Services on Demand

Journal

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of Contemporary Management

On-line version ISSN 1815-7440

JCMAN vol.21 n.1 Meyerton 2024

https://doi.org/10.35683/jcman1049.252

RESEARCH ARTICLES

Insights into the effects of ISO 9001:2015 on quality and process improvement in the South African packaging industry: A leadership perspective

Raveen RathilallI, *; Kishan SinghII; Manduth RamchanderIII

IDepartment of Operations and Quality Management, Durban University of Technology, South Africa. Email: raveenr@dut.ac.za. ORCID: https://orcid.org/0000-0003-0699-2293

IIDepartment of Operations and Quality Management, Durban University of Technology, South Africa. Email: Kishan@gibsolutions.co.za. ORCID: https://orcid.org/0000-0001-5950-1393

IIIDepartment of Operations and Quality Management, Durban University of Technology, South Africa. Email: ManduthR@dut.ac.za. ORCID: https://orcid.org/0000-0002-3827-2349

ABSTRACT

PURPOSE: The purpose of this study was to explore how ISO 9001:2015 certification affects the level of continuous improvement, process integration, and process re-engineering within the South African (SA) Packaging Industry. Furthermore, the study aimed to establish the perceptions of key industry leaders on the effectiveness of ISO 9001:2015 in enhancing quality and process improvement.

DESIGN/METHODOLOGY/APPROACH: The study adopted a qualitative research approach, utilising semi-structured interviews as the primary data collection method. The research sample consisted of packaging leadership representatives from packaging organisations across the country. The sample was stratified according to the various packaging substrates.

FINDINGS: The findings identified that ISO 9001:2015 integration in the packaging industry is primarily focused on manufacturing processes and products and that managers tend to overlook the potential for value-add through business functions process integration. Furthermore, the study highlighted that the Continual Improvement processes were reactive rather than proactive and that there is a lack of evidence of Business Process Re-engineering (BPR) within the industry.

RECOMMENDATIONS: It is recommended that the industry adopts an integrated process management approach to streamline operations and implement BPR methodically, focusing on high-yield processes and using dedicated teams, along with Lean Six Sigma (LSS) tools, to drive targeted process improvements. Furthermore, it is suggested that the industry fosters a strong quality culture with proactive leadership for successful BPR and LSS adoption.

MANAGERIAL IMPLICATIONS: This paper offers practical recommendations that are within the manager's scope of control and can be readily implemented in their specific organisational contexts. Adoption of these recommendations is anticipated to yield advantages in terms of sustainable business practices while mitigating the challenges associated with conventional change management processes.

JEL CLASSIFICATION: L69, L23, L15

Keywords: ISO 9001:2015; Continuous Improvement; Process; Business Process Re-engineering; Lean Six Sigma

1. INTRODUCTION

The ISO 9001:2015 standard serves as a worldwide benchmark, signifying adherence to an internationally recognised regulatory standard for Quality Management (Evi & Gantino, 2023). It demonstrates an organisation's dedication to quality and instils confidence in its ability to consistently deliver high-quality products and services while also facilitating continuous improvement of its Quality Management System (QMS) (Dinu, 2017). Although ISO standards are not legally mandatory on a global scale, their widespread adoption over the years has made them virtually indispensable in practice (Alshahrani & Husain, 2023). Consequently, many international businesses now require their suppliers to obtain ISO certification to maintain global supply chain relations (De Oliveira et al., 2016). Furthermore, Chiarini and Cherrafi (2023) assert that organisations willingly choose ISO 9001:2015 certification due to its consistent demonstration of addressing challenges related to cost reduction, process simplification, coping with shorter product life cycles, managing growing product complexity, and adapting to ever-changing market dynamics.

However, merely adhering to the implementation and requirements of a QMS is found to be insufficient and may prove inadequate when considering the long-term sustainability and pursuit of organisational excellence (West & Cianfrani, 2016). The primary objective of the standard is to define the QMS requirements rather than prescribing specific methods for achieving them, as pointed out by Sá et al. (2022). The QMS itself does not highlight the significance of quality cost methods, specific tools, and techniques for continuous improvement, as well as the establishment of a structured deployment approach to address global challenges. Additionally, it does not provide guidance on the selection of particular methods for process deployment (West & Cianfrani, 2016). Therefore, the adoption of specific quality techniques or methodologies, such as Lean Six Sigma (LSS) or Business Process Re-engineering (BPR), may be required as appropriate to surpass mere compliance and elevate the effectiveness of the QMS in establishing and maintaining controlled processes, achieving internal operational effectiveness, and ensuring utmost customer satisfaction (Fonseca & Domingues, 2018; Sá et al., 2022). There must be a commitment to managing the entire system with quality processes; otherwise, there is a risk of having a false sense of continuous improvement and customer satisfaction (Santos et al., 2023). As market competition intensifies, successful change management, quality improvement, and process enhancement become imperative for an organisation's survival and success (Patmawati et al., 2023).

The aim of this study was to ascertain the influence of ISO 9001:2015 certification on continuous improvement, process integration, and process re-engineering in South African Packaging organisations. Furthermore, the study investigated the perceptions of the key industry leaders within the SA Packaging sector regarding the efficacy of ISO 9001:2015 in facilitating quality and business process improvement. This paper commences with a literature review pertaining to Continuous Improvement, Process Management, LSS, and BPR, followed by the delineation of the methodology employed. Thereafter, a discussion of the data analysis and findings are presented, which culminates in four recommendations for possible adoption within the SA packaging industry.

2. LITERATURE REVIEW

2.1 Context of study

The SA Packaging industry includes a diverse range of products and services that serve various sectors, such as food and beverage, pharmaceuticals, cosmetics, and consumer goods. The industry's value chain comprises four principal segments, namely packaging raw material suppliers, packaging converters or manufacturers, packaging brand-owners and the retail sector (Braithwaite et al., 2019). Raw material suppliers are responsible for producing the raw materials that form the foundation of packaging products, encompassing plastics, glass, paper, and metal. The term "converter" within the packaging industry refers to a manufacturer converting raw materials into consumer and industrial packaging. The brand-owners hold legal ownership over specific brands, while the retail sector serves as the final link in the value chain, facilitating the distribution of packaged goods to consumers. Notably, the total packaging sector contributes approximately 1.4% to South Africa's Gross Domestic Product (GDP) (BMI Research, 2022), signifying its economic relevance in the national context. However, like many other industries in the current business context, the SA Packaging industry faces several challenges. These challenges include the escalation of raw material costs, growing environmental concerns surrounding packaging waste, and the pressing need for more efficient waste management practices (Muller, 2018; BMI Research, 2022). Addressing these challenges is, therefore, imperative for the industry's sustainable growth and its contribution to a more environmentally responsible business landscape.

2.2 ISO 9001:2015 Quality Management System

The ISO 9001:2015 standard is built on a set of seven quality management principles, which form the foundation of the standard's requirements (Canbay & Akman, 2023; Chiarini & Cherrafi, 2023). These principles include customer focus, leadership, engagement of people, process approach, improvement, evidence-based decision-making, and relationship management to enhance performance to achieve quality goals and meet stakeholder expectations (ISO 9001:2015). Customer focus emphasises understanding and meeting customer requirements, while leadership establishes a quality-focused culture. Engaging people fosters a skilled workforce, and the process approach enhances resource utilisation. Improvement prioritisation leads to continuous enhancements, and evidence-based decision-making informs effective actions. Relationship management cultivates beneficial partnerships, fostering quality enhancement and success (Evi & Gantino, 2023).

The standard integrates a process approach and risk-based thinking to drive a process model that follows the Plan-Do-Check-Act (PDCA) cycle to attain desired outcomes throughout all business processes (Fonseca et al., 2023). According to the ISO 9001:2015 standard, the organisation must engage in planning, execution, monitoring, and improvement activities throughout the PDCA cycle (Sá et al., 2022). The standard's clauses cover various aspects, such as context analysis, risk-based thinking, leadership commitment, resource management, performance evaluation, and continual improvement (ISO 9001:2015).

