Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Acta Structilia

On-line version ISSN 2415-0487

Print version ISSN 1023-0564

Acta structilia (Online) vol.29 n.1 Bloemfontein 2022

http://dx.doi.org/10.18820/24150487/as29i1.4

RESEARCH ARTICLE

Appropriate building repair and maintenance strategies using multi-criteria decision-making analysis - a Delphi study

Mohammad KheradranjbarI; Mirali MohammadiII; Shahin RafieeIII

IDepartment of Civil Engineering, Karaj Branch, Islamic Azad University, Karaj, Iran. Email: <Kherad.ranjbar@kiau.ac.ir>, ORCID: https://orcid.org/0000-0002-5660-9400

IIAssociate Professor in Civil Engineering, Department of Civil Engineering, Faculty of Engineering, Urmia University, PO Box 165, Urmia 5756115311, Iran. Phone: +989141410650, email: <m.mohammadi@urmia.ac.ir>, https://orcid.org/0000-0001-7194-9393

IIIProfessor in Mechanical Engineering of Agricultural Machinery, Faculty of Agricultural Engineering and Technology, University College of Agriculture & Natural Resources, University of Tehran, Karaj, Iran. Email: <shahinrafiee@ut.ac.ir>

ABSTRACT

As an influential and significant factor in improving the service of building components and elements, maintenance plays an essential role in maintaining reliability, availability, and quality, as well as increasing efficiency and security. Therefore, how to define this maintenance system and determine the appropriate criteria and strategies for that play an important role in the cost and longevity of the buildings after construction and during their operation. The purpose of the article is to determine the effective criteria for evaluating buildings based on maintenance and repair (R&M) and finally determining the appropriate strategy for the maintenance of residential buildings, using multi-criteria decision-making methods. These criteria were first identified by reviewing the literature and using the Delphi method to obtain the opinions of maintenance experts. The criteria were then prioritized, based on the SWARA method, and the results were compared and evaluated. Based on comparison, safety, health, environment, and proper utilisation were rated the top four criteria to consider for building R&M. Finally, using the VIKOR1 method, it was found that the breakdown maintenance (BM) and corrective maintenance (CM) strategies are the best strategies to use for the R&M of residential buildings.

Keywords: Building maintenance, building repair, repair and maintenance, multi-criterion decisionmaking, Delphi method, SWARA,VIKOR

ABSTRAK

As 'n invloedryke en beduidende faktor in die verbetering van die onderhoud van geboukomponente en -elemente, speel instandhouding 'n noodsaaklike rol in die handhawing van betroubaarheid, beskikbaarheid, kwaliteit en die verhoging van doeltreffendheid en sekuriteit. Daarom, hoe om hierdie instandhoudingstelsel te definieer en die toepaslike kriteria en strategieè daarvoor te bepaal, is belangrik vir die koste en langdurigheid van die geboue na konstruksie en tydens die bedryf daarvan. Die doel van die artikel is om die effektiewe kriteria vir die evaluering van geboue op grond van onderhoud en herstel (R&M) te bepaal en uiteindelik die toepaslike strategie vir instandhouding van residensièle geboue te bepaal deur gebruik te maak van multi-kriteria besluitnemingsmetodes. Hierdie kriteria is eers ge'identifiseer deur 'n literatuurstudie en die Delphi-metode is gebruik om instandhoudingskundiges se menings daaroor te verkry. Daarna is die kriteria geprioritiseer op grond van die SWARA-metode, en die resultate is vergelyk en geèvalueer. Gebaseer op vergelyking, is veiligheid, gesondheid, omgewing en behoorlike benutting as die top vier kriteria aangewys om te oorweeg vir die R&M van geboue. Laastens, met behulp van die VIKOR-metode, is gevind dat die breakdown maintenance- (BM) en corrective maintenance- (CM) strategieè die beste strategieè is om te gebruik vir die R&M van residensièle geboue.

Sleutelwoorde: Gebou-instandhouding, gebouherstel, herstel en instandhouding, multi-kriterium-besluitneming, Delphi-metode, SWARA, VIKOR

1. INTRODUCTION

The need to design, deploy and use maintenance systems in all industries is one of the most important factors in maintaining capital and it is important in terms of security and economy. The issue of maintenance in the construction industry is not exempt from this rule and has been considered globally, especially in developed countries (Katabi & Almasian, 2016: 1). The main purpose of building R&M is to optimise the capability of building equipment and elements to achieve maximum efficiency, reduce failure and breakdown. Its minor objectives include increasing readiness and reliability, as well as reducing additional costs. Considering that proper utilisation of buildings increases their useful life and that their R&M method has a significant impact on building costs during operation, it is necessary to conduct studies to determine the appropriate criteria in this regard. Building assessment based on R&M is important for two reasons. First, the assessment should be done in several phases. The first phase is from the design to the repair management stage. The second phase is the assessment of the availability and features related to the useful life data, which is inherently heterogeneous, inaccurate, uncertain, and incomplete (Talon, Boissier & Lair, 2008).

Since numerous criteria are involved in the assessment of R&M of buildings (Khodayari & Abdollahzadeh, 2018: 281), it can be said that recognising and ranking those criteria and determining and prioritising appropriate R&M strategies of the building based on the mentioned criteria is of special importance. Various R&M policies have been provided and the application of each strategy has different advantages and disadvantages depending on the type of industry (Do et al., 2015). Many researchers have applied multi-criteria decision-making techniques separately or simultaneously to determine the R&M criteria and related strategies in different industries. Each of them examined this issue from a different perspective. However, the main problem facing experts and managers in the construction industry is the failure to understand and prioritise the key and appropriate criteria of the R&M system and finally choose the most appropriate R&M policy.

