Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.122 n.10 Johannesburg Oct. 2022

http://dx.doi.org/10.17159/2411-9717/1439/2022

PROFESSIONAL TECHNICAL AND SCIENTIFIC PAPERS

Water production as an option for utilizing closed underground mines

J. DvofacekI; P. MalikovaI; R. SousedikovaI; S. HeviankovaI; P. RysII; I. OsickovaI

IFaculty of Mining and Geology, VSB-Technical University of Ostrava, Czech Republic. ORCID: J. Dvofacek: https://orcid.org/0000-0003-0487-9764; P. Malikova: https://orcid.org/0000-0002-7117-8215; R. Sousedikova: https://orcid.org/0000-0003-1857-7097; S. Heviankova: https://orcid.org/0000-0002-6370-6874

IIMuncipality Bruntal, Czech Republic

SYNOPSIS

Each mining project goes through the same life-cycle, from prospecting and exploration to closure and post-closure periods. This prompts the question whether the closure of a mine constitutes the end of its life-cycle or whether the decommissioned mine can be employed for some other purpose. Best-practice references indicate that there are many viable options. In our opinion, the production of service water is one such option.

Laboratory research was carried out on the water from a flooded underground coal mine in Ostrava-Karvina coal district, Czech Republic, concerning the production of service water from pumped mine-water. The research proved the practical feasibility of service or process water production. Given the effect of global climate change with regard to water resources, good prospects for this additional resource can be assumed since the water has to be pumped in any case for safety reasons.

Keywords: underground mine, mine closure, service water production.

Introduction

Mining activities have for millenia provided minerals, energy, and building materials for human society. The lifespan of mineral deposit exploitation differs, depending on the deposit size, the intensity of mining, renewal of mining, as well as other factors.

Regardless of specific factors, each mining project is subject to the same life-cycle: the search for new deposits (prospecting and exploration), mine development, operation, and closure and post-closure periods (van Zyl, Scoble and Wilson, 2007). The mine life-cycle lengths can be calculated in years, but they can be measured in centuries. Notwithstanding the actual characteristics of the deposit, its exploitation inevitably comes to an end, for a variety of reasons: economic (low commodity price or high operational cost), geological (e.g. decrease in ore grade), technical (adverse geotechnical conditions), regulatory (safety or environmental breaches), policy changes (e.g. mining as a threat to the environment), social or commodity pressures (e.g. from environmental or community action groupings), closure of downstream industries or markets (e.g. coal mines affected by closure of power stations), flooding or inrush (Laurence, 2006).

Mining activities concern artisanal and small-scale mining (Mhangara, Tsoeleng, and Mapurisa, 2020), as well as large multinational companies (Robinson, 2016). Legal mining activities have always been subject to the supervision of state authorities, mainly for safety reasons. In recent decades, supervision and regulation in terms of environmental protection has been increasing. As such, mine closure and post-closure activities have been regulated by national legislation (e.g. Sutton and Weiersbye, 2007; Flores, Lima and Herrmann, 2007; Sutton et al, 2008; Cobby, 2007; Rankin et al, 2007). Legislation related to mine closure or environmental factors is generally concerned with the safety of operations and minimizing the environmental impact of closure. These provisions also concern the technicalities of closing deep underground mines, especially as regards closing of ventilation and entrance shafts.

A good question can be asked, namely, does a mine closure mean the end of the mine life-cycle or can it be employed to serve other purposes?

Mine closure from a technical point of view

The history of mining activities in the Czech Republic dates back many centuries. Nevertheless, the last decade of the 20th century witnessed fundamental economic changes, which, together with steadily growing pressure for environmental protection, led to a decline in mining activities and closure of many mines. Deep-level mining of coal, which was one of the most important commodities, was significantly affected.

In the Czech Republic, the basic methods of technical liquidation of underground mines are as follows:

> Flooding

> Backfill by loose (non-solidified) material

> Hydraulic backfill (solidified material)

> A combination of the above.

Closure of underground mines followed by flooding

For a long time, flooding of mines has been a typical and most frequently used method of technical closure. Typically, the main mine workings leading to the surface are sealed and the mine is left to nature. The prerequisite for the method is the removal of all machinery and materials which might contaminate the mine water.

Backfilling of main underground workings with loose material

This is a frequently applied closure method. The shaft intersections with horizontal workings are closed by dams, and the mining equipment is removed. Cheap, easily available materials are used for backfilling - barren tailings, wash dirt, quarry aggregate, demolition debris, etc. The technical closure of underground mines by loose backfill is incomplete as it concerns only the shaft proper. The remaining underground spaces are left open and become flooded.

Backfilling with solidified material

In the past, mixtures of ash and wash dirt were used for backfilling purposes, especially for closing of the horizontal workings. In a relatively short time, such mixtures solidify spontaneously, forming a concrete-like material. Both investigations and practical experience have shown that other industrial waste can also be utilized for similar hydraulic backfill provisions. The solidified backfill can be used for packing of all underground workings.