Fonseca et al. (2021) reported that ISO 9001:2015 implementation within the various business sectors has led to substantial organisational improvements, including expand ed opportunities for international market trading, operational advancements, increased profitability, and effective measures to reduce internal costs, enhanced productivity, and improve overall efficiency. All of these positive outcomes can be traced back to the fundamental objective of reducing business process variation or alternatively increasing process consistency or precision, as supported by West and Cianfrani (2016). Therefore, to achieve alignment with the principles of consistency and precision on a clause-by-clause basis, the integration of quality tools and techniques, as advocated by Castello et al. (2020), can facilitate a practical and sustainable operation of the ISO 9001:2015 standard.

2.3 Process Management

A business process is characterised as a linked sequence of activities that use resources to transform raw materials into finished products (Alawag et al., 2023). It underscores an organisation's dedication to a comprehensive strategy for developing interconnected activities across all operations (Pradnyana & Listartha, 2021). Managing a business process is a complex task as it encompasses multiple departments, management levels, and organisational boundaries. It requires a deep understanding of the process steps, the individuals involved, the exchange and processing of information during these steps, and the technologies employed (Reijers, 2021). Rungruengkultorn and Boonsiri (2022) elaborate on the significance of optimising and aligning these elements to enhance the production efficiency of products and services. Consequently, organisations must prioritise the implementation of efficient process controls in order to elevate the quality of their products and services (Isaksson et al., 2023).

The realisation of products and services to meet consumer needs relies solely on the implementation of integrated and coordinated business processes (Reijers, 2021). Recognising that value is created within these processes, Isaksson et al. (2023) emphasise the advantageous nature of the process approach in comprehending organisations as intricate systems. The process approach incorporates organisational innovation and effective process management, prioritising interconnected processes and adherence to key principles, which in turn results in enhanced management, increased capitalisation, and empowered employees for successful project outcomes (Alieva & Davronova, 2023). Continuously improving business processes is vital for generating additional consumer value, enhancing effectiveness, increasing efficiency and promoting adaptability to meet changing customer and business requirements (Pradnyana & Listartha, 2021). Therefore, in order to optimise organisational performance, it is imperative for these processes to address challenges arising from interconnected business processes, divergent stakeholder interpretations, and inconsistent organisational policies. This can be achieved through the employment of visualisation, alignment, and standardised processes (Abubakre et al., 2021). This approach is closely linked to quality certifications, as organisations seeking to implement quality standards naturally promote the improvement of their processes (Chión et al., 2020).

2.4 Continuous Improvement

Continuous Improvement is a systematic approach to enhancing product, process, and service performance within an organisation (Carnell, 2022; Alshahrani & Husain, 2023). It involves an ongoing effort to identify and eliminate waste, streamline processes, and make incremental and breakthrough advancements to improve quality and achieve optimised outcomes (Vinodh et al., 2021). According to Zighan and Ruel (2023), continuous improvement operates at both strategic and operational levels within an organisation. The objective is to bring about substantial improvements in the short and long term by promoting effective management practices and instilling a culture of ongoing improvement in the organisation's processes. Mishra and Duffy (2023) affirm that a robust quality culture empowers each individual within an organisation to actively participate in enhancing quality practices and to consistently identify and implement improvements across all operational processes.

The level of continuous improvement maturity is linked to employee engagement and their willingness to contribute ideas for product and process improvements. This creates an environment conducive to ongoing development and nurtures social aspects like motivation and creativity within work groups (Santos et al., 2023). Patmawati et al. (2023) characterise this as soft quality management, emphasising its focus on human-centric aspects and the establishment of adaptive quality systems that enable organisations to respond effectively to changing environments while fostering a culture of continuous improvement. In their study, Lizarelli et al. (2023) found that increased adoption of continuous improvement behaviour improved product and process innovation performance, especially in organisations demonstrating higher levels of continuous improvement behaviour maturity. Liu (2023) supports the notion that quality should be pervasive throughout an organisation and overseen by all individuals within the organisation.

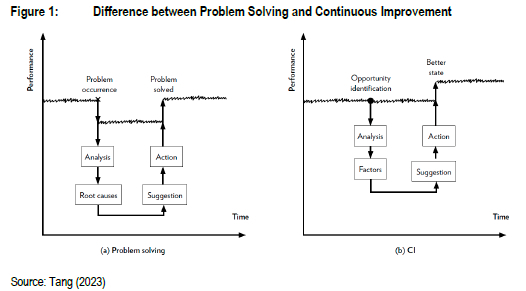

Tang (2023) draws attention to the distinction between reactive problem-solving methodologies, which are centred on root cause analysis (RCA), and the proactive nature of continuous improvement, which prioritises influencing factors, as depicted in Figure 1. This highlights the primary difference between routine quality work, where addressing root causes occurs reactively, and continuous improvement, which adopts a proactive approach to driving progress. According to Bagodi et al. (2021), quality management utilises specific problem-solving approaches known as "quality tools" as well as the application of broader and more encompassing methods termed "quality techniques", which integrate various quality tools and methodologies. Therefore, as can be seen in Figure 1, the diagram on the left-hand side presents a visual representation of the relationship between problem-solving methodologies which rely on the application of fundamental quality tools. Some of the commonly used quality tools include checklists, brainstorming, PDCA cycles, and process diagrams (Bagodi et al., 2021; Sa et al., 2022). In contrast, the diagram depicting Continuous Improvement on the right-hand side of Figure 1 elucidates the correlation between the continuous improvement process and the integration of advanced quality techniques. Castello et al. (2020) assert that continuous improvement, as a quality technique, transcends the confines of a single quality tool, necessitating more contemplation, skill, and training for effective implementation. This includes incorporating quality techniques like LSS or BPR.

The choice between problem-solving or continuous improvement remains subjective due to their inherent similarities, and both are needed to drive improvement (Tang, 2023). Consequently, the comprehensive approach of combining problem-solving methodologies and continuous improvement processes enhances overall quality and organisational effectiveness by acknowledging the perpetual changes in customer needs and the business environment, leading to endless opportunities for growth and progress (Jbeily, 2022). This approach emphasises the importance of proactive and iterative continuous improvements while also acknowledging the occasional necessity of major overhauls as the organisation strives to achieve its predetermined goals through an ongoing process of improvement (Evi & Gantino, 2023). The authors further suggest that organisations must prioritise and enhance these techniques to surpass the minimum ISO 9001:2015 requirements to achieve greater competitiveness.

2.5 Lean Six Sigma

Lean manufacturing aims to maximise efficiency and eliminate all sources of waste within an organisation (Araman & Saleh, 2023). It is based on five principles, which include defining value from a customer's perspective, identifying non-value-added activities in the value stream, creating continuous flow in all processes, establishing pull systems, and pursuing perfection to maximise the value-adding components in an organisation (Kumar et al., 2022). The implementation of Lean manufacturing necessitates cultural and behavioural changes among individuals within the organisation (Aripin et al., 2023). It can be applied to any production floor and utilises flexible tools such as Value Stream Mapping, Just-In-Time (JIT) inventory, Kanban systems, and rapid changeover methods to effectively lower manufacturing costs, uphold quality standards, and ensure timely and complete delivery (Habib et al., 2023).

Six Sigma is a defect reduction strategy that effectively reduces variation to enhance process performance and maintain consistency in the quality of the process outputs through the utilisation of statistical tools (Muhammad et al., 2022). It employs a five-step approach known as DMAIC, which serves to Define a process to improve, Measure the baseline and target performance of the process, Analyse the process data to determine the key process inputs that affect the outputs, Improve the process to optimise the outputs, and, finally, to Control the improved process for sustaining the improvement (Mittal et al., 2023; Paulmino & Marquez, 2023). From a statistical perspective, Six Sigma is a numerical concept denoting an exceptionally high level of quality with a target of 3.4 defects per million opportunities, equivalent to an accuracy of 99.99%. This metric represents the closest approximation to achieving perfection in quality that is realistically attainable (Patel & Patel, 2021; Araman & Saleh, 2023).

