Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.122 n.6 Johannesburg Jun. 2022

http://dx.doi.org/10.17159/2411-9717/1881/2022

TAILINGS EDITION

http://dx.doi.org/10.17159/2411-9717/1881/2022

A review of EN 16907 on earthworks (extractive waste) in the context of South African mine residues

F. HörtkornI; Y. NarainsamyII

IKarlsruhe University of Applied Sciences, Karlsruhe, Germany

IIUniversity of Pretoria, Pretoria, South Africa

SYNOPSIS

Rather quietly, a new generation of European norms dealing with earthworks has been developed over the past few years, in particular a part of EN 16907 pertaining to extractive waste. Whereas the majority of the parts deal with routine geotechnical aspects, one part deals specifically with tailings dams. The standard is currently in draft form but if this becomes a European Standard, members of the European Union are bound to comply with the regulations. As such, the standard has the capacity to influence mining in Europe and potentially in South Africa. In this paper we review the standard and compare it to the South African standard on mine residues and the recently published Global Industry Standard on Tailings Management (GISTM). We conclude found that although the European norm makes great strides towards increasing tailings dam safety, there is room for improvement. The current South African standard has served well since its inception, but can be improved by using concepts from the European and global tailings standards.

Keywords: tailings, tailings management, EN 16907, SANS 10286, GISTM.

Introduction

Recent tailings dam failures around the world have resulted in increased scrutiny of the safety of these structures. The failures have highlighted the real social, environmental, and reputational risk that tailings dams can pose if not managed correctly. For example, the failure of the Fundäo tailings dam in 2015 resulted in the pollution of 668 km of watercourses from the Doce River Basin to the Atlantic Ocean (do Carmo et al., 2017). In 2019, as a result of the Feijäo tailings dam failure, 259 people were reported to have died (Vale, 2019). These events have prompted many regulators to review the statutory framework within which tailings dams are designed, licenced, and operated. The intent of this paper is to review the recently published draft European Standard on hydraulic placement of extractive waste. This standard is discussed within a context of the South African legislative framework and comparisons are drawn with the recently published Global Tailings Standard on Tailings Management (GISTM). Similar types of reviews and comparisons have been undertaken by others (e.g. Poswa and Davies, 2017; Wates and Lyell, 2018).

National standards

One method to regulate the practice of tailings dam design, construction, and operation is the development and promulgation of national standards. As these documents take time to be developed and published, several large mining houses have developed their own internal standards on tailings management (e.g. Anglo American, 2019; Rio Tinto, 2020). With all these standards being published, it remains the responsibility of the dam owner to ensure that the internal and local and/or regional standards are met. This typically means the planning, design, construction, operation, and closure will be done according to a combination of standards. It is important to note that the different standards must be consistent and must not contradict each other. This is particularly relevant when local requirements are compared to international best practice.

An interesting case history where multiple standards were involved is the issue of mercury levels in the rivers downstream of the now closed Victor Diamond Mine. As the mine is located in Canada, monitoring was done according to the Canadian Environmental Quality Guidelines (CEQG). De Beers Canada Incorporated (De Beers), the owners of the mine, published annual mercury reports as part of the monitoring programme. In their 2013 report, De Beers acknowledged that although the observed mercury levels were well below those required by the CEQG, they were above those recommended by the US Environmental Protection Agency (US EPA). A few years later, it was alleged that De Beers was not publicly disclosing all the results of the mercury levels recorded at the monitoring points as mandated. This case went to court, and it was found that, despite the mercury levels being within the CEQG requirements, De Beers did not disclose the results as mandated (Ecojustice, 2021). Although De Beers was not found guilty of not using the US EPA standard, it was this initial disclosure that led to the court case by concerned activists. This case therefore highlights some of the potential complexities that arise when multiple standards are used.

Risk in the context of tailings dams

In the development of national standards, a fine balance needs to be found between efficient engineering and adequate safety, especially where the public and the environment are involved. Broadly speaking, incidents relating to tailings dam safety can be placed in one of three categories: engineering-related, operations-related, and regulatory-related (e.g. Morgenstern, 2018). Engineering-related refers to incidents caused by deficiencies in the design, construction, and associated quality control and quality assurance of tailings dams. Operations-related refers to incidents that are due to deviations from activities described in the Operations, Maintenance and Surveillance (OMS) manual. Regulatory-related refers to decisions taken (or not taken) by regulatory authorities that contributed to the incident. A comprehensive standard must therefore address each of these three aspects to achieve the target of zero harm to people and the environment.

In the following sections, three standards which address these aspects are discussed. The first is the draft European Standard on Extractive Waste (EN 16907). The second is the South African National Standard on Mine Residue (SANS 10286), and the third is the GISTM. We then present a discussion of these standards and their implications in a South African context.

Technical analysis

Although standards by nature are wide-ranging and consider the entire life-cycle of a tailings dam, the key aspect relating to the safety of tailings dams is the assessment of their stability. Traditionally, earthen slopes and embankments have been assessed by means of limit equilibrium analysis using effective stress parameters such as the friction angle and cohesion intercept. However, there are limitations to this approach in the sense that undrained shearing cannot be appropriately assessed, especially for loose, saturated contractive material. The use of undrained strengths has become more prevalent as it has been shown that undrained failure mechanisms may have led to recent failures (e.g. Morgenstern et al., 2016; Robertson et al., 2019). It is important to consider undrained failure mechanisms since under the same effective stress, peak undrained strengths are typically only half that of peak drained strength (e.g. Olson and Stark, 2003). Furthermore, it is becoming popular to regard these mechanisms as brittle behaviour. During the review, specific attention was paid to the handling of the slope stability assessment of tailings dams.

