Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Acta Structilia

versão On-line ISSN 2415-0487

versão impressa ISSN 1023-0564

Acta structilia (Online) vol.30 no.1 Bloemfontein 2023

http://dx.doi.org/10.38140/as.v30i1.7115

RESEARCH ARTICLE

A conceptual quality improvement protocol for Free State public works projects

Lehlohonolo ThuloI; Fidelis EmuzeII; Elizabeth TheronIII

IM.Eng. Graduate, Department of Civil Engineering, Central University of Technology, Free State (CUT), Bloemfontein, South Africa. Email: <lehlohonolothulo@ymail.com>, ORCID: https://orcid.org/0009-0004-6187-2002

IIHead, Department of Built Environment, Central University of Technology, Free State (CUT), Bloemfontein, South Africa. Email: <femuze@cut.ac.za>, ORCID: https://orcid.org/0000-0001-7714-4457

IIIDepartment of Civil Engineering, Central University of Technology, Free State (CUT), Bloemfontein, South Africa. Email: <etheron@cut.ac.za>, ORCID: https://orcid.org/0000-0003-4588-9440

ABSTRACT

Materials delivered on public works project sites deviate from technical specifications, with detrimental implications for the quality of the construction process and product. When delivered materials differ from specifications, quality issues such as defects and re-work ensue at greater cost to the clients. The inadequate application of concepts and techniques of quality improvement also appears to perpetuate the problems. This study aims to find answers as to which quality improvement protocol would ensure that materials are delivered on construction sites as specified by the engineers. A case-based design with multiple data-collection techniques and points was expedited in the study. The primary data collected through a semi-structured, self-administered questionnaire, semi-structured interviews, and purposive sampling from the Department of Public Works and Infrastructure's technical personnel provided the platform for compiling a quality improvement protocol contextualised for the Department of Public Works and Infrastructure in the Free State, which constituted the case study. The statistical and textual data outlined how the department could address quality planning, quality control, and quality improvement concerning materials delivery for public works projects. The article's contribution is the proposed quality improvement protocol that should guide the specification and delivery of construction materials for projects.

Keywords: Construction, construction material, infrastructure, materials, public works, quality improvement

ABSTRAK

Materiaal wat gelewer word vir openbare werke projekte wyk af van tegniese spesifikasies met nadelige gevolge vir die kwaliteit van die konstruksieproses en produk. Met aflewering variëer materiale van spesifikasies, en gehalte kwessies soos defekte en addisionele werk volg, met die kliënt wat addisionele kostes ervaar. Hierdie probleme dui op 'n gebrek aan kwaliteit tydens beide die ontwerp en konstruksieproses rakende materiaalbestuur. Die onvoldoende toepassing van kwaliteitverbetering konsepte en tegnieke blyk ook by te dra tot die bogenoemde probleme. Die doel van die studie is dus om 'n gepaste kwaliteitverbeteringsprotokol te vind wat sal verseker dat afgelewerde materiale voldoen aan die nodige ingenieurs-spesifikasies. 'n Gevallestudie-gebaseerde ontwerp met veelvuldige data-insamelingstegnieke is gebruik om die studie te bespoedig. Dit is gebaseer op pragmatisme as navorsingsfilosofie wat daarop gemik is om werklike probleme op te los. Die primêre data is versamel met behulp van 'n semi-gestruktureerde, self-geadministreerde vraelys, semi-gestruktureerde onderhoude en dokumentontleding. Dit het die platform verskaf vir die samestelling van 'n kwaliteitsverbeteringsprotokol wat gekontekstualiseer is vir die Departement van Openbare Werke en Infrastruktuur in die Vrystaat provinsie. Die statistiese en geskrewe data toon hoe die departement die kwessies rakende kwaliteit-beplanning, -beheer, en -verbetering met betrekking tot materiaallewering op Openbare Werke projekte kan aanspreek. Die artikel se bydrae is die voorgestelde gehalteverbeteringsprotokol rakende die spesifikasie en aflewering van konstruksiemateriale.

1. INTRODUCTION

Quality variations such as wrong materials, flaws, and material amounts are widespread in construction, according to international studies (Mashwama, Aigbavboa & Thwala, 2017: 447). Many studies have been conducted to quantify the cost of re-work in the construction sector because of quality issues. The reported estimates generally specify that they only include the directly measurable cost of re-work and that additional hidden expenses are not included. Re-work costs between 10% and 15% and accounted on average for 12.4% of total project costs (Al-Janabi, Abdel-Monem & El-Dash, 2020: 669).

South Africa also experiences issues with the quality of construction. It is noted that completing a project on time, on budget, and to quality standards is a challenge because the shortest duration and lowest cost can conflict with quality (Emuze & Mhlwa, 2015: 1232). Difficulties with material quality can harm construction projects in South Africa, causing cost and schedule overruns at clients' expense (Emuze & Mhlwa, 2015: 1224). When the delivered materials differ from the specifications, problems with quality arise, resulting in defects and re-work. This adds to the overall cost of a project, which is classified as quality cost. Requests for Information (RFIs) are also common, resulting in project delays and extensions.

The Free State Provincial Department of Public Works and Infrastructure (DPW&I) is responsible for designing and building new infrastructure, upgrading, rehabilitating, and maintaining existing facilities through public works projects in the Free State province of South Africa (DPW&I, 2022: Online). According to monthly project reports from the DPW&I in 2020, materials delivered on public works project sites deviated from technical specifications, with detrimental implications of non-compliance with quality requirements, resulting in defects and re-work. When delivered materials differ from specifications, two quality issues ensue. First, defects and re-work lead to additional project cost, which is classified as quality cost. Quality costs include the cost of prevention, the cost of an appraisal, and the cost of failure (Forbes & Ahmed, 2020: 100). Secondly, RFIs and waiting for revised designs and specifications lead to time delays and extended project duration. It is, therefore, important to investigate construction quality challenges in the Free State DPW&I, in order to develop a quality improvement protocol for delivering materials on construction sites as specified by engineers.

2. LITERATURE REVIEW

2.1 Construction quality challenges

One of the criteria that determines client satisfaction levels is the quality of the work in the construction industry. Quality-related issues such as re-work are projected for later stages of the construction process (Yaghootkar & Gil, 2012: 130; Delisle, 2020: 426).

Forbes and Ahmed (2020: 95) cite Juran that quality may be interpreted as "fitness for use", "fitness for intended use", "conformance to requirements", or "conformance to specifications". Customers could regard quality as meeting their needs and expectations at a cost that represents value. Despite the knowledge of these definitions, the industry in South Africa is facing problems related to the standard of construction quality expected by clients (Emuze & Smallwood, 2011: 5). Client discontent might result in a decrease in the construction firm's market share and profit because of the implications for the project's productivity (El-Gohary & Aziz, 2014: 4; Alaghbari, Al-Sakkaf & Sultan, 2019: 88).

The cost of poor-quality construction is associated with the prevention, discovery, and resolution of defects (Mashwama et al., 2017: 477; Kerfai, Bejar Ghadhab & Malouche, 2016: 589). Activities that generate prevention costs include developing and implementing quality inspection procedures, performing systematic product inspections, investigating the causes of quality errors, as well as educating and motivating personnel on quality management. Assessment costs are a result of activities performed to minimise the consequences of errors. These activities include inspecting purchased goods, handling damaged products, as well as registering and reporting quality defects (Ellis & Martin, 2019: 160).

Incidents of non-conformance influence the contractor, as they result in re-work penalties that can drastically reduce production (Rivas et al., 2011: 317). According to Emuze and Mhlwa (2015: 1230), a variety of factors such as changes in quality can cause re-work.

Bowen, Edwards and Cattell (2015: 86) stated that, because of corruption and political influence, contractors are awarded contracts despite poor performance; policy formulation and governance are entrusted to people who lack the necessary expertise, education, and experience, and economic constraints have resulted in technical specifications being compromised, resulting in the use of low-cost, low-quality materials. Milford (2010: 19) stated that the government's lack of capability has resulted in an inefficient and time-consuming process of funding building projects and payment backlogs of more than six months in some instances.

Ramabodu and Verster (2010: 137) identified the quality-related elements that contributed to cost overruns in public work projects in the Free State province, South Africa. They established that incomplete design information affects project cost overruns. Chen and Luo (2014: 65) stated that incorrect specifications and poor delivery of construction materials are the forerunners of unacceptable quality in projects. According to Wanberg et al. (2013: 2), one crucial factor contributing to poor-quality design information is the designers' reluctance to thoroughly check for errors, due to the high demands of their job. However, as evidenced in literature on construction management, design information is frequently insufficient (Wanberg et al., 2013: 2). When this deficiency occurs, it can result in an increase in design revisions, coordination issues, re-work and, in the worst-case scenario, deaths (Lopez et al., 2010: 399).

