Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of the Southern African Institute of Mining and Metallurgy

versión On-line ISSN 2411-9717

versión impresa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.122 no.11 Johannesburg nov. 2022

http://dx.doi.org/10.17159/2411-9717/1492/2022

PROFESSIONAL TECHNICAL AND SCIENTIFIC PAPERS

Applicability of the risk ranking methodology designed for water reservoirs to tailings storage facilities

D. NisicI; D. KnezevicI; A. CyjeticI; N. NisicI; V. JovanovicII

IUniversity of Belgrade, Faculty of Mining and Geology, Belgrade, Serbia. ORCID: D. Nisic: ORCID: https://orcid.org/0000-0002-6470-9567

IIInstitute for Technology of Nuclear and Other Mineral Raw Materials, Serbia

SYNOPSIS

The risks associated with operating water reservoirs and tailings storage facilities (TSFs) are different because of their different purposes, methods of construction and operation, and characteristics of the materials impounded and their flow behaviour. Regardless of the differences, these two types of structures are often put in the same category when it comes to risk assessment and the application of relevant methodologies, which may result in unrealistic outcomes. In this paper we investigate whether it is possible to apply the risk ranking methodology designed for water reservoirs to TDFs and overview the key differences between these two types of structures. We also provide a comparative analysis of the results obtained by conducting a risk assessment of the operation of a TSF, applying the method recommended by the International Commission on Large Dams (ICOLD), and analyse the results using the failure mode and effects analysis (FMEA) technique. It is concluded that a more realistic evaluation of risk levels can be obtained by adopting a systematic approach to risk assessment in accordance with the traditional risk definition on which the FMEA technique is based.

Keywords: risk assessment, water reservoir, tailings storage facility, TSF, ICOLD, FMEA.

Introduction

The International Commission on Large Dams (ICOLD) is an international professional organization founded in 1928 to develop standards, and provide technical education for engineers in the field of design, construction, and maintenance of hydraulic structures. Since the 1980s ICOLD has extended its scope of activities to include tailings storage facilities (TSFs). Over this period, many rules that applied to water reservoirs were also put into effect for dealing with TSFs. The lack of motivation and responsibility, and the lack of applicable legislation on TSF risk assessment, led to a situation in which the existing risk assessment methods for water reservoirs were unofficially assumed to be valid for TSFs. Such practice completely ignores the obvious physical, geomechanical, hydraulic, rheological, and other differences between reservoirs for water storage and TSFs. The justification for such practice was found wanting in statistical surveys of accidents that have occurred over time. A new risk standard was developed for the management and design of tailings dams and was incorporated in 2020, The Global Industry Standard of Tailing Management (GISTM, 2020).

In the 21st century a total of 33 accidents have been recorded on water reservoirs, while in the same period 45 failures have occurred at TSFs (WMTF, 2018). In this period, 739 people died in accidents at water reservoirs, while 437 deaths were the direct result of accidents at TSFs (ICOLD, 2001). Historically the largest number of casualties at a water reservoir was recorded in 1889 at the South Fork Dam in the USA, when 2200 people were killed due to dam crest overtopping (Lempérière, 2017).

The severest accident that occurred at a TSF took place in 1966 at the Plakalnica lead and zinc TSF in Bulgaria, when due to several days of intense rainfall a massive slurry spill took place covering a distance of 8 km and killing 488 people (WMTF, 2018).

This paper lays down a basic hypothesis, according to which water-retention dams and the embankments at TSFs cannot be put in the same category and therefore it is not possible to apply the same methodology for risk ranking to both cases. Accordingly, the aim of this paper is to point out the differences between these two types of structures and the materials stored in them, and in line with this, to analyse the applicability of one of the most frequently used approaches for the risk ranking of such structures, i.e., the ICOLD methodology for large dam risk rankings.

Differences between water reservoirs and TSFs

Purpose and method of construction

A comparison of water reservoirs and TSFs reveals that there are more differences than similarities between them. The basic difference is due to their purpose.

A water reservoir is a major infrastructure facility and has multiple important functions: irrigation, electricity production, water supply, flood prevention, recreation, waterway regulation, fish farming, etc. (ICOLD, n.d.). These multiple purposes are crucial for economic and social development, and ensure that there is a high yield of water from the dam

On the other hand, a TSF, while being also a major structure, is used to store mine residue from a mineral processing plant.

