Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Acta Structilia

On-line version ISSN 2415-0487

Print version ISSN 1023-0564

Acta structilia (Online) vol.26 n.1 Bloemfontein 2019

http://dx.doi.org/10.18820/24150487/as26i1.1

RESEARCH ARTICLES

Factor analysis of quality assurance practices in small and medium-sized road-construction projects: A South African perspective

Kgashane Stephen NyakalaI; Jan-Harm PretoriusII; Andre VermeulenIII

IDr Kgashane Stephen (K.S.) Nyakala, Lecturer, Department of Operations Management, Tshwane University of Technology, South Africa. Phone: +27 84 435 8730, email: <nyakalaks@tut.ac.za> ORCID: https://orcid.org/0000-0002-5160-3747

IIProf. Jan-Harm Christiaan (J.H.C.) Pretorius, Professor, Postgraduate School of Engineering Management, University of Johannesburg, South Africa. Phone: +27 11 559 3377, email: <jhcpretorius@uj.ac.za> ORCID: https://orcid.org/0000-0002-2023-749X

IIIDr. Andre Vermeulen, Senior Research Associate, Postgraduate School Engineering Management, University of Johannesburg, South Africa. Phone: +27(0) 82 786 8076, email: <avermeulen@uj.ac.za> ORCID: https://orcid.org/0000-0001-5744-4030

ABSTRACT

Although implementing quality assurance (QA) processes in construction is important in the South African economy, small and medium-sized enterprises (SMEs) faced difficulties in improving rural road infrastructure and high-quality roads. Hardly any effort is made on to how sustain quality in road-project construction through suitable construction strategy in local governments. This article aims to analyse and examine the quality of road-construction projects built by SMEs contractors in Mopani District Municipality, South Africa. The article follows a quantitative survey approach in which a three-section questionnaire was administered to 160 purposively selected road- building practitioners in South African construction SMEs. The questionnaire was structured into three parts, which sought the participants' profile, identified the quality assurance practices (QAPs) incorporated in the construction SMEs' road-building programmes, and identified the factors that negatively influence the implementation of QA processes. Data was analysed using the Statistical Package for the Social Sciences (SPSS) version 23. Descriptive statistics was used to determine the reliability of the various constructs, mean scores, and standard deviations. The empirical findings established eight QAPs that were reliable and valid for implementation processes that can control or minimise their causes of poor quality in projects undertaken by construction SMEs' level of skill acquisition. These are: project planning and control techniques; project construction design; process implementation and process improvement; financial management; organisational structures; involvement of people, as well as quality standards and measurements. The eight factors attained high Cronbach Alpha values above the recommended 0.70, which indicates high internal consistencies among the sub-scales. This article is significant in that project managers working in similar environments may use the results of this study either as diagnostic tools or as a reference benchmark for strategic interventions in solving construction projects-related problems. The researchers also recommend that these practices are for QA in construction projects undertaken by SMEs in South Africa

Keywords: South Africa, SME construction projects, quality assurance practice, road construction

ABSTRAK

Alhoewel implementering van gehalteversekeringsprosesse in konstruksie belangrik is in die Suid-Afrikaanse ekonomie, het klein en medium-grootte ondernemings (KMO's) probleme ondervind met die verbetering van landelike padinfrastruktuur en hoëgehalte-paaie. Min moeite word gedoen oor hoe om gehalte in die bou van padprojekte deur middel van geskikte konstruksiestrategieë in plaaslike regerings te handhaaf. Hierdie artikel het ten doel om die gehalte van padbouprojekte wat deur MKO-kontrakteurs in Mopani Distrikmunisipaliteit in Suid-Afrika gebou is, te analiseer en te ondersoek. Die artikel volg ' n kwantitatiewe opnamebenadering waarin ' n drie-afdeling vraelys aan 160 doelgerigte padbou-praktisyns in Suid-Afrikaanse konstruksie-KMO's gestuur is. Die vraelys is in drie dele gestruktureer, die deelnemers se profile, die ïdentifisering van gehalteversekeringspraktyke (QAPs) in die konstruksie-KMO se padbouprogramme, en die faktore wat die implementering van KV-prosesse negatief beïnvloed. SPSS-weergawe 23, die Statistiese Pakket vir die Sosiale Wetenskappe, is gebruik om die data te ontleed. Beskrywende statistiek is gebruik om die betroubaarheid van die verskillende konstrukte, gemiddelde tellings en standaardafwykings te bepaal. Die empiriese bevindinge het agt KVP's vasgestel wat betroubaar en geldig was vir implementeringsprosesse wat hul oorsake van swak gehalte in projekte wat deur konstruksie-KMO's onderneem word, se vlak van vaardigheidsverkryging kan beheer of verminder. Dit is: projekbeplanning en beheertegnieke; projek konstruksie ontwerp; verwerking van implementering en prosesverbetering; finansiële bestuur; organisatoriese strukture; betrokkenheid van mense, en gehalte standaarde en metings. Die agt faktore het hoë Cronbach Alpha-waardes bo die aanbevole 0.70 bereik wat dui op hoë interne geldigheid tussen die subskale. Hierdie artikel is beduidend omdat projekbestuurders wat in soortgelyke omgewings werk, die resultate van hierdie studie gebruik as diagnostiese gereedskap of as verwysende maatstaf vir strategiese intervensies in die oplossing van konstruksieprojekte-verwante probleme

Sleutelwoorde: Gehalteversekeringspraktyk, KMO-konstruksieprojekte, pad-konstruksie, Suid-Afrika

1. Introduction

The road-construction industry in Southern Africa is challenging, because there are many multifaceted responsibilities and operational procedures to adhere to (Mofokeng & Thwala, 2012: 712; Windapo & Cattel, 2013; George, 2016: 24). Road-construction SMEs can be described as those SMEs who work on road-construction projects, comprising some components of the design and control of road-construction works as well as the quantity of building materials, tools, equipment, plant, transport and other services (Rumane, 2011). The South African local government is obliged to provide roads to the local communities they serve. The provision of adequate roads contributes to economic growth, development and redistribution of a good roads network infrastructure (Nyakala, Vermeulen, Pretorius & Munyai, 2017: 636; Statistics South Africa, 2017). The upgrading of rural roads networks not only contributes to improve the socio-economic conditions of communities, but also supports the establishment of effective co-ordinating constructions throughout government to promote efficiency in road service delivery (Fang & Wu, 2013: 139).

The annual report on South African SME construction projects mentions 30.1% to 39.4% inefficiency, poor quality of rural road-building, and lack of construction-process planning among SMEs contractors (Statistics South Africa, 2017). The SME road-construction industry has experienced a demand for an increased number of projects in rural road-building. The complexity of managing and executing these projects is challenging. Despite the amount of SME road contractor's activity available, South Africa still does not perform well when compared to other countries worldwide (CIDB, 2012; Tshivhase & Worku, 2012: 41; George, 2016: 23). South Africa is mostly characterised by the failure of SME road-construction entrepreneurial capacity, which is largely characterised by low levels of entrepreneurial education, incomplete accessibility of road-network infrastructure, high demand for roads in rural connectivity, crisis management, and liveability (Mofokeng & Thwala, 2012; Fang & Wu, 2013; Nyakala et al., 2017: 640). This has led to the improper implementation of rural road-construction projects, causing considerable problems such as drastic changes in product and process implementation, customer expectations, competitive behaviours as well as supplier attitudes for contractors (Tshivhase & Worku, 2012: 43; Aigbavboa & Thwala, 2014: 771; Nyakala, 2017). Unless local contractors raise their performance standards relative to foreign competitors, the current situation will deteriorate (Aigbavboa & Thwala, 2014: 712).

It is against this background that this study not only examines the QAPs incorporated in the rural road infrastructure of construction SMEs, but also determines the factors that positively influence the practice of road-construction SMEs. Identifying such factors will help SMEs management to understand the processes of improving the quality of construction projects and to successfully implement, monitor and deal with QAPs in road-construction SMEs (Ahadzie, Proverbs & Olomolaiye, 2008: 675).

