Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the South African Institution of Civil Engineering

versão On-line ISSN 2309-8775

versão impressa ISSN 1021-2019

J. S. Afr. Inst. Civ. Eng. vol.54 no.2 Midrand Jan. 2012

TECHNICAL PAPER

Coastal defences on the KwaZulu-Natal coast of South Africa: a review with particular reference to geotextiles

S Corbella; D D Stretch

ABSTRACT

Modern coastal defences have to satisfy economic, environmental and sustainability criteria. The balancing of these criteria can make the implementation of coastal defences socially, environmentally and politically complicated. Durban's local authority, the eThekwini Municipality, has had experience with numerous forms of coastal defences in its attempts to balance the operations of a port and associated beach erosion problems. In March 2007 the KwaZulu-Natal coastline suffered severe damage from an extreme storm event which necessitated the installation of additional coastal defences. This paper evaluates Durban's experiences of coastal defences, and details the successes and failures to provide practical insight to those faced with similar circumstances or considering the implementation of coastal defences.

Key words: coastal defences, geotextiles, groynes, beach nourishment, KwaZulu-Natal coast

INTRODUCTION

The implementation of coastal defences has historically been dependent on the value of the hinterland and the nature of the coastline. In addition, environmental and sustainability considerations have become more prevalent in the implementation of coastal defences and are often the governing factors when determining an appropriate defence (Zanuttigh et al 2005; Airoldi et al 2005; Moschella et al 2005). Consideration of these three factors often leaves municipalities and coastal engineers struggling to find a solution that optimally satisfies all the requirements.

Durban is an important port city located on the east coast of South Africa (Figure 1). The local government was faced with a challenge concerning coastal defences when an extreme event in March 2007 devastated the KwaZulu-Natal coastline. This paper reviews the defences implemented before, during and after the event and identifies their successes and failures. The description of these successes and failures is intended to aid authorities and interested and affected parties to make insightful decisions when undertaking a coastal defence. The review also identifies the importance of monitoring with respect to coastal management. Durban's beach profiles have been recorded since 1973 and have played an integral part in the municipality's coastal management.

Gilbert and Vellinga (1990) identified five alternative ways to mitigate the damage of coastal storms, namely accommodation, protection, beach nourishment, retreat and the do-nothing alternative. These solutions can be further divided into two major categories of "hard" and "soft" engineering solutions. Hard solutions typically result in permanent structures that have continual effects on the environment. Soft solutions are the environmentally preferred options and do not involve permanent structures. Durgappa (2008) defined groynes, breakwaters, seawalls, revetment, etc, as hard solutions, and only beach nourishment as a soft solution. We suggest that the soft category should include accommodation, retreat and the use of geotextile sand-filled containers (GSC). Although soft solutions are always a priority they are often difficult to implement effectively. Accommodation is essentially part of a management or planning programme to reduce risk; an example being the establishment of setback lines or designing structures to accommodate occasional flooding. Retreat is the relocation of existing structures to a less vulnerable area, and is often seen as a last resort because of its socio-economic complications (French 2001).

While the eThekwini Municipality (Durban's local government authority) did implement retreat and the do-nothing approach in the aftermath of the March 2007 event, the experiences from these solutions were trivial and did not warrant inclusion in this review. Minor public-owned structure were relocated outside of vulnerable zones following their failure, without any public objections. Private properties were not protected with public funds and many of them recovered naturally. Setback lines were successful in mitigating damage during the March 2007 event and are considered an essential part of coastal planning. This review is limited to physical defences and precludes setback lines.

The review aims to compare Durban's coastal defence experiences with international experiences in an attempt to highlight and recommend successful practices. The review commences with a brief history of Durban's beach protection and then describes Durban's coastal defence experiences with respect to: groynes, beach nourishment, loffelstein walls, geotextile sand-filled containers, geotextile tubes and geotextile wraps. The conclusion recommends coastal defences based on the Durban experience.

A BRIEF HISTORY OF DURBAN'S BEACH PROTECTION

Durban's history of beach protection has largely revolved around efforts to effectively operate a port. There is evidence of the beaches being stable for a period of almost 100 years prior to the commencement of harbour works (Kinmont 1954; CSIR 1976).

In 1857 construction began on the north and south breakwaters of the harbour. It soon became necessary to deepen the channel to cater for vessels with larger draughts, and dredging operations commenced in 1895. Dredging operations intensified from 1897 onwards and this marked the onset of erosion (Kinmont 1954). The channel dredging remained at approximately 650 000 m3/year, which was about equal to the longshore drift estimated at that time, meaning no sand was reaching the beaches north of the harbour.

In response to the beach erosion the eThekwini Municipality started pumping sediment as beach nourishment to the south and central beaches in 1935 (Barnett 1999). What followed were a series of different schemes implemented to discharge dredged material to the beaches. These schemes included a failed fixed bypass scheme attempted between 1950 and 1953.

