Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.122 n.12 Johannesburg Dec. 2022

http://dx.doi.org/10.17159/2411-9717/1950/2022

PROFESSIONAL TECHNNICAL AND SCIENTIFIC PAPERS

Ventilation optimization through digital transformation

T. ChikandeI; H.R PhillipsII; F.T. CawoodIII

IZimbabwe Platinum Mines, Zimbabwe. https://orcid.org/0000-0001-7886-339X

IIVisiting Professor, University of the Witwatersrand, Johannesburg, South Africa (Posthumous)

IIIFormer Director, Wits Mining Institute, University of the Witwatersrand, Johannesburg, South Africa

SYNOPSIS

Underground mines require electricity to operate both the main surface fans and auxiliary systems, with primary ventilation systems typically accounting for approximately 40-60% of the mine's overall electricity consumption. The primary reason for this considerable expense is that most underground ventilation systems are designed for peak demand, regardless of the actual demand, which is commonly dictated by diesel equipment usage in trackless mining operations. Most platinum mines on the Great Dyke in Zimbabwe tend to operate their ventilation systems at this peak level, despite the mine's air quantity being well in excess of the 'true' ventilation needs. This is due to a lack of appropriate ventilation controls. The authors designed and installed a ventilation-on-demand system at one of the bord and pillar platinum mines to minimize the use of redundant air in underground operations. Fourth industrial revolution techniques were applied to the environmental monitoring and tracking systems thereby optimizing air quantity demands. The mine managed to reduce its annual power consumption by 23% through the implementation of manual control and time-of-day scheduling levels of the ventilation-on-demand concept. There was also a 6% productivity improvement, mainly attributable to an increased face time as a result of the significant reduction in the re-entry period following a blast. This paper introduces a novel concept of ventilation optimization through digital transformation targeting mainly room and pillar platinum mines. A system was designed, installed, and commissioned, though there is currently an ongoing optimization process to harness the full benefits such as productivity enhancement, reduced power costs, and improved worker health.

Keywords: mine ventilation, ventilation on demand, internet of things, power savings, ventilation optimization.

Introduction

In mechanized platinum mines, underground air is contaminated primarily by diesel vehicles and blasting operations. Research shows that mine ventilation systems consume enormous amounts (40-60 of the total) of electrical energy, hence the need to identify potential energy saving opportunities through the adoption of digital transformation (Acuna and Allen, 2017). Digital transformation is the process of using digital technologies to create new or modify existing business processes, culture, and customer experiences to meet changing business and market requirements. Mine ventilation systems have been given augmented attention in recent decades as a result of the ever-increasing cost of energy, increased degree of mechanization, and increasingly stringent health and safety regulations (Hardcastle and Kocsis, 2001). There is still room for improvement in optimizing the key performance indicators in mining, i.e., safety, productivity, and costs, by maintaining the required air quantity in working areas based on the nature of activities undertaken. For example, in a large mechanized operation, if the mine wishes to reduce air quantity through eliminating redundant air supply, the resultant power consumption or cost will be reduced due to the cubic relationship of fan speed and power (Bluhm and Smit 2014).The increased power demand from ventilation systems due to increased mechanization necessitates optimization of the amount of air delivered underground through the application of fourth industrial revolution techniques. The fourth industrial revolution is characterized by the convergence and complementarity of emerging technology domains, including nanotechnology, biotechnology, new materials, and advanced digital production. It is a fusion of advances in artificial intelligence (AI), robotics, the Internet of Things (IoT), 3D printing, genetic engineering, quantum computing, and other technologies. Ventilation on demand systems, coupled with advanced control processes to modulate the quantity of air supplied by main surface fans and auxiliary fans, can optimize underground ventilation systems.

The use of fourth industrial revolution concepts can enhance productivity and safety, reduce costs of ownership, and enable monitoring of all processes in real time (Cawood, 2019). The IoT, together with other digital revolution techniques, is investigated and implemented in the mining industry mainly for process optimization by identifying and eliminating bottlenecks along the mining value chain.

