Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of the Southern African Institute of Mining and Metallurgy

versión On-line ISSN 2411-9717

versión impresa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 no.2 Johannesburg ene. 2012

JOURNAL PAPER

The application of GRP and thin spray liner support products in a typical block cave mining method to enhance safety and productivity

P.H. Ferreira; A. Piroddi

Minova, South Africa

SYNOPSIS

A typical sub-level block cave mining extraction method employs an undercut level to establish a cavity in hard rock, and as such requires special support methods and products to be installed during the development phase.

The undercut level development in the block cave orebody is then sacrificial, and support elements will eventually report to the crusher and perhaps conveyor belt systems for transportation to surface. The choice of support products installed in the undercut level development should take cognizance of the detrimental effect these could have on the mining system such as cutting of conveyor belts, obstructing crushers, safety aspects, and productivity.

This work explores the probability and practicality of making use of new-generation support products to make the operation safer as well as enhance productivity in the development phase and during the undercut operation.

This paper will investigate the use of glass reinforced plastic (GRP) rockbolts and GRP mesh instead of conventional steel bolts and mesh along with resin capsule-filled holes with the GRP bolts. Complementing this with thin spray liner (TSL) application as another means of creating a safer operating environment, as well as a productive support medium, will also be addressed. These proposed items are envisaged to reduce production downtime and improve the safety of our people. These items are all easy and light to handle, cuttable and crusher friendly, as they will break up during the crushing process.

Keywords: thin spray liners, GRP bolts.

Introduction

Pressure to provide a workplace free from injuries and fatalities has added to the worldwide market pressure to improve profits and margins in the mining industry.

A rockfall study (Potvin et al. 2001) conducted in 26 Australian underground metal mines has shown that over 90% of rockfall injuries involved in rocks smaller than 1 ton. Furthermore, studies have shown that most injuries in underground mines have occurred within a few metre of the active face. This suggests that the current approaches in controlling the small pieces of exposed rocks near the active face where mineworkers are consistently exposed can be improved. The approaches used range from using no surface support to the installation of mesh (steel and fibre), and in poor ground conditions the installation of shotcrete.

While applying the current methodology near the face would likely reduce the risks of rockfall injuries, it could negatively impact the operations with regards to cost and mining cycle times.

Thin spray liners (TSLs) can address the abovementioned problem. The installation of surface support using remote and rapid spraying techniques has the potential to minimize interference with the mining cycle and reduce costs. TSLs can be applied essentially on or at the face to keep the small key blocks in place and reduce the potential of gravity-induced fallouts of small pieces of rock.

The products discussed in this paper were all developed by Minova RSA, the intent being to compare the characteristics of each type of product against the others, rather than against those of competitive products. For the purpose of this investigation, Minova RSA has chosen to evaluate their products against the following set of criteria:

Characteristics of various TSLs

Ease of application

Product quality performance

Spray ability and coverage

Comparison to shotcrete

Scale of interference with the mining cycle.

The first part of this paper will describe the characteristics of Capcem KT - TSL range.

The second part of the paper will describe the characteristics of the glass fibre reinforced bolts and mesh.

Thin spray liner characteristics

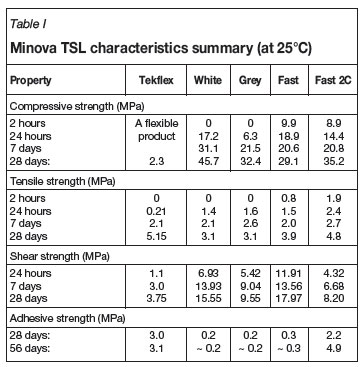

The technical characteristics of Minova RSA's range of Capcem KT- TSL products are shown in Table I.