The so-called Paterson Groynes were built between 1954 and 1956. These two groynes were constructed to stabilise the central beaches in light of the fact that maintenance dredging was not providing the required quantities. The groynes did little to alleviate the problem.

Further effort was made to mitigate beach erosion in 1966 when construction of the underwater mound commenced. It was aimed at protecting the central and northern beaches against storm waves. The mound was never completed to its design height (Barnett 1999), and in 1977 the CSIR found it more beneficial to pump the sand available for the mound directly to the beaches.

The long-standing sediment supply problem was eventually solved by the sand bypass scheme, completed in 1982, and the new groynes were completed in 1985. These groynes, called the Bay of Plenty and North Beach Piers (Figure 2), replaced the Paterson Groynes. In 1989 a third groyne, the Dairy Beach Pier (Figure 2), was constructed (Mather et al 2003). The sand bypass scheme consisted of a concrete hopper and a series of four booster stations, each approximately 700 m apart and connected with a 400 mm diameter high-density polyethylene pipe. The hoppers could receive 5 000 m3 of fluidised sand. This sand would then be re-dredged by a fluidising and pumping mechanism at the hopper station and could then be pumped to various outlets between Vetch's (Figure 1) and Bay of Plenty beach, totalling approximately 3.5 km.

The widening of the Durban harbour in 2007 necessitated the demolition of the hopper station. A new design has been completed and the scheme is due to be operational by 2013. Until such time there is a temporary scheme, consisting of a bund in the northern breakwater and operating similarly to the original scheme.

Table 1 provides an inventory of all the physical defences that have been installed in the eThekwini Municipality, and shows the date of installation, the length of coast defended and comments on the performance of these defences. The length of the defence is only an estimation and does not include ad hoc defences that have been installed by private home owners. The eThekwini coastline is approximately 100 km and it is estimated that 11% of it is defended. Almost 90% of these defences are made up of rock revetments, loffelstein walls and geotextile sand bags. The bulk of the defences are loffelstein walls, which were installed in the Bluff, Umdloti and Umhlanga Rocks in the 1980s. These retaining walls make up 34% of all eThekwini's coastal defences. The oldest form of coastal defence is rock revetments. Almost the entire stretch of Durban's central beaches is protected by rock revetments. The rock that was installed in the 1900s is now permanently covered by sand, but makes up 29% of eThekwini's coastal defences. The first geotextile sand bags were installed in 2007, but they already make up 24% of the eThekwini coastal defences.

THE MARCH 2007 EVENT

The March 2007 storm event refers to the storm's climax on the 19th and 20th of March 2007. Approximately 350 km of the KwaZulu-Natal (KZN) coastline was subjected to severe erosion (Breetzke et al 2008).

An extreme high tide cycle of 18.6 years and an offshore storm coincided to produce wave heights of up to 8.5 m. The combination of equinox tide level and peak storm-wave setup resulted in a water level of almost 2.7 m above chart datum (Phelps et al 2009).

What followed were a multitude of coastal defences, many implemented under emergency conditions. The remainder of this paper reviews the successes and failures of defences before and after the 2007 event.

GROYNES

Groynes are shoreline stabilisation structures that retard the natural flow of sediment causing accretion. They are constructed perpendicularly to the shoreline and are designed to provide a minimum beach width. Durban's groyne field was constructed between 1985 and 1989 (Figure 2). This groyne field, in conjunction with the sand bypass scheme, has been successfully maintaining a stable beach over their existence. The groynes are semi-permeable rock groynes, making the beach width dependent on the rock elevation. The rock levels are monitored annually by the eThekwini Municipality and were adjusted to their design levels in 2009 with a combination of rock and geotextile sand bags.

The piers are constructed on precast friction piles, so the elevation of the sand determines the stability of the structure. The dynamic environment necessitates monitoring, and scour levels around the piles are determined every six months.

Corrosion of reinforcing steel is a major concern for all coastal structures. Although the groynes are still in relatively good condition it is worth noting corrosion observations.

When the Bay of Plenty and North Beach Groynes were constructed in 1985 the handrail posts were reinforced with ordinary high-tensile steel bars with a concrete cover of 50 mm (a minimum cover of 25 mm was specified). The Dairy Beach Groyne was constructed four years later in 1989 with handrail posts consisting of hot-dipped galvanised high-tensile steel reinforcing bars, but with only 25 mm concrete cover. By 2010 all of the Dairy Beach handrail posts had to be replaced with polymer concrete posts as a result of severe concrete spalling. The superstructures and piles of all three piers were constructed similarly, but the galvanised Dairy Beach Pier was in a far superior condition than the two older groynes. The fact that the steel in the handrail posts was galvanised, had less concrete cover and was installed more recently implies that concrete cover cannot be neglected because the reinforcing is galvanised. A 20 mm concrete cover is inadequate to protect a galvanised bar under highly corrosive conditions (Yeomans 2004), and SANS 10100-2:1992 specifies 60 mm concrete cover in extreme environments for normal density concrete. The eThekwini Municipality Coastal Department use galvanised steel in all their coastal structures with a minimum cover of 60 mm.

