Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.122 n.6 Johannesburg Jun. 2022

http://dx.doi.org/10.17159/2411-9717/1918/2022

TAILINGS EDITION

http://dx.doi.org/10.17159/2411-9717/1918/2022

GISTM: Who are the responsible individuals?

C.J. MacRobertI; J. WatesII; A. CoetzeeIII; G. HowellIV

IStellenbosch University, South Africa. ORCID: https://orcid.org/0000-0002-7141-1339

IIJohn Wates Consulting, South Africa

IIIImpala Platinum Holdings Ltd, South Africa

IVSRK Consulting, South Africa

SYNOPSIS

The Global Industry Standard on Tailings Management (GISTM) requires mining companies to make four key appointments as part of their tailings management structure. These four positions are an Accountable Executive with policymaking responsibilities, a Responsible Tailings Facility Engineer with operational responsibility, an Engineer of Record to ensure facilities are designed, operated, and closed safely, and an Independent Tailings Review Board to assess safety drivers regularly. Little guidance on the traits of these individuals is available in a South African context. Consequently, the tailings community of practice was surveyed to develop a table of ideal competencies and establish the flexibility in meeting these traits.

Keywords: tailings, safety, GISTM, management structure, responsible individuals.

Introduction

The safe operation of tailings dams revolves around having the correct management structure in place. Tailings dams are 'living structures' in that they are constantly growing and changing. This growth needs to be managed and decisions taken to ensure the facility conforms to the original design intent. The management need becomes even more acute if the original design is no longer fit for purpose and changes need to be made to ensure the facility remains safe.

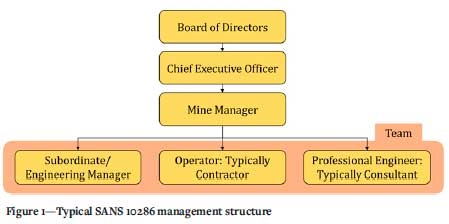

In South Africa, SANS 10286 (SABS, 1998) has been adopted by many mining companies (Wates and Lyell 2018). Since the adoption of SANS has been so pervasive it likely that the courts would refer to it as a benchmark in the absence of other legislation. At its core this standard defines a management structure, where the key roles are a 'Manager', an 'Operator', and a 'Professional Engineer'. The Manager's main role is appointing the individuals to the key roles, the Operator's main role is to manage and operate the facility, whereas the Professional Engineer is required to design and carry out inspections that provide assurance of conformance.

A typical implementation of this structure in South Africa is shown in Figure 1. The Board of Directors appoints a Chief Executive Officer who in turn appoints a Mine Manager. The Mine Manager could fulfil the SANS 10286 'Manager' role, but this is typically subordinated to an engineering manager (often the metallurgical/plant manager). The 'Operator' role is often outsourced to a contractor, although this could be fulfilled by a mine employee. A 'Professional Engineer' is also required (but not for low hazard facilities) and is typically an outsourced consultant although some mining companies have internal technical divisions that fulfil this role. It is largely expected that the 'Operator' and 'Professional Engineer' are supported by others in carrying out their duties.

These different role players can also hold legal appointments. For instance, the Mine Manager usually holds the 3.1 appointment stipulated in the Mine Health and Safety Act No. 29 of 1996. The subordinate/ engineering manager usually holds either a 2.13.1 or 2.6.1 appointment as stipulated in the Mine Health and Safety Regulations. Mines often also require the Operator and Professional Engineer to be 2.6.1 appointees, although the necessity of this is disputed. For the Engineer, this appointment would be limited to off-site, consulting, or technical responsibilities only.

While this standard has been successfully used over many years it has some shortcomings. For instance, the term 'Manager' is used generically so its meaning is sometimes not clear, for example, it can refer to the owner, a representative of the owner, the mine manager, and specific tailings appointees of the mine manager. Further, the management structure largely pertains to a given facility and it is not clear how this integrates into the wider structure of a mining company.

