Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.122 n.9 Johannesburg Sep. 2022

http://dx.doi.org/10.17159/2411-9717/1916/2022

PROFESSIONAL TECHNICAL AND SCIENTIFIC PAPERS

Determination of the stress state prior to excavation in an underground slate mine using flat jack and numerical methods

A. Alonso-JiménezI, II; M. Arlandi-RodríguezI, III; C. Lopez-JimenoI; and A. García-BerrocalI

IUniversidad Politécnica de Madrid, Spain. ORCID: A. Alonso-Jiménez: https://orcid.org/0000-0002-4260-1758; M. Arlandi-Rodríguez: https://orcid.org/0000-0001-7935-671X; A. García-Berrocal: https://orcid.org/0000-0001-9000-6542; C. Lopez-Jimeno: https://orcid.org/0000-0002-3229-6059

IICentro Nacional Instituto Geológico y Minero de España (IGME-CSIC)

IIITúneles y Geomecanica S.L., Spain

SYNOPSIS

Spain is a major producer of dimension stone, which is one of the most important industrial sectors in the northwest of Spain. This justifies the maintenance of these industries, although the technical and environmental requirements for their continuity are increasingly demanding. The main target of this paper is to present a new methodology in order to obtain k-ratio stress values on the basis of flat jack measurements and finite element numerical back- analysis with Rocscience© RS2 software. Continuous iterations were performed to try to find a relationship between the k0 and the measured stress in the tunnel roof and sidewalls. It focuses on technical aspects of the method for designing mine chambers in the slate industry that were previously mined by open pit methods. The size of the chambers impacts the operating cost, and the dimensioning of a correct support ensures better efficiency and safety. Correct knowledge of the k0 therefore is critical for the design of the support. The proposed new method entails a simplification of the classical procedure for estimating the k-ratio.

Keywords: in-situ natural stress, flat jack test, underground slate mine, back-analysis, FEM numerical methods.

Introduction

Spain is the world's leading producer of roofing slate. In the last 25 years, operations have moved from opencast to underground mines with large chambers, using a transference system, filling the previously mined chambers with waste. The chambers have remarkable dimensions, generally in the order of 150 000 m3, with widths of 25 to 30 m and heights of 50 to 60 m.

According to Hoek (2000), natural stresses can be described in a simplified way by dividing them between horizontal and vertical stress.

The horizontal stresses acting on an element of rock at a depth z below the surface are much more difficult to estimate than the vertical stresses. Normally, the ratio of the average horizontal stress to the vertical stress is denoted by k such that:

This simplified procedure is very useful for providing input data to numerical stress-strain models based on the use of commercial software.

To analyse the stability of chambers of such size, it is essential to have very reliable and precise geotechnical parameters, especially the stress state prior to excavation. This paper presents a method to obtain the virgin stress field, based on the use of measurements taken with a flat jack in the access adits to the mine chambers, and subsequent numerical back-analysis using finite element methods in 2D.

Location and description of the mine

Spain accounts for approximately 80% of the international roofing slate market (Sanz and Gonzalez-Barros, 2008). The economic value of this activity is particularly important in the southeast of Galicia (Valdeorras, Orense) and the west of León (La Cabrera), where large and small companies produce high-quality slate roof tiles. The best roofing slate is mined in massive metapellitic formations of a lower metamorphic degree than the greenschist facies (Roberts, Morrison, and Hiron, 1990; (Garcia-Guinea and Martinez-Frias, 1992; The Natural Stone Cluster, 2016).

This work was carried out in the 'A Fraguiña' Mine in Carballeda de Valdeorras (Orense, Galicia, Spain) as shown in Figure 1. The mine is owned by CAFERSA.

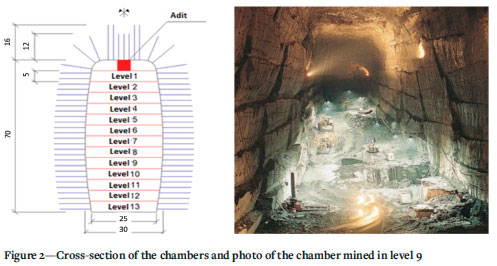

In this mining district, slate mining began with large opencast quarries, with waste dumped in large outdoor tips. When the height of the quarry fronts exceeded 100 m, and the tips covered a large surface area, the mining concept was changed, and the deposit began to be mined in large underground chambers of remarkable dimensions (30 m wide x 50 m high x 120 m long). Once an underground chamber was completely excavated, it was filled with waste from new chambers in operation.

