Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Acta Structilia

On-line version ISSN 2415-0487

Print version ISSN 1023-0564

Acta structilia (Online) vol.25 n.2 Bloemfontein 2018

http://dx.doi.org/10.18820/24150487/as25i2.6

RESEARCH ARTICLES

The impact of the Construction Regulations 2014 on a water utility's projects' health and safety (H&S) performance in South Africa

Mandy MalindiI; John SmallwoodII

IMaster's graduate, Department of Construction Management, Nelson Mandela University, Port Elizabeth, South Africa. Phone: +27 0-11-682-0078, e-mail: <mandymalindi@gmail.com>

IIDepartment of Construction Management, Nelson Mandela University, Port Elizabeth, South Africa. Phone: +27 0-41-504-2790, e-mail: <john.smallwood@mandela.ac.za>

ABSTRACT

The construction industry plays a major role in South Africa's economic development. Despite its importance, the poor health and safety (H&S) performance and associated costs to the industry are a concern. The literature review indicates that improved H&S performance can be achieved on a project where there is a collaborative approach among all stakeholders during the six project stages. This study focuses on the impact of the Construction Regulations 2014 on a water utility's projects' H&S performance. It determines the H&S involvement of client representatives and internal project stakeholders during the six project stages. It also addresses their commitment towards H&S, measures taken by them during planning and design, in contracts to improve H&S, and to select conscious contractors, and the extent of their H&S participation in construction H&S. Mixed methods research (a questionnaire survey and four case study projects) was used to collect the data required for the study. A total of 67 responses were obtained from the five stakeholder groups from the water utility, namely client representatives, designers, quantity surveyors (QSs), project managers (PMs), and construction H&S (CHS) professionals to obtain information regarding their H&S involvement during the six project stages. Four case study projects (three pre-Construction Regulations 2014 and one post-Construction Regulations 2014) were obtained, using a stratified random sampling technique and a checklist to obtain information regarding the stakeholder H&S involvement during the six project stages and the overall project performance. The study found that the Construction Regulations 2014 are perceived to have had an impact on the water utility's H&S performance. There is a direct relationship between stakeholder H&S involvement and project H&S performance. The integration of H&S in the initial project phases; early involvement of CHS professionals, and H&S training for stakeholders are among the recommendations arising from this study.

Keywords: Clients, construction health and safety professionals, designers, project managers, quantity surveyors

ABSTRAK

Die konstruksiebedryf speel 'n belangrike rol in Suid-Afrika se ekonomiese ontwikkeling. Ten spyte van die belangrikheid daarvan, is die swak gesondheids-en veiligheids (G&V)-prestasie en verwante koste kommerwekkend. Die literatuuroorsig dui daarop dat verbeterde G&V-prestasie behaal kan word op 'n projek waar daar tydens die ses projekfases 'n samewerkende benadering onder alle belanghebbendes is. Hierdie studie fokus op die impak van die Konstruksie Regulasies 2014 op 'n watertoevoerprojek se G&V-vertoning. Dit bepaal die G&V-betrokkenheid van kliëntverteenwoordigers en interne projekbelanghebbendes gedurende die ses projekfases. Die artikel ondersoek ook hul verbintenis tot G&V en die maatreëls wat hulle tydens beplanning en ontwerp geneem het in kontrakte om G&V te verbeter. Verder ondersoek die artikel die kies van G&V-bewuste kontrakteurs asook die omvang van hul G&V-deelname aan konstruksie G&V. Die gemengde metode van navorsing ('n vraelysopname en vier gevallestudie-projekte) is gebruik om die data vir die studie te verkry. 67 Response is verkry vanuit die vyf watertoevoerprojekbelanghebbendes, naamlik kliëntverteenwoordigers, ontwerpers, bourekenaars (QS's), projekbestuurders (PM's) en konstruksie-G&V (GVP) professionele persone om inligting oor hul G&V-betrokkenheid te verkry gedurende die ses projekte stadiums. Vier gevallestudies (drie voor-Konstruksie Regulasies 2014 en een na-Konstruksie Regulasies 2014) is verkry deur gebruik te maak van 'n gestratifiseerde ewekansige steekproefnemingstegniek. 'n Kontrolelys is gebruik om inligting oor die belanghebbendes se G&V-betrokkenheid tydens die ses projekfases te verkry asook die algehele projekprestasie. Bevindinge toon dat die Konstruksie Regulasies 2014 'n impak het op die G&V van die watertoevoerprojek. Daar is 'n direkte verhouding tussen die belanghebbendes se G&V-betrokkenheid en die projek se G&V-prestasie. Die integrasie van G&V in die aanvanklike projekfases; vroeë betrokkenheid van die GVP-professionele persone, en G&V-opleiding vir belanghebbendes is van die aanbevelings wat uit hierdie studie voortspruit.

Sleutelwoorde: Bourekenaars, kliënte, konstruksie gesondheids- en veiligheidspersoneel, ontwerpers, projekbestuurders

1. Introduction

The construction industry is considered to be risky, as it experiences high accident rates and ill-health problems (Muiruri & Mulinge, 2014: 2). The South African Department of Labour reported a rise in accidents during the period 2004/2005 to 2007/2008, with 162 fatalities in 2007/2008, excluding motor vehicle accidents, and 396 non-fatal accidents, namely temporary or permanent disablements (DoL, 2012: online; cidb, 2009: 2).

To improve South African H&S performance, the Minister of Labour published a Government Notice under Section 43 of the OHS Act containing the Construction Regulations 2014, which repealed the Construction Regulations 2003 (RSA, 2014). In line with international trends, the Construction Regulations in South Africa include the client and the final end-user (cidb, 2009: 17). The intention of the Construction Regulations is to reduce the number of fatalities, injuries, and disease plaguing the construction industry. However, despite the promulgation of the Construction Regulations, a disproportionate number of accidents continue to occur in South Africa. The disabling injury incidence rate (DIIR) for the contractors undertaking work for the water utility, that is the subject of the study over the past three years, is above the industry average of 0.98 (cidb, 2009: 4), and a high level of H&S non-compliance is experienced on their related construction sites. This deficient performance, therefore, prompts the question as to whether clients and project stakeholders involved in the water utility's projects become adequately involved in construction H&S during the six stages of the project. This study focuses on the impact of the Construction Regulations 2014 on a water utility's projects' H&S performance. The aim of this study is to determine the H&S involvement of client representatives and internal project stakeholders during the six project stages. The research objectives include their commitment towards H&S; measures taken by them during planning and design, in contracts to improve H&S, and to select conscious contractors, and the extent of their H&S participation in construction H&S.