Therefore, choosing a maintenance strategy is a kind of multi-criteria decision problem. The best option can be selected from the possible solutions based on evaluating multiple criteria (Bowersox & Closs, 1996: 283). Choosing the right R&M strategy for a building with combined decisions prevents premature deterioration of buildings during operation. Therefore, the appropriate R&M strategy should be effective and based on certain criteria to identify and enhance building lifespan, operation, equipment, and elements, as well as reduce costs (Kheradranjbar, Mohammadi & Rafiee, 2022a: 2). Although identifying and prioritising design and implementation defects are addressed in the building maintenance system, the construction industry is mainly focused on the design, supervision, and execution of the building relative to the R&M. If the issue is addressed, it is mostly qualitative. Therefore, determining the quality criteria of building R&M will help the experts determine the effective sub-criteria of the building R&M system, formulate the codes and national regulations, and choose the appropriate R&M strategy, increasing longevity and reducing the costs during the operation.

Given the lack of comprehensive research in identifying and prioritising criteria and selecting the most appropriate R&M policy, the important issue is the relationship between the factors and the appropriate techniques to determine the relationship and evaluate the proper criteria. This article seeks to determine and prioritise the basic criteria and then select the appropriate maintenance policy in the R&M system of buildings to identify and analyse them in the buildings' assessment with a multi-criteria decisionmaking technique.

2. LITERATURE REVIEW

2.1 Repair and maintenance methods

An appropriate method should be provided for the R&M of projects, especially construction projects. For this purpose, one must first note the main reason for the maintenance policy in construction projects, in other words, one must first define the scope of the problem to carry out this process. Then collect data and basic information to define the defects, identify and prioritise the relevant problems and defects, and finally proceed to plan solutions and organise and guide the implementation and control of solutions (Kelly, 2006: 19-28).

R&M includes a set of activities designed to prevent sudden breakdown of equipment and facilities. Repairs are carried out when the equipment fails, does not function properly, or its operation is delayed (Shi & Zeng, 2016). The main purpose of R&M is to extend the life of equipment and reduce the costs in the most efficient manner that is defined from the time of installation of equipment and during operation (Golchi et al., 2018: 2). R&M is an optimal way to achieve a satisfactory level of reliability, in order to reduce costs during the useful life of the building (Das, Lashkari & Sengupta, 2007). The cost of maintaining and repairing buildings increases exponentially from the time of construction. If regularly inspected and evaluated buildings are neglected, this can lead to exorbitant costs; thus planning a maintenance management system can be especially important in reducing maintenance costs (Moriconi & Naik, 2010).

Various maintenance policies are applied in R&M, of which the most well-known and widely used one include emergency maintenance (EM), breakdown maintenance (BM), corrective maintenance (CM), preventive maintenance (PM), pre-dictive maintenance (PdM), total productive maintenance (TPM), and proactive maintenance (PRM). Caballé et al. (2015: 103-105) briefly describe the policies used in this study.

EM: Repair and preparation are done after the first breakdown and there is no prior preparation to deal with them; the experiences gained are neither recorded nor evaluated.

BM: The repair process takes place after a breakdown has occurred, but prior preparation has been made for defects, cause, required corrective actions, repair instructions, tools, parts, and other equipment required.

CM: After creating signs of a defect that does not cause the equipment to stop, special planning is done to correct the equipment defects and return them to their original state at the appropriate time.

PM: Maintenance of buildings and equipment at specific intervals and according to a specific schedule.

PdM: At certain intervals, several equipment components such as vibration, pressure and temperature are measured. Based on this data, decisions are made to repair or replace parts and equipment.

TPM: Maintenance is not solely the responsibility of the repairman and is part of the day-to-day maintenance process.

PRM: Effective R&M is done to improve performance, reduce the need for maintenance, and eliminate the causes of failures, and instead of waiting for failures to occur, the management will have taken action previously and be in a good position.

Different indicators and approaches have been used to select the most appropriate maintenance strategy. Due to budget constraints, a systematic approach is needed to more efficiently allocate limited resources to the maintenance and repair system. The maintenance system is not simply a technical process, but a socio-technical problem. Therefore, several criteria must be considered and turned into a multi-criteria decision-making (MCDM) problem (Das & Nakano, 2021).

2.2 Repair and maintenance criteria

Various building codes and regulations have been provided to improve the quality of the building in terms of design, construction, repair, and maintenance. These codes assess building quality based on different criteria. Criteria are used to compare and rank maintenance policies; different classifications of these criteria have been proposed (Wang, Chu & Wu, 2007: 152). According to several experts, these criteria are grouped into four main groups: cost, value added, safety, and feasibility (Zaim et al., 2012: 18). Some criteria such as hardware, software and costs of training, reliability, and equipment reliability are measurable and quantitative; however, others such as safety, flexibility, acceptance by workers, and product quality are qualitative and face problems in measurement. Quantitative and qualitative criteria are classified into four main categories: economic, technical, social, and environmental (Shafiee, 2015: 380). Since the codes related to buildings change over time, according to the costs of buildings, for their proper maintenance and repair, new criteria should be proposed to develop these codes and finally determine the appropriate strategies for maintenance and repair of the building (Martin, Tognetti & Hill, 2016).

The main criteria for selecting appropriate maintenance policies that have been most emphasied in previous research are profitability, accessibility, environment, safety, and reliability (Sherafat, Karimi & Davoodi, 2017: 718-719).

Since the scope of this research is Iran and according to the existing codes and regulations in the construction sector, articles in the framework of R&M criteria and experts' opinions, basic criteria in technical, social, economic and environmental fields are addressed (Khodayari & Abdollahzadeh, 2018: 281-282).