Groynes are an expensive investment and are often difficult to construct. They also have the potential to intensify erosion if not designed correctly. This was the case in 1936 when a loose stone groyne was constructed.

It accentuated erosion on either side of the groyne, so it had to be removed (Kinmont 1954). A strong rip current is often induced by a groyne, which can be precarious to bathers and requires the presence of life guards. Their effective and safe functionality necessitates a fair amount of monitoring, and consequentially requires a good management structure.

The groyne field did not prevent the 2007 event from overtopping the promenade and damaging the adjacent commercial node. The wave heights also exceeded the soffit of the deck and broke numerous precast concrete slabs. With such an extreme event it is not expected that the groynes will completely prevent damage, but they did minimise the impacts by providing a beach buffer between the promenade and the ocean.

In Durban's case the groynes have been worth the expense and effort, providing not only stable beaches but a recreational attraction to the public. The groynes are currently exceeding their 20 year design life and, other than some minor concrete spalling, are still in a safe operating condition.

BEACH NOURISHMENT

Beach nourishment is the supply of sand to beaches usually from offshore dredging and is an environmentally preferred method of shore protection (Belkessa et al 2008). This technique is used worldwide usually in combination with a shoreline stabilisation technique. Europe has adopted beach nourishment as central to its soft engineering strategy (Hamm et al 2002; Hanson et al 2002). The additional sediment on the beach essentially shifts the wave run-up further away from inland infrastructure, creating a buffer.

To protect dunes from erosion the dry beach has to be flat and wide enough to approximate to the Bruun-type equilibrium profile at the raised water level (Dette & Raudkivi 2002). This profile shape, and thus a nourishment volume, are difficult to estimate. The so-called equilibrium profile develops from predominant wave action, so a storm profile will be different from a calm weather profile. This is also true when widening a beach, as the wave conditions may change seaward. A way of avoiding this is to base the nourished profile on a desired historic profile. This in itself is erroneous since a beach that is being nourished is typically eroding and therefore is not at an equilibrium profile. A numerical beach response model is usually used to predict changes in the nourished profile. When attempting to reclaim beach for recreational purposes the inability to predict a fill volume can result in a failed project. The recently acquired dry beach can adjust under wave action and return the dry beach width to the pre-nourishment dry width. Although the sand is not lost, but simply moved to an unstable portion in the lower profile, the nourishment in terms of reclaiming recreational beach would have failed. The existence of a good and substantial beach profile record is needed to perform a suitable nourishment design.

Compared to other coastal protection, nourishment is cheaper, but it is still very expensive to not see a visible result. Taxpayers are often happier knowing that their contribution is in a visible seawall as opposed to thousands of cubic metres of sand sitting just offshore. It is therefore extremely important to not undernourish a beach.

The 2007 storm event had left the beaches in a similar state as in 1982, but the hopper was no longer available to replenish the starved beaches. The issue was intensified by the looming 2010 World Cup and prompted the city engineers to initiate a beach nourishment project where offshore sediment would be dredged and pumped ashore.

A 900 mm diameter pipe was laid 1.4 km from the north breakwater of the harbour to Addington beach (Figure 3). An offshore borrow site that had previously been used to reclaim Berths D to G within the harbour was used. The site was surveyed and sediments sampled to ensure that the grading was suitable. Sediment grading is important, as fines produce plumes and increase the sediment's erosion susceptibility. At the same time the sediment cannot be too coarse as traversing the beach can become an uncomfortable barefoot experience. A good way of determining a suitable grading is to compare the grading of a popular and stable recreation beach with that of the borrow site. It was found that the borrow site was slightly coarser (a mean of 304 urn) than the destinations, Vetch's and Addington Beach (Figure 1). The project was undertaken in two phases, the first in 2009 and the second in 2010, each phase contributing approximately 250 000 m3 of sediment to the beaches.

A project of such a nature is technically trivial, but management intensive. The dredger is chartered on an hourly rate, so the more sand that is pumped the smaller the cubic metre cost. At the time the dredger's standby rate was R36 000 an hour, necessitating that no delays were incurred at the discharge pipe. The success of the project was largely indicative of good project management.

The project was successful as it introduced new high-quality course sediment (about 500 000 m3) into the system, aiding a correction in the sediment budget. The project was unfortunately not a complete success. The importance of creating a suitable beach profile was neglected in the first phase of pumping, largely due to time constraints. The resulting profile was quickly corrected to an equilibrium profile which produced unexpected earthworks costs to counteract the 3 m scarp that had formed. The borrow site was originally surveyed with a single scan sonar, as a higher-resolution multi-beam was considered an unnecessary expense since the site had been dredged extensively in the past. The initial dredging phase was without incident, except dredging of small ammunitions. The second dredging phase saw the dredging of steel elements (Figure 4) resulting in the cracking of the dredger impeller.