2. Literature review

Road-construction organisations display distinctive characteristics, combined with the varying demands of the industry's stakeholders, which includes uniting varied investors, clients, consulting professions and contractual engagements (Badu & Owusu-Manu, 2011: 271; CIDB, 2012). Applying total quality management (TQM) principles in road-construction processes entails the involvement of everyone, where TQM has the potential to improve customer satisfaction and confidence in the organisation's products/services, staff performance, teamwork and better management of workers within companies (Arditi & Gunaydin, 1997; Haupt & Whiteman, 2004: 166). Understanding the relationship between process quality and product quality could consequently be useful in cultivating the QAPs that can reduce poor quality practices in road-construction projects. In order to understand the implementation process of QAPs in road-construction SMEs, it is important to introduce the present theory on the quality practices processes included in this study. The current theory focuses on the overall concepts of quality practices in the construction project and project management structures.

2.1 Quality assurance in SMEs

QA in SME construction projects is one part of quality system management. QA involves establishing project-related policies, procedures, standards, training, guidelines and systemic activities implemented in a quality system to fill quality requirements (Basu, 2004; Freeman-Bell & Balkwill, 1996; Aziz & Abdel-Hakam, 2016; Panuwatwanich & Nguyen, 2017). Having specific procedures, clear policies, standards, training, guidelines and systems designed to maximize employee performance in facilitating a business' strategic objectives correlates with project success by directing attention, motivating and maintaining an efficient quality-management system (Arditi & Gunaydin, 1997; Nyakala, 2017).

Various researchers on quality-management approaches have agreed that, unless SME contractors play an active role and take the lead to improve productivity through quality-management systems in the civil construction industry, efforts and gains made by individuals and departments will be short-lived (Arditi & Gunaydin, 1997; Basu, 2004; Bierman, Marnewick & Pretorius, 2013). In South Africa, project managers and project consultants are responsible for the overall construction success related to delivering infrastructure projects within the approved costs and time as well as the necessary quality and supervision. For any built-environment project to improve its competitive abilities in the construction industry, it should be able to determine the cost of poor quality and its impact on productivity and profitability (Mahmood, Ahmed, Panthi & Kureshi, 2010). Therefore, SMEs cannot view quality as an expensive process, an expensive product, or time consuming, but rather as quality assurance that can improve their competitive capabilities in the marketplace (Mofokeng & Thwala, 2012: 713; Kruger, Ramphal & Maritz, 2014).

2.1.1 Level of skill-acquisition process

Mofokeng & Thwala (2012: 722) postulate that the construction organisations need to spearhead the capacitation of employees through the process of skill acquisition and facilitate employees' new skills. Aziz & Gunaydin (1997) note that opportunities for skills development in the construction industry have grown significantly and t h a t the main drivers are growth of businesses and infrastructures, environmental pressures and sustainability, as well as management commitment. The success of construction projects is grounded on the individual competencies of site managers or project managers responsible for the execution process (Fotopoulos & Psomas, 2009). Vermeulen, Nyakala & Pretorius (2018: 2) clarified the main contributors of South African construction-project participants as the designer or architect, the client, the project/construction manager and the contractors. These are then extended with many subteams with their own leaders who perform different functions.

2.1.2 Project planning and control techniques

Successful implementation of QA processes requires effective planning and control techniques, operations and review as well as stakeholder approval for business-project activities (Nyakala et al., 2017: 650). To effectively implement their QAPs, construction SMEs must meet their approved quality objectives and detailed requirements. Windapo & Cattel (2013) state that effective planning is essential for the successful execution of a project. A project manager holds the same responsibilities, facilitates a formal system for record-keeping, and provids work breakdown detail to all stakeholders (CIDB, 2012). Construction-project management should include the design and execution of the infrastructure, the environmental impact of the job, the successful scheduling, budgeting, accessibility and delivery of building resources, the inconvenience to the public affected by construction delays and bidding (Arditi & Gunaydin, 1997; Rumane, 2011; Tshivhase & Worku, 2012: 62). SME road contractors must use formal techniques of project management to enable citizens to have quality road networks and access to public services such as education, health facilities, and the movement of labour between workplaces (Vermeulen et al., 2018: 2). In addition, quality controls are required to prevent the deterioration of maintenance backlogs, and focus the efforts of the project manager on the daily control of the numerous activities of the project (Thorpe, Summer & Duncan, 1996; Panuwatwanich & Nguyen, 2017).

2.1.3 Project-construction design

The context of project-construction design within construction SMEs raised the question as to how senior project managers could adopt measurement tool in relation to QA processes and scope of work reporting on mistakes by the project team. Kerzner (2013) also supports this view, stating that the chief engineer is responsible for organising technical personnel optimisation of construction scheme, improving the technical measures, and providing technical support for the effective cost control. According to Kam and Hamid (2014: 603), an example of an industry that heavily adopted the technology was manufacturing. As identified by Dallasega, Marengo, Nutt, Rescic, Matt & Rauch (2015), computerised project management has been introduced in construction organisations such as Microsoft Project and Oracle Primavera. Dallasega et al. (2015) further state that technical inspection of the construction progress with a high level of reliability was applicable in the early stages of a construction project. One major practical issue that has dominated the road-construction projects for many years concerns the unpredictability in project-construction designs creating complications when implementing processes of QA to the industry.

2.1.4 Process implementation

The senior management team need to highlight the importance of applying proper management in dealing with the processes of QA in construction. A recent study conducted by Aziz et al. (2016) found that, having more experienced and capable construction managers as well as skilled labourers helped enable the industry to develop at a faster rate either nationally or internationally. The study showed that the proper process implementation of the quality-assurance system helped organisations better organise and synchronise their operations by documenting their procedures and clearly defining responsibilities and tasks among employees and subdivisions (Gotzamani & Tsiotras, 2001). Project management also includes practical implementation (Olawale & Sun, 2015). It is widely accepted and well- documented that implementing QA processes presents a good opportunity for organisations that want to respond to the challenge.

2.1.5 Financial management skills

Financial management is a key factor influencing the construction industry. The timely completion of road-construction projects is considered one of the key factors referring to project achievement as well as quality and safety (Aziz et al., 2016). In line with this, a cost-effective policy, competence and profitability are the main determinants of construction-project planning, covering activities needed to deliver quality in the work to meet the project requirements (Mahmood et al., 2010). Costs of restructuring the process must be controlled in order to eradicate the causes of poor quality and related preventive activities. This encompasses, for example, preparation, monitoring and analysis, project review, and quality improvement programmes (Nyakala et al., 2017: 650). Quality training and project control systems are essential for innovation and for technology advancement, as well as for improving the standard of living (Obare et al., 2016). The implementation of project control systems perpetuates them as engines whereby the growth objectives of developing countries can be achieved (Ahadzie et al., 2008).

2.1.6 Quality standards

Quality standard represents organisational performance through construction-project management, quality policy, organisational structures and successful implementation of quality management practices by construction SMEs in the country (Vermeulen et al., 2018: 3). The success of any construction organisation depends on how corporate strategies adopt continuous quality-improvement practices (Kerzner, 2013). This will be supplemented in practical terms by implementing total quality strategies and empower employees in the construction project to identify opportunities and develop them more efficiently (Gardiner, 2005). During building operations, there must be quality control to ensure that the roads are constructed to the expectations of all role-players (Honnakker, Carayon & Loushine, 2010: 954). Quality control verifies that processes are performed in a satisfactory manner (Kruger et al., 2014). Quality product procedures, product reliability, standards and dimensions are essential. These allow the contractor to evaluate and assess project processes against applicable standards, quality management tools and techniques, total quality management (TQM), cause-and-effect diagrams, policies and procedures (Gardiner, 2005).