Identification of such H&S involvement will ensure that proper strategies are put in place to deal with construction H&S issues during the six project stages, which, in the long term, will cause a reduction in accidents that occur on construction projects.

2. Literature review

2.1 Construction H&S management

The construction industry is regarded as the most hazardous industry with complex processes and unique challenges that influence H&S management and contribute to a high number of incidents, including fatalities (Saifullah & Ismail, 2012: 604; Kamardeen, 2013: 2; Sunindijo & Zou, 2015: 29). A report from the DoL (2012) states that the building and construction sector is one of the high-risk sectors that was compensated more than R287 million for occupational injuries in 2010/2011 and experienced 171 fatalities and 755 injuries from 2007 to 2010.

According to Kikwasi (2009: 61), H&S management is inadequate in the industry, due to H&S not being taken seriously by parties involved in construction projects; clients and consultants being more concerned with quality of work than with H&S; inadequate H&S personnel and equipment; construction workers not trained or made aware with respect to the need to comply with H&S requirements; H&S not being budgeted for; H&S not being considered at the tendering stage and, as a result, clients expecting contractors to bear H&S-associated costs during project execution, and lastly, clients and contractors assuming that not making allowance for H&S reduces the project and construction cost.

The poor H&S performance and non-participation by key project stakeholders such as clients and designers motivated the promulgation of the construction H&S legislation in 2003 to foster multi-stakeholder interventions and participation (Agumba, Pretorius & Haupt, 2016: 70). The Construction Regulations (RSA, 2014) stipulate all H&S requirements in the construction industry that must be complied with by the client, the client's agent, the designer, the principal contractor, and the contractors.

The 2014 amendments include the construction work permit (CWP), and the registration of construction H&S professionals with the South African Council for the Project and Construction Management Professions (SACPCMP) in terms of Act No. 48 (RSA, 2000). These changes are intended to drive a H&S cultural change to ensure collaboration of all key stakeholders on all matters of H&S throughout the project. However, the industry has not fully implemented the CWP process, due to the exemption notice given by the Minister in July 2015. The vast majority of organisations with construction projects of less than R40 million have not fully realised its impact.

The Construction Regulations are perceived to have had a positive impact in terms of reducing H&S accidents and have increased the level of H&S awareness. They have also increased PMs' and general contractors' consideration of, or reference to H&S (cidb, 2009: 11). However, they have not increased designers' and QSs' consideration of, or reference to H&S.

2.2 H&S in the six construction project stages

Figure 1 shows the project stages, as defined by the SACPCMP, used for this study.

Various project stakeholders influence construction H&S throughout the six project stages. Research indicates that clients, designers, PMs, and QSs influence and can contribute to H&S. However, their involvement is not constant; it differs during the various project stages (Powell, 2012: 23). The client and the asset management staff are highly involved in Stages 1 and 2, less involved in Stage 3, and then more involved at take-over at the end of Stage 5; the designer is mostly involved in Stage 3, and usually involved in Stages 2, 4 and 5.

A study undertaken by Phoya & Eliufoo (2015: 424) among key project stakeholders such as clients, PMs, architects, engineers, QSs, site managers, and workers found that power is a predominant factor in terms of stakeholders' participation in H&S management. It was also found that power has the potential to influence H&S performance. The diverse sources of power among project stakeholders created opportunities for them to participate in H&S in the various project stages. It was found that clients and PMs have substantial influence throughout the project stages, whereas other stakeholders such as architects, engineers, and QSs had substantial influence when they executed their duties in specific project stages. However, the use of influence was generally low, due to low levels of knowledge relative to H&S risk management among stakeholders. Their perception was that their participation would lead to increased cost, time wastage, and that it was not their responsibility. CHS professionals are not involved during the appropriate stages to influence the design or any critical H&S issues (Deacon & Smallwood, 2016: 6). The lack of knowledge of construction, formal and continued education, support from clients, and the buy-in at many levels are some of the barriers faced by CHS professionals, thus preventing them from ensuring adequate levels of H&S (Deacon, 2009: 3). This indicates that H&S involvement is "fragmented resulting in varying degrees of statutory compliance", thus increasing project risk. The SACPCMP has developed professional roles and responsibilities that are aligned to the six project stages for each of the CHS professional categories to manage these challenges.

2.2.1 Stage 1 (project initiation and briefing) and Stage 2 (concept and feasibility)

Research confirms that clients play a key role in project implementation. This is also reflected in the United Kingdom's CDM regulations of 2015, and the South African Construction Regulations 2014 that require them to manage H&S throughout the project (Phoya & Eliufoo, 2015: 424). Clients can positively influence project H&S performance, since they contribute to the funding of the project, and are able to include H&S during objective identification and project brief (Saifullah & Ismail, 2012: 606). Due to constraints during the development of a project brief, the client may reduce the project budget, add new project criteria, change project objectives, and accelerate the design or the construction efforts of the project that play an essential role in accident occurrences (Said, Shafiei & Omran, 2009: 128). According to Lopes, Haupt and Fester (2011: 9), common H&S problems encountered during construction could be avoided if H&S was considered during the project brief and design phase (Saifullah & Ismail, 2012: 606).

2.2.2 Stage 3 (design)

The design phase provides an opportunity to eliminate hazards before they appear on the construction site. The ability to eliminate hazards diminishes as the project progresses. Research indicates that QSs have a direct influence on construction H&S by drawing up specifications that ensure contractors make adequate provision for H&S, whereas designers have a direct influence on construction H&S when they consider H&S in their designs. Saifullah and Ismail (2012: 606) state that most of the H&S issues arise from inadequate design, due to design professionals not taking responsibility owing to a lack of H&S education and training, lack of H&S design tools, and their attempt to limit their liability exposure (Saifullah & Ismail, 2012: 606). Studies undertaken by Gambatese, Behm and Rajendran (2007: 676) and by Tymvios and Gambatese (2015: 1) provide evidence of the link between a project's design and construction site injury and fatality incidents.

