Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

R&D Journal

On-line version ISSN 2309-8988

Print version ISSN 0257-9669

R&D j. (Matieland, Online) vol.33 Stellenbosch, Cape Town 2017

Development of a combustion visualisation hybrid rocket motor

R ThebaI; KL VealeII; CP BemontIII

ISAIMechE Student Member. Discipline of Mechanical Engineering. University of Kwa-Zulu Natal, Durban, South Africa. rtheba@live.co.za

IISAIMechE Member. Discipline of Mechanical Engineering. University of Kwa-Zulu Natal, Durban, South Africa. veale@ukzn.ac.za

IIIDiscipline of Mechanical Engineering. University of Kwa-Zulu Natal, Durban, South Africa. bemontc@ukzn.ac.za

ABSTRACT

The Phoenix Hybrid Sounding Rocket Programme in the University of KwaZulu-Natal's Mechanical Engineering department has so far only utilised pure paraffin wax and nitrous oxide as the propellant combination in their hybrid rockets. Knowledge of regression rate behaviour is required for the design and performance characterisation of hybrid rocket propulsion systems. The regression rate is the rate at which the fuel recedes in the direction perpendicular to the burning fuel surface. A hybrid slab motor was purpose designed for regression rate analysis. Optimum oxidiser-to-fuel (O/F) ratios obtained from literature and NASA CEA were used with interpolation to define the fuel grain dimensions, and the oxidiser and fuel mass flow rates. The slab motor, with windows for direct regression rate visualisation, was designed based on these parameters. It was manufactured from a combination of brass and stainless steel for structural rigidity, thermal properties and material compatibility with nitrous oxide. The design also includes a compact feed system used to supercharge the nitrous oxide run tank, while minimising pressure losses. The motor was designed to accommodate both pure and aluminised fuel grains. From literature, aluminium additives in the fuel have been shown to increase the regression rate of the system. Different regression rate measurement techniques, discussed in this paper, will be implemented to obtain the relevant data. These include visualisation of the regression process and obtaining the mass flow rate data over the burn time. The pre and post combustion grain volumes will also be significant here in order to calculate the regression rate. The regression rate data obtainedfrom these investigations are imperative in the improvement of future launch vehicles in the Phoenix Programme.

Additional keywords: Metallised, Aluminised, O/F ratio, Paraffin wax, Regression rate

Nomenclature Roman

𝑎 Regression rate coefficient

A Area [m2]

B Blowing Parameter

C Specific Heat [J/kgK]

F Thrust [N]

G Mass flux [kg/m2s]

h Port height [m]

L Latent heat [J/kg]

𝑚̇ Mass flow rate [kg/s]

P Pressure [Pa]

Q Heat Flux [W]

𝑟̇ Regression rate [m/s]

r Radius [m]

T Temperature [K]

V Velocity [m/s]

w Port width [m]

x Axial distance down the port [m]

Greek

𝛼 Dynamic pressure exponent

𝛽 Dynamic thickness exponent

𝜇 Gas dynamic viscosity [Pas]

𝜌 Density [kg/m3]

Subscripts

b Burnt

e Exit

ent Entrainment

c Convection

Ci Specific heat of the liquid

CH Stanton number

CHo Stanton number without blowing

f Fuel

Fr Roughness parameter

g Gas

he Effective heat of evaporation of the liquid fuel

hm Effective heat of melting of the solid fuel

hv Effective heat of gasification of the solid fuel

Lg Grain length

Np Number of ports

0 Ambient

ox Oxidiser

p Port

r Radiation

t Total

v Vaporisation

1 Absolute

Superscripts

n Oxidiser mass flux coefficient

Abbreviations

O/F Oxidiser-to-fuel ratio

CEA Chemical Equilibrium with Applications

FEA Finite Element Analysis

SU Stanford University

TU Tokai University

1 Introduction

A hybrid rocket constitutes a combination of both solid and liquid propellants. In classical hybrid motors, the fuel is a solid grain, while the oxidiser is a liquid, hence they are stored in separate tanks, as seen in Figure 1.

Hybrid rockets are increasingly popular due to the advantages they provide over solid and liquid rockets such as [2]:

1. Safety - propellants are separated by phase and distance, hindering the risk of explosion.

2. Environmental friendliness - the by-products are generally carbon dioxide and water.

3. Throttling - oxidiser flow rate is easily adjustable.

4. Grain robustness - due to the limited reactivity of hybrids they are not dangerous and are not prone to fuel grain cracking.

