Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.123 no.7 Johannesburg Jul. 2023

http://dx.doi.org/10.17159/2411-9717/2300/2023

COPPER COBALT EDITION

Characterization of firebricks used in copper smelting furnaces of the 19th century, Atacama, Chile

A. NazerI; N. ToroII; O. PavezIII, IV; J. GuerreroIV

IDepartamento de Construcción, Universidad de Atacama, Copiapó 1531772, Chile. ORCID: A. Nazer: http://orcid.org/0000-0002-0176-2344

IIFaculty of Engineering and Architecture, Universidad Arturo Prat, Iquique 1100000, Chile. ORCID: N. Toro: http://orcid.org/0000-0003-4273-3563

IIIRegional Center for Research and Sustainable Development of Atacama, CRIDESAT, Universidad de Atacama, Copiapó, Chile. ORCID: O. Paves: http://orcid.org/0000-0001-5720-351X

IVDepartamento de Ingeniería en Metalurgia, Universidad de Atacama, Chile. ORCID: J. Guerrero: http://orcid.org/0000-0002-0867-7070

SYNOPSIS

In the 19th century, mining in northern Chile was of great economic importance. Today, the ruins of the copper smelters and abundant fragments of refractory bricks from their furnaces remain. The refractory materials have not been previously studied. the origin, physical and chemical properties, and compressive strength of 10 different samples of historical refractory bricks collected on-site were investigated. The characterization results showed that the bricks are silico-aluminous, unlike the magnesium-chromium bricks used by current foundries. It was determined that 90% of them were produced in the UK and 10% were manufactured in Chile. The phases present are mullite, quartz, cristobalite, and tridymite, and the chemical composition corresponds mainly to SiO2. The compressive strength of the historical bricks is similart to those currently used,. These results may contribute to the knowledge of the 19th century mining and metallurgical historical heritage of Chile and the UK.

Keywords: characterization; firebrick; non-destructive testing; 19th-century smelting; cultural heritage.

Introduction

In the 19th century, the so-called Norte Chico region, nowadays comprising the Atacama and Coquimbo administrative regions, played a fundamental role in the Chilean economy due to its outstanding mining and metallurgical production (Pérez et al., 2021). In northern Chile, valuable secondary veins containing copper-rich minerals were found. On the surface, oxidized copper minerals such as chrysocolla, malachite, and atacamite, were present. However, at greater depths, the richness of the deposit lay in abundant copper sulphides, such as chalcopyrite, chalcocite, and covellite. In the 19th century, the ores exploited were of high grade and were treated by direct smelting. The copper-rich material was sorted manually since mineral concentration technologies did not exist at that time.

In previous studies, the authors located 41 copper smelters in the Atacama Region, which were active during the 19th century and a few until the first decade of the 20th century (Nazer et al., 2016).

The growth of these metallurgical centres gave rise to settlement that housed the mining workers and their families, and which included facilities for commerce, religious worship, art and culture, education, transport (rail links), cemeteries, and offices (Sernageomin, 2020; Toro, et al., 2021). The copper produced was mainly exported to the UK. The copper boom caused a remarkable increase in the population of Atacama, going from 2 000 to 24 000 inhabitants between 1803 and 1872. During the period from 1843 to 1872, the region generated a total income close to 200 million Chilean pesos, with more than half of this amount resulting from exports of copper bars, minerals, and primarily anodes. At the beginning of the 1830s in the province of Huasco, perhaps the most important development in copper mining was the introduction of reverberatory furnaces to replace the sleeve furnace. Reverberatory furnaces required specialized work and the incorporation of new refractory materials (Venegas, 2007).

Nazer et al. (2016) identified four types of copper smelting furnaces that were used in the northern Chile in the 19th century:

> 'Modern system' reverberatory furnace, in which several of these furnaces were served by a single chimney

> Ancient system' reverberatory furnace, each with its own chimney

> Calcination furnace, used to eliminate volatile elements from the mineral concentrates

> Sleeve or wind furnace, which used a bellows to improve combustion. This is a clay furnace, of low efficiency, and consumes a considerable amount of firewood.

