Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Acta Structilia

On-line version ISSN 2415-0487

Print version ISSN 1023-0564

Acta structilia (Online) vol.28 n.1 Bloemfontein 2021

http://dx.doi.org/10.18820/24150487/as28i1.3

RESEARCH ARTICLES NAVORSINGSARTIKELS

Implementation of the value re-engineering concept in the Nigerian construction industry: exploratory study

Dr Ibrahim JibrinI; Prof. Winston ShakantuII

IPhD student, Department of Construction Management, Faculty of Engineering, the Built Environment and Technology, Nelson Mandela University, PO Box 77000, Port Elizabeth, 6031, South Africa. Phone: (+234) 8036481755, email: <dabban53@gmail.com>

IIDepartment of Construction Management, Nelson Mandela University, Port Elizabeth, South Africa Email: <winston.shakantu@mandela.ac.za> ORCID: https://orcid.org/0000-0002-4334-5004

ABSTRACT

Value Re-Engineering (VRE) is considered a critical analysis and radical redesign of existing construction processes to achieve breakthrough improvements in performance measures. The dissatisfaction of customers' value offered by the Nigerian Construction Industry (NCI) necessitated a rethink of a new approach to the customers' need. Hence, this article aims to explore the implementation of VRE in the NCI as a possible solution for the industry to resolve the challenges of customers' dissatisfaction. A qualitative research approach was used to identify incremental adoption for the implementation of VRE in the NCI. Qualitative data was collected, using a structured tick-box questionnaire interview schedule with 34 key stakeholders in the NCI, including seven directors, nine project managers, nine quantity surveyors, and nine engineers. The tick-box interview schedule explored the level of importance of the activities of the implementation process in the eight phases (steps) for VRE take-off in the NCI. Using QSR Nvivo 12 (a qualitative content analysis tool), the tick-box data was given a numerical score, on a 5-point Likert scale, so that the data could be rated and reported quantitatively. This included frequencies and percentages. The exploratory research findings indicate that there is a significant need for the process to be re-engineered and for establishing a VRE organisational structure critical to achieving the successful implementation and adoption of VRE. Other most important activities for the successful implementation of VRE include evaluating the impact of new technologies; monitoring employee attitudes, customer perceptions, and supplier responsiveness, as well as identifying disconnects (anything that prevents the process from achieving the desired results and, in particular, information transfer between organisations or people). Identifying the customers' needs by the NCI helps create the market value of the product being produced by the industry players. On the other hand, this improves the global competitive market for the industry by adopting the radical redesign process for the industry.

Keywords: Construction industry, implementation, incremental adoption, Nigeria, Value Re-Engineering

ABSTRAK

Waarde-ingenieurswese (VRE) word beskou as 'n kritieke ontleding en radikale herontwerp van bestaande konstruksieprosesse om deurbraakverbeterings in prestasiemaatreëls te bewerkstellig. Die ontevredenheid oor kliënte se waarde wat die Nigeriese konstruksiebedryf (NCI) bied, het 'n herbesinning oor 'n nuwe benadering tot die behoeftes van klante nodig gemaak. Daarom beoog hierdie artikel om die implementering van VRE in die NCI te ondersoek as 'n moontlike oplossing vir die bedryf om die uitdagings van klante se ontevredenheid op te los. 'n Kwalitatiewe navorsingsbenadering is gebruik om inkrementele aanneming vir die implementering van VRE in die NCI te identifiseer. Kwalitatiewe data is versamel met behulp van 'n geskeduleerde onderhoudskedule vir die afmerkvraelys met 34 belangrike belanghebbendes in die NCI, waaronder sewe direkteure, nege projekbestuurders, nege bourekenaars en nege ingenieurs. In die afmerk-onderhoudskedule is die belangrikheid van die aktiwiteite van die implementeringsproses in die agt fases (stappe) vir VRE-bekendstelling in die NCI ondersoek. Met behulp van QSR Nvivo 12 ('n instrument vir kwalitatiewe inhoudsanalise) is die afmerk-data 'n numeriese waarde op 'n 5-punt Likert-skaal gegee, sodat die data kwantitatief beoordeel en gerapporteer kon word. Dit het frekwensies en persentasies ingesluit. Die verkennende navorsingsbevindinge dui aan dat daar 'n beduidende behoefte bestaan vir die herstrukturering van die proses en die vestiging van 'n VRE-organisasiestruktuur wat noodsaaklik is vir die suksesvolle implementering en aanvaarding van VRE. Ander belangrikste aktiwiteite vir die suksesvolle implementering van VRE sluit in die evaluering van die impak van nuwe tegnologieë; monitering van houdings van werknemers, persepsies van klante en reaksie op verskaffers, asook die identifisering van ontkoppelings (enigiets wat verhoed dat die proses die gewenste resultate behaal, en veral inligtingoordrag tussen organisasies of mense). Die identifisering van die klante se behoeftes deur die NCI help om die markwaarde te skep van die produk wat deur die bedryfsrolspelers vervaardig word. Aan die ander kant verbeter dit die wêreldwye mededingende mark vir die bedryf deur die radikale herontwerpproses vir die bedryf aan te neem.

Sleutelwoorde: Implementering, inkrementele aanneming, konstruksiebedryf, Nigerië, waarde-ingenieurswese

1. INTRODUCTION

Project delays, cost overruns, poor quality work, as well as poor health, safety and environmental records signal that there is room for improvement in the Nigerian Construction Industry (NCI) (Jusoh & Kasim, 2017: 82). Steven (2014) as well as Ding, Jiang, Ng and Zhu (2017: 456) elucidate that, due to clients' dissatisfaction with the services delivered by the construction industry, major reforms are required in the construction industry's process and structure.