2.2.3 Stage 4 (tender documentation and procurement)

According to Wells and Hawkins (2010: 3), procurement systems are instrumental in promoting H&S practices. However, minimum attention is paid to improve procurement standards. A study undertaken by Haupt and Hefer (2015: 456) found that H&S was not adequately addressed in standard forms of construction contracts used in South Africa. Similar studies found that contract documentation did not provide contractors with the opportunity to price for H&S for improving H&S performance (Kikwasi, 2009: 58), and the H&S specifications in the tender documents are marginally project-specific and relatively lengthy (Smallwood, 2007: 338). Research indicates that there is limited emphasis on H&S requirements, and that budgeting for H&S in the contract documents ranged from 0.21% to 1.99% of the contract value (Latib, Zahari, Hamid & Yee, 2016: 53). However, according to the cidb (2009: 9), the cost of H&S is approximately 5.0% of the value of a contract.

According to Saifullah and Ismail (2012: 608), the traditional procurement system focuses on tender cost, thus restricting contractors to work more efficiently. Such competitive tendering marginalises H&S (Smallwood & Venter, 2002: 59).

2.2.4 Stage 5 (construction)

PMs play a vital role in the execution of projects (Phoya & Eliufoo, 2015: 424) and are empowered by the conditions of the contract to issue instructions and inspect the contractor's work on behalf of the client. Research indicates that continuous monitoring and reviewing of H&S management practices are required in order to improve the poor H&S record and to enhance overall legal compliance. A study revealed that 60% of clients conduct periodic job-site H&S inspections or H&S audits; 50% of them participate in contractor H&S meetings; 20% of them participate in the investigation of all lost workday injury accidents, and 3% of clients employ H&S personnel on the project site to monitor injury incidence rate (Said, Shafiei & Omran, 2009: 130).

2.2.5 Stage 6 (project close-out)

The last major phase of a construction project is when a client receives and approves all reports as required by the terms and conditions of the award, and notifies the contractor of the final acceptance and closure of the project (Mpanza, Mututo & Pearl, 2008: 134). A study conducted among PMs determined that inadequate or lack of H&S or H&S non-compliance indirectly impacts on the overall project performance parameters of productivity, quality, cost, client perceptions, environment, and schedule (cidb, 2009: 8). Research recommends that, at this stage, both successes and problems on the project should be identified through a 'lessons learned' process, which can be applied during Stage 1 of future projects, in order to improve project performance.

3. Research methodology

This study focused on the impact of the Construction Regulations 2014 on a water utility's projects' H&S performance and addressed the H&S involvement of client representatives and internal project stakeholders during the six project stages. The study used a mixed methods design, in which quantitative and qualitative data were collected and analysed. Conclusions were then integrated (Leedy & Ormrod, 2015: 329). A questionnaire survey and four case study infrastructure projects were used to obtain data from a large water utility in South Africa, within which several substantial construction projects were undertaken. The case study is a type of applied qualitative research, in which in-depth data are gathered relative to a single individual programme or event for the purpose of learning more about an unknown or poorly understood situation (Leedy & Ormrod, 2015: 329). The case study was found most appropriate for investigating the extent of stakeholder H&S involvement during the six project stages over a period based on the overall project performance as a result of the Construction Regulations. This complemented the quantitative research.

3.1 Sampling method and size

A combined list of 137 staff members, consisting of client representatives and project stakeholders working within the water utility, was obtained from the internal online directory available on the intranet. The staff list was stratified in five stakeholder groups, namely client representatives (17), designers (49), QSs (4), PMs (53), and CHS professionals (14).

A simple stratified random sampling selection method resulted in a sample size of 67, representing client representatives (11), designers (14), QSs (4), PMs (27), and CHS professionals (11). The sample size for construction-related professionals was calculated in accordance with the table recommended by Krejcie & Morgan (1970: 608) and required sample size calculator by The Research Advisors (2006). The table gives recommended sample sizes for general research activities, applicable to any defined population. From the required sample size calculator based on the table, the recommended sample size for a population of 137, a confidence level of 95%, and a margin of error (degree of accuracy) of 8.6% would be 67. This recommendation validates the sample size of 67 as efficient for the population of 137.

The case study compared historic data from a sample of four projects based on a stratified random sample of projects selected by separating the projects into mutually exclusive sets, or strata and then drawing a simple random sample from each stratum. This list of projects was then generated from Systems Applications and Products (SAP), and the following criteria were used to separate the projects into strata:

A. Pre-Construction Regulations 2014 completed process plant construction projects;

B. Pre-Construction Regulations 2014 completed pipeline construction projects;

C. Pre-Construction Regulations 2014 completed upgrade of dam projects, and

D. Post-Construction Regulations 2014 construction projects falling under the Annexure 1 CWP requirement that is still in progress.

3.2 Data collection

The questionnaire was evolved based on the findings emanating from the literature review. It consisted of fifteen (15) questions, fourteen (14) being close ended, using a 5-point Likert scale, and one being open ended, the latter allowing for the recording of general comments. The survey used a single instrument for all respondent groups and was pre-tested. The questionnaire was e-mailed and posted to client representatives and project stakeholders to the target population within the water utility. Respondents were asked to indicate the importance of various parameters: the level of contribution by various stakeholders during the six project stages; the importance of H&S during the six project stages; the extent to which H&S can be influenced during the six project stages; the level of H&S involvement by various stakeholders during the six project stages; the frequency of H&S actions undertaken by the various stakeholders during the six project stages; the factors that contribute to optimum H&S, and the contribution of the Construction Regulations 2014 on a project. While 52 of the respondents completed the questionnaire via email and replied via email, 15 respondents hand-delivered the questionnaire to the researcher. Further information was requested from those who replied using emails, where clarity was required.

For the case studies, three completed pre-Construction Regulations 2014 projects and one active post-Construction Regulations 2014 project were selected. The selection criteria for the case study projects included projects that expended 100 000 person hours, had contract values in excess of R100 million, and had project H&S information that was available. The active project selected was the only CWP project undertaken by the water utility to obtain recent information after the amendments made to Construction Regulations 2014.

All project documents were examined against a scorecard checklist based on a study done by Huang (2003: 120) that contained a list of client and project stakeholder H&S actions that had a direct impact on influencing H&S performance and included aspects of project context; selection of contractor; contractual H&S requirements; contractor H&S programme requirements, and client's involvement in project H&S management. This scorecard evaluated the level of client and project stakeholder involvement per project and determined the pattern of compliance to the Construction Regulations during the different periods measured as a percentage.