2.3 Repair and maintenance strategies and frameworks

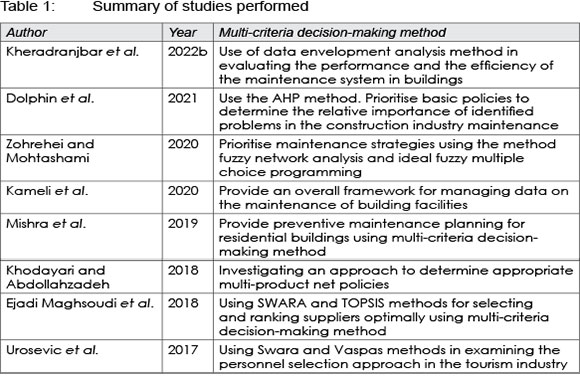

Kheradranjbar et al. (2022) identified and prioritised effective criteria in the maintenance system of residential buildings, using a combination of multi-criteria decision-making methods. In the proposed method, first the weight of the criteria was calculated and then the criteria were prioritised, based on multi-criteria fuzzy and non-fuzzy decision-making methods. Finally, by considering the ratings obtained from these methods, the final ranking of the criteria was calculated using the average rating and Copland method which ranked safety and health criteria the highest (Kheradranjbar et al., 2022b). In a study using the AHP method and a Likert-based survey, Dolphin et al. (2021) prioritised basic policies to determine the relative importance of problems identified in the R&M sector of the Hong Kong construction industry, and finally recommended policies such as registration of RMAA workers, intensifying monitoring and enforcement, and provision of loan services for safety can overcome problems. Zohrehei & Mohtashami, (2020) presented a new method for selecting the optimal maintenance strategy based on fuzzy network analysis and ideal fuzzy multi-choice planning. They first calculated the fuzzy weights of the components by fuzzy network analysis method and then prioritized the R&M operation by defining the obtained weights, writing the ideals and the objective function, and fuzzy multi-choice goal programming (Zohrehei & Mohtashami, 2020).

Kameli et al. (2020) proposed a system that uses the industry foundation class data structure (IFC) and reader and facility identification database (RFID) to connect the BIM model simultaneously and demonstrate the accessible information via the Internet on a tablet. This approach provides a general framework for managing the data on maintenance of building facilities. This framework calls for the proposed system for preventive maintenance and reporting based on it. This system was used in a case study of building R&M in a football stadium and the results showed that it is useful for managing its R&M (Kameli et al., 2020).

Mishra et al. (2009) addressed time-based reliability modelling and preventive maintenance planning for residential buildings. Their purpose was to reduce the damages caused by the storm, using the gamma process to model random damage to building components. Using multi-criteria simulation and decision-making, Khodayari and Abdollahzadeh (2008) examined an approach to determine appropriate maintenance policies and multi-product repairs in a food industry production unit. The main criteria in selecting the R&M policies were profit, productivity, accessibility, environment, safety, and reliability. Using a computer simulation and multi-criteria decision-making, they selected the best policy for each production line separately.

In a study of selection and ranking of optimal suppliers, Ejadi Maghsoudi et al. (2018) used the SWARA and TOPSIS multi-criteria decision-making methods. After determining the criteria and decision alternatives for constructing the decision matrix using the past literature, they selected suppliers and then constructed the decision matrix. Using the new SWARA weight method, they obtained the ideal weights of the decision criteria and ranked the suppliers by merging the obtained weights with the help of the TOPSIS method. Finally, they concluded that the SWARA-TOPSIS method can be used as a suitable and accurate tool for ranking and evaluating similar problems.

In examining the personnel selection approach in the tourism industry, based on the SWARA-WASPAS methods, Urosevic et al. (2017) stated that managers should have the necessary knowledge, skills, and competencies to make timely decisions to react to the changes that happened in their organisations. They thus presented the linear version of the personnel selection method in the tourism sector, using the SWARA-WASPAS methods. The proposed approach was used as well as its efficiency in a numerical example and the results showed that the introduced method has a high validity and the proposed approach can also be used to solve problems in other areas.

For purposes of this study, the following thirteen (13) criteria (factors) that affect the R&M of buildings are considered to assess maintenance strategies: safety, health, proper utilisation, energy saving, economic saving, reliability, culture-building, environment, citizenship rights, intelligence, value added, risk, and comfort. Out of 13 criteria, 9 criteria were selected with the opinion of supervisors and consultants and provided to experts. These building maintenance and repair criteria have been selected based on their concept of literature and maximum research. Finally, the meaning of the final eight criteria is as follows:

Safety: The degree or degree of distance from danger. In fact, this condition has the potential to damage employees, equipment and buildings, destroy materials or reduce efficiency in performing a predetermined task (Golabchi & Amiri, 2015: 7).

Health: Providing the physical and mental needs of residents and preventing accidents (Hatami et al., 2019: 50).

Proper utilisation: Utilisation in the building can be expressed in the sense of efficiency and quality of equipment in providing service and maximum use of equipment, resources, and facilities (Bakhtiari, Dehghanizadeh & Hosseinipour, 2014: 52).

Energy saving: The sense of changing the pattern of energy consumption by making optimal use of energy resources in a way that does not change economic well-being (Naderian & Haji Mirzaei, 2007: 36).

Environment: In this study, the environment is the building of a residence in which all components and people living in it and other natural, artificial and social factors that are in contact with each other and affect the process of life in the building (Sarmadi & Masoumifard, 2016: 39-40).

Economic savings: The sense of better use of limited resources such as time, cost, etc., by using new methods (Bagheri & Makarizadeh, 2009: 66).

Accessibility: The length of time an asset and equipment can be used, if needed. In fact, accessibility indicates how much equipment is available when needed (Dhillon, 2008: 60).

Reliability: This refers to the possibility of a system operating smoothly and correctly under specified and predetermined conditions for a given interval (Karbasian, Ghandehary & Abedi, 2011: 22).

To select the most appropriate building maintenance strategy using multi-criteria decision-making methods based on the determined criteria, the following widely used net strategies are considered for this study: emergency maintenance (EM), breakdown maintenance (BM), corrective maintenance (CM), preventive maintenance (PM), pre-dictive maintenance (PdM), total productive maintenance (TPM), and Proactive maintenance (PRM).

3. RESEARCH DESIGN

The purpose is to determine the criteria affecting the building R&M system and then select the most appropriate maintenance strategy in buildings, using multi-criteria decision-making methods. A quantitative research design was used, in which a questionnaire survey collected data that allows researchers to generalise their findings from the consensus of a group of experts (Brady, 2015: 6). Using the Delphi study method, survey data were obtained from three rounds. A Delphi study conducts a series of rounds to examine divergence and achieve consensus among a group of experts, using controlled feedback, anonymity, statistical aggregation of group responses, and repetition (Sourani & Soheila, 2014: 56; Linstone & Turoff, 2002: 11; Rajendran, 2006: 110; Skulmowski, Hartman & Kran, 2007: 2-3). In Round 1, extracted from sources and existing laws and regulations, nine (9) effective criteria in the R&M system of buildings were identified as the initial factors used to assess maintenance strategies. In this round, experts proposed the accessibility criterion. In Rounds 2 and 3, initial and additional factors affecting R&M were identified and rated, using a 5-point Likert scale until consensus was reached. Likert-scale measurement was used, because statements could be analysed on the mean rating for agreement of experts. Statements with the highest rating indicate that most of the experts agree that the factor affects R&M system in buildings.