5. Fuel versatility - various propellant combinations are readily available.

6. Low cost - the overall cost of a hybrid rocket is relatively low as it is less complex compared to liquid rockets, and therefore requires less hardware. Fuel grain manufacturing is also cheaper than solid grains due to the safety aspect with regards to its handling, storage and transportation.

As well as the remarkable benefits of hybrids, there are also certain disadvantages associated with them for example, low fuel regression rates [3]. Conventional hybrid rockets use traditional polymeric fuels such as hydroxyl terminated poly-butadiene (HTPB) which are associated with low regression rates principally because they evaporate too slowly. This greatly hinders the performance capabilities of the motor and requires complex multi-port fuel grains to increase the burning rate of the solid mass of fuel [4]. In addition, these fuels have a low combustion efficiency because portions of the fuel will remain unburned, especially with multiport grains [3]. The adoption of paraffin wax replaces these fuel grains with simple, single port geometries thus simplifying the rocket motor design. Studies have shown that paraffin-based fuels have a three to four times increase in regression rate compared to traditional fuels. This is due to the hydro-dynamically unstable liquid layer which is formed on the fuel grain surface upon melting. It results in a mass entrainment mechanism in which fuel droplets are sheared from the surface of the grain and pulled into the oxidiser stream where combustion occurs. This is supported by the low surface tension and viscosity of paraffin-based fuels [5].

Although these fuels have revolutionised hybrid rocketry, they are by no means perfect. The low energy density of paraffin wax fuels has reduced launch vehicle performance. The requirement for larger oxidiser tanks due to the increase in optimum O/F ratios, a low specific impulse is achieved [3]. Studies have shown that with the addition of metal additives such as aluminium to the fuel grain, the optimum O/F ratio is reduced and the regression rates of these fuels can be enhanced by almost four times, while also significantly improving the propulsion system's mass to thrust ratio. The aluminium particles leave the fuel surface encapsulated in molten paraffin droplets, which increases the mass burning rate of the fuel grain [6]. The aluminium can burn and release more energy thereby further increasing regression rates. By comparing the regression rates of pure paraffin wax and aluminised fuel grains, an optimum formulation for increasing regression rates will be sought without compromising the simplicity, safety and cost benefits that hybrid rockets provide [3].

Sasolwax 0907 with nitrous oxide is unexplored in a slab motor. Investigations will provide a deeper understanding of the regression rate behaviour of the propellant combination.

2 Literature Review

The purpose of this project is to design and build a hybrid slab motor which can be used to investigate the behaviour of regression rate in paraffin-based fuels. The characterisation of the regression rate behaviour of paraffin-based fuel grains will provide the opportunity to develop hybrid rockets with better thrust-to-weight ratios, while achieving greater launch vehicle performance.

2.1 The Phoenix Hybrid Sounding Rocket Programme

The Phoenix Hybrid Sounding Rocket Programme has built numerous hybrid sounding rockets using pure paraffin wax (Sasolwax 0907) and nitrous oxide as the propellant combination [7]. The first flight vehicle, Phoenix 1A was launched from Overberg Test Range, South Africa in August 2014. It used blackened paraffin wax fuel and nitrous oxide. During the launch, the vehicle experienced nozzle damage which prevented it from achieving its design altitude of 10 km. The second vehicle, Phoenix 2A was a paper design used to determine the size of vehicle that would be required to reach a 100 km apogee with a 5 kg payload. The result was a 12 m tall rocket [8]. The most recent flight vehicle in the Phoenix family is Phoenix 1B, and is designed to be the workhorse vehicle in the hope of advancing hybrid propulsion technology and maybe one day providing a permanent launch facility in South Africa [9]. In addition, the Phoenix Programme consists of two lab-scale motors which are being used to determine the regression rate behaviour of paraffin-based fuel grains with nitrous oxide.

2.2 Regression Rate Theory

Regression rate is a vital parameter in the design and performance characterisation of a hybrid rocket motor and therefore understanding it is crucial.

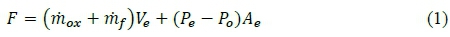

The rocket thrust equation is shown in equation 1 and depicts how thrust is generated in a rocket which consists primarily of mass being pushed out of the nozzle at high velocity.