2.1.7 Organisational structure and improvement programmes in SMEs

SME construction organisations are less able to deal with 'disclosures' in the global economy and, as a result, are mostly vulnerable. SME road-construction projects need to be managed and controlled in order to allow goal-setting for reconstruction, growth and improvement in the construction industry (Vermeulen et al., 2018). In the South African local government, such knowledge gaps are critically confronted by a lack of communication technologies. These gaps further include inadequate connectivity and mobility to reach out and open up new opportunities as well as improper physical infrastructure and economic developments. Enhancing competitiveness in the construction industry is measured to be a strategic prospect if it seems to be improving quality developments and incorporating engineering-management principles and practices (Freeman-Bell & Balkwill, 1996). Contractor development tools that meet the challenges of globalisation are nowadays viewed as techniques that frequently maintain the management of construction projects, multitudes of data, and tight deadlines that are characteristic of numerous industries and their extremely competitive settings (Badu & Owusu-Manu, 2011). Contractors need computerised systems that follow the value chain in construction-project delivery (Arditi & Gunaydin, 1997). This supports the notion that quality must be built-in during design and be achieved through communication, development and improvement (Bierman et al., 2013; Olawale & Sun, 2015).

Organisational structure should put in place structures to support people and organisations in their pursuit of better quality. Such procedures comprise an extensive variability of tools to plan work activities, gather data, analyse outcomes, monitor progress, and solve problems (Bierman et al., 2013: 44). Fotopoulos & Psomas (2009) state that techniques need to be used and focus on improving quality activities in the construction industry. Basu (2004) suggests statistical techniques of experimental design to optimise process sceneries in order to decrease scrap or increase yield. Project managers responsible for this frequently note process implementation, process optimisation, and practical implementation, future systems of the process, process expertise and process design (Kerzner, 2013).

2.1.8 Involvement of people

Leadership can influence project success by creating an environment in which project teams contribute towards success (Helander, 2004). Dallasega et al. (2015: 954) argue that an organisation's success depends increasingly on having opportunities to learn, meet, teamwork and practising new skills. This can evidently influence project success. According to Badu & Owusu-Manu (2011: 270), the critical success factor lies in the construction organisations' real commitment to quality improvement and their true target of certification, which finally commands the way in which, and the depth to which the standards are implemented. Employee involvement and empowerment has been identified as influential in planning on-site construction process and organisational performance (Windapo & Cattel, 2013). It is consequently important for workforces to be involved and empowered in the construction planning process by, for example, being able to prepare and meet project teams, use equipment and the skills and knowledge required to do work effectively (Thorpe et al., 1996; Rumane, 2011). Employees should further be able to share resources, schedule project activities and respond to memos and emails to construction senior management (Aigbavboa & Thwala, 2014: 773). It is also important for SME contractors to be committed to, and involved in the processes of QA implementation at SME-led project level.

2.2 Factors that influence quality-assurance practices of road-construction projects

A study by Obare, Kyalo, Mulwa & Mbugua (2016: 420) points out that the quality cost model, the evaluation of quality management practices, customer focus, teamwork, employee empowerment, education and continuous improvement influence project success. In addition, Fotopoulos & Psomas (2009) also assert that performing check-up, analysis, and corrective actions seemed to obtain customer's satisfaction. Martin and Lewis (2014) indicate that an effective communication system between project team leaders and management is crucial for the success of construction projects. Windapo and Cattel (2013) postulate that this is generally influenced by alignment of management commitment and subordinate actions. Van Wyk (2003) indicates that effective designers' performance evaluation in construction projects positively influences the success of a project. Jarkas and Younes (2014: 61) stipulate that, in situations where management commitment is ineffective, these should be revised, or new control actions be implemented, thus enabling continuous improvement in construction projects. In reviewing the literature, a number of studies have criticised the systems of managing quality during the construction process (Arditi & Gunaydin, 1997). It has been recommended that the failure of many road-construction projects in South Africa may partially be ascribed to th e poor quality of roads constructed by SME contractors in the country (Dangalazana & Newadi, 2005; Statistics South Africa, 2017). Nkomo, Desai & Peerbhay (2016: 42) opines that developing key success criteria for rural development initiatives provides a positive contribution to projects. For the purposes of this study, work programmes, stakeholder involvement, national standards, quality control, strategic planning, recording changes, expert evaluations, evaluations during the construction stage, cost control, policy formulation, employee skills, employee involvement, employee qualifications, and employee responsibility are set and form the initial fifteen critical success aspects of QAPs.

3. Methodology

The purpose of this research is to determine the factors that influence QAPs that can be implemented for road-construction SMEs to facilitate or inhibit their projects, in order to achieve project success. A quantitative research design was used, in which the use of structured questionnaire surveys enables researchers to generalise their findings from a sample population (Bryman, 2012: 232; Creswell, 2014). In the questionnaire, 15 original critical success aspects for QAPs were extracted and set as the variables of quality assurance practices that SMEs should follow. Another 35 questions on the "level of implementation" and "importance" of each QAP were extracted (Pallant, 2013: 192). Exploratory Factor Analysis (EFA) was utilised to reduce these measured variables to smaller quality assurance practices (constructs). According to Pallant (2013: 192), EFA can be considered a type of technique that analyses the characteristics (unidimensionality) of each of the defined QAPs (original variables), in order to reduce it to a common score (smaller number of factors) by examining relationships among these quantitative factors. Several factor-analysis methods are available, but principle component analysis (PCA) was used, because the Eigenvalues could be extracted, which explains whether the factors tested had or had not a noticeable effect on people's responses to the variables in the original test (analysed construct) (Rossoni, Engelbert & Bellegard, 2016: 201; Yang, Shen & Ho, 2009: 163-164; Pallant, 2013: 192).

3.1 Sampling method and response rate

Construction SMEs based in local municipalities of the Mopani District Municipality constituted the study's population. A total of 160 questionnaires were returned, representing a 64% response rate of the 250 questionnaires distributed. This was mainly supported by the list secured from the Department of Transport and Road. A total number of 102 registered construction SMEs participated in this study.

3.2 Data collection

Using the drop-and-collect and email methods, 250 questionnaires were distributed to the prospective respondents who worked on the road-construction projects in the local municipalities of Limpopo province, South Africa, from November 2016 to August 2017. Topics on quality assurance practices used in the questionnaire were extracted from reviews of the literature, resulting in the compilation of a questionnaire divided into three sections. Section A obtained the biographic profile of the targeted population, namely age, the highest educational level, the number of years' experience in the business, and the type of ownership in the business. Anonymity and confidentiality were guaranteed. Participants were not requested to provide personal details such as names, identity numbers and their physical address. However, pseudo numbers and names were used to classify the participants for purposes of data analysis.

In section B, respondents rated questions on 15 quality assurance practices that could influence effectiveness of road construction. The data from these measurements forms the variables used in the EFA, which tested the validity and reliability of the factors.

In section C, respondents rated 35 questions on the construct 'level of implementation' achieved at their business for each practice. They then rated the construct 'importance' of each practice in achieving a high-quality road-construction project. The data from these measurements forms the variables used in the EFA, to test the relationships in the variables among the 'level of implementation' and the relationship in the variables 'importance' of each factor. To reduce the respondent's bias, closed-ended questions were preferred for section B and C (Teddlie & Tashakkori, 2003: 232).

3.3 Analysis and interpretation of the data

The Statistical Package for the Social Sciences (SPSS) version 23 was used to conduct descriptive and statistical analysis of the data computing the frequencies, mean scores and standard deviations (Field, 2013; Pallant, 2013). SPSS was further utilised to determine the feasibility of conducting a factor analysis of the QAPs survey results relating to the QA processes implementation in the construction-project delivery.

To rank the influence of the initial 15 critical success aspects of QA processes on road-construction projects, the aspects were rated on a four-point Likert scale. Likert-type or frequency scales use fixed choice response formats and are designed to measure attitudes or opinions (Bowling, 1997; Leedy & Ormrod, 2014: 185). The following scale measurement was used regarding mean scores, where 1 = Not at all influential (>1.00 and <1.74); 2 = Slightly influential (>1.75 and <2.49); 3 = Moderately influential (>2.50 and <3.24), and 4 = Extremely influential (>3.25 and <4.00). To rank the 'level of implementation' and the 'importance' for each practice, 35 quality assurance practices were rated on a five-point Likert scale. The following scale measurement was used regarding mean scores, where 1 = Very poor/Not at all important (>1.00 and <1.80); 2 = Poor/ Slightly important (>1.81 and <2.60); 3 = Average/Neutral (>2.61 and <3.40); 4 = Good/Moderately important (>3.41 and <4.20), and 5 = Excellent/Extremely important (>4.21 and <5.00).