Several instances of performance improvements have been attributed to Lean and Six Sigma as standalone systems. However, it is important to acknowledge that researchers have identified inherent weaknesses associated with each technique (Tiwari et al., 2022; Kumar et al., 2023; Paulmino & Marquez, 2023). For instance, Lean, when employed in isolation, fails to exert statistical control over processes, while Six Sigma, when used independently, cannot eliminate all sources of waste (Alexander et al., 2022). Consequently, the integration of Lean and Six Sigma emerged as a strategic approach that capitalises on the respective strengths of both systems while mitigating their individual weaknesses (Rathilall & Singh, 2018; Francescatto et al., 2023). Referred to as the integrated Lean Six Sigma technique, this balanced approach combines the DMAIC framework and the statistical methodology for reducing variation from Six Sigma while integrating Lean's focus on value creation and waste reduction (Flor Vallejo et al., 2020). Lean Six Sigma integrates human and process elements into a programme that links and sequences the unique improvement tools and principles of both techniques to effect the improvement towards an overall approach for innovation and business growth (Alexander et al., 2022). It is a proven process management and effective continuous improvement technique to increase process performance, enhance customer satisfaction, and drive positive bottom-line results across diverse business sectors (Patel & Patel, 2021; Orji & U-Dominic, 2022; Tiwari et al., 2022).

Recent developments in operations and quality management have integrated LSS methodologies with sustainability (Muhammad et al., 2022) and digitalisation (Samanta et al., 2023). These concepts expand traditional principles, facilitating timely adaptation to market demands. After gaining a deeper understanding of these quality concepts, the authors reached the conclusion that the primary factors responsible for driving them are process management and continuous improvement.

2.6 Business Process Re-engineering

BPR has long been recognised as an effective strategy to revitalise business processes (Siregar, 2022). It compares value derived from current business processes against the expected value by challenging assumptions, taking a fresh look at new ideas, and eliminating non-value-added activities (Bhaskar, 2018; Grant & Yeo, 2022). This approach steers the necessity of re-evaluating and restructuring an established business process to enhance value delivery to customers and stakeholders in order to engage in business re-engineering (Chiekezie et al., 2022). However, it is important to note that if a business is already operating profitably, its processes are generally effective and may not require re-engineering or re-inventing. Instead, constant monitoring and measurement are usually sufficient to maintain value derivation (Choudhary & Riaz, 2023). Nonetheless, to keep pace with the rapidly advancing technology and to ensure business growth and economic sustainability in today's dynamic business environment, businesses must proactively embrace change and adopt new ideas, as well as improve their business processes to become more efficient in achieving their business goals (Fikry et al., 2023).

In the current business context, it is essential to understand that BPR stands apart from typical business modifications such as automation, downsizing, and restructuring (Bhaskar, 2018; Chiekezie et al., 2022). BPR offers the opportunity to completely redesign processes within an organisation, incorporating technological advancements and information systems to reconfigure machines and knowledge and modify behaviour (Linarti et al., 2023). Unlike quality techniques, such as Kaizen, that focus on incremental improvements or specific problem-solving, BPR aims for revolutionary change (Zaini & Saad, 2019). The choice between BPR and optimisation through these quality techniques depends on the available investment and the expected rate of return, which should be analysed on a case-by-case basis considering the complexity and financial well-being of the business. However, Meriem and Cherif (2020) emphasise that BPR and Kaizen should not be perceived as discrete improvement tools but rather as complementary approaches. The authors propose that Kaizen can serve as a reasonable starting point for BPR, and both approaches can be combined harmoniously, leveraging their respective strengths and similarities.

3. METHODOLOGY

This study incorporated the qualitative research design as the methodology to yield a deeper understanding and novel insight into the research objectives (Creswell & Creswell, 2018), which was to analyse the influence of ISO 9001:2015 certification on South African packaging businesses, with specific emphasis on its role in fostering continuous improvement, process integration, and process re-engineering to promote sustainable business practices. The qualitative research method involved gathering response data through interviews and observations (Sekaran & Bougie, 2016). The initial part of the study was to review the concepts related to continuous improvement, process integration, and process re-engineering as vital elements for sustainable business practices. This step aimed to establish the rationale for the constant adaptation of business processes to enhance overall performance. The next part of the study incorporated fieldwork to investigate leadership perceptions regarding the effectiveness of ISO 9001:2015 certification in enhancing quality and business process improvement within the South African packaging industry. A set of open-ended, structured interview-type questions was used for this part of the study to obtain leadership views in pursuit of fulfilling the research objectives. The interview instrument was deemed appropriate so that the authors could adapt the questions if necessary, clarify doubts, and ensure that the responses were properly understood by repeating or rephrasing the questions (Sekaran & Bougie, 2016).

3.1 Questionnaire design

The research instrument (interview discussion guide) was informed by ISO 9001, BPR, and LSS systems and practices. The structure of the research instrument consisted of 24 items that measured the participant's biometric data (6 items), ISO 9001:2015 certification age and certification body (2 items), and open-ended interview questions covering salient aspects of quality management systems, interrogating ISO 9001:2015 impact on the business, customer focus, business efficiency, leadership support, and BPR (16 items). The interview questions sought to extract leadership-level information relating to the actual ISO 9001:2015 implementation and its influence on the business processes within the organisation.

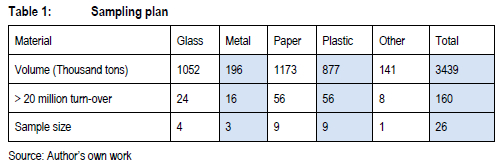

3.2 Sampling strategy

The sampling strategy was based on packaging manufacturers with a turnover of greater than R20 million per annum, which is the "core" of the packaging industry, comprising approximately 160 companies in South Africa (Packaging SA, 2020). According to Leavy (2017), a minimum sample size of 20 interviews is recommended for qualitative research in order to achieve comparative and saturation adequacy. However, given the cultural heterogeneity in South Africa, the decision was made to approach 26 packaging manufacturers to participate in this study. The sample size of 26 was deemed to be more than satisfactory, as evidenced by the results presented in Table 1. The sampling plan was stratified, which is an efficient technique when differentiated information is needed (Sekaran & Bougie, 2016). The sampling strategy included selecting cross-sectional samples of packaging manufacturers with a turnover of greater than R20 million per annum, split across the mainstream packaging materials and packaging material volume, as represented in Table 1.

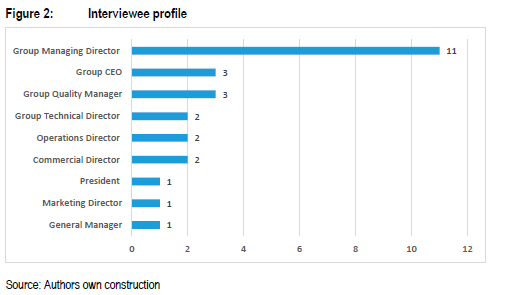

The target participants were business leaders, including general managers (GM), chief executive officers (CEO), managing directors (MD), and technical and marketing directors. These individuals represented the packaging leadership in SA, and they represent various geographical regions and packaging substrates. Their diverse backgrounds made them well-suited to provide a comprehensive assessment of the extent to which ISO 9001:2015 has influenced quality and business process improvement in support of sustainable business performance. An analysis of the cross-section of the interviewees indicated the integrity of the interviewee profiles against the SA packaging industry, confirming the impartiality of the data. The respondents were selected to align with the cross-section weighting of the packaging material types to ensure that the study results reflected the industry cross-section fairly.

3.3 Execution of interviews

The authors formally set up appointments with 26 leaders of the packaging industry, achieving 100% of the sample size. The interview sessions required the interviewee to respond to a fixed set of open-ended discussion questions, and one selected author transcribed the responses on a laptop, capturing as much of the interviewee's exact words as possible. The interview session duration averaged approximately 50 minutes. More than 60% of the interviews were face-to-face, with the balance being virtual, given the full calendars and limited availability of these individuals. Upon completion of the interview, the authors refined the grammar, punctuation, and layout of the responses. In order to enhance the trustworthiness of the study, the authors emailed each interviewee a copy of their respective responses. This was done to verify the accuracy with which the authors had captured the interviewees' ideas and thoughts. None of the responses were amended or rejected by the interviewees.