The IoT is a system of interrelated computing devices, mechanical and digital machines, objects, animals, or people that are provided with unique identifiers (UIDs) and the ability to transfer data over a network without requiring human-to-human or human-to-computer interaction (Kumar, 2019). Mining on the Great Dyke of Zimbabwe poses several challenges, including fluctuating mineral prices, safety concerns, productivity optimization, and low metal grades (Matthews, 2020). Underground mining operations are a technically challenging and hazardous environment for workers through inadequate ventilation, exposure to dust, heat, and gas, as well as the threat of rockfalls or even a more widespread mine collapse.

Recent studies have shown that ventilation systems in highly mechanized platinum mines could be responsible for 40 to 60% of the mines' energy consumption (de Souza, 2018). The full ventilation on demand concept has not been adopted or rolled out in any bord and pillar mining operation worldwide due to the nature of mining operations (Develo et al., 2016). Efficient air distribution in bord and pillar platinum mines can be achieved through the integration of IoT and empirical techniques extracted from real-time data. The ventilation system is capable of being adjusted in real time to meet the triggered ventilation demand based on the activities being undertaken. This paper describes various options to optimize and apply the concept to hard rock bord and pillar platinum mines operating on the Great Dyke.

A review of relevant literature

Although the concept of ventilation in underground mines may seem relatively simple, getting the right quantity and quality of air to where it is needed when it is needed in an expanding mining environment is an elaborate operation that requires an array of ventilation components. Typical ventilation systems consist of main surface fans, air regulators, and underground doors that distribute air through the mine. Air requirements in an area depend on the number of people and the machinery deployed there.

The fourth industrial revolution has been evolving for many years and has created an ever-increasing motivation for mining companies to embrace digital transformation to optimize mining key performance indicators (KPIs). The IoT, artificial intelligence, and data analytics are all components of the fourth industrial revolution and have impacted on the way companies operate (Cawood, 2019). Most mining companies are considering harnessing such emerging technologies and others have been proactively exploring fourth industrial revolution solutions over the last decade (Cawood, 2019). Substantial benefits and efficiencies are expected from the implementation of fourth industrial revolution techniques, and Cawood (2021) pointed out that such technologies have potentially lucrative benefits in the extraction of minerals. Extensive work has also been undertaken in other mining activities such as the exploration field, which has seen some development of sensing technologies in the modelling of geological deposits (Abrahamsson, et al., 2009).

Some fruitful gains from digital transformation include time-saving, lower energy costs, improved health and safety of employees, and better predictive maintenance which will subsequently improve machine availability (Kumar et al., 2019).

Creamer (2018) highlighted that the mining industry is the economic driver of much of Africa, hence the need to embrace digital transformation in all mining operations.

Creamer (2018) also pointed out that there is a gap that needs to be bridged in the mining sector regarding fourth industrial revolution technologies. In addition, there are currently dips in local performance indicators in the mining sector despite it being at the dawn of a technology revolution. It is imperative to adopt digital transformation throughout the whole mining value chain to improve processes aligned to value. Cawood (2019) highlighted that digital transformation in the mining industry should be anchored on automation, decision support, and analytics. Matthews (2020) pointed out that the drive towards the application of fourth industrial revolution techniques is mainly attributable to changing global demand, market volatility, and increased costs. Ventilation, being a critical facet of any underground mining operation, should therefore not be ignored because it accounts for a large percentage of power costs, as well as being vital for the health and safety of employees. Digital transformation in mine ventilation will provide great insight into safety, process optimization, and enhanced operational efficiencies. However, there is still little clarity on how fourth industrial revolution technology will unfold and what its overall bearing on ventilation systems will be (Acuna and Allen, 2017).

This paper focuses on ventilation optimization through digital transformation. An optimized ventilation system was developed and installed for trial purposes at one of the Zimbabwean platinum mines and is therefore used as a base case for illustrating the benefits of VOD (ventilation on demand) systems.

VOD architecture

VOD is the ability to direct air in an underground mine to the area that requires it, at the quantity needed for the local activities and ambient conditions at the time (Acuna and Allen, 2017). According to Tran-Valade and Allen (2013), there are five control strategies that are considered for VOD:

> User control, also referred as manual control (level 1)

> Time of day scheduling (level 2)

> Event based (level 3)

> Tagging (level 4)

> Environmental (level 5).