For analysis of the internal reliability of the factors in the questions on quality-assurance practices, Cronbach's alpha values were tested (Kolbehdori & Sobhiyah, 2014: 347; Wahab, Ayodele & Moody, 2010: 67). Tavakol and Dennick (2011: 54-55) and Yount (2006) suggest that the acceptable values of Cronbach's alpha would range from 0.70 to 0.95. In the current study, a cut-off value of 0.70 was adopted. Furthermore, the optimal inter-item correlations mean (factor loadings) should range from 0.2 to 0.4, in order for the factor to be reliable (Pallant, 2013: 134). However, in this study, a value of 0.4 and above was adopted.

To confirm whether the data from the measurements was sufficient for factor analysis (test the validity), the Kaiser-Meyer-Olkin (KMO) test (Lorenzo-Seva, Timmerman & Kiers, 2011; Kaiser, 1994) and the Bartlett's sphericity test (Hair, Black, Babin & Andersen, 2014: 110) were performed. In the KMO test, as the values of the test vary from 0 to 1, values above 0.7 are recommended as being desirable for applying EFA (Hair et al., 2014), and a statistically significant Bartlett test (p < 0.05) indicates that sufficient correlations exist between the variables to continue with the analysis (Hair et al., 2014: 110; Pallant, 2013: 190).

For factor extraction, Principal Components Analysis (PCA) was used to summarise most of the information into a minimum number of factors, by concentrating the explanatory power on the first factor (find the principal components of data) (Rossoni et al., 2016: 102). In PCA, when the number of variables (measures) is between 20 and 50, it is more reliable to use Eigenvalues to extract factors, as it makes interpretation simpler (Johnson & Wichern, 2007). The highest Eigenvalues in the data is, therefore, the principal components in the data, which are retained to form a set of few new variables (less than the original variables started with in the analysis).

3.4 Limitation(s) of the study

It can be noted that the study was not conducted across South Africa; therefore, the findings cannot be generalised.

4. Results and discussion

4.1 Respondents' profile

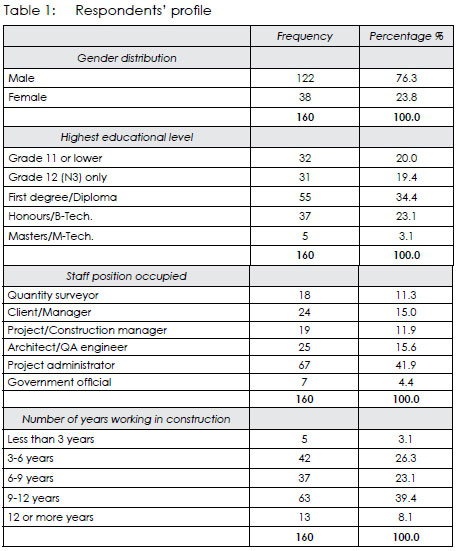

Table 1 displays the demographic profile of participants. It is obvious that the majority (41.9%) of the respondents were project administrators, male (76.3%), and had either a First degree/Diploma (34.4%) or a Honours/B-Tech. degree (23.1%); only 8.1% of the respondents had 12 years' or more experience in road construction.

4.2 SMEs' profile

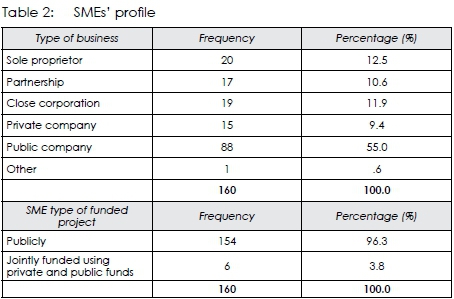

Table 2 shows the emerging contractors' profile according to the nature of their business and the funding received of their business. It is evident that the majority of the SMEs work for either public companies (55%) or are sole proprietors (12.5 %) and that most of the SME-led projects were publicly funded (96.3%), while only 3.8% were jointly funded using private and public funds.

4.3 Critical success aspects of quality-assurance practices incorporated in the construction SMEs

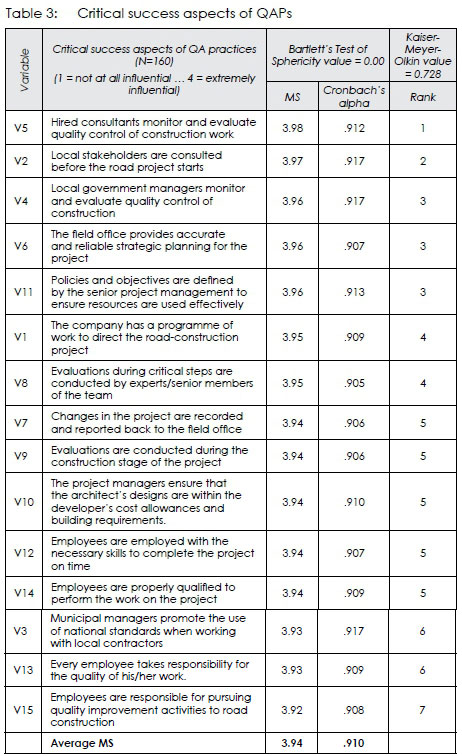

Table 3 ranks the mean scores to show which of the 15 critical quality-assurance factors have an influence when they are applied in practice in road SMEs.

With an average MS of 3.94, results in Table 3 show that respondents perceive all critical success aspects identified as extremely influential when applying QAPs in road construction. 'Hired consultants monitor and evaluate quality control of construction work' with a MS of 3.97 is rated the most influential QAP within road SMEs. The Cronbach's alpha was greater than 0.70 at 0.910, indicating acceptable internal reliability, as recommended by Hair et al. (2014: 102). It also means that there was a strong relationship between the implementation of QA practices and the effectiveness of road-construction SME-led projects. The Kaiser-Meyer-Olkin (KMO) of 0.728 with Bartlett's Test of Sphericity of p< 0.000, indicates consistency with the recommended KMO cut off value of 0.70 and Bartlett's Test of Sphericity of p< 0.05, as suggested by Pallant (2013: 190). These results suggest that factor analysis could be conducted with the data. The significance in the results showed that respondents accepted all road-construction effectiveness aspects to be relevant when considering the QA practices implementation.

4.3.1 Exploratory factor analysis for critical success quality-assurance practices

The 15 critical success variables were subjected to EFA to study the trend of inter-correlations between variables and to group these variables with similar characteristics into a set of reduced factors according to the hidden components in the collected data. The results report the factor extraction, Eigenvalues, correlation and interpretation.

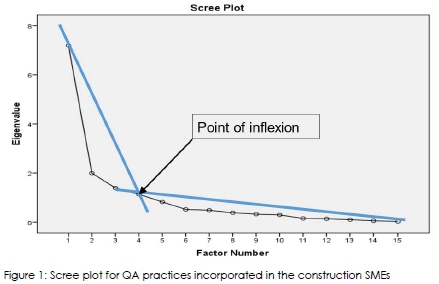

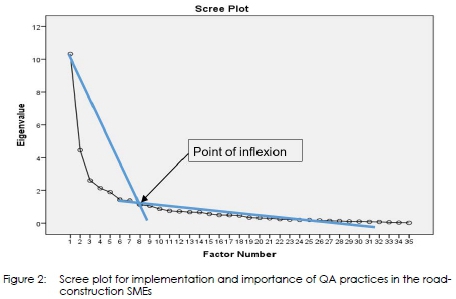

In Figure 1, the scree plot consists of the Eigenvalues and the data points above the break (point of inflexion), which are the components that are meaningful to retain for rotation. Using a cut-off value of initial Eigenvalues greater than one (> 1.0), 4 components explain a cumulative variance of 78.07%.