3.4 Method of data analysis

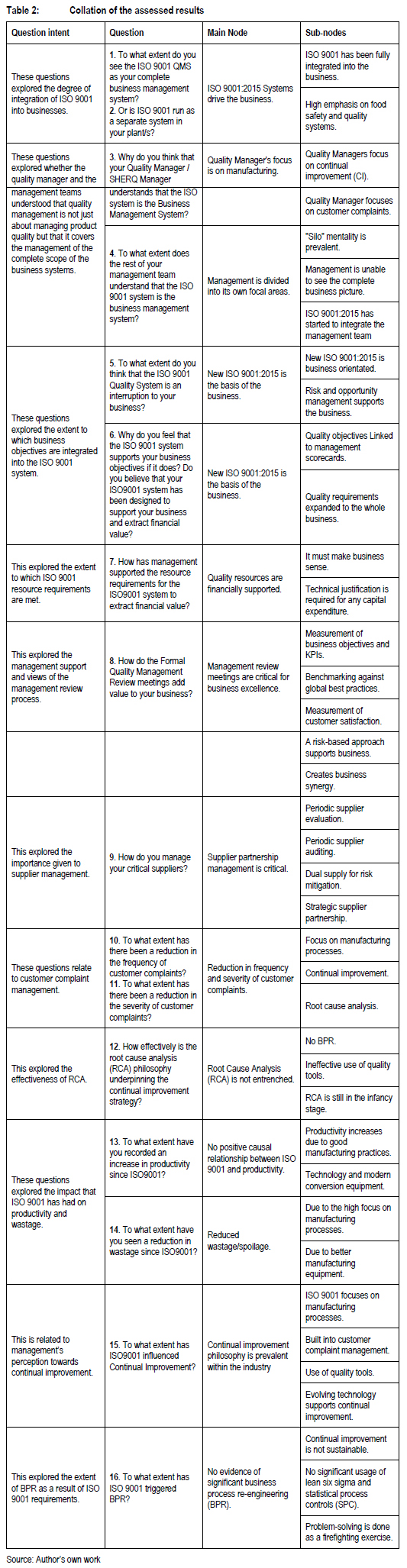

The analysis and interpretation of the data were guided by qualitative research methods and were informed by the guidelines set out by Bazeley (2018). This approach was deemed to provide a robust and credible framework for the analysis of the data, as it promotes the principles of validity and reliability, as advocated by Spiers et al. (2018). While software options like ATLAS.ti and NVivo are available for qualitative analysis, the researchers chose to perform the thematic analysis using the matrix analysis method as described by Groenland (2014). The rationale behind this selection was primarily based on the relatively small number of transcripts that had to be analysed. Accordingly, Microsoft Excel was used to conduct the Matrix Analysis process. Thematic nodes and sub-nodes were employed to organise and analyse the data, applying descriptive analyses to identify significant trends in the participants' responses. This involved collating the transcript responses of all 26 participants to each of the 20 questions on a spreadsheet, allowing for a clear and concise view of the 26 responses to a common question, which was referred to as "common question - cross-section of interviewees". The questions were arranged horizontally on the spreadsheet, with each row representing each of the 20 questions. For instance, the first row corresponded to Question 1, the second row corresponded to Question 2, and so forth. The responses to each question were then recorded in the columns, with each column corresponding to a specific transcript response. This process showed repetitive trends and phrases in the transcript responses, allowing common response nodes to be identified.

Where appropriate, sub-nodes that connected to the main node were also identified by identifying common phrases. This was carried out for each of the transcript questions. In addition, to enhance the validity of the analysis, the authors also examined a cross-section of each of the transcript responses for a common interviewee, referred to as "common interviewee - cross-section of questions", identifying nodes and sub-nodes. Nodes and sub-nodes arose from the majority of the responses. The responses were also weighted according to the individuals and their positions within the industry to strengthen the validity of the analysis. The results of this method were collated, and the emerging nodes and sub-nodes are presented in Table 2.

The qualitative analysis rationale discussed above will yield similar results if executed as described. The authors verified this as they independently analysed the initial data before agreeing to the nodes and sub-nodes categories. The patterns of the responses of the qualitative research were analysed and categorised into specific opportunities for improvement in alignment with the research objectives.

3.5 Ethical considerations

The anonymity and confidentiality of the participants were maintained to ensure that the study was conducted ethically. The Institutional Research Ethics Committee at a large public university on the east coast of South Africa approved the research prior to the commencement of the study. The research ethical clearance certificate, together with background information on the study, was made available to the participants during the fieldwork.

4. FINDINGS AND DISCUSSION

Of the 26 interviewees, 38.5% represented the paper and board packaging substrate, 19.2% represented the metal packaging substrate, 34.6% represented the plastic packaging substrate, while 7.7% represented glass and other substrates. The paper and plastic packaging sector makes up approximately 80% of the SA packaging GDP by value, and 73.1% of the 26 interviewees represented this substrate. Approximately 81% of the organisations have been ISO 9001 certified for more than 12 years, indicating that the responses of the interview panel came predominantly from mature ISO 9001 certified organisations.

Figure 2 displays the distribution of respondents according to their job titles. It is evident that this particular sample selection encompasses individuals holding pivotal roles within their respective organisations, thus signifying the representation of influential and authoritative figures from the industry.

The analyses of the interview responses to each of the 16 questions are presented in Table 2.

The general interviewee comments for Questions 1 and 2 were that ISO 9001 systems are not regarded as being separate from the business system. Given the high focus on food safety, leadership viewed the management systems as critical for the attainment of quality. This correlates with West & Cianfrani (2016) and Solomon et al. (2017), that consistent and predictable results are obtained when organisations are managed by understanding their business processes and how these processes are sequenced and interrelated as a coherent system to achieve desired results.

In response to Question 3, the general consensus was that quality managers tend to focus mainly on manufacturing processes and products, as opposed to all business processes that support manufacturing processes. This contradicts the concept of the process management approach as advocated by Reijers (2021), which emphasises the significance of integrated processes to ensure business synergy and customer satisfaction. It was also noted that continual improvement strategies are predominantly centred around the manufacturing processes and products and were not applied in the wider business processes which critically support the manufacturing processes. The expansion of the Continuous Improvement thinking to human resources, engineering, logistics, sales and marketing, and other areas of the business was not evident. Furthermore, it was observed that quality managers spend significant effort in managing customer complaints, ensuring that the RCA conducted by the manufacturing personnel are effective prior to being released to the customer. This is an area of business management that needs to redefine the purpose of the quality manager in quality management system design, especially when required to bring about the business synergy of all critical business processes, as advocated by Zighan and Ruel (2023).

Question 4 feedback highlighted that managers tend to focus on their own functional areas. Although they do manage their own departments well, they are unable to see the complete business picture. They are unable to extract greater business value by integrating with every other business functional department. A "silo" mentality exists that tends to exclude full business integration. A CEO from the rigid plastic, metal, and glass substrate elaborated as follows:

"I am also not convinced that it adds much value internally in other areas of the business outside of our quality system."

This statement indicates that the quality system is regarded as a manufacturing and product quality system within the business systems, a seemingly unintegrated process approach. This stands in contradiction to the integrated approach, which requires the entire business to be analysed in terms of business operation flow, showing the core process as well as all the support processes (Solomon et al., 2017). The significance of departmental processes lies in their sequences and interactions. These crucial elements must be clearly presented within the quality system, as reported by Chión et al. (2020). The integrated approach enables efficient decision-making regarding process throughput and also aids in troubleshooting when processes do not achieve their intended results.

Another evident theme was that the new ISO 9001:2015 standard, given its focus on risk and opportunity management and business contingency planning, with lesser emphasis on documentation, has brought about greater management acceptance and participation in the quality systems within the business. Therefore, quality managers can bring about business systems appreciation by adopting the integrated process approach that is emphasised by ISO 9001:2015.