So, in the case of a water reservoir it is of general interest to maintain adequate safety levels over the full operational cycle, to provide constant water quality, and to maintain the operation of all the facilities within necessary limits. In case of a TSF the main purpose is to safely store mine residues and to minimize impacts to downstream water resources and communities.

In the first case, the objective implies maintaining the water reservoir at the highest level of safety, which as a rule, exceeds the statutory minimum requirements while maintaining profitability, while in the second case the objective in the past was to maintain the TSF at a level that just basically meets the statutory minimum standards, which implies lower costs and ultimately higher profits. Today, goals have changed, and the safety of downstream communities is considered an extremely high priority because of frequent accidents.

The construction of a dam and other reservoir structures, considering their use and purpose, will last for several years, while the construction of a TSF will be completed within a maximum time-frame and in parallel with its operation (McLeod and Murray, 2003).

In the case of water reservoirs, it is essential to finalize the construction of all the necessary structures before the operation starts.

> The characteristics of dam construction materials (concrete, rock, earth) must be known, predetermined, and controlled.

> The overflow spillways must be designed to pass the design basis flood, which is a function of the hazard class of the dam, constructed from certified materials, and located where easily accessible.

> In addition to the service spillway, it is necessary to construct auxiliary spillways that protect the dam from extremely high water inflows. The capacity of these spillways must cater for PMF conditions.

> Dam foundations are usually built on soil and/or rock, the properties of which are well defined. Construction must meet strict standards, and quality control testing must be conducted to provide assurance that the technical specifications have been met.

> In Serbia the dam freeboard should not be less than 1.5 m for dams less than 15 m high and not less than 2 m for dams over 20 m in height (Standard SRPS, 1980). Similar standards apply in other countries.

> Continuous, and in most cases automated, monitoring of the dam and all surrounding facilities is conducted during the entire period of construction and operation.

As regards to TSFs the following features are characteristic. The properties of the materials used to construct the initial dam are known and controlled. However, for upstream raised facilities, subsequent embankment lifts are usually constructed with the coarser fractions of the available tailings material; the grain-size composition of this material is not always adapted to the requirements of embankment construction, and priority is usually given to the maximum utilization of the useful component. As a result, the quality of the material from which embankments are built largely varies, depending on the construction stage (in terms of size, chemical and mineral composition, porosity, permeability, etc.). The authors are of the view that the main problem with upstream construction is that the upstream lifts are built on previously deposited tailings, which may be weak and the composition of which is often different to that assumed during the dam design. A second significant problem is that upstream dams are difficult to drain adequately, so that tailings saturation is more difficult to control and becomes a critical factor for long-term stability.

In the case of TSFs built on flat terrain, where possible, the decant systems are sized for the probable maximum precipitation (PMP) conditions: they are centrally located, and their performance depends on the size and the location of the settling pond. In other words, at certain periods during operation, if TSFs are not well operated, the position of the tailings pond may be inadequate and lead to incomplete or deficient use of the spillways, particularly in events of extremely high water inflows due to heavy rainfall.

In TSFs, situated in mountainous terrain, free water is usually discharged through floating pump stations, which are sized to meet the needs of the plant that uses this water. The floating pump station is usually placed against the topography opposite to the embankment where the pond is located. This often impedes easy access to the floating pump station. During operation, certain disturbances or unforeseen and sudden inflows of water can occur, due to which the tailings settling pond may encroach too close to the embankment, thereby endangering the stability of the embankment and of the entire TSF.

Auxiliary spillways are built only at large TSF on hill sides in mountainous terrain, while TSFs build on flat ground do not usually have open spillways.

Initial dam foundations are built in compliance with the rules that are applied to reservoir dam foundations and considering the final height of the dam.

In Serbia, the freeboard at the perimeter embankment is increased by 1 m according to local regulations (Knezevic' et al., 2014).

The dam and surrounding facilities are regularly monitored, but in most cases, this operation is not automated.