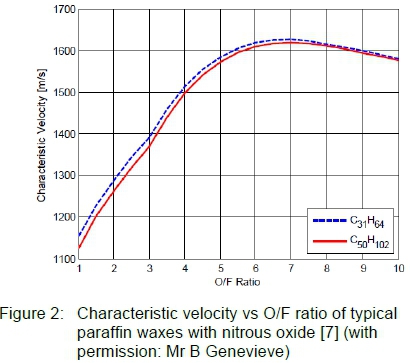

This mass flow in hybrid propulsion systems incorporates the mass from the oxidiser and from the fuel. Rocket thrust is proportional to the total mass flow rate of the propellants. Increasing the mass flow rate of a fuel for a given oxidiser mass flow is the consequence of an increased regression rate [10]. This in turn would enhance the thrust capability of the motor (see equation 2). A high optimum O/F ratio for paraffin wax fuels however, would reduce this performance. The large payload counteracts the enhanced thrust levels. Atmospheric or backpressure would also adversely affect the motor's thrust. A decrease in pressure results in a lower density and hence lower thrust. If the motor is not operating at optimum conditions, an increase in the oxidizer mass flow rate would influence the nozzle exit velocity due to choking not occurring at the nozzle throat. This is essential for thrust requirements of the rocket motor. These factors are why regression rate is significant in hybrid propulsion design - it relates directly to the mass flow rate of the propellants.

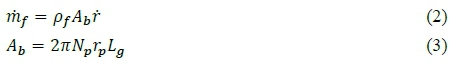

Regression rate is a vital aspect of propulsion system design as it affects factors such as thermodynamic conditions, O/F ratio shifts, specific impulse, optimal additive concentration and characteristic velocities. Figure 2 illustrates the performance of Sasolwax 0907 (C50H102) and C31H64, typically used by Stanford University (SU) at a chamber pressure of 40 bar and 5.99 nozzle expansion ratio. The results are similar with C31H64 having a slightly better performance. Both waxes have an optimal O/F ratio of approximately 7 [7].

Regression rate studies are critical to the physical dimensions of the hybrid system as it effects the performance capabilities and, thrust levels, and hence the overall design. The use of high regression rate fuels such as paraffin with metal additives shows great potential in a wide variety of applications, such as space tourism, solar system exploration and launch vehicle performance [11].

2.2.1 Classical Regression Rate Theory

Hybrid fuels burn via a combustion process that results in sublimation, pyrolisation and vaporisation of the fuel. This mechanism is slow and therefore results in the low regression rates achieved by classical fuels. Usually, a larger burning surface area of the fuel, or multiport fuel grains are used to increase the regression rate. The classical regression rate model is therefore highly dependent on diffusion limited combustion and is based on the work conducted by Marxman, Gilbert, Muzzy and Wooldridge in the 1960's [12].

The diffusion limited combustion is modelled as a turbulent diffusion flame, whereby the reactions occur in an infinitely thin flame zone within the boundary layer. The combustion process is dominated by the heat transfer from the flame to the fuel surface [12].

2.2.2 Non-Classical Regression Rate Theory

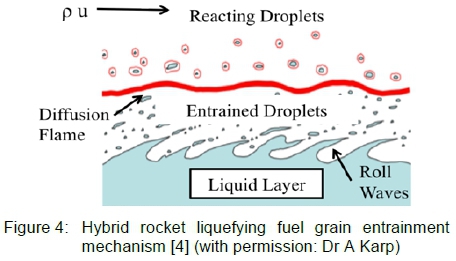

In the 1990's, research conducted by Stanford University into cryogenic fuels for the use of hybrid rockets led to an interesting discovery of high regression rate paraffin-based fuels. These fuels do not solely rely on evaporation like traditional polymeric fuels and are therefore able to achieve higher regression rates. These fuels are commonly known as liquefying fuels. Convection and radiation causes heat to transfer into the fuel grain and a thin liquid layer forms on the surface. The turbulent oxidiser stream causes an instability and shears the surface of the liquid layer resulting in roll waves. Droplets are entrained into the flow due to the low viscosity of the fuel. Once the droplets reach the diffusion flame, combustion occurs. The droplet entrainment mechanism is thought to rely significantly on the low surface tension and low viscosity of the fuel being used [11]. Figure 4 depicts the process.

It should be noted that not all fuels that form a melt layer will react in this way. Fuels such as ABS (Acrylonitrile-Butadiene-Styrene) have a 7 times higher viscosity than paraffin and even though it forms a melt layer, it is too viscous to allow droplet entrainment [13]. The following factors contribute to the high regression rates achieved by paraffin-based fuels:

1. The effective heat of gasification is reduced.

2. The blocking factor is altered due to the two phase flow within the boundary layer. This changes the convective heat flux.