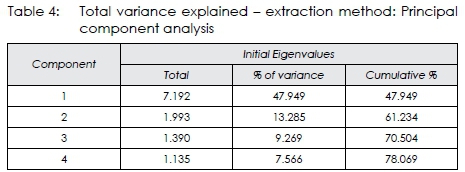

The scree plot confirms the finding of retaining four components. As a result, components from five to fifteen are not significant and thus not included for rotation. Table 4 shows the four factors that are meaningful to retain, where factor one explains 47.949 % of the total variance, factor two (13.285%), factor three (9.269%), and factor four (7.566%).

Using Principal Component Analysis and Varimax with Kaiser Normalization rotation method with significant factor of .04, Table 5 shows the correlation between components and variables after rotation. Correlation exists between variables 1, 5, 6, 7, 8, 9, 10, 12, and 13, as they all loaded onto Component 1 label as Project planning, control and construction. Correlations were identified between variables 6, 7, 8, 9, 12, 13, 14, and 15 label Component 2: Level of skill acquisition and involvement of people. Variables 1, 2, 4, 6, 8, and 11 show correlation, as they loaded onto Component 3 label Process implementation and process improvement. Correlations exists in variables 3, 9, 10, and 11 label as Component 4: Quality standards and measurements.

In Factor 1: Project planning, control and construction (variables 1, 5, 6, 7, 8, 9, 10, 12, and 13), the variables that had high loading are Evaluations are conducted during the construction stage of the project (0.916) and Evaluations during critical steps are conducted by experts/senior members of the team (0.902). Studies on quality-assurances practices incorporated in the construction SMEs show similarity to variables in Factor 1: afford directives about the usage of measurement tools for construction projects (Gardiner, 2005; CIDB, 2012; Aziz & Abdel-Hakam, 2016; George, 2016); enhance team work and better performance (Obare et al., 2016); enable the success of QA process implementation in the road-construction projects (Nyakala, 2017).

In Factor 2: Level of skill acquisition and involvement of people

(variables 6, 7, 8, 9, 12, 13, 14, and 15), the variables that scored high weights are Employees are responsible for pursuing quality improvements activities to road construction (0.931) and Employees are properly qualified to perform the work on the project (0.927). These findings are consistent with similar results obtained for quality-assurances practices incorporated in the construction SMEs such Mofokeng & Thwala (2012); Obare et al. (2016). Van Wyk (2003) summarised that, while project success still depends on formal project-management systems (project planning, cost control, and so on) and the availability of skilled people, the key point is that team members need to work with each other in a supportive setting in order to achieve successful project outcomes (Arditi & Gunaydin, 1997; Aigbavboa & Thwala, 2014); this leads to an increased ability for the designer and client to develop a shared understanding (Nkomo, Desai & Peerbhay, 2016). Leadership skills are important in leading the workforce (Kerzner, 2013). Martin et al. (2014) found that the effectiveness of construction SMEs needs to be supported by strong leadership that binds employees to form multifunctional and self-working groups.

In Factor 3: Process implementation and process improvement

(variables 1, 2, 4, 6, 8, and 11), the variables with high scores are The company has a programme of work to direct the road-construction project (0.751) and Local stakeholders are consulted before the road project starts (0.729). This finding agrees with similar studies that identified quality-assurances practices for road-construction SMEs such as Tshivhase & Worku (2012); Windapo & Cattel (2013); Vermeulen et al. (2018). Rumane (2011) notes that quality-assurances practices assures well-designed constructions, roads and provides skilled, practical advice, and work directly with designers and clients.

In Factor 4: Quality standards and measurements (Variables 3, 9, 10, and 11), the variables that had high loading are Policies and objectives are defined by the senior project management to ensure resources are used effectively (0.794) and Municipal managers promote the use of national standards when working with local contractors. (0.603). Studies on quality-assurances practices incorporated in the construction SMEs show similarity to variables in Factor 4: Ability to measure abilities and perform continuous improvement exercises (Honnakker et al., 2010; Kolbehdori & Sobhiyah, 2014) and ability to measure output (Mahmood et al., 2014). The significance of a quality standards and measurements have also been emphasised by Kam & Hamid (2014).

4.4 Quality of implementation and importance of quality-assurance practices

Table 6 ranks the mean scores to show which of the 35 variables measured have an influence on the quality of QA implementation and the importance of QA variables when they are applied in practice in road-construction SMEs.

The respondents indicated that only 13 assurance quality practices (AQPs) are excellently (>4.21 and <5.00) implemented in their practices, but the following AQPs scored mean score ratings above (>4.40), The organisational structure is aligned with QA processes (4.54); Planning, leading and control are facilitated effectively to ensure successful implementation of tasks (4.51); The quality of the road is defined, established and controlled at both strategic and process/operational levels (4.49); The organisation improves the execution of strategies and plans through formal structures, e.g. meetings (4.48), and Customer feedback systems are in place to link all business process-related communication (4.42). Although respondents indicated the level of implementation as good (>3.41 and <4.20), the following AQPs were ranked the lowest: Up-to-date training is provided for employees (3.53); Employees have a high level of satisfaction with the training programme (3.53), and Management is committed to providing QA/QC training (3.54).

The Cronbach alpha was greater than 0.70 at 0.959, indicating acceptable internal reliability as recommended by Hair et al. (2014: 102). The Kaiser-Meyer-Olkin (KMO) measure was 0.797, indicating that the data were sufficient for factor analysis. The Bartlett's Test of Sphericity (p=0.00) with significance of p<0.05 showed that there is some relationship between the variables. These results suggest that the data on the quality of implementation of QAPs can be used for factor analysis.

The respondents indicated all 35 AQPs applied in practice in road-construction SME as extremely important (>4.21 and <5.00), but the following scored mean score ratings above (>4.90): Quality control of construction work is conducted by supervising, monitoring, inspections and evaluations (4.96); QA procedures are applied to describe monitoring of survey implementation in actual settings (4.96); Unforeseen and/or different geotechnical conditions are described during the construction design (4.94); Scope of work or specification supports the reporting of mistakes by the project team (4.93); Management is committed to providing QA/QC training (4.92); Employees have a high level of satisfaction with the training programme (4.92); The design of road construction is formally reviewed (4.91); The organisational structure is aligned with QA processes (4.91), and Planning, leading and control are facilitated effectively to ensure successful implementation of tasks (4.91).

The Cronbach alpha was greater than 0.70 at 0.823, indicating acceptable internalreliability as recommendedby Hair et al. (2014: 102). The Kaiser-Meyer-Olkin (KMO) measure was 0.797, indicating that the data were sufficient for factor analysis. The Bartlett's Test of Sphericity (p=0.00) with significance of p<0.05 showed that there is some relationship between the variables. These results suggest that the data on the important QAPs can be used for factor analysis.

4.4.1 Exploratory factor analysis for implementation and importance of quality-assurance practices

The 35 variables measuring the Quality of QA implementation and the importance of QA variables were subjected to EFA to study the trend of inter-correlations between variables and to group these variables with similar characteristics into a set of reduced factors according to the hidden components in the collected data. The results report the factor extraction, Eigen values, correlation and interpretation.

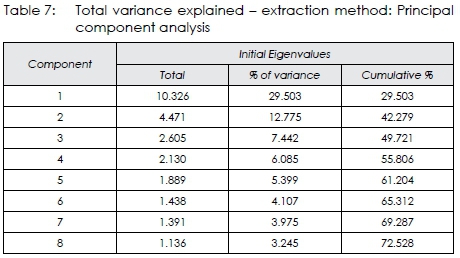

In Figure 2, the scree plot consists of the Eigenvalues and the data points above the break (point of inflexion). These components are meaningful to retain for rotation. Using a cut-off value of initial Eigenvalues greater than one (> 1.0), there were 8 components that explain a cumulative variance of 72.528%.

The scree plot confirms the finding of retaining 8 components. As a result, variables from 9 to 35 are not significant and thus not included for rotation. Table 7 shows the 8 components that are meaningful to retain, where component 1 explains 29.503% of the total variance; factor 2, 12.775%; factor 3, 7.442%; factor 4, 6.085%; factor 5, 5.399%; factor 6, 4.107%; factor 7, 3.975%, and factor 8, 3.245%.