The cracking of the impeller was a major setback in the project and resulted in a large insurance claim. In hindsight an expensive multi-beam survey may have been more economical should the insurance not have covered the delays.

RETAINING WALLS

Retaining walls in the coastal context are different from seawalls. In Durban a large number of dry-stacking, interlocking retaining walls have been used inappropriately or have developed into an inappropriate situation as a result of chronic erosion. Although there are various types of dry-stacking interlocking walls, Durban's coastal retention structures are loffelstein walls. Water-loffel is a variation of loffelstein, having interlocking wings. They are commonly used for hydraulic applications and had been extensively used as seawalls at Brighton Beach, Umhlanga and Umdloti. Seawalls are the most common form of coastal defence and the physical barrier between the land and sea is often considered most desirable by residents (French 2001). Unfortunately they can create a static coast and are one of the least environmentally acceptable solutions. Loffelstein walls are essentially coastal retention structures that are constructed at the backshore and are not intended to withstand direct wave action. Unfortunately, due to chronic erosion, the walls at Umhlanga and Umdloti are exposed to wave attack fairly regularly. Although in these situations a more substantial defence, such as the fibre-glass sheet piles at Ansteys Beach, is preferable, the loffelstein walls have performed relatively well.

A large portion of these walls failed during the 2007 event. The failures were a result of water down-rush, and overtopping washing sediment out from behind the walls. This combination of sediment loss caused the walls to collapse (Figure 5). This failure mechanism highlights the need to have substantial drainage and filtration behind the walls. A geotextile filter layer ensures that water can drain from behind the wall while the filter retains the sediment. Some of the walls that had a geotextile filter parallel to the wall still failed, while none of the walls that had a filter parallel and perpendicular to the wall failed. It is felt that these perpendicular geotextile tiebacks (Figure 6) limit the likelihood of sediment escaping through gaps in the parallel filter. This was the only failure mechanism experienced during the event, as none of the walls were undermined. This was a consequence of the walls being either founded on rock or on a bed of gabion mattresses below the lowest scour profile.

Although loffelstein walls are not a favourable solution, the majority of the loffels that failed during the event were reinstated. Only certain sections of the walls had failed and it was more economical to retain a continuous loffel wall. Where walls were severely damaged they were replaced with geotextile sand bags.

GEOTEXTILE SAND-FILLED CONTAINERS (GSC)

The use of GSCs was initiated in the USA, the Netherlands and in Germany more than 50 years ago (Saathoff et al 2007). GSCs have become increasingly popular because of their multitude of applications, as well as their environmental benefits. GSCs are often spoken of as a soft engineering solution. This is not entirely correct because a soft solution is one that does not impede the natural morphology of the coast. The GSCs prevent erosion, so can develop a static shoreline. They are considered a soft solution because, if an unforeseen environmental impact ensues, they can easily be sliced open and removed, spilling sand back onto the beach.

Allan & Komar (2002) observed the effectiveness of an artificial dune for shore protection by surveying a dune constructed with sand-filled geotextile bags covered by loose sand and dune vegetation from 1999 to 2002.

They reported that the dune survived fairly extreme conditions, which included overtopping, but noted that it was still to be seen if it would cope with the more severe storms.

Heerten et al (2008) did extensive research into the effectiveness of GSCs to mitigate coastal erosion. They described the successful use of GSCs on the island Sylt in Germany where geotextile cushions were covered with sand and sand trap fences. The geotextile was exposed after the second largest storm surge, yet it had prevented a 2.5 m above normal water level and waves exceeding 5 m from eroding the dune.

Recio & Oumeraci (2008) also did extensive research on geotextile bags. Through rigorous model testing they were able to consider all the forces acting on the containers, as well as the effects of container deformation. The impact of wave action and submergence causes sand to be moved inside the bag from the back to the exposed face. This movement has two negative effects. It decreases the contact area between bags, thus reducing the friction forces, and it increases the surface area in the front of the bag, making it more susceptible to drag forces.

GSCs are a relatively new technology and have only recently found application in South Africa. Their advantages include being cost effective and easily transported, which make them ideal for emergency work. The geotextile can be easily cut and removed if required, but at the same time permanent containers are susceptible to vandalism. This issue has been combatted by a composite vandal-deterrent geotextile which traps 3 kg of sand per square metre within the geotextile. Although this significantly increases the resilience and durability of the container (Saathoff et al 2007) it has little effect on the penetration of a knife. GSCs used to protect dunes should always be covered with sand and vegetated to protect them from vandals and to restore a natural appearance to the coastline. Vegetation has the advantage of mitigating blown sediment and stabilising backshore morphology (Udo et al 2002).

Based on the documented success of GSCs in Australia (Restall et al 2002; Saathoff et al 2007), the municipality decided to pursue their installation as an emergency and permanent measure. The use of GSCs or geotextile sand bags became the eThekwini Municipality's favoured form of sea defence after the 2007 event. Their extensive use and associated experience warrant an extended section dedicated to their application.