3.3 Data analysis and interpretation of findings

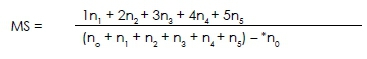

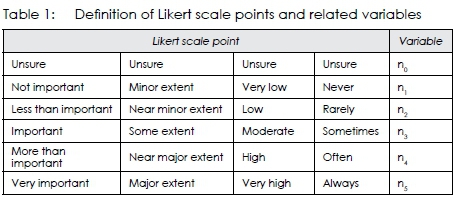

Responses from the questionnaire were captured using the Excel software program, and the analysis of data consisted of the calculation of descriptive statistics to depict the frequency distribution and central tendency, namely a mean score (MS), of responses to fixed response questions. To interpret the findings, the fixed response items were ranked according to the central tendency of responses. MSs were calculated as follows:

* n0 were removed relative to non-importance questions.

The variables are referenced in Table 1.

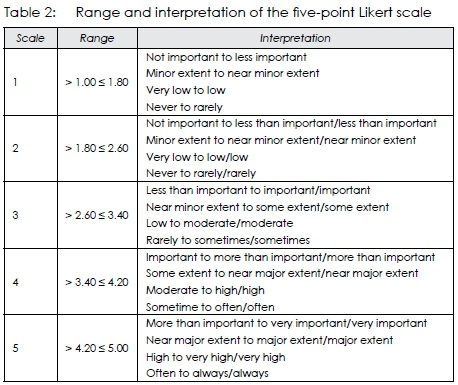

In order to describe the data in more detail, the following ranges and interpretation were used in analysing the weighted MS, as referenced in Table 2.

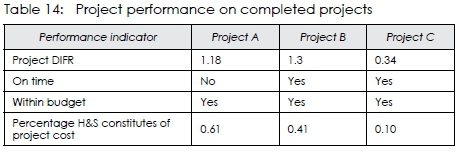

The documentation from the sampled case study projects was examined according to each of the 25 criteria on the checklist scorecard. The information reviewed was interpreted as criteria either being met, or not being met, respectively, by way of 'yes' and 'no' responses and captured using the Excel software program. The data for each project was given a percentage score to show the level of involvement in the project and grouped according to the bins as determined by Huang (2003: 120): < 52% (weak involvement); > 52% < 88% (moderate involvement); > 88% (strong involvement). This data was compared with the project performance for each project, i.e. on time, DIFR, within budget, and the percentage H&S constituted of the project.

4. Findings and discussion

4.1 Questionnaire results

4.1.1 The importance of project parameters

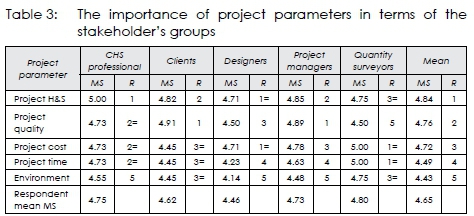

Table 3 indicates the importance of five parameters to the respondents on a scale of 1 (not important) to 5 (very important), and a MS ranging between 1.00 and 5.00.

The respondent mean MSs are all between > 4.20 < 5.00, indicating that stakeholders perceive H&S, quality, cost, time, and environment as more than important to very important/very important parameters to measure successful projects.

Both clients and PMs perceive quality as the most important project parameter, and H&S as the second most important parameter. Designers perceive cost and H&S as the most important project parameter, and thereafter quality as the second most important parameter. QSs consider project cost and time as the most important project parameters, and CHS professionals perceive project H&S as the most important project parameter.

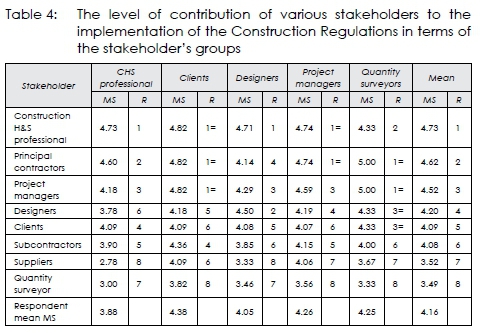

4.1.2 The level of contribution of the various stakeholders to the implementation of the Construction Regulations 2014

Table 4 indicates the level of contribution of the various stakeholders to the implementation of the Construction Regulations 2014 in terms of the stakeholder's groups on a scale of 1 (minor) to 5 (major), and a MS ranging between 1.00 and 5.00.

The respondent mean MSs are > 3.00, indicating that respondents perceived all eight stakeholders to contribute to the implementation of the Construction Regulations. CHS professionals, principal contractors, and PMs are the only stakeholders with MSs > 4.20 < 5.00, indicating that they are deemed to make between a near major to major/major contribution to the implementation of the regulations. PMs, designers, and CHS professionals view themselves as major contributors to the implementation of the Construction Regulations.

4.1.3 The importance of H&S; the extent to which project H&S can be influenced, and the level of H&S involvement during the six project stages

Table 5 indicates i) the importance of H&S; ii) the extent to which project H&S can be influenced, and iii) the level of H&S involvement during the six project stages on a scale of 1 (not important/minor/very low) to 5 (very important/major/very high), and a MS ranging between 1.00 and 5.00.

The respondent mean MSs are > 3.00 for (i) and (ii), indicating that all stakeholders perceive H&S to be important, and that it can be influenced during the six project stages.

For item (i), Stages 5, 6, 3, and 4 have MSs that are > 4.20 < 5.00; therefore, H&S can be deemed to be between more than important to very important/very important during these stages. It is notable that H&S is perceived to be more important in Stage 5 and ranked first among the other stages, whereas Stages 2 and 1 were ranked fourth and fifth based on their MSs.

For item (ii), Stages 5, 6, and 3 have MSs > 4.20 < 5.00, indicating that H&S can be influenced between a near major to major/major extent during these stages. The vast majority of the stakeholders ranked Stage 5 as the first stage at which H&S can be influenced, and ranked Stages 2 and 1 as the stages when H&S can be least influenced.

For item (iii), the respondent mean MSs for clients, designers, PMS are > 3.00, indicating that these stakeholders are involved in H&S during the six project stages. Stages 3 to 6 have MSs above the mid-point score of 3.00, indicating H&S involvement during these stages. It is notable that Stage 5 has a MS > 4.20 < 5.00, indicating high to very high/very high involvement during this stage.