The adoption and implementation of the Value Re-Engineering (VRE) technique in the construction industry would help boost the application techniques such as Lean Construction (LC), Total Quality Management (TQM), Building Information Modelling (BIM), Value Management/Value Engineering (VM/VE), and so forth (Ding et al., 2017: 457). Asikhia and Awolusi (2015: 2) reiterate that VRE is considered a critical analysis and radical redesign of existing construction processes to achieve breakthrough improvements in performance measures. However, hardly any research focuses on VRE in the NCI, especially the incremental adoption and implementation process that improves customer value offering. Therefore, a wide gap has been identified in the VRE implementation in the NCI. VRE is a new way of thinking that offers potential solutions, and it is slowly being included as part of standard industry working. Customers' dissatisfaction with value offered by the NCI requires a new approach to the customers' needs (Safa, Sabet, MacGillivray, Davidson, Kaczmarczyk, Haas, Gibson & Rayside, 2015: 625).

Consequently, the call for the incremental adoption and implementation of VRE in the NCI would be a breakthrough solution for the industry to resolve the challenges of customers' dissatisfaction faced in terms of escalating budget, delay in delivery time, and poor quality of project delivery, leading to building collapse (Soares, 2013: 2). Incremental adoption of VRE to construction process re-engineering by the NCI is to learn as much as possible from other industries that have had to respond to massive cultural changes (Ashworth, 2012: 73). Yahaya (2020: 7) attributed some of the challenges faced in the adoption and implementation of VRE in the NCI to lack of awareness and derived benefits obtained using the new technique by the stakeholders in the industry. However, the innovation aspect of VRE, especially the adoption and implementation processes, is overlooked, and very little is understood in the NCI. It is, therefore, important to examine the incremental adoption of VRE in the construction industries. This article explores the importance level of incremental adoption and implementation of VRE, in order to improve the implementation process in the NCI.

2. LITERATURE REVIEW

To understand how the VRE can work for the NCI, it is essential to know the type of value techniques presently used by the general construction industry, namely LC, BIM, TQM and VM/VE.

2.1 Construction value techniques

2.1.1 Lean construction

The LC process is a derivative of the lean manufacturing process. It is concerned with the elimination of waste activities and processes that create no added value (Ashworth, 2012: 192). Ashworth (2012: 192) further expresses that LC is a philosophy about managing and improving the construction process to profitably deliver what the customer and the construction client require. Huzaimi, Jamil & Syazli (2016: 634) view LC as promises resulting in managing the construction process and achieving the project's goals by eliminating waste.

Collaboration and continuous improvement through stakeholder involvement enable team members to identify opportunities for eliminating the activities that do not add value (Meng, 2012: 189; Andrew & Sarhan, 2013: 24). LC is about achieving a balanced use of people, materials, and resources, and facilitating an organisation to reduce costs, eliminate wastes, and deliver projects on time. Marhani, Jaapar, Azmi and Bari (2012: 87) advocate that LC is aimed at reducing waste, increasing productivity, as well as health and safety in fulfilling the client's requirements of the construction industry.

The cost, duration and quality of construction project delivery improved greatly as a result of LC (Sacks, Koskela, Dave & Owen, 2010: 972; Tezel & Nielsen, 2013: 237). Subsequently, LC has been applied in the UK, the USA, Japan and some other countries (Sacks et al., 2010; Sadreddini, 2012: 29). LC is about smooth running operations flowing effectively, while optimising resource usage and viewing projects as practising sustainability, even at a more detailed level (Fazli, 2011: 33). According to Harmon (2014: 477), LC represents a separate methodology that focuses on eliminating waste from process flows and is now often considered to be one of the tools that Six Sigma teams (members from the executive leadership committee of a company) ought to employ.

2.1.2 Building information modelling

BIM is a digital representation of the building process to facilitate the exchange and interoperability of information in digital format (Jupp & Awad, 2018: 361). BIM represents a fundamental change for individual disciplines and in the construction industry as a whole (Arayici & Aouad, 2011: 189). According to Coates, Arayici, Koskela, Kagioglou, Usher, and O'Reilly (2010: 8) as well as Arayici and Coates (2012: 179), owners are starting to force architects and other design professionals, construction managers and construction companies to adopt BIM. BIM is rapidly transforming the design and the construction industry worldwide. BIM individually has been adopted in a great number of applications such as supply chain management. BIM plug-in can serve as a supporting tool for planning and decision-making in logistics and supply chain management in the construction industry (Chen & Nguyen, 2019: 301).

Furthermore, Tomek and Kalinichuk (2015: 563) show that the BIM integrated product and process model facilitate improvements in the construction process, particularly with respect to collaborative design, project coordination, reduction in project duration, reduction in costs, claims and disputes, as well as improvements in product quality.

Chen, Liu and Hua (2017: 177) posit that BIM has been considered a possible solution to common problems in the construction industry, such as rework and slow delivery, as well as an innovative resource providing potential competitive advantage for construction organisations. The adoption of BIM in a construction organisation cannot always guarantee the expected positive value for the organisation, whether the structure of BIM technology fits the business process of a construction organisation during BIM implementation, or during the interaction between BIM technology and the VE of a construction organisation that create value at the process level (Arayici & Coates, 2012: 179).

2.1.3 Total quality management

TQM is a management philosophy and company practices that aim to harness the human and material resources in the construction industry as the most effective way to achieve the construction industry objectives (Lau, Li, Tang & Chau, 2016: 561). Iruobe, Ojambati, Akinpade and Iruobe (2012: 345) stated that TQM consists of a set of systematic activities carried out by the entire construction industry to effectively and efficiently achieve its objectives, thereby providing products and services at a level of quality that satisfies customers at the appropriate time and price. TQM not only leads to increased productivity, higher standards, improved systems and procedures, as well as greater motivation and increased public satisfaction for the construction industry operatives. TQM also seeks to reduce costs and ensure savings by the construction industry players (Naidoo & Reddy, 2008: 38).

2.1.4 Value management/value engineering

VM addresses the value process during the concept, definition, implementation and operation phases of a construction project. It encompasses a set of systematic and logical procedures and techniques to enhance construction project value throughout the life of the facility (Akaka, Vargo & Lusch, 2013: 2). VM embraces the whole value process and includes value planning, VE and value reviewing (Atabay & Galipogullari, 2013: 40). The VM approach offers a crucial method for the client to achieve a better built environment and a good opportunity to encourage upgrading in the construction process (Al-Yami & Price, 2006: 2). According to Olanrewaju (2013: 2), the VM approach reduces the risk of project failure, lowers cost, shortens projects schedules, improves quality, functions, and performance, and ensures high reliability and safety.