Manufacture

Kaytech Engineered Fabrics was approached to manufacture and supply the GSCs. The bag dimensions were initially 2 x 2.5 x 0.5 m which resulted in a fill-weight of approximately 4 tons. These dimensions were based on a geotextile container of 2.6 x 1.9 x 0.58 m used in Australia (Hornsey et al 2011). After the emergency production of bags had subsided Kaytech refined their manufacture and optimised the bag size to 2.1 x 1.8 x 0.55 m. The bags consist of a double layer, an inner geotextile and an outer UV-stabilised staple filament polypropylene. The two fabrics are bonded together and stitched into a bag. The bag contains two chutes that can be extended from the bag creating a conduit to convey sand into the bag. Since the pioneering of the first bags numerous manufacturers have entered the market.

The filling of the bags required a steel frame (Figure 7). The manufacture of this frame should be governed by the geometry and layout of the bag. This proved to be an issue, as new bag manufacturers entered the market and the manufacture of the bag evolved. When the bag's chute diameter varied the frame's funnel diameter remained constant, and this necessitated the removal of some stitching to allow installation of the bag into the frame. This is problematic as the stitching has a tendency to run, potentially causing the bag to pull open.

The stitching of the bags is done in the factory by sewing machines and the seam forms 80% of the bag material strength. The chutes, however, have to be sealed on site and this is done by hand-stitching with nylon string. This stitch is therefore the weakest part of the bag and has been mitigated by placing the bags with the hand-stitched portion facing landwards. Supervision and quality control of the hand-stitching is essential, as labour has a tendency to fluctuate quality, which may lead to the leaking of sand. A manufacturing technique which has proved to successfully increase quality is the prepunching of holes. This means the spacing of hand-stitches is pre-defined and so ensures more consistency with regard to the quality of stitching. All that still has to be ensured then is that the nylon is knotted correctly. A handheld sewing machine was initially used to stitch the bags, but was abandoned during the emergency work following associated installation delays. The reintroduction of the sewing machine has not been supported, due to cost implications, as well as there being no present evidence of the adverse effects of hand-stitching.

Installation

The bags were originally filled to 80% of their capacity (based on the German construction technique (Oumeraci et al 2003)), ensuring that the sand is sufficiently compacted by flooding with water. If the bags are filled any more it becomes difficult to stitch them closed, jeopardising the quality of the stitch. Overfilling the bags also causes rounding. Since some of the bag's stability is determined by its mass and friction, it was hypothesised that the more rounded it is the less contact each bag would have with the surrounding bags, lowering the stability. Not filling the bags to capacity allows them to be levelled for the next bag layer, as well as providing a large contact area. It must be noted that the findings of Hornsey et al (2011) contradict this theory, showing that the Australian practice of filling bags to capacity is more stable.

In certain circumstances there may be uncertainty as to where the lowest scour level is or additional confidence is required in minimising the undermining risk. This was accommodated by providing a Dutch toe (self-healing toe). A Dutch toe is a row of bags in front of the wall's toe and tied back into the bottom bags. The theory is that, as the beach profile approaches the founding level of the bag wall, the Dutch toe will settle giving the structure an additional 2 m (length of one bag) scour resistance.

Slope

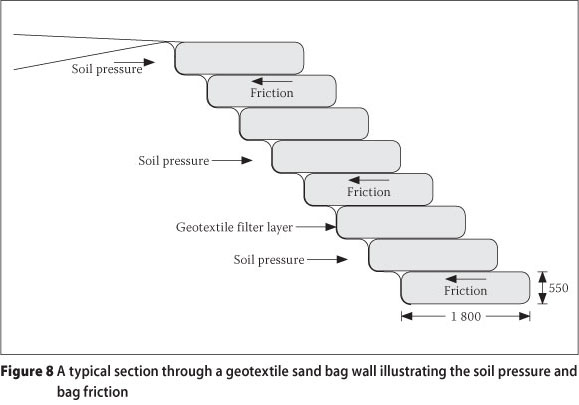

The slope of the bag-protected dune is still debated, with engineers designing slopes from 30° to 45°. The stability of the bag wall is dependent on the friction forces that develop between the bags, which is a function of their roughness, the net normal force (weight above the contact area) and the contact area. Recio & Oumeraci (2008) identified, from flume tests, that the friction between containers affects the hydraulic stability much more than assumed in past and present literature. In order for the bags to be stable this frictional force must be equal to or greater than the active soil force behind the bags (Figure 8). Therefore, although the friction increases as the bag wall approaches the vertical, so does the active soil pressure. A balance of these two forces was used to calculate an optimum bag slope. Figure 9 shows the number of stable bags through a range of slopes. The calculation includes a safety factor used on the soil properties. For comparativeness, results shown ignore cohesion, place the water table below the bag wall, and use a constant soil weight of 18 kN/m3 and a friction angle of 30°. Active pressures were calculated using Coulomb's active earth pressure coefficient. The bag dimensions and weight are as previously stated.