2.2 Monitoring and control challenges

Quality deviation is demonstrated by the non-conformance of work to specified requirements, affecting quality. This becomes clear when a project falls short of meeting the client's needs and specifications (Biadacz, 2020: 36). Bikitsha and Amoah (2020: 3) suggested that productivity and construction quality have declined in South Africa, and conflicts over quality deviation among unsatisfied customers are consequently frequent in the sector (Bikitsha & Amoah, 2020: 7; Negron, 2020: 226). The monitoring and control of deviation from design specifications in the construction industry influence quality, time, cost, and productivity. Deviation often results in re-work. Suresh et al. (2017: 32), as well as Taggart, Koskela and Rooke (2014: 830) highlighted five key causes of re-work: a lack of human resource competency, a lack of leadership and communication, inefficient engineering and reviews, incorrect construction planning and scheduling, as well as an insufficient supply of materials and equipment.

A severe shortage of construction skills has affected the quality of construction work output in South Africa (Windapo, 2016). The skills provided to the industry through the Further Education and Training (FET) system are frequently insufficient to meet the needs of the construction industry (CIDB, 2004). According to Mbande (2010:18), there is a link between an increase in community protests in South Africa, because of a lack of service delivery and an acute shortage of building skills.

According to Moschidis, Chatzipetrou and Tsiotras (2018: 11), design effectiveness is far more important than merely attempting to assess quality design productivity. Considering that many design outcomes need to be standardised and straightforward, productivity measures are hard to achieve (Ayach, Anouar & Bouzziri, 2019: 111). Furthermore, accurate design performance indicators are discovered only later, during construction (Šatanová et al., 2015: 1158). While the project team disperses once the project is completed, operation standards are not evaluated. The evaluation criteria are design and constructability cost (Moschidis et al., 2018: 11). Design documentation accuracy and usability are also considered. To assess the overall effectiveness of the design quality, various weights are assigned to each criterion depending on the project's needs (Glogovac & Filipovic, 2018: 1540). This method is criticised because it only permits design effectiveness evaluations after a project has been completed rather than during construction (Moschidis et al., 2018: 11).

The degree to which management participates in and supports the implementation of quality in the construction project environment is critical in ensuring that work meets specifications. However, because of a reported shortage of skilled supervisory workers, supervision in the South African construction industry is under duress (Emuze, Smallwood & Han, 2014: 240). There is no regular monitoring or supervision, errors are not recognised early, and continual correction of poor work is common because of the claimed shortage (Chopra & Singh, 2015: 1228). Continuous corrective work occurs on project sites when work needs to be monitored and overseen frequently or when the quality of supervision falls short of expectations (Negron, 2020: 226).

Quality deviations in construction work can similarly occur when upper management of a project is overly concerned with cutting costs and shortening the timeline (Butt, Naaranoja & Savolainen, 2016: 1585; Akkermans & Van Oorschot, 2018: 115). Quality deviations might also occur when access to a firm's quality policies and goals are not adequately conveyed (Saffar & Obeidat, 2020: 79). In South Africa, there is hardly any correlation between employee performance and compensation. This discourages workers from attempting to produce services of the highest quality (Aghimien et al., 2018: 342). In addition, workers lack the necessary training to produce the desired quality (Emuze & Smallwood, 2013: 1616; Verster & Fourie, 2018: 67). Unskilled or incompetent artisans, who continue to work in a demoralising environment, will continue to produce poor work, leading to re-work and reducing the quality of projects (Davies et al., 2017: 73; Raymond, James & Kabubo, 2017: 30). Through monitoring and control, management can commit to and show dedication to quality, and workers will logically follow suit (Marin-Garcia & Bonavia, 2015: 3263; Neirotti, 2020: 1980).

2.3 Quality improvement

The construction industry in South Africa is facing problems related to the standard of construction quality expected by clients (Emuze & Smallwood, 2011: 5). To improve quality, public-sector projects should adhere to an externally approved ISO 9001 Quality Management System (QMS) (Obunwo, Chinyio & Suresh, 2015: 764). The implementation of a total quality management (TQM) system in the construction project environment includes educating and motivating personnel on quality management (Othman, 2012: 44).

Cost management means that adequate price escalation is allowed for in tender documents, which include a financial feasibility analysis, then proceeds to all the costs associated with purchasing all the project's resources (Enshassi, Sundermeier & Zeiter, 2017:14). Cost escalations in contracts may be a result of unforeseen external circumstances that need to be considered and budgeted for (for example, changes to the agreed scope of work) (Welde & Dahl, 2021: 1007). Cost control should be done to guarantee that all work is completed appropriately. Thus, by adding contingency, cost overruns in contracts may be absorbed so that project overruns are avoided (Welde & Dahl, 2021: 1007).

Project planning is defined as the creation of a set of instructions that tell the project team exactly what needs to be done, when it needs to be done, and what resources to use to create the project's deliverables successfully (Davis, 2014: 190). Including quality specifications in project planning may improve the quality of projects. Therefore, the project plan and planning processes should be well established during the planning phase of projects (Davis, 2014: 190; Marcelino-Sádaba et al., 2014: 328). According to Lopez et al. (2010: 399), the planning phase comprises nine primary components, namely objective, programme, schedule, budget, forecast, organisation, policy, process, and standard. Although the Project Management Body of Knowledge (PMBOK) identifies 44 processes, with 21 of them being planning procedures (Yaghootkar & Gil, 2012: 130), Magnaye, SSC and Varma (2020: 60) identified seven planning processes for quality improvement: defining project objectives, identifying activities, establishing precedence relationships, making time estimates, determining project completion time, comparing project schedule objectives, and determining resource requirements to meet objectives. A project plan that includes an overview, project objectives, general strategy, contractual factors, timetables, resources, personnel, risk management plan, and evaluation methods for the project is essential for project managers to ensure that the project is completed correctly and to the satisfaction of all stakeholders. According to Lopez et al. (2010: 399) and Negron (2020: 215), the quality benefits of effective project planning include reduced uncertainty, improved operational efficiency, a foundation for monitoring and controlling work, better understanding of project objectives, project finished on time, current material delivered on time, no delays during delivery, limited amount of re-work, limited confusion and misunderstanding, up-to-date knowledge of the status of the material by everyone at any given time, accurate, concise reports to management, leading indicators of potential deviations, and complete control over the material processes.

Appointing competent officials, workers, and service providers may improve quality in executing public-sector projects. Therefore, sufficient knowledge of the work, quality standards, co-ordination of work activities, and competence in scheduling are required for supervisors and project managers during project implementation (Negron, 2020: 226; Emuze & Smallwood, 2013: 1616).

Using the services of professional, skilled, and experienced engineers for design specification is essential to improve quality because correct interpretation of requirements eliminates unnecessary repetition of limited provisions and omits unnecessary information. Excellent client-consultant-contractor interaction and communication on specification needs improves project performance in terms of cost, quality, and time (Emuze & Smallwood, 2011: 5).

According to Bowen et al. (2015: 86), corruption in public projects occurs primarily because of opportunities that arise during the procurement process, notably during the tendering and bid review stages. Bowen et al. (2015: 86) stated further that more procedural transparency and stricter control mechanisms would aid in the fight against corruption. Forensic detection approaches should be developed and used, especially in the tender review process, where more advanced statistical and analytic techniques could be used. This strategy would not only aid in the detection of corruption but also serve as a deterrent, especially if coupled with harsher punishments for corrupt behaviour (Bowen et al. 2015: 72).

3. RESEARCH METHOD

3.1 Research design

The research design was exploratory, based on a pragmatic case study research philosophy (Saunders, Lewis & Thornhill, 2019). The study adopted a mixed methods approach, using quantitative and qualitative data-collection methods to investigate construction quality challenges in the Free State DPW&I (Creswell & Poth, 2016: 75). The questionnaire survey posed the same questions to senior management, engineers, project managers, inspectors, artisans, quantity surveyors, architects, GCs, client department officials, SCM practitioners, as well as monitoring and evaluation practitioners involved in DPW&I projects. Semi-structured interviews were conducted with officials from the design, construction, and maintenance divisions. The interviews provided valuable primary data and allowed participants to consider the difficulties associated with DPW&I project quality. The reason for collecting both quantitative and qualitative data is to elaborate on specific findings from the breakdown of the interview results, such as similar project quality challenges suggested from the respondents' groups (Creswell & Creswell, 2017: 215).