The concept of VE is the reduced cost of products or services involving engineering principles (Harini & Widyarti, 2018: 75). These techniques attempt to achieve at least the same quality as planned at minimum cost. VE is the most appropriate technique to regulate value in construction projects, as other techniques focus on time and quality rather than value (Karunasena & Gamage, 2017: 80). Arivazhagan, Partheeban, Guru and Priya Rachel (2017: 65) contend that VE is a systematic method to raise the value of goods, products and services by undertaking an investigation of intention. VE gets closer to cost control, because it looks at ways to reduce costs on specific items or activities (Atabay & Galipogullari, 2013: 39). However, it does not look at the total project picture or check the daily performance; it focuses only on specific items in the design, procurement or construction area.

2.2 Adoption and implementation of VRE in the construction industry

Eke and Adaku (2014: 116) emphasise that industries can operate proactively by adopting the VRE process, in order to achieve remarkable improvement in their organisational performance. According to Madane and Joshi (2018: 1844), incremental adoption and implementation of VRE can be applied to any organisation, company or industry to enhance their corporation and bring about the desired change.

For the construction industry, effective execution of Process Re-engineering (PR) significantly enhances the industry approach that adds to the competitive advantage of such industry (Akam, Okeke, Kekeocha & Onuorah, 2018: 15). Similarly, Dachyar and Sanjiwo (2018: 2) emphasise that the study of PR is a veritable tool to enhance employee satisfaction, teamwork and cooperation, quality of service delivery as well as attainment of organisational strategic goals.

Incremental adoption of VRE implementation is considered an efficient solution of redesign in the construction industry processes and activities (Sungau, Ndunguru & Kimeme, 2013: 210). Accordingly, Omidi and Khoshtinat (2016: 430) reaffirmed that the industries become the object of permanent transformations after the incremental adoption and implementation of VRE. However, Eke and Adaku (2014: 116) argue that, in countries where VRE is incrementally adopted and implemented, the construction industry markets of such countries were reshaped greatly.

A review of literature revealed five key adoption phases of the VRE implementation process, namely preparing for re-engineering; mapping and analysing process; designing the process; implementing the re-engineered process, and improving continuously (Emerie-Kassahun & Molla, 2013: 575).

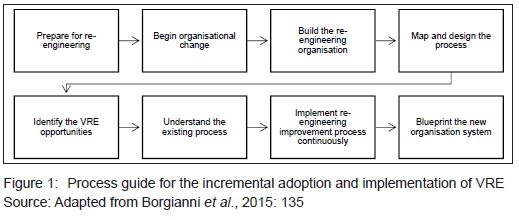

Preparing VRE for incremental adoption and implementation in the construction industry is done in phases. The implementation begins with the way in which industries try to adopt the process that makes it easy and convenient for its operation, in order to achieve the customer desired value (Lilian, Uzochukwu & Francisca 2015: 24). Figure 1 shows the process guide for the incremental adoption and implementation of VRE in the construction industry: prepare for organisational re-engineering; begin organisational change; build the re-engineering organisation; map and design the process; identify the VRE opportunities; understand the existing process; implement re-engineering improvement process continuously, and blueprint the new organisation system (Borgianni, Cascini & Rotini, 2015: 135).

During the incremental adoption and implementation phase, roles and responsibilities are designed to provide the quality of particular functions within the construction industry (Chen, Yang & Tai, 2016: 249).

However, the organisational structure for the construction industry to those of the project management team in VRE enhancing customer value satisfaction of the work when incremental adoption and implementation of VRE in the construction industry/firm are jointly executed (Ilin, Kalinina, Levina & Iliashenko, 2016: 2). However, the approach can be adopted as for full-cycle construction in the construction industry (Khrustalev, 2015; Ilin et al., 2016: 3).

VRE implementation is a consecutive process encompassing key implementation activities that are needed to redesign the customer value process (Sikdar & Payyazhi, 2014: 980). Therefore, the incremental adoption and implementation of VRE in the construction industry for each of these identified VRE phases will be elicited in this study through empirical investigation.

3. RESEARCH METHODOLOGY

3.1 Research design

The purpose of this research was to assess the level of incremental adoption and implementation of VRE in the NCI. Following the phenomenological paradigm (a form of qualitative research that focuses on the study of an individual's lived experiences), this study used a qualitative research approach (Creswell, 2014: 14). This approach allows for the use of structured interviews, enabling researchers to generalise their findings from a sample of a population (Mustafa, 2012: 191; Creswell, 2014). During the interviews, a tick-box questionnaire (answers were ticked by the researcher) collected perceived experiences from interviewees on VRE adoption and implementation in their firms. A qualitative research approach supports the use of checkboxes to measure data (Mathers, Fox & Hunn, 2009: 20). The qualitative data was given a numerical score, on a Likert scale, so that the data can be analysed quantitatively and presented by means of descriptive statistics (Brown, 2011: 11; Saidu, 2016: 157). For this study, the frequencies were used to calculate percentages of the importance of the VRE adoption and implementation activities (Bhattacharyya & Johnson, 2014).

3.2 Population and sampling methods

The population of the study included 30 (private or public) construction Arms in Abuja, Nigeria, that are listed in the Federation of Construction Industry (FOCI) and licensed by the Corporate Affairs Commission (CAC) to operate in the Nigerian built environment under the Companies and Allied Matters Act 1990, and been duly registered as an agent for VAT collection under "the Value Added Tax (VAT) Decree No. 102 of 1993" (NBS, 2019).

Using purposive sampling, nine of the 30 construction companies with a capital base of USD4.6 million (R79.9 million) and above were selected based on the premise that they execute building and civil engineering work. Purposive sampling enables the researcher to select participants (stakeholders) from 10-15 different construction firms based on perceived experience and survival in business for investigation that is likely to give the ideal information on VRE adoption and implementation as a result of their experience (Leedy & Ormrod, 2014: 154). From the nine construction companies, 34 key stakeholders, including seven directors, nine project managers, nine quantity surveyors and nine engineers, were identified as the sample to participate in the study. According to Leedy and Ormrod (2014: 147), the typical research sample size of the phenomenological study ranges between Ave and 25 participants in structured interviews.