3. Heat transfer is enhanced as the roll waves increases the surface area and roughness of the fuel grain.

Karabeyoglu's derivation of the regression rate of hybrid propellants is summarised below from [13] and [14]. The total regression rate of a hybrid fuel (𝑟𝑡) is the sum of the regression rates for vaporisation (𝑟𝑡) and entrainment (𝑟ent).

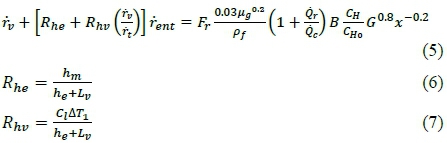

The combination of entrainment and evaporative mass transfer at the liquid gas interface is given as an energy balance (see equations 5, 6 and 7):

Where is the blocking factor.

is the blocking factor.

The roughness factor (equation 8) accounts for the increased heat transfer due to wrinkling and is empirically defined:

Manipulation of the above equations results in a simplified model (equation 9) of the entrainment regression rate equation:

The simplest form of the regression rate equation is shown in equation 10 and is dependent on the regression rate coefficient, the oxidiser mass flux, and the oxidiser mass flux coefficient. The two coefficients a and n are the ballistic coefficients dependent on the propellant combination of the system. The coefficient a is dependent on the oxidiser mass flux of the motor, and the n governs the chemical composition of the paraffin wax with the nitrous oxide. The ballistic coefficients are assumptions based on the propellant combination of a given rocket motor for the regression rate equation and assist in simplifying the original equation developed by Marxman [13, 14].

The Phoenix Hybrid Sounding Rocket Programme uses a grade of paraffin wax called Sasolwax 0907. The data available for this wax is limited and therefore determining the ballistic coefficients are essential for the advancement of the Phoenix Programme as they govern the motor's design and performance.

Experimental regression rates obtained from these tests will be later used to determine the ballistic coefficients for Sasolwax 0907 with nitrous oxide.

2.3 Lab-Scale and Slab Motors

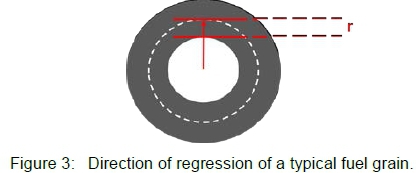

A slab motor is one in which the fuel grain is rectangular in shape and the regression rate is measured in the Cartesian plane. In this motor arrangement, the fuel is located on only one side of the chamber. It is used to model a small segment of a typical fuel grain configuration. Slab motors often have windows to visualize the combustion reaction. A cylindrical lab-scale motor, however, has the same fuel grain configuration as a flight motor but is much smaller in size. The regression rate of cylindrical motors is measured in the polar plane.

2.4 Hybrid Slab Motors

There is little research that investigates hybrid slab motors. Studies on these motors have been principally explored by two groups.

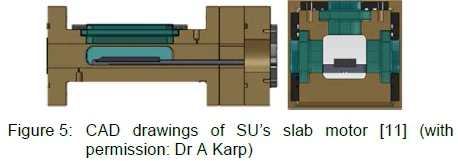

Stanford University (SU) has conducted combustion studies on the previously mentioned entrainment mechanism for paraffin-based fuels. Their studies consisted of a series of tests conducted in a slab motor (see figure 5) at low pressures. Their system comprises of a flow rectifier, a combustion chamber, and nozzle [11].

Figure 6 shows a magnified view of a test on blackened paraffin wax, which is simply paraffin wax with the addition of a black dye which limits the radiation penetration. The flame was observed to be made up of elongated structures. The liquid layer could also be seen forming just above the fuel's surface. Roll waves which result in instabilities are located above the liquid layer and droplets are entrained at or below the flame. These instabilities are beneficial in the combustion process of the propellants.

Tokai University (TU) has experimentally determined the relationship between the melt layer viscosity and regression rate. Ethylene vinyl-acetate copolymer was added to pure paraffin wax to alter the viscosity of the melt layer [15].

3 Slab Motor Design and Parameters

The principal objective of the slab motor outlined in this paper was to determine the regression rate behaviour of pure paraffin wax (Sasolwax 0907) with nitrous oxide. Aluminised fuel grains were also investigated. Research suggests that an additive concentration of 40% aluminium is optimal for increased regression rates [6].