Largely in response to disparate management structures globally, the Global Industry Standard on Tailings Management (GISTM) was recently published (GTR, 2020). This attempts to remove ambiguity by expanding and better defining the management structure. The standard also assigns explicit responsibilities and accountabilities to individuals with standardized titles. The stated objective of this management structure is to ensure 'the safety of tailings facilities and for minimising the social and environmental consequences of a potential tailings facility failure' (GTR, 2020, p. 25).

GISTM defines four roles, an Accountable Executive (AE), a Responsible Tailings Facility Engineer (RTFE), an Engineer of Record (EOR) and an Independent Tailings Review Board (ITRB). Important functions of these four appointments are summarized from the Tailings Management Good Practice Guideline (ICMM, 2021) in Table 1. The main function of the AE is to be accountable and responsible for ensuring management structures are in place at all facilities within a mining company. The RTFE is accountable for the integrity of one or more named facilities. An EOR, working with the RTFE, ensures that a facility is designed, constructed, and decommissioned safely. On a regular basis, the underlying drivers of safety need to be assessed by an ITRB (or a single senior reviewer). Importantly, the ITRB does not have decision-making authority. The AE remains responsible for setting safety criteria, which the EOR in collaboration with the RTFE makes design decisions to achieve.

Figure 2 illustrates a possible way to implement the GISTM management structure in a South African context. The 'core team' shown in Figure 2 has similarities to the SANS 10286 'team' highlighted in Figure 1. Differences include the RTFE being a more dedicated role filled by an individual trained in aspects relating to tailings engineering, rather than being a manager with tailings responsibilities. Another difference is that the term 'Operator' refers to the entire mining operation in GISTM. To avoid potential confusion in the South African context, the 'Operator' shown in the core team, retains its original meaning and is the entity responsible for operating the tailings facility. The final member of this core team is the EOR who fulfils largely the same function as the Professional Engineer required in SANS 10286. Copeland (2018) provides an overview of the EOR role in a South African context. As with SANS 10286, GISTM expects the Operator and EOR to be assisted by others in performing their duties.

GISTM's main addition is the 'extended team' shown in Figure 2, which clearly integrates a facilities management structure into that of the mining company and introduces independent review. The AE is a senior executive reporting directly to the Board or CEO to ensure the risks associated with tailings facilities receive necessary oversight. While the link between the RTFE and AE is explicitly shown, the AE will necessarily interact with the Mine Manager, and in some cases the AE is positioned directly between the CEO and Mine Manager. A corporate tailings expert may also be appointed to provide technical advice to the AE in larger mining companies. Additionally, larger mining companies may appoint executives below the AE for specific regions or commodities. The ITRB is introduced to provide regular reviews of underlying safety drivers. The makeup of the ITRB will vary depending on the issues of concern and need only be a single person for low and significant consequence facilities.

As mines adopt GISTM, the question arises as to who these individuals should be within the South African context. This has implications both in the short term (as supply of skills is limited) and in the long term (to guide training requirements). To try and answer these questions a review of international practices and a survey of the tailings community of practice was undertaken.

Survey

The Southern African Institute of Mining and Metallurgy (SAIMM) carried out a survey of industry to obtain views relating to qualifications, experiences, and competencies of the various appointees envisaged in GISTM. An online survey was distributed to SAIMM members, selected individuals active in the tailings community of practice and on social media platforms.

As GISTM is relatively new, the first survey page included a brief explanation of the intentions of the survey and GISTM definitions of the four main appointees (AE, RTFE, EOR, and ITRP). Participants were asked to familiarize themselves with the appointees and then indicate if they were familiar with them before proceeding. The survey ended if participants responded 'No'.

Following this orientation page, a series of questions were asked to establish participant's backgrounds. This included which sector they currently worked in, what their level of responsibility was, what professional/vocational background they came from, when they obtained their undergraduate qualification, and finally in which geographical region they predominantly work in.

Four sections followed, dealing sequentially with the RTFE, AE, EOR, and the ITRB roles (definitions for each were restated). At the start of each section, potential requirements for each role were given and participants were asked to rank appropriateness according to consequence classification.