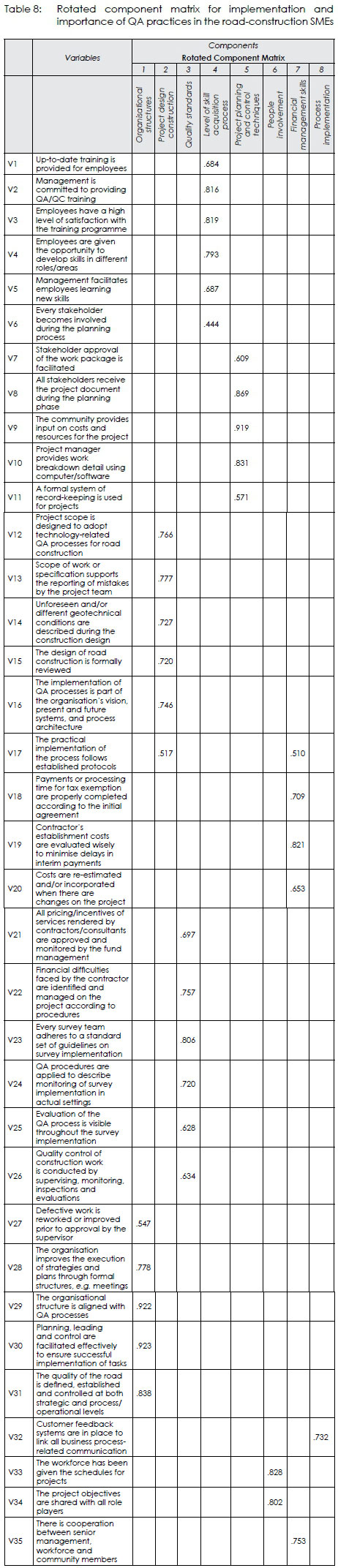

Using Principal Component Analysis and Varimax with Kaiser Normalization rotation method and with a significant factor of .04, Table 8 shows the correlation between components and variables after rotation. Correlation exists between variables 27, 28, 29, 30, and 31, as they load onto Component 1 label as Organisational structures. Correlations were identified between variables 12, 13, 14, 15, and 16, which loaded onto Component 2: Project design construction. Variables 21, 22, 23, 24, 25, and 26 show correlation, as they loaded onto Component 3 label as Quality standards. Correlations exist between variables 1, 2, 3, 4, 5, and 6, which all loaded onto Component 4: Level of skill acquisition process. Correlations were identified between variables 7, 8, 9, 10, and 11, which loaded onto Component 5: Project planning and control techniques. Variables 33 and 34 show correlation, as they loaded onto Component 6 label as People Involvement. Variables 17, 18, 19, 20, and 35 show correlation, as they loaded onto Component 7 label as Financial management skills. Variable 32 loaded onto Component 8: Process implementation.

In Factor 1: Organisational structures (component 1), the variables that had high loading are, for example, Planning, leading and control are facilitated effectively to ensure successful implementation of tasks (0.923); The organisational structure is aligned with QA processes (0.922), and The quality of the road is defined, established and controlled at both strategic and process/operational levels (0.838). Studies on the quality of implementation and importance of QAP in SMEs road-construction projects show similarity to variables in Factor 1: in building construction, Nguyen, Ogunlana & Lan (2004) found 4 critical success factors: comfort; competence; commitment, and communication.

In Factor 2: Project design construction (component 2), the variables that scored high weights are: Scope of work or specification supports the reporting of mistakes by the project team (0.777) and Project scope is designed to adopt technology-related QA processes for road construction (0.766). These findings concur with results obtained from similar studies such as Gotzamani & Tsiotras (2001); Haupt (2004); Kerzner (2013). Studies on the barriers of emerging contractors in developing countries show similarity to variables in Factor 1: poor site management (planning, organising, leading, controlling, and coordinating) (Gardiner, 2005); lack of understanding of quality (Honnakker et al., 2010); inadequate information and poor constructability (Badu & Owusu-Manu, 2011); majority of road-construction SMEs are not actively using the critical incident technique (George, 2016).

In Factor 3: Quality standards (component 3), the variables with high scores are: Every survey team adheres to a standard set of guidelines on survey implementation (0.806); Financial difficulties faced by the contractor are identified and managed on the project according to QA procedures (0.757), and QA procedures are applied to describe monitoring of survey implementation in actual settings (0.720). Similar findings were obtained in a survey undertaken on construction quality, which investigated the perceptions of a range of stakeholders and various construction sectors (Fotopoulos & Psomas, 2009; Nyakala, 2017). Enhancing construction quality standards has also been at the core of various initiatives in the construction industry (Statistics South Africa, 2017).

In Factor 4: Level of skill acquisition process (component 4), the variables that had high loading are: Employees have a high level of satisfaction with the training programme (0.819); Management is committed to providing QA/QC training (0.816), and Employees are given the opportunity to develop skills in different roles/areas (0.793). Efforts relating to continuing involvement of all stakeholders are needed to ensure the existence of general agreements and proper project control (Jarkas & Younes, 2014), and provide employees with assistance to help them use specific analysis tools (Kerzner, 2013). Skills shortages and insufficient workforce training, lack of management, and lack of strict quality control are the challenges facing the construction organisations involved in the construction of road projects (Kolbehdori & Sobhiyah, 2014).

In Factor 5: Project planning and control techniques (component 5), the variables that scored high weights are: The community provides input on costs and resources for the project (0.919); All stakeholders receive the project document during the planning phase (0.869), and Project manager provides work breakdown detail using computer/software (0.831). These findings concur with results obtained from similar studies such as Freeman-Bell & Balkwill (1996); Haupt & Whiteman (2004), and George (2016). Introduce tools and techniques to identify improvement opportunities (Rumane, 2011). This should include self-assessment, quality costing and benchmarking (Basu, 2004), and determinants of construction-project success (Mofokeng & Thwala, 2012).

In Factor 6: People Involvement (component 6), the variables with high scores are: The workforce has been given the schedules for projects (0.828), and The project objectives are shared with all role players (0.802). These findings concur with results from other studies on the implementation and importance of QAP. Involve employees responsible for performing the processes in the construction projects (Van Wyk, 2003; Fang & Wu, 2013); recognise and reward individual contributions to the process team (Bierman et al., 2013); improvement and development of formal meetings as communication systems help design team members (Obare et al., 2016), and enhance good project performance (Nyakala et al., 2017); improve and solve problems (Panuwatwanich & Nguyen, 2017).

In Factor 7: Financial management skills (component 7), the variables that had high loading are: Contractor's establishment costs are evaluated wisely to minimise delays in interim payments (0.820); There is cooperation between senior management, workforce and community members (0.753), and Payments or processing time for tax exemption are properly completed according to the initial agreement (0.709). Studies on the quality of implementation and importance of QAP in SMEs road-construction projects show similarity to variables in Factor 7: Availability of fund/resources has been ranked highest in recent researches (Aziz & Abdel-Hakam, 2016; George, 2016; Nyakala, 2017). Jarkas & Younes (2014) state that finance, properties, efforts, and leadership should always be available throughout the project's life.

In Factor 8: Process implementation (component 8), only one variable scored high weights: Customer feedback systems are in place to link all business process-related communication (0.732). These findings concur with results obtained from similar studies such as Nguyen and Ogunlana (2004), and Jogdand and Deshmukh (2017).

Several researches on factors affecting process implementation have proposed either specific factors or general factors (Aridti & Gunaydin, 1997; Ahadzie et al., 2008; Olawale & Sun, 2015). Their studies found conflict among project participants, material shortage, unavailability of resources, poor quality of available equipment, and unavailability of highly experienced qualified project managers.

5. Conclusion

In this study, the quality-assurance practices of SME contractors relating to the local government of the Limpopo province, South Africa, were analysed via a questionnaire created from a suitable context based on the road quality paradigm. The study established that, although some QAPs are perceived as extremely important, the level of implementation of these practices in road-construction SMEs is not excellent. Based on the results obtained, the majority of the respondents indicated that training practices such as up-to-date training for employees; satisfaction with training programmes, and management's commitment to provide QA/QC training are not yet excellently implemented in their firms.