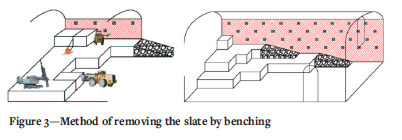

The excavation of a chamber begins by excavating the upper adit, which gives shape to its dome (Figure 2). This adit also serves to determine the location of the chamber. From there it is widened laterally until it reaches the full width of the chamber (about 25 to 30 m), thus completing the 'dome'. The slate extracted from this area is not used but is all discarded as waste. The productive extraction of the slate begins from the base of the dome by benching (Figure 3), as would be done in an opencast quarry. The excavation of the blocks is carried out by means of a mechanical cutting saw to prevent vibrations affecting the size and quality of each extracted block. Benching and extraction continues until mining reaches the lower level of the chamber.

The chamber is supported by passive cable anchors, anchored with grout, 15.2 mm in section and 8 m to 12 m long, in a 2 x 2 m configuration. Electro-welded mesh is used to prevent the fall of small stones.

Geology and geomechanics of the site

The slates mined correspond to the so-called 'Formación Agüeira' of the Upper Ordovician. The slates occur interbedded with quartzite and sandstone. Structurally, the deposit is located in the Truchas Syncline (Sastre and Calleja, 2004).

According to Julivert, Truyols, and Philippot (1974), the area under study would belong to the Western Asturina-Leonese Zone of the Hesperian Massif. Within this zone, according to Perez-Estaún, Crimes, and Marcos (1974), it belongs to the Truchas Syncline domain. The age of the quartzite and slate is Lower-Middle Ordovician.

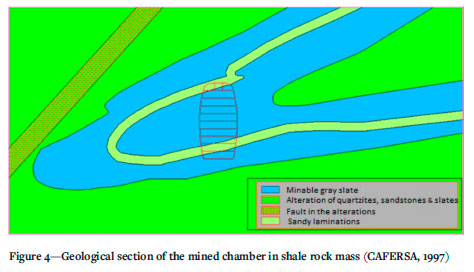

Figure 4 shows a cross-section of the deposit, with the approximate position of the slate chambers.

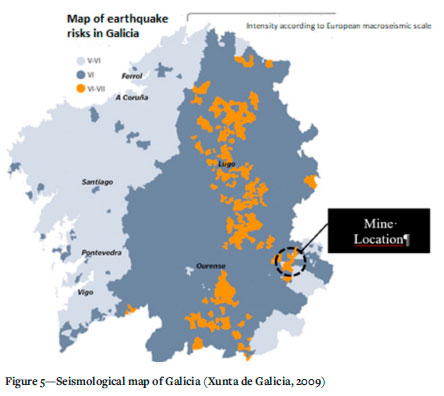

The area in which the mining district is located is classified as grade VI-VII, according to the European macro-seismic scale, and a large number of small-medium earthquakes are regularly recorded in the area (Figure 5). Considering the presence of a reverse fault near the mined chamber area, high k-ratios were expected, i.e. greater than, as observed in other mines in the district (CAFERSA, 1997).

The geotechnical characteristics of slates are well known. The rock material and the rock mass of the mine have good geotechnical qualities and a very low degree of fracturing. If this was not the case, i.e., poor quality ground and a high degree of fracturing, the deposit would not have been of interest for the extraction of slate since the extracted block would have been too small and the recovery (the ratio between the volume of marketable material and the volume of the chamber) would have been too low.

The mining method and geomechanical characteristics are very well known in this Spanish mining district. CAFERSA has been mining slate in open pit and underground mines for more than 35 years (Matías Rodriguez, 2006), and the quality of its product is defined by a good selection of the mining area. The geomechanical parameters of the rock are shown in Table I (CAFERSA, 1997):

Problem statement

The chamber size required for the deposit to be profitable is of such a magnitude that an accurate knowledge of the geotechnical parameters of the rock mass. Through surveys, in-situ testing, and laboratory tests, good values of the strength properties and deformation of the ground were obtained. However, the initial field stress conditions prior to excavation were not known. The value of the k-ratio was generally obtained only once mining of a chamber was complete. In-situ measurements were used in a back analysis exercise using numerical modelling. The fc-ratio was found to be generally around 1.4. However, in order to design new safe and low-cost chambers in other areas of the site, it is necessary to have a methodology that would determine the stress ratio before mining the chamber.