A particular feature of some TSFs is the disposal of the tailings into a series of specially engineered, discrete cell impoundments. The entire surface is divided into a series of cells and tailings deposition is cycled between the cells to provide staged filling of the impoundment and to facilitate partial consolidation and stabilization of the tailings layers deposited during previous stages. This sequence of operations can bring about a significantly different level of risk (for example, if an accident happens at a currently inactive cell which is not receiving deposits of fresh tailings, environmental impacts will not necessarily occur). The total storage capacity represents the sum of the capacities of each cell.

Also, the existence of tailings beaches that serve as buffer zones between the embankment and the settling pond is a significant difference compared to water reservoirs where free water is in direct contact with the dam. These beaches can provide additional strength and resistance to failure, which is not the case in water dams.

Characteristics of stored materials

Reservoirs store water, the characteristics of which have been well studied, understood, and proven. Layers of sludge accumulate at the bottom of the reservoir. These sediment loads are derived from the watershed and transported via watercourses that supply the reservoir.

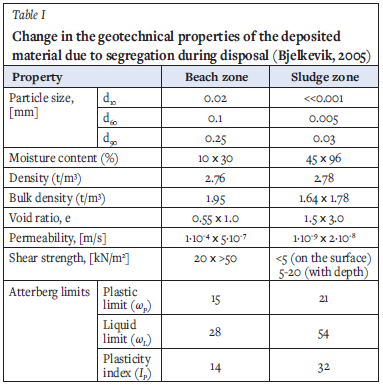

TSFs always contain liquid and solids in different proportions. Variations are illustrated in Table I (Bjelkevik, 2005).

> The embankment consists predominantly of large frictional or non-cohesive grain material with limited moisture content.

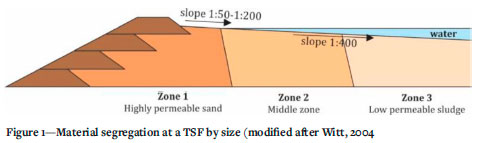

> Segregation of solid grains by size and density occurs on the tailings beach, where larger and heavier grains are deposited closer to the embankment while the finer and lighter grains are closer to the tailings pond. The material between the embankment and the pond ranges from frictional to cohesive with variable saturation.

> The water in the pond has a low concentration of the finest particles that settle slowly.

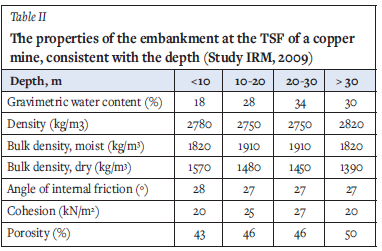

> In the embankment the tailings densities by natural consolidation as the height of the facility increases, and in this way the properties of the embankment change slowly but continuously, (Table II) (MDT, 2016).

> The segregation of material by size occurs on the tailings beach. The tailings is partly or completely saturated and slopes towards the pond. The beach slope is variable, from as steep as 1:50 (vertical to horizontal) down to 1:200. The beach is defined as the distance between the edge of the free water in the pond and the embankment. This distance is variable.

> The clarified water is collected at the lowest point in the beach. The base of the pond may comprise of fine solids sludge, which is completely saturated and has poor geotechnical properties. The material that lies between the clear water and the settled tailings may comprise a suspension of solids. The depth of the water varies, and the slope of the subaqueous beach may be as low as 1:400 but may vary substantially.

Figure 1 shows an idealized two-dimensional section which illustrates how segregation of the tailings brings about a gradation of properties(modified after Witt, 2004).

While the water characteristics are relatively stable and predictable, the characteristics of the deposited mixture of water and tailings are variable, particularly in terms of their rheological and soil mechanics properties.

Water such as contained in water dams and in tailings ponds exhibits Newtonian behaviour, while the behaviour of the mixture of water and tailings is non-Newtonian, being very complex with yield stress and viscosity depending on the solid-to-liquid ratio. If the mass fraction of solids in the slurry is less than 10% it is considered a Newtonian fluid, but if the density of waste slurry increases it is regarded as non-Newtonian fluid (Jovanovic et al., 2003).

Wastes of mineral origin when mixed with water to form a slurry are usually considered as ideal plastic systems, i.e., Bingham fluids. This cannot be applied to the waste generated during phosphate ore processing since its flow behaviour has all the characteristics of a turbulent flow and the parameters of viscosity and strength are lower than for other waste materials (Boger, Scales, and Sofra, 2006; Wasp, Kenny, and Gandhi, 1977; Bain and Bonnington, 1970). The plastic systems do not undergo yielding at stresses that are below the flow stresses typical for such systems. When these stresses are achieved, the plastic systems start behaving as fluids. The cause of this phenomenon is the constant interaction between slurry particles (Knezevic', 1996).