For Questions 5 and 6, the interviewees expressed a sense of appreciation for the new ISO 9001:2015 standard because it demonstrates a greater sense of practical business management. The reason for this could be that the previous ISO 9001 standards tended to focus excessively on documented policies and procedures, failing to address real business needs, while the new ISO 9001:2015 standard, which focuses on business risk and opportunity, brings about greater participation and commitment to quality requirements. Chiarini and Cherrafi (2023) corroborate the idea that revisions to the standard are necessary because the local and global business environments that organisations operate in are constantly evolving. The ISO 9001:2015 standard also needs to adapt to such changes. Furthermore, the ISO 9001:2015 standard was deemed to be supportive of the business objectives, with the need for specific quality objectives to be integrated into manager's personal scorecards and periodically revised in line with changing business strategies. Jbeily (2022) concurs that senior management must demonstrate commitment to business ideals and ethos, especially when it comes to the execution of business strategies and quality objectives. The commitment should be evident in their perception of employees as invaluable assets through a participatory leadership style that fosters a sense of belonging and happiness within the workforce. Moreover, senior management support is instrumental in propelling the quality culture of an organisation towards the attainment of quality objectives (Mishra & Duffy, 2023).

The common theme elicited by Question 7 was the interviewees' acknowledgement that resources for quality improvement are generally financed based on the justification for technical capital expansion and business needs. This alludes to the point that the implementation and use of a cost of quality process serve as an effective instrument for communicating operational information to management, thereby fostering a mechanism that encourages proactive actions to drive improvements (West & Cianfrani, 2016). With this information, the business can calculate where to allocate additional resources to enhance product quality and profitability.

For Question 8, the interviewees generally viewed the management review process as being extremely beneficial to the business, specifically those aspects relating to the review of performance indicators, business risks and opportunities and action decisions. This was a mechanism to get managers to realise the risks, challenges, and contributions of their counterparts from all of the functional areas of the business, promoting the business synergy that is required, especially when dealing with customer requirements and satisfaction. These insights align with Chiarini and Cherrafi's (2023) findings, which highlight that the management review process encompasses critical performance dimensions, including customer satisfaction, internal auditing, and data analysis from monitoring and measurement. These data and information undergo thorough evaluation during the management review, culminating in the implementation of continuous improvement initiatives.

In response to Question 9, leadership stressed that a strategic partnership approach to supplier or subcontractor management is vital, where the emphasis should be on a longer-term, sustainable relationship rather than on a relationship based purely on pricing, which is encouraged by Chountalas and Lagodimos (2019). Suppliers and subcontractors must demonstrate solid business systems and value derivation through a risk-managed, triple-bottom-line approach. Leadership was of the opinion that supplier relationships were critical and that supplier auditing, supplier performance evaluation, and supplier development were essential, as well as good business practices. Given that internal processes are significantly dependent on incoming material quality, it is imperative that supplier relationships and specification integrity are maintained.

The interviewees acknowledged in Questions 10 and 11 that customer complaint frequency and severity showed a reducing trend since the ISO 9001:2015 implementation. The interviewees believe that this is most likely due to the excessive focus on manufacturing processes and product quality by the manufacturing and quality departments. These findings corroborate the research conducted by Alshahrani and Husain (2023), which emphasised the critical role ISO 9001:2015 plays in meeting or exceeding customer expectations and effectively resolving errors in processes or product components to achieve better product and service quality. A president from the pharmaceutical packaging and glass substrate said the following:

"Always difficult to say or give a finite answer, but ISO 9001 certainly has lowered the risk of non-conforming products affecting our customers. On average, a 5 % year-on-year reduction in quality issues was measured."

The general view of the interviewees for Question 12 was that root cause analysis needed reinforcement since it was mainly driven through the use of quality tools to achieve continual improvement through slow and steady Kaizen-style methodology instead of significant re-engineering of business processes to deliver a paradigm shift in business performance. Kaizen is renowned for its focus on incremental improvements (Carnell, 2022), and it is employed by organisations worldwide to achieve continuous improvement through small steps and eliminate losses that are tailored to each organisation's specific needs (Androniceanu et al., 2023). An MD from the diversified packaging substrate said the following on RCA:

"Our Quality Manager has been trained, and he has cascaded such logic to all stakeholders within the business. Every customer complaint investigation uses RCA to elucidate the root cause and to eradicate it so that solutions are sustainable and there is no recurrence of the problem."

The authors gauged from the responses of the interviewees that, typically within the industry, RCA and Continuous Improvement are usually due to product and process failures that are addressed after the event. This observation aligns with Tang's (2023) study that reactive problem-solving methodologies concentrate on identifying root causes.

The general responses for Question 13 indicated that productivity improvements over the years were not causally linked to ISO 9001 but rather attributed to technology advancements, good manufacturing practices, and more efficient conversion equipment. This aligns with the assertion of Fetais et al. (2022) that modifications to enhance business productivity are necessary in a fast-changing global environment characterised by intense competition and technological advancement. The authors, therefore, infer that the ISO 9001:2015 system requirements do not specifically call for productivity improvement but rather for productivity improvements through effective process engineering and improved process management by adopting Lean manufacturing and Six Sigma principles, which are closely related to the responses to Questions 15 and 16 of the interview.

For Question 14, a reduction in wastage was evident and measured, but the general responses of the interviewees were that this was not directly attributable to ISO 9001:2015 implementation. Instead, it was a result of the high focus on manufacturing processes and product quality. In addition, improvements in technology and manufacturing equipment also contributed to a reduction in wastage. Leadership indicated that segments of lean manufacturing techniques were deployed to a greater extent within the manufacturing arena and not across the business, which has contributed to reduced wastage. The authors summarise that the industry has demonstrated a reduction in wastage, although not directly as a result of ISO 9001:2015, but indirectly as a result of the higher focus on manufacturing processes that are bought about by the ISO 9001:2015 standard. However, it is possible to reduce wastage even further by the deliberate adoption of Lean manufacturing, Six Sigma techniques, and BPR, which closely relates to the responses to Questions 15 and 16 of the interview.

The general responses for Question 15 highlighted that while Continual Improvement philosophies were prevalent in the industry, there is still a recognised need for greater focus in this area, as interviewees pointed out that continual improvements are closely tied to customer complaint management. The detection of processes and product failures, whether through customer complaints or internal audits, drives the emphasis on problem eradication, fostering a culture of continual improvement. Zighan and Ruel (2023) demonstrated that establishing a successful continuous improvement culture requires substantial and sustained leadership support, adherence to principles, allocation of sufficient resources, and active participation of employees. In the words of a CEO participant from the paper and corrugated substrate:

"Root cause analysis and continual improvement are definitely weak areas; skills dwindle over the years, and the training is not adequate. A few plants are good, other plants generally are not as good, and continual improvement is more as a result of product failure or system failure, making this a reactive continual improvement approach."

Although continuous improvement strategies were evident, they seemed to be primarily responsive to firefighting processes and product-related issues, leading to solutions that were often not sustainable. As a result, the leadership perceived the current continual improvement methods as being reactive in nature. However, by employing effective BPR and incorporating Lean manufacturing and Six Sigma principles from a proactive perspective, it becomes feasible to design sustainable improvements into processes. This approach aligns with the findings of Evi and Gantino (2023), which emphasise the importance of a proactive stance in detecting and eliminating failures rather than relying on resolving problems after they occur.

For Question 16, the common theme that arose was that ISO 9001:2015 system requirements have not placed specific demands on BPR. Hence, there is generally no evidence of BPR within the SA packaging industry. This finding supports the works of Fonseca and Domingues (2018) and Sá et al. (2022). Additionally, many interviewee responses showed that there was no significant use of LSS and SPC in the manufacturing and other areas of the business. According to a CEO participant from the glass packaging substrate:

"We realised that we had low-hanging fruit, and to try and capitalise on this, we started off by employing Six Sigma black belts, and we had them in our organisation for 6 years. These black belts worked purely on projects using DMAIC to enhance the business and put in methods and processes to sustain these benefits."

The authors point out that although this respondent achieved some level of improvement with LSS, generally, the interviewees confirmed that BPR was not used extensively in the industry. An ex-MD from the paper and corrugated substrate said:

"We did plug a lot of holes at the time, but re-engineering of processes were not a high priority. There was no significant use of stats and lean six sigma improvement techniques."