Combinations of the above methods have also been practised -backfill in aqueous medium or hydraulic backfill and backfill by loose material in the same shaft. The combination of the methods is realized by employing the components in approximately equal proportions (Dvofacek and Sterba, 2006).

Technical liquidation by loose or hydraulic backfill prevents access to underground workings, which excludes the possibility of future repurposing of underground mines. In contrast, a flooded underground mine cannot be considered as irrevocably closed. Mining can be resumed after the water has been pumped out or, following partial dewatering, some method of closing the pit by the backfill medium solidifying in humid environment can be used.

Nevertheless, resumption of mining per se is only one of many repurposing options. Research on the matter has specified many other options for re-using decommissioned mines.

Repurposing options for decommissioned underground mines

The literature on the subject refers to the following principal options of reusing underground mines:

Geotourism and cultural heritage

A place or object that makes a unique contribution to the history of humanity and nature can be listed as a World Heritage Site. The UNESCO World Heritage List includes cultural property, industrial and natural monuments, cultural and natural landscapes. There are also sites related to the history of mining -e.g. the mines of Rammelsberg and Zollverein coal mine industrial complex in Essen (Germany), the Falun Copper Mountain mining area (Sweden), the mining landscape of Cornwall and West Devon (UK), the Sewel mining settlement (Chile), Jazan Iwami silver mines (Japan) and others (Rybar, 2016). At the end of the 20th century, many mining industry activities were severely restricted in regions with a long mining tradition. As a partial solution to social problems in these regions, mining attractions and museums have been established and are open to the general public. One of the most well-known underground educational guided tours in Europe is the Salt Mine of Wieliczka and Bochnia in Poland (UNESCO World Heritage Centre, 2022). There are dozens of similar mines around the world - e.g. in USA (Crystal Gold Mine in Idaho, Copper Queen Mine in Arizona etc.) (National Mining Association, 2021). The Edgar Mine in Colorado (USA) (Colorado School of Mines, 2022) and Reiche Zeche in Freiberg (Germany) (Grab et al, 2011) offer also education and research opportunities.

Recreational and medical purposes

Reclamation as a restoring of cultural landscape with the possibility of recreation is more common as regards surface mining (e.g. Stenhouse, Evans, and Thomas, 2006). Recreational repurposing of closed underground mines also occurs. An example is the salt mine of Bochnia, Poland, where 250 m below the surface a full-size field for playing volleyball, basketball, or tennis was created (Popielak and Zieba, 2007). In the same site, speleotherapy has been practised. This is a kind of respiratory therapy that involves inhaling of the mineral-infused air in the micro-climate of a salt mine, which can be beneficial for the treatment of cutaneous disorders, asthma, and other respiratory ailments.

Electricity generation

The difference in elevation between the pit opening and the bottom makes the application of the pumped-storage hydroelectricity (PSH) method possible. In times of low electricity demand, excess electrical power is used to pump water into the upper reservoir located at the pit opening. Low-cost surplus (off-peak) electric power is used to run the pumps. When there is a higher demand, water is released back into the lower reservoir through a turbine, generating electricity. Several repurposing projects regarding decommissioned deep underground mines have been implemented in the USA, Finland, and Australia. In the Czech Republic, a pilot-scale pumped-storage hydroelectricity project was implemented at the Jeremenko mine water pit using an elevation difference of 580 m (MPO, 2015).

Using geothermal energy from mine water for heating and cooling

In a flooded deep underground mine, there is a large rock-water interface across which geothermal heat transfer can occur. This provides for large heat energy reservoirs. The renewable energy of these reservoirs can be tapped by making bores into the existing flooded mines or using their pit openings if available. Pit water is pumped to local heat-exchanger stations, where heat is transferred via heat exchangers to the local heating network. The cooled water is returned to the pit at a similar temperature to minimize the thermal impact. It can also be discharged at the surface. This is called an open cycle. In a closed cycle, the mine water does not circulate, but a heat exchanger is immersed in it and the heat energy is transferred to the liquid that circulates in the piping system of the heat pump. In summer, pit water can be pumped from shallower parts of the reservoir at a lower temperature and used for cooling. There are many such successful projects worldwide, e.g. in Germany, Holland, Norway, Russia, Spain, Great Britain, the USA, Canada, and the Czech Republic (Hall, Scott, and Shang, 2011; Ramos, Breede and Falcone, 2015; Preene and Younger, 2014; Watzlaf and Ackman, 2006; Janson et al., 2016; Bracke and Bussmann, 2015; Loredo et al., 2017; Korb, 2012; Banks et al., 2019; Michalek et al., 2007; TU Bergakademie Freiberg, 2022).