The five identified strategies can be used individually or in concert. This paper will focus more on manual control and time of day scheduling (levels 1 and 2 application) since the other levels have not yet been achieved and are still under investigation. Prevailing trends within the global mining industry, including operating at greater depth, are generally demanding significant air quantities, not only for ventilation but also for cooling purposes. The drive to minimize greenhouse gas emissions in countries heavily reliant on coal-fired power stations increases the importance of managing power consumption in the mining industry (Hardcastle and Kocsis, 2001).

The current ventilation mechanism at most mines operating on the Great Dyke in Zimbabwe entails the use of a negative pressure system (exhaust ventilation application). Figure 1 shows a ventilation layout for a typical mechanized board and pillar operation. A VOD model was developed by the a-uthors and was applied to a mechanized mine that uses four 850 kW primary surface fans and twelve underground auxiliary fans. Each main surface fan has a rated motor capacity of 850 kW with a duty of 200 m3/s and a static pressure of 3.1 kPa. Foul air is exhausted out of the mine through upcast shafts and the intake air is drawn into the mine via a series of declines and fresh air intakes raise-bored from surface. Ventilation walls are built along roadways which are mined at every tenth stope panel. Intake air is controlled into each section by means of regulators, which are normally placed in each roadway. The mines currently use brattices to regulate air flowing into all production sections. Such brattices were replaced with automatic doors during the VOD trial. The louvers are manually controlled depending on sectional demand, which depends on the number of people and the amount of operational equipment in any section. The designed and installed VOD system comprises a communication backbone (Long Term Evolution network or LTE) , tagging and tracking system, variable speed fan drives, and air quality stations. LTE is a standard for wireless broadband communication for mobile devices and data terminals.

Foul air is exhausted by means of a negative pressure system using main surface fans and fresh air enters the mine via a series of intake shafts and declines. Energy efficiency of mine ventilation systems, including automated ventilation control, is achieved by means of an algorithm for optimal ventilation control, controlled recirculation, and dynamic assignment of air quantity lower limits in real-time mode. The authors designed an optimized VOD system that links tagging and tracking systems and environmental monitoring stations with primary and auxiliary ventilation systems. The amount of air drawn into a section will be automatically determined by the number and types of diesel equipment in use, the heat load, number of people working in a particular section, and other exceptional airborne pollutants.

The VOD system designed and trialed by the authors consists of the key components shown in Figure 2.

In addition to reducing the fan power consumption, the VOD system was developed to ensure a healthy underground working environment through:

> Dilution of hazardous substances which affect the health and safety of employees

> Climate control through modulation of air quantity to create a conducive working environment

> Quicker evacuation of blasting gases, thereby improving productivity

> Better utilization of existing infrastructure, thereby resulting in better control of capital and operating expenditure by minimizing additional costs associated with redundant air

> Producing accurate and consistent ventilation survey measurements.

The VOD system utilizes airflow sensor feedback to perform an online optimization process on main ventilation fans and underground auxiliary fans. Some of the system components incorporated into the VOD structure include:

> Variable speed drives (VSDs) - All primary and auxiliary fans are equipped with variable speed drives so that fans can be allowed to run at different speeds based on the actual demand. The air quantity delivery is controlled through changes in the rotational speed of new fans.

> Automated ventilation doors - these are installed in all main roadways of each section and ventilation district. Each automatic door is equipped with sensors so that the quantity of air entering a section can be controlled and is primarily dependent on the deployment of operational equipment and personnel in that particular zone. Louvres will automatically adjust depending on air demand.

> Main surface fans - these form the basis of the system since the air quantity for each fan is controlled by using VSDs informed by environmental monitoring stations.

> Tagging and tracking system - selectively delivers appropriate air volumes to the production workings according to the various mining activities being undertaken. It is essential to know where, when, and for how long these air quantities are needed. In mechanized bord and pillar mines, this means knowing the location of production, development, and service vehicles, together with their characteristics. This is achieved using a vehicle identification and tracking system. All vehicles and cap lamps are equipped with electronic chip sensors for tracking capability and this subsequently determines the desired quantities of air to dilute heat and other pollutants. The tag readers are located at strategic points throughout the mine to give live readings throughout the shift.