According to Aracena (1884), the copper smelting process typically involved three successive smelting stages, with an ore feed containing up to 13% copper. The first smelting produced a matte containing 43 to 45% copper, which then underwent a second fusion to increase the grade to 68-70% copper. The third and final smelt produced bars with a purity of 98-99%. This metallurgical process was known as the 'ancient system. The average time for the first and second smelts was normally 5¼ hours, while the third smelt took between 27 and 28 hours. Later, a radical innovation reduced the successive smelting stages to just two, resulting in a significant time saving in the production of copper bars. This smelting process was called 'Napier's improved system, or 'reformed system. Based on historical statistics, Nazer et al. (2016) estimated that approximately 6 t of copper ore and 5 t of coal were needed to obtain 1 t of copper with a purity of 96-97% using the reformed system.

The fusion temperatures in the furnace reached approximately 1200°C. Nazer et al. (2016) studied four samples of copper slags from dumps in the Atacama Region. The slags were chemically classified as acidic slags and consisted mainly of SiO2 (38-49%), Fe2O3 (18-37%), CaO (8-26%), and Al2O3 (5-8%). The mineralogical compositions and structure showed diversity; one sample was amorphous, while the other three had a crystalline structure with some amorphous character. The major mineral phases were diopside, fayalite, magnetite, cristobalite, and clinoferrosilite.

The fall in international mineral prices from 1874 (MemoriaChilena, 2021), together with the inefficient extraction techniques and dependence on foreign capital, created increasing problems for copper mining, which resulted in the closure of numerous operations. In 1879, Chile accounted for 30% of world copper production; in 1890, 9.7%; and, in 1900, only 5.5% (Gonzalez, et al., 2016). Several factors contributed to this decline, including changes in global copper demand, competition from other copper-producing countries, the growing economic significance of nitrate production, depletion of deposits, the War of the Pacific between Chile and the Peru-Bolivian Confederation, lack of capital, and technological stagnation (Mamalakis, 1967). The inhabitants abandoned the mining towns, which gradually fell into decay.

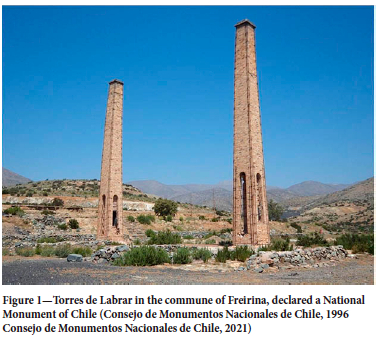

Few vestiges of copper smelting remain today, and these remnants coukd totally disappear in the future. Figure 1 shows the ruins of a smelter, with only the chimneys remaining standing. These chimneys, the only examples of their kind, have been declared a National Monument of Chile, in the category of Historical Monument (Consejo de Monumentos Nacionales de Chile, 1996).

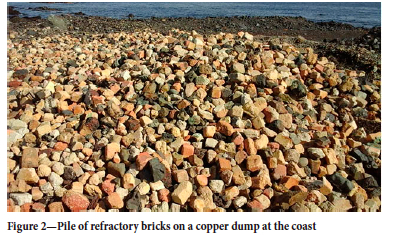

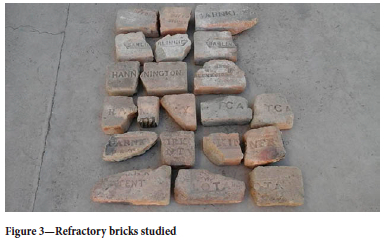

Among the residues found in the abandoned mining settlements are a great variety of refractory bricks that were used in the copper smelting furnaces, which are mostly broken, with the manufacturers' names partially or totally missing(see Figure 2). Until now, no studies have been reported that characterize these bricks. The objective of this research was to characterize 10 different types of refractory bricks (Figure 3), using various laboratory techniques to determine the chemical and mineralogical composition, mechanical resistance by a non-destructive method, the density, and in addition to identify the manufacturers. The results of this study can contribute to the knowledge of these materials that are a significant part of the Chilean mining and metallurgical heritage.