3.2 Population, sample, and response rate

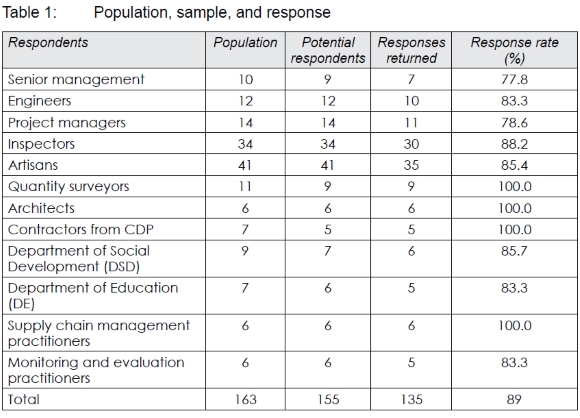

A combined list of 163 engineering and built environment professionals was obtained from the Free State provincial DPW&I and other provincial client departments. The list was stratified between professionals involved in senior management, engineers, project managers, inspectors, artisans, quantity surveyors, architects, contractors from CDP, department of social development, department of education, supply chain management practitioners, monitoring and evaluation practitioners (see Table 1). Using purposive sampling, 152 participants were selected to take part in the study because they worked on projects in various capacities within facilities, which represent the sample size of the questionnaire survey (Creswell & Poth, 2016: 75). The sample size table by Krejcie and Morgan (1970: 608) recommends a sample size of 118 for a population of 170. As 135 valid responses were received, this equated to a response rate of 89%. In addition to the survey, 33 respondents were identified from engineering and the built environment professionals from the Free State provincial DPW&I and other provincial client departments, and invited to participate in face-to-face and telephone interviews. Only 30 participants agreed to take part in the study.

3.3 Data collection

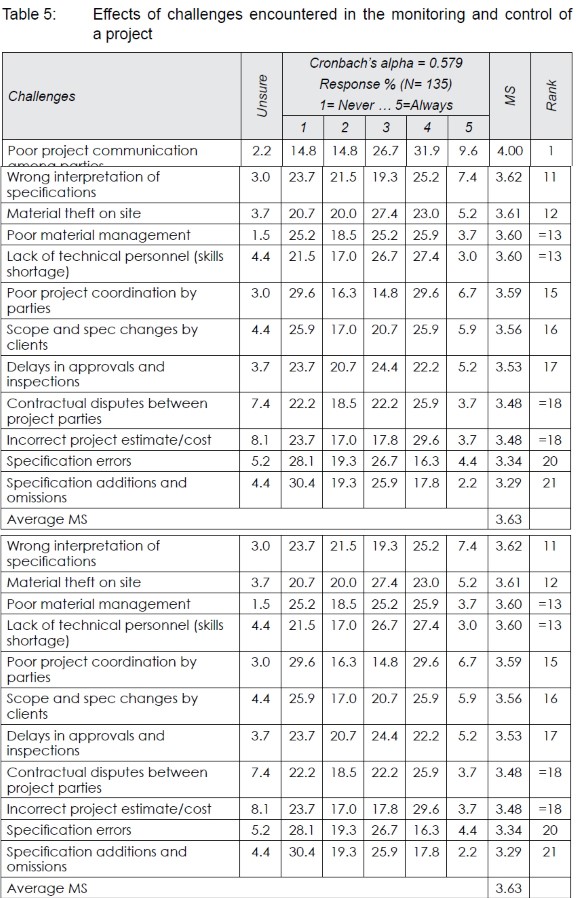

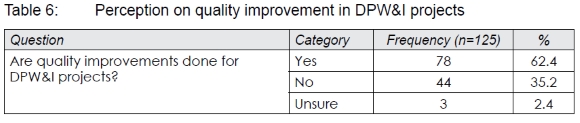

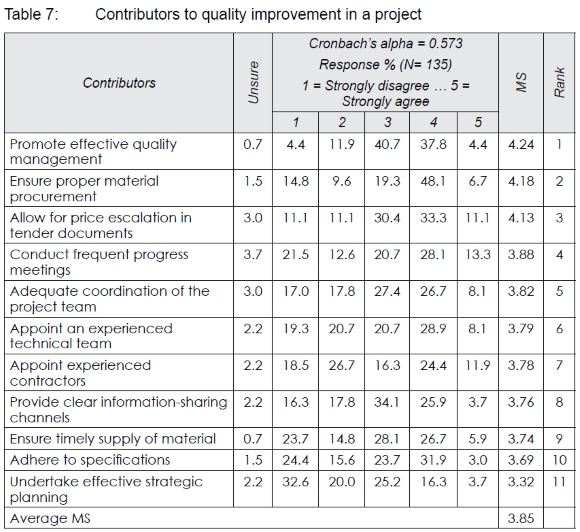

A questionnaire survey was conducted between May 2021 and August 2021 among 152 professionals working within DPW&I facilities in the Free State province, South Africa (see Table 1). The four-section questionnaire included closed-ended questions to reduce the respondents' bias and facilitate coding of the questionnaire (Akintoye & Main, 2007: 601). The first section, on the respondents' profile, obtained general demographics about the respondents, including education level, job profile, work position, project in which the respondents are involved, and the professional experience of each respondent. Section two had eight Likert-scale statements on 'quality challenges', and two 'yes' and 'no' questions (see Tables 3 and 4). Section three on 'monitoring and control challenges' had 21 Likert-scale statements (see Table 5). Section four on 'quality improvement' had one 'yes' and 'no' question, and 15 Likert-scale statements (see Tables 6 and 7), where participants were asked to indicate their agreement level with the statements that reflected the three project quality constructs.

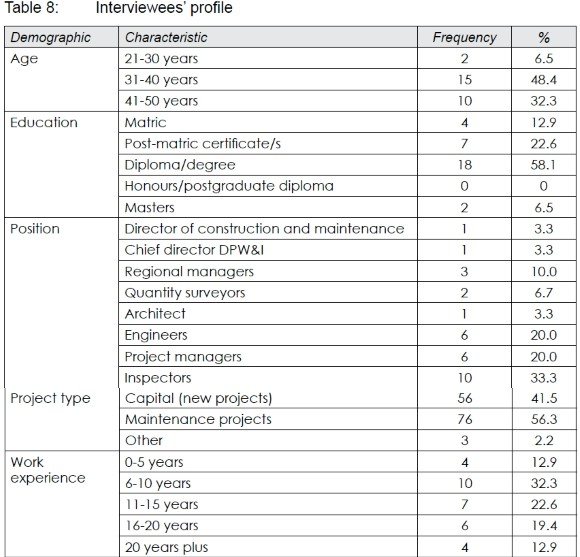

Between February 2021 and May 2021, semi-structured interviews (Creswell & Poth, 2016: 75) were conducted with 30 officials from the design, construction, and maintenance divisions within DPW&I facilities in the Free State province, South Africa. Only people with authority and relevant industry experience were interviewed. These included director of construction and maintenance, chief director, regional managers, quantity surveyors, architects, engineers, project managers, and inspectors. The first step was to identify potential participants and then contact them by telephone and e-mail. A covering letter explaining the purpose of the interviews was delivered by hand to some of the participants, while e-mails were sent to those who requested that the letters be e-mailed when approached by telephone. Questions about the three project quality constructs (QP, QC, and QI) were asked in person and over the phone in one-on-one interviews. Notes were taken during interviews. The interview protocol allowed participants to consider the difficulties associated with DPW&I project quality.

3.4 Data analysis

The statistical data were manually entered into an MS Excel Spreadsheet after carefully checking for errors (data cleaning) and incomplete data. Thereafter, the data was analysed using descriptive statistics to generate mean scores and percentages. For the questionnaire survey, a 5-point Likert scale was used to obtain the opinions of the respondents and to analyse the results. For analysis and interpretation, the scale measurement between 1 and 5 was used. Likert-type or frequency scales are designed to measure attitudes or opinions (Joshi et al., 2015: 396). The rating in the MS was done on a 5-point Likert scale, where 1 = Never/Strongly disagree (>1.00 and <1.80); 2 = Rarely/Disagree (>1.81 and <2.60); 3 = Sometimes/ Neutral (>2.61 and <3.40); 4 = Often/Agree (>3.41 and <4.20), and 5 = Always/Strongly agree (>4.21 and <5.00), as recommended by Kilic (2016: 47).