Non-energy utilization of mine water

This may include the use of mine water for irrigation purposes and for the production of drinking water.

Irrigation: An example is a project in South Africa, where mine water discharged into the Upper Olifants River Catchment in Mpumalanga Province, which polluted the local river, was treated. Pollution could be prevented by collecting and treating mine water to a quality where it could be used for irrigation (van Zyl et al., 2001). Another case involves a direct re-use of mine drainage water for agricultural irrigation in the Hunter Valley, Australia (International Association of Hydrogeologists, 2018). At the Butte site in Montana, USA, the Mine Waste Technology Program funded a long-term pumping test on a well that intercepts the 600-foot level of the horizontal workings. Water in the flooded mine could be utilized for irrigating areas that have been revegetated for mine site rehabilitation purposes (Nordwick et al., 2008).

Drinking water production: An older example comes from Northern Upshur County, West Virginia, USA. In 1981, more than 70 towns or villages derived all or part of their water from coal mines. Mines in the southern part of the state had coal seams with a low sulphur content, and acid mine drainage was usually not a problem. Water from the free drainage mines in the north and west part of the region generally had greater hardness, sulphate, iron, and manganese than water from the flooded mines in the southern part of region. Most mine water requires some treatment (Hobba, 1987). A good example is provided by the eMalahleni Water Reclamation Plant, South Africa. The plant treats water from three Anglo American thermal coal operations and from South Witbank Colliery of BHP Billiton. The desalinated water is delivered to the local municipality drinking water system, meeting some 20% of its daily water requirements. This situation can be adaped to alternative sources of water for mining operations: (i) dewatering, (ii) desalination, (iii) mine or residential waste water (Toledano et al., 2014).

Obtaining of industrial minerals - the case of uranium

When underground uranium mines are flooded after their closure, the level of uranium dissolved in the water increases. Mine water from flooded uranium mines thus represents a significant source of uranium. The Olsi-Drahonin uranium deposit in the Czech Republic is an example of uranium recovery as a by-product of running a mine water purification plant. Since 1996, the excess mine water has been purified, using ion exchange technology. In the period 1996-2006, the uranium yield was 1500-3000 kg/a (Michalek et al., 2008).

Restoration of mining activities

Development of mining industries is cyclical. Mining activities may be suspended only to be resumed at a later point when technical or economic problems of extraction and processing of raw materials have been solved (e.g. water inflow) or demand for minerals renewed. Tin production in the Slavkov Forest region, Western Bohemia, Czech Republic could serve an example. Primary deposits have been extracted since the end of the 14th century, and the tin deposit was variably utilized and abandoned, especially in the 17th and 19th centuries. A new pit development was started in 1971. Underground operations were terminated in 1991, and underground workings with a large remaining ore reserve were flooded (Rudne doly, 2014).

Underground natural gas storage

Uranium mine No. 16 near Pribram, Czech Republic, was in operation from 1957 to 1991. The construction of an underground cavern reservoir in the granite massif was begun in 1992. In 1998, the filling of the underground storage facility designed for a pressure of 11 MPa, was started, enabling the storage of 72 million m3 of natural gas. This can balance the differences between summer and winter gas consumption and provide compensation for fluctuations in gas consumption and supply (iPROSPERITA, 2018).

Gas extraction

Even after a coal mine has been closed, methane continues to leak from the coal deposit underground and can be used as an energy source. The decommissioned mine of Paskov, Ostrava-Karvina Coal Basin, Czech Republic, provides a good example. Its three pits have been closed to depths of 150 to 285 m by gas plugs. A degassing pipeline passes through the plugs, leading to an exhaust station which provides a mixture of methane and air for energy generation purposes. A similar system is in operation in North Rhine-Westphalia, Germany (Trejbal, 2009).

Civil applications

There are many cases of utilizing the underground space of closed mines. Examples of such utilization include offices, warehousing space, and manufacturing in Kansas City limestone mines, USA; cheese aging in Ollomont Mine, Italy; storage of oil in Harsbacka Mine, Sweden; steel company plant and storage of goods in Randolph Mine, USA, (Peila and Pelizza, 1995).

Waste disposal facilities

If geological conditions of abandoned mines are suitable concerning permeability and insulation of workings, the mines can be used as depositories for waste, such as fly-ash (e.g. Nakatatsu Mine, Japan), industrial waste (Codana Mine, Italy), or even chemical waste (Walsall Wood Colliery, UK) (Peila and Pelizza, 1995).

Experimental laboratories and research facilities

Besides purpose-built underground spaces, closed or active deep mines can be utilized for research and various underground activities, like those of the Japan Microgravity Centre of Sunagawa Mine, Japan (Peila and Pelizza, 1995). There are some underground facilities reserved for research activities in the framework of the European Underground Laboratories Association network - underground infrastructures in Switzerland, common coal mine in Poland, the deepest active hard-rock mine in Europe situated in Finland, former silver mine Reiche Zeche in Germany etc. (European Underground Laboratories Association, 2020). Research, education and practical training in actual mining conditions are offered by some of them (Barakos et al., 2019; Mischo, 2015).