> Monitoring system - an environmental monitoring system allows for an activity-based ventilation system to provide and maintain adequate working conditions within all production workings. Firstly, the required air quantity to all working faces must be maintained. For this reason, non-intrusive ultrasonic airflow sensors were installed along the main haulages and inside fan drifts. Secondly, the quality of air delivered to all working areas must also be monitored and for this reason, gas sensors, diesel particulate matter (DPM) sensors, and dust sensors were installed in all sections. To ensure the equipment operators are always exposed to safe underground environmental conditions, DPM sensors were installed on dump trucks and load haul dump machines (LHDs).

> Data management and communication systems - these include the process logic of ventilation control systems by which information is processed and outcomes determined (Kumar et al., 2019). The VOD system requires a communication backbone which runs from surface to underground operations. Fibre-optic cables and a Long-Term Evolution (LTE) network were installed covering both surface and underground operations. The software to integrate all system components is being configured and this will be maintained annually through a license key.

> Operator workplace - all data was integrated into one server so that reports and trends can be extracted using any connected device either on surface or underground. Data collected and analysed by the system sensors includes ventilation KPIs such as air quantity, air velocity, airborne pollutant values, and fan pressure readings. Other information to be graphically displayed includes:

• Mine ventilation overview layout

• Det-ails regarding performance of main surface fans

• Ventilation layout for each section

• Rate of change alarms and advanced alarm statistics for mine ventilation

• Production statistics displays - current and historical trends

• Overall mine ventilation KPIs

• Total energy consumption, run-time, energy statistics per fan, and mode of operation

• Trends and logged data for all important data-sets.

The VOD control philosophy ensures the capability of a system to alter environmental conditions in a ventilation district and comprises smart sensors and control servers. Automatic fire suppression systems are also installed in areas with a high fire load index. There are five levels of VOD. The mine is currently operating on level 2 and is in the process of trialling level 3, as described below.

User control or manual control

User control strategy is the first level that allows for manual control or setting of operational points for the different components of the ventilation system. These include the following:

> Main and secondary fans - Main fans can be connected to start directly online or be equipped with soft starters or variable frequency drives (VFDs) to save energy (Tran-Valade and Allen, 2013). It is more common to have auxiliary fans connected to steel ducting, but soft starters should be considered for energy savings and safety when considering flexible ducting. All main surface fans (4 x 850 kW) were equipped with VFDs. This was considered as the first step towards automation and the mine reduced its energy consumption by 36% as described later.

> Regulators and doors - Regulators are used for controlling airflow by increasing the airway resistance, thereby decreasing the air quantity. The mine installed automated ventilation doors (non-airlock) to prevent the flow of air while still allowing travelling and transportation to take place. The doors are efficient, economical, and require minimum maintenance. Figure 3 shows typical automatic doors installed at the mine.

> Manual operational point settings - can be divided into two subcategories

(a) Fixed setting: For fans these settings correspond to on or off, or in a case where a VSD is available, to set the frequency of the fan drive to deliver just the air quantity required (Tran-Valade and Allen, 2013). For regulators and doors, the fixed settings correspond to a percentage of the opening from zero to 100%.

(b) Proportional integral derivative (PID) control loop: This is a feedback control loop to achieve a desired set-point based on a measured process variable (Tran-Valade and Allen, 2013). In this case, the set-point is the opening of the regulator or door, and the measured process variable is the air quantity. This capability is not available at the manual or first level, but in the third level, as described below.

Time of day scheduling

The second control strategy achieved was Time of day scheduling. This refers to the concept of triggering different set-points of the fans, regulators, and doors based on the time input to follow a certain schedule (Tran-Valade and Allen, 2013). Assuming that the sensor deployment in the mine is limited or nonexistent, as could be the case for this level, then the logical extension of level 1 (manual control) is to couple it with a timer to trigger sequences of changes in the set-point of the ventilation system such as fans, doors, and regulators in a semi-automated way (Tran-Valade and Allen, 2013). This application is a limited version of the main concept behind level 2, which from a broader point of view should be called the 'action trigger'. If the action trigger concept is constrained to act based on a timer only, the result is effectively Time of day scheduling. If the action trigger could be coupled to other environmental variables or data as triggers, the opportunity for different applications and savings could be enhanced even further. However, this also requires a more extensive deployment of sensors underground. The mine programmed all main surface fans to run at different speed set-points depending on time of the day. This is described later in this paper.