All the critical success aspects were rated as extremely influential, with a weighted average score higher than 3.90. Among all indicators, 'Hired consultants monitor and evaluate quality control of construction work', with a mean of 3.97, had the highest rating and hence, was regarded as the most influential indicator. Correlation of critical success aspects variables using factor analysis identified factors 1, 5, 6, 7, 8, 9, 10, 12, and 13 as 'Project planning, control and construction; factors 6, 7, 8, 9, 12, 13, 14, and 15 as 'Level of skill acquisition and involvement of people'; factors 1, 2, 4, 6, 8, and 11 as 'Process implementation and process improvement', and factors 3, 9, 10, and 11 as 'Quality standards and measurements'.

All of the QAPs were rated as extremely important, with an average score higher than 4.21. 'Quality control of construction work is conducted by supervising, monitoring, inspections and evaluations' and 'QA procedures are applied to describe monitoring of survey implementation in actual settings', with a mean of 4.96, had the highest rating and hence, was regarded as the most important indicator.

Only 13 of the 35 QAPs were rated as being implemented excellently, with an average score higher than 4.40. 'The organisational structure is aligned with QA processes', with a mean of 4.54, had the highest rating and was regarded as the most excellent indicator.

Correlation of the QAP implementation and importance variables using factor analysis identified factor 1 as 'Organisational structures'; factor 2 as 'Project design construction'; factor 3 as 'Quality standards'; factor 4 as 'Level of skill acquisition process'; factor 5 as 'Project planning and control techniques'; factor 6 as 'People Involvement'; factor 7 as 'Financial management skills', and factor 8 as 'Process implementation'.

It is recommended that SME road-construction firms explore these 8 QAPs and monitor, inspect and evaluate QA at both strategic and operational or process levels in their firms. Chief Executive Officers (CEOs) and project managers/administrators should formulate policies, QA standards and regulations to support QA implementation by introducing practical QA guidance, training, and the measurement of awareness, compliance and selfless adherence to quality. In addition, QA training by QA experts for local governments should be undertaken in SME construction firms.

Professional bodies such as the CIDB and the Government should also formulate specific policies, QA standards and regulations to support QA implementation by introducing state incentives such as tax credit for clients, professionals and contractors who comply with QA in SMEs road-construction projects. This will enhance application of QA in the South African SMEs road-construction industry.

6. Further areas of research

Further study could determine that these reliable and valid QAPs can be used to successfully measure quality of roads infrastructure in construction projects undertaken by construction SMEs. Future studies could employ a more rigid research methodology to implement sustainable QA process efficiency, in order to achieve an improved road quality task at local government level. Furthermore, to justify these statements, these QAPs should be validated in a national study, in order to ensure that they positively influence the successful delivery of road-construction projects. This study can also be conducted in other African countries for comparative purposes.

References

Ahadzie, D.K., Proverbs, D.G. & Olomolaiye, P. 2008. Critical success criteria for mass housing building projects in developing countries. International Journal of Project Management, 26(6), pp. 675-687. https://doi.org/10.1016/j.ijproman.2007.09.006 [ Links ]

Aigbavboa, C.O. & Thwala, W.D. 2014. Challenges faced by Black-owned small and medium construction companies: A case study of Nelspruit-Mbombela Municipality, South Africa. Journal of Economics and Behavioural Studies, 6(10), pp. 771-778. [ Links ]

Arditi, D. & Gunaydin, H.M. 1997. Total quality management in the construction process. International Journal of Project Management, 15(4), pp. 235-243. https://doi.org/10.1016/S0263-7863(96)00076-2 [ Links ]

Aziz, R.F. & Abdel-Hakam, A.A. 2016. Exploring delay causes in road construction projects in Egypt. Alexandria Engineering Journal, 55(2), pp. 1515-1539. https://doi.org/10.1016/j.aej.2016.03.006 [ Links ]

Badu, E. & Owusu-Manu, D. 2011. An overview of construction activities in Kumasi. In: Adarkwa, K.K. (Ed.). The future of the tree -Towards development and growth. KNUST, Kumasi, Ghana: Kumasi University Printing Press, pp. 270-289. [ Links ]

Basu, R. 2004. Implementing quality: A practical guide to tools and techniques, enabling the power of operational excellence. Bedford Row, UK: Thompson. [ Links ]

Bierman, M., Marnewick, A. & Pretorius, J.H.C. 2013. Productivity management in the South African civil construction industry - factors affecting construction productivity. Journal of the South African Institution of Civil Engineering, 58(3), pp. 37-44. https://doi.org/10.17159/2309-8775/2016/v58n3a5 [ Links ]

Bowling, A. 1997. Research methods in health. Buckingham: Open University Press. [ Links ]

Bryman, A. 2012. Social research methods. 4th edition. New York: Oxford University Press. [ Links ]

CIDB (Construction Industry Development Board). 2012. The construction industry as a vehicle for contractor development and transformation. [Online]. Available at: <http://cidb.org.za/Documents/KC/cidb_Publications/Ind_Reps_Other/ind_reps_VehicleTrasformation_March12.pdf> [Accessed: 20 February 2016]. [ Links ]

Creswell, J.W. 2014. Research design: Qualitative, quantitative and mixed methods approaches. 4th edition. Thousand Oaks, CA: Sage. [ Links ]

Dallasega, P., Marengo, E., Nutt, W., Rescic, L., Matt, D.T. & Rauch, E. 2015. Design of a framework for supporting the execution management of small and medium sized projects in the AEC-industry. The 4th International Workshop on Design in Civil and Environmental Engineering. [ Links ]

Dangalazana, T. & Newadi, M.R. 2005. An exploratory study into the challenges facing the emerging contractors involved in the construction of low-cost housing in Wells Estate and Ikamv'elihle Townships in the Nelson Mandela Metropolitan, South Africa. World Congress on Housing: Transforming Housing Environment through Design. 27-30 September, Pretoria, South Africa. [ Links ]

Fang, D. & Wu, H. 2013. Development of a safety climate interaction (SCI) model for construction projects. Safety Science, 57(1), pp.138-149. https://doi.org/10.1108/02656710910928798 [ Links ]

Field, A. 2013. Discovering statistics using IBM SPSS statistics. 4th edition. Thousand Oaks, CA. Sage. [ Links ]

Fotopoulos, C.B. & Psomas, E.L. 2009. The impact of "soft" and "hard" TQM elements on quality management results. International Journal of Quality and Reliability Management, 26(2), pp. 150-163. [ Links ]

Freeman-Bell, G. & Balkwill, J. 1996. Management in engineering: Principles and practice. Englewood Cliffs, NJ: Prentice-Hall. [ Links ]

Gardiner, P.D. 2005. Project management: A strategic planning approach. New York, NY, USA: Palgrave MacMillan Ltd. [ Links ]

George, H. 2016. Eliciting the financial challenges facing emerging contractors in developing countries using the critical incident technique: A case of South African construction industry. Business and Management Horizons, 4(2), pp. 23-33. https://doi.org/10.5296/bmh.v4i2.10289 [ Links ]

Gotzamani, K.D. & Tsiotras, GD. 2001. An empirical study of the ISO 9000 standards' contribution towards total quality management. International Journal of Operations Production Management, 21(10), pp. 1326-1342. https://doi.org/10.1108/EUM0000000005972 [ Links ]

Hair, J.F., Black, W.C., Babin, B.J. & Anderson, R.L. 2014. Multivariate data analysis. 5th edition. Upper Saddle River, NJ: Prentice Hall. [ Links ]

Haupt, T.C. & Whiteman, D.E. 2004. Inhibiting factors of implementing total quality management on construction sites. The TQM Magazine 16(3), pp. 166-173. https://doi.org/10.1108/09544780410532891 [ Links ]

Helander, A. 2004. Customer care in system business. Doctoral thesis. Helsinki: Helsinki School of Economics. [ Links ]

Honnakker, P., Carayon, P. & Loushine, T. 2010. Barriers and benefits of quality management in the construction industry: An empirical study. Total Quality Management, 21(2), pp. 953-969. https://doi.org/10.1080/14783363.2010.487673 [ Links ]