Based on the above overview, it can be estimated that harnessing hydrothermal energy from the flooded underground pits after closure constitutes a major benefit for society. Currently, utilizing pit water for the production of drinking or industrial water plays rather a secondary role. Nevertheless, if we consider that there are many renewable energy sources (e.g. sun, wind) relatively easily available and water is an irreplaceable commodity, it can be assumed that utilizing deep underground mine water for the production of drinking or industrial water offers an exceptional potential.

Options for water production utilizing pit water in the Czech Republic

The Ostrava-Karvina basin (OKR) with its four sub-basins is the most significant coal region in the Czech Republic, and the only deep coal deposit that is currently exploited. In the early 1970s, production of coal was in excess of 24 mt/a. In 1991, the process of mine decommissioning and closure began. This has continued ever since, although mining in the Karvina sub-basin is still active. The closed mines in the Ostrava-Karvina district were flooded. For security reasons and to prevent uncontrollable inflows from flooded mines in the Ostrava sub-basin, a system of water level maintenance was implemented in the flooded mines.

The water level of the flooded mines in the Ostrava district is kept at a lower level than that of the interconnections to still active mines in the Karvina part of the Ostrava-Karvina basin. To provide for this purpose, two water pumping stations have been put into operation at the former mines of Jeremenko and Zofie. Pumped water is discharged directly into the local rivers, and the whole process is closely monitored (Martinec et al., 2005).

The total volume of water pumped from the Jeremenko pit reaches approximately 5.5 million cubic metres per annum. Mine water pumping and treatment is a long-term and expensive process. In the Czech Republic, recent climate change occurrence has been associated with rising average temperatures and precipitation decline. The question is whether the pit water can be used for production of industrial or drinking water.

Research case study

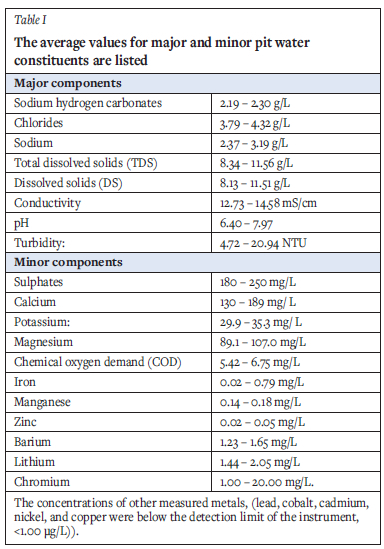

The mine water of the Jeremenko pit falls into the category of natural, very strongly mineralized water of the chemical type, Cl, HCO3-Na, i.e. brackish water of sodium chloride type. Organic and microbiological pollution of the tested mine water is minimal and in fact negligible, taking the given purpose into account. The composition of the pit water was monitored from March 2020 to October 2020 at regular intervals of 14 days. The monitored indicators were as follows.

> Temperature, dissolved oxygen, power of hydrogen (pH) and conductivity were measured by multimeter, (WTW GmBH Multi340i, WTW, Prague, Czech Republic). All parameters were measured according to the standards: CSN 75 7342 Water quality - Determination of temperature; CSN ISO 17289 Water quality -Determination of dissolved oxygen - Optical sensor method; CSN ISO 10523 Water quality - Determination of pH, CSN EN 27888 Water quality - Determination of electrical conductivity (ISO 7888:1985)

> Turbidity was measured by turbidimetric analysis according to CSN EN ISO 7027-1. Water Quality -Determination of turbidity - Part 1: Quantitative Methods

> Acid neutralizing capacity (ANC4,5), basic neutralizing capacity (BNC8,3), chemical oxygen demand (COD), and chlorides (Cl-) were quantified by titrimetric analysis. All parameters were measured according to CSN 75 7372 Water Quality - Determination of base neutralizing capacity (acidity); CSN EN ISO 9963-1 Water Quality

- Determination of alkalinity - Part 1: Determination of total and composite alkalinity; CSN EN ISO 99632 Water Quality - Determination of alkalinity - Part 2: Determination of total and carbonate alkalinity; CSN EN ISO 8467 Water Quality - Determination of permanganate index; CSN ISO 9297 Water Quality - Determination of chloride. Silver nitrate titration with chromate indicator (Mohr's method)

> Carbonate species (HCO3 or H2CO3) were determined from neutralization capacities according to CSN EN 75 7373 Water Quality - Calculation of carbon dioxide form (species)

> Total dissolved solids (TDS) and dissolved solids (DS) were quantified gravimetrically according to CSN 75 7346 Water quality - Determination of dissolved solids; CSN EN 872 Water quality - Determination of suspended solids -Method by filtration through glass fibre filters

> Spectrometric analysis was carried out for lead, cadmium, chromium, copper, nickel, cobalt, barium, lithium, calcium, magnesium, potassium, sodium, iron, manganese, and zinc contents. All elements were measured by atomic absorption spectrometry (AAS) using a Varian AA280FS instrument (Agilent, Santa Clara, CA, USA) (Table I).