The involvement of clients in construction H&S during the various project stages is between moderate to high/high, except for Stage 4, which is between low to moderate/moderate. The involvement of designers in construction H&S in Stage 3 is between moderate to high/high, and in the other remaining Stages it is between low to moderate/moderate. The involvement of PMs in construction H&S in Stages 4 and 6 is between moderate to high/high; Stage 5 is between high to very high/very high, and in Stages 1 to 3 it is between low to moderate/moderate. The involvement of QSs in construction H&S in Stages 1 to 3 is between very low to low/ low; Stage 4 is between low to moderate/moderate; Stage 5 is between high to very high/very high, and Stage 6 is between moderate to high/high. The involvement of CHS professionals in construction H&S in Stages 1 and 2 is between low to very low/very low; Stage 3 is between very low to low/low; Stage 4 is between low to moderate/moderate; Stage 5 is between high to very high/ very high, and Stage 6 is between moderate to high/high.

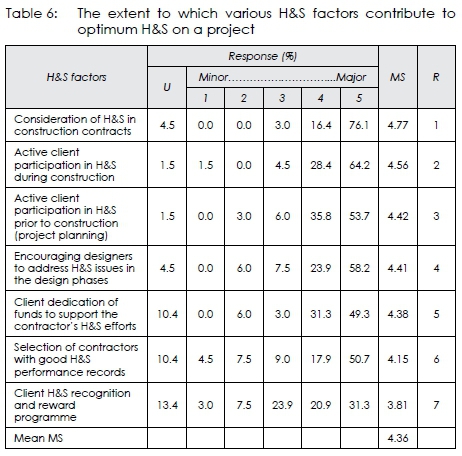

4.1.4 The extent to which various H&S factors contribute to optimum H&S on a project

Table 6 indicates the extent to which various factors contribute to optimum H&S on a project, on a scale of 1 (minor) to 5 (major), and in terms of MSs ranging between 1.00 and 5.00.

The mean MS is > 3.00, showing that all stakeholders perceive the various H&S factors rated to contribute to optimum H&S on a project. It is notable that the top five ranked factors 'Consideration of H&S in construction contracts'; 'Active client participation in H&S during construction'; 'Active client participation in H&S prior to construction (project planning)'; 'Encouraging designers to address H&S issues in the design phases', and 'Client dedication of funds to support the contractor's H&S efforts' have > 4.20 < 5.00, indicating a near major to major/major contribution to optimum H&S on a project.

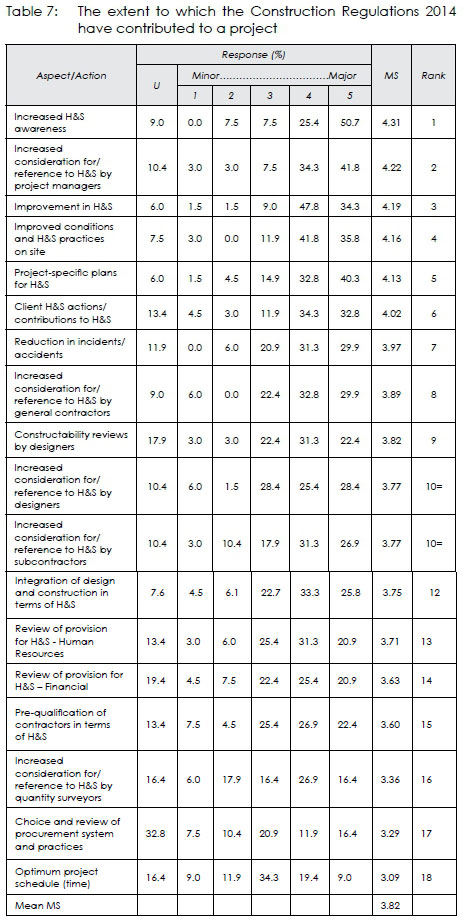

4.1.5 The extent to which the Construction Regulations 2014 have contributed to a project

Table 7 indicates the extent to which the Construction Regulations 2014 have contributed to a set of positive aspects/actions on a project, on a scale of 1 (minor) to 5 (major), and in terms of MSs ranging between 1.00 and 5.00.

The mean MS is > 3.00, showing that the respondents perceived the Construction Regulations 2014 to contribute to a set of positive aspects/actions on a project. It is notable that the top two ranked aspects/actions, namely 'Increased H&S awareness' and 'Increased consideration for/reference to H&S by project managers' have MSs > 4.20 < 5.00, indicating between a near major to major/major contribution on a project. It is notable that 32.8% of the respondents were unsure as to the choice and review of procurement system and practices. This is attributed to the low to moderate/moderate involvement of stakeholders in Stage 4.

4.1.6 The frequency at which H&S actions are perceived to be undertaken during the six project stages

Tables 8 to 13 present the frequency at which the respondents perceive H&S actions to be undertaken during the six project stages in terms of a frequency range unsure, never, rarely, sometimes, often, and always. The H&S actions undertaken during the six project stages are ranked based upon a MS ranging between 1.00 and 5.00.

Table 8 presents the frequency at which the respondents perceive the four H&S actions to be undertaken during Stage 1.

Given that three of the four H&S actions' MSs > 3.00, these actions can be deemed to be prevalent during this stage. It is notable that three H&S actions, namely 'Set project H&S goals', 'Involve the H&S agent in project initiation meetings' and 'Determine the optimum contract duration' fall within the range > 2.60 < 3.40, between rarely to sometimes/sometimes. The respondent mean MS of all actions for CHS professionals, PMs, and QSs is perceived to be undertaken at a frequency between rarely to sometimes/sometimes, whereas clients and designers perceive these actions to be undertaken between sometimes to often/often.

Table 9 presents the frequency at which the respondents perceive the nine H&S actions to be undertaken during Stage 2.

The CHS professionals', designers' and PMs' mean MSs signify that they perceive all H&S actions to be undertaken at a frequency between rarely to sometimes/sometimes on average, whereas the clients' and QSs' mean MSs signify that they perceive all H&S actions to be undertaken between sometimes to often/often on average.

Six H&S actions (66.7%) have MSs of > 3.00. However, no H&S actions' MSs fall within the range > 4.20 < 5.00, between often to always/always. The MSs of 'Compile a draft H&S specification' and 'Identify general H&S issues in the project inception report' fall within the range > 3.40 < 4.20, between sometimes to often/ often. The MSs of five H&S actions that are ranked third to seventh fall within the range > 2.60 < 3.40, between rarely to sometimes/ sometimes. It is notable that the last two ranked H&S actions' MSs, namely 'Audit specialists undertaking investigations' and 'Involve the H&S agent in design meetings' fall within the range > 1.80 < 2.60, between never to rarely/rarely.

Table 10 presents the frequency at which the respondents perceive the seven H&S actions to be undertaken during Stage 3.