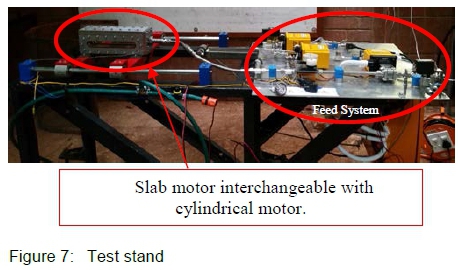

The slab motor test stand was developed in conjunction with a cylindrical lab scale motor with which the regression rate data can be verified. To ensure consistency between the tests, the same test stand was used and designed to enable the motors to be easily interchangeable.

Figure 7 depicts the test stand setup. The feed system is on the right and consists of a feed line, a dump line, and a purge line which will also be used to supercharge the nitrous oxide tank for the motors. The oxidiser tank is situated to the right of the test stand and feeds the nitrous oxide through the system and into the combustion chamber. The chamber shown is for the slab motor but is interchangeable with the cylindrical motor. Both motors have been designed to accommodate the testing of pure and aluminised fuel grains.

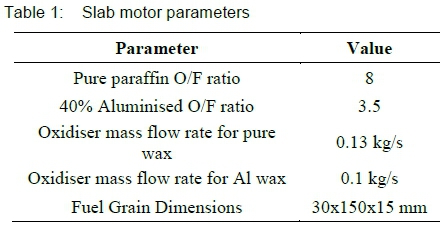

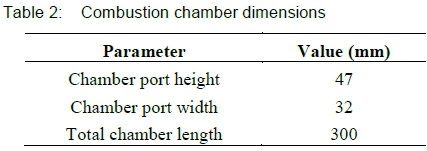

Using optimum O/F ratios for both fuel grains obtained from research and NASA CEA, the parameters for the hybrid slab motor visualisation test stand were calculated and are given in Table 1.

The slab motor test stand was designed to enable visualisation of the regression rate of the fuel grains. The oxidiser enters the feed system and passes through the injector before it reaches the combustion chamber. The fuel grain is housed in the combustion chamber and with ignition, combustion occurs.

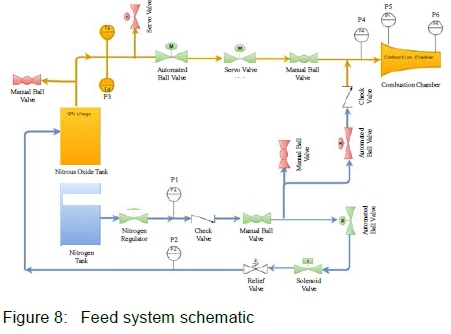

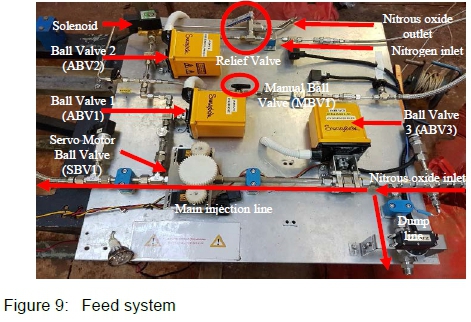

3.1 Feed System

The feed system (see Figure 8 Figure 9) was designed to provide the oxygen rich environment required for combustion. Due to the various safety concerns regarding nitrous oxide, many precautions had to be incorporated into the design such as a purge gas line to ensure safety after a hot fire test, and a relief valve for an outlet of the oxidiser in the instance that it exceeds a pressure of 85 bar. The feed system is made up of / inch tubing for the main feed line and V inch tubing for all other lines. It includes four pressure transducers, three automated ball valves for operation of the oxidiser and purge gases, two manual ball valves and one servo motor as additional safety precautions. Stainless steel was the material of choice for all the components due to its compatibility with nitrous oxide. The design is compact and has minimum bends to reduce pressure losses [16].

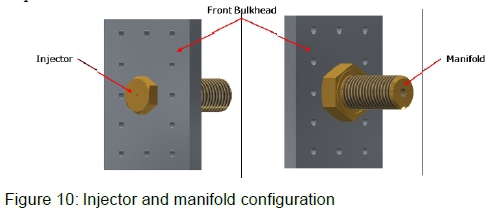

3.2 Injectors

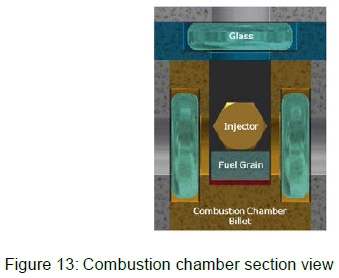

Pure and aluminised fuel grains require different oxidiser mass flow rates and therefore two different injectors have been designed. The injectors fit into the front bulkhead of the combustion chamber by means of a manifold (see Figure 10). The injectors each have a single orifice of diameters 1.3 mm and 1.5 mm for pure and 40% aluminised fuel grains respectively. The selection of orifice size was based on the oxidiser mass flow rates and fuel grain dimensions calculated, and ease of manufacture. The calculations of which can be found in [17]. Brass was the material of choice for its compatibility with nitrous oxide and, because of the requirement of the small holes.