Based on the measurement results for selected physico-chemical indicators, and with regard to the purpose of further use, it is necessary to choose such treatment processes that are able to significantly reduce the concentration of pit water ions. Such processes include membrane and ion exchange processes. For values of dissolved substances above 1 g/L, it is convenient to use membrane processes. At values lower than 1 g/L, ion exchange processes are more suitable (Traiblazer Technologies, 2022). It is often appropriate to combine these processes, for example where it is necessary to remove the maximum amounts of solutes (requirement for some process waters).

The analysis enables development of a technology for production of service or process water from the treated pit water that meets legislative provisions of the Czech Republic.

According to our research and in terms of electrodialysis (ED) applications, there is an increased risk of high concentration of HCO3 ions (around 2 g/L) in combination with a higher concentration of Ca2+ ions (around 150 mg/L), which leads to the formation of insoluble salts (CaCO3). This effect might gradually reduce the efficiency of membrane separation, reduce the flow of final products, and degrade their quality. The pit water must be pre-treated. The aim of water treatment and pre-treatment procedures is to minimize the carry-over of other substances into the treated pit water. Therefore, reagent compositions are chosen that correspond to the nature of the composition of the treated pit water, and there is also an obvious focus on the cost of the pre-treatment procedures.

Electrodialysis is an electromembrane separation method, the principle of which is based on the migration of ions in an electric field between the cathode and the anode.

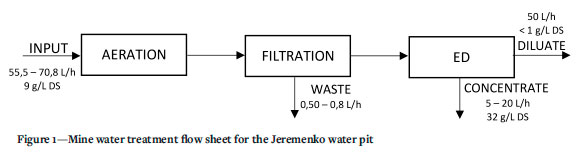

Electrodialysis tests were performed by running a batch mode on laboratory-scale unit, EDR-Z/10-1.0 (MEGA, Straz pod Ralskem, Czech Republic) in laboratory conditions at a potential of 14 V. A 2% Na2SO4 solution was used as the electrolytic solution. Heterogeneous ion-selective membranes, RALEX®AM(H)-PP and RALEX®CM(H)PP, were used. The effective area of the ED module was 1 344 cm2. The ratio of diluate to concentrate was 1:1. Figure 1 illustrates the process.

Results and discussion

The results testified to the applicability of the proposed technology. Addition of oxygen precipitated carbonates and stabilized the pH values. This pre-treatment method ensures reduction of the concentration of HCO3 ions by 1/2 at the expense of reducing the concentration of Ca2+ ions up to tens of units per milligram. The concentrations of the monitored indicators in the diluate and concentrate are given by Table II.

Desalination of 2L of the feed water was tested for 30 minutes reduced the initial conductivity from 13.940 mS/cm to 0.349 mS/cm.

The diluate compositions indicated that the water was of low mineral content and could be used as service or process water or could be further treated by reverse osmosis to produce demineralized water (water free of all solutes).

The concentrate can be used to obtain salts or could by be applied as a kind of technical salt solution, for example to maintain roads in winter. Depending on the degree of concentration, a more concentrated solution can then be obtained.

In the drinking water production, the procedure would be significantly more complicated. In addition to complying with a number of legislative requirements, it would be necessary to supplement the technology by remineralization and disinfection, and it would also be needed to address water transport to consumers across a range of allotments with private and municipal owners. The mine is located in the town centre, which complicates the whole matter of drinking water provision and we do not see this option as feasible at present. Also, costs play an important role.

In the absence of a concrete technical project, costs are difficult to specify. Saving costs for water pumping would be economically interesting because water must be pumped continuously for safety reasons. Furthermore the owner of the pit does not wish to release the necessary economic indicators.

Conclusion

Prima facie, the mine shutdown and decommissioning seem to be the final end of the mine life-cycle, followed only by costs of monitoring, ensuring public health and safety, environmental restoration, and rehabilitation.

Experience suggests that under favourable natural and technical conditions, closed mines can be repurposed in various ways so as to offer significant benefits.

Some options for using closed mines have their alternatives - goods can be stored in surface objects, natural phenomena can also be studied on the surface, energy can be obtained from other sources.

In principle, there is no alternateive for the production of service or drinking water - perhaps with the exception of costly desalination of seawater.

There are increased concentrations of salts in the mine water, and we examined the efficiency of the method of electrodialysis to desalinate mine water.