3.3 Data-collection methods

From 2 December 2019 to 15 March 2020, the researcher conducted face-to-face structured interviews with the 34 participants, in order to collect data from construction firms that execute building and civil engineering work in Abuja, Nigeria. The interviews took place mainly at the interviewee's offices and lasted from 45 to 75 minutes.

Based on the process guide for the incremental adoption and implementation of VRE (see Figure 1), the structured interview guide contained eight constructs (different stages of adoption and implementation) with a total of 67 items (activities for all the stages) that made up the phase adoption and implementation. To assess how important the implementation activities are in VRE in the NCI, the interviewees were requested to indicate which of the 67 items were considered in their firms. All items considered were ticked off on the interview guide list.

At the start of the interviews, the researcher stated the purpose of the research, and guaranteed that the information given by the respondents would be treated as confidential and that no names would be mentioned in the research (Gray, 2009: 69). This was to ensure a true reflection of the respondents' views and to meet the ethical criterion of confidentiality (Gray, 2009: 73).

3.4 Data analysis and interpretation of findings

QSR Nvivo 12, a qualitative content analysis tool, was used to analyse and interpret the collected tick-box data (QSR International, 2021). The tick-box data was given a numerical score, on a 5-point Likert scale, so that the data could be rated quantitatively, based on cut-off points, as highlighted by Saidu (2016: 157). For this study, the cut-off points, expressed in frequencies, are further converted to percentages to calculate the importance level of the VRE adoption and implementation activities in the NCI. Likert-scale ratings are effective where numbers can be used to quantify the results of measuring behaviours, attitudes, preferences, and even perceptions (Wegner, 2012: 11).

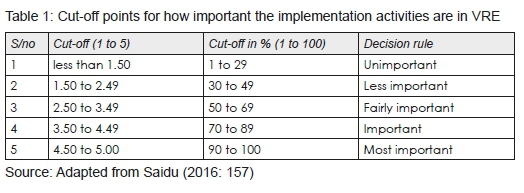

For the purposes of analysis (see Table 1), it is important to note that the following scale measurement was used regarding cut-off point percentages, where 1 = unimportant (1% to 29%); 2 = less important (30% to 49%); 3 = fairly important (50% to 69%); 4 = important (70% to 89%), and 5 = most important (90% to 100%). Data was presented using frequencies and cutoff point percentages to report the results for the four interview groups: D (7); PM (9); QS (9); E (9).

3.5 Limitations

The study is limited to the implementation of VRE in the NCI, focusing on both private and public construction companies executing building and civil engineering work located in Abuja. It can be noted that the study was not conducted across Nigeria; therefore, the findings cannot be generalised.

4. RESULTS AND DISCUSSION

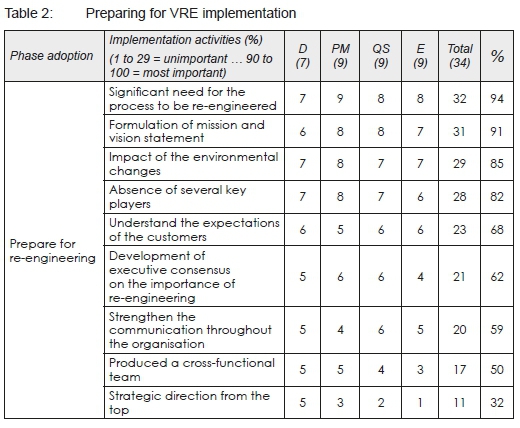

4.1 Preparation for value re-engineering implementation

In preparation for VRE implementation (see Table 2), nine implementation activities are involved in this phase. With ratings above 90%, the significant need for the process to be re-engineered (94%) and the formulation of mission or vision statements (91%) are the most important activities in preparing for incremental adoption and implementation of VRE. These results are validated by the findings of Sungau et al. (2013: 5) that the process of re-engineering required the critical identification of mission and vision of the area to be re-engineered. This indicates that certain reasons must arise that will require the need for change before the mission or vision are accomplished. Lilian et al. (2015: 23) argue that the impact of environmental changes (85%) and the absence of several key players that will implement VRE techniques (82%) are important aspects to consider while adopting and implementing VRE in any construction organisation.

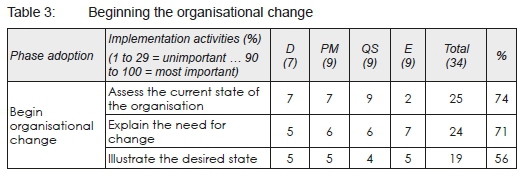

4.2 Begin the organisational change

Beginning the organisational change as shown in Table 3 consists of three implementation activities. Assessing the current state of the organisation (74%) and explaining the need for change (71%) were rated as important activities in preparing for incremental adoption and implementation of VRE. These results are in line with the findings of llin et al. (2016: 8) which indicated that commencing the redesign process in construction Arms will require reasons for the need and the current operation system and why the change. According to Khrustalev (2015: 4), illustrating the desired state for organisational change is deemed to be fairly important in incremental adoption and implementation when beginning the organisational change for VRE process in construction firms.

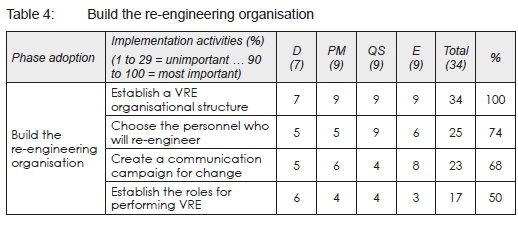

4.3 Build the re-engineering organisation

Table 4 indicates that, with a rating of 100%, establishing a VRE organisational structure is the most important activity required in building the re-engineering organisation for VRE incremental adoption and implementation. It is also pertinent that choosing the personnel who will re-engineer is an important activity in building the re-engineering organisation for the new system. Llin et al. (2016: 8) state that this forms the basic process of restructuring and requires specialist ideas in achieving the redesign process. However, creating a communications campaign for change and establishing the roles for performing VRE in the construction industry are fairly important (Khrustalev, 2015: 4). Communication is the centre to all activities in the industry, as it drives the engine of growth in the industry. Using a communication campaign cannot be ignored when redesigning the process.