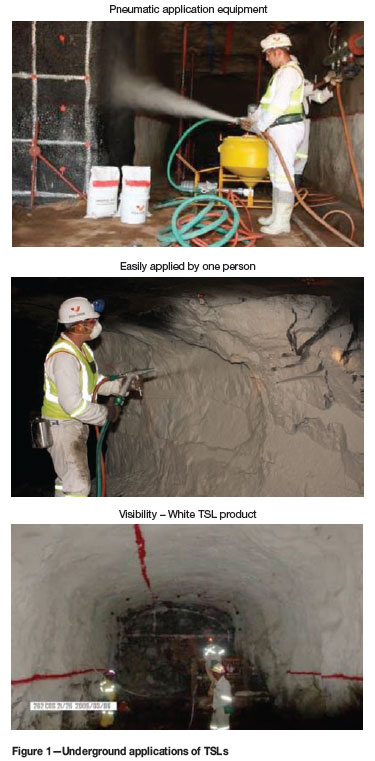

The Capcem KT range of TSLs provides a protective coating to rock, concrete, or coal surfaces that are susceptible to deterioration on exposure to mine atmosphere, or are employed as a TSL for support. (Figure 1)

These products are all propelled by compressed air onto the rock surface. A full liquid TSL that does not require compressed air for propulsion onto the rock surface is in an advanced stage of development.

Critical requirements of TSLs have been identified as follows:

Adequate pot life when mixing i.e. more than 30 minutes

Factory pre-mixed products for consistent performance of product

Fast development of strength for rapid performance after two hours of application i.e. compressive, tensile, and shear strength

Excellent adhesion i.e. bonding to the substrate

Visibility of the coating (white or light in colour).

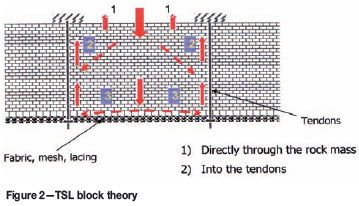

The support performance of TSLs is determined largely by the substrates onto which it is attached. The TSLs can greatly assist in maintaining the initial integrity of the rock mass under general loading conditions.

To ensure effective surface support design, it is important to fully understand the required reinforcing capabilities of the skin support. In friable ground conditions, the first function of a TSL is to prevent the unravelling and loosening of fragments, thus maintaining the rock mass integrity. If unravelling is not prevented, the support resistance within the rock mass will gradually decrease and the demand on the surface support will consequently increase.

Being in intimate contact with the rock surface, the coating action of TSLs bridges joints, effectively penetrates fractures, and bonds the rock mass together, thus restricting interblock movement.

Figure 2 illustrates the interaction between various support components in a support system, represented as a reinforced beam loaded in an orthogonal direction.

Pneumatic application equipment

Classification of TSL characteristics

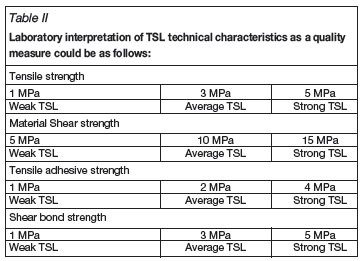

Laboratory interpretation of TSL technical characteristics could be as follows.

The classification in Table II should be read in conjunction with the geotechnical requirements for the specific loading conditions that may be expected, and may not all be equally important or applicable.

In selecting the most suitable TSL, cognisance must be taken of the specific requirements and intended application of the TSL. For example, in a static environment the requirement may be for a TSL with a high uniaxial compressive strength, where tensile strength capabilities are less critical.

Underground application

Minova RSA TSLs are currently being extensively used in platinum and chrome mines, with relatively limited application in other hard-rock and diamond mines. The Capcem KT range is used in most applications, with specialized Tekflex applications in vertical settler dams and raise boreholes for sealing against water leakage and in excavations requiring flexibility.

The success of applications stems from ease of mixing and spraying and ultimately the cleaning of equipment after use. All this leads to quick and cost-effective spraying cycles and will determine the success of the TSL application. Good surface preparation is also essential for a good bond.