This paper describes a back-analysis technique, based on 2D stress data obtained in the access adits by means of the flat jack method. These instruments are provided locally by geomechanical companies, and has been successfully applied in other mines in this district (CAFERSA, 1992).

Methodology developed

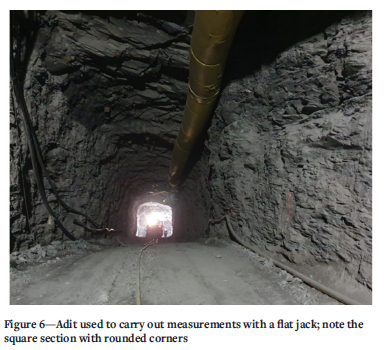

The measurements of the stress field were carried out in an adit to the chamber, which was 300 m deep. The rocky massif in the chosen environment had a geotechnical quality similar to that of the chamber to be mined. The tunnels and adits in this mine have very good geomechanical characteristics. They are square in shape with rounded corners and no support is required for their stabilization. Each adit is usually 5 m high and 5 m wide, and the rock is usually free of discontinuities, except for the cleavage of the slate.

Excavation of the adits is usually done by blasting since it is the cheapest and easiest method of execution. For this reason, the ground around the excavation usually presents a small, damaged zone (EDZ) (Qihao 2021; Kwon, et al., 2009) which has been empirically estimated (through clean-up) to have an approximate thickness of 0.5 m.

To carry out the test, the adit was visually inspected (Figure 6), and an area without discontinuities, and of the best possible geotechnical quality, was found. In addition, an area was chosen in which the damage generated by blasting was of the least magnitude possible.

It was proposed that three readings would be carried out in total: one in the roof, another in the right sidewall, and another in the left sidewall. The roof reading was made right in the centre and those in the sidewalls were measured at a height of 2 m; this height was chosen because was approximately the middle of the total height from the ground. However, the sidewall position is not relevant in the back-analysis process. Once the stress readings were made at the locations considered, numerical stress-deformation modelling was carried out using finite element software, for different fc-ratio values, keeping the rest of the geotechnical parameters of the rock and the rock mass constant. These results were compared with those obtained in the flat jack tests and, in this way, a fc-ratio value could be assigned for the measurement site.

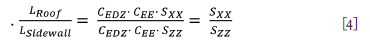

To properly assess the results of the stress measurements, it was considered that the reading procedure could involve two possible factors that could alter the reading value. The first is experimental errors, which could occur during execution of the test. The second could be due to performing the test in the zone disturbed by blasting (EDZ). Thus, it was assumed that the value of the flat jack reading (L) could be expressed as:

where:

LRoof = Reading obtained with flat jack in roof.

LSidewalls = Reading obtained with flat jack in sidewall.

CEDZ = Disturbances in the reading value due to the execution of the test in the EDZ zone

CEE = Disturbances in the reading value due to experimental errors

SXX = Real value of stress in tunnel roof

SZZ = Real stress value in sidewalls

The values of both CEDZ and CEE would be less than unity.

Along the lines outlined by various authors, such as Monge and Arlandi (2003), if we assume that the CEDZ and CEE coefficients are equal in the roof and sidewalls, the ratio between roof and sidewall stress tensors would be:

Therefore, performing the back-analysis based on the ratio between the roof reading and those of the sidewalls would be more appropriate than performing it on direct readings, since the different errors and perturbations of the real value could be reduced in this way.

Measurements with flat jack

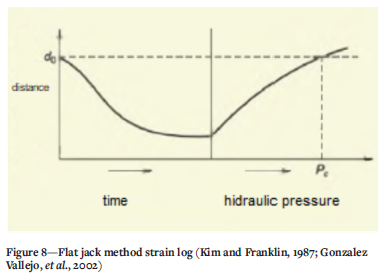

Initially reference points are made on the rock surface at about the centre point of where the flat jack slot will be cut. An initial distance reading is made between the two reference points. Subsequently, the slot is cut for the flat jack and the reference points will move towards each other in a compressive environment. The flat jack is then grouted into the slot (Figure 7c) and a new measurement of the distance between the reference points (2Li) is made (Figures 7b and c). Once the grout has cured, the jacks are pumped up until the reference points return to their original position. The pressure required to achieve this return to the original distance between reference points corresponds to the original stress along the axis perpendicular to the groove (Figure 8). A digital micrometer (Mitutoyo model ID C125b) with a resolution of 0.001 mm was used to measure the deformation. The flat jack had a thickness of 3.8 mm and dimensions of 102 mm x 203 mm.