An MD from the rigid packaging substrate said the following during the interview:

"Our company doesn't use Six Sigma; that's a bit like a Masters in Business Administration (MBA), but we do use good common sense, not really BPR, with statistical measures and calculation of sigma values and reducing sigma values to reduce variation. But the managers are here do constantly find better ways of doing things; we don't really bring in consultants to enhance processes."

The authors summarise that given the limited use of BPR and LSS within the industry, this is a focal area to extract greater business value. It is possible to design improvements into processes through effective BPR and the adoption of Lean manufacturing, JIT, and Six Sigma principles.

5. SUMMARY OF KEY FINDINGS

Firstly, it was noted that while ISO 9001:2015 is fully integrated into the business, the focus on quality tends to be concentrated on manufacturing processes and products rather than all supporting business processes. Consequently, RCA was primarily driven by the use of quality tools for continual improvement, as opposed to significant re-engineering of business processes. Furthermore, both RCA and Continual Improvement were found to be approached as a reactive mechanism rather than a proactive strategy, resulting in a decline in customer complaint frequency and severity. In addition, productivity improvements were attributed to technology advancements, good manufacturing practices, and more efficient equipment, with no direct causal link to ISO 9001. Similarly, waste reduction was not directly attributable to ISO 9001 implementation but rather a result of a high focus on manufacturing processes and product quality.

Secondly, the study found that managers tend to focus on their own functional areas rather than exploring the potential for value extraction through integration with other departments. Although there is an appreciation of the transformative potential of ISO 9001:2015, greater managerial participation and commitment are necessary to establish strategic business objectives. Thirdly, it was observed that the cost of quality was used as the basis for business expansion and review processes and played a central role in informing action decisions. Fourthly, a strategic partnership approach to supplier/subcontractor management was deemed vital, emphasising a longer-term, sustainable relationship rather than purely financial considerations. Lastly, the study found that the system requirements of ISO 9001:2015 do not impose specific demands on BPR, and as a result, there is a general absence of evidence of BPR within the SA packaging industry.

6. RECOMMENDATIONS

Based on the discussion of the results and findings, improvement opportunities for RCA, supplier chain management, integrated process management, and adoption of BPR and LSS initiatives are necessary elements to improve processes and reduce variation. RCA will not produce positive effects unless supported by the entrenchment and sustainability of the solutions for continual improvement (Zighan & Ruel, 2023). However, the incremental Kaizen style continual improvement contrasts with the 'radical change' BPR techniques, which will provide, if adopted, a paradigm shift in business performance as a result of a more proactive approach to process engineering (Zaini & Saad, 2019).

Drawing from Solomon et al. (2017) and Reijers (2021), wherein the authors recommended that the quality managers design the integrated process management approach into the QMS to bring about business synergy by clearly defining the sequences and interactions of all critical business processes and by enforcing the quality requirements of each of these process outputs. The findings of the current study show that this practice is limited to manufacturing processes in the packaging industry. Therefore, it is recommended that, firstly, the entire business should be mapped by removing all non-value-adding steps and creating an optimised process flow, showing the sequences and interfaces of each business process (Heher & Chen, 2017). Furthermore, the quality requirements of every critical output should be defined as it sequentially feeds into the subsequent process. The interactive input and output, clearly illustrating the interdependence of the complete business management system, should be shown in a comprehensive process map. This integrated process approach then enables process output and information to flow through the process interfaces where the output of process A becomes the input to process B, as espoused by Pradnyana and Listartha (2021), ultimately ensuring a streamlined approach to achieving the end result, which is customer satisfaction.

Secondly, to execute BPR, it is recommended that the target processes should be identified using the Pareto 80/20 principle, as recommended by Schuh et al. (2023), based on the yield of financial value and yield of efficiency. Then, the BPR procedure should be executed by using a dedicated project team, and sustained success should then be determined by periodic measurement and monitoring. Thirdly, it is recommended that LSS philosophy should be adopted by applying the LSS tools to targeted processes using basic business logic such as quality as a function of percentage defects, price as a function of lean, and delivery as a function of JIT.

Finally, it is recommended that the leadership must champion the quality culture of the organisations to aid the attainment of business quality objectives, especially for the adoption of BPR and LSS, which will necessitate a change in organisational culture (Fonseca & Domingues, 2018). Under these recommended conditions, the authors propose that a reduction in variation within each process will result in a reduction in the overall variation of business performance, resulting in greater consistency of output as the business matures and processes integrate.

7. IMPLICATIONS OF STUDY

This research has several implications for both academic and practical contexts. In academic settings, the study can serve as a valuable resource to aid in the instruction of business sustainability and its various elements that impact both the organisation and its customers. From a practical standpoint, the research has significant economic implications, as the adoption of the recommendations has the potential to increase both financial benefits and customer satisfaction. As such, the recommendations can be leveraged by practitioners as a tool to enhance organisational performance and ultimately increase financial returns. Given the current challenges associated with globalisation, every business must achieve a competitive advantage by differentiation, as pointed out by Schuh et al. (2023). Therefore, exploiting the rationale behind defining quality requirements for every critical output is imperative, given its sequential impact on the subsequent process.

8. CONCLUSION

The aim of this study was to examine how ISO 9001:2015 certification affects continuous improvement, process integration, and process re-engineering in South African Packaging organisations. The findings revealed that, despite a strong emphasis on manufacturing processes and product quality within the South African packaging industry, there were potential areas for improvement in several key aspects of organisational operations, including RCA, supplier chain management, integrated process management, and the adoption of BPR and LSS initiatives. It is envisaged that the adoption of the recommendations that emanate from this study will further optimise business processes within the South African packaging industry, reducing product costs, reducing lead times, and improving product quality.

9. LIMITATIONS AND FUTURE WORK

The study's limitations arise from its exclusive focus on packaging leadership representatives, leading to a restricted number of participants due to the specific nature of this target group's portfolio. Additionally, the qualitative research approach used lacks statistical rigour and generalisability compared to quantitative studies, as indicated by Bazeley (2018). To strengthen the study and its implications, future research could consider a larger and more diverse sample and incorporate a mix of qualitative and quantitative methods to enhance the practical implications and recommendations.

REFERENCES

Abubakre, M., Fayoumi, A. & Eleburuike, I. 2021. Implementing process improvement initiative: the role of visualisation and standardisation methods. Business Process Management Journal, 27(3):965-986. [https://doi.org/10.1108/BPMJ-10-2020-0474]. [ Links ]

Alawag, A.M., Alaloul, W.S., Liew, M.S., Musarat, M.A., Baarimah, A.O., Saad, S. & Ammad, S. 2023. Critical success factors influencing total quality management in industrialised building system: A case of Malaysian construction industry. Ain Shams Engineering Journal, 14(2):101877. [https://doi.org/10.1016/j.asej.2022.101877]. [ Links ]

Alexander, P., Antony, J. & Cudney, E. 2022. A novel and practical conceptual framework to support Lean Six Sigma deployment in manufacturing SMEs. Total Quality Management & Business Excellence, 33(11-12):1233-1263. [ Links ]

Alieva, S.S. & Davronova, N. 2023. Financial Recovery of Enterprises in the Conditions of Innovative Economy. Pioneer: Journal of Advanced Research and Scientific Progress, 2(3):163-169. [ Links ]

Alshahrani, M.A. & Husain, K.S. 2023. The effectiveness of the implementation of ISO 9001 on SMEs performance: the case of an emerging economy. International Journal of Quality & Reliability Management, 1-23. [https://doi.org/10.1108/IJQRM-08-2022-0233]. [ Links ]

Androniceanu, A., Enache, I.C., Valter, E.N. & Raduica, F.F. 2023. Increasing Energy Efficiency Based on the Kaizen Approach. Energies, 16(4):1930. [https://doi.org/10.3390/en16041930]. [ Links ]

Araman, H. & Saleh, Y. 2023. A case study on implementing Lean Six Sigma: DMAIC methodology in aluminium profiles extrusion process. The TQM Journal, 35(2):337-365. [https://doi.org/10.1108/TQM-05-2021-0154]. [ Links ]