Stress-induced fracturing was observed in the rock mass surrounding the excavation and wedge type failure of rock occurred at the intersections of these fractures and lowangled joint sets, creating a very rough and uneven rock surface in the immediate hanging- and sidewalls of the excavation. The condition of the rock mass around a tunnel is to a large degree controlled by the rock strength and the stresses it will be subjected to during its life cycle. In highstress conditions, sound design and excavation techniques are required to reduce early fracturing damage and to prepare the rock walls for the installation of support.

In these conditions, the installation of support at an early stage after exposure of the rock surface can significantly improve the prevailing ground conditions. It has become common practice in the deep-level scenario to apply a thin layer of shotcrete as soon as possible after the blast to inhibit the adverse effect of stress fracturing and weathering, and to maintain safe working conditions till such time that secondary and more permanent support can be installed. However, it is often difficult to maintain the shotcrete within a reasonable distance from the advancing face, due mainly to logistical constraints and difficulty of fully integrating the shotcrete into the development cycle. TSLs have the potential to reduce accident levels and increase productivity, as the rapid spraying techniques involves minimal interference with the mining activity. In friable ground conditions, the first function of a TSL is to inhibit the unravelling and loosening of of fragments, thus maintaining the rock mass integrity.

In relatively large excavations, tunnels, and a mechanized production environment, TSLs are very well suited to a robotic arm spray system for fast and efficient applications.

If unravelling is not prevented, the support resistance within the rock mass will gradually decrease and the demand on the surface support will consequently increase. Being in intimate contact with the rock surface, the coating action of TSLs bridges joints, effectively penetrate fractures, and bonds the rock mass together, thus restricting inter-block movement. More permanent structural support such as thick shotcrete can be applied on top of the TSLs with good bonding.

Capcem KT

Product description

Capcem KT White and Grey have very similar properties and are supplied as a single-component powder (pre-mixed in the factory) to which water is added. The main difference between Capcem KT White and Grey is the cement used, and KT White cures to a brilliant white finish, while KT Grey cures to a light cement-grey finish. Capcem KT Fast is a product developed by Minova RSA with the intention to provide early aerial support coverage to underground excavations, offering strength after 2 hours. Capcem KT Fast 2C and Tekflex consist of two packed components-a premixed powder and a liquid polymer forming a kit.

The Capcem KT range forms a semi-rigid support membrane that assists the rock to retain its initial integrity by reducing the adverse effects of scaling, spalling, and weathering. It is supplied in 25 kg bags which produce on average 15 litres of product when mixed with 5.4 litres of water or polymer. It can theoretically cover 3.4 m2 if applied 5 mm thick to a flat surface. However, due to the roughness factor of the underground rock, it is estimated that 2.5 m2 can be covered by one 25 kg bag or kit.

Application methodology

Typical mixing arrangement

The contents of a number of 25 kg bags of Capcem KT White, Grey, or Fast are mixed together with clean water as per recipe, for approximately 4 minutes and then pumped (using an electric pump or compressed air driven pump), through a 25 mm hose to the spray nozzle some 15 m away, from where it is sprayed onto the hanging- and sidewalls either by hand-held or robotic arm arrangement. The spray tempo is in the region of 500 to 800 litres per hour for effective application.

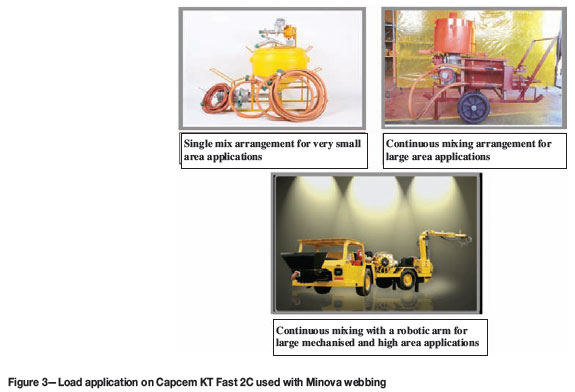

With continuous mixing of the TSL whilst spraying, a surface area of some 45 m2 can be covered in 30 minutes. The total cycle time is thus some 35 minutes, measured from the time the operators enter the tunnel until they move out (Figure 3).