Cronbach's alpha values were conducted in line with Wahab, Ayodele and Moody (2010: 67) to determine the internal reliability of the constructs. Acceptable Cronbach's alpha ranged from 0.70 to 0.95 (Taber, 2018: 1273). Thus, a cut-off value of 0.70 was adopted for this study.

According to Mayer (2015: 55), data coding is a model in which data is broken down, conceptualised, and rearranged to reveal theory. Coding is simply the process of converting data from raw and unstructured data to theory. To accomplish this, interview transcripts were analysed, using constant comparison to create categories, and the categories were coded accordingly (Creswell & Poth, 2016: 76). In analysing the textual data that emerged from the interviews, the inductive data analysis approach was used, as described by Creswell and Poth (2016: 76). In other words, during the analysis, patterns and themes were developed from the bottom up, by arranging the units of information. Transcripts, hand-written and typed with precise information, were read several times to get a general impression of them. Significant phrases or sentences from each transcript that were directly related to the lived experience of construction material specification and delivery were identified. The information was compressed into themes and quotes, and relationships between the categories were identified. Finally, the data was displayed in the form of figures, tables, and discussions.

4. RESULTS

4.1 Questionnaire survey results

4.1.1 Respondents' profile

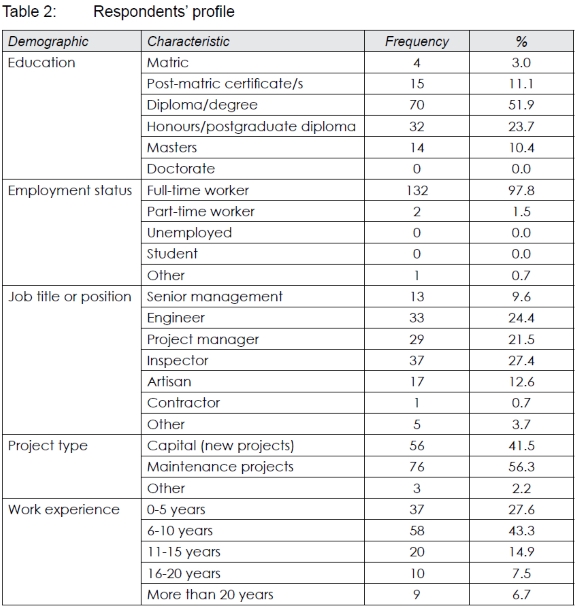

The first part of the survey questionnaire contained questions on the demographic profile of the respondents who are in the best position to comment on the knowledge set that participants should possess. Table 2 shows the education, employment status, job title, project type, and the length of work experience of the respondents.

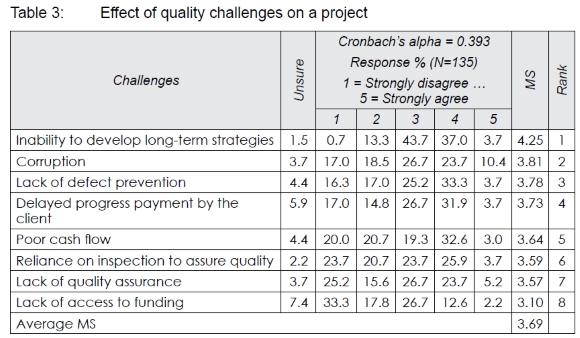

4.1.2 Quality challenges in DPW&I

With an average mean score of 3.69, results in Table 3 show that respondents agreed that all challenges may influence the quality of DPW&I projects. The Cronbach's alpha value was less than 0.60, indicating questionable internal reliability, as recommended by Hair et al. (2019). Respondents strongly agreed (MS=4.5) that the inability to develop long-term strategies is the main challenge that could affect the quality of DPW&I projects. Based on mean scores between 3.41 and 3.81, respondents agreed that corruption, lack of defect prevention, delayed progress payment by the client, poor cash flow, reliance on inspection to assure quality, and lack of quality assurance (QA) are challenges that could have an effect on the quality in DPW&I projects.

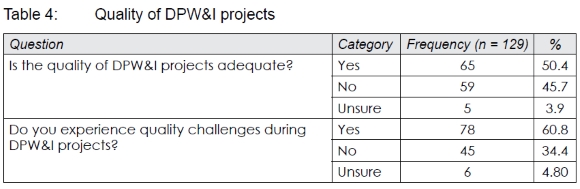

Regarding the quality of DPW&I projects, two questions were asked. First, is the quality of DPW&I projects adequate? In response, more than half (50.4%) of the respondents opined that the quality of public works projects is adequate, while 45.7% of them believed that the quality of public works projects is not adequate, as shown in Table 4. Secondly, do you experience quality challenges during the execution of DPW&I projects? In response, 60.8% of the respondents indicated that quality challenges are experienced with DPW&I projects, while 34.4% of the respondents stated that quality challenges are not experienced.

4.1.3 Monitoring and control challenges in DPW&I projects

Table 5 shows the frequency at which respondents encountered issues related to monitoring and control, ranging from 1 (Never) to 5 (Always). The Cronbach's alpha value was close to 0.6, indicating questionable internal reliability for the construct, 'monitoring and control challenges', as recommended by Hair et al. (2019). It is noted that the average mean score of 3.63 suggested that all 21 challenges occur often to always. Poor project communication among parties (MS=4.00) was ranked first amongst challenges encountered during the monitoring and control of a project. Damage of material during transportation (MS=3.90) and payment delays from clients (MS=3.90) were often encountered and were ranked second.

With mean scores between 3.41 and 4.20, respondents indicated that the following challenges often occur during the monitoring and control of projects: Inadequate cash flow (MS=3.85), incompetent contractors (MS=3.76), poor planning (MS=3.74), non-availability of specific materials (MS=3.74), variations in material quantities (MS=3.20), re-work (MS=3.64), price escalation (MS=3.64), wrong interpretation of specifications (MS=3.62), material theft (MS=3.61), poor material management (mS=3.60), skills shortage (MS=3.60), poor project coordination (MS=3.59), scope changes by clients (MS=3.59), delays in approvals and inspections (MS=3.53), contractual disputes (MS=3.48), and incorrect project estimates (MS=3.48).

4.1.4 Quality improvement in DPW&I projects

Table 6 shows that more than half (62%) of the respondents indicated that QI is done during public works projects. This was favourable for the department. In addition, 35% of the respondents mentioned that no QI is done during public works projects, and 2% of the respondents are not sure.

Table 7 shows the ranking of contributors that can improve quality in a project. The Cronbach's alpha value was less than 0.60, indicating questionable internal reliability for the construct 'quality improvement', as recommended by Hair et al. (2019). The average mean score of 3.85 indicates that respondents agreed that all 11 contributors may improve quality in DPW&I projects. With mean scores above 4.12, respondents strongly agreed that promoting effective quality management (MS=4.24), ensuring proper material procurement (MS=4.18), and allowing price escalation in tender documents (MS= 4.13) are the top three quality improvement contributors for DPW&I projects.

With mean scores between 3.41 and 4.20, respondents agreed that conducting frequent progress meetings (MS=3.88), adequate coordination of the project team (MS=3.82), appointing an experienced technical team (MS=3.78), appointing experienced contractors (MS=3.78), providing clear information-sharing channels (MS=3.76), ensuring timely supply of material (MS=3.74), and adhering to specifications (MS=3.69) improve quality in the execution of DPW&I projects.

4.2 Semi-structured interview results

4.2.1 Interviewees' profile

The interviewees' demographic profile results in Table 8 show that most of them (80%) are aged between 31 and 50 years and involved in maintenance projects (56.3%). Most of the interviewees (33.3%) are inspectors and others are also employed as engineers, project managers (22.1% each), and regional managers (10%). Most of the interviewees (80.7%) have either a post-matric certificate (22.6%) or a diploma/degree (58.1%), and 6.5% have a master's degree. Although 32.3% of the interviewees have between six- and ten-years' work experience, a slight majority (54.9%) have 11 years' work experience or more. This proves that the interviewees are qualified to work in the DPW&I and have adequate experience to give information that could help in making deductions on quality planning, quality control, and quality improvement in DPW&I projects.

The results of the interviews indicate how quality planning (QP), quality control (QC) and quality improvement (QI) determine the specification and delivery of construction materials for DPW&I projects. Interviewees were asked questions pertaining to their knowledge of quality on the planning, control, and improvement, in terms of specification and delivery of construction materials and not on the reasons why QP, QC and QI in DPW&I projects were not followed.

4.2.2 Quality planning

4.2.2.Í What is your perception on the quality of DPW&I projects?