Each section also contained specific questions regarding each role. With respect to the RTFE, participants indicated whether the role should be dedicated (i.e., a sole responsibility) and whether the role can be shared between mines. Participants were also asked whether the AE role should be dedicated. Guidance was also requested on the number of appointments an EOR can hold.

The penultimate question asked participants to indicate the flexibility in meeting minimum requirements associated with each role. An open question for additional comments closed out the survey. A copy of the survey is available from the lead author.

Results

Participants

A total of 56 complete responses were received, with 50 indicating they were familiar with the GISTM appointees. Most participants came from mining companies (42%) and tailings consultancies (28%), the remainder indicated they were academics, contractors, or in allied fields. No regulators participated. Twenty-four per cent (24%) of respondents identified themselves as senior executives. Just under half (48%) identified themselves as filling at least one of the GISTM roles.

Twenty-six per cent (26%) came from a chemical (including process and metallurgical) engineering background, 34% from a civil (including geotechnical and geoenvironmental) engineering background, and 20% from a mining engineering background. Three participants had a mechanical/electrical engineering background, three an earth science (geological/environmental) background and one a commercial (law/business/accounting) background. Most of the participants (94%) worked in Africa.

A quarter of participants had at least 35 years of work experience following the completion of their undergraduate studies. On average participants had 26 years of experience and 92% of participants had at least 10 years of working experience. Considering the responses to these background questions, the participants are considered representative of the tailings community of practice in southern Africa.

Survey interpretation

One shortcoming of the survey was the interpretation of the 'Not appropriate for any consequence classification facility" response. This could be interpreted as either 'Not required' or 'Not suitable'. The authors, therefore, exercised their judgement in distinguishing between these responses based on the context of each potential requirement.

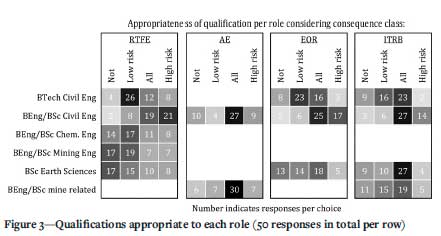

Qualifications

Figure 3, shows that many considered an engineering degree in civil engineering an appropriate qualification for the RTFE for all to high-risk facilities. Many considered a Bachelor of Technology in civil engineering appropriate for lower risk facilities. Very few considered a background in civil engineering inappropriate (i.e. not required) for the RTFE. Chemical engineering, mining engineering, and earth sciences backgrounds were considered less appropriate with many seeing these as not suitable. In the context of SANS 10286, the mine engineer responsible for tailings was typically the metallurgical/plant manager. Given that many tailings facility failures can be related to the plant (e.g. slurry density, split between coarse and fine materials, and water balance) it is perhaps wise for the RTFE to have a thorough understanding of these aspects.

Fewer qualifications were suggested for the EOR, with a Bachelor of Technology in civil engineering deemed more appropriate for all to low-risk facilities, and an engineering degree in civil engineering for all to high-risk facilities (Figure 3). A background in earth sciences was also seen as appropriate for all to low-risk facilities, however, a large group saw this qualification as inappropriate (i.e., not suitable).

For the AE role, many considered any mining-related engineering degree appropriate (Figure 3). A civil engineering background was also deemed appropriate, although several participants indicated not appropriate (i.e. not required). For the ITRB the modal answers suggested the proposed qualifications were deemed appropriate for all facilities, although degrees in civil engineering trended higher, with Bachelor of Technology in civil engineering, earth sciences degrees, and mine-related degrees trending lower.