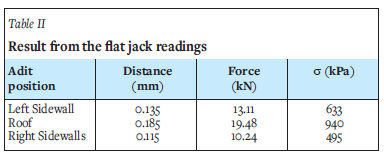

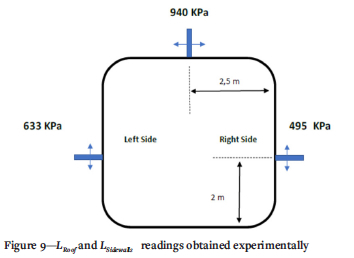

Table II provides the results obtained from the flat jack readings as shown in Figure 9. The roof tunnel value was 940 kPa and the average of the two sidewalls was 564 kPa.

Thus, the k-ratio (Sxx / Szz) had a value of 940/564 = 1.667.

Numerical back-analysis

The procedure was developed on the basis of comparing the experimental measurements with the values obtained numerically for different values of fc-ratio, assuming the rest of the geomechanical parameters of the measurement positions to be constant. As previously justified, the comparison is made on the Sxx / Szz ratio rather than on the direct reading of the flat jack.

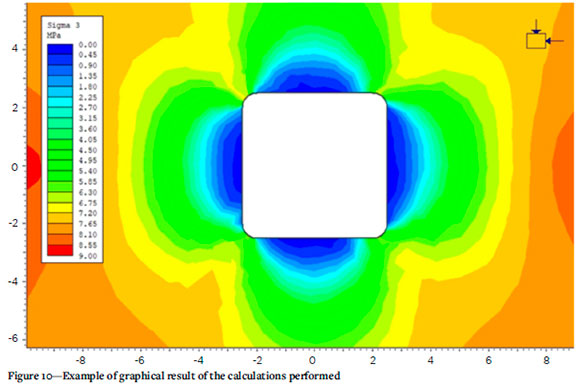

To carry out the numerical modelling, RS2 (RocScience, 2021) was used. The calculations were carried out at a depth of 300 m, using the geotechnical parameters indicated in the previous sections. Calculations were made for c-ratio values of 0.25, 0.50, 0.75, 1.00, 1.25, 1.50, 1.75, and 2.00. Figure 10 shows an example of graphical result of the calculations performed directly from the numerical modelling program.

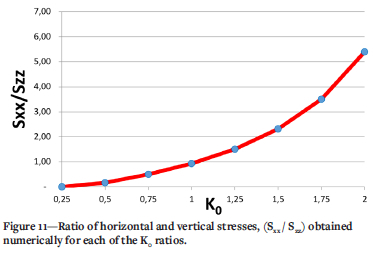

Table III show the values obtained for the SXX / SZZ ratio with variable k-ratio values.

These results can be represented graphically as in Figure 11.

Analysis of results

The flat jack tests carried out in the adit provided a value Sxx / Szz = 1.667. This value corresponds to a k-ratio of 1.33, according to Figure 11, and substantially coincides with the k-ratio values that were determined in the mine from the instrumentation data after mining had taken place, i.e. fc-ratio of 1.4 (CAFERSA, 1997). The described method is therefore validated by these measurements. The great advantage of the 'new' methodology is that the fc-ratio can be determined before excavating the chamber and, in this way, it allows for an appropriate design of the size and the support before excavation.

Conclusions

The underground slate mines of Galicia (Spain) are excavated using large chambers. They are in a geologically favourable zone to determine stress ratios (k-ratios). In the past, the fc-ratio was determined only after excavation of the first underground chambers was completed. A back-analysis showed that the fc-ratio was approximately 1.4. However, in order to design the excavation and support requirements, it was necessary to define the fc-ratio before mining the chamber. A methodology was developed using stress readings from flat jacks carried out in the adit that was mined to access the chamber. This methodology determined the value of the fc-ratio by means of a numerical back-analysis. The proposed method involves a comparison between the values of the stresses obtained from the flat jacks and the numerical values from a 2D elastic model. The method minimizes the errors that could be introduced into the readings by experimental errors and other rock-dependent factors.