Materials and methods

Collection of Samples

Refractory bricks were collected from abandoned mining settlements in the Atacama Region, particularly from the towns of Púquios, Pan de Azúcar, Playa Negra, Totoral, Carrizal Bajo, Llanos de Challe, Canto del Agua, Vizcachitas, and Agua Amarga. The bricks collected were in small pieces with the manufacturer's mark printed in bas-relief; smaller quantities of whole bricks were also obtained. The samples were bagged and identified according to their origin and transferred to the laboratory of the Department of Construction at the University of Atacama. The bricks were cleaned by careful brushing to prepare them for physical, chemical, mineralogical, and mechanical characterization.

Manufacturer identification

Refractory bricks were identified by the manufacturer's mark engraved on one of their faces. Subsequently, several bricks of the same brand were selected. An internet search was carried ou to find information about the manufacturers.

Selection of bricks to study

Among the large number of refractory brick fragments collected in situ, several carrying the same manufacturers mark were found in different mining settlements of the 19th century, so it was assumed that these were widely used bricks. Of the total samples, only 10 different types were selected and bearing the following manufacturer's marks: Barlinnie, Garkirk, Garkirk Patent, Glenboig, Hannington, Lota, Ramsay, Rufford Stourbridge, Skinner, and Tcarr.

Characterization

To obtain the samples for characterization in the laboratory, a part of each refractory brick was broken off and ground in a disk pulverizer to a particle size less than 0.075 mm (-200#). The powders obtained were chemically analysed by atomic absorption spectr ometry(Shimadzu 6601F).

The mineral species in the refractory bricks were aidentified by X-ray diffraction (Brucker D8 Advance). Real density was determined by the pycnometer method. The apparent density, on the other hand, was determined on the complete sample according to the NCh 116:2008 method (Instituto Nacional de Normalización, 2008) using an electromechanical scale with a capacity of 6 kgf. To obtain the resistance to compression, the Schmidt hammer (Proseq brand) was used according to the Chilean standard ^111565:2009 (Instituto Nacional de Normalización, 2009), which is a non-destructive method used to determine the compressive strength of rock samples and construction materials such as concrete. The instrument was calibrated, and to determine the reliability of the results, modern refractory bricks were tested, which had been tested by the destructive method required by current regulations. The procedure applied was as follows: the historical brick samples were polished with a polishing stone, and then the Schmidt hammer was used in a direction perpendicular to the brick surface. In each determination, 20 strokes are applied in different areas of the sample to obtain results with a statistically reliable mean. The values obtained were corrected using the manufacturer's table of values.

Results and discussion

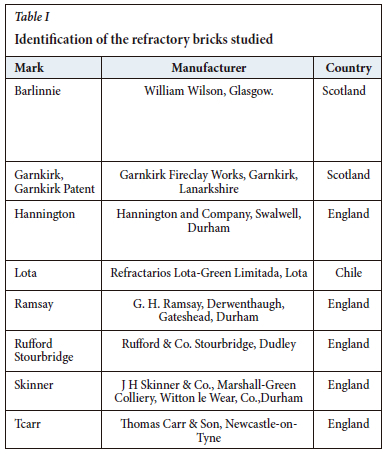

The identification of refractory bricks collected in situ was carried out visually on those specimens on which the manufacturer's mark could be easily read. For those brick fragments where identification was not evident, a rigorous internet search was carried out. The origin and manufacturer of the bricks are listed alphabetically in Table I.

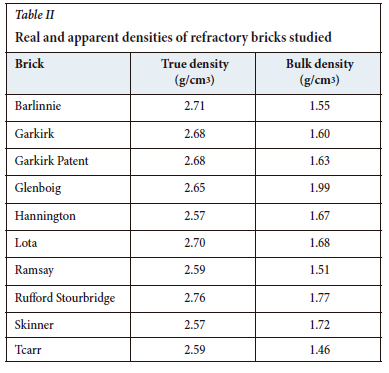

The real and apparent densitues of the refractory brick samples are shown in Table II, The real density of the samples varies between 2.57 and 2.76 g/cm3, for the Hannington and Rufford Stourbridge brands, respectively, while the apparent density is in the range 1.46 to 1.99 g/cm3 for the brands Tcarr and Glenboig, respectively.

