Operational problems

Currently, a Japanese expert must be present at overcoring sites, which doesn't allow overcoring to be flexibly scheduled. Not all overcoring tools are available in South Africa. To enable regular implementation of the BX CCBO technique in South African gold mines, we have to spend time to establish a group consisting mainly of South African personnel, who can supervise overcoring and procure the necessary tools in South Africa.

Concluding remarks

In South African gold mines, many small drilling machines are used to drill holes with small diameters, but this equipment is not so often used for stress measurements. With the small machine, we were able to implement a BX CCBO stress measurement at a South African gold mine.

We found the BX CCBO technique needs only 10 cm of overcoring, fundamentally increasing the chance of successful overcoring in a rock mass in less than good condition. It was also confirmed that, using the shift boss cage, we could complete one overcoring and associated tasks within 2.5 hours - within one normal shift at the Moab Khotsong mine, where only 3 hours per shift can be worked at the site. In principle, therefore, if a small drilling machine, used in routine geological drilling, is already rigged at the site, we would be able to carry out multiple overcorings within a relatively short period of time.

The above results illustrate the advantage of the BX CCBO technique, which potentially enables more frequent stress measurements to contribute to safety in South African gold mines.

Acknowledgements

This project would not have been possible without the assistance of the Moab Khotsong mine and Anglogold Ashanti. We also thank the mine and Anglogold Ashanti for the permission to publish this paper, and Raymond Vermeulen, Khanya Luthuli, Wian Blom, and Gilbert Morema (technicians from Open House Management Solutions Ltd and Seismogen CC) for their great assistant at the site. Lesedi Drilling and Mining Contracting Company Ltd carried out drilling for overcoring. Hiroshi Tanaka and Akiyoshi Takada of Akema Boring Ltd manufactured indispensable tools, and Osamu Murakami, Akiko Kamito, Koichiro Miyara, Alex Milev, and Frans Nortje assisted shipping from Japan to South Africa. We also thank Professor Kiyotoshi Sakaguchi for his kind suggestions, and the reviewers for their comment that improved our manuscript.

The activities were funded by JST/JICA, SATREPS, the Japan Science Promotion Society grant in aid, by the Ministry of Education, Culture, Sports, Science and Technology (MEXT) of Japan (S-21224012), under its Observation and Research Program for Prediction of Earthquakes and Volcanic Eruptions (No. 2401), and by Ritsumeikan University and GCOE Earth Science, Tohoku University.

References

Aoki, K. and Kato, H. 2006. Stress state in a pillar in room-and-pillar mining -Stress measurement at a pillar in multi-layered room-and-pillar mining at a 70m depth. 2006 Fall Meeting. The Mining and Materials Processing Institute of Japan, Abstract B3-4, 11 September 2006, Fukuoka, Japan (in Japanese). [ Links ]

Durrheim, R., Ogasawara, H., Nakatani, M., Yabe, Y., Kawakata, H., Naoi, M., Murphy, S.K., Wienand, J., Lenegan, P., Milev, A. M., Murakami, O., Yoshimitsu, N., Kgarume, T., Cichowics, A., and SATREPS research group. 2012. Establishment of SATREPS experimental sites in South African gold mines to monitor phenomena associated with earthquake nucleation and rupture. Proceedings of the 6th International Seminar on Deep and High Stress Mining. Potvin, Y. (ed.). ACG, Perth, Australia. pp. 173-187. [ Links ]

Gay, N.C. 1975. In situ stress measurements in southern Africa. Tectonophysics, vol. 29. pp. 447-459. [ Links ]

Hofmann, G.F. and Scheepers, L.J. 2010. Simulating fault slip areas of mining induced seismic tremors using static boundary element numerical modelling. Proceedings of the 5th International Seminar on Deep and High Stress Mining. Jan, M.V.S. and Potvin, Y. (eds.). ACG. pp. 395-412. [ Links ]

Kim, K and Franklin, J.A. 1987. Suggested method for rock stress determination. International Journal of Rock Mechanics and Mining Science and Geomechanical Abstracts, vol. 24, no. 1. pp. 53-73. [ Links ]

Kobayashi, S., Nishimura, N., and Matsumoto, K. 1987. Displacements and strains around a non-flat-end borehole. Proceedings of the 2nd International Symposium on Field Measurements in Geomechanics, Kobe, Japan, vol. 2. pp. 1079-1084. [ Links ]

Lachenicht, R. 2000. Orepass Stability Assessment at Great Noligwa Mine. Project Report, Document No GNM-REP-010. [ Links ]

Leeman, E.R. and Hayes, D.J. 1966. A technique for determining the complete state of stress in rock using a single borehole. Proceedings of the 1st Congress of International Society for Rock Mechanics, Lisbon, vol. 2. pp. 17-24. [ Links ]

Lucier, A.M., Zoback, M.D., Heesakkers, V., Reches, Z., and Murphy, S.K. 2009. Constraining the far-field in situ stress state near a deep South African gold mine. International Journal of Rock Mechanics and Mining Science, vol. 46. pp. 555-567. [ Links ]

Matsuki, K., Kaga, N., Yokoyama, T., and Tsuda, N. 2004. Determination of three dimensional in situ stress from core discing based on analysis of principal tensile stress. International Journal of Rock Mechanics and Mining Science, vol. 41, no. 7. pp. 1167-1190. [ Links ]

Sakaguchi, K., Obara, Y., Nakayama, T., and Sugawara, K. 1992. Accuracy of rock stress measurement by means of conical-ended borehole technique. Journal of the Mining and Materials Processing Institute of Japan, vol. 108. pp. 455-460. [ Links ]

Stacey, T.R. and Wesseloo, J. 1998. Evaluation and upgrading of records of stress measurement data in the mining industry. Final Project Report, GAP511b. Safety in Mines Research Advisory Committee, Johannesburg. pp. 1-31. [ Links ]

Stacey, T.R. and Wesseloo, J. 2002. Applications of indirect stress measurement techniques (non strain gauge based technology) to quantify stress environments in mines. Final Project Report, GAP858. Safety in Mines Research Advisory Committee, Johannesburg. pp.1-67. [ Links ]

Sugawara, K. and Obara, Y. 1999. Draft ISRM suggested method for in situ stress measurement using the compact conical-ended borehole overcoring (CCBO) technique. International Journal of Rock Mechanics and Mining Science, vol. 36. pp. 307-322. [ Links ]

Wesseloo, J. and Stacey, T.R. 2006. Updated in situ stress database for

Southern African. In situ Rock Stress. Lu, Li, Kj0rholt, and Dahle (eds.). Taylor & Francis. pp. 467-471.

Wiles, T. 2012. Map3D User's Manual. Mine Modelling Pty Ltd. http://wwww.map3d.com [Accessed10 February 2012] [ Links ].

© The Southern African Institute of Mining and Metallurgy, 2012. ISSN2225-6253. This paper was first presented at the, Southern Hemisphere International Rock Mechanics Symposium (SHIRMS) 2012, 15-17 May 2012, Sun City, South Africa.