Event-based

The third control strategy is the Event-based strategy. Tran-Valade and Allen (2013) indicated that it is the 'automatic trigger of prescribed actions in reaction to configured events'. This control strategy can be summarized as the action trigge function based on alternative inputs other than the timer and the environmental variables. Just like the Time of day scheduling, this control strategy uses the same principle as the action trigger but based on any variable available that could be conveyed to the software making the decision. It could potentially be a combination of variables with a certain logic. The potential for applications of this control strategy is significant, for example, optimizing blast fume clearance and mine fire response. Additionally, the Event-based strategy can also be used to trigger cascade use of fans, for example to turn a booster fan on if an auxiliary fan is turned on, to secure the supply of fresh air across the main drift (Nie. and Wei, 2017).

Tagging and tracking

The fourth control strategy is Tagging and tracking. This represents a major step forward in both the capacity to understand where people and equipment are located, and in terms of infrastructure required to locate them (Tran-Valade and Allen, 2013). This control strategy requires the implementation of a tagging and tracking system, and integration of its associated communication system with the ventilation software. The airflow distribution of the mine can then be based on the location of personnel and equipment. It is also based on rules to calculate the air quantity that must be assigned to each parameter. The tagging control strategy is commonly associated with the concept of ventilation on demand as the air quantity can be allocated across the mine according to the location data of both personnel and equipment that is generated in real time, (Wang et al., 2014). The tagging and tracking system was recently commissioned but is not currently linked to the VOD system. That will be the next step towards the optimzation process of underground ventilation systems.

Environmental

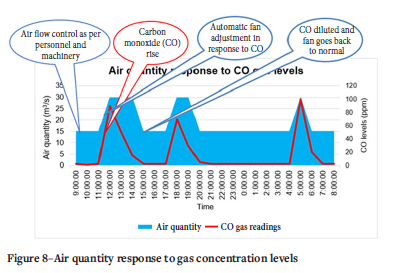

The fifth control strategy is Environmental and considers the automatic control of ventilation systems based on real-time environmental data. This can be based on several sensor inputs such as gas, dust, DPM, temperature (heat stress) etc., assuming the sensors can work underground and provide real-time information. In this regard, the performance of dust and DPM online sensors is still work in progress, but with encouraging results in recent years (Wang et al., 2014). Environmental control will be used in two ways, (a) as a fail-safe in case of flammable or noxious gas exceeding safe limits or (b) as the ultimate control strategy. Coupled with any of the other control strategies, the environmental strategy acts as a fail-safe in case of an environmental variable exceeding the pre-set boundaries, for example high CO (carbon monoxide) or a temperature above the heat rejection of 27.5°C for unacclimatized workers. This could be referred to as the quantity and quality approach of the environmental control strategy. As a stand-alone strategy environmental control allows the ventilation system to distribute the airflow according to environmental variables such as gas or dust concentration (Wang et al., 2014). Figure 4 shows a typical gas sensor interface at the mine. The gas detection system has been commissioned but not configured and linked to the main ventilation system at this time.

The mine has already applied both level i and level 2 stages of a VOD strategy. Preliminary results over the past three months showed some significant power savings and an increased productivity because of the increased face time by utilizing a portion of the re-entry period. At the last optimization stage, changes in the modulation of air quantity will be initiated by one of the following.

1. Increased air quantity demands due to additional vehicles or personnel entering a ventilation district. For this reason, all vehicles and employees are being monitored by a tagging and tracking system.

2. Environmental conditions within a particular ventilation district. Such conditions are currently monitored using realtime air quality monitoring stations comprising gas, dust, air quantity, and temperature sensors. When any of the parameters is above the specific pollutant's Occupational Exposure Limit (OEL), the system will automatically adjust to ensure that airborne pollutants are diluted and reduced to concentrations below the OEL.

3. Timing parameters - less air is required during nonproductive periods such as shift changeovers. Other timing parameters include blast clearance periods, maintenance, holiday periods, and other non-production activities such as safety talks and machine maintenance. Modulation of airflow will also be set to be time-based.