Given that only 28.6% of the H&S actions have MSs > 3.00, these actions can be deemed to be little prevalent during the design development stage. It is notable that the last ranked H&S action's MS, namely 'Involve the H&S agent in design meetings' falls within the range > 1.80 < 2.60, between never to rarely/rarely. The CHS professionals', designers', and QSs' mean MSs signify that they perceive all H&S actions to be undertaken between rarely to sometimes/sometimes on average, whereas the clients' mean MS signifies that they perceive all H&S actions to be undertaken between sometimes to often/often on average. Lastly, the PMs' mean MS signifies that they perceive these actions to occur between never to rarely/rarely.

Table 11 presents the frequencies at which the respondents perceive the seven H&S actions to be undertaken during Stage 4.

All stakeholder groups show a respondent mean MS of > 3.00, indicating that the respondents perceived H&S actions to be prevalent during the tender documentation and procurement stage. It is notable that one H&S action's MS, namely 'Provide a project-specific H&S specification/H&S information as part of the tender documentation' falls within the range > 4.20 < 5.00, between often to always/always. The sixth ranked H&S action's MS, namely 'Pre-qualify or select contractors based on H&S performance' falls within the range > 2.60 < 3.40, between sometimes to rarely/rarely. It is notable that the last ranked H&S action's MS, namely 'To avoid competitive tendering' falls within the range > 1.80 < 2.60, between never to rarely/rarely. It is notable that 46.3% of the respondents were unsure about 'Avoid competitive tendering'.

Table 12 presents the frequencies at which the respondents perceive the twelve H&S actions to be undertaken during Stage 5.

All stakeholder groups show a respondent mean MS of > 4.20, indicating that the respondents perceived H&S actions to be prevalent often to always/always during the construction management and documentation stage. The top ten H&S actions' mean MSs fall within the range 4.20 and 5.00, between often to always. The last ranked H&S action's mean MS, namely 'Provide funds above and beyond the contract value to promote H&S' falls within the range 2.60 and 3.40, between sometimes to rarely.

Table 13 presents the frequencies at which the respondents perceive the seven H&S actions to be undertaken during Stage 6.

All stakeholder groups show a respondent mean MS > 3.00, indicating that the respondents perceived H&S actions to be prevalent during the project close-out stage. The CHS professionals', clients', and designers' mean MSs signify that they perceive all H&S actions to be undertaken between sometimes to often/often on average, whereas the PMs' mean MS signifies that they perceive all H&S actions to be undertaken between rarely to sometimes/sometimes on average. The first four ranked H&S actions have MSs > 3.40 < 4.20, between sometimes to often/often. The last three ranked H&S actions' mean MSs fall within the range > 2.60 < 3.40, between rarely to sometimes/sometimes.

4.2 Case study results

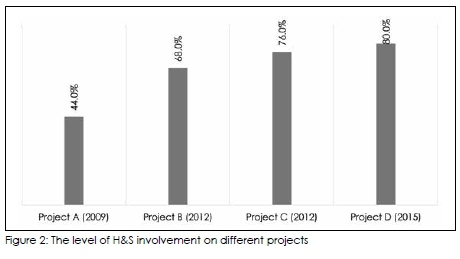

Figure 2 indicates the percentage scores of the level of H&S involvement of the stakeholders in the sampled projects and the year in which the projects commenced. Project A, undertaken in 2009, had a score of 44%, indicating a weak stakeholder involvement, and projects B and C, undertaken in 2012, had scores of 68% and 76%, respectively, indicating a moderate involvement. It is notable that project D, undertaken in 2015 after the promulgation of the Construction Regulations 2014, scored 80%, indicating a moderate involvement. This is, however, significantly higher than projects B and C.

4.2.1 Pre-Construction Regulations 2014: Projects A, B and C

During the project file review for three sampled projects, it was noted that the 'build only' contract had little involvement across all project stages for projects A, B and C. PMs, QSs, and CHS professionals had little involvement during Stages 1 to 3. This is supported by questionnaire data where all three stakeholders ranked these stages as those with their least involvement. Research found that clients and project stakeholders did not realise the significance of placing H&S in the initial phases of a project.

Stage 4 of these projects indicated greater involvement, by making provision for CHS professionals, as well the requirement of an approved H&S policy to be part of tender submission. In addition, Projects B and C also required contractors to provide historic DIFRs to assist in tender adjudication.

Stages 5 and 6 of projects A to C indicated greatest involvement of stakeholders through the monitoring and enforcing of H&S requirements on projects sites, including the measurement of contractor H&S performance. This is further supported by questionnaire data that indicated greater involvement of CHS professionals and PMs during the last three stages of the project rather than in the first three. The significantly better scores for stakeholder involvement for projects B and C, undertaken in 2012, can be attributed to additional actions undertaken in all six project stages.

4.2.2 Post-Construction Regulations 2014: Project D

Project D, undertaken post-Construction Regulations 2014, had a 80% level of involvement, indicating a moderate involvement, but significantly higher than the projects undertaken pre-Construction Regulations 2014. As opposed to projects A to C, project D used a design and build contract that is more favourable. This is supported by literature, as this type of contract complements H&S through the integration of the design and construction processes.

4.2.3 Level of involvement vs. project performance

To determine the pattern of compliance with the Construction Regulations 2014, the project performance of the three completed sample projects was assessed using the project DIFR, and if the project was completed on time and within budget as reflected in Table 14. There is a direct relationship between stakeholder involvement and project H&S performance, also taking into consideration the percentage that H&S contributes of the total project cost. Based on the sampled project BOQs, the percentage H&S constituted of project cost ranged from 0.10% to 0.61%, with only project A falling within the range 0.5% to 3.0%, cited by Smallwood (2004) for implementing H&S. However, it could not be established if the cost of H&S was proportionally reflected on the payment certificates, as they were not verified.

To reach a level of strong involvement, it was identified that stakeholders will need to opt more for design and build contracts, evaluate H&S training through testing, and participate in H&S recognition programmes. Furthermore, H&S actions should be undertaken in the initial phases in order to achieve better H&S performance.

5. Discussion of findings

This study focused on the impact of the Construction Regulations 2014 on a water utility's projects' H&S performance. It determined the degree of H&S involvement of client representatives and internal project stakeholders, namely designers, PMs, QSs and CHS professionals during the six project stages. It also examined their commitment towards H&S; measures taken by them during planning and design, in contracts to improve H&S, and to select conscious contractors, and the extent of their H&S participation in construction H&S.

5.1 Involvement of clients and project stakeholders

PMs, QSs, and CHS professionals are more prominent from Stages 4 to 6, whereas their involvement is low in the first three stages; clients are prominent in all stages of the project with a moderate to high/ high involvement, except for Stage 4 with a low to moderate/ moderate involvement. Designers are prominent in Stage 3, due to their expertise required during this stage and have low to moderate/ moderate involvement in the other stages.

5.2 Stakeholder commitment towards H&S

All stakeholders can be deemed to be committed to H&S, as they not only perceive it as the most important project parameter, but also believe that it can be significantly influenced during all stages of a project. They regard H&S as important to very important across all phases of a project, but more so in the construction stage that was ranked first, followed by project close-out, design, tender documentation, concept and feasibility, and initiation and briefing stage. The stakeholders perceived H&S to be more influenced during the later stages rather than the earlier stages of projects. All stakeholders contribute to some extent to H&S. However, the vast majority of the respondents regard CHS professionals, contractors, and PMs as the primary stakeholders. Designers, PMs and CHS professionals perceived themselves as a major contributor to the implementation of Construction Regulations 2014.

5.3 Measures taken by stakeholders during the project planning and design stage

Measures taken by stakeholders during the project planning and design stage are inadequate to address project H&S needs, as only 20% of H&S actions are undertaken at frequencies between sometimes to often/often. The case study data confirmed that implementing H&S actions during project planning and design translated to better client involvement, and consequently better project performance, as observed from the sampled projects.

5.4 Measures taken by stakeholders in construction contracts to improve H&S

All stakeholders perceive 'Provide a project specific H&S specification/H&S information as part of the tender documentation' to be the measure most frequently taken during construction contracts to improve H&S. They also ranked first the 'Consideration of H&S in construction contracts' as the factor that contributes the most to optimum H&S on a project. Secondary data revealed that they have progressively improved in taking measures to improve H&S over time. Older contracts made no provision for review and approval of résumés of H&S personnel on projects as opposed to the 'newer' projects.

5.5 Measures taken by stakeholders to select H&S-conscious contractors

All stakeholders perceive that the selection of contractors with good H&S performance records has the potential to make between some contribution to a near major/near major contribution to optimum H&S on a project. The case study data confirmed that projects, where H&S performance was used to select H&S-conscious contractors, showed both better stakeholder involvement and better project performance. It can be concluded that any measure taken to select H&S-conscious contractors improves project H&S.

5.6 The extent of their H&S participation in construction H&S

All stakeholders are regarded to participate in project H&S at varying levels during the six stages of projects. Clients are significantly involved in Stages 1 and 6; designers in Stage 3; QSs in Stages 4 and 5, and PMs and CHS professionals in Stage 5. In these respective stages, their involvement was deemed to be high to very high/ very high. Active client participation in H&S during construction was found to make a near major to major/major contribution to optimum H&S on a project. The case study data confirmed that projects with greater client involvement were more likely to be finished on time and within budget.

5.7 The impact of Construction Regulations 2014 on H&S performance

The Construction Regulations 2014 are perceived to have had an impact. 'Upstream activities'; 'Increased H&S awareness on projects', and having prompted for the need for PMs to consider/reference to H&S more frequently predominate. In addition, H&S actions are undertaken during all six stages of projects, but more significantly during Stage 5, and the frequency of H&S actions undertaken during the six project stages varies with each stakeholder, depending on the stage in which they are involved.

From the case study projects, the level of stakeholder involvement in H&S increased drastically over the years with improved project performance suggesting compliance, and the impact of the Construction Regulations on the project performance. The study also indicated that there is a direct relationship between stakeholder involvement and project H&S performance. The greatest H&S involvement of stakeholders in projects was during Stages 5 and 6, and the least during Stages 1 to 3.

6. Conclusions

Research indicates that improved H&S performance can be achieved on a project where there is a collaborative approach among all stakeholders during the project stages. Their attitude and involvement in H&S will impact on the H&S performance of contractors downstream. Based on the findings, it can be concluded that the clients' and project stakeholders' H&S involvement influences H&S performance. The impact of the Construction Regulations 2014 is evident in the water utility, as some of the H&S actions are undertaken during the six project stages, more so in Stage 5. In addition, the four case study projects provide evidence of their involvement in influencing project H&S performance. Furthermore, H&S awareness on projects, as well as having prompted for the need for project managers to consider/reference to H&S more frequently predominates among the list of 'upstream', 'midstream' and 'downstream' aspects/actions. This is significant, as PMs play a crucial role in driving further H&S improvements with the other stakeholders in order to integrate H&S in the design and construction phase, as revealed from the research. The study determined that the construction phase is still regarded as the most important stage to address H&S and this requires a mind-shift of the stakeholders to focus on the initial stages of the project in order to realise the benefits of H&S on a project. This will allow the water utility to progress to the transformative phase that will place emphasis on the integration of H&S into decision-making, eliminating H&S risks, and fostering a H&S culture.

7. Recommendations

H&S should be integrated in the initial stages of the project by streamlining all business processes to accommodate H&S in the planning and design phases of a project as well as to involve the CHS professionals to assist with the facilitation of H&S management. Literature confirms the gap in terms of built environment educational programmes not adequately addressing H&S. It is, therefore, necessary to plan for H&S training for stakeholders to improve their H&S contributions on a project. Cost estimates for H&S should be established at the design stage so that it is relevant to the project, and the evaluation process should be improved in order to select competent contractors. Follow-up research should be conducted to investigate if there are any improvements within the construction industry during the six project stages after the expiry of the CWP exemption period. Further research on the cost of H&S should be conducted to determine the costs of implementing H&S in order to establish cost estimates for H&S on future projects; a client and project stakeholder project H&S model for the six project stages based on best practices and legal requirements should be evolved, and the role of designers should be investigated to ascertain their contributions with respect to improving H&S performance, and their level of compliance to Construction Regulations 2014.

References

Agumba, J., Pretorius, J.M. & Haupt, T. 2016. Health and safety management practices in small and medium enterprises in the South African construction industry. Acta Structilia, 20(1), pp. 66-88. [ Links ]

Cidb (Construction Industry Development Board). 2009. Construction Health and Safety in South Africa. Status & Recommendations. [online] Available at: <http://www.cidb.org.za/publications/Pages/Health-and-Safety.aspx> [Accessed: 10 December 2016]. [ Links ]

Deacon, C. 2009. Linking H&S construction in the public sector: A case study. [online] Available at: <http://www.achasm.co.za/Portals/5/ACHASM_2013_CT_Linking-HS-to-Construction.pdf?ver=2015-08-13-133245-170> [Accessed: 10 December 2016]. [ Links ]

Deacon, C. & Smallwood, J. 2016. The integration of design, procurement and construction relative to health and safety. In: Proceedings of the International Sustainability Ecology Engineering Design for Society (SEEDS) Conference, 14-15 September 2016, Leeds University. Leeds: LSI Publishing, pp. 329-340. [ Links ]

DoL (Department of Labour). 2012. Department of Labour meets chiefs of construction industry to improve the status of occupational health and safety in the industry. [online] Available at: <http://www.labour.gov.za/DOL/media-desk/media-alerts/department-of-labour-meets-chiefs-of-construction-industry-to-improve-the-status-ofoccupational-health-and-safety-in-the-industry>[Accessed: 8 November 2016]. [ Links ]

Gambatese, J.A., Behm, M. & Rajendran, S. 2007. Design's role in construction accident causality and prevention: Perspectives from an expert panel. Safety Science, 46(4), pp. 675-691. https://doi.org/10.1016/j.ssci.2007.06.010 [ Links ]

Huang, X. 2003. The owner's role in construction safety. PhD thesis. Florida, USA: University of Florida. [ Links ]

Kamardeen, I. 2013. OHS electronic management systems for construction. New York: Routledge. https://doi.org/10.4324/9780203871522 [ Links ]

Kikwasi, G.J. 2009. Client involvement in construction safety and health. In: Hinze, J., Bohner, S. & Lew, J. (Eds). Proceedings of the CIB W99 International Conference 14th Rinker International Conference on Evolution of, and Directions in Construction Safety and Health, 9-11 March 2009, Gainesville, Florida. Rotterdam, The Netherlands: CIB, pp. 55-69. [ Links ]

Krejcie, R.V. & Morgan, D.W. 1970. Determining sample size for research activities. Educational and Psychological Measurement, 30(3), pp. 607-610. https://doi.org/10.1177/001316447003000308 [ Links ]

Latib, F.A., Zahari, H.Z.A., Hamid, A.R.A & Yee, K.C.W.H. 2016. Implementing occupational safety and health requirements in construction project. Journal of Advanced Research in Applied Sciences and Engineering Technology, 5(1), pp. 53-63. [ Links ]

Leedy, P.D. & Ormrod, J.E. 2015. Practical research: Planning and design. 11th edition. Harlow: Pearson. [ Links ]

Lopes, M., Haupt, T.C. & Fester, F.C. 2011. The influence of clients on construction health and safety conditions in South Africa. Occupational Health Southern Africa, March/April, pp. 9-14. [ Links ]

Mpanza, N., Mututo, J.G. & Pearl, R.G. 2008. Effectiveness of project debriefing procedures: A case study of the KZN region of South Africa. In: Proceedings of the 5thPostgraduate Conference on Construction Industry Development, 16-18 March 2008, Bloemfontein. Brooklyn Square: cidb, pp. 129-138. [ Links ]

Muiruri, G. & Mulinge, C. 2014. Health and safety management on construction projects sites in Kenya: A case study of construction projects in Nairobi county. In: Proceedings of the FIG Congress 2014: Engaging the Challenges - Enhancing the Relevance, 16-21 June, Malaysia. Malaysia: Pejuta, pp.1-14. [ Links ]

Phoya, S. & Eliufoo, H. 2015. Influences of stakeholders' power on their participation in H&S risk management in construction projects in Tanzania. In: Proceedings of the 9thBuilt Environment Conference, 2-4 August 2015, Durban. Durban: Association of Schools of Construction of Southern Africa, pp. 421-434. [ Links ]

Powell, G. 2012. Construction contract preparation and management - From concept and completion. Hampshire: Palgrave Macmillan. [ Links ]

RSA (Republic of South Africa). 2000. Project and Construction Management Professions Act, Act 48 of 2000. Pretoria: Government Printer. [ Links ]

RSA (Republic of South Africa). 2014. Construction Regulations. Regulation R. 84 in terms of the Occupational Health and Safety Act (Act 85 of 1993). Pretoria: Government Printer. [ Links ]

Said, I., Shafiei, M.W.M. & Omran, A. 2009. The roles of clients in enhancing construction safety. Annals of the Faculty of Engineering Hunedoara - Journal of Engineering, vii(2), pp.127-134. [ Links ]

Saifullah, N.M. & Ismail, F. 2012. Integration of occupational safety and health during preconstruction stage in Malaysia. Procedia - Social and Behavioral Sciences 35, pp. 603-610. https://doi.org/10.1016/'.sbspro.2012.02.127 [ Links ]

Smallwood, J.J. 2004. The influence of clients on contractor health and safety (H&S). In: Khosrowshahi, F. (Ed.). Proceedings of the 20th Annual ARCOM Conference, 1-3 September 2004, Heriot Watt University. Association of Researchers in Construction Management, 2, pp.1095-105. [ Links ]

Smallwood, J.J. 2007. The nature and contents of health and safety (H&S) specifications. In: Proceedings of the 2ndBuilt Environment Conference, 17-19 June 2007, Port Elizabeth, South Africa. Association of Schools of Construction of Southern Africa, pp. 337-349. [ Links ]

Smallwood, J. & Venter, D. 2002. The influence of project managers on construction H&S in South Africa. The Australian Journal of Construction Economics and Building, 2(1), pp. 57-69. https://doi.org/10.5130/AJCEB.v2i1.2887 [ Links ]

Sunindijo, R.Y. & Zou, P.X.W. 2015. Strategic safety management in construction and engineering. West Sussex: John Wiley & Sons, Ltd. [ Links ]

The Research Advisors. 2006. Required sample size. [online] Available at: <http://research-advisors.com> [Accessed: 30 October 2018]. [ Links ]

Tymvios, N. & Gambatese, J.A. 2015. Perceptions about design for construction worker safety: Viewpoints from contractors, designers, and university facility owners. Journal of Construction Engineering and Management, 142(2), pp. 1-11. [ Links ]

Wells, J. & Hawkins, J. 2010. Promoting construction health and safety through procurement: A briefing note for developing countries. London: Engineers against Poverty. Institution of Civil Engineers (ice). [ Links ]

Peer reviewed and revised

*The authors declared no conflict of interest for this title or article