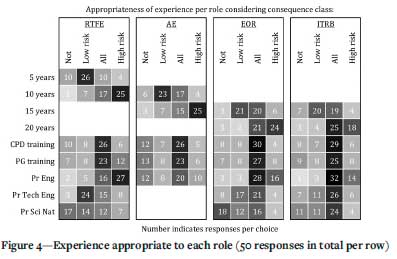

Experience

For the RTFE, it is evident that less than 5 years of experience is considered less suitable but that 10 years is largely considered appropriate in more extreme cases (Figure 4). This range for the AE was 10 to 15 years, for both the EOR and ITRB this was 15 to 20 years. The distribution of responses across roles for continuous professional development (CPD) and postgraduate (PG) training was very similar, although need for training was marginally higher for the EOR and ITRB. This result, particularly the appropriateness of PG training, was interesting. It is most likely that 'appropriate' was being interpreted as 'suitable' rather than 'required' in this case.

For the RTFE, professional registration as an Engineer (Pr Eng) was largely considered appropriate for high-risk facilities, with registration as a Professional Engineering Technologist (Pr Tech Eng) appropriate for lower risk facilities (Figure 4). Registration as a Professional Natural Scientist (Pr Sci Nat) was not considered appropriate for the RTFE by many, but others saw it appropriate for low-risk facilities. The need for the AE to be a Pr Eng was less explicit compared to other roles with a larger number of respondents seeing it as not appropriate (i.e., not required).

For the EOR, Pr Eng was considered most appropriate, especially for high-risk facilities, a Pr Tech Eng was also considered appropriate but more so for low-risk facilities, a Pr Sci Nat was not considered appropriate by many, but others saw it appropriate for low-risk facilities. The appropriateness of the three types of professional registration for the ITRB showed similar trends to the EOR, except that a Pr Sci Nat was considered more appropriate.

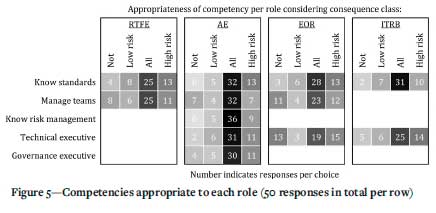

Competencies

For the suggested competencies for each role, there was little in the distribution of responses to suggest a stated competency was not considered appropriate for a given role (Figure 5). Attention is drawn to two aspects: first is the divided opinion for the EOR to be a technical executive ('Executive experience in a technical discipline'). This reflects practice in that the EOR does not need to be an executive within a consultancy. The second aspect we wish to highlight is that many saw the suggested competencies for the AE being considered highly appropriate for 'All' facilities. This reflects how GISTM necessitates considerable stakeholder engagement to be driven by the AE. The AE, therefore, needs a wide range of competencies with soft-skills being foremost.

Division of labour

A minority of respondents indicated that the RTFE role should be a dedicated role on a mine (Table II). The necessity of a dedicated role was linked more to the consequence classification of the facility rather than the stage or performance of the facility. Comments received suggested a dedicated role is ideal but often not practical. Time and support were also identified as important deciding factors. A dedicated role may not be necessary if sufficient group level support is provided. A site may have several low risk facilities requiring considerable oversight justifying a dedicated role, whereas a single well-resourced very high consequence facility may not need a full-time RTFE.

Again, a minority of respondents indicated that the RTFE should not be shared between facilities, with the suitability of sharing linked to lower risk facilities (Table II). Sharing an RTFE was also seen to be dependent on workload and proximity of facilities. An important consideration raised was potential conflicts of interest arising from who the RTFE is employed by. For instance, if the RTFE is employed by a mining company (head office) they may have limited agency to affect decisions on a mine.

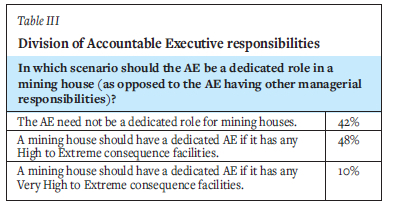

Just under half (42%) of respondents did not see the necessity of a mining company having a dedicated AE (Table III). Those that did indicate a necessity of a dedicated role, linked this to the consequence classification of facilities within a mining company's portfolio. Considering the proportion of High to Extreme consequence facilities globally (Franks et al. 2021) mining companies may increasingly have dedicated AEs.