Minova RSA had done tests with TSLs on numerous panels to determine the relative performance of the products. Tests were done with TSLs only and also with a combination of TSLs with a relatively thin webbing sprayed over. The results are illustrated in Figures 4-6 and Table III

One could conclude that TSLs offer a practical solution for limited ground support, and if used in conjunction with appropriate webbing and followed in extreme cases by a layer of shotcrete, they offer a superb practical and mechanized solution to ground support in a sacrificial or permanent tunnel or excavation environment, with the safest application method and with very few people involved. All applications from the application of webbing to TSL to shotcrete can be done mechanized, remotely and rapidly (Table IV).

Spray equipment

The ease of application of TSLs will ensure minimal interference with the development cycle and improve safety and productivity. The equipment required for TSLs is small compared to conventional shotcrete equipment and can readily be moved between sites. There are various types of TSL pumping and mixing equipment available; however, the use of equipment with independent mixing and pumping arrangements is recommended to reduce application cycle times.

Logistics

In the case of 25 mm shotcrete, approximately 158 x 25 kg bags are required to cover an area of 45 m2, which equates to ±4 tons of material. In the case of 5 mm TSLs such as Capcem KT, 23 x 25kg bags or ½ ton of material is required to cover 45 m2.

The use of TSLs can significantly reduce the demand on the already burdened logistical systems of the mine while maintaining safer mining conditions right at the advancing face. A typical conventional development cycle might consist of the following:

Cleaning operations

Making safe

Installation of temporary support (jacks and netting)

Marking off support holes

Drilling and installation of support

Marking off of the round

Drilling the round

Charging up and blasting

Removing temporary support

Re-entry.

Depending on the requirements, the application of surface support liners should ideally be integrated into the overall production cycle where it is most practical and causes the least interference with the development cycle. If it is required to apply the surface liner from the last line of permanent support up to the face, then ideally this activity should take place immediately after the installation of temporary support or even permanent support if a resin bolt installation is chosen.

In a bad ground undercut development end, the support regime might call for the following support:

A bolting pattern

Shotcrete at 25 mm thickness

Steel mesh and/or lace installation

Shotcrete at 50 mm thickness.

With the new-generation support available the following could be proposed:

GRP or synthetic netting installation with netting installing unit mounted to face jumbo

5 mm TSL on washed and made safe development rock surface with robotic arm applicator

A GRP and resin capsule bolting pattern with a mechanized bolter. This could be adequate to safely allow critical and inline activities to continue at the face, and then follow up with

50 mm shotcrete approximately 20 m behind the advancing face.

What we attempt to demonstrate is that a combination of TSLs, appropriate netting, GRP bolts, and shotcrete will offer the same support resistance but with less material, faster development cycles, safer development methods, and support products that can be broken up and destroyed when the undercut level gets blasted away and the product goes through the crushers.

Allowance must be made in the production cycle for at least half an hour for the application of the TSL, assuming the product and equipment is on site. This excludes the time taken to set up the equipment and the cleaning afterwards. Furthermore, it could be advantageous to spray a thin layer of TSL over the previously sprayed surface of the previous blast to increase the TSL thickness to say 8 mm and produce a good and consistent cover and protection.

Conclusion

Rock-related accidents are the major cause of injuries and fatalities in underground mines, and most of these accidents occur near the active faces where workers spend most of their time. One of the major causes of instability is lack of support and/or coverage between support units. Support tendons alone do not provide sufficient rock reinforcement in friable ground conditions and hence allow the potential of gravity induced fallout of small pieces of rock.

TSLs have the potential to benefit the mine by offering improved productivity, profitability, and safety. From a manufacturing perspective, it is very unlikely that all the characteristics that TSL could have can be included in one 'super' product. For this reason the proper selection and application of the correct TSL is very important to be able to significantly improve ground conditions and reduce related injuries.