From the eighteen responses received, thirteen respondents (72%) indicated that quality of DPW&I projects in the Free State province is declining. Interviewees 4, 7, 8, and 10 indicated that the general perceptions of quality during public works projects are negative, although Interviewees 12, 14, 15, 17 and 30 indicated that it is satisfactory. Interviewee 18 indicated that the quality is not good and not up to government standard. Interviewee 19 commented that wrong materials are used on the projects and that projects are finished late. He stressed the importance of QP on DPW&I projects. A common concern among Interviewees 3, 20, 21, 22, and 25 was that quality during public works projects has declined and is no longer up to the required standard. Interviewee 27 stated that

... quality is no longer important, quality dropped and officials are not competent. Service providers are incompetent, even government officials are incompetent. Quality has dropped immensely in the past years.

Interviewee 29 mentioned that quality during DPW&I projects has dropped and is no longer maintained, partly because of interferences from politicians.

4.2.2.ii How is QP done in DPW&I projects?

According to Interviewee 1, a major part of activities performed during DPW&I are related to planning, co-ordinating, and executing projects. However, Interviewee 5 commented that some DPW&I projects do not meet their targets because of the poor quality of management practices such as planning. One of the practices of the poor quality of management cited is top management's failure to discipline individuals who do not meet key performance areas or at least provide training for them.

Interviewees 6, 9, and 11 stated that planning of projects has a significant impact on the success of the projects. In summary, according to the results, Interviewees 16, 18, 23, and 26 emphasised that regular meetings are held with all responsible government officials and regular site visits are done. These meetings ensured that quality guidelines, regulations and procedures for specification, resources, and quality of standard practices and activities are followed. Interviewee 27 mentioned that

there needs to be specification and bill of quantities and also important aspects of projects should be determined. There is a design, monitoring and evaluation project team that ensures that labour and materials that are procured follow established standards. This monitoring and evaluation ensure inspection is done to check quality and also make sure service providers comply with specification.

4.2.2.iii How do you think QP processes related to specification and delivery of construction materials on DPW&I projects are expedited?

Interviewees 1, 2, 4, 5, 7, 8, 9, and 15 suggested that it is essential to expedite the QP processes related to specification and delivery of construction materials on DPW&I projects. For instance, some of them mentioned that planning processes could be expedited through planning for the entire project and establishing major deliverables. It is also important to deal with service providers who are able to deliver materials in time, using a supply chain management (SCM) section. Interviewees 16, 17, 18, and 20 indicated that the process is expedited by the use of established standards and specification, as well as identified key stakeholders responsible for the projects. The use of established standards makes work easy and makes it possible to identify specification errors during delivery. Interviewee 21 mentioned that materials for the project should be available, the needs of customers should be identified, and process and controls should be developed. Interviewee 22 stated that

there is the need to encourage stakeholder participation and bring all stakeholders up to speed on the project as well as establish project specification and delivery of construction materials.

Interviewees 25, 26, 28, 29, and 30 argued that QP processes could be expedited, using established standards, QP, QC and QI, and performance reviews.

4.2.2.iv What challenges do you come across at the planning stage of a project?

Overall, the responses of Interviewees 3, 5, 6, 7, 9, and 10 showed that challenges are usually encountered at the planning phase of a project. For example, Interviewees 11, 13, 14, and 15 identified late delivery of materials and incompetent officials with inadequate skills as some of the challenges. Ineffective communication among stakeholders, lack of accountability, and differences among stakeholders are cited as some of the challenges at the planning phase of a project. Interviewee 17 commented that "corruption, lack of competent officials and budget constraints affect planning of projects".

However, Interviewees 18, 19, and 20 mentioned that lack of details, accountability, lack of clear goals, and unrealistic deadlines also pose a challenge to projects, especially at the planning stage. Interviewee 22 revealed that

limited engagement of different stakeholders and parties in the project, changing needs of clients and major decisions taken by management, even though they are not directly involved in the projects, were some of the many challenges faced at the planning stage of the project.

Interviewees 23, 25, 26, and 30 stated that, in some cases, there is lack of clarity on goals that affect the successful completion of projects.

4.2.3 Quality control

4.2.3.i How is QC done in DPW&I projects?

Interviewees 2, 5, 6, 7, and 10 stated that quality is one of the most important factors in the success of construction projects. Interviewees 11, 13, and 16 acknowledged that quality of DPW&I projects, as well as project success, could be regarded as fulfilment of expectations. Interviewees 17 and 19 argued that QC measures in the construction industry are a key method in managing the goal to the client's satisfaction. They expressed further that

QC measures on public works projects could be achieved by daily visits to work sites to inspect works done, hold regular meetings and discuss matters relating to the quality of the work, and ensure that the right thing is done by the contractor.

Interviewees 22, 24, 27, 29, and 30 explained that QC is done on public works, by ensuring the use of high-quality materials, adherence to bill of quantities, and compliance with specification.

4.2.3.ii How do you think QC processes related to specification and delivery of construction materials on DPW&I projects are expedited?

Interviewees 2, 4, 8, and 11 acknowledged that QC processes related to specification and delivery of construction materials to the Department of Public Works need to be expedited. Interviewees 12, 13, 14, and 15 indicated that this could be achieved by complying with government standards and by following the public works' procedures and standards. Interviewees 16, 17, 18, 20, and 22 commented that it is important to identify quality issues, record and address them, and appoint qualified and deserving contractors to undertake projects. They added that regular meetings should be held to discuss quality issues which are identified, and that materials should be stored closer to the project sites.

4.2.3.iii During the monitoring and controlling phase of a project, what challenges do you come across?

Interviewee 19 stated that "many challenges are encountered during monitoring and evaluation phase of projects". Interviewees 20, 22, 23, 26, and 27 indicated that some of the challenges include delayed payment to contractors or service providers, disputes between parties involved in a project which are often taken onto project sites, inability to meet deadlines, and contractors not following specified standards and specifications of the job. They cited lack of communication, lack of customer satisfaction, non-compliance with specification and bill of quantities, incorrect quantities of materials delivered to project sites and, in some cases, incorrect delivery of materials as some of the challenges encountered. Interviewees 28, 29, and 30 revealed that some of the contractors are incompetent and changes during the course of the projects are some of the challenges.

4.2.4 Quality improvement

4.2.4.i How do you think QI processes related to specification and delivery of construction materials on DPW&I projects are expedited?

Interviewees 2, 3, 6, 10, 11, and 18 mentioned that QI processes related to specification and delivery of construction materials to Department of Public Works could be expedited through a continuous QI process and proper planning with involvement of all stakeholders participating at the beginning of the project. Interviewees 20, 22, 24, 25, 27, and 30 cited the use of quality materials according to standard specification, continuous training of service providers, and using competent contractors and artisans with experience as some of the ways in which QI could be expedited.

4.2.4.ii What are the challenges associated with QI of a project?

According to Interviewees 1, 3, 7, and 15, delivery of quality projects on time in the construction industry is critical to the clients' satisfaction. However, Interviewee 17 stressed that, in some cases, the delivery is hampered by challenges, while other interviewees revealed that lack of funding, budget constraints, slow delivery of construction materials to site, and limited resources pose a challenge to QI. Interviewees 19 and 22 emphasised further that lack of an integrated model for QI management, lack of appropriate training for officials, lack of communication, lack of co-operation among the officials and staff members, and interference from management are possible challenges encountered. Interviewees 23, 24, 25, 26, and 29 indicated that "employees were not interested in acquiring more knowledge to improve their level of understanding of QI". Lack of a data-collection and monitoring system was a major challenge that affects QI of projects.

5. DISCUSSION

5.1 Implications of questionnaire survey results

Based on the findings, the major contributing quality challenges in the planning, monitoring, and control in DPW&I projects include the inability to develop long-term strategies (MS=4.5), poor project communication among parties (MS=4.00), damage of material during transportation (MS=3.90), and payment delays from clients (MS=3.90).

Although all 11 contributors may improve quality in DPW&I projects, promoting effective quality management (MS=4.24), ensuring proper material procurement (MS=4.18), and allowing price escalation in tender documents (MS=4.13) were the top three QI contributors for DPW&I projects.

5.2 Implications of interview results

A common concern was that quality in DPW&I projects has declined and is no longer up to the required standard. Interviewees mentioned poor-quality management practices, lack of accountability, lack of communication, late and incorrect quantities in delivery of materials, incompetent officials with inadequate skills, non-compliance with specification and bill of quantities, lack of clear goals, and lack of a data-collection and monitoring system as some of the quality challenges in DPW&I projects.