Aripin, N., Nawanir, G. & Hussain, S. 2023. Lean Culture for a Successful Lean Manufacturing Implementation: An Empirical Evidence From Malaysian Manufacturing Industry. International Journal of Industrial Management, 17(2):76-83. [https://doi.org/10.15282/ijim.17.2.2023.90371. [ Links ]

Bagodi, V., Thimmappa Venkatesh, S. & Sinha, D. 2021. A study of performance measures and quality management system in small and medium enterprises in India. Benchmarking: An International Journal, 28(4):1356-1389. [https://doi.org/10.1108/BIJ-08-2020-0444]. [ Links ]

Bazeley, P. 2018. Mixed methods in my bones": Transcending the qualitative-quantitative divide. International Journal of multiple research approaches, 10(1):334-341. [ Links ]

Bhaskar, L.H. 2018. Business process reengineering: A process based management tool. Serbian Journal of Management, 13(1):63-87. [https://doi.org/10.5937/sim13-13188]. [ Links ]

BMI Research. 2022. South African Packaging Industry Overview. [Internet: BMi Research - Valued Insights Partner; downloaded on 31 July 2023]. [ Links ]

Braithwaite, D.H., Groenewaldt, G., Kruger, K.S., Padgett, J., Scholtz, P.A. & Smith, M.A. 2019. Overview of the South African packaging industry. Bedfordview, Johannesburg: BMi Research. [ Links ]

Canbay, K. & Akman, G. 2023. Investigating changes of total quality management principles in the context of Industry 4.0: Viewpoint from an emerging economy. Technological Forecasting and Social Change, 189:122358. [https://doi.org/10.1016/j.techfore.2023.122358]. [ Links ]

Carnell, M. 2022. Caring About Cadence. Quality Progress, 55(2):40-42. [ Links ]

Castello, J., De Castro, R. & Marimon, F. 2020. Use of quality tools and techniques and their integration into ISO 9001: A wind power supply chain case. International Journal of Quality & Reliability Management, 37(1):68-89. [https://doi.org/10.1108/IJQRM-07-2018-0171]. [ Links ]

Chiarini, A. & Cherrafi, A. 2023. Integrating ISO 9001 and Industry 4.0. An implementation guideline and PDCA model for manufacturing sector. Total Quality Management & Business Excellence, 1-26. [ Links ]

Chiekezie, O.M., Nwankwo, C.D. & Elomba, C.S. 2022. Business Process Re-Engineering and Economic Sustainability of Brewing Firms in South-East Nigeria. International Journal of Business and Management Research, 3(2):44-59. [ Links ]

Chión, S.J., Charles, V. & Morales, J. 2020. The impact of organisational culture, organisational structure and technological infrastructure on process improvement through knowledge sharing. Business Process Management Journal, 26(6):1443-1472. [https://doi.org/10.1108/BPMJ-10-2018-0279]. [ Links ]

Choudhary, R. & Riaz, N. 2023. A business process re-engineering approach to transform business process simulation to BPMN model. Plos one, 18(3):p.e 0277217. [https://doi.org/10.1371/journal.pone.0277217]. [ Links ]

Chountalas, P.T. & Lagodimos, A.G. 2019. Paradigms in business process management specifications: a critical overview. Business Process Management Journal, 25(5):1040-1069. [https://doi.org/10.1108/BPMJ-01-2018-0023]. [ Links ]

Creswell, J. W. & Creswell, J. D. 2018. Research Design: Quantitative, Qualitative, and Mixed Methods Approaches. 5th ed. Sage Publications. [ Links ]

De Oliveira, P.S.G., Da Silva, D., Da Silva, L.F., Tecilla, M.C. & Dos Santos Lopes, M. 2016. Proposition factor model of World Class Manufacturing in Brazilian enterprises. Independent Journal of Management & Production, 7(2):488-502. [https://doi.org/10.14807/ijmp.v7i2.336]. [ Links ]

Dinu, V. 2017. Quality management and business excellence. Amfiteatru Economic Journal, 19(44):5-7. [ Links ]

Evi, E.L. & Gantino, R. 2023. Implementation Audit Internal of Quality Management System ISO 9001:2015 in the Purchasing Activities Technical Department at Pt Sango Indonesia. Journal of Economics, Finance and Accounting Studies, 5(2):75-88. [https://doi.org/10.32996/jefas.2023.5.2.8]. [ Links ]

Fetais, A., Abdella, G.M., Al-Khalifa, K.N. & Hamouda, A.M., 2022. Business Process Re-Engineering: A Literature Review-Based Analysis of Implementation Measures. Information, 13(4):185(1-9). [https://doi.org/10.3390/info13040185]. [ Links ]

Fikry, M.D., Rozas, I.S. & Amin, F.M. 2023. Implementation of Business Process Reengineering To Minimize Customer Complaints. Return: Study of Management, Economic and Business, 2(4):367-388. [https://doi.org/10.57096/return.v2i04.90]. [ Links ]

Flor Vallejo, V., Antony, J., Douglas, J.A., Alexander, P. & Sony, M. 2020. Development of a roadmap for Lean Six Sigma implementation and sustainability in a Scottish packing company. The TQM Journal, 32(6):1263-1284. [https://doi.org/10.1108/TQM-02-2020-0036]. [ Links ]

Fonseca, L., Cardoso, M.C., Pereira, M.T. & Ávila, P. 2021. ISO 9001 certification benefits: A principal component analysis. FME Transactions, 49(4):835-841. [https://doi.org/10.5937/fme2104835F]. [ Links ]

Fonseca, L., Domingues, P., Nóvoa, H., Simpson, P. & Sá, J.D.G. 2023. ISO 9001: 2015: the view from the conformity assessment community. Total Quality Management & Business Excellence, 34(5):558-579. [ Links ]

Fonseca, L.M. & Domingues, J.P. 2018. The best of both worlds? Use of Kaizen and other continuous improvement methodologies within Portuguese ISO 9001 certified organizations. The TQM Journal, 30(4):321-334. [https://doi.org/10.1108/TQM-12-2017-0173]. [ Links ]

Francescatto, M., Neuenfeldt Júnior, A., Kubota, F.I., Guimaräes, G. & de Oliveira, B. 2023. Lean Six Sigma case studies literature overview: critical success factors and difficulties. International Journal of Productivity and Performance Management, 72(1):1-23. [https://doi.org/10.1108/IJPPM-12-2021-0681]. [ Links ]

Grant, D. & Yeo, B. 2022. A business process reengineering method. Issues in Information Systems, 23(1). [https://doi.org/10.48009/1_iis_2022_101]. [ Links ]

Groenland, E. 2014. Employing the Matrix Method as a Tool for the Analysis of Qualitative Research Data in the Business Domain. [Internet: http://dx.doi.org/10.2139/ssrn.2495330; downloaded on 31 July 2020]. [ Links ]

Habib, M.A., Rizvan, R. & Ahmed, S. 2023. Implementing lean manufacturing for improvement of operational performance in a labeling and packaging plant: A case study in Bangladesh. Results in Engineering, 17:p.100818. [https://doi.org/10.1016/j.rineng.2022.100818]. [ Links ]

Heher, Y.K. & Chen, Y. 2017. Process mapping: A cornerstone of quality improvement. Cancer Cytopathology, 125(12):887-890. [ Links ]

Isaksson, R., Ramanathan, S. & Rosvall, M. 2023. The sustainability opportunity study (SOS)-diagnosing by operationalising and sensemaking of sustainability using Total Quality Management. The TQM Journal, 35(5):1329-1347. [https://doi.org/10.1108/TQM-01-2022-0038]. [ Links ]

ISO 9001. 2015. SANS 9001:2015 Quality management system requirements. Pretoria: South African Bureau of Standards. [ Links ]

Jbeily, A.H. 2022. Impact of Total Quality Management (TQM) on the Competitive Priorities of Lebanese Industries. European Journal of Business and Management Research, 7(4):313-320. [https://doi.org/10.24018/ejbmr.2022.7.4.1592]. [ Links ]