Introduction to glass fibre reinforced plastic bolts and mesh

In 1985 Weidmann AG, a company in Switzerland, started with the development and manufacture of a range of glass fibre reinforced plastic (GRP) rockbolts which were then used for the first time in tunnelling projects in Switzerland. The GRP bolts were installed as permanent support together with steel mesh and shotcrete in numerous tunnels constructed by the single-shell method.

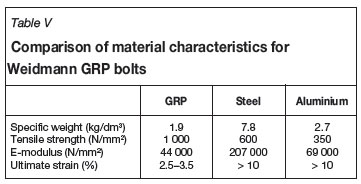

GRP bolt technology has since found widespread application in the mining and civil engineering industries. Compared to steel, glass fibre reinforced plastics have advantages that can be traced to the properties of the composite material. It offers high resistance to corrosion, high tensile strength, light weight, and is easily cut through.

The application of glass fibre reinforced plastics offers various possibilities. In cooperation with Rockbolt Systems (Switzerland), the Minova group offers a range of GRP bolts suitable for various rock support applications.

Minova RSA has also developed a range of TSLs suitable for use as underground containment support or for weathering protection.

GRP description

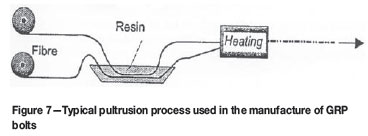

GRP bolts consist simply of a composite of resin and fibre that is manufactured through the pultrusion manufacturing process which was developed in the early 1970s. The raw materials (fibre and resin) are pulled through a die, which gives the rod its shape and dimension. The rods consist of approximately 75% glass fibre and 25% resin. The fibre threads are continuous, and no damage or cutting of fibres during the manufacturing process (Figure 7).

GRP properties

Due to the high tensile strength and relative high modulus of GRP, the bolt has a high and immediate load-bearing capacity if applied with fast setting resin capsules. The high flexibility is well suited for application without couplings in confined locations and the low weight facilitates ease of handling. The high resistance to corrosion of GRP bolts makes them ideal for use in highly corrosive environments.

GRP bolts have several advantages compared to steel bolts:

Corrosion resistant-the material is durable and as part of the final lining supports a structure during its whole lifespan

Cuttability-avoids damage to cutter heads and does not delay excavation

Continuous thread-threading over the whole length facilitates coupling

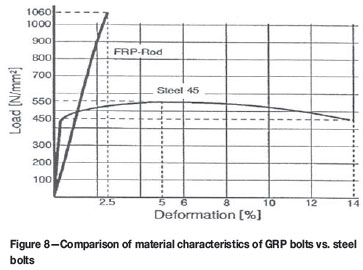

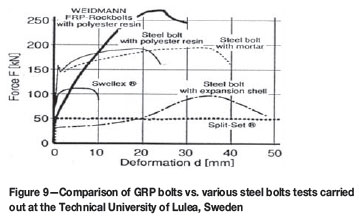

High tensile strength-approximately double the load of a steel bar with the same diameter (Figure 8, 9 and Table V)

Flexibility-GRP bolts can bend and therefore be used in confined spaces without the use of coupling elements

Low weight-a GRP bolt is only a quarter of the weight of a steel bolt of the same dimension.

Types of GRP bolts

GRP bolts are well suited to be used as primary or secondary support as a standalone support unit or as an integral part of support systems. There are four different types of GRP bolts available; namely, the all-thread bolt K60 and J64, the self drilling tubular rod, and the cable bolt.

K60 and J64 bolt

The all-thread K60 bolt can easily be installed using polyester resin capsules, thus leading its self very well towards mechanization, or it can be grouted into place by the use of cement capsules or pumpable grout.

The J64 injection bolt (tube) was developed to facilitate the injection of cementitious grout, epoxy, or silicate resin for ground consolidation or water sealing applications (Figure 10).

Self-drilling bolt

The self-drilling bolt was developed for use in weak rock or soil and can be coupled to lengths up to 20 m, depending on rock or soil conditions. The bolts are suitable for use with a rotary drilling machine and can effectively penetrate rock with a hardness of approximately 60 MPa.