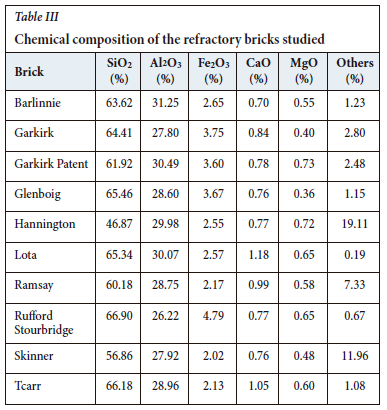

The chemical analyses are presented in Table III. In general, the bricks containedavery high percentage of SiO2 and Al2O3. The Rufford Stourbridge brick had the highest SiO2 content with a value of 66.90%, while the Barlinnie brick contained 31.25% AhO3. The bricks in general had a low content of CaO, MgO, and Fe2O3. Given the high values of SiO2 and Al2O3 that the bricks present, they would be classified as the aluminous silica type.

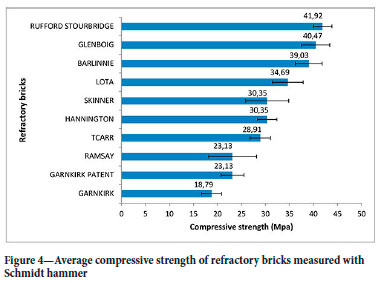

The results of the compressive strength tests of the bricks are presented in Figure 4. The maximum values were obtained for the Rufford Stourbridge and Glenboig bricks, at 41.92 MPa and 40.47 MPa, respectively, while the minimum values was for Garnkirk at 18.79 MPa. The strength of the Ramsay and Garnkirk Patent bricks was 23.13 MPa.

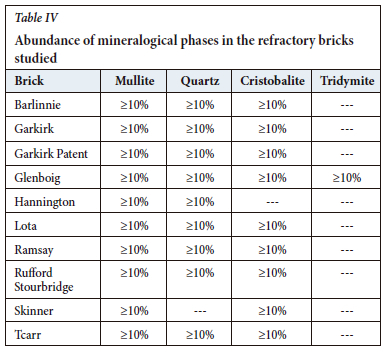

The mineralogical analysis showed that the phases present consisted of mullite (Al4,56 Si1,44 O9.72), quartz (SiO2), cristobalite (SiO2), and tridymite (SiO2). The relative abundances of the phases are shown in Table IV

Discussions

The difference in compressive strength observed between the different bricks would be related to the compaction method of the fresh clay mortar before firing. On the other hand, the compressive strength values can be related to the apparent densities shown in Table II, from which it can be deduced that bricks with a low apparent density have a higher porosity, which adversely affects thw final strength. On the other hand, bricks may have suffered from microcracking due to thermal shock. Refractory materials are formulated to withstand rapid changes in temperature without fracturing. However, when subjected to repeated cycles of heating and cooling, especially if they occur rapidly, microcracks and fissures can arise in the material. These microcracks can weaken the brick's structure over time and affect its performance and durability in high-temperature applications. Moreover, these microcracks or fissures can provide pathways for the entry of gases or liquids into the interior of the brick, which could increase its porosity, consequently impacting its strength and durability. Today's refractory bricks differ from the studied bricks in their chemical composition and mineralogy. The refractory bricks analysed in this study are composed of a high percentage of SiO2 and Al2O3 and can be classified as aluminous silica bricks.