Considering the current climate change and the condition the drinking water sources, positive expectancy can be assumed for this additional water source.

We used electrodialysis, a well-known method for desalination of water. For the specific conditions of the Jeremenko pit water, we verified the application of the method for the production of service or process water.

Utility water production can be regarded as incidental to the technological and safety urgency of the continuous pumping of the Jeremenko pit water. Pumping prevents overflow from the flooded mines in the Ostrava sub-basin in to the active part of the Ostrava-Karvina coal basin.

The flooding of a mine is not to be considered as a final stage of the mine life-cycle as these are options for future repurposing action, inclusive the use of the mine water.

References

Banks, D., Athresh, A., Al-Habaibeh, A., and Burnside, N. 2019. Water from abandoned mines as a heat source: practical experiences of open and closed loop strategies, United Kingdom. Sustainable Water Resources Management, vol. 5, March 2019. pp. 29-50, [ Links ]

Barakos, G., de P. Bueno, M., Luukkanen, S., Mischo, H., Zhang, Z., Gonzales, M.S., Holopainen, P., and Remes, A. 2019. The Minetrain Project: Developing an advanced level training program for mining industry professionals in an actual deep mine site. Society for Mining, Metallurgy & Exploration, Littelton, CO. https://www.onemine.org/document/abstract.cfm?docid=249457 [accessed 31 January 2022] [ Links ]

Bracke, R. and Bussmann, G. 2015. Heat storage in deep hard coal mining infrastructures. Proceedings of World Geothermal Congress, Melbourne, Australia, 19-25 April 2015. International Geothermal Association. [ Links ]

Cobby, G. 2007. Western Australian regulatory approach to mining approvals and mine closure. Proceedings of the Second International Seminar on Mine Closure, Santiago, Chile, 16 - 19 October 2007. Fourie, A., Tibett, M. and Wiertz, J. (eds). Australian Centre for Geomechanics, Nedlands, Western Australia. pp. 103-106. [ Links ]

Colorado School of Mines. 2022. Edgar Mine. https://tour.mines.edu/edgar-mine/ [accessed 24 January 2022] [ Links ]

CSN (Czech State Norm). https://csnonline.agentura-cas.cz [accessed 4 February 2022]. [ Links ]

Dvoracek, J. and Sterba, J. 2006. The choice of the technical liquidation of underground mine workings. Proceedings of the First International Seminar on Mine Closure, Perth, Australia, 13-15 September 2006. Fourie, A. and Tibett, M. (eds). Australian Centre for Geomechanics, Nedlands, Western Australia. pp. 257-260. [ Links ]

European Underground Laboratories Association. 2020. The underground laboratories in the EUL. https://undergroundlabs.network/underground-laboratories/ [accessed 27 January 2022] [ Links ]

Flores, J.C.C., Lima, H.M., and Herrmann, H. 2007. Mine closure - Legal, social and environmental aspects in Brazil. Proceedings of the Second International Seminar on Mine Closure, Santiago, Chile, 16-19 October 2007. Fourie, A., Tibett, M., and Wiertz, J. (eds). Australian Centre for Geomechanics, Nedlands, Western Australia. pp. 79-88. [ Links ]

Grab, T., Storch, T., Gross, U., and Wagner, S. 2011. Performance of geothermal thermosyphons using propane. Proceedings of VIII Minsk International Seminar Heat Pipes, Heat Pumps, Refrigerators, Power Source. Minsk, Belarus 12-15 September 2011. doi: 10.1615/HeatPipeScieTech. v2.i/4.60 [ Links ]

Hall, A., Scott, J.A., and Shang, H. 2011. Geothermal energy recovery from underground mines. Renewable and Sustainable Energy Reviews, vol. 15, no. 2. pp. 916-924 [ Links ]

Hobba, Jr., W.A. 1987. Underground coal mines as a source of water for public supply in northern Upshur County, West Virginia. Water Resources Investigations Report 84 - 4115. US Geological Survey, Charleston, WV. 38 pp. [ Links ]

International Association of Hydrogeologists. 2018. Mining Enterprises & Groundwater. Strategic Overview Series. https://iah.org/wp-content/uploads/2018/12/IAH_SOS_MiningEnterprisesGroundwater.pdf [accessed 7 October 2020] [ Links ]

iPROSPERITA. 2018. Podzemni zasobnik Haje slavi 20 let (The Haje underground reservoir of Haje celebrates 20th anniversary). https://www.iprosperita.cz/vyrobky-a-sluzby/8952-podzemni-zasobnik-haje-slavi-20-let [accessed 26 January 2022] [ Links ]

Janson, E., Boyce, A.J., Burnside, M., and Gzyl, G. 2016. Preliminary investigation on temperature, chemistry and isotopes of mine water pumped in Bytom geological basin (USCB Poland) as a potential geothermal energy source. International Journal of Coal Geology, vol. 164, July 2016. pp. 104-114. [ Links ]