The bolts are set in place with cementitious grout or chemical grout and are most suitable for piling ahead of an advancing face developed in poor ground conditions (Figure 11).

GRP Mesh

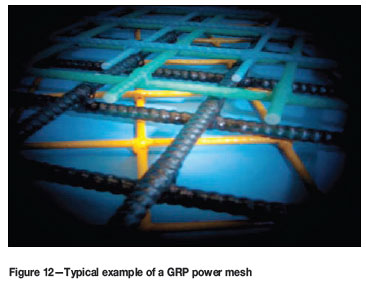

FiReP® FRP POWERMESH was developed to comply with standard grid applications while providing the added benefits of durability and cut ability. High load capacity at each joint, compared to that of welded mesh, is unique and makes the design of fibre reinforced polymer (FRP) grid-reinforced RC structures a viable option for engineers and mining support structures.

Example

Unit standard 100 x 100 x 6 mm, rod diameter 6 mm

Breaking load of 6 mm rod >28.3 kN. Ultimate strength of 6 mm rod >1 000 N/mm2

Tensile E-modulus 60 000 N/mm2 and load of knot >3 kN and >5 kN

Overall dimensions 2 000 x 800 mm.

Other options

Available rod size 3 mm-12 mm

Other mesh sizes available on request

Polyester/epoxy/vinyl ester resin

Non-flammable

Anti-static coating

Corrosion resistance

FiReP® FRP rockbolt systems are corrosion resistant and therefore the only currently available rockbolt system that can be regarded as permanent, even under difficult conditions with aggressive water and rock deformations. Corrosion is the most pressing material problem worldwide. With capital, downtime, and material costs rising, corrosion prevention is high on many industries' list of priorities. Every minute, several tons of steel are lost to corrosion. The cost of corrosion protection is enormous. Even with protection the corrosion problem is only delayed, but not solved. Correctly applied FiReP®FRP rockbolt systems support the construction over its entire life.

Because of its anti-corrosion concept, the FiReP® FRP rockbolt technology is used increasingly for soil reinforcement and ground anchoring.

Single-lining support systems

Because of the durability of the materials, FiReP® FRP rockbolt systems can be utilized not only as a temporary support, as with regular steel rockbolts, but also integrated into the calculation for the final load-bearing structure. In situ concrete shells can therefore be reduced or even eliminated.

This so-called single-lining tunnel construction method is widely used in Europe in military and civil caverns. The final support consists solely of rockbolts and reinforced shotcrete. With the improvements achieved using those materials, single-lining tunnels will further increase in importance.

The cost reductions, especially in the large-scale cross-Alpine tunnels are enormous. The construction costs of a railway tunnel for low speed or a highway tunnel with moderate traffic can be reduced by up to 50%. (Figure 12)

Applications of GRP

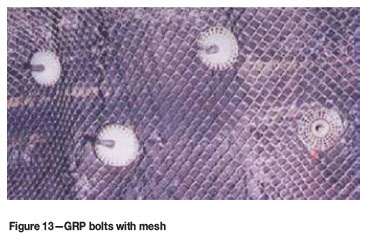

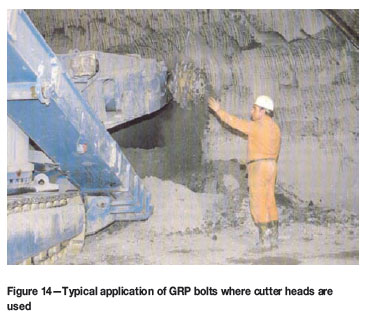

GRP bolt technology is especially well suited for use as temporary support units where cutter heads are used for excavation in hard or soft ground conditions. The cuttability of GRP allows the cutters to cut through the bolt without causing damage to the cutting heads and costly delays, and GRP can easily be broken in a rock crusher reducing significantly damage to equipment (Figure 13).