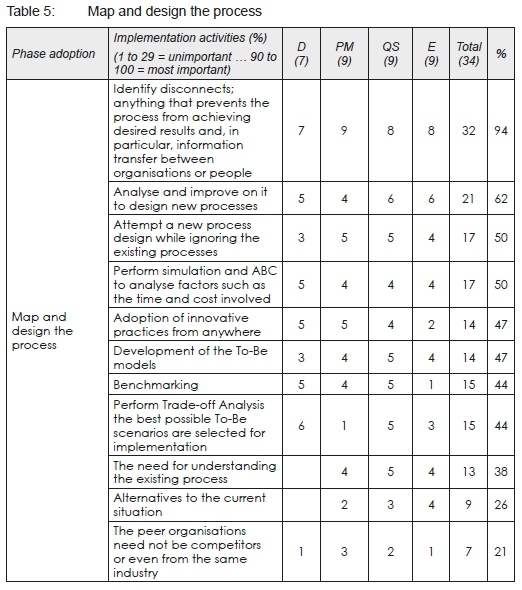

4.4 Map and design the process

The map and design of the process consists of 11 implementation activities (see Table 5). With a 94% rating, interviewees perceived identifying disconnects, which prevent the process from achieving desired results, as the most important activity in adopting and implementing VRE. Analysing and improving new processes design (62%) is in line with Eke and Adaku (2014: 114). Interviewees perceived attempting a new process design, while ignoring the existing processes, and performing simulation and analysing factors such as the time and cost involved, as fairly important in mapping and designing the process to be re-engineered. Madane and Joshi (2018: 1843) believe that less important or unimportant activities in the process of mapping and designing the process are innovative practices that can be adopted from anywhere, developing the To-Be models, benchmarking, performing trade-off analysis the best possible To-Be scenarios, understanding the existing process, alternatives to the current situation and the peer organisations need not be competitors are vital in mapping and designing the process for phase adoption of VRE.

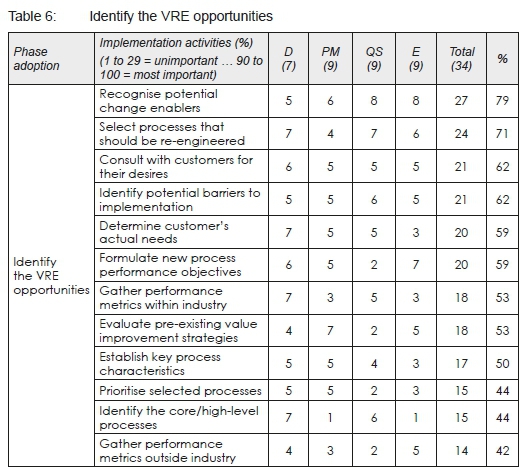

4.5 Identifying the VRE opportunities

When identifying the VRE opportunities, 12 activities are considered (see Table 6). During this stage, important implementation activities include recognising potential change enablers (79%) and selecting the processes that should be re-engineered (71%). Fairly important activities to consider during the identifying of VRE opportunities stage include consulting with customers for their desires, identifying potential barriers to implementation, determining customer's actual needs, formulating new process performance objectives, gathering performance metrics within industry, evaluating pre-existing business strategies, and establishing key process characteristics. These results agree with the findings of Fasna and Gunatilaka (2019: 2574). However, the interviewees regard identifying the core/high-level processes, prioritising selected processes, and gathering performance metrics outside industry as less important in identifying VRE opportunities during phase adoption.

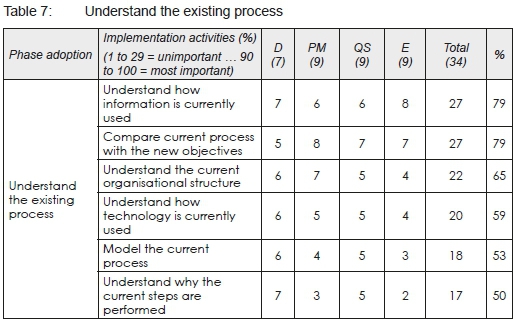

4.6 Understanding the existing process

During VRE adoption and implementation, the 'understanding of the existing process' stage considers six activities (see Table 7). With ratings of 79% each, important activities during this stage include comparing the current process with the new objectives and understanding how information is currently used. With ratings between 50% and 65%, fairly important implementation activities include understanding the current organisational structure, understanding how technology is currently used, modelling the current processes and understanding why the current steps are performed, as implementation activities in understanding the VRE existing process. These findings are in line with the results of Omidi and Khoshtinat (2016: 426) as well as those of Dachyar and Sanjiwo (2018: 8).