Korb, M.C. 2012. Minepool Geothermal in Pennsylvania. 2012. Proceedings of the PA AML Conference 'New Frontiers in Reclamation', August 2-4, 2012. pp. 1-22. https://2012.treatminewater.com/KorbMinepoolGeothermal2012.pdf [ Links ]

Laurence, D.C. 2006. Why do mines close? Proceedings of the First International Seminar on Mine Closure, Perth, Australia, 13-15 September 2006. Fourie, A. and Tibett, M. (eds). Australian Centre for Geomechanics, Nedlands, Western Australia. pp. 83-94. [ Links ]

Loredo, C., Ordonez, A., Garcia - Ordiales, E., Alvarez, R., Roqueñi, N., Cienfuegos, P., Pena, A., and Burnside, N.M. 2017. Hydrochemical characterization of a mine water geothermal energy resource in NW Spain. Science of the Total Environment, vol. 576, January 2017. pp. 59-69. [ Links ]

Martinec, P., Schejbalova, B., Hortvi'k, K., and Mani'cek, J. 2005. The effects of coal mining on the landscapes of the Ostrava region. Moravian Geographical Reports, The Czech Academy of Science, Institute of Geonics, vol. 13, no. 2. pp. 13-26. [ Links ]

Mhangara, P., Tsoeleng, L.T., and Mapurisa, W. 2020. Monitoring the development of artisanal mines in South Africa. Journal of the Southern African Institute of Mining and Metallurgy, vol. 120, no. 4. pp. 299-306. [ Links ]

Michalek, B., Holeczy, D., Jeli'nek, P., and Grmela, A. 2007. Vyuziti tepelne energie dulnich vod zatopenych hlubinnych dolu (Utilization of thermal energy from flooded underground mines). Acta Montanistica Slovaca, vol. 12, no. 1. pp. 92-98. [ Links ]

Michalek, B., Rapantova, N., Grmela, A., and Hajek, A. 2008. Quasi - stagnant mine waters of flooded uranium deposits as a utilizable uranium source. Proceedings of the Third International Seminar on Mine Closure, Johannesburg, South Africa, 14 - 17 October 2008. Fourie, A., Tibett, M., Wiersbye, I. and Dye, P. (eds). Australian Centre for Geomechanics, Nedlands, Western Australia. pp. 509-519. [ Links ]

Mischo, H. 2015. Underground experimental mines for technology and mining equipment research and development. Proceedings of SME Annual Conference and Expo and CMA 117th National Western Mining Conference - Mining: Navigating the Global Waters, Denver, USA, 15-18 February 2015. Society for Mining, Metallurgy & Exploration, England, CO. pp. 368-371. [ Links ]

MlNISTR PRUMYSLU ZAHAJIL PROVOZ JEDINECNE VODNl' ELEKTRARNY V OSTRAVE. 2015 (Minister of Industry has launched a unique hydroelectric power plant in Ostrava, 2015). MPO, 20 July 2015. https://www.mpo.cz/cz/rozcestnik/pro-media/tiskove-zpravy/ministr-prumyslu-zahajil-provoz-jedinecne-dulni-vodni-elektrarny-v-ostrave-160566/ [accessed 03 April 2020" [ Links ]

National Mining Association. 2021. Mining Museums and Tours. https://nma.org/about-nma-2/resources/mining-museums-and-tours/ [accessed 27 January 2022] [ Links ]

Nordwick, S., Petritz, K., Manchester, K., Joyce, H., and Bless, D.R. 2008. Resource recovery from flooded underground mines. Proceedings of US EPA/ NGWA Remediation of Abandoned Mine Lands Conference, Denver, Colorado, 2-3 October 2008. US Environmental Protection Agency. [ Links ]

Peila, D. and Pelizza, S. 1995. Civil reuses of underground mine openings: A summary of international experience. Tunnelling and Underground Space Technology, vol. 10, no. 2. pp 179-191. [ Links ]

Popielak, R.S. and Zieba, K. 2007. Medieval salt mine - A modern tourist attraction with an ancient history. Proceedings of the Second International Seminar on Mine Closure, Santiago, Chile, 16 - 19 October 2007. Fourie, A., Tibett, M. and Wiertz, J. (eds). Australian Centre for Geomechanics, Nedlands, Western Australia. pp. 869-877. [ Links ]

Preene, M. and Younger, P.L. 2014. Can you take a heat? - Geothermal energy in mining. Mining Technology, vol. 123, no. 2. pp. 107-118. [ Links ]

Ramos, P.E., Breede, K., and Falcone, G. 2015. Geothermal heat recovery from abandoned mines: a systematic review of projects implemented worldwide and a methodology for screening new projects. Environmental Earth Sciences, vol. 73, March 2015. pp. 6783-6795. [ Links ]