3.1 Sampling and expert panel selection

Delphi sample sizes depend more on group dynamics in reaching consensus than on their statistical power (Okoli & Pawlowski, 2004: 19). The target population included specialists and university professors who were members of Iran Construction Engineering Organization (IRCEO). Using non-probability sampling and targeted judgemental methods (Mashayekhi et al., 2005: 199-204), initially five (5) researchers, including specialists and university professors in the field of building engineering who were members of IRCEO and active in the field of building maintenance, were nominated to participate in this research. The other members of the panel were introduced through these people. Delphi panel members were introduced from construction specialists and prominent university professors in the field of building maintenance. All those invited must be members of IRCEO for at least 5 years, in addition to building maintenance expertise, and finally the number of Delphi panel members was 24. All experts responded to rounds one, two and three. In the Delphi process, general rules-of-thumb indicate that 14-30 people for a homogeneous population (that is, experts coming from the same discipline such as, for example, specialist members of IRCEO) are generally considered to be sufficient to achieve consensus (Clayton, 1997: 378).

3.2 Data collection

During July and August 2021, three rounds of data collection, using the Delphi method and questionnaires, were performed. Questionnaires for each round were distributed and collected electronically via email. In round 1, a list of nine (9) effective criteria (citizenship rights, reliability, energy saving, comfort, environment, economic savings, proper utilisation, health, and safety) for R&M that were extracted from literature was provided to the experts. They were asked to rate the criteria, using a 5-point Likert scale, on the importance that it would have on evaluating a building, based on R&M conditions. In addition, they were asked to submit their ideas about other factors not on the list. The accessibility criterion was proposed in this round of the Delphi method. In round 2, the factors that were proposed in the first round (accessibility), along with the primary factors (safety, health, proper utilisation, energy saving, economic saving, reliability, environment, citizenship rights, and comfort) extracted from the literature, were included in the questionnaire. In round 2, experts were asked to reconsider their judgement on the issues raised or to state their reasons for disagreement. In all rounds of the Delphi process, to determine the importance of the factors affecting the R&M of the building, the following scale was used, where 1 = very low impact (>1.00 and <1.80); 2 = low impact (>1.81 and <2.60); 3 = medium impact (>2.61 and <3.40); 4 = high impact (>3.41 and <4.20), and 5 = very high impact (>4.21 and <5.00). In round 3, criteria for comfort and citizenship items were introduced with "very low" and "low ratings" and were dropped. Consensus and non-consensus items rated "medium", "high", and "very high" in rounds 1 and 2 were provided to each panel member. Members were requested to rate these factors in terms of their importance in evaluating a building, based on R&M conditions. Statistical and qualitative feedback was provided to each expert in round 3. The outcome of round 3 indicated that there was a consensus (Tengan & Aigbavboa, 2017: 1972) among the experts regarding the building R&M system characteristics, stated in Table 4, and thus no need for round 4.

3.3 Analysis and interpretation of the data

3.3.1 Questionnaires analysis

Descriptive analysis was used for the respondents' profile information, in which the frequencies and percentages were generated and reported. The Kendall coordination coefficient was used after performing three rounds of the Delphi method to determine the degree of consensus among panel members. The validity and reliability of the questionnaires were calculated using Lawshe (for expert panel validity) and Cronbach's alpha (for questionnaire validity), respectively.

Content validity rate (CVR) was used to quantify the votes of the panel members.

Where "CVR" is the linear and direct conversion of panel group members who selected the phrase "required", denotes the number of specialists who answered the "required" option, and nE represents the total number of specialists. Ifthe calculated value is greater than the value in Table 2, the content validity of that item is accepted.

3 The CVRt differs from the CVR only in the notation. The "t" designates 'task' (Lawshe, 1975: 571).

Content valid ity index (CVI) was used to determine the validity of the questionnaires. The CVI represents the comprehensiveness of judgements about the validity or applicability of the final model, test, or tool.

"CVR" is the linear and direct conversion of the panel members who se lected the phrase "necessary", and "retained numbers" is the number of remaining items (Lawshe, 1975: 567-568). Table 2 shows the CVR results related to the numerical mean of the judgements and the results of acceptance or rejection of building maintenance system criteria.

3.33.2 Facto r andstrategy analysis

This research applied multi-criteria decision-making methods to prioritise the criteria for factors and strategies that are important to evaluate a building, based on R&M conditions. The multi-criteria decision-making process consists of four basic steps: identification and assessment, weighting, selection of the best option and sensitivity analysis, and selection of the final option. Multi-criteria decision-making is a suitable method fo analysiηg the complexities of issues that can be used as an efficient method for co mparative assessment of different options with respect t o multiple and contrasting aspects (Diakoulaki & Karangelis, 2007; Santoyo-Castelazo & Azapagic, 2014). One of the advantages of this method is to consider human preferences along with computational issues. Operations research techniques such as the multi-criteria decision-making tool (MCDM), which includes multi-criteria decision-making (MADM) and multi-objective d ecision-making (MODM) have been developed to assist decision makers for evaluating.

In this study, as part of MCDM, the SWARA decision-making method was used to analyse the factors and strategies that are important to evaluate a building, based on R&M conditions. In this method, the criteria are ranked b ased on value. Accordingly, the most important criterion is ranked first and the least important criterion is ranked last. The SWARA method provides for weighting the criteria in multi-criteria decision-making problems (Kersuliene, Zavadskas & Turskis, 2010: 245-250). Using the SWARA method, experts each consider their own opinions and information in decision-making (Ejadi et al., 2018: 4-5) and each decision maker is involved in assessing his/ her weight and rankings for ranking factors and in the negotiation stage that consists of all participants (Zarbakhshnia, Soleimani & Ghaderi, 2018). In the first step, the research criteria should be extracted from different sources and, in the next steps, these factors should be assessed and the dependent criteria should be removed, in order to finalise the set of criteria.