The decline and sub-standard of quality have gradually become a norm and accepted in DPW&I projects, as confirmed by the results of this study.

An example of quality deviation was illustrated by the interviewee who stated that "quality is no longer a priority; quality has deteriorated, and administrators are incompetent, incompetent service providers, and incompetent government officials". In recent years, quality has deteriorated dramatically. As an illustration, an interviewee indicated that: "corruption, lack of competent officials and budget constraints affect the planning of projects".

As a result, it appears that non-compliance has become the 'standard', to the point where interviewees argued that regulations must be enforced, and specification and delivery of construction material must be reviewed and inspected regularly. They suggested that regular meetings should be held to discuss quality issues which are identified, and that materials should be stored closer to the project sites.

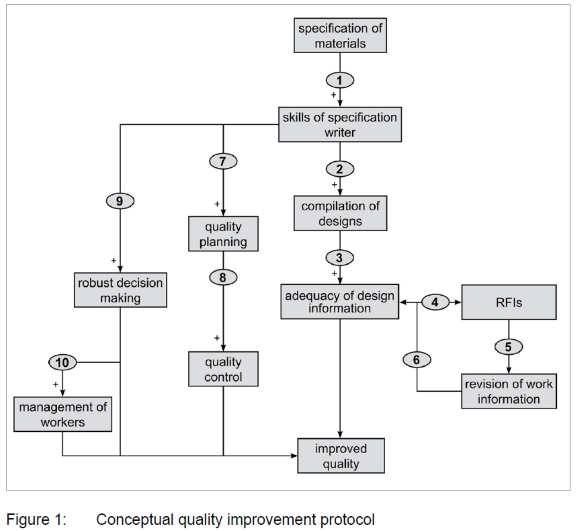

6. CONCEPTUAL QUALITY IMPROVEMENT PROTOCOL

With the literature and theoretical review as a foundation, 10 steps are proposed and viewed as a QI protocol based on statistical and textual data outlining how the DPW&I could address QP, QC and QI concerning materials delivery and specification for DPW&I projects.

A QI protocol (Figure 1) was developed based on a case study of DPW&I, the variables identified in the survey, and the interviewees' responses. The numerical values in the figure represent the steps to follow in the protocol. The value ranges from + to -, with + indicating a positive relationship between the 10 steps and - indicating a negative relationship between the 10 steps.

6.1 Specification of designs and materials

In the construction industry, it is usually assumed that the quality of designs and specifications produced for project activities are determined by the skills of the designers of these documents (Lopez et al., 2010). The first three steps (Steps 1-3) of the conceptual QI protocol show how specification of materials, skills of specification writer, compilation of designs, and adequacy of design information link positively toward the core foundation of the protocol, namely improved quality.

Results from this study show that DPW&I project managers receive or demand project specifications. Project managers in the DPW&I were qualified in specific disciplines such as civil engineering, mechanical engineering, electrical engineering, and construction management. In this study, engineers did the specifications for construction/infrastructure projects and works inspectors did the specifications for maintenance projects. This shows that employing experienced engineers for design specification is essential to improve quality because correct interpretation of requirements eliminates unnecessary repetition of work.

6.2 Adequacy of design information and RFIs

The adequacy of design information further links negatively to RFIs (Step 4). It is fundamental that DPW&I technical personnel have appropriate writing skills to guide the specification and delivery of construction materials. Developing and improving the writing skills of both the specification writer and the designer will assist these DPW&I officials to have better knowledge of the design process. When the design process is understood well and specification skills are developed, the quality of material delivery can be improved in DPW&I projects.

The study determined that, if the adequacy of information falls short of required expectations, RFIs might lead to increased re-work, which might be delayed by the approval of designs (Step 5). Emuze et al. (2014: 230) stated that, in construction management, design information is frequently inadequate and may lead to increases in design changes, coordination problems, and re-work (Lopez et al., 2010: 402).

However, when the revision work is ready, after the design processes have undergone appropriate QC (Step 8) procedures to remove errors, the design information might be deemed adequate, and the material specification revised (Step 6).

In this study, specification was linked to the delivery of construction materials in DPW&I projects. Results show that incorrect specifications, the RFI, and poor delivery of construction materials was experienced during the execution of DPW&I projects. RFIs and re-work (quality deviation) are, therefore, of major concern during DPW&I projects, where they have the tendency to transform into practice 'norms'. Quality deviation can be managed and modified if the people concerned are prepared to make the effort (Step 6) (Tabish & Jha, 2015).

6.3 Quality planning and quality control

It is arguable that a way forward to improve quality during DPW&I projects is to embrace QP (Step 7) and QC (Step 8) interventions that link positively to all the other steps in the protocol. Results from the study show that project managers and engineers were involved in QP and QC in DPW&I projects and that QC was done by the works inspectors (supervisors), who inspected materials for compliance with specifications.

The results indicate how QP determines the specification and delivery of construction materials for DPW&I projects. This suggests that poor QP could manifest into issues such as corruption, a lack of defect prevention, delayed progress payment by the client, poor cash flow, reliance on inspection to assure quality, a lack of quality assurance, and a lack of access to funding.

A project plan that includes long-term strategies, contractual factors, timetables, resources, qualified personnel, risk-management plan, effective quality management, effective project communication, cost control, data collection, monitoring system, and evaluation methods for the project is essential for project managers to ensure that the project is completed correctly and to the satisfaction of all stakeholders.

Still within the same analogy, the degree to which supervisors can successfully inspect the work completed, due to conducting QC, maximises project improvement (Step 8). The study suggests that inspectors check materials for the correctness of specifications and damage of material during transportation. This can be done for maintenance projects, for which service providers deliver materials to the maintenance section and inspectors inspect the materials and delivery to sites. Project managers should be responsible for receiving construction materials on site. Nevertheless, a uniform, standard form for QC is required for neutrality and greater understanding among project managers and inspectors.

6.4 Decision-making and management

The skills of specification writers and management could influence the robustness of their decision-making abilities (Step 9), as well as their ability to manage DPW&I officials (Step 10). The result of the study shows that lack of details, accountability, lack of clear goals, and unrealistic deadlines also pose a challenge to projects, especially at the planning stage. An engineer, who was interviewed, revealed that

limited engagement of different stakeholders and parties in the project, changing needs of clients and major decisions taken by management, even though they are not directly involved in the projects, were some of the many challenges faced at the planning stage of the project.

Other interviewees stated that, in some cases, there is lack of clarity on goals that affect the successful completion of projects.

According to Schoonwinkel and Fourie (2019: 28), project managers make extensive use of their experience and engineering judgement for managing changes during project execution. It is, therefore, recommended that project managers and engineers be carefully selected, based not only on experience, but also on the necessary decision-making skills and competencies.

6.5 Quality improvement

In the protocol, QI processes relate to specification and delivery of construction materials, QP, QC, decision-making, and the ability to lead DPW&I officials. Results of the study indicate that, although QI was done during DPW&I projects, there is a negative relationship between QI and the planning stage of a project, as well as the monitoring and control phases of a project.

Quality project delivery in the construction industry is critical to the clients' satisfaction. Therefore, a protocol showing a positive relationship between the planning stage of a project and the monitoring and control phase of a project, as well as quality challenges on a project is ideal to improve quality. A continuous QI process and proper planning with the participation of all stakeholders from the start of the project is necessary to address challenges such as lack of funding, budget constraints, slow delivery of construction materials to site, and limited resources. Quality could also improve by using an integrated model for QI management, which should include appropriate training for officials, effective communication, and enhancing co-operation among officials and staff members.

7. CONCLUDING REMARKS

The purpose of this study was to develop a QI protocol to ensure that materials are delivered to construction sites as specified by the engineers in the DPW&I. The study examined QI protocol and the impact of specification and delivery of construction materials, QP, QC, decision-making, and the ability to lead DPW&I officials. The results support the literature that problems related to material quality on construction projects occur in South Africa, causing cost and schedule overruns. In essence, the specification and delivery of construction materials requires QP and QC to enable better decision-making. The ability to lead DPW&I officials is an essential variable that must be considered as it exhibits a persistent ability to inhibit high-quality performance in DPW&I projects.

Using the DPW&I as a case study, quality issues were identified with the clarifications about how they tend to increase in projects. Notable aspects of QI such as promoting effective quality management must be addressed in DPW&I. The findings of this study reinforced the notion that quality deviation in the form of specification and delivery of construction material produces unacceptable project quality. For example, in the study, it was suggested that defects, re-work, and RFIs are linked through quality deviation factors that lead to additional project costs. Such factors are manifested in the attitudes and behaviours of people in construction.