Kumar, N., Hasan, S.S., Srivastava, K., Akhtar, R., Yadav, R.K. & Choubey, V.K. 2022. Lean manufacturing techniques and its implementation: A review. Materials Today: Proceedings, 64:1188-1192. [https://doi.org/10.1016/Lmatpr.2022.03.481]. [ Links ]

Kumar, S., Swarnakar, V., Phanden, R.K., Khanduja, D. & Chakraborty, A. 2023. Role of Lean Six Sigma in manufacturing setting: a systematic literature review and agenda for future research. The TQM Journal. [https://doi.org/10.1108/TQM-12-2022-0338]. [ Links ]

Leavy, P. 2017. Research design. New York, NY: Guilford Press. [ Links ]

Linarti, U., Anugrah, D.H. & Asih, H.M. 2023. Business Process Reengineering Involving Information Technology in a Tin Mining Company. Journal of Industrial Engineering and Education, 1 (1):119-130. [ Links ]

Liu, M. 2023. Uncover a deeper understanding of quality culture through the MCI Model. Quality Progress, 56(6):26-33. [ Links ]

Lizarelli, F.L., Toledo, J.C.D., Gambi, L.D.N. & Gonçalves, C.L. 2023. Continuous improvement behaviors and impacts on innovation. The TQM Journal, 35(2):366-388. [https://doi.org/10.1108/TQM-07-2021-0205]. [ Links ]

Meriem, B. & Cherif, B. 2020. Business process Reengineering and Total Quality Management Better Together Case study: The Toyota production system. Economic and Managerial Research Journal, 14(3):289-308. [ Links ]

Mishra, S. & Duffy, M.J. 2023. How to spot a high-level quality culture in an organization. Quality Progress, 56(6):10-15. [ Links ]

Mittal, A., Gupta, P., Kumar, V., Al Owad, A., Mahlawat, S. & Singh, S. 2023. The performance improvement analysis using Six Sigma DMAIC methodology: A case study on Indian manufacturing company. Heliyon, 9(3). [https://doi.org/10.1016/j.heliyon.2023.e14625]. [ Links ]

Muhammad, N., Upadhyay, A., Kumar, A. & Gilani, H. 2022. Achieving operational excellence through the lens of lean and Six Sigma during the COVID-19 pandemic. The International Journal of Logistics Management, 33(3):818-835. [https://doi.org/10.1108/IJLM-06-2021-0343]. [ Links ]

Muller, C. 2018. Packaging and the environment. In: The Institute of Packaging SA ed. A handbook of packaging technology. 10th ed. Cape Town: The Institute of Packaging SA, 193-210. [ Links ]

Orji, I.J. & U-Dominic, C.M. 2022. Organizational change towards Lean Six Sigma implementation in the manufacturing supply chain: an integrated approach. Business Process Management Journal, 28(5/6):1301-1342. [https://doi.org/10.1108/BPMJ-04-2022-0169]. [ Links ]

Packaging SA. 2020. Scale of the SA Packaging Industry. [Internet: https://www.packagingsa.co.za/info-library/scale-of-the-sa-packaging-industry/; downloaded on 14 February 2020]. [ Links ]

Patel, A.S. & Patel, K.M. 2021. Critical review of literature on Lean Six Sigma methodology. International Journal of Lean Six Sigma, 12(3):627-674. [https://doi.org/10.1108/IJLSS-04-2020-0043]. [ Links ]

Patmawati, S., Dewi, V.M. & Asbari, M., 2023. THE Effect of Short-Term and Long-Term Learning in Quality Management and Innovation. Journal of Information Systems and Management, 2(1):21-26. [ Links ]

Paulmino, R.J.A. & Marquez, C.A. 2023. Critical Success Factors of Lean Six Sigma Implementations in Philippine Food Manufacturing Companies. Philippines: Manila (Proceedings of the International Conference on Industrial Engineering and Operations Management; 7-9 March. 1255-1266). [ Links ]

Pradnyana, I.M.A. & Listartha, I.M.E. 2021. Business process improvement design of complaints on technical information system problems using the business process improvement method. Journal of Physics: Conference Series, 1810(1):p. 012031. [https://doi.org/10.1088/1742-6596/1810/1/012031]. [ Links ]

Rathilall, R. & Singh, S. 2018. A lean Six Sigma framework to enhance the competitiveness in selected automotive component manufacturing organisations. South African Journal of Economic and Management Sciences, 21(1):1-13. [https://doi.org/10.4102/sajems.v21i1.1852]. [ Links ]

Reijers, H.A. 2021. Business Process Management: The evolution of a discipline. Computers in Industry, 126:p.103404. [https://doi.org/10.1016/j.compind.2021.103404]. [ Links ]

Rungruengkultorn, P. & Boonsiri, S. 2022. Warehouse processes improvement using Lean Six Sigma and RFID technology. International Journal of Mathematics and Computer Science, 17(3):1175-1186. [ Links ]

Sá, J.C., Vaz, S., Carvalho, O., Lima, V., Morgado, L., Fonseca, L., Doiro, M. & Santos, G. 2022. A model of integration ISO 9001 with Lean six sigma and main benefits achieved. Total Quality Management & Business Excellence, 33(1-2):218-242. [ Links ]

Samanta, M., Virmani, N., Singh, R.K., Haque, S.N. & Jamshed, M. 2023. Analysis of critical success factors for successful integration of Lean Six Sigma and Industry 4.0 for organizational excellence. The TQM Journal. [https://doi.org/10.1108/TQM-07-2022-0215]. [ Links ]

Santos, D., Zammar, A., Zammar, G., da Luz, A.A., Soares, A.M., Pagani, R.N. & Kovaleski, J.L., 2023. Quality Management: Literature Review and a Framework Proposal. Economic and Social Development: Book of Proceedings, 366-374. [ Links ]

Schuh, G., Schmitz, S. & Schopen, M. 2023. Procedure for Hybrid Process Analysis and Design. Gottfried Wilhelm Leibniz Universität Hannover. [ Links ]

Sekaran, U. & Bougie, R. 2016. Research methods for business: A skill building approach. 7th ed. United Kingdom, UK: John Wiley & Sons. [ Links ]

Siregar, I.W. 2022. A Literature Review on Business Process Reengineering. American International Journal of Business Management, 4(7):123-133. [ Links ]

Solomon, N.P., Bester, A. & Moll, M. 2017. Diffusion of a quality management system: A case study. South African Journal of Industrial Engineering, 28(2):149-164. [http://dx.doi.org/10.7166/28-2-1762]. [ Links ]

Spiers, J., Morse, J.M., Olson, K., Mayan, M. & Barrett, M. 2018. Reflection/Commentary on a past article: Verification strategies for establishing reliability and validity in qualitative research. International Journal of Qualitative Methods, 17(1):1-2. [ Links ]

Tang, H. 2023. Synthesize and Unify. Quality Progress, 56(2):36-43. [ Links ]

Tiwari, S.K., Singh, R.K. & Srivastava, S.C., 2022. An integrated lean Six Sigma model for enhancing the competitive advantage of industries. Recent Advances in Industrial Production: Select Proceedings of ICEM 2020. 437-448. [ Links ]

Vinodh, S., Antony, J., Agrawal, R. & Douglas, J.A. 2021. Integration of continuous improvement strategies with Industry 4.0: a systematic review and agenda for further research. The TQM Journal, 33(2):441-472. [https://doi.org/10.1108/TQM-07-2020-0157]. [ Links ]

West, J.E. & Cianfrani, C.A. 2016. ISO 9001:2015 - What's Vital. Quality Progress, 49(9):53-54. [ Links ]

Zaini, Z. & Saad, A. 2019. Business process reengineering as the current best methodology for improving the business process. Journal of ICTin Education, 6:66-85. [https://doi.org/10.37134/jictie.vol6.7.2019]. [ Links ]

Zighan, S. & Ruel, S. 2023. SMEs' resilience from continuous improvement lenses. Journal of Entrepreneurship in Emerging Economies, 15(2):233-253. [https://doi.org/10.1108/JEEE-06-2021-0235]. [ Links ]

* Corresponding author