The flnal must be factors that are independent of each other. In the next steps, these factors are provided to the experts to determine their rank, whereupon they are placed in the SWARA method algorithm to extract their weight (Kersuliene et al., 2011).

3.3.2.Í Steps of the SWARA method

Step 1: The criteria are categorised in descending order based on expected objectives.

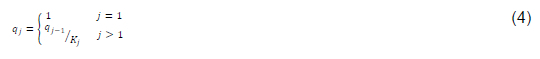

Step 2: From the second criterion, experts state the relative importance of criterion j in relation to the previous criterion and this performs for each specific criterion . This ratio is the comparative significance of the mean value, Sj.

Step 33: The coefficient k is determined as follows:

Step 4: Determine the recalculated weight as follows:

Step 5: The final weight of the assessment criteria is determined as follows:

Τhis s h ows the I i neage weight of the criterion j and indicates the number of criteria (Ka raba sevic , Stanujkic & Urosevic, 2015: 45-46).

In thi s stud y, a s part of MADM, the VIKOR method was used to evaluate and pri oritise three out of seven most widely used net R&M strategies in the industry.

VIKOR is a Serbian term meaning consensual solution and multi-criteria optimisation. This method was first introduced by Opricovic in 1998 and later develope d by Opricovic and Tzeng in 2004 (Opricovic & Tzeng, 2004: 47-49). The emphasis of this method is on ranking and selecting from a set of options and determining agreed solutions to the problem with conflicting criteria (Chen & Wang, 2009). The multi-criteria ranking index of this mathod istae d eg ree of proximity to the ideal option (Liu et al., 2014). In re0ent years, the VIKOR method and its development as a new solution to multi-criteria decision problems has received much attention. With the help of this method, different options can be ranked based on different criteria. In situations where the decision maker is not able to identify and express the advantages of an issue at the time of its initiation and design, this method can be consid ered an effective tool for decision-making (Talon, Boissier & Lair, 2008).

3.3 .2 . i i Steps of thoe VIKOR method

In a multi-criteria deois ion problem with n criteria and m options, the steps of th e implementation algorithm to select the best option using the VIKOR method are:

Step 1: Form a decision matrix and a weight vector of criteria.

Step 2: Norma l i se the d ec i s ion matrix using Equation (5).

Step 3: Determine the ideal positive point f* and negative f for each criterion.

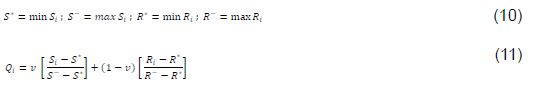

Step 4: Determine the utility (Si).

Step 5: Calculate the Vicker index (Q) according to equations (10) and (11).

Step 6: In th e final step of the Victor technique, the options are sorted into three groups from small to large, based on the values of R, Q, and S. The best option is to have the smallest Q if the following two conditions are met:

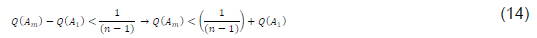

Condition one: If options A, and A2 are ranked first and second among m, then relation (12) must be established.

Condition two: Option A1 must be recognised as the top rank in at least one of the groups R and S. If the first condition is not met, both options will be the best option. If the second condition is not met, options A, and A2 are both selected as the top option.

Step 7: Ifcondition one is not established, a set of options will be selected as the top option.

The maximum value of m is calculated according to the following equation:

4. RESULTS AND DISCUSSION

4.1 Experts profile

Table 3 shows the composition and characteristics of panel members to determine the criteria. Most (41.6%) of the experts have construction expertise; 62.5% of the experts had a Ph.D. degree, and 37.5% of the experts had an M.Sc. degree.

4.2 Factor and strategy results and discussion

In this study, the Kendall coordination coefficient was used to determine the degree of consensus among panel members. In round 2, the Kendall coefficient was 0.581 and Cronbach's alpha coefficient was 0.831 in the questionnaires. In round 3, based on the average opinion of the experts (MS rating), the criteria that had little and very little effect in round 2 were removed and expert opinions were asked again about the importance of the criteria. Finally, in round 3, with mean score ratings above 3.41, eight (8) parameters were accepted as assessment criteria of maintenance system (see Table 4). The Kendall coordination coefficient for the members' responses to the order of the eight criteria is 0.603 and the Cronbach's alpha coefficient is 0.707, which has not grown significantly in two consecutive rounds and shows the consensus among the members. The difference between Kendall coefficient in rounds 2 and 3 was 0.022. In addition, professors and experts confirmed the apparent or formal validity of the questionnaires. Although Lawshe's proposed method states that the minimum number of members to determine the content validity is 4 people, in this study, 14 experts were selected to ensure the results. Then, by calculating the CVR, the content validity index of CVI = 0.80 was obtained, so the validity of the questions is confirmed (Lawshe, 1975: 567-571).

Considering the general consensus on the criteria raised in relation to the factors affecting R&M, in the next step, experts determined the importance of each criterion. Then to increase the accuracy using the SWARA method the weight of each parameter was assessed and finally the rank of each index was determined.

First, the criteria were ranked according to the opinion of experts and then the coefficient was calculated using the formula expressed in the third step (see 3.3.2.i). Then the weight and the final weight were recalculated based on the fourth and fifth steps (see 3.3.2.i), respectively, the results of which are shown in Table 5.

In this test, safety with the most important criterion with the rank of 1 and economic savings with the least important criterion was introduced. Examining the values in Table 5, it was observed that the rank of safety, health and environment criteria have a higher priority, which indicates the high importance of these criteria compared to other criteria. Since the data entered into the methods used were reviewed based on the experts' opinions, the results can be used for the building M&R system.