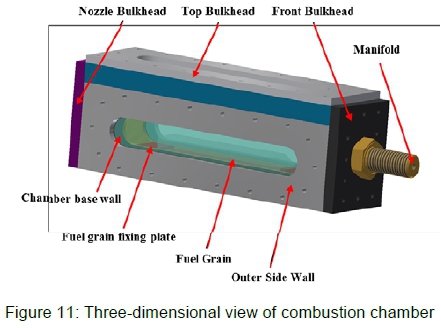

3.3 Combustion Chamber

The combustion chamber was designed to run at ambient conditions as well as at 5 and 10 bar pressures. Research suggests that regression rate is independent of chamber pressure at low oxidiser mass fluxes [4]. The chamber is relatively small in comparison to the cylindrical motor and has a fuel grain width of only 30 mm (see Table 2 and figure 11 for specifications). The inner height of the chamber was calculated by initially assuming a regression rate of 1.5 mm/s for pure paraffin wax (2 mm/s for 40% aluminised paraffin), obtained from NASA CEA and literature [17]. The oxidiser mass flux was then calculated (see equation 9). Initial ballistic coefficients, a and n were assumed based on [7], and then using equations 11 and 12 to determine a port height for the calculated oxidiser mass flow rate of 0.13 kg/s, determined from iterative calculations and detailed in [17].

These parameters were selected based on previous slab motor designs, ideal operating conditions and iterative calculations. The combustion chamber was designed around the dimensions of the fuel grain dimensions and oxidiser mass fluxes [17]. An assembled view of the combustion chamber is shown in Figure 11.

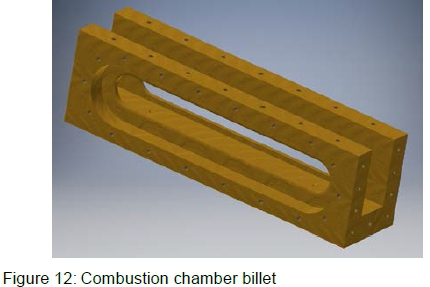

The width of the chamber was designed to house the fuel grain snuggly on the sides, as in a typical hybrid rocket motor configuration but also to minimise side burning of the fuel. The chamber base was constructed from a brass billet (see Figure 12) for ease of manufacture, sealing and structural rigidity. The walls are 20 mm thick to accommodate the 14 mm thick glass windows.

The outer side walls and the top bulkhead are made of 8 mm and 20 mm thick 304L stainless steel respectively. Discretion was used in the selection of these thicknesses in order to prevent warping [17]. The initial tests were conducted without the top window to ensure that the system is functioning as required. The top bulkhead will then be replaced with one incorporating a viewing port window so as to also enable visualisation of the entrainment mechanism and combustion from the top.

The outer side walls and the walls of the chamber base are bolted together so that the glass is held in position. FEA simulations were conducted to determine a thickness of 14 mm for the glass. The analyses proved that this thickness would not break under the operating conditions of the combustion environment [17]. Recesses were machined into the chamber base walls to house the quartz glass with two 1.5 mm silicone gaskets. A tolerance was included to account for the movement of the glass in its gaskets. An oval shaped and chamfered window has been used to reduce stress concentrations.

All plates were bolted to the chamber base and silicone gaskets were used to seal the remaining plates as well as to provide a buffer between the steel and glass, as shown in Figure 13.

The bulkheads of the chamber were machined from 12 mm thick stainless steel, and were designed so that they may be removed. The rear nozzle plate is interchangeable as the tests will be run at pressures of 1, 5 and 10 bar, induced using the different nozzles.

3.4 Fuel Grain Mould

The fuel grain mould was made up of two aluminium halves that were bolted together (see Figure 14). All fuel grains were cast with the same dimensions, with the mould designed to cast a fuel grain size of 150 mm x 30 mm x 15 mm. The protruding section, circled in red, was used to create the leading edge of the fuel grain to assist in the combustion process.

The wax was initially melted completely, outside of the mould, before being poured into the oven pre-heated mould. The mould was then cooled in an oven with the temperature being gradually reduced to control how shrinkage occurs and therefore prevent cracking. Figure 15 Figure 16 show two fuel grains that have been cast.