The study further demonstrated that quality deviation can be managed and modified if the affected parties are willing to try. Although the study suggested that addressing the absence of an integrated model for QI management, inadequate training for officials, lack of communication, lack of cooperation among the officials and staff members, and management interference would lessen the problem, there is reason to believe that these measures can only produce marginal improvements until there is a clear shift in the mindset of the people involved. Management, specification writers, and suppliers would all need to adopt new mindsets to change their attitudes and behaviours, in order to prevent undesirable project quality outcomes.

All parties involved in DPW&I projects should collaborate to accomplish the following objectives: evaluate how QP determines the specification and delivery of construction materials to public works projects, evaluate how QC affects the specification and delivery of construction materials to public works projects, evaluate how QI would ensure that the specification and delivery of construction materials to public works projects meet stipulated deliverables, and develop a protocol that will engender QI in relation to specification and material delivery to public works projects. The DPW&I should aim for best practices in enforcing the QI protocol, by considering the following factors: employment of qualified engineering and building environment professionals, as well as competent contractors.

The DPW&I should make information about the QI protocol available on their website. It would be extremely beneficial to the officials if the DPW&I encouraged and enforced the implementation of the QI protocol. When it comes to construction procurement, client departments must take a consistent approach. This can be accomplished by developing and agreeing on pre-qualification criteria for principal contractors who bid using bid documents. It is also suggested that the DPW&I consider systems that have the potential to improve performance and quality.

REFERENCES

Aghimien, D., Oke, A., Aigbavboa, C. & Ontlametse, K. 2018. Factors contributing to disabling injuries and fatalities in the South African construction industry. In: Joint CIB W099 and TG59 International Safety, Health, and People in Construction Conference, 1-3 August, Salvador, Brazil. Salvador, Brazil: Marketing Aumentado, pp. 337-345. [ Links ]

Akintoye, A. & Main, J. 2007. Collaborative relationships in construction: The UK contractors' perception. Engineering, Construction and Architectural Management, 14(6), pp. 597-617. https://doi.org/10.1108/09699980710829049 [ Links ]

Akkermans, H. & Van Oorschot, K. 2018. Relevance assumed: A case study of balanced scorecard development using system dynamics. In: Kunc, M. (Eds). System dynamics. OR essentials. London: Palgrave Macmillan, pp. 107-132. https://doi.org/10.1057/978-1-349-95257-1_4 [ Links ]

Alaghbari, W., Al-Sakkaf, A. & Sultan, B. 2019. Factors affecting construction labour productivity in Yemen. International Journal of Construction Management, 19(1), pp. 79-91. https://doi.org/10.1080/15623599.2017.1382091 [ Links ]

Al-Janabi, A., Abdel-Monem, M. & El-Dash, K. 2020. Factors causing re-work and their impact on projects' performance in Egypt. Journal of Civil Engineering and Management, 26(7), pp. 666-689. https://doi.org/10.3846/jcem.2020.12916 [ Links ]

Ayach, L., Anouar, A. & Bouzziri, M. 2019. Quality cost management in Moroccan industrial companies: Empirical study. Journal of Industrial Engineering and Management, 12(1), pp. 97-114. https://doi.org/10.3926/jiem.2749 [ Links ]

Biadacz, R. 2020. Quality cost management in the SMEs of Poland. The TQM Journal, 33(7), pp. 1-38. https://doi.org/10.1108/TQM-09-2019-0223 [ Links ]

Bikitsha, L. & Amoah, C. 2020. Assessment of challenges and risk factors influencing the operation of emerging contractors in the Gauteng province, South Africa. International Journal of Construction Management, 22(2), pp. 1-10. https://doi.org/10.1080/15623599.2020.1763050 [ Links ]

Bowen, P., Edwards, P. & Cattell, K. 2015. Corruption in the South African construction industry: Experiences of clients and construction professionals. International Journal of Project Organisation and Management, 7(1), pp. 72-97. https://doi.org/10.1504/IJPOM.2015.068003 [ Links ]

Butt, A., Naaranoja, M. & Savolainen, J. 2016. Project change stakeholder communication. International Journal of Project Management, 34(8), pp. 1579-1595. https://doi.org/10.1016/j.ijproman.2016.08.010 [ Links ]

Chen, L. & Luo, H. 2014. A BIM-based construction quality management model and its applications. Automation in Construction, 46(1), pp. 64-73. https://doi.org/10.1016/j.autcon.2014.05.009 [ Links ]

Chopra, A. & Singh, B. 2015. Unleashing a decisive approach to manage quality costs through behavioural investigation. Business Process Management Journal, 21(6), pp. 1206-1223. https://doi.org/10.1108/BPMJ-07-2014-0064 [ Links ]

CIDB (Construction Industry Development Board). 2004. SA Construction Industry Status Report. Synthesis review on the South African construction industry and its development. Pretoria, South Africa: CIDB. [ Links ]

Creswell, J.W. & Creswell, J.D. 2017. Research design: Qualitative, quantitative, and mixed methods approaches. Newbury Park, CA: Sage Publishing. [ Links ]

Creswell, J.W. & Poth, C.N., 2016. Qualitative inquiry and research design: Choosing among five approaches. Thousand Oaks, CA: Sage Publications. [ Links ]

Davis, K. 2014. Different stakeholder groups and their perceptions of project success. International Journal of Project Management, 32(2), pp. 189-201. https://doi.org/10.1016/j.ijproman.2013.02.006 [ Links ]

Davies, A., Dodgson, M., Gann, D. & MacAulay, S. 2017. Five rules for managing large, complex projects. MIT Sloan Management Review, 59(1), p. 72-78. [ Links ]

Delisle, J. 2020. Working time in multi-project settings: How project workers manage work overload. International Journal of Project Management, 38(7), pp. 419-428. https://doi.org/10.1016/j.ijproman.2020.04.001 [ Links ]

DPW&I (Department of Public Works & Infrastructure). 2022. [Online]. Available at: <http://www.publicworks.fs.gov.za/> [Accessed: 11 December 2022]. [ Links ]

El-Gohary, K.M. & Aziz, R.F. 2014. Factors influencing construction labor productivity in Egypt. Journal of Management in Engineering, 30(1), pp. 1-9. https://doi.org/10.1061/(ASCE)ME.1943-5479.0000168 [ Links ]

Ellis, L. & Martin, H. 2019. Factors influencing triple constraints in public sector projects in Trinidad and Tobago. Management, Procurement and Law, 172(4), pp. 157-169. https://doi.org/10.1680/jmapl.18.00047 [ Links ]

Emuze, F.A. & Mhlwa, C. 2015. Managing quality on construction sites in South Africa: An Eastern Cape study. Journal of Construction Project Management and Innovation, 5(2), pp. 1224-1237. [ Links ]

Emuze, F. & Smallwood, J. 2011. Improving project delivery in South African construction. Proceedings of the 27th Annual Association of Researchers in Construction Management (ARCOM) Conference, 5-7 September 2011, Bristol, UK. Association of Researchers in Construction Management, pp. 5-7. [ Links ]

Emuze, F. & Smallwood, J. 2013. Mapping 're-work'-related findings in South Africa? In: Proceedings of the 7th International Structural Engineering and Construction Conference, 18-23 June 2013, Honolulu, USA, pp. 1615-1620. [ Links ]

Emuze, F., Smallwood, J. & Han, S. 2014. Factors contributing to non-value adding activities in South African construction. Journal of Engineering, Design and Technology, 12(2), pp. 223-243. https://doi.org/10.1108/JEDT-07-2011-0048 [ Links ]

Enshassi, A., Sundermeier, M. & Zeiter, M.A. 2017. Factors contributing to rework and their impact on construction projects performance. International Journal of Sustainable Construction Engineering and Technology, 8(1), pp. 12-33. [ Links ]

Forbes, L.H. & Ahmed, S.M. 2020. Lean project delivery and integrated practices in modern construction. London, UK: Routledge. https://doi.org/10.1201/9780429458989 [ Links ]

Glogovac, M. & Filipovic, J. 2018. Quality costs in practice and an analysis of the factors affecting quality cost management. Total Quality Management & Business Excellence, 29(13-14), pp. 1521-1544. https://doi.org/10.1080/14783363.2016.1273105 [ Links ]

Hair, J.F., Black, W.C., Babin, B.J. & Anderson, R.E. 2019. Multivariate data analysis. 8th edition. United States: Cengage Learning. [ Links ]