In the event of a slurry breach, the flood wave is considerably higher than in cases of water inflow (by 1-6 m), but the velocity of slurry flow is considerably lower, due to increased resistance brought about by the viscosity effects (Komatina and Jovanovic, 1997). Since the liquefied tailings will not flow as far as water would, the damage to structures caused by liquefied tailings will be more localized, while at greater distances only environmental damage occurs. The damage caused by the release of water is associated with high flow velocity, and depending on terrain configuration, it can affect areas at great distances. On the other hand, the flow of slurry will be significantly slowed down by obstacles such as bridges, structures, narrow passages, and ravines, and will increase the height of the flood wave upstream, in contrast to the situation in which there is a release of water.

Therefore, the flow of water waves and slurry waves cannot be identical, and neither are the amounts of material released, the distances that the material will travel, the height and the velocity of the waves, or many other properties. Accordingly, the consequences cannot be identical, and since the risk is a function of the likelihood of a breach and the consequences arising from that breach, the level of risk for water reservoirs and TSFs will be considerably different.

Based on all the foregoing, it can be concluded that TSFs and water reservoirs should not be placed in the same category when it comes to risk assessment, since it may lead to either underestimation or overestimation of the risk associated with their operation.

Risk ranking methodology designed for water reservoirs

ICOLD methodology

In 1989 ICOLD implemented, and then in 2010 revised, the methodology for risk ranking of large water dams. This system has been also widely applied for TSFs because of its simple concept that provides for quick application and easy interpretation of results.

According to ICOLD a large dam is one with a height of 15 m or more. Dams that are 5-15 m high and have a reservoir volume of more than 3 Mm3, they are also classified as large dams (ICOLD, 2011).

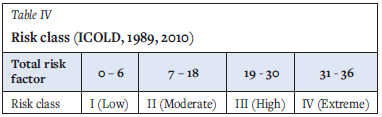

The risk ranking for large water dams, according to the ICOLD methodology, involves consideration of the parameters in Table III, which provides in parentheses the weighting factors for each parameter, whereby after the quantification and weighting, the risk classes are determined according to Table IV (ICOLD, 1989; 2010).

Analysing the parameters considered in the risk ranking of large dams (Table III), it may be noted that the adoption of the first three parameters is based on an objective judgment, while the evaluation of the fourth parameter is subjective, and its magnitude depends on the opinion of the assessor. ICOLD provides very limited guidelines on how to quantify this parameter. Also, the first two parameters represent the physical dimensions of the dam (capacity and height), and the other two are related to its environment or setting, being the endangered population and material damage. The weighting ratio between these two groups of parameters is 1:2 (0.33:0.67). The increase of the weighting factor for the first group of parameters, from low to extreme, is 2, while for the second group it is 4. The total weight that can be assigned thus ranges from zero (where the capacity is below 0.1 Mm3, the height is below 15 m, the evacuation of people is not necessary, and there is no damage) to 36 (where capacity is above 120 Mm3, height above 45 m, evacuation of more than 1000 persons is required, and damage is high).

Risk ranking includes the evaluation of each of the four factors assigned to every dam and all the factors will be added to obtain the total value that places each dam into one of the four risk classes given in Table IV.

Table IV shows that the weighting factors are not evenly distributed (9 points for each class would define equal weighting). Namely, the first class (low) and the fourth class (extreme) are reduced to a range of 5 to 6 points, while the two middle classes are extended to a range of 12 points. This immediately suggests that the fewest number of dams belong to the categories low or extreme classes. The largest number of dams should be classified within the range of moderate to high-risk classes. Experience shows that the biggest problem is when a dam is close to the marginal values between moderate and high-risk categories (15-22 points) and in many cases it seems to be the consequence of the application of weighting factors.