GRP bolts are typically used at collieries during stooping operations, the collar and holing positions for raise boring machines, or at the collar and holing position for tunnel boring machines, and in aggressive corrosive environments (Figure 14).

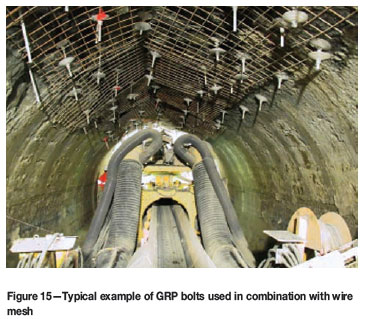

GRP bolts can be used as a standalone support or in combination with various types of support media. In poor or friable ground conditions, GRP can be used in combination with webbing, netting, mesh, shotcrete, or TSLs (Figure 15).

GRP bolts can also be used as self-drilling bolts in the appropriate applications. Resin is generally injected through the bolt to consolidate the very weak or friable rock (Figure 16).

The very nature of the block cave mining method makes it ideal for exploring the benefits that could be derived from the use of GRP technology. The undercut development is sacrificial and the installed support will be destroyed once the undercut blasting and ore production commences.

The installed support will eventually report to the draw points where it could cause obstruction; or worse, end up on the conveyor belt systems with the potential of cutting the belts or cause obstructions in the crusher. The inherent properties of GRP can overcome the shortcomings of conventional steel-type support and enhance safety and productivity.

In areas where poor or friable ground conditions are encountered, it is often necessary to consider the use of containment support in addition to tendon support. Common practice is to install wire mesh and lacing or shotcrete or a combination of wire mesh and shotcrete. Although these types of support are generally very effective in stabilizing very weak ground conditions, they are time-consuming and costly, not to mention the logistical problems they may create.

Several TSLs suitable for various mining environments and geotechnical conditions are available and could be well suited as additional support or consolidation medium in the undercut level development in a block cave where this may be required. TSLs offer a cost-effective support solution as alternative or supplementary support to shotcrete in areas where the building of a structure is not a requirement.

The main advantages of TSLs compared to shotcrete is the ease of application, speed of application, early strength, much reduced transportation of material, less labour intensiveness, and cost-effectiveness. TSLs can be used as a temporary or permanent support, depending on the requirements and prevailing geotechnical conditions.

As a temporary support, the TSL can be incorporated into the daily production cycle to maintain safe mining conditions at the face. This allows permanent support to be installed at a later stage without causing unnecessary production delays.

Typical undercut development support strategy and alternate considerations

The support strategy selected for a block cave undercut level is generally site-specific and to a large extent depends on the undercut level design and local conditions. Drift support and reinforcement typically consists of polyester resin capsule-anchored bolts.

Resin bolting offers immediate active and permanent support, and the support regime is enhanced by the addition of an appropriate TSL applied directly at the development face after the blast. It is enhanced even further by the installation of the cutable GRP power mesh or synthetic webbing along with the TSLs.

Mesh can be installed mechanically by means of a mesh installer unit mounted on the face jumbo.

GRP bolts can be installed with a dedicated bolter unit making use of a carousel bolting unit. The use of containment support such as shotcrete or mesh is considered only if conditions warrant its use.

GRP bolts are well suited to be used in the mechanized environment and hence can be used as an alternative to conventional steel bolts without compromising productivity or safety. They can also be used in combination with TSLs, shotcrete, and mesh. GRP bolts are approximately 20% more expensive than resin-anchored steel bolts of the same diameter. However, in some mining applications the benefits that are derived from GRP far outweigh the additional cost.

Shotcrete and/or wire mesh are commonly used to support undercut drifts where the containment of rock support may be required to ensure that excavations remain open and safe for their designed life. However, shotcrete or wire mesh does not readily fit in with the development cycle, and often result in reduced development efficiencies or support backlog.

Should the mining conditions permit, TSLs may be considered as a cost-effective alternative or addition to shotcrete and other types of containment support. The main advantage of TSLs is that they can easily be integrated into the mining cycle providing support concurrent with the face.