References

AFERSA. 1992. Estudio Geologico y Minero de la concesion minera "A Fraguiña". Madrid. [ Links ]

CAFERSA. 1997. Estudio Geotecnico de la Ampliación de Labores en la Mina "A fraguiña", Explotación de la Cámara "0" y Cámaras Transversales. O Barco de Valdeorras: CAFERSA. [ Links ]

García-Guinea, J. and Martinez-Frias, J. 1992. Recursos Minerales de España. C.S. (ed.) Colección Textos, Universitarios. [ Links ]

Gonzalez Vallejo, L. I., Ferrer , M., Ortuño , L., and Oteo, C. 2002. Ingeniería Geológica. Madrid: Pearson Education. doi:1o.21701/bolgeomin.128.2.oo8 [ Links ]

Hoek, E. 2000. Practical Rock Engineering. https://www.rocscience.com [ Links ]

Julivert, M., Trüyols, J., and Philippot, A. 1974. Les formations siluriennes de la zone cantabrique et leurs faunes. Bulletin de la Société géologique de France, vol. 7, no. 1. pp. 23-35. [ Links ]

Kim, K. and Franklin, J. 1987. Suggested methods for rock stress determination. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, vol. 24, pp. 53-73. [ Links ]

Kwon, S., Lee, C.S., Cho, S.J., Jeon, S.W., and Cho, W.J. 2009. An investigation of the excavation damaged zone at the Kaeri underground research tunnel,. Tunnelling and Underground Space Technology, vol. 24, no. 1. pp. 1-13. doi:https://doi.org/10.1016/j.tust.2008.01.004 [ Links ]

Marchan Sanz, C. and Regueiro Gonzalez-Barros, M. 2008. La piedra natural en España: evolución y perspectivas. Boletín Geominero. pp. 395-403. doi:https://doi.org/10.21701/bolgeomin.128.2.008 [ Links ]

Matías Rodriguez, R. 2006. La mineria subterranea de pizarra. Energia y Minas, vol. 3. pp. 6-12. [ Links ]

Monge, J.C. and Arlandi, M. 2003. Numerical solution for the deformations of tunnels in rock masses and its application to estimate in situ stress ratio k0.10th ISRM Congress. International Society for Rock Mechanics and Rock Engineering. Sandton, South Africa. Retrieved from http://tunelesygeomecanica.es/descargas [ Links ]

Munro, R. 2018. Jacking test. Encyclopedia of Engineering Geology. (ed.). P.T. Bobrowsky. Springer. doi:10.1007/978-3-319-73568-9_175 [ Links ]

Perez-Estaún, A., Crimes, T. P., and Marcos, A. 1974. Upper Ordovician turbidites in western Asturias: A facies analysis with particular reference to vertical and lateral variations. Palaeogeography, Palaeoclimatology, Palaeoecology, vol. 15, no. 3. pp. 169-184. [ Links ]

Qihao, S., Fengshan, M., Jie, G. G., Haijun, Z., and Guang, L. 2021. Excavation-induced deformation and damage evolution of deep tunnels based on a realistic stress path. Computers and Geotechnics, vol. 129. doi:https://doi.org/10.1016/j.compgeo.2020.103843 [ Links ]

Roberts, B., Morrison, C., and Hiron , S. 1990. Low grade metamorphism of the Manx Group: A comparative study of white mica crystallinity techniques. doi:https://doi.org/10.1144/gsjgs.147.2.0271 [ Links ]

Rocscience. 2021. [ Links ]

Sastre, M.R. and Calleja, L. 2004. Caracterización del comportamiento elástico de materiales pizarrosos del Sinclinal de Truchas mediante ultrasonidos. Trabajos de geología, vol. 24. pp. 153-164. [ Links ]

The Natural Stone Cluster. 2016. Informe sectorial. https://clusterpiedra.com/wp-content/uploads/2018/01/Informe-sectorial-CLUSTER-PIEDRA-2016.pdf [ Links ]

Xunta De Galicia. 2009. Special Civil Protection Plan against Seismic Risk in Galicia. https://ficheiros-web.xunta.gal/emerxencias/plans/memoria-sismigal-cas.pdf [ Links ]

Correspondence:

Correspondence:

A. Alonso-Jiménez

Email: antonio.alonsoj@alumnos.upm.es