Applicability of ICOLD methodology to TSFs

Some uncertainties concerning the application of this methodology to TSFs appear even when adopting the weighting factor for storage capacity. As this system is initially intended for water reservoirs, where in case of a dam breach, all the water stored in the reservoir will flow out, it is reasonable to perceive the actual volume of the water stored within the reservoir as a potential environmental threat. However, this is not the case for TSFs since in the event of a dam breach it is most likely that all free water from the tailings pond would flow out together with a variable proportion of the tailings. In some rare cases as much as 100% of the deposited tailings can flow out, e.g., the failure at the El Cobre New Dam, Chile in 1965 (WMTF, 2018). Accordingly, the question arises as to whether the weighting factor of the capacity parameter should be adopted based on the volume of the storage space or on the actual potential quantity of the material that will be released in the event of a breach. The assumptions that are made regarding the volume of water and tailings that will be released influence the number of persons to be evacuated and the damage to the environment caused by the peak flood wave, hence the overall risk factor varies considerably depending on the approach followed to calculate the volume of tailings that will be released. A more realistic tailings release scenario will certainly reduce potential exposures.

In addition, the ICOLD methodology fails to provide a clear definition of the damage caused by the release of tailings contained in the TSF. In the event of a failure and the uncontrolled release of tailings, the environmental damage will not have the same extent or severity in the area surrounding the storage facility and cannot be regarded as a simple addition of impacts. ICOLD defines that the damage should be considered downstream of the embankment, and in the case of tailings facilities in mountainous terrain it is not difficult to determine the direction in which the flood wave will move. If the facility is located on flat land this is not the case. In such situations it is necessary to carry out a segment analysis or to consider the worst-case scenario of flood wave movement, so it is impossible to obtain an unambiguous assessment of the damage.

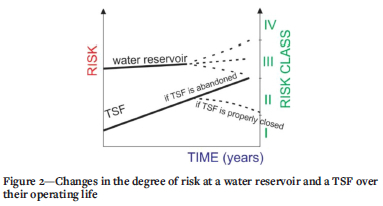

Risk is not a constant and it varies depending on the stage of TSF operation, the level of management, environmental conditions, and many other factors. If it is hypothetically assumed that the height of the water retention dam is over 45 m, its storage capacity is less than 120 Mm3, with an expected need to evacuate more than 100 persons and a moderate damage expectancy, this reservoir would be categorized as risk class III, from the outset once filled with water. Over a longer period, it is possible that its risk class will increase, decrease, or remain unchanged, depending on changes in population density or on construction or removal of structures and installations in the downstream area.

On the other hand, if this dam is compared to a TSF initially divided into three cell impoundments with a 3 m high initial embankment and a storage capacity less than 1 Mm3 per cell, considering its low height and small storage capacity initially, this facility may represent a threat to only a small number of people and may cause minor damage. Hence in the beginning of its life-cycle this cell-type TSF would be assigned a risk class I or II. For some years this TSF will, according to ICOLD, remain in class I or II, and may never be categorized as class III, which is the starting position for the water reservoir.

So, in the case of water reservoirs, the risk class is not likely to vary much over time. On the other hand, the risk class for a similar sized TSF can vary significantly.

The possible changes in the classification for the previously considered comparison of a dam and TSF over time are shown graphically in Figure 2.

Accordingly, in terms of the level of risk, as per ICOLD, the TSF is in a far more favourable position and over many years it will be assigned a lower risk class than the water reservoir. The ICOLD methodology does not recognize the actual risk associated with each structure such as may be associated with the effectiveness of dam lifts and the level of maintenance of built structures. The assumption is that the execution of lifts and level of maintenance is in accordance with the specifications and is thus representative of the best-case scenario. For TSFs, the assumption of the best-case scenario cannot be a priori accepted, and because of the long period of construction, the difficulties with the choice of materials, and applied machinery/equipment, it must always be analysed in conjunction with the actual structure condition and the condition of the TSF itself. Therefore, risk ranking will not show a continuously increasing trend but rather a fluctuating tendency. In TSFs the risk is variable, and it may increase or decrease with the length of its operation life since the maintenance level is constantly changing, depending on mine performance, on the management policy, and the skill of the workers involved in its construction and operation, or whether the dam is closed properly or abandoned.