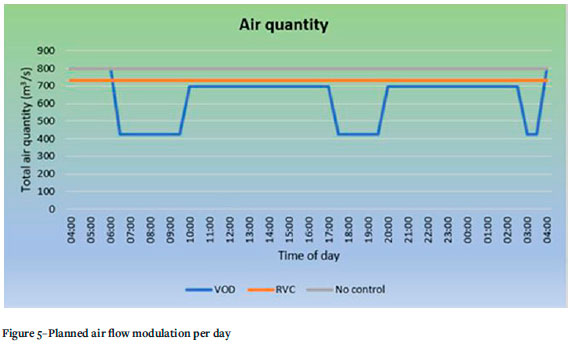

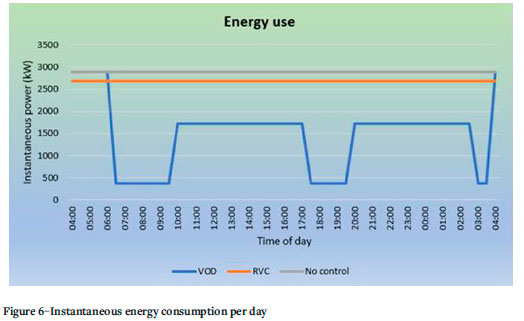

From a mine timetable for a typical day-shift, it can be noted that for some activities the air quantity can be reduced to 40% of the normal requirements through the use of VSDs. As a starting point, the flow was reduced to 50% during non-productive periods as illustrated in Figure 6. The primary fans were programmed to run at full speed during the first two hours of re-entry to allow for quicker blast clearance before being reduced to 50% for peak production time when all diesel machines were at the working faces. Since the mine has currently not reached its full production, VSDs are currently set at a maximum speed of 85% during peak production face times to supply the required total air flow of 700 m3/s. Figure 5 shows how air flow varies when (i) there is no control on main surface fans, (ii) when control is by means of radial vane controls (RWCs), and (iii) through time of day scheduling (VOD level 2 control).

Power measurements were captured directly from the system and the results obtained demonstrated significant power savings. Each 850 kW fan equipped and controlled using RWCs consumes an instantaneous power of 671 kW at a RVC setting of 85% to give a flow of 175 m3/s

VFDs were commissioned to start the implementation of VOD. For the same air quantity, the instantaneous power reduced significantly from 671 kW to 426 kW. This reveals a power reduction of 36.5%, which translates to 2.1 MWh per year per fan (obtained from (671 - 426) x 24 x 365), thus a combined annual power cost saving of US$1.1 million (assuming four fans running and an average unit electricity cost of US$0.1292 per kWh).

The system was designed to monitor both air quantity and quality in real time. For time-of-day scheduling, the main surface fans were programmed to modulate air quantity as shown in Figure 5, and the total measured power varies as illustrated in Figure 6.

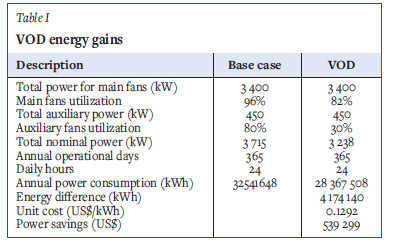

The overall energy gains by implementing VOD level 2 were derived from a zero base and Table II shows the assumptions used in deriving the predicted annual energy savings. The base case does not include VOD and represents the current set-up at all operations in the research area. It assumed 100% air quantity supply throughout the year without any airflow moulation and 96% utilization was factored in to cater for maintenance periods. It can be concluded that by rolling out a full VOD system at the mine where the trials are being undertaken, an annual power saving of approximately US$0.5 million can be achieved for primary fans with a combined power load of 3.4 MW (850 kW x 4) as shown in Table I.