Figure 9 illustrates that the angle range of 18° - 26° can retain the most soil - the flatter the slope of the wall, the less the wave loading, but the greater the wave run-up. This simple calculation does not consider the hydraulic stability of the bags, and because the sand is displaced to the bags' front face by the lifting and dropping of the exposed portion, it is thought that the less bag length that can be lifted the more stable the bags would be. It is felt that the increased restriction of this movement is what makes the bags more stable at steeper slopes (Hornsey et al 2011) and not the increased friction.

The bags are prone to vandalism and degradation by ultraviolet radiation. They also look untidy once people have traversed them and they have been subject to wave action. The bags should therefore be covered with sand and vegetated. Since beach sand generally cannot maintain a slope greater than 30° it also dictates that the bags should follow a similar slope. The ground conditions, space restrictions and retained height all influence the bag wall slope, and therefore a standard orientation cannot be specified. Each situation should be considered independently.

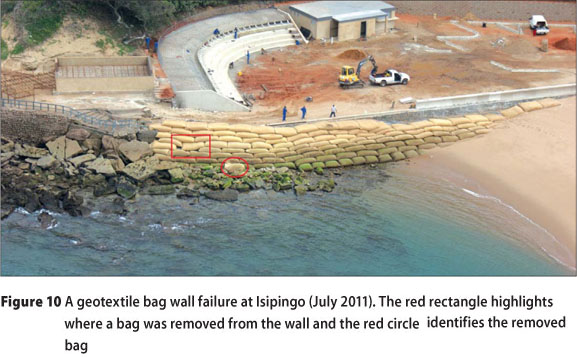

Geotextile sand bag performance

The bags endured their first substantial test on 26 July 2011 from a significant wave height of 5 m, and all the issues identified in the literature were realised. Vandalised bags leaked sand and created weak spots in the walls. The lower layers of bags shifted forward making the lower wall face steeper. This appears to be the combination of three factors: the bags not being filled sufficiently, the bags leaking sand and the bags' geotextile elongation. All these factors enable the sand to move to the bag's exposed face, lowering the friction forces and increasing the drag forces. In an extreme case a bag was completely removed from the lower portion of a wall (Figure 10). We propose that our local bags need some refinement in terms of elongation and that stringent quality controls are required during installation. The significance of bag deformation is perhaps more evidence that the Australian method of filling the bags to capacity and using a 45° slope is more appropriate.

GEOTEXTILE TUBES

Geotextile tubes have been used all over the world and have been particularly successful in the construction of artificial reefs. The geotextile tube was experimented with, as it was potentially faster, cheaper and more structurally sound than using geotextile sand bags. The theory was that the 1.4 m diameter by 25 m tube could be laid in position and then pumped full of sand (Figure 11). This, however, was not as simple in practice.

Pumping slurry into the tube caused air to be trapped in the tube which had limited venting points. The slurry was also pumped at a ratio of about 30% sand to 70% water. The geotextile drained slowly, causing the tube to fill with water and air faster than it could expel them, resulting in the slurry discharge pipe being forced out the tube inlet. This issue was overcome by having scuba divers inside the tube directing the pump discharge. The tube also had to be braced every 5 m.

The tube was successfully installed and has been in place for almost four years without any issues. Structurally the tube is more stable than individual bags, as it is continuous, weighs more and only has one piece of hand stitching. The tube has the added advantage of being able to be placed and filled in the water. With all the complications associated with the tube it ended up costing twice as much as installing the geotextile sand bags. Although it was discontinued due to its difficult installation and associated costs, its use has been successful in other applications (Cantre 2002; Shin & Oh 2007; Alvarez et al 2007). We propose that similar success is possible if more appropriate equipment is used.

GEOTEXTILE WRAP

The geotextile wrap was used as an alternative to the geotextile sand bags where access was limited, and has proved to be a reliable alternative (Yasuhara & Recio-Molina 2007). A 5.3 m by 25 m geotextile fabric was used to create an in-situ sand bag or tube. The geotextile is laid flat, half is topped with sand and the other half is then folded over and stitched on the landward side. This method allows all the work to be done by hand. If the wrap will not be exposed (always to be covered by sand or by geotextile bags) bidim may be used. If the bidim will be exposed to sunlight and wave action it should be replaced with 1200 g/m2 ultraviolet-treated (UV) geocontainer fabric, as the bidim is not UV-protected and pulls apart under wave attack. The long continuous hand-stitching is the main weakness of the wraps, but also makes the installation cost effective and has become increasingly popular amongst private homeowners along the KwaZulu-Natal coast.

CONCLUSION

Durban has had a long history of beach protection and some of its recent experiences have been shared in this review. From these experiences it is recommended that soft solutions, primarily as a combination of coastal setback lines, beach nourishment and GSCs be prioritised. Admittedly soft solutions are not always practical or appropriate.

Durban's groyne field has been a valuable investment aiding in successfully stabilising the central beaches since their construction.