It can therefore be concluded that the assessment of risk ranks associated with operating TSFs should be approached differently and should take into consideration the large number of parameters that affect the level of risk. This is now done commonly across the world with the Global Industry Standard on Tailings Management (GISTM), Canadian Dam Association (CDA), Australian National Committee on Large Dams (ANCOLD), and South Africa National Standard (SANS) classification systems, which are based on consequence classes only. For these systems, risk is considered to be site-specific and is a function of the actual condition of each TSF at a point in time (GISTM, 2020; CDA, 2016; ANCOLD, 2012; SANS, 1998).

Comparative risk ranking according to the ICOLD methodology and FMEA technique

One of the most frequently used qualitative risk assessment techniques is the failure modes and effects analysis (FMEA), which involves a systematic analysis of all failure modes, a detailed assessment of their effects and a breakdown of events leading to those that can be isolated and mitigated (Pamukcu, 2015; Joshi and Joshi, 2014). The FMEA risk assessment technique for TSFs specifically involves a detailed analysis of all probable failure scenarios, their mechanisms, and the consequences that follow (Valis and Koucky, 2009). This approach makes the FMEA technique more reliable and more realistic than the ICOLD methodology for risk ranking.

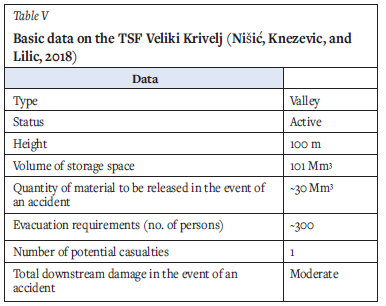

To verify this claim, a comparative risk ranking was performed using both the ICOLD methodology and the FMEA technique. As the subject of assessment, one of the most hazardous TSFs in Serbia is singled out, the TSF Veliki Krivelj in Bor. The risks associated with operating this facility have been discussed and studied on several occasions, providing an informed basis for a comparative analysis (Lekovski, Mikic, and Krzanovic, 2013; Zivkovic et al., 2014; Nisic, Knezevic', and Lilic, 2018; Nisic and Knezevic, 2018).

To assess the risks with the FMEA technique the research results that were previously obtained applying the same technique are used. These results were based on three potential accident scenarios: seismic, hydrological and hydro-technical (defects associated with the structure). For the sake of comparability, the consequences that are used in both approaches are equal, such as the number of persons to be evacuated and the damage downstream. Table V shows the data relevant for this comparative analysis.

The data provided in Table V was used for a comparative analysis of risk ranking results, (Table VI).

Based on the results given in Table VI, it is possible to observe some crucial differences between these two approaches. According to the ICOLD approach, the class of risk is a constant value and is rated as high, while according to the FMEA approach, risk ranges from negligible to high, depending on the failure mode. It is obvious that the ICOLD approach is blind to the nature, mechanism (failure mode), and timing of the failure at the TSF. Also, it may be noted that FMEA is based on a traditional risk definition, according to which the risk is the product of probability of occurrence of a hazardous event and the consequences of the event, while ICOLD has an unambiguous approach to damage, and considers it as a constant category, so consequently the risk class of the TSF is constant. In addition, the concept of damage is not clearly defined and the person trying to assess the risks using the ICOLD approach may have a dilemma whether to include potential human casualties, or merely consider the material damage caused. This, however, can however be clearly defined in the FMEA approach and each consequence category is separately analysed, which has decisive influence on their final ranking.

Moreover, when using ICOLD methodology for ranking TSF risk, there is also a dilemma whether the storage capacity should be considered as the total amount of the deposited tailings or just the amount of the material discharged due to TSF failure. In the case of the TSF Veliki Krivelj, the weighting factor of both quantity indicators places capacity in the high category, so there is no difference in the final risk class, regardless of the initial capacity. With the FMEA technique this is not the case and the consequence ranking depends exclusively on the actual quantity of discharged material and subsequently also on the other characteristics of the flood wave, such as the distance that the tailings will travel after failure.

Conclusion

Superficially, water reservoirs and TSFs appear to be similar structures, but only at first glance. However, their different purposes, principles of construction and operation, flow behaviour of the impounded material, and ultimately, failure rates make them remarkably dissimilar. Putting these facilities in the same category for risk classification purposes (as per ICOLD) would suggest the presence of a long-term superficiality of assessment by responsible and qualified professionals, and as a result the actual risk is either overestimated or underestimated. Fortunately, this practice has now been changed and TSFs are now classified according to their potential to do harm. The ICOLD classification that has been referenced in this paper is now no longer in use.