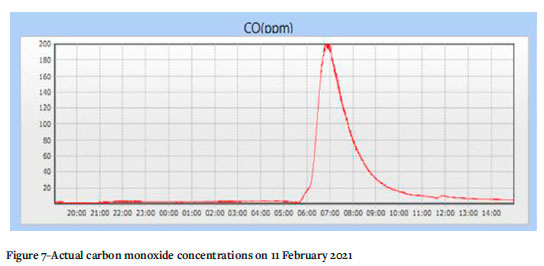

In addition to power savings, there was a 6% productivity improvement due to increased face time. The system also created conducive working conditions, prompting the underground workforce to produce more efficiently. The minimum re-entry period for the mine was four hours, which conforms with the Zimbabwean legislation and regulations (Zimbabwe, 1989). Realtime monitoring was used to establish the actual time required to clear all blasting fumes, and this was later used as the 'true' re-entry period for the mine. After a blast gas concentrations such as carbon monoxide increase up to a peak value and then gradually decrease, depending on the type of explosives used and the ventilation adequacy. Figure 7 shows how carbon monoxide concentration varies with time in a 24-hour period which includes the blast window at the mine. Figure 8 shows the ventilation system's response to changing CO levels. Real-time monitoring of gases reduces the risk of sending underground employees to poorly ventilated areas which haven't been fully cleared of gases.

VOD systems allow mines to clear blasting fumes faster than the projected time by allowing fans to operate at full speed.

The mine where trials are taking place was simulated and the results revealed that the blasting fumes will clear in 2 hours. This finding was then substantiated by real-time gas readings taken after conducting a blast, as shown in Figure 7. A re-entry exemption from the normal four hours to two hours was applied for and approved by the Zimbabwe Ministry of Mines. The mine utilized the additional two hours gained by reducing re-entry time and converted it into face time as a productivity enhancement strategy. This, however, increased operating costs in the form of additional labour and incentivizing the current employees through overtime payment. Table II shows the annual projected production gains at the trialled mine.

Production gains were made, having increased the speed of surface fans in the blasting window and instituted accurate monitoring of air quality The additional production time gained improved productivity, to an additional revenue of US 1.8 milllion as shown in Table II.

Financial evaluation

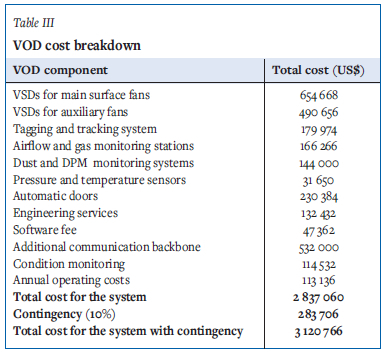

A feasibility study was conducted before carrying out the trial. The VOD system is linked from the underground operations to surface system servers, which will also in future be linked with the employee database. A financial evaluation of the designed system was based on actual quotations and invoices from suppliers of each of the system components. The benefits of this system include improved health and safety of underground workers, increased productivity, and reduced power costs. The cost components of the system are shown in Table III

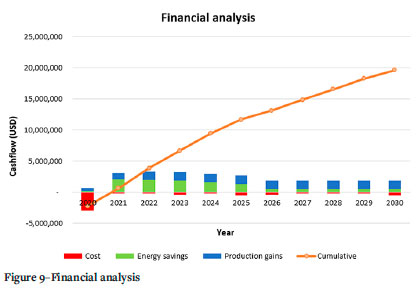

From the achieved and predicted gains (both productivity and energy gains), it can be concluded that the payback period of the whole VOD system is about 1.5years. A 10-year financial analysis of the system is shown in Figure 9.

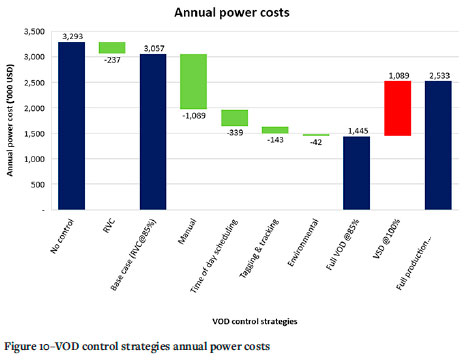

The mine has since achieved level 2 VOD. From full production going forward, starting in the year 2025, power cost gains will be averaging US$0.5 million per annum as compared to the ramping up period from 2021 to 2024, when there will be huge power savings. The average annual savings are projected to be 23% (US$2.533 million from 3.293 million) if the full VOD system is rolled out, as shown in the waterfall chart in Figure 10.