3 5 Testing and Regression Rate Measurement Techniques

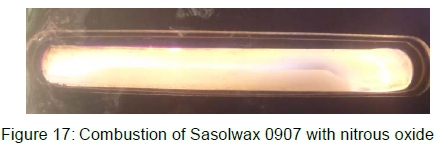

Experiments were conducted in a secure facility at the Mechanical Engineering building. GoPro Hero 3+ cameras were positioned on either side of the glass windows in order to visualise combustion and regression of the fuel grain. Figure 17 depicts the combustion which occurred with pure Sasolwax 0907 and nitrous oxide. Critical analyses of these images will be used to determine the entrainment characteristics of the fuel composition.

Regression rate measurements were obtained using more than one method and are listed below.

1. Measuring the change in weight of the nitrous oxide run tank over the burn time.

2. Determining the fuel mass before and after the burn.

3. Obtaining volumetric measurements of each fuel grain before and after the experiments.

The oxidiser mass flow rate was calculated from graphs that were obtained from LabVIEW and DIAdem. There are, however, complexities surrounding this method. The data was plotted as a graph generated with LabVIEW and the rate of change of the mass was calculated by differentiating the curve with respect to time. The accuracy of the oxidiser mass flow rates obtained from these graphs were ± 10 g/s. The accuracy of this method due principally to time lag in data-capture readings and to load-cell resolution.

The uncertainty resulting from mass measurements of the fuel grains are ± 0.01 g. The graduated cylinder consisted of an uncertainty of ± 2 cm3. The systematic errors are the result of the digital scale and graduated cylinder resolutions.

Alternatively, as TU has done, markings can be made on the side window to identify the times at which the fuel regresses to each depth using a high speed camera [15]. This method also involves inaccuracies as the fuel may not burn evenly across its surface area.

The tests that were conducted in this chamber include those for pure fuel grains. 40% aluminised fuel grains and chamber pressures between 2.5 and 10 bar will also be investigated in a separate study.

4 Hot Fire Testing

Three successful hot fire tests were conducted with pure paraffin wax fuel grains at atmospheric pressure. The igniters were made from firelighter match heads and copper wire. The lead wires were connected to a 12 V battery to form an E-match.

Figure 18 represents an image taken from a hot fire test. GoPro cameras were placed on either side of the glass windows in order to capture the relevant regression rate data.

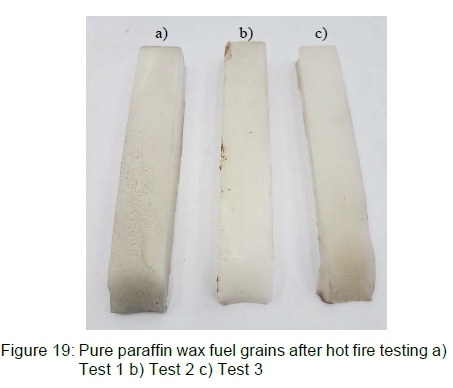

The results from the three tests can be seen in Figure 19.

All three fuel grains had a similar shape after the burn which suggests consistency between the results. The fuel burnt more at the front due to the thin boundary layer. Side burning was also apparent, as there was a 4.5 mm gap between the fuel grain and the quartz glass.

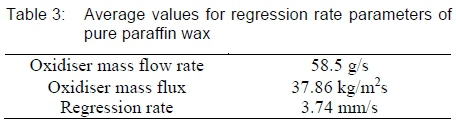

Oxidiser mass flow rates were calculated from tank measurement graphs obtained from DIAdem. The results varied between 5 to 6 g/s due to differences in supercharging pressures and fuel grain dimensions.

Oxidiser mass fluxes had to be calculated individually for each test due to the slight differences (1 to 2 mm) in fuel grain dimensions. These small variances caused a discrepancy of at least 3 kg/m2s.

The regression rates were calculated by measuring the volume of each fuel grain before and after the burn. The combustion times were attained from the video footage at 8.5 seconds. The cube root of the volume over the burn time enabled the estimation for regression rates.

The average of each variable can be found in Table 3.

5 Conclusion

A hybrid rocket slab motor visualisation test stand was developed to investigate the behaviour of regression rates on pure and 40% aluminised paraffin wax fuel grains.

Combustion of Sasolwax 0907 was successful with nitrous oxide at atmospheric pressure. The unique nature of the experiments provide a deeper understanding of the regression rate behaviour of the fuel composition with oxidiser.