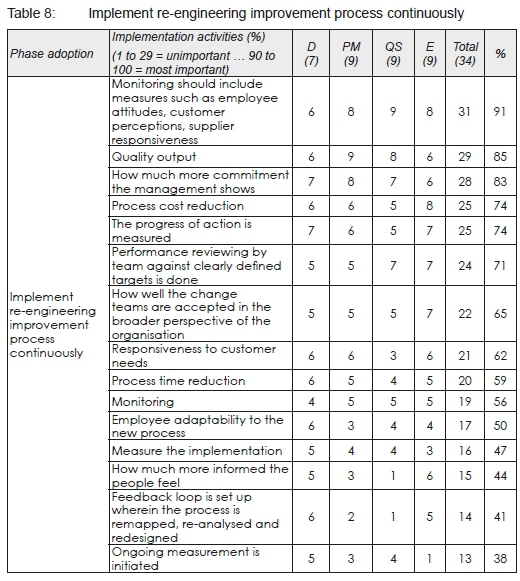

4.7 Implement re-engineering improvement process continuously

In the stage where the re-engineering improvement process should be implemented continuously, 15 activities are considered (see Table 8). During this stage, the most important implementation activity is monitoring that should include measures such as employee attitudes, customer perceptions, and supplier responsiveness. With ratings of between 71% and 85%, other important activities to consider include quality output; how much more commitment the management shows; process cost reduction; the progress of action measured, and performance reviewing by team against clearly defined targets done. These results are validated by Omidi and Khoshtinat (2016: 426). Fairly important implementation activities included how well the change teams are accepted in the broader perspective of the organisation; responsiveness to customer needs; process time reduction; monitoring, and employee adaptability to the new process. With ratings of between 38% and 47%, activities considered to be of less importance during continuous implementation of the re-engineering improvement process include measuring the implementation process; how much more informed the people feel; setting up feedback loop, wherein the process is remapped, re-analysed and redesigned, and if an ongoing measurement is initiated. These findings agree with those of Dachyar and Sanjiwo (2018: 8).

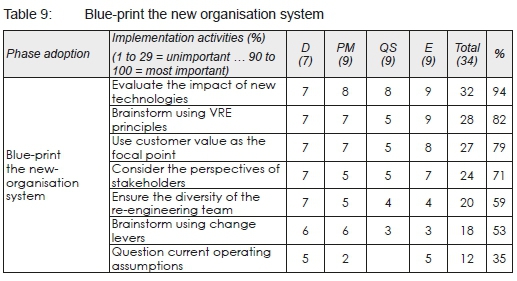

4.8 Blue-print the new-organisation system

Table 9 shows the rating results for the seven implementation activities during the stage of blue-printing the new organisation of VRE adoption and implementation. With a 94% score, impact evaluation of new technologies is rated the most important activity considered in blue-printing the new organisational system. These findings agree with those of Omidi and Khoshtinat (2016: 426). Dachyar and Sanjiwo (2018: 8) opine that brainstorming using VRE principles (82%); using customer value as the focal point (79%), and considering the perspectives of stakeholders (71%) were important activities in VRE incremental adoption and implementation for blue-printing the new organisational system. In line with Madane and Joshi (2018: 1843), interviewees perceived less important activities in VRE adoption and implementation for blue-printing the new organisation as ensuring the diversity of the re-engineering team; brainstorm using change levers, and questioning the current operating assumptions.

5. CONCLUSION AND RECOMMENDATION

The empirical findings from the study indicate that establishing a VRE organisational structure is considered most important in redesigning the process in an organisation in achieving the implementation success. This can only be identified through the significant need for the process to be re-engineered by evaluating the impact of the new technologies on the implementation of the VRE stage. The study further concludes that identifying disconnects in anything that will prevent the process from achieving the desired results and, in particular, information transfer between organisations or people, are prevented in order to achieve the objective of the implementation process. The study, therefore, recommends that the professionals in the industry be trained and retrained in the re-engineering improvement process continuously, through the implementation of proper monitoring of employee attitudes, customer perceptions and supplier responsiveness, while trying a new system for customer satisfaction in an organisation.

REFERENCES

Akaka, M.A., Vargo, S.L. & Lusch, R.F. 2013. The complexity of context: A service ecosystems approach for international marketing. Journal of International Marketing, 21(4), pp. 1-20. https://doi.org/10.1509/jim.13.0032 [ Links ]

Akam, G.U., Okeke, M.N., Kekeocha, M.E. & Onuorah, A.N. 2018. Business process reengineering resources and the performance of quoted brewing Arms in Nigeria. Asian Business Research Journal, 3(1), pp. 15-25. https://doi.org/10.20448/journal.518.2018.31.15.25 [ Links ]

Al-Yami, A.M. & Price, A.D.F. 2006. A framework for implementing sustainable construction in building briefing project. In: Boyd, D. (Ed.). Proceedings of the 22nd Annual ARCOM Conference, 4-6 September. Birmingham, UK: Association of Researchers in Construction Management, pp. 327-337. [ Links ]

Andrew, S. & Sarhan, F. 2013. Performance measurement in the UK construction industry and its role in supporting the application of lean. Australasian Journal of Construction Economics and Building, 13(1), pp. 23-35. https://doi.org/10.5130/AJCEB.v13i1.3069 [ Links ]

Arayici, Y. & Aouad, G. 2011. Technology adoption in the BIM implementation for lean architectural practice. Automation in Construction, 20(2), pp. 189-195. DOI: 10.1016/j.autcon.2010.09.016. https://doi.org/10.1016/j.autcon.2010.09.016 [ Links ]

Arayici, Y. & Coates, P. 2012. A system engineering perspective to knowledge transfer: A case study approach of BIM adoption. In: Xinxing, T. (Ed.). Virtual reality - Human computer interaction. London, UK: IntechOpen Limited, pp. 179-206. DOI: 10.5772/51052 [ Links ]

Arayici, Y., Coates, P., Koskela, L., Kagioglou, M., Usher, C. & O'Reilly, K. 2011. BIM adoption and implementation for architectural practices. Structural Survey, 29(1), pp. 7-25. https://doi.org/10.1108/02630801111118377 [ Links ]

Arivazhagan, O., Partheeban, P., Guru, V. & Priya Rachel, P. 2017. Application of value engineering in construction job sites - A case study. International Journal of Engineering Research & Technology (IJERT), 6(02), pp. 65-68. https://doi.org/10.17577/IJERTV6IS020054 [ Links ]

Ashworth, A. 2012. Contractual procedures in procurement in the twenty-first century. 6th edition. Edinburgh Gate, England: Pearson Education Ltd. [ Links ]

Asikhia, U.O. & Awolusi, D.O. 2015. Assessment of critical success factors of business process re-engineering in the Nigerian oil and gas industry. South African Journal of Business of Management, 46(2), pp. 1-14. https://doi.org/10.4102/sajbm.v46i2.87 [ Links ]

Atabay, S. & Galipogullari, N. 2013. Application of value engineering in construction projects. Journal of Traffic and Transportation Engineering, 1(1), pp. 39-48. DOI: 10.17265/2328-2142/2013.12.005 [ Links ]