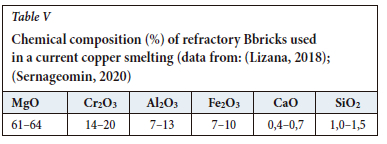

The different chemical compositions of the old refractory bricks and those used currently would be related to the type of material smelted. The current grades, with low concentrations of valuable minerals and higher content of gange minerals, require higher temperatures for smelting, necessitating more resistant refractories, regardless of the furnace design. During much of the 19th century, the sleeve furnace was used, which could only process the oxidized minerals in the upper part of the copper deposits; when sulphide minerals were treated, a brittle mixture called 'sandstone' resultes, which was discarded as slag (Memoria Chilena, 2021; Folchi, 2001). Later, at the end of the 19th century, the reverberatory furnace, which was able to treat sulphide ores, replaced the sleeve furnace. Therefore, the metal product, as well as the slag, was different from those currently produced in copper furnaces. Possibly, given the metallurgical characteristics of the minerals treated in the sleeve furnaces, refractory bricks were required that were mainly composed of SiO2 and Al2O3, very different from the current ones, which are mainly composed of MgO and Cr2O3 (Table V). On the other hand, according to information on the real density and compressive strength of current refractory bricks (C. Contreras, Engineer at Empresa Nacional de Minería, personal communication) the compressive strength of current refractory bricks ranges from 16 to 39 MPa, while the bricks studied are in the range 19 to 42 MPa. A similar situation occurs with the true density, 2.57-2.71 g/cm3 for old bricks and 3.0-3.2 g/cm3 for current bricks.

The bricks sampled in this study primarily consisted of SiO2-Al2O3 and showed no signs of contact with slag and matte. Their surfaces were remarkably clean without any crystallized residues resulting from mineral fusion.

Conclusions

Ten types of refractory bricks that were used in 19th century copper smelting furnaces in the Atacama Region of Chile were studied. The samples were found at different sites in the region, so it could be assumed that they were common at the time. Almost all of the bricks studied came from factories in the UK, five of them from England, four from Scotland, and only one from Chile. The chemical characterization indicated that in the bricks are aluminous silica, unlike the refractory magnesia-chrome bricks currently used in copper smelting furnaces. The mineralogical characterization showed a predominance of mullite, cristobalite, and quartz. The apparent densities were in the range 1.46 to 1.99 g/ cm3. The resistance to compression, measured by means of a nondestructive test, was in the range of 18.8 to 41.9 MPa.

No characterization studies have been published on these refractory bricks to date. The results obtained in this study may contribute to the historical heritage of 19th-century mining in Chile.

Declaration of interest statement

The authors declare they have no conflict of interest.

Acknowledgments

The authors thank the Office of the Vice Dean for Research and Postgraduates of the University of Atacama for financing the DIUDA Regular Project N° 22342/2017.

References

Aracena, F.M. 1884. Apuntes de viaje. La industria del cobre en la Províncias de Atacama y Coquimbo. Valparaíso, Chile. [ Links ]

Consejo de Monumentos Nacionales de Chile, 1996. Decreto Exento n. 357 de Las Chimeneas de Labrar Amplía y fija límites, 2021. https://www.monumentos.gob.cl/servicios/decretos/357_1996 [ Links ]

Consejo de Monumentos Nacionales de Chile, 2021. Monumentos Nacionales. https://www.monumentos.gob.cl/ [ Links ]

Cochilco, 2020. Base de datos del cobre. [Online]. Available: http://www.cochilco.cl:4040/boletin-web/ [ Links ]

Kitching, D. 2021. Old Bricks - history at your feet. https://www.brocross.com/Bricks/Penmorfa/Pages/england20.htm [ Links ]

Kitching, D. 2021. Old Bricks - history at your feet - Foreign bricks. https://www.brocross.com/Bricks/Penmorfa/Pages/foreign.htm [ Links ]

Folchi, M. 2001. La insustentabilidad de la industria del cobre en Chile: los hornos y los bosques durante el siglo XIX. Rev. Mapocho, vol. 49, pp. 149-175 [ Links ]

Gonzalez, S., Richard, N., Figueroa, v., and Godoy Orellana, M. 2016. Minería en el desierto de Atacama, no. 52. [ Links ]

Instituto Nacional de Normalización. 2008. Norma chilena NCh1116:2008. Áridos para morteros y hormigones - Determinación de la densidad aparente. Santiago. [ Links ]