The results determined suggest that Sasolwax 0907 is a high regression fuel that burns about three times faster than traditional fuel compositions.

The hybrid rocket slab motor has successfully been utilised to determine the regression rate of paraffin-based fuels at atmospheric pressure.

Future testing will include 40% aluminised fuel grains, different oxidiser mass fluxes, and chamber pressures in order to determine the ballistic coefficients for the fuel composition.

References

1. Space Propulsion Group, Hybrid Rocket Propulsion Overview, www.spg-corp.com/space-propulsion-group-resources.html, 2012.

2. Toru S, The Forefront of Space Science, Japan Aerospace Exploration Agency, www.isas.jaxa.jp/e/forefront/2012/shimada/index.shtml, 2012.

3. Karabeyoglu A, Hybrid Rocket Propulsion for Future Space Launch, Department of Aeronautics and Astronautics, Stanford University, Aero/Astro 50th Year Anniversary, 2008.

4. Chandler AA, Jens ET, Cantwell BJ and Hubbard GS, Visualization of the Liquid Layer Combustion of Paraffin Fuel at Elevated Pressures, 63rd International Astronautical Congress, Naples, Italy, 2012.

5. Karabeyoglu MA, Zilliac G, Cantwell BJ, De Zilwa S and Castelluci P, Scale-Up Tests of High Regression Rate Liquefying Hybrid Rocket Fuels, American Institute of Aeronautics and Astronautics, 2003, 1162, 6-9. [ Links ]

6. Evans B, Boyer E, Kuo KK, Risha G and Chiaverini M, Hybrid Rocket Investigations at Penn State University's High Pressure Combustion Laboratory: Overview and Recent Results, 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Denver, USA, 2009.

7. Genevieve B, Development of a Hybrid Rocket Sounding Motor, MSc Thesis, University of KwaZulu-Natal, Durban, South Africa, 2013. [ Links ]

8. Leverone F, Performance Modelling and Simulation of a 100 km Hybrid Sounding Rocket, MSc Thesis, University of KwaZulu-Natal, Durban, South Africa, 2013. [ Links ]

9. Balmogim U, Design and Development of the Phoenix- 1B Hybrid Rocket, MSc Thesis, University of KwaZulu- Natal, Durban, South Africa, 2017. [ Links ]

10. Hall N, Rocket Thrust Equation, National Aeronautics and Space Administration, www.grc.nasa.gov/www/k-12/airplane/rockth.html, 2015.

11. Chandler A, Jens E, Cantwell BJ and Hubbard GS, Visualization of the Liquid Layer Combustion of Paraffin Fuel for Hybrid Rocket Applications, 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Atlanta, 2012.

12. Marxman G and Gilbert M, Turbulent Boundary Layer Combustion in the Hybrid Rocket, International Symposium on Combustion, 1963, 9(1), 371-383.

13. Boronowsky KM, Non-homogeneous Hybrid Rocket Fuel for Enhanced Regression Rates Utilizing Partial Entrainment, Masters Thesis, San Jose State University, San Jose, USA, 2011. [ Links ]

14. Chandler AA, An Investigation of Liquefying Hybrid Rocket Fuels with Application to Solar System Exploration, PhD Thesis, Stanford University, 2012. [ Links ]

15. Nakagawa I, Hikone S and Suzuki T, A Study on the Regression Rate of Paraffin-based Hybrid Rocket Fuels, 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Denver, USA, 2009.

16. Maharaj CS, Performance Characterisation of Metal Additives in Paraffin Wax Hybrid Rocket Fuel Grains, MSc Thesis, Department of Mechanical Engineering, University of KwaZulu-Natal, Durban, 2017 (In preparation). [ Links ]

17. Theba R, The Development of a Paraffin Wax/Nitrous Oxide Hybrid Rocket Slab Motor, MSc Thesis, Department of Mechanical Engineering, University of KwaZulu-Natal, Durban, 2017. [ Links ]

18. Cantwell BJ, Similarity Solution of Fuel Mass Transfer, Port Mass Flux Coupling in Hybrid Propulsion, Journal of Engineering Mathematics, 2013, 84(1) 19-40. [ Links ]

19. Dlamini MA, Ramruthan N and Theba R, Hybrid Slab Motor Visualisation Test Stand, Technical Report, Department of Mechanical Engineering, University of KwaZulu-Natal, Durban, 2014.

Received 8 February 2017

Revised form 30 November 2017

Accepted 5 December 2017