Bhattacharyya, G.K. & Johnson, R.A. 2014. Statistics: Principles and methods. 7th edition. Hoboken, NJ: John Wiley & Sons. [ Links ]

Borgianni, Y., Cascini, G. & Rotini, F. 2015. Business process reengineering driven by customer value: A support for undertaking decisions under uncertainty conditions. Computers in Industry, 68, pp. 132-147. https://doi.org/10.1016/j.compind.2015.01.001 [ Links ]

Brown, J.D. 2011. Quantitative research in second language studies. In: Hinkel, E. (Ed.). Handbook of research in second language teaching and learning. (Vol. 2). New York: Routledge. [ Links ]

Chen, B., Liu, A.M.M. & Hua, Y. 2017. An exploration of the interaction between BIM technnology and the businesss process of a construction organization in BIM implementation. Building Information Modelling (BIM) in Design, Construction and Operations ii 177, 169, pp. 177-189. DOI: 10.2495/bim170171 [ Links ]

Chen, J., Yang, L. & Tai, H. 2016. Automation in construction process reengineering and improvement for building precast production. Automation in Construction, 68, pp. 249-258. DOI: 10.1016/j.autcon.2016.05.015 [ Links ]

Chen, P. & Nguyen, T.C. 2019. A BIM-WMS integrated decision support tool for supply chain management in construction. Automation in Construction, Elsevier, 98, pp. 289-301. DOI: 10.1016/j.autcon.2018.11.019 [ Links ]

Coates, P., Arayici, Y., Koskela, L., Kagioglou, M., Usher, C. & O'Reilly, K. 2010. The key performance indicators of the BIM implementation process. In: The International Conference on Computing in Civil and Building Engineering (ICCBE 2010), 30 June-2 July, Nothingham, UK: Nottingham University Press, pp. 1-12. [ Links ]

Creswell, J.W. 2014. Research design: Qualitative, quantitative and mixed-methods approaches. 4th edition. Thousand Oaks, CA: Sage Publications. [ Links ]

Dachyar, M. & Sanjiwo, Z.A.H. 2018. Business process re-engineering of engineering procurement construction (epc) project in oil and gas industry in Indonesia. Indian Journal of Science and Technology, 11(9), pp. 1-8. DOI: 10.17485/ijst/2018/v11i9/92741 [ Links ]

Ding, Z., Jiang, S., Ng, F. & Zhu, M. 2017. A new TRIZ-based patent knowledge management system for construction technology innovation. Journal of Engineering, Design and Technology, 15(4), pp. 456-470. https://doi.org/10.1108/JEDT-03-2016-0017 [ Links ]

Eke, G.N. & Adaku, N.A. 2014. Business process reengineering in organizational performance in Nigerian banking sector. Academic Journal of Interdisciplinary Studies, 3(5), pp. 113-124. DOI: 10.5901/ajis.2014. v3n5p113 [ Links ]

Emerie-Kassahun, A. & Molla, A. 2013. BPR complementary competence: Definition, model and measurement. Business Process Management Journal, 19(3), pp. 575-596. https://doi.org/10.1108/14637151311319950 [ Links ]

Fasna, M.F.F. & Gunatilake, S. 2019. Issues in implementing Business Process Reengineering (BPR) projects. In: Rahman, M.A. (Ed.). Proceedings of the 9thinternational conference on industrial engineering and operations management (IEOM 2019), 5-7 March, Bangkok, Thailand: IEOM Society International, pp. 2567-2576. [ Links ]

Fazli, I. 2011. Total Quality Management (TQM) and sustainable company performances: Examining the relationship in Malaysian firms. International Journal of Business and Society, 12(1), pp. 31-52. [ Links ]

Gray, D.E. 2009. Doing research in the real world. 2nd edition. London: Sage Publications. [ Links ]

Harini, M.W. & Widyarti, M. 2018. Implementation of value engineering for construction efficiency. Asian Journal of Applied Sciences, 06(2), pp. 71-77. [ Links ]

Harmon, P. 2014. Business process change. 3rd edition. Wyman Street, Waltham, USA: Morgan Kaufmann. [ Links ]

Huzaimi, A., Jamil, A. & Syazli, M. 2016. The integration of lean construction and sustainable construction: A stakeholder perspective in analyzing sustainable lean construction strategies in Malaysia. In: Procedia - Procedia Computer Science, 100, pp. 634-643. DOI: 10.1016/j.procs.2016.09.205 [ Links ]

Ilin, I.V., Kalinina, O.V., Levina, A.I. & Iliashenko, O.Y. 2016. Approach to organizational structure modelling in construction companies. In: Andreev, V. (Ed.). 5th International Scientific Conference (IPICSE-2016), Moscow, Russia, 16-17 October, MATEC, Web of Conferences, 86(05028), pp. 1-8. https://doi.org/10.1051/matecconf/20168605028 [ Links ]

Iruobe, O.J., Ojambati, T.S., Akinpade, J.A. & Iruobe, T. 2012. An investigation into the impact of total quality management application in the construction industry (a case of training). Journal of Emerging Trends in Engineering and Applied Sciences, 3(2), pp. 344-348. [ Links ]

Jupp, J. & Awad, R. 2018. A change management perspective on BIM-FM implementation. In: Lamb, M. (Ed.). AUBEA 2017: Australasian Universities Building Education Association Conference, 3-5 July, Melbourne, Australia. EPiC Series in Education Science, 1, pp. 361-350. DOI: 10.29007/1tln [ Links ]

Jusoh, Z.M. & Kasim, N. 2017. Influential factors affecting materials management. Management and Production Engineering Review, 8(4), pp. 82-90. DOI: 10.1515/mper-2017-0039 [ Links ]

Karunasena, G. & Gamage, K.R. 2017. A decision-making formula for value engineering applications in the Sri Lankan construction industry. Journal of Financial Management of Property and Construction, 22(1), pp. 77-91. DOI: 10.1108/JFMPC-01-2016-0001 [ Links ]