Jogdand, P. & Deshmukh, S.S. 2017. Development of building quality measurement tool: Building construction quality index (BCQI). International Research Journal of Engineering and Technology (IRJET), 4(1), pp. 1020-1026. [ Links ]

Johnson, R.A. & Wichern, D.W. 2007. Applied multivariate statistical analysis. 6th edition. Upper Saddle River, NJ: Pearson. [ Links ]

Kaiser, H. 1994. An index of factorial simplicity. Psychometrika, 39, pp. 31-36. https://doi.org/10.1007/BF02291575 [ Links ]

Kam, K.J. & Hamid, A.H.A. 2014. The true motives behind the adoption of QLASSIC- CIS 7:2006. as a quality assurance initiative in construction industry. International Journal of Quality and Reliability, 32(6), pp. 603-616. https://doi.org/10.1108/IJQRM-07-2013-0108 [ Links ]

Kerzner, H.R. 2013. Project management: A systems approach to planning, scheduling, and controlling. Hoboken, NJ: John Wiley & Sons. [ Links ]

Kolbehdori, S. & Sobhiyah, M.H. 2014. Effect of negotiations about the formation of construction consortium on consortium successful performance in Iran's construction industry. International Journal of Management, Accounting and Economy, 1(5), pp. 346-349. [ Links ]

Kruger, D., Ramphal, R. & Maritz, M. 2014. Operations management. 3rd edition. Cape Town: Oxford University Press Southern Africa. [ Links ]

Jarkas, A.M. & Younes, J.H. 2014. Principal factors contributing to construction delays in the State of Qatar. International Journal of Construction Project Management, 6(1), pp. 39-62. [ Links ]

Leedy, P.D. & Ormrod, J.E. 2014. Practical research: Planning and design. 10th edition. Boston: Pearson. [ Links ]

Lorenzo-Seva, U., Timmerman, M.E. & Kiers, H.A. 2011. The Hull method for selecting the number of common factors. Multivariate Behavioral Research, 46(2), pp. 340-364. https://doi.org/10.1080/00273171.2011.564527 [ Links ]

Mahmood, S., Ahmed, S.M., Panthi, K. & Kureshi, N.I. 2010. Determining the cost of poor quality and its impact on productivity and profitability. Built Environment Project and Asset Management, 4(3), pp. 296-311. https://doi.org/10.1108/BEPAM-09-2013-0034 [ Links ]

Martin, A. & Lewis, M. 2014. Pinpointing safety leadership factors for safe construction sites in Trinidad and Tobago. Journal of Construction Engineering and Management, 140(2), 040133046. DOI: https://doi.org/10.1061/(ASCE)CO.1943-7862.0000795 [ Links ]

Mofokeng, G. & Thwala, W.D. 2012. Mentorship programmes within the Small and Medium Sized Contractor Development Programme: A case study of the Free State province, South Africa. Journal of Economics and Behavioural Studies, 4(12), pp, 712-722. [ Links ]

Nkomo, S.L., Desai, S. & Peerbhay, K. 2016. Assessing the conditions of rural road networks in South Africa using visual observations and field-based manual measurements: A case study of four rural communities in KwaZulu-Natal province. Review of Social Sciences, 1(2), pp. 42-55. https://doi.org/10.18533/rss.v1i2.24 [ Links ]

Nguyen, L.D., Ogunlana, S.O. & Lan, D.T.X. 2004. A study on project success factors in large construction projects in Vietman. Engineering, Construction and Architectural Management, 11(6), pp.404-413. https://doi.org/10.1108/09699980410570166 [ Links ]

Nyakala, K.S. 2017. Developing a road construction quality assurance process measurement tool: The case of Mopani District Municipality. Ph.D. thesis in Engineering Management, University of Johannesburg, South Africa. [ Links ]

Nyakala, K.S., Vermeulen, A., Pretorius, J.H.C. & Munyai, T. 2017. Implementation of quality assurance practices and effectiveness of the road construction industry: A case of South African local municipalities. In: Proceedings of the 2017 Global Business and Technology Association Conference, full date of conference, place of conference, pp. 636-650. [ Links ]

Obare, J.O., Kyalo, D.N., Mulwa, A.S. & Mbugua, J. 2016. Implementation process of project control systems and performance of rural roads construction project in Kenya: Role of project team experience diversity. European Scientific Journal, 12(29), pp. 408-422. https://doi.org/10.19044/esj.2016.v12n29p408 [ Links ]

Olawale, Y. & Sun, M. 2015. Construction project control in the United Kingdom: Current practice, existing problems, and recommendations for future improvement. International Journal of Project Management, 33(3), pp. 623-637. https://doi.org/10.1016/j.ijproman.2014.10.003 [ Links ]

Pallant, J. 2013. SPSS, Survival manual: A step-by-step guide to data analysis using IBM, SPSS. 5th edition. London: Allen & Unwin. [ Links ]

Panuwatwanich, K. & Nguyen, T.T. 2017. Influence of organisational culture on total quality management implementation and firm performance: Evidence from the Vietnamese construction industry. Management and Production Engineering Review, 8(1), pp. 5-15. https://doi.org/10.1515/mper-2017-0001 [ Links ]

Rossoni, L., Engelbert, R. & Bellegard, N.L. 2016. Normal science and its tools: Reviewing the effects of exploratory factor analysis in management. Revista de Administração, 51(2), pp. 198-211. https://doi.org/10.5700/rausp1234 [ Links ]

Rumane, R.J. 2011. Quality management in construction projects. Boca Raton, Florida: CRC Press Taylor & Francis Group, LCC. [ Links ]

Statistics South Africa. 2017. Statistical release manufacturing: Production and sales (Preliminary) April 2017. [Online] Available at: <http://www.statssa.gov.za/publication/P30412/P30412April2017.pdf> [Accessed: 25 May 2017]. [ Links ]

Tavakol, M. & Dennick, R. 2011. Making sense of Cronbach's alpha. International Journal of Medical Education, 2, pp. 53-55. https://doi.org/10.5116/ijme.4dfb.8dfd [ Links ]

Teddlie, C. & Tashakkori, A. 2003. Handbook of mixed methods in social and behavioural research. London: Sage. [ Links ]

Thorpe, B., Summer, P. & Duncan, J. 1996. Quality assurance in construction. Surrey, UK: Gower Publishing Ltd. [ Links ]

Tshivhase, L. & Worku, Z. 2012. Barriers toward the development of emerging contractors in the Limpopo province. African Journal of Science, Technology, Innovation and Development, 4(1), pp. 41-62. [ Links ]

Van Wyk, L. 2003. A review of the South African construction industry: Economic, regulatory and public sector capacity influences on the construction industry. Pretoria: CSIR. [ Links ]

Vermeulen, A., Nyakala, K.S. & Pretorius, J.H.C. 2018. Development of a road quality assurance measurement tool in construction projects. In: Proceedings of the 2018 International Conference on Management of Technology (2018 IAMOT), 22-26 April, Birmingham, England. Aston University Business School: Operations and Information Management Group, pp.1-14. [ Links ]

Wahab, O.M., Ayodele, A.E. & Moody, J.O. 2010. TLC phytochemical screening in some Nigerian Loranthaceae. Journal of Pharmacognosy and Physiotherapy, 2(5), pp. 64-70. [ Links ]

Windapo, A.O. & Cattel, K. 2013. The South African construction industry: Perceptions of key challenges facing its performance, development and growth. Journal of Construction in Developing Countries, 18(2), pp, 65-79. [ Links ]

Yang, J., Shen, Q. & Ho, M. 2009. An overview of previous studies in stakeholder management and its implications for the construction industry. Journal of Facilities Management, 7(2), pp. 159-175. https://doi.org/10.1108/14725960910952532 [ Links ]

Yount, R. 2006. Research design and statistical analysis in Christian ministry. 4th edition. Fort Worth, TX: Southwest Baptist Theological Seminary. [ Links ]

Peer reviewed and revised February 2019

Published June 2019

* The authors declared no conflict of interest for the article or title