In the next step, using the SWARA method, the maintenance strategies of the building were ranked using the experts' opinions and based on its efficiency and application in the construction industry and the conditions of Iran, so that appropriate maintenance strategies were selected. Table 6 shows the results.

According to the results in Table 6, it was found that three strategies, namely emergency maintenance (EM), breakdown maintenance (BM), and corrective maintenance (CM), have the highest priority in the maintenance system of buildings. Therefore, these three strategies with higher priority are considered the main strategies of building R&M. By calculating the effective weight of each criterion by the SWARA method, in order to prevent the dependence of research results on the personal tastes and judgements of experts in the forward research approach, prioritisation and selection of appropriate maintenance and building strategies was determined using the VIKOR method (Zhang & Wei, 2013). The VIKOR method was used for this purpose, according to the weight of the criteria obtained for ranking and selecting the appropriate strategy for R&M of the building. Table 7 shows the results of the criteria weight and the ideal surface distance from the options.

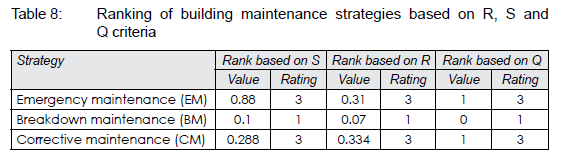

The ranking of building R&M strategies are arranged based on the values of three utility criteria (S, regret (R) and VIKOR index (Q) with size (v = 0.5) (see 3.3.2.ii). Table 8 shows the calculation results.

5. CONCLUSION AND RECOMMENDATIONS

Selecting appropriate R&M criteria for building assessment is a matter of strategic decision-making. Managers can prioritise and select the characteristics of the building maintenance system based on the decision-making methods described in this article. Multi-criteria decision models can be placed in the framework of the decision-making approach (principled, analytical, behavioural, and instructional). That is, managers who use definite non-fuzzy models use a guiding approach, and when they use probabilistic and fuzzy models, they use an analytical approach.

In this study, using the Delphi method, eight effective criteria in maintenance of buildings were identified and the impact of seven maintenance systems in the construction industry were ranked using multi-criteria decision-making techniques.

To select the appropriate strategy for R&M of buildings, the eight criteria were compared and ranked by experts on a 5-point Likert scale and then, using the SWARA method, the criteria were weighted as part of the process of selecting the best option among the options for better and more efficient decision-making. Thus, these methods were used to calculate the weights of decision-making criteria and ranking and final selection. By comparing the criteria, it was determined that the safety criterion has the highest priority and that the criteria of health, environment, and proper utilisation have the second to fourth ranks.

Finally, with the knowledge of the results of prioritisation of eight criteria, the VIKOR method was used to select the best appropriate building R&M strategy from the seven maintenance systems and it was found that the strategies emergency corrective maintenance (CM) and breakdown maintenance (BM) are the best strategies in the building R&M system. This allows engineers, specialists, and planners to decide on a strategy for the building maintenance system. This strategy should be determined according to the safety criteria as the highest priority. Its sub-criteria should be considered more carefully in the maintenance system. It is suggested that managers and maintenance specialists assess the buildings by determining sub-criteria based on the eight criteria, in order to ensure that the R&M process of the building moves in line with the predetermined goals. It is also suggested for further research, in order to reduce the method error and approach the models and more realistic methods, using fuzzy decision-making methods.

Conducting this study was accompanied by some limitations that can be pointed out: the lack of proper knowledge among those involved in the R&M of buildings, about the subject of the research, which made the work difficult for cooperation.

REFERENCES

Bagheri, F. & Makarizadeh, V. 2009. Analysis of building saving opportunities from economic and environmental perspectives. 7th National Conference on Energy (Energy Sustainability. Supply Security, Demand Management and Consumption Pattern Modification), Tehran, pp. 64-67. https://civilica.com/doc/92171. [in Farsi] [ Links ]

Bakhtiari, S., Dehghanizadeh, M. & Hosseinipour, S.M. 2014. Analysis of labor productivity and efficiency in cooperative sector: A case study of industrial cooperatives in Yazd province. Journal of Management and Development Process, 27(3), pp. 45-73. [in Farsi] [ Links ]

Bowersox, D. & Closs, D. 1996. Logistical management: The integrated supply chain management. New York: Mc Graw-Hill. [ Links ]

Brady, S.R. 2015. Utilizing and adapting the Delphi method for use in qualitative research. International Journal of Qualitative Methods, 14(5), pp. 1-6. https://doi.org/10.1177/1609406915621381 [ Links ]

Caballé, N.C., Castro, I.T., Pérez, C.J. & Lanza-Gutiérrez, J.M. 2015. A condition-based maintenance of a dependent degradation-threshold-shock model in a system with multiple degradation processes. Reliability Engineering & System Safety, 134, pp. 98-109. https://doi.org/10.1016/j.ress.2014.09.024 [ Links ]

Chen, L.Y. & Wang, T.C. 2009. Optimizing partners' choice in IS/IT outsourcing projects: The strategic decision of fuzzy VIKOR. International Journal of Production Economics, 120(1), pp. 233-242. https://doi.org/10.1016/j.ijpe.2008.07.022 [ Links ]

Clayton, M.J. 1997. Delphi: A technique to harness expert opinion for critical decision-making tasks in education. Educational Psychology, 17(4), pp. 373-386. https://doi.org/10.1080/0144341970170401 [ Links ]

Das, K., Lashkari, R.S. & Sengupta, S. 2007. Machine reliability and preventive maintenance planning for cellular manufacturing systems. European Journal of Operational Research, 183(1), pp. 162-180. https://doi.org/10.1016/j.ejor.2006.09.079 [ Links ]

Das, R. & Nakano, M. 2021. A multi-criteria decision-making model using socio-technical attributes for transportation bridge maintenance prioritisation. International Journal of Construction Management, ahead of print, pp. 1-7. https://doi.org/10.1080/15623599.2021.1899560 [ Links ]

Dhillon, B.S. 2008. Mining equipment reliability. In: Pham, H. (Ed.). Mining equipment reliability maintainability and safety. London: Springer, pp. 57-70. https://doi.org/10.1007/978-1-84800-288-3_4 [ Links ]