European Standard EN 16907 - Earthworks

A specific series of documents, the EN 16907 series, deals with earthworks and comprises seven parts (CEN, 2021). Whereas the majority of the parts deal with routine geotechnical aspects such as material classification, soil treatment with lime, and quality control, there is one part that deals with tailings material and tailings dams. This part of the code is referred to as 'Earthworks -Part 7: Hydraulic placement of extractive waste'.

Brief history of the Eurocodes

The European Commission decided in 1975 to develop a programme to reduce trade barriers as much as possible. Part of the programme was devoted to developing a new generation of standards that are applicable to all member countries of the European Union (EU). The new generation of standards was meant to:

> Ensure standardized design approaches throughout Europe

> Ensure a common base for research and development

> Harmonize different national approaches

>- Simplify tendering processes within Europe.

The body tasked with developing these standards is known as European Committee for Standardization (CEN), comprising countries that are members of the EU. If a common European standard is agreed upon, this standard will have to implemented -within a transition period - replacing a national code without any alteration. As such, the numbering of the code and the title remain the same; the only indication that one is dealing with a European Code is the prefix. For instance, the German prefix is DIN and German standards therefore start with DIN EN. For individual members there is, however, the opportunity to amend the code by a national annex. It is important to note that separate national codes may only exist if the topic is not regulated in any form by a European Code. Further some codes are introduced by regulating authorities and hence must be considered, others are more indicative in nature. Although one is, strictly speaking, not forced to apply the code, the code is seen as best practice and therefore has relevance.

With regard to the building and construction environment the first Eurocodes were published in the 1980s. They were official introduced in Germany in 2012. The biggest change with the new generation of Eurocodes was the move away from the global factor-of-safety concept to the partial safety factor concept, together with the introduction of partial safety factors. This makes a direct comparison of specific values to codes that incorporate the global factor-of-safety concept very difficult or nearly impossible.

Components of EN 16907

The EN 16907 series has been developed by a technical committee consisting of members of the EU (CEN/TC 396 'Earthworks'). Some parts of the Code have been formally adopted - some parts, for instance Part 7, are currently submitted to the formal vote of the member countries and will most likely be introduced shortly. To provide an overview of the whole series of EN 16907, the individual parts are listed below.

> EN 16907-1:2018: Earthworks - Part 1: Principles and general rules

> EN 16907-2:2018: Earthworks - Part 2: Classification of materials

> EN 16907-3:2018: Earthworks - Part 3: Construction procedures

> EN 16907-4:2018: Earthworks - Part 4: Soil treatment with lime and/or hydraulic binders

> EN 16907-5:2018: Earthworks - Part 5: Quality control

> EN 16907-6:2018: Earthworks - Part 6: Land reclamation earthworks using dredged hydraulic fill

> EN 16907-7:2018: Earthworks - Part 7: Hydraulic placement of extractive waste.

When comparing the individual parts, it becomes clear that parts 1 to 6 are related to construction activities that are related to infrastructure aspects such as road construction. This becomes particularly obvious in Part 2, which refers to other European Standards describing classical geotechnical tests, such as the various parts of EN 14688: Geotechnical investigation and testing - Identification and classification of soil, or EN ISO 14689: Geotechnical investigation and testing - Identification and classification of rock.

Part 7 of EN 16907 however, deals, with 'extractive waste', or what is also referred to as 'tailings material'. From a geotechnical aspect these materials are a very specific subset of natural soils and rocks but are used in a different environment (mining). To a certain extent this is acknowledged and accounted for in Part 7, which is described below in more detail.

EN 16907-7:2018 Hydraulic placement of extractive waste Overview

Part 7 of EN 16907 consists of 12 chapters plus Annexes A-N, totalling 101 pages and describes various aspects from the design phase to closure which are applicable to the various forms of 'waste facilities', e.g. dams, confining embankments. As the authors are of the opinion that the term 'waste' might be misleading and could lead - subject to local legislation - to misunderstandings or even trigger approval processes that might be not relevant to such a facility, the term 'tailings dam' will be used instead. It is important to note that Part 7 of EN 16907 does not define, establish, or specify detailed elements of the design of a tailings dam but provides overall recommendations to follow in order to comply with 'good regulatory and engineering practice'. Instead, it refers to the design principles as described in Eurocode 7 plus the relevant National Annexes. A key objective of this part of the standard is to ensure both short-term and long-term safe disposal of extractive waste.

Content

It is not necessary to describe Chapters 1 to 6 in detail as these chapter are similar to most standards and deal with topics such as the scope, references, terms, and definitions and abbreviations (Chapters 1 to 4), provide a brief and basic overview of the phases of mining projects (Chapter 5), or information with regard to the characterization of mine waste facilities according to European legislation, which subsequently defines what management documentation is required in detail (Chapter 6). Chapters 7 to 12, however, provide more information for the owner, operator and designer and are therefore described below.

> Chapter 7: Site and Material Characterization: This chapