Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Clean Air Journal

versión On-line ISSN 2410-972X

versión impresa ISSN 1017-1703

Clean Air J. vol.28 no.1 Pretoria 2018

http://dx.doi.org/10.17159/2410-972x/2018/v28n1a10

RESEARCH ARTICLE

Fine PM emission factors from residential burning of solid fuels using traditional cast-iron coal stoves

Ncobile C NkosiI; Stuart J PikethII; Roelof P BurgerIII

IUnit for Environmental Sciences and Management North-West University, Potchefstroom, 2520, South Africa nomhawunkosi93@gmail.com

IIUnit for Environmental Sciences and Management North-West University, Potchefstroom, 2520, South Africa, roelof.burger@nwu.ac.za

IIIUnit for Environmental Sciences and Management North-West University, Potchefstroom, 2520, South Africa, stuart.piketh@nwu.ac.za

ABSTRACT

Residential burning of solid fuels is a major source of fine particulate matter (PM25), which degrades indoor and ambient air quality in low-income settlements. The adverse impact of fine particulate emissions on the environment and human health is well-documented in other countries such as China and India; however, there is need for local studies to report on emission factors from residential burning of solid fuels. An emission factor quantifies the total mass of a pollutant emitted per amount of fuel burned. Emission factor is an input parameter in air quality modelling to forecast a pollutant concentrations over time and when calculating total emissions from a specific source. Local emission factors are central to managing air quality for they give results that are representative of the source compared with international emission factors. Quantifying emissions, understanding household fuel use patterns and interaction with the stove (stove operation behaviour) during a burning event is fundamental when designing emission control strategies. The aim of the study is to quantify fine particulate matter emissions from residential coal burning using systematic field measurements. The objectives of the study are (i) to characterize stove operation behavior effect on the emissions and (ii) to quantify PM25 emission factors using field measurements. Isokinetic (2015) and direct (2014) stack sampling tests were done to observe how PM emissions profiles change with stove operation behavior and to quantify PM25 emitted per kilogram of fuel burned. Fine PM emission profiles change with stove operation behavior with an emission factor ranging 6.8 g.kg-1 and 13.5 g.kg-1. The study results implies that residential coal burning is a major source of fine particulate matter in the residential area. As demonstrated that stove operation behaviour affect stove to fuel combination emissions; it is therefore suggested that those factors leading to increase emissions should be kept minimum.

Keywords: Residential burning, emission factor, low-income settlements, particulate matter

Introduction

Solid fuels (coal, wood and dung) are the most common and frequently used energy sources in low-income settlements. This is due to their multi-purpose functionality, availability and affordability. Low-income households burn solid fuels in inefficient stoves resulting in increased emissions of incomplete combustion products (Worobiec et al., 2011). In kwaDela, a low income residential area in the Highveld, the annual solid fuel consumption in kwaDela is about 512 tons (Nkosi et al., 2017). Study conducted by Nkosi et al. (2017), revealed that solid fuel as the most common energy source with a total annual consumption of 512 tons.

Emissions from residential burning degrade ambient air quality and cause indoor air pollution leading to adverse impacts on human health (Smith et al., 2013). Fine particulate matter has been specifically identified as the most hazardous to human health due to its ability to infiltrate deeper parts of the respiratory system (Lee, 2010). There is a well- documented literature linking emissions of fine PM to cardiovascular and respiratory diseases (Seaton et al., 1995; Rehfuess et al., 2006; Albers et al., 2015). In 2007 emissions from residential combustion of solid fuels accounted for up to 75 % of the ambient concentration of fine particulate matter in Soweto, with a peak concentration of 110 Ug.m-3 (Nuwarinda et al., 2007). Similarly also 2007, residential burning accounts for up to 62.1 % of fine particulate matter ambient concentrations in Qalabotjha (Nuwarinda et al., 2007).

An emission factor (EF) is used to quantify the total amount of a pollutant emitted per amount of fuel burned (Amaral et al., 2016). Emission factors from residential burning are highly variable because they are governed by many factors can that be classified into (i) appliance characteristics (size of the stove, combustion air supply the design and size of the burning chamber), (ii) stove operation factors (lighting method used, and refueling intervals) (Schmidl et al., 2011).

Tissari et al., (2007) investigated the impact of stove operation on particulate and gaseous emissions using Mansory heaters and sauna stoves. Findings were that fine particulate emissions decreased with time after the ignition and there was a direct proportional relationship between fuel mass load and fine PM emissions. When doubling the fuel quantity the total amount of PM emitted was 1.9 times higher. Similar PM emission trends were observed by Johansson et al. (2004), large fuel batches had PM emissions that were 4 times higher when compared with small batches.

High ash content from previous burning events blocks air from entering the combustion chamber and also inhibits smokes from escaping, thus resulting in indoor air pollution (Garcia-Maraver, 2014). Ash also makes it difficult to light and for fuel to catch the fire thus results in combustion in low temperatures. Combustion conditions and fuel composition are primary determinants of the PM emission factors measured (Campbell, 1908).

Using emission factors that are not local and do not consider spatial difference in fuel type, composition, and stove operation behavior when quantifying the emissions may lead to an overall underestimation/ overestimation of PM emissions in developing countries (Sheng et al., 2013). For example, the amount of ash produced in South African coal is higher by a factor of 3 when compared with coal from the United States (Pretorius et al., 2015).

There is a need for local emission factors to reduce uncertainties related to data availability and EFs variation. One of the factors that causes variation in EF measured is the experimental method used (Shen et al., 2010). Laboratory derived PM EFs may be different from EFs derived in the field due to the difference in the burning conditions. According to Sheng et al., (2013) laboratory generated emission factors underestimate environmental conditions which are often uncontrolled, such includes wind speed, temperature and humidity. PM emissions from two laboratory experiments were 2 to 4 times lower than PM EFs measured from the field Roden et al (2006 and 2009). Important variables that have an effect on PM emissions such as the material and method used to start the fire, and uncontrolled refueling were excluded in a laboratory environment (Shen et al., 2013). Therefore, ignition method and fuel used when sampling flue gas in the field were the same with that of households used daily. Therefore, a better representation with actual ambient conditions compared with laboratory generated PM EFs can be drawn.

In contrast studies conducted in the laboratory (Tissari et al., 2009) and field environment (Tissari et al., 2007) reported that there is no significant difference on fine PM emissions measured from the field or laboratory environment. Fine PM from the field were less (2.7 g.kg-1) when compared to laboratory measurements (5 g.kg-1).

The aim of the study is to quantify fine particulate matter emission factors from residential coal burning using systematic field measurements. The results are essential in determining the amount of PM emitted and is essential for emission inventory and can also be used as an input parameter during modelling and source apportionment studies.

Material and Methods

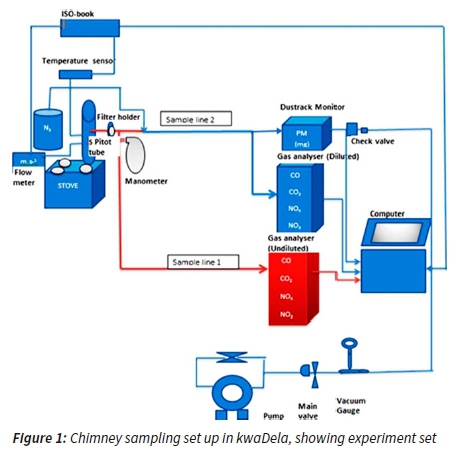

The methodology used in the study is similar to Sheng et al., 2013. Figure 1 shows a gas and PM sampling train that was set up in two kwaDela randomly selected houses.

The emission test were conducted using coal and wood purchased from local stores, exactly the ones where hops and coal sites where the residents usually buy. For ignition the residents used paper and wood, then after the fire is established, coal was added into the stoves. Traditional cast-iron coal stoves are the commonly used solid fuel burning devices in the residential area therefore were used for the field tests experiments. The coal stoves are primarily used for cooking, boiling water and space heating (Nkosi et al., 2017). The stove consist of a combustion chamber, cooking plates, a baking area and a chimney extending to the outside through the roof. Inside the chamber just below the fire bed are openings that allow ash from burned coal to be transferred to the ash-tray. The plates are also used as openings where the fuel is loaded.

The stoves are sold with a steel extension used to reshuffle the fire or remove ash that falls on the sides of the ashtray. Before each test experiment, the stoves and chimney were thoroughly cleaned to remove ash from previous burning events.

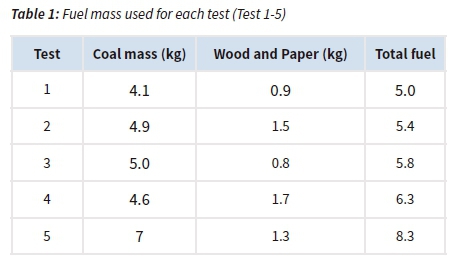

The amount of fuel used during the field experiments was measured with a calibrated digital Adam GFK floor scale. Stove operation (Stove cleaning, refueling times) and burning patterns (burning events start and end time) were recorded in a field note book. The notes were used to understand the DustTrakTM concentration profiles for each experiment. Table 1 shows the type and amount of solid fuels used for each experiment test.

For 2014 field experiment, gravimetric PM concentrations were used instead of real time DustTrakTM measurement due to instrument malfunction during the sampling tests. 86R Teflon tubing (43 mm diameter, 1 urn pore size) and quartz (47 mm diameter, 2.2 um pore size) membrane filters were used to collect PM emitted. Before use, borosilicate thimbles were washed with acid to decrease their trace metal content. Quartz thimbles were preheated at 900 °C for about 2 hr, also washed with acid to stabilise their weight and reduce their metal content. The filters used have about 99.9% efficiency with approximated 0, 2 heating loss. A Mettler Toledo balance was used to weigh the mass of the filters before and after sampling. A factory calibrated TSI DustTrakTM II Aerosol Monitor 8530 was set to zero then used to measure particulate concentration (ug.m-3) at averaged over a minute.

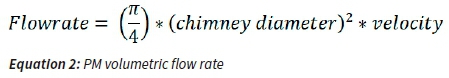

An S type Pitot tube pressure meter with an accuracy of ± 5 %was used to measure the flow pressure. The velocity is calculated from the gas flow pressure (P2 - P1), difference between the static and direct pressure flow is recorded as the velocity of the flue gas. The velocity measured was used to determine the sampling tunnel gas flow m3.s-1, for every PM concentration measured (Equation 2).

A High-Volume Air Sampler monitor was adjusted at 5 minute interval to control flue gas flow during the sampling experiment. The flow rate ranged between 3 to 5 L.min-1, it was slightly increased when the concentrations were low and decreased when they were high. A calibrated digital pressure Calc TM flow meter reader measured the flow rate averaged over a minute. Two gas analysers Horiba, (PG 350, PG 250) equipped with a Non-dispersive Infrared Absorption sensor measured diluted and undiluted gases at 10 seconds interval (CO, CO2, O2, SO2 and NOX). Prior each test the analysers were initialized (zero) and span calibrated. The dilution ratio was calculated and multiply the PM concentration measured as shown in equation 1.

COu Refers to the undiluted carbon monoxide concentration and COd refers to the carbon monoxide diluted concentration.

To account for dilution, the calculated dilution ratio was applied to the DustTrakTM II PM concentrations before emission rates calculations. An ISO BOOK equipped with a flow meter and K-type thermocouple monitor was used to measure flue gas temperature inside the chimney. The diameter of the diluter used was 11, 5 cm therefore, a single sampling point was used to extract the flue gas.

The requirement for stack particulate sampling techniques is that the flue gas measured is representative of the gas stream inside the sampling tunnel. The velocity homogeneity, number of sampling points and isokinetic withdrawal determines if the sampled flue gas is a good representative (Hildermann et al., 1984). To reduce uncertainties associated with flue gas sampling, a dilution system that complies with EPA direct chimney sampling conditions and the code of Federal Regulations, isokinetic sampling method in accordance with US EPA and heating systems were used. The flue gas sampled was diluted with pure nitrogen gas to simulate ambient conditions, avoid condensation of the particles, gases and capture secondary particles. Nitrogen gas was chosen due to its ability to reduce about 60-80 % of artifacts that may occur under stove combustion conditions (Wien et al., 2001). Isokinetic system was implemented for all tests sampling to prevent particles deposition or deviation from the gas flow pattern sampling. This was achieved by monitoring the nozzle gas sampling rate and the velocity of the gas flowing inside the sampling duct. A filter heating system (80 °C) was used to remove any moisture that could cause particle size growth. Using a heating system also prevents particle loss along the inlet line, high temperatures along the heated line give the particles kinetic energy (Hildermann et al., 1984). Gaseous and particulate matter measurements began immediately after ignition and until the last second of the burning event duration. The sampling tests in 2014 lasted for 2 hours however 2015 tests lasted for 3 hours. The extension of the burning duration in 2015 was due to the slight increase in the PM concentration observed just before the dying stage of the fire in 2014. Therefore 2015 field test sampling duration was extended to 3 hours to capture the concentration increase during the dying stage of the fire. Test 1, represent a resident who would light the fire, leave it undisturbed until the fire burns out. Test 2 is a resident who lights the fire with 2 refueling events while test 3 pokes the fire after ignition. To account for DustTrakTM over-estimation, a correction factor calculated by comparing online measurements with exposed filters that were gravimetrically analysed was applied to the concentration before calculating the emission rates (Language et al., 2016). PM mass flow rate was determined from the equation 2.

Where (π/4)*(chimney diameter)2 accounts for the chimney circumference (m3). n is the constant value for pie equals to 3.14. Velocity (s-1) refers to the flue gas speed inside the chimney measured by the Pitot tube. The flow rate is product of both the chimney circumference and velocity. The DustTrakTM PM concentrations mg.m-3 were multiplied with the corresponding flow rate (m3.s-1) to determine the total PM emitted per second as shown in Equation 3.

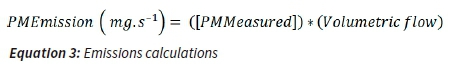

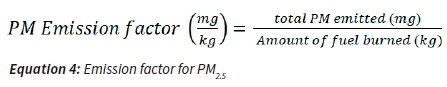

Where PMEmission is the amount (mg) of particulate matter emitted for the period of the burning event and is the product of the ([PMMeasured]) (mg.m3) particulate matter concentration measured by the DustTrakTM II and the Volumetric flow (m3.s-1). Equation 4 was used to determine the emission factor.

PM Emission factor is the total amount of PM emitted per kilogram of fuel burned. It is calculated by dividing the total emissions (Total PM emitted) from each test by the total amount of fuel burned (Amount of fuel used) during the event.

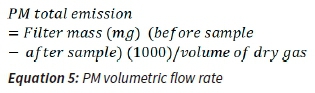

After sampling the filters were placed in a container and kept in a zip lock bag for less than 48 hours to avoid contamination and loss of particles. To remove any moisture accumulated during sampling, a laminar flow was used to dry the filters. Field blanks were used to account for the filters PM loss and gain during the field experiment tests. The total amount of PM collected from the tests and field blanks was gravimetrically analyzed with a high precision digital balance (Mettler Toledo). The filter mass and flow rate readings difference before and after sampling were used to determine total fine PM sampled in grams Equation 5. The obtained PM gain from field blanks was subtracted from the total PM mass derived from the field tests experiments.

Where Filter mass (mg) (before sample- after sample) is the filter mass difference calculated from mass recorded before and after the test experiment. (1000) converts the mass from mg to g. volume of dry gas is the flow meter reading difference of the respective experiment test.

Quality control

A total of six field tests were done but due to instrument malfunction, only five tests were used to estimate fine PM emission factor. The number of measurements is constrained by the fact that the sampling of field measurements have a huge impact on the household's themselves. When considering the ethical implication of the experimental results. It is better to limit the number of observations since this is the first time PM emissions were sampled from the households. Daily household energy use patterns were used in order to carry-out experiment under real use scenarios. Before each test the instruments (sampling lines) were cleaned with compressed air and checked for leaks.

Results and Discussion

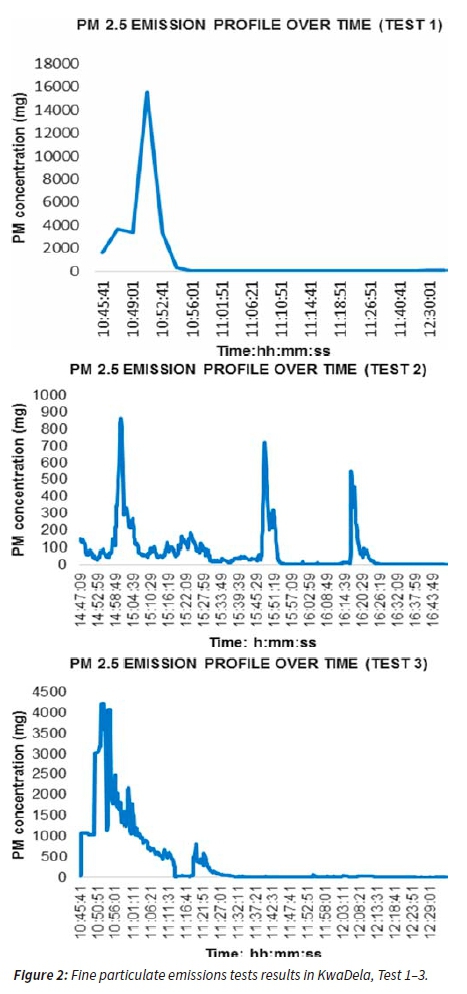

Particulate matter emissions peaks were associated with the following fire stages, (i) the beginning of the burning event (ignition), (ii) when the fire was being reshuffled (iii) when fuel is reloaded, Figure 2. Test 1 has a single spike, test 2 has three and test 3 has only two. Above 80 % of the total emissions from test 1 and 3 were emitted during the 30 minutes of the burning event. The DustTrak™ real time PM concentrations showed that emissions on test 2 were distributed throughout the burning event with the ignition phase having the highest emission. Spikes on test 4 and 5 could not be identified because emissions were not measured with a DustTrakTM but collected with filters. High emissions of fine particulate matter were identified at the beginning of the burning event and during a refueling event. Test 1 and 3 had high emissions when compared to test 2.

Emissions from ignition stage result from combustion of wood, paper, and emissions from refueling result from coal combustion.

Findings of our study are similar to those of Tisarri et al. (2009) where during refueling, fuel combustion occurs at high temperatures producing large amount of ash which is a source of fine particulate matter. High emissions of fine particulate matter at high combustion rate are caused by oxygen deficiency in the combustion chamber and inadequate mixing of fuel and air (Tisarri et al., 2007). Results from a separate study on emissions of PM from traditional stoves indicated that about 98 % of total PM is emitted during ignition and refueling (Maddalena et al., 2014).

The amount of fuel used for test 1 and 2 is almost the same with a difference of 0.4 kg however, test 1 PM emissions are almost two times higher than test 2. The difference in the amount of fuel used in test 1 and 3 is 0.8 kg but the amount of PM emitted from both tests do not vary significantly. For test 2 the emissions are distributed throughout the burning event with high emissions occurring on the first 30 minutes (Ignition phase) and least emission during the last hour (refueling) of the event. Table 2 presents filter based emission factors, amount of fuel used, and filter mass before and after test 4 and 5 field experiment. Less fuel (6.32 kg) was used for test 4 compared with test 5 (8.26 kg) however, test 4 has almost 2 times more emissions compared with test 5. Studies done by Shen et al. (2013) on the effect of fuel mass load on PM emission factors reported that fuel mass load does not have a significant impact of amount of PM emitted and PM size distribution. Lamberg et al. (2011) conducted a study in a laboratory environment, his findings were that there is a negative correlation between fuel load and PM emissions. Decreasing fuel quantity decreases the flue gas residence time in the combustion chamber due to high air flow, therefore, results in insufficient mixing of flue gas and combustion air. PM mass concentration emitted increases with increase in excess air inside the combustion chamber (Johansson et al., 2003). This may explain why emissions for test 4 where higher than test 5 even when more fuel was used for test 4 compared with test 5.

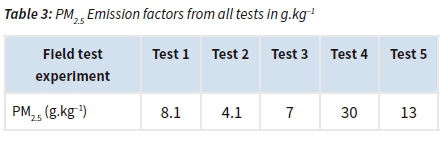

In agreement with the current study a field study done in Malawi quantifying fine particulate emissions from burning of solid fuels using traditional combustion methods reported an emission factor of 7.1 g.kg-1 (Wathore et al., 2017). The reported emission factors were highly variable with a standard deviation of ±1.3 g.kg-1. Jordan and seen (2005), Schmidl et al., (2011) confirmed that the difference in supply and regulation of combustion air results in variation of the emission factors.

The large variation in the current study emission factors may have also resulted from simultaneously using PM concentration measured with DustTrakTM and filters, also using a small number of field tests experiments. Moreover not considering other factors known to have influence on the emission such as particle size and moisture may introduce uncertainties in the emissions factors.

One disadvantage of using a dilution system is that it causes the condensed material to go unmeasured. This explains why in the current study the emissions measured with the filter are more than DustTrakTM emissions. Similar observations were made by Tissari et al. (2008a) when he measured fine PM emissions from sauna stoves using filters and an electronic low-pressure impactor. The emission measurements from the impactor were 8 % lower than filter-based measurements.

A two-tailed chi-square test (at the 95% confidence level) was used to determine the Pearson Chi square and likelihood ratio for gravimetric and real-time DustTrak based calculated emission factors. The P- value for gravimetric emission factors was 0.157 with a likelihood ratio of 0.096. For the real time DustTrak calculated emission factors the P value was 0.199 with a likelihood ratio of 0.159.

The emission factors calculated from DustTrak measurements were not significantly variable with a standard deviation of ±.2.1 g.kg-1. Whereas the filter derived emission factors had a standard deviation of ±8.5 g.kg-1. The filter based emissions were up to 7 times higher when contrasted with DustTrak™ II emissions. The error from using five field tests was minimised by using a "bootstrapping" simulation method to extrapolate the calculated emission factor to 500 samples. Bootstrap simulation was used quantify the uncertainty in the mean emission factor of all test results at 95% confidence interval.

Conclusion

Fine PM emission profiles change with stove operation behavior with an emission factor of 6.8 g.kg-1 to13.5 g.kg-1. The study results suggest that stove operation behaviour such as fire poking and refuelling lead to high emissions during a burning event. Even though emissions were not calculated based on the different fire stages in the current study, all the tests graphs show high emissions to be occurring from the ignition phase of the fire followed by refuelling. Having a small sample and significant variation within the sample introduces uncertainties to the final emissions value. Therefore there is a need to conduct field studies using large sample size to account for the emissions variability. The study suggest that real time stove mass and combustion chamber temperature readings during the burning event should be reported with the emissions to better understand the emissions profiles.

Acknowledgments

I would like to thank SASOL for funding the project and Climate Research group for assisting with data collection.

References

Albers P., Wright C., Voyi K., and Mathee A. 2015, 'Household fuel use and child respiratory ill health in two towns in Mpumalanga, South Africa', S Afr Med J, 105 (7):573. [ Links ]

Amaral S.S., Andrade de Carvalho J., Martins M A., Costa, M.A.M., and Pinheiro C., 2016, 'Particulate matter emission factors for biomass combustion'. Atmosphere, 7, 1-25. [ Links ]

Campbell M., 1908, 'A practical classification for low- grade coals', Economic Geology. 3(2):134-142. [ Links ]

Garcia-Maraver A., Zamorano M., Fernandes, U. Rabacal, M., and Costa, M. 2014, 'Relationship between fuel quality and gaseous and particulate matter emissions in a domestic pellet-fired boiler', Fuel, 119:141-152. [ Links ]

Hildermann L. M, Cass G. R; Markowski G. R., 1984, 'A Dilution Stack Sampler for Collection of Organic Aerosol Emissions: Design, Characterization and Field Tests', Aerosol Science and Technology, 10:1, pp.193-204 [ Links ]

Johansson L.S., Leckner B., Gustavsson, L., Cooper, D., Tullin, C., and Potter A., 2004, 'Emission characteristics of modern and old-type residential boilers fired with wood logs and wood pellets,' Atmos. Environ. 38: 4183-4195. [ Links ]

Johansson L.S., Tullin C., Leckner, B., and Sjovall P., 2003, 'Particle emissions from biomass combustion in small combustors', Biomass & Bioenergy 25:435-446 [ Links ]

Jordan T.B., Seen A.J., 2005, Effects of Airflow Setting on the Organic Composition of Wood heater Emissions. Environmental Science and Technology, 39, pp.3601-3610. [ Links ]

Lamberg H., Sippula O., Tissari J., Jokiniemi J., 2011,' Effects of air staging and load on fine-particle and gaseous emissions from a small-scale pellet boiler', Energy& Fuels, 25:4952-4960 [ Links ]

Language B, Piketh S J., and Burger R P., 2016, 'Correcting respirable photometric particulate measurements using a gravimetric sampling method' The Clean Air Journal, 26 (1):10-14. [ Links ]

Lee W. S., 2010, 'fine particulate matter measurements and international standardization for quality and emission measurements from stationary sources', Fuel, 874-882. [ Links ]

Maddalena R. M., Lunden M. L., Wilson D., Ceballos C. W., Kirchstetter, T.L., Slack J. L., and Dale L., 2014, 'Quantifying Space Heating Stove Emissions Related to Different Use Patterns in Mongolia', Energy and Environment Research, 4:360-369. [ Links ]

Nkosi N C., Piketh J.S., Burger P. R., and Annegarn J. H., 2017, 'Variability of domestic burning habits in the South African Highveld: A case study in the KwaDela Township', In: International Domestic Use of Energy. Cape Town, South Africa, 03-05 April 2017. [ Links ]

Nuwarinda H., 2007, 'Air Pollution Study of a Highveld Township during a Basa Njengo Magogo Rollout', Unpublished Masters Dissertation. Johannesburg: University of Johannesburg. [ Links ]

Pretorius I., Piketh S J., Burger R.P., and Neomagus, H., 'A perspective on South African coal fired power station emissions', Journal of Energy in Southern Africa, 26(3), 27-40 [ Links ]

Rehfuess E., Mehta S., and Prüss-Üstün, A., 2006, 'Assessing Household Solid Fuel Use: Multiple Implications for the Millennium Development Goals', Environ Health Perspect, 114(3):373-378. [ Links ]

Roden C., Bond T., Conway S., and Pinel A., 2006, 'Emission Factors and Real- Time Optical Properties of Particles Emitted from Traditional Wood Burning Cookstoves', Environmental Science & Technology, 40(21):6750-6757. [ Links ]

Roden C., Bond T., Conway S., Osorto Pinel A., MacCarty N., and Still, D., 2009, 'Laboratory and field investigations of particulate and carbon monoxide emissions from traditional and improved cook stoves', Atmospheric Environment, 43(6):1170-1181. [ Links ]

Schmidl C., Luisser M., Padouvas E., Lasselsberger L., Rzaca M., Ramirez-Santa Cruz C., Handler M., Peng G., Bauer H., and Puxbaum H., 2011, 'Particulate and gaseous emissions from manually and automatically fired small scale combustion systems', Atmospheric Environment, 45:7443-7454. [ Links ]

Seaton A., MacNee W., Donaldson K., and Godden D., 1995, 'Particulate air pollution and acute health effects', The Lancet, 345:176-178. [ Links ]

Shen G., Tao S., Wei S., Chen Y., Zhang Y., and Shen H., et al. 2013, 'Field Measurement of Emission Factors of PM, EC, OC, Parent, Nitro-, and Oxy- Polycyclic Aromatic Hydrocarbons for Residential Briquette, Coal Cake, and Wood in Rural Shanxi, China', Environmental Science & Technology, 47(6):2998-3005. [ Links ]

Shen G., Yang Y., Wang W., Tao S., Zhu C., and Min Y. et al., 2010, 'Emission Factors of Particulate Matter and Elemental Carbon for Crop Residues and Coals Burned in Typical Household Stoves in China', Environmental Science & Technology, 44(18):7157-7162. [ Links ]

Smith K R., Frumkin H., Balakrishman K., Butler C D., Chafe Z A., Fairlie I., Kinney P., Kjellstrom T., Mauzerall D L., McKone T E., McMichael J A., Scneider M., 2013, 'Energy and Human Health' Annual review of Public Health, 34(1): 159-188 [ Links ]

Tissari J., Hytonen K., Sippula O., and Jokiniemi, J ., 2007, A novel field measurement method for determining fine particulate and gas emissions from residential wood combustion. Atmospheric Environment 41:8330-8344. [ Links ]

Tissari J., Hytonen K., Sippula O., and Jokiniemi, J., 2009, 'The effect of operation conditions on emissions from mansory heaters and Sauna Stoves', Biomass and Bioenergy, 33:513-520. [ Links ]

Tissari J., Lyyränen J., Hytönen K., Sippula O., Tapper U., Frey, A., Saarnio K., Pennanen A.S., Hillamo R., Salonen R.O., Hirvonen M.-R., Jokiniemi J., 2008a, 'Fine particle and gaseous emissions from normal and smoldering wood combustion in a conventional masonry heater', Atmos. Environ. 42, 7862-7873. [ Links ]

Wathore R., Mortimer K., Grieshop A P., 2017, 'In-Use Emissions and Estimated Impacts of Traditional, Natural- and Forced-Draft Cookstoves in Rural Malawi', Environ.Sci. Technol.51, 1929-1938. [ Links ]

Wien S., England G., Loos K., Ritter K., Gurney D., McCarthy J., Leibowitz B., Joseph J., and Franco G., 2001, 'PM2.5 Speciation Profiles and Emissions Factors from Petroleum Industry Gas fired Sources', International Emission Inventory Conference, One Atmosphere, One Inventory, Many Challenges, May 1-3, Denver. CO. [ Links ]

Worobiec A., Potgieter-Vermaak S. S., Berghmans P., Winkler H., and Burger R. P. et al., 2011, 'Air Particulate Emissions in Developing Countries .A Case Study in South Africa', Anal. Lett, 44 (11), 1907-192. [ Links ]

Received: 13 March 2018

Reviewed: 10 April 2018

Accepted: 11 May 2018