Conclusions

Ventilation remains an expensive necessity for underground mining. Current mining trends, including the increased degree of mechanization, would generally result in demands for more air and consequently increased power consumption. Power usage is not only a cost issue but is increasingly becoming an environmental issue when, worldwide, the mining industry is trying to reduce greenhouse gas emissions. In Southern Africa, with its primary reliance on coal-fired power stations and a constrained electricity supply, this is acutely relevant.

For Zimbabwean platinum mines, it is believed that by reviewing the way ventilation systems are designed and exploring future technologies that reduce energy demands, considerable savings in electricity usage can be achieved. Optimized ventilation systems in mechanized bord and pillar mines remain challenging; however, the application of fourth industrial revolution techniques will prevent ventilation from being cost-prohibitive. The implementation of ventilation--on demand systems can significantly reduce ventilation power consumption by a nominal 23%.

References

Abrahamsson, L., Johansson, B., and Johansson, J. 2009. Future of metal mining: Sixteen predictions. International Journal of Mining and Mineral Engineering, vol. 1, no. 3. pp. 305-311. [ Links ]

Acuna, E. and Allen, C. 2017. Totten mine ventilation control system update: implementation and savings achieved with Level 1 user control and future plans. Colorado School of Mines. [ Links ]

Bluhm, S. and Smit, H. 2014. Planning ventilation and refrigeration requirements. Ventilation and Occupational Environment Engineering in Mines. 3rd edn. Mine Ventilation Society of South Africa, Johannesburg. pp. 773-804. [ Links ]

Cawood, F. 2019. Beyond 2020: The future of mining in a world of technology. Mining Review Africa. https://www.miningreview.com/central-africa/future-mining-technology/[accessed 23 May 2020] [ Links ]

Cawood, F. 2021. uMining's year ahead will demand deep innovation. https://www.bizcommunity.com/Article/196/723/211911.html [accessed 1 March 2021] [ Links ]

Creamer, M. 2018. Exciting new mining research thrust. https://www.engineeringnews.co.za/article/exciting-new-mining-researchthrust-2018-04-27 [accessed 15 October 2020] [ Links ]

De Souza, E. 2018. Cost-saving strategies in mine ventilation. CIM Bulletin, vol. 9, no. 2. pp. 1-7. [ Links ]

Develo, E., Pillalamarry, M., and Garab, E. 2016. Improving the ventilation system. Journal of the Southern African Institute of Mining and Metallurgy, vol. 116, no. 4. pp. 301-305. [ Links ]

Hardcastle, S.G. and Kocsis, C.A. 2001. Ventilation designs for an automated underground metal mine. Proceedings of the 7th International Mine Ventilation Congress. pp. 779-786. [ Links ]

Kumar, S., Tiwari, P., and Zymbler, M. 2019. Internet of Things is a revolutionary approach for future technology enhancement: A review. https://journalofbigdata.springeropen.com/articles/10.1186/s40537-019-0268-2 [accessed 23 October 2020] [ Links ]

Matthews, C. 2020. Zimbabwe's Chitando says country's mining sector has entered new heights. https://www.miningmx.com/news/markets/40120-zimbabwes-chitando-says-countrys-mining-sector-has-entered-new-heights/ [accessed 14 January 2021] [ Links ]

Nie, X.X. and Wei, X. 2017. Optimization and practice on the reform schemes of ventilation system in the Jinqu Gold Mine. Mining Research and Development, vol. 37, no. 8. pp. 86-89. [ Links ]

Tran-Valade, T. and Allen, C. 2013. Ventilation-On-Demand key consideration for the business case. CIM, Toronto. [ Links ]

Wang, H.N., Peng, B., and Peng J.L 2014. Analysis of commonly existing ventilation problems and the optimal approach to deal with them in large-size mines. Journal of Safety and Environment, vol. 14, no. 3. pp. 24-27. [ Links ]

Zimbabwe. 1989. Explosives regulations. Statutory Instrument 72 of 1989. [ Links ]

Correspondence:

Correspondence:

T. Chikande

Email: chikandet@yahoo.com

Received: 15 Dec. 2021

Revised: 29 Sep. 2022

Accepted: 5 Oct. 2022

Published: December 2022