Experience has shown that concrete cover should be seriously considered as corrosion mitigation, even when providing galvanised reinforcing. It is recommended that all structures, including seawalls and GSCs, be founded on rock or at a depth that ensures structural stability when the lowest historical scour level is exceeded.

Beach nourishment and geotextile sand bag seawalls are the eThekwini Municipality's preferred soft protection to be implemented in conjunction with coastal setback lines. A successful beach nourishment project can be executed by substantial preliminary research of the borrow site, as well as good project management. For a geotextile sand bag defence it is recommended that the bags are filled to capacity and installed at a slope of 45°, covered in sand, and vegetated. Although geo-textile wraps have proven their reliability as coastal protection (Yasuhara & Recio-Molina 2007) the municipality's experiences have only found them to be an appropriate substitute for the bags in severely restricted areas. In areas of high vulnerability it is recommended that a bidim wrap be installed and draped with bidim prior to overlaying it with one or two layers of geotextile sand bags. The bidim wrap acts as a second defence against extreme events, as well as a substantial filter layer, which has proved to be significant. A Dutch toe should also be installed as additional risk mitigation of undermining. The bags' elongation at breaking point still needs to be refined and parity has to be achieved on the filling percentage of the bags' capacity.

Many situations require more robust solutions than geotextile sand bags or beach nourishment. Such situations need to be individually accessed, but rock revetments and sheet-piled seawalls have been successfully installed in Durban.

A good monitoring system is essential for successful coastal management. The beach profiles recorded in Durban since 1973 have been instrumental in the design of all its coastal defences from seawalls to beach nourishment. To the authors' best knowledge the record is the most extensive in South Africa and is the core of the eThekwini Municipality's coastal management and defences.

The March 2007 event gave the eThekwini Municipality the opportunity to be innovative. It is hoped that other organisations will be able to convert the failures into successes and use the success stories to improve the sustainability of defending our coast.

REFERENCES

Allan, J C & Komar, P D 2002. A dynamic revetment and artificial dune for shore protection. Proceedings, 28th International Coastal Engineering Conference, Vol 2, Cardiff, pp 2044-2056. [ Links ]

Alvareza, I E, Rubiob, R & Ricaldeb, H 2007. Beach restoration with geotextile tubes as submerged breakwaters in Yucatan, Mexico. Geotextiles and Geomembranes, 25: 233-241. [ Links ]

Airoldi, L, Abbiati, M, Beck, M W, Hawkins, S J, Jonsson, P R, Martin, D, Moschella, P S, Sundelof, A, Thompson, R C & Aberg, P 2005. An ecological perspective on the deployment and design of low-crested and other hard coastal defence structures. Coastal Engineering, 52: 1073-1087. [ Links ]

Belkessa, R, Houma, F, Ciortan, R, Mezouar, K 2008. Protection works of the sea coast in Algeria. Proceedings, 7th International Conference on Coastal and Port Engineering in Developing Countries, COPEDEC VII, 196, 11, Dubai. [ Links ]

Breetze, T, Parak, O, Celliers, L, Mather, A & Colenbrander, D R (Eds) 2008. Living with coastal erosion in KwaZulu-Natal: a short-term, best practice guide. KwaZulu-Natal Department of Agriculture and Environmental Affairs, Cedara, Pietermaritzburg. [ Links ]

Barnett, K A 1999. The Management of Durban's beaches: an historical perspective. Proceedings, 5th International Conference on Coastal and Port Engineering in Developing Countries, COPEDEC V, Cape Town. [ Links ]

Cantre, S 2002. Geotextile tubes - analytical design aspects. Geotextiles and Geomembranes, 20: 305-319. [ Links ]

CSIR 1976. Status quo of the Durban Beach protection investigation. Report No. C/SEA 7607, CSIR: Stellenbosch. [ Links ]

Dette, H H & Raudkivi, A J 2002. Beach and storm- tide protection on the coast of the Baltic Sea. Proceedings, 28th International Coastal Engineering Conference, Vol 3, Cardiff, pp 3298-3307. [ Links ]

Durgappa, R 2008. Coastal protection works. Proceedings, 7th International Conference on Coastal and Port Engineering in Developing Countries, COPEDEC VII, Dubai, Paper No 97. [ Links ]

French, P W 2001. Coastal Defences: processes, problems and solutions. New York: Routledge. [ Links ]

Gilbert, J & Vellinga, P 1990. Strategies for adaption to sea level rise. Report of the Coastal Zone Management Subgroup, Intergovernmental Panel on Climate Change. World Meteorological Organization and U.N. Environmental Programme: the Netherlands. [ Links ]

Hamm, L, Capobianco, M, Dette, H H, Lechuga, A, Spanhoff, R & Stive, M J F 2002. A summary of European experience with shore nourishment. Coastal Engineering, 47: 237-264. [ Links ]

Hanson, H, Brampton, A, Capobianco, M, Dette, H H, Hamm, L, Laustrup, C, Lechuga, A & Spanhoff, R 2002.Beach nourishment projects, practices, and objectives - a European overview. Coastal Engineering, 47: 81-111. [ Links ]