Joshi, A., Kale, S., Chandel, S. & Pal, D.K. 2015. Likert scale: Explored and explained. British Journal of Applied Science & Technology, 7(4), pp. 396-403. https://doi.org/10.9734/BJAST/2015/14975 [ Links ]

Kerfai, N., Bejar Ghadhab, B. & Malouche, D. 2016. Performance measurement and quality costing in Tunisian manufacturing companies. The TQM Journal, 28(4), pp. 588-596. https://doi.org/10.1108/TQM-10-2013-0119 [ Links ]

Kilic, S. 2016. Cronbach's alpha reliability coefficient. Psychiatry and Behavioral Sciences, 6(1), pp. 47-48. https://doi.org/10.5455/jmood.20160307122823 [ Links ]

Krejcie, R.V. & Morgan, D.W. 1970. Determining sample size for research activities. Educational and Psychological Measurement, 30(3), pp. 607-610. https://doi.org/10.1177/001316447003000308 [ Links ]

Lopez, R., Love, P.E., Edwards, D.J. & Davis, P.R. 2010. Design error classification, causation, and prevention in construction engineering. Journal of Performance of Constructed Facilities, 24(4), pp. 399-408. https://doi.org/10.1061/(ASCE)CF.1943-5509.0000116 [ Links ]

Magnaye, R.B., SSC, B.J.S. & Varma, N. 2020. Bridging the gap between practice and undergraduate teaching of operations management: The case of public liberal arts colleges. International Journal of Operations and Quantitative Management, 26(1), pp. 59-64. https://doi.org/10.46970/2020.26.1.3 [ Links ]

Marcelino-Sádaba, S., Pérez-Ezcurdia, A., Lazcano, A.M.E. & Villanueva, P. 2014. Project risk management methodology for small firms. International Journal of Project Management, 32(2), pp. 327-340. https://doi.org/10.1016/j.ijproman.2013.05.009 [ Links ]

Marin-Garcia, J.A. & Bonavia, T. 2015. Relationship between employee involvement and lean manufacturing and its effect on performance in a rigid continuous process industry. International Journal of Production Research, 53(11), pp. 3260-3275. https://doi.org/10.1080/00207543.2014.975852 [ Links ]

Mashwama, N., Aigbavboa, C. & Thwala, W. 2017. An assessment of critical success factors for the reduction of the cost of poor quality from construction projects in Swaziland. Procedia Engineering, 196(2017), pp. 447-453. https://doi.org/10.1016/j.proeng.2017.07.223 [ Links ]

Mayer, I. 2015. Qualitative research with a focus on qualitative data analysis. International Journal of Sales, Retailing & Marketing, 4(9), pp. 53-67. [ Links ]

Mbande, C. 2010. Overcoming construction constraints through infrastructure delivery. s.l., s.n., pp. 18-20. [ Links ]

Milford, R. 2010. Public capacity payment and procurement issues should be a challenge to the operations of contractors in South Africa. In: Fifth Built Environment Conference of the Association of Schools of Construction of Southern Africa. Durban, South Africa, pp. 18-20. [ Links ]

Moschidis, O., Chatzipetrou, E. & Tsiotras, G. 2018. Quality costing and quality management maturity in Greece: An exploratory multi-dimensional data analysis. International Journal of Productivity and Performance Management, 67(1), pp. 171-191. https://doi.org/10.1108/IJPPM-08-2016-0152 [ Links ]

Negron, L., 2020. Relationship between quality management practices, performance and maturity quality management: A contingency approach. Quality Management Journal, 27(4), pp. 215-228. https://doi.org/10.1080/10686967.2020.1809582 [ Links ]

Neirotti, P. 2020. Work intensification and employee involvement in lean production: New light on a classic dilemma. The International Journal of Human Resource Management, 31(15): pp. 1958-1983. https://doi.org/10.1080/09585192.2018.1424016 [ Links ]

Obunwo, C., Chinyio, E. & Suresh, S. 2015. Relative contributions of project quality to customer satisfaction in Nigerian road construction projects. In: A.B. Raidén & E. Aboagye-Nimo (Eds). Proceedings of the 31st Annual ARCOM Conference, 7-9 September, Lincoln, UK: Association of Researchers in Construction Management, pp. 763-772. [ Links ]

Othman, A. 2012. An innovative protocol for improving the ethical behaviour of the quantity surveying profession in South Africa. International Journal of Construction Management, 12(3), pp. 43-62. https://doi.org/10.1080/15623599.2012.10773194 [ Links ]

Ramabodu, M.S. & Verster, J.J.P. 2010. An evaluation of cost overruns in public sector projects in the Free State province of South Africa. In: Proceedings of the 5th Built Environment Conference, 18-20 July, Durban South Africa, pp. 18-20. [ Links ]

Raymond, K., James, W. & Kabubo, C. 2017. Common construction site hazards in Nairobi County, Kenya. American Journal of Construction and Building Materials, 1(1), pp. 26-33. [ Links ]

Rivas, R., Borcherding, J., Gonzalez, V. & Alarcon, L. 2011. Analysis of factors influencing productivity using craftsmen questionnaires: Case study in a Chilean construction company. Journal of Construction Engineering and Management, 137(4), pp. 312-320. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000274 [ Links ]

Saffar, N. & Obeidat, A. 2020. The effect of total quality management practices on employee performance: The moderating role of knowledge sharing. Management Science Letters, 10(1), pp. 77-90. https://doi.org/10.5267/j.msl.2019.8.014 [ Links ]

Šatanová, A., Závadský, J., Sedliačiková, M., Potkány, M., Závadská, Z. & Holíková, M. 2015. How Slovak small and medium manufacturing enterprises maintain quality costs: An empirical study and proposal for a suitable model. Total Quality Management & Business Excellence, 26(11-12), pp. 1146-1160. https://doi.org/10.1080/14783363.2014.916477 [ Links ]

Saunders, M., Lewis, P. & Thornhill, A. 2019. Research methods for business students. New York: Pearson. [ Links ]

Schoonwinkel, S. & Fourie, C.J. 2016. A risk and cost management analysis for changes during the construction phase of a project. Journal of the South African Institution of Civil Engineering, 58(4), pp. 21-28. https://doi.org/10.17159/2309-8775/2016/v58n4a3 [ Links ]

Suresh, S., Olayinka, R., Chinyio, E., Renukappa, S. 2017. Impact of knowledge management on construction projects. Management, Procurement and Law, 170(1), pp. 27-43. https://doi.org/10.1680/jmapl.15.00057 [ Links ]

Taber, T.S. 2018. The use of Cronbach's Alpha when developing and reporting research instruments in science education. Research in Science Education, 48(1), pp. 1-24. https://doi.org/10.1007/s11165-016-9602-2 [ Links ]

Tabish, S. & Jha, K. 2015. Success factors for safety performance in public construction projects. The Indian Concrete Journal, 89(2), pp. 58-72. [ Links ]

Taggart, M., Koskela, L. & Rooke, J. 2014. The role of the supply chain in the elimination and reduction of construction rework and defects: An action research approach. Construction Management and Economics, 32(7-8), pp. 829-842. https://doi.org/10.1080/01446193.2014.904965 [ Links ]

Verster, T. & Fourie, E. 2018. The good, the bad, and the ugly of South African fatal road accidents. South African Journal of Science, 114(7-8), pp. 63-69. https://doi.org/10.17159/sajs.2018/20170427 [ Links ]

Wahab, O.M., Ayodele, A.E. & Moody, J.O. 2010. TLC phytochemical screening in some Nigerian Loranthaceae. Journal of Pharmacognosy and Phytotherapy, 2(5), pp. 64-70. [ Links ]

Wanberg, J., Harper, C., Hallowell, M. & Rajendran, S. 2013. Relationship between construction safety and quality performance. Journal of Construction Engineering and Management, 139(10), 04013003. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000732 [ Links ]

Welde, M. & Dahl, R.E. 2021. Cost escalation in road construction contracts. Transportation Research Record, 2675(9), pp. 1006-1015. https://doi.org/10.1177/03611981211005462 [ Links ]

Windapo, A.O. 2016. Skilled labour supply in the South African construction industry: The nexus between certification, quality of work output and shortages. SA Journal of Human Resource Management, 14(1), article 750. http://dx.doi.org/10.4102/sajhrm.v14i1.750 [ Links ]

Yaghootkar, K. & Gil, N. 2012. The effects of schedule-driven project management in multi-project environments. International Journal of Project Management, 30(1), pp. 127-140. https://doi.org/10.1016/j.ijproman.2011.02.005 [ Links ]

Received: October 2022

Peer reviewed and revised: January 2023

Published: June 2023

DECLARATION: The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.