Khrustalev, A. 2015. The crisis will wipe out up to 30% of construction companies in Russia. RIA Realty. [Online]. Available at: <http://riarealty.ru/anlysis_interview/20150120/404182124.html> [Accessed: 10 June 2019]. [ Links ]

Lau, A.W.T., Li, Y.S., Tang, S. & Chau, K.W. 2016. TQM application by engineering consultants in Hong Kong. The TQM Journal, 28(4), pp. 561587. DOI: 10.1108/TQM-06-2014-0049.8 [ Links ]

Leedy, P. & Ormrod, J.E. 2014. Practical research: Planning and design. 10th edition. London: Pearson Education Limited. [ Links ]

Lilian, O.O., Uzochukwu, O.C. & Francisca, O.N. 2015. Business process reengineering and organizational performance of selected automobile firms in southeast of Nigeria. European Journal of Business, Economics and Accountancy, 3(5), pp. 12-43. [ Links ]

Madane, S. & Joshi, D. 2018. Business process re-engineering in construction industry: Present senario. International Research Journal of Engineering and Technology (IRJET), 5(7), pp. 1843-1846. [ Links ]

Marhani, M.A., Jaapar, A., Azmi, N. & Bari, A. 2012. Lean construction: Towards enhancing sustainable construction in Malaysia. Procedia -Social and Behavioral Sciences, Elsevier, 68, pp. 87-98. DOI: 10.1016/j.sbspro.2012.12.209 [ Links ]

Mathers, N., Fox, N. & Hunn, A. 2009. Surveys and questionnaires. The NIHR RDS for the East Midlands/Yorkshire & the Humber. [ Links ]

Meng, X. 2012. The effect of relationship management on project performance in construction. International Journal of Project Management, 30(2), pp. 188-198. https://doi.org/10.1016/j.ijproman.2011.04.002 [ Links ]

Mustafa, A. 2012. Research methodology. 2nd edition. India: AITBS Publishers. [ Links ]

Naidoo, P. & Reddy, P.S. 2008. Total quality management and benchmarking in South African local government: Towards improved service delivery. Politeia, 27(3), pp. 37-53. [ Links ]

NBS (National Bureau of Statistics). 2019. Nigerian Annual Report of NBS for economic planning. [Online]. Available at: <https://nigeria.opendataforafrica.org> [Accessed: 20 June 2019]. [ Links ]

Olanrewaju, A.A. 2013. A critical review of value management and whole life costing on construction projects. International Journal of Facility Management, 4(1), pp. 1-12. [ Links ]

Omidi, A. & Khoshtinat, B. 2016. Factors affecting the implementation of business process reengineering: Taking into account the moderating role of organizational culture (Case study: Iran Air). Procedia - Economics and Finance, 36(16), pp. 425-432. DOI: 10.1016/S2212-5671(16)30058-2 [ Links ]

Osuji, I. & Ishola, T.O. 2013. Business research methodology. Lagos: National Open Univercity of Nigeria. [ Links ]

QSR International. 2021. Nivido 21. [Online]. Available at: <https://www.qsrinternational.com/nvivo-qualitative-data-analysis-software/home> [Accessed: 12 June 2020]. [ Links ]

Sacks, R., Koskela, L., Dave, B.A. & Owen, R. 2010. Interaction of lean and building information modeling in construction. Journal of Construction Engineering and Management, 136(9), pp. 968-980. DOI: 10.1061/(ASCE) CO.1943-7862.0000203 [ Links ]

Sadreddini, A. 2012. Time for the UK construction industry to become lean. Proceedings of the Institution of Civil Engineers. Civil Engineering, 165(5), pp. 28-33. DOI: 10.1680/cien.11.00009 [ Links ]

Safa, M., Sabet, A., MacGillivray, S., Davidson, M., Kaczmarczyk, K., Haas, C.T., Gibson, G.E. & Rayside, D. 2015. Classification of construction projects. World Academy of Science, Engineering and Technology. International Journal of Civil, Environmental, Structural, Construction and Architectural Engineering, 9(6), pp. 625-633. [ Links ]

Saidu, I. 2016. Management of material waste and cost overrun in the Nigerian construction industry. Unpublished PhD thesis. Department of Construction Management, Nelson Mandela University, Port Elizabeth, South Africa. [ Links ]

Sikdar, A. & Payyazhi, J. 2014. A process model of managing organizational change during business process redesign. Business Process Management Journal, 20(6), pp. 971-998. https://doi.org/10.1108/BPMJ-02-2013-0020 [ Links ]

Soares, R. 2013. Reengineering management of construction projects. International Journal of Business and Social Science, 4(7), pp. 1-6. [ Links ]

Steven, M. 2014. Quality improvement techniques in construction. London: Routledge imprint of the Taylor & Francis Group. [ Links ]

Sungau, J., Ndunguru, P.C. & Kimeme, J. 2013. Business process re-engineering: The technique to improve delivering speed of service industry in Tanzania. Independent Journal of Management and Production, 4(1), pp. 208-227. DOI: 10.14807/ijmp.v4i1.68 [ Links ]

Tezel, A. & Nielsen, Y. 2013. Lean construction conformance among construction contractors in Turkey. Journal of Management in Engineering, 29(3), pp. 236-250. DOI: 10.1061/(ASCE)ME.1943-5479.0000145 [ Links ]

Tomek, R. & Kalinichuk, S. 2015. Agile PM and BIM: A hybrid scheduling approach for a technological construction project. Procedia - Engineering, 123, pp. 557-564. DOI: 10.1016/j.proeng.2015.10.108. [ Links ]

Wegner, T. 2012. Applied business statistics methods and Excel-based applications solutions manual. 4th edition. Cape Town: Juta. [ Links ]

Yahaya, I. 2020. Utilisation of technology to improve construction logistics in Nigeria. Unpublished PhD thesis. Department of Construction Management, Nelson Mandela University, Port Elizabeth, South Africa. [ Links ]

Received: September 2020

Peer reviewed and revised: February 2021

Published: June 2021

* The authors declared no conflict of interest for the article or title