Heerten, G, Klompmaker, J & Partridge, A 2008. Design and construction of waterfront structures with special designed non-woven geotextiles. Proceedings, 7th International Conference on Coastal and Port Engineering in Developing Countries, COPEDEC VII, Paper No 93, Dubai. [ Links ]

Hornsey, W P, Carley, J T, Coghlan, I R & Cox, R J 2011. Geotextile sand container shoreline protection systems: design and application. Geotextiles and Geomembranes, 29(4): 425-439. [ Links ]

Kinmont, A 1954. Beach erosion and protection. Proceedings, The Institute of Municipal Engineers, 33rd Annual Conference, Durban. [ Links ]

Mather, A A, Kasserchun, R & Wenlock, H 2003. City of Durban Sand Bypass Scheme: 20-year performance evaluation. Proceedings, 6th International Conference on Coastal and Port Engineering in Developing Countries, COPEDEC VI, Colombo, Sri Lanka. [ Links ]

Moschella , P S, Abbiati, M, Àberg, P, Airoldi, L, Anderson, J M, Bacchiocchi, F, Bulleri, F, Dinesen, G E, Frost, M, Garcia, E, Granhag, L, Jonsson, P R, Satta, M P, Sundelof, A, Thompson, R C & Hawkins, S J 2005. Low-crested coastal defence structures as artificial habitats for marine life: using ecological criteria in design. Coastal Engineering, 52: 1053-1071. [ Links ]

Oumeraci, H, Hinze, M, Bleck, M & Kortenhaus, A 2003. Sand-filled geotextile containers for shore protection. Proceedings, COPEDEC VI, Colombo, Sri Lanka. [ Links ]

Phelps, D, Rossouw, M, Mather, A A, & Vella, G F 2009. Storm damage and rehabilitation of coastal structures on the east coast of South Africa. Proceedings, Institute of Civil Engineers Conference, Edinburgh, Scotland. [ Links ]

Recio, J & Oumeraci, H 2008. Hydraulic stability of geotextile sand containers for coastal structures: process-oriented studies towards new stability formulae. Proceedings, 7th International Conference on Coastal and Port Engineering in Developing Countries, COPEDEC VII, Dubai, Paper No 110. [ Links ]

Restall, S J, Jackson, L A, Heerten, G & Hornsey W P 2002. Case studies showing the growth and development of geotextile sand containers: an Australian perspective. Geotextiles and Geomembranes, 20(5): 321-342. [ Links ]

Saathoff, F, Oumeraci, H & Restall, S 2007. Australian and German experiences on the use of geotextile containers. Geotextiles and Geomembranes, 25(4-5): 251-263. [ Links ]

SANS 10100-2:1992. Code of practice for the structural use of concrete. Part 2: Materials and execution of work. Pretoria: South African Bureau of Standards. [ Links ]

Shin, E C & Oh, Y I 2007.Coastal erosion prevention by geotextile tube technology. Geotextiles and Geomembranes, 25: 264-277. [ Links ]

Udo, K, Takewaka, S & Nishimura, H 2002. Long- term morphological change of backshore dunes. Proceedings, 28th International Coastal Engineering Conference, Cardiff, Vol 3, pp 3786-3798. [ Links ]

Yasuhara, K & Recio-Molina, J 2007.Geosynthetic wraparound revetments for shore protection. Geotextiles and Geomembranes, 25: 221-232. [ Links ]

Yeomans, S R 2004.Galvanized steel reinforcement in concrete. Oxford: Elsevier. [ Links ] Zanuttigh, B, Martinelli, L, Lamberti, A, Moschella, P, Hawkins, S, Marzetti, S & Ceccherelli V U 2005. Environmental design of coastal defence in Lido di Dante, Italy. Coastal Engineering, 52: 1089-1125. [ Links ]

Contact details:

Contact details:

166 KE Masinga Road

Durban

400'

South Africa

T: +27 31 311 7312

E: corbellas@durban.gov.za

Contact details:

School of Engineering

University of KwaZulu-Natal

Durban

South Africa

404

T +27 31 260 1064

E: stretchd@ukzn.ac.za

STEFANO CORBELLA (Member SAICE) received his BSc degree in civil engineering cum laude from the University of KwaZulu-Natal, South Africa. He completed the requirements for an MSc in coastal engineering summa cum laude and is currently upgrading the MSc to a PhD. He s a practicing coastal engineer at the eThekwin Municipality's Coastal Stormwater anc Catchment Management Department.

PR0F DEREK STRETCH Is Professor of Hydraulics and Environmental Fluid Mechanics at the University of KwaZulu-Natal. He currently occupies the eThekwini-sponsored Chair in Civil Engineering and is Director of the Centre for Research in Environmental, Coastal & Hydrologica Engineering. His research group focuses on the bio-hydrodynamics of estuarine systems, coastal and shoreline processes, and understanding turbulence and mixing in environmental flows.