Diakoulaki, D. & Karangelis, F. 2007. Multi-criteria decision analysis and cost-benefit analysis of alternative scenarios for the power generation sector in Greece. Renewable and Sustainable Energy Reviews, 11(4), pp. 716-727. https://doi.org/10.1016/j.rser.2005.06.007 [ Links ]

Do, P., Voisin, A., Levrat, E. & Iung, B. 2015. A proactive condition-based maintenance strategy with both perfect and imperfect maintenance actions. Reliability Engineering & System Safety, 133, pp. 22-32. https://doi.org/10.1016/j.ress.2014.08.011 [ Links ]

Dolphin, W.S.Y., Alshami, A.A.M., Tariq, S., Boadu, V., Mohandes, S.R, Ridwan, T. & Zayed, T. 2021. Effectiveness of policies and difficulties in improving safety performance of repair, maintenance, minor alteration, and addition works in Hong Kong. International Journal of Construction Management, in press, pp. 1-30. https://doi.org/10.1080/15623599.2021.1935130 [ Links ]

Ejadi Maghsoudi, A., Saghaei, A. & Hafez Al-Kitab, A. 2018. Evaluation and ranking of contractors in massive construction projects using Sawara-Multi Mora integrated decision-making method. 11th International Conference on Accounting and Management and 8th International Conference on Entrepreneurship and Open Innovation; Tehran. https://civilica.com/doc/777773. [in Farsi] [ Links ]

Golabchi, M. & Amiri, M. 2015. Project safety management: With the approach of construction projects. Kãrgar, Iran: Pars University of Architecture and Art. ISBN: 9786009482528. [in Farsi] [ Links ]

Golchi, A.H., Gholami, J., Safavi, S.A. & Al Hashem, R.S.A. 2018. New approach in building maintenance and repair. 12th National Conference on Maintenance and Repairs, Tehran. https://civilica.com/doc/844897/. [in Farsi] [ Links ]

Hatami, H., Razavi, S.M., Eftekhari Ardebili, H. & Majlessi, F. 2019. Comprehensive public health book, chapter 2.Tehran: Arjmand Book, 3(1), pp. 48-57. [in Farsi] [ Links ]

Karbasian, M., Ghandehary, M. & Abedi, S. 2011. Optimization of reliability centered maintenance based on maintenance costs and reliability with consideration of location of components. Production and Operations Management,1(1), pp. 19-30. [ Links ]

Kameli, M., Majrouhi Sardroud, J., Hosseinalipour, M., Behruyan, M. & Ahmed, S.M. 2020. An application framework for development of a maintenance management system based on building information modeling and radio-frequency identification: Case study of a stadium building. Canadian Journal of Civil Engineering, 47(6), pp. 736-748. https://doi.org/10.1139/cjce-2019-0107 [ Links ]

Karabašević, D., Stanujkić, D. & Urošević, S. 2015. The MCDM model for personnel selection based on SWARA and ARAS methods. Management, 20(77), pp. 43-52. DOI: 10.7595/management.fon.2015.0029 [ Links ]

Katabi, A. & Almasian, F. 2016. Review of maintenance and repair strategies in construction projects. 3rd International Conference on Architecture, Structure and Civil Engineering. 17-20 August, Norwegian Research Institute of Science and Technology, Norway. https://civilica.com/doc/562527. [in Farsi] [ Links ]

Kelly, A. 2006. Managing maintenance resources. Amsterdam: Elsevier Butterworth-Heinemann. [ Links ]

Kersuliene, V., Zavadskas, E.K. & Turskis, Z. 2010. Selection of rational dispute resolution method by applying new step-wise weight assessment ratio analysis (SWARA). Journal of Business Economics and Management, 11(2), pp. 243-258. https://doi.org/10.3846/jbem.2010.12 [ Links ]

Kersuliene, V., Zavadskas, E.K. & Turskis, Z. 2011. Integrated fuzzy multiple criteria decision-making model for architect selection. Technological and Economic Development of Economy, 17(4), pp. 645-666. https://doi.org/10.3846/20294913.2011.635718 [ Links ]

Kheradranjbar, M., Mohammadi, M.A. & Rafiee, S. 2022a. Evaluating the efficiency of building repair and maintenance system using data envelopment analysis method. JSCE, 8(4), Serial Number 53. DOI:10.22065/JSCE.2021.274367.2377. [in Farsi] [ Links ]

Kheradranjbar, M., Mohammadi, M.A. & Rafiee, S. 2022b. Prioritize building maintenance system strategies using a combination of multi-criteria decision-making methods. JSCE. Ahead of print. Accepted manuscript. Available Online. 10.22065/JSCE.2022.311579.2611. [in Farsi] [ Links ]

Khodayari, M. & Abdollahzadeh, S. 2018. An approach to determine appropriate multi-product maintenance policies using multi-criteria simulation and decision-making. Industrial Management, 10(2), pp. 279-296. DOI: 10.22059/imj.2018.248555.1007365. [in Farsi] [ Links ]

Lawshe, C.H. 1975. A quantitative approach to content validity. Personnel Psychology, 28(4), pp. 563-575. https://doi.org/10.1111/j.1744-6570.1975.tb01393.x [ Links ]

Linstone, H.A. & Turoff, M. 2002. The Delphi method: Techniques and application. Reading, MA: Addison-Wesley Pub. Co., Advanced Book Program. [ Links ]

Liu, H.C, You, J.X, Zhen, L. & Fan, X.J. 2014. A novel hybrid multiple criteria decision-making model for material selection with target-based criteria. Materials & Design, 60, pp. 380-390. https://doi.org/10.1016/j.matdes.2014.03.071 [ Links ]

Martin, Z., Tognetti, B. & Hill, H. 2016. Navigating historic to present US model code provisions for the repair of damaged buildings. Practice Periodical on Structural Design and Construction, 21(1), article numer: 4015013. https://doi.org/10.1061/(ASCE)SC.1943-5576.0000265 [ Links ]