This paper, consistent with the established research objectives, presents the key differences between these two types of facilities to prove the hypothesis that there can be no grounds for reverting to the practice of classifying TSFs in the same category as water dams. The analysis of one of the most used methodologies for rating the risk associated with water retention dams, provided by ICOLD, points out all the deficiencies of such an approach, which are particularly obvious when applied to TSFs. This analysis is additionally sustained by providing a comparative risk assessment and ranking of one of the most hazardous TSFs in Serbia, the TSF Veliki Krivelj, using the ICOLD methodology and the FMEA risk assessment technique, which is based on a traditional risk definition and allows a systematic risk analysis. It may be noted that the risk assessment with the FMEA technique gives more realistic results, and that risk assessment cannot be conducted without considering the actual condition of the TSF, different scenarios and impact mechanisms of potential failures, as well as the actual quantities of the material that might be discharged, which will have a decisive influence on the final consequences. In order to reduce the responsibility of TSF users, these facilities were most often identified with water dams. This bad practice has become common and caused a lot of conflicts in the risk for evaluation.

The ICOLD methodology for risk ranking that has been compared to the FMEA approach in this paper is clearly not suitable for tailings storage facilities. It is therefore recommended that its use be terminated and that the GISTM classification system be adopted for tailings storage facilities in future. This paper illustrates very well how a classification system that has been developed for one type of structure cannot always be used for another, although the structures are seemingly similar.

Author Contributions

Conceptualization: [Dragana Nisic and Dinko Knezevic]; Methodology: [Dragana Nisic]; Data curation: [Neda Nisic and Aleksandar Cvjetic]; Writing-original draft preparation: [Dragana Nisic and Dinko Knezevic]; Writing-review and editing: [Aleksandar Cvjetic and Vladimir Jovanovic]; Visualization: [Neda Nisic and Vladimir Jovanovic]; Project administration: [Neda Nisic].

References

ANCOLD. 2012. Guidelines on the consequence categories for dams. Australian National Committee on Large Dams. https://www.ancold.org.au/?product=guidelines-on-the-consequence-categories-for-dams-october2012 [ Links ]

Bain, A.G. and Bönningtön, S.T. 1970. The Hydraulic Transport of Solids by Pipeline. Pergamon Press. [ Links ]

Bjelkevik, A. and Knutsson, S. 2005. Swedish tailings: Comparison of mechanical properties between tailings and natural geological materials. Proceedings of the International Conference on Mining and the Environment, Metals and Energy Recovery, Stockholm, 27 June-1 July. pp. 117-129. SveMin. urn: urn:nbn:se:ltu:diva-28132 [ Links ]

Boger, D.V., Scales, P.J., and Sofra, F. 2006. Rheological Concepts. Paste and Thickened Tailings - A Guide (2nd Edn). Jewell, R.J. and Fourie, A.B. (eds). Australian Centre for Geomechanics, Perth, Australia. https://doi.org/10.36487/ACG_repo/863_21 [ Links ]

CDA. 2016. Canadian Dam Association consequence classification ratings for dams. https://open.alberta.ca/dataset/e598d71f-9baa-4f33-98d1-2417f9bf7d93/resource/08db72bd-6fef-48d4-8c62-72c33c44d9a3/download/cda-classificationratingsdams-apr2016.pdf [ Links ]

GISTM. 2020. Global Industry Standard on Tailings Management, Consequence Classification Tables (Annex 2). https://globaltailingsreview.org/wp-content/uploads/2020/08/global-industry-standard_EN.pdf [ Links ]

MDT. 2016. Mining Technical Design for the Elevation of VK Tailings Storage Facility at Field 1 to 390 meters a.s.l. Institute of Mining and Metallurgy Bor, Bor. [ Links ]

ICOLD. 1989. Bulletin 72, Revision. Selecting seismic parameters for large dams, Guidelines. International Committee on Large Dams. Paris. [ Links ]

ICOLD. 2001. Tailings dams: Risk of dangerous occurrences: Lessons learnt from practical experiences (vol. 121). United Nations Publications, International Committee on Large Dams, Paris. [ Links ]

ICOLD. 2009. Bulletin 72, Selecting seismic parameters for large dams, Guidelines. International Committee on Large Dams, Paris. [ Links ]