Instituto Nacional de Normalización, 2009. Norma chilena NCh1565:2009. Hormigón - Determinación del índice esclerométrico. Santiago. [ Links ]

Lizana, D. 2018. Análisis del efecto en los refractarios de convertidores Pierce Smith al adicionar 'CaO' y 'AhO3' en las escorias de conversion. Universidad Técnica Federico Santa María [ Links ]

Mamalakis, M. 1967. The American Copper Companies and the Chilean Government, 1920-1967: Profile of an Export Sector. Discussion paper no. 45, Yale University Economic Growth Center, New Haven, Connecticut. [ Links ]

Memoria Chilena. 2021. Capitalismo minero y expansion econômica en el Norte Chico: Los ciclos mineros del cobre y la plata (1820-1880). http://www.memoriachilena.gob.cl/602/w3-article-727.html#presentacion [ Links ]

Mosier, D.L. 2021. Imported and out-of-state bricks-Hannington. https://calbricks.netfirms.com/brick.hannington.html [ Links ]

Mosier D.L. 2021. Imported and out-of-state bricks- TCARR. https://web.archive.org/web/20191223120842/https://calbricks.netfirms.com/brick.tcarr.html [ Links ]

Nazer, A., Paya, J., Borrachero, M.V., and Monzó, J. 2016. Caracterización de escorias de cobre de fundiciones chilenas del Siglo XIX. Revista de Metalurgia. vol. 52, no. 4. p. 083. [ Links ]

Nazer, A. 2016. Caracterizaciôn y determinación de las propiedades cementantes de escorias de cobre del siglo XIX de la Región de Atacama, Chile para su uso en construcción, Doctoral theses. Universitat Politécnica de Valencia, Valencia, Spain. [ Links ]

Pérez, K., Toro, N., Gálvez, E., Robles, P., Wilson, R., and Navarra, A. 2021. Environmental, economic and technological factors affecting Chilean copper smelters - A critical review. Journal of Materials Research and Technology. vol. 15. pp. 213-225. [ Links ]

Sernageomin. 2020. Datos Públicos Depósito de Relaves. https://www.sernageomin.cl/datos-publicos-deposito-de-relaves/ [ Links ]

Scotland's Brick and Tile Manufacturing Industry. 2021a. Barlinnie. https://www.scottishbrickhistory.co.uk/barlinnie/ [ Links ]

Scotland's Brick and Tile Manufacturing Industry. 2021b. Garnkirk. https://www.scottishbrickhistory.co.uk/garnkirk-3/ [ Links ]

Scotland's Brick and Tile Manufacturing Industry. 2021c. Garnkirk Patent. https://www.scottishbrickhistory.co.uk/garnkirk-patent/. [ Links ]

Scotland's Brick and Tile Manufacturing Industry. 2021d Glenboig. https://www.scottishbrickhistory.co.uk/glenboig-2/ [ Links ]

Scotland's Brick and Tile Manufacturing Industry, 2021e. Ramsay. https://www.scottishbrickhistory.co.uk/ramsay/ [ Links ]

Sellos Extranjeros. 2021. Gran Bretana (en Ruso), Heddon. http://www.v-smirnov.ru/brit7.htm [ Links ]

Sernageomin. 2020. Anuario de la Minería de Chile 2020. Servicio Nacional de Geología y Minería, Santiago. [ Links ]

Toro, N., Ghorbani, Y.N., Turan, M.D., Robles, P., and Gálvez, E. 2021. Gangues and clays minerals as rate-limiting factors in copper heap leaching: A review. Metals Basel, vol. 11, no. 10. p. 1539. [ Links ]

Venegas, H. 2007. Auge y Caída de la Minería Chilena del Cobre. ¿Una Historia que se Repite? Contribuciones. Científicas y Tecnológicas. pp. 6-19. [ Links ]

Correspondence:

Correspondence:

A. Nazer

Email: amin.nazer@uda.cl

Received: 31 Aug. 2022

Revised: 1 Aug. 2023

Accepted: 1 Aug. 2023

Published: July 2023