A combination of GRP mesh or synthetic webbing covered by a layer of appropriate TSLs along with GRP bolt installations and followed by structural thickness of shotcrete makes much sense in a sacrificial development environment.

Conclusion

With recent technological advancement of support products and methodologies today, we are able to work safer, smarter, and more productively with appropriate support requirements for excavations.

The combination of a fully mechanized system of support, commencing with the making safe of a working development end with a scaler and high-pressure water jetting of the rock surface to eliminate uncontrolled falls of smaller rock pieces, followed by the mechanized installation of a webbing if required and this being covered with an appropriate thick layer of the correct TSL, allows in-line development activities to take place at higher tempos and perhaps safer than is generally the case today.

The application of a thinner layer of shotcrete on top of the TSL and webbing and bolts on the installed support completes a well supported development end with good quality support installed safely.

The authors believe that there is much merit in further investigating the economical application and implementation of appropriate new technology in mining and tunneling operations.

References

ARCHIBALD, J.F. Assessment of wall coating materials for localized wall support in underground mines. Report of Phase 4 Investigations for the Mining Industry Research Organization of Canada (MIROC), 1992. 34 pp. [ Links ]

ARCHIBALD, J.F. and DEGAGNE, D.O. Recent Canadian Advances in the application of spray-on polymeric linings. Mining Health and Safety Conference, April 2000, Sudbury, Ontario, 2000. [ Links ]

ARCHIBALD, J.F. Assessing acceptance criteria for and capabilities of liners for mitigating ground falls. Mining Health and Safety Conference, Sudbury, Ontario, 2001. [ Links ]

BROWN, E.T. Block Caving Geomechanics Handbook. The International Caving Study 1, 1997-2000. Julius Kruttschnitt Mineral Research Centre, University of Queensland, Australia, 2000. p. 224. [ Links ]

ESPLEY, S., TANNANT, D.D., BAIDEN, G., and KAISER, P.K. Design criteria for thin spray-on membrane support for underground hardrock mining. Canadian Institute of Mining and Metallurgy Annual Meeting, Calgary, 1999. [ Links ]

KUIJPERS, J. Evaluation of membrane support behaviour. Surface Support Liners: Membranes, shotcrete and Mesh. Australian Centre for Geomechanics, Perth, 2001. [ Links ]

LEWIS, B. Mondi Rock-HoldTM the development of this structural membrane support. Surface Support Liners: Membranes, shotcrete and Mesh. Australian Centre for Geomechanics, Perth, 2001. [ Links ]

NAISMITH, W.A. and STEWARD, N.R. Comparative performance testing of ultrathin structural liners. 2nd International Seminar on Surface Support Liners: Thin Sprayed Liners, Shotcrete, Mesh. The Southern African Institute of Mining and Metallurgy, Sandton, South Africa, Sect. 18, 2002. [ Links ]

POTVIN, Y. Towards a common understanding of TSL applications in mines. 2nd International Seminar on Surface Support Liners: Thin Sprayed Liners, Shotcrete, Mesh. The Southern African Institute of Mining and Metallurgy, Sandton, South Africa, 2002. [ Links ]

SPEARING, A.J.S., OHLER, J., and ATTOGBE, E. The effective testing of thin support membranes for use in underground mines. Surface Support Liners: Membranes, Shotcrete and Mesh, Australian Centre for Geomechanics, Perth, Australia, 2001. [ Links ]

STACEY, T.R. Membrane support mechanics, loading mechanisms, desired membrane performance, and appropriate test methods. Colloquium 2001, Shotcrete and Membrane Support, The Southern African Institute of Mining and Metallurgy, 2001. [ Links ]

This paper was first presented at the, MineSafe Conference, 15-18 August 2011, Emperors Palace, Hotel Casino Convention Resort, Johannesburg.

© The Southern African Institute of Mining and Metallurgy, 2012. SA ISSN 0038-223X/3.00 + 0.00.