Rankin, M.G., Almenara, A., Rodriguez, A., and Tremblay, G.A. 2007. Abandoned mines in Peru - Prioritisation of environmental remediation. Proceedings of the Second International Seminar on Mine Closure, Santiago, Chile, 16 - 19 October 2007. Fourie, A., Tibett, M. and Wiertz, J. (eds). Australian Centre for Geomechanics, Nedlands, Western Australia. pp. 111-119. [ Links ]

Robinson, I. 2016. The globalization of the South African mining industry. Journal of the Southern African Institute of Mining and Metallurgy, vol. 120, no. 4. pp. 769-775. [ Links ]

Rudne doly. 2014. Utlum tezby lozisek Sn - W rud a likvidace Dolu Stannum (1). (Reducing extraction of Sn - W ore deposits and the liquidation of the Stannum Mine (1)). https://www.zdarbuh.cz/reviry/rd-pribram/utlum-tezby-lozisek-sn-w-rud-a-likvidace-dolu-stannum-1/ [accessed 08 October 2020] [ Links ]

Rybar, P. 2016. Bansky turizmus (Mining tourism). Edicne stredisko. Fakulta BERG, Kosice, Slovenska republika. [ Links ]

Stenhouse, P.B., Evans, C.M., and Thomas, D. 2006. Rehabilitating a historical coal mine in Wangoloa, New Zealand - A holistic approach to mine closure. Proceedings of the First International Seminar on Mine Closure, Perth, Australia, 13 - 15 September 2006. Fourie, A. and Tibett, M. (eds). Australian Centre for Geomechanics, Nedlands, Western Australia. pp. 279-283. [ Links ]

Sutton, N.W. and Weiersbye, I.M. 2007. South African legislation pertinent to gold mine closure and residual risk. Proceedings of the Second International Seminar on Mine Closure, Santiago, Chile, 16-19 October 2007. Fourie, A., Tibett, M. and Wiertz, J. (eds). Australian Centre for Geomechanics, Nedlands, Western Australia. pp. 89-102. [ Links ]

Sutton, M., Pretorius, H., Nel, J.H., Julyan, F., and Rex, H.G. 2008. Closure planning and estimating within the Southern Africa division of a global gold miner. Proceedings of the Third International Seminar on Mine Closure, Johannesburg, South Africa, 14-17 October 2008. Fourie, A., Tibett, M., Weiersbye, I., and. Dye, P. (eds). Australian Centre for Geomechanics, Nedlands, Western Australia. pp. 145-159. [ Links ]

Toledano, P., Thomashausen, S., Maennling, N., and Shah, A. 2014. A framework to approach shared use of mining - Related infrastructure. Columbia Center on Sustainable Investment, Columbia University. http://ccsi.columbia.edu/files/2014/05/A-Framework-for-Shared-use_March-2014.pdf [accessed 08 October 2020] [ Links ]

Traiblazer Technologies. 2022. Revolutionary water recovery solutions. https://www.tbtech.co.za [accessed 26 January 2022] [ Links ]

Trejbal, Z. 2009. Possibilities of utilizing gas from abandoned underground mines. GeoScience Engineering, vol. LV, no. 2. pp 29-38. [ Links ]

TU Bergakademie Freiberg. 2022. Reiche Zeche Freiberg. https://geothermie.iwtt.tu-freiberg.de/en-monitoring-exhibition-mine-reiche-zeche-freiberg.html [accessed 26 January 2022] [ Links ]

UNESCO World Heritage Centre. 2022. https://whc.unesco.org/en/list/32 [accessed 11 February 2022] [ Links ]

VAN ZYL, H.C., MAREE, J.P., VAN NiEKERK, A.M., VAN ToNDER, G.J., and NAiDoo, C. 2001. Collection, treatment and re-use of mine water in the Olifants River Catchment. Journal of the South African Institute of Mining and Metallurgy, vol. 101, no. 1. pp. 41-46. [ Links ]

Van Zyl, D.J.A., Scoble, M., and Wilson, G.W. 2007. Mine life cycle systems models and integrated mine closure for sustainability. Proceedings of the Second International Seminar on Mine Closure, Santiago, Chile, 16-19 October 2007. Fourie, A., Tibett, M. and Wiertz, J. (eds). Australian Centre for Geomechanics, Nedlands, Western Australia. pp. 217-223. [ Links ]

Watzlaf, G.R. and Ackman, T.E. 2006. Underground mine water for heating and cooling using geothermal heat pump systems. Mine Water and the Environment, vol. 25, March 2006. pp. 1-14. [ Links ]

Correspondence:

Correspondence:

J. Dvofacek

Email: jaroslav.dvoracek@vsb.cz

Received: 26 Nov. 2020

Revised: 14 Feb. 2022

Accepted: 13 Jul. 2022

Published: October 2022