On average respondents suggested each EOR should have no more than five appointments, however, this ranged between 3 and 10. Of respondents that provided rationale for the number of appointments, most linked the number of appointments to the consequence classifications associated with the facilities. Other key factors included the experience and capabilities of the individual and team available to the EOR, and the time available for the EOR to visit each facility.

Flexibility

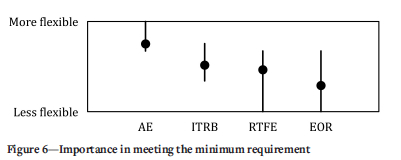

In the short term, there is likely to be a shortage of appropriate personnel to take up these roles. Consequently, participants were asked to rank the required traits for each of the four roles from less to more flexible. Solid round symbols in Figure 6 are the mean responses and the solid lines are the interquartile ranges. This suggests that the AE role is considered the most flexible followed by the ITRB, RTFE and finally the EOR. This ranking likely also reflects the responsibility held by the various roles in ensuring the safety of a tailings facility.

Suggested requirements

Based on the survey results, a review of relevant literature, and the consensus of the authors, Table IV is proposed as a list of minimum or ideal requirements for the various GISTM appointees to which South African mining companies should strive. Given that an ideal candidate is often difficult to find, the authors suggest that greater weight should be placed on demonstrated competencies and years of experience. The required traits of the four appointees are ranked from most flexible to least flexible from left to right.

Summary

Disparate tailings facility management structures globally have resulted in a consolidated effort to define a global standard. The resulting Global Industry Standard on Tailings Management defines four key roles: an Accountable Executive (AE), a Responsible Tailings Facility Engineer (RTFE), an Engineer of Record (EOR), and an Independent Tailings Review Board (ITRB). In a South African context, there is little guidance on the traits required by these individuals. Consequently, this paper explored the management structure proposed in GISTM in relation to the widely adopted SANS 10286 structure. Further, a survey of the local tailings community of practice was undertaken and results were interpreted in light of international practices. From this, a list of minimum or ideal requirements for each role was proposed (see Table IV).

List of notations

AE Accountable Executive

CEO Chief Executive Officer

EOR Engineer of Record

ITRB Independent Tailings Review Board

RTFE Responsible Tailings Facility Engineer

Acknowledgements

The authors wish to thank Gugu Charlie, Camielah Jardine, Nazli Mamdoo, and Sam Moolla of the SAIMM for assisting in rolling out the survey. We also thank the participants for spending time completing the survey.

References

Copeland, A.M. 2018. What it means to be an engineer of record. Proceedings of the 6th International Mining and Industrial Waste Management Conference, Legend Golf and Safari Resort, Limpopo, 29-31 October. SAICE. [ Links ]

Franks, D.M., Stringer, M., Torres-Cruz, L.A., Baker, E., Valenta, R., and Thygesen, K. 2021. Tailings facility disclosures reveal stability risks. Science Reports, vol. 11, no. 1. p. 5353. doi: 10.1038/s41598-021-84897-0 [ Links ]

Global Tailings Review, GTR. 2020. Global Industry Standard on Tailings Management. https://globaltailingsreview.org/global-industry-standard/ [ Links ]

International Council on Mining and Metals, ICMM. 2021. Tailings Management: Good Practice Guide. https://www.icmm.com/en-gb/guidance/environmental-stewardship/tailings-management-good-practice [ Links ]

South African Bureau of Standards SABS. 1998. SANS 10286 Management of mine residue. South African Bureau of Standards, Pretoria. [ Links ]

Wates, J.A and Lyell, K.A. 2018. A review of the evolution of tailings management and the impact on improved safety in South Africa. Proceedings of the 6th International Mining and Industrial Waste Management Conference, Legend Golf and Safari Resort, Limpopo, 29-31 October. SAICE. [ Links ]

Correspondence:

Correspondence:

C.J. MacRobert

Email: macrobert@sun.ac.za

Received: 23 Nov. 2021

Revised: 27 Mar. 2022

Accepted: 18 May 2022

Published: June 2022