Mashayekhi, A.N, Farhangi A.A., Mo'meni, M. & Ali Doosti, S. 2005. Investigating the critical factors affecting its application in governmental organizations of Iran: A Delphi survey. Quarterly Modarres Human Sciences, (Tome 42) Management, pp. 191-231. [in Farsi] [ Links ]

Mishra, S., Vanli, O.A., Kakareko, G. & Jung, S. 2019. Preventive maintenance of wood-framed buildings for hurricane preparedness. Structural Safety, 76, pp. 28-39. https://doi.org/10.1016/j.strusafe.2018.07.002 [ Links ]

Moriconi, G. & Naik, T.R. 2010. Monitoring system to provide assurance for maintenance of structures. Practice Periodical on Structural Design and Construction, 15(1), pp. 4-8. https://doi.org/10.1061/(ASCE)SC.1943-5576.0000019 [ Links ]

Naderian, M.A. & Haji Mirzaei, S.M.A. 2007. Pathology of saving programs in Iran. Energy Economics, 90&91, pp. 22-44. [in Farsi] [ Links ]

Okoli, C. & Pawlowski, S.D. 2004. The Delphi method as a research tool: An example, design considerations and applications. Information & Management, 42(1), pp. 15-29.1 https://doi.org/10.1016/j.im.2003.11.002 [ Links ]

Opricovic, S. & Tzeng, G.H. 2004. Compromise solution by MCDM methods: A comparative analysis of VIKOR and TOPSIS. European Journal of Operational Research, 156(2), pp. 445-455. https://doi.org/10.1016/S0377-2217(03)00020-1 [ Links ]

Rajendran, S. 2006. Sustainable construction safety and health rating system. Civil construction and environmental engineering. Ph.D. thesis. Oregon State University, Corvallis, Oregon. [ Links ]

Santoyo-Castelazo, E. & Azapagic, A. 2014. Sustainability assessment of energy systems: Integrating environmental, economic and social aspects. Journal of Cleaner Production, 80, pp. 119-138. https://doi.org/10.1016/j.jclepro.2014.05.061 [ Links ]

Sarmadi, M. & Masoumifard, M. 2016. A study on the role of ICT-based education in decreasing environmental challenges (with emphasis on urban environment). Scientific Journal of Environmental Education and Sustainable Development, 4(2), pp. 38-50. [in Farsi] [ Links ]

Shafiee, M. 2015. Maintenance strategy selection problem: An MCDM overview. Journal of Quality in Maintenance Engineering, 21(4), pp. 378-402. https://doi.org/10.1108/JQME-09-2013-0063 [ Links ]

Sherafat, A., Karimi, F. & Davoodi, S.M.R. 2017. Proposing a comprehensive maintenance model using meta-synthesis. Journal of Industrial Management, 9(4), pp. 691-734. [in Farsi] [ Links ]

Shi, H. & Zeng, J. 2016. Real-time prediction of remaining useful life and preventive opportunistic maintenance strategy for multi-component systems considering stochastic dependence. Computers & Industrial Engineering, 93, pp. 192-204. https://doi.org/10.1016/j.cie.2015.12.016i [ Links ]

Skulmoski, J., Hartman, T. & Krahn, J. 2007. Delphi method for graduate research. Journal of Information Technology Education, 6(1), pp. 1-21. https://doi.org/10.28945/199 [ Links ]

Sourani, A. & Sohaila, M. 2014. The Delphi method: Review and use in construction management research. International Journal of Construction Education and Research, 11(1), pp. 1-23. https://doi.org/10.1080/15578771.2014.917132 [ Links ]

Talon, A., Boissier, D. & Lair, J. 2008. Service-life assessment of building components: Application of evidence theory. Canadian Journal of Civil Engineering, 35(3), pp. 287-300. https://doi.org/10.1139/L07-109 [ Links ]

Tengan, C. & Aigbavboa, C. 2017. A Delphi technique approach towards the need for and relevance of construction project monitoring and evaluation practices. Journal of Construction Project Management and Innovation, 7 SI(1), pp. 1968-1976. https://hdl.handle.net/10520/EJC-af2ee106f [ Links ]

Urosevic, S., Karabasevic, D., Stanujkic, D. & Maksimovic, M. 2017. An approach to personnel selection in the tourism industry based on the SWARA and the WASPAS methods. Economic Computation & Economic Cybernetics Studies & Research, 51(1), pp. 75-88. [ Links ]

Wang, L., Chu, J. & Wu, J. 2007. Selection of optimum maintenance strategies based on a fuzzy analytic hierarchy process. International Journal of Production Economics, 107(1), pp. 151-163. https://doi.org/10.1016/j.ijpe.2006.08.005 [ Links ]

Zaim, S., Turkyilmaz, A., Acar, M.F, Al-Turki, U. & Demirel, O.F. 2012. Maintenance strategy selection using AHP and ANP algorithms: A case study. Journal of Quality in Maintenance Engineering, 18(1), pp. 16-29. https://doi.org/10.1108/13552511211226166 [ Links ]

Zarbakhshnia, N., Soleimani, H. & Ghaderi, H. 2018. Sustainable third-party reverse logistics provider evaluation and selection using fuzzy SWARA and developed fuzzy COPRAS in the presence of risk criteria. Applied Soft Computing, 65, pp. 307-319. https://doi.org/10.1016/j.asoc.2018.01.023 [ Links ]

Zhang, N. & Wei, G. 2013. Extension of VIKOR method for decision-making problem based on hesitant fuzzy set. Applied Mathematical Modelling, 37(7), pp. 4938-4947. https://doi.org/10.1177/1748006X19850702 [ Links ]

Zohrehei, I. & Mohtashami, A. 2020. A novel method for selecting optimum maintenance strategy using Fuzzy Analytic Network Process and Fuzzy Multi-Choice Programming approach. Journal of Industrial Management Perspective Faculty of Humanities, 15(51), pp. 31-50. [in Farsi] [ Links ]

Received: October 2021

Peer reviewed and revised: March 2022

Published: June 2022

DECLARATION: The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

1 Vlse Kriterijumsk Optimizacija Kompromisno Resenje.