ICOLD. 2011. Small dams, design, surveillance and rehabilitation. International Committee on Large Dams, Paris. [ Links ]

ICOLD. n.d. Role of dams. https://www.icold-cigb.org/GB/dams/role_of_dams.asp [ Links ]

Joshi, G. and Joshi, H. 2014. FMEA and alternatives v/s enhanced risk assessment mechanism. International Journal of Computer Applications, vol. 93, no. 14. pp. 33-37. [ Links ]

Jovanovic', M., Kapor, R., Komatina, D., Djordjevic, D., Stefanovic, N., and Jancic, V. 2003. Numerical simulation of hydraulic consequences of dam failures on coal ash disposal sites. Water Management Industry. [ Links ]

KnezeviC, D., Torbica S., Rajkovic Z., and Nedic M. 2014. Industrial waste disposal. Faculty of Mining and Geology, Belgrade [in Serbian]. [ Links ]

KnezeviC, D. Kolonja, B., and Stankovic, R. 1996. Hydraulic transport of mineral raw materials. Faculty of Mining and Geology, University of Belgrade, Belgrade [in Serbian]. [ Links ]

Komatina, D. and Jovanovic', M. 1997. Experimental study of steady and unsteady free surface flows with water-clay mixtures. Journal of Hydraulic Research, vol. 35, no. 5. pp. 579-590. [ Links ]

Lekovski, R., Mikic, M., and Krzanovic, D. 2013. Impact of the tailing dumps on the living environment of Bor and protective measures. Mining and Metallurgy Engineering Bor, vol. 2. pp. 97-116. [ Links ]

Lempérière, F. 2017. Dams and floods. Engineering, vol. 3, no. 1. pp. 144-149. [ Links ]

McLeod, H., Murray, L., and Berger, K.C. 2003. Tailings dam versus a water dam, What is the design difference. Proceedings of the ICOLD Symposium on Major Challenges in Tailings Dams. 15. p. 12. [ Links ]

NisiC, D. and KnezeviC, D. 2018. Risk-based classification of industrial waste storage facilities. Inzynieria Mineralna, vol. 20. [ Links ]

NisiC, D., KnezeviC, D., and Lilic, N. 2018. Assessment of risks associated with the operation of the tailings storage facility Veliki Krivelj, Bor (Serbia). Archives of Mining Sciences, vol. 63, no. 1. pp. 165-181. [ Links ]

Pamukcu, C. 2015. Analysis and management of risks experienced in tunnel construction. Acta Montanistica Slovaca, vol. 20, no. 4. pp. 271-281. [ Links ]

SANS. 1998. The Code of Practice for Mine Residue Deposits - SANS 10286 (Ed.1.00). The South African Bureau of Standards, South Africa [ Links ]

Institute for Standardisation of Serbia. 1980. Standard SRPS U.C5.020. Design of embankment dams and hydraulic embankments, Technical conditions. [ Links ]

Valis, D. and Koucky, M. 2009. Selected overview of risk assessment techniques. Problemy Eksploatacji, no. 4. pp. 19-32. [ Links ]

Wasp, E.J., Kenny, J.P., and Gandhi, R.L. 1977. Solid-liquid flow: Slurry pipeline transportation. [Pumps, valves, mechanical equipment, economics]. Series on Bulk Material Handling. Gulf Publishing. 224 pp. [ Links ]

Witt, K.J. and Schönhardt, M. (eds.). 2004. Tailings Management Facilities -Risks and Reliability. Report of the European RTD project TAILSAFE. http://www.tailsafe.com/ [ Links ]

WTMF, 2018. World mining tailings failures database. https://worldminetailingsfailures.org/ [ Links ]

Zivkovic, N., Mihajlovic, E., Zivkovic, L., and Bozilov, A. 2014. Risk management of disastrous events on tailings in 'RTB Bor', Serbia, Annual of the University of Mining and Geology St. Ivan Rilski. Mining and Mineral Processing, vol. 57. no. 2. [ Links ]

Correspondence:

Correspondence:

D. Nisic

Email: dragana.nisic@rgf.bg.ac.rs

Received: 19 Jan. 2021

Revised: 16 Dec. 2021

Accepted: 26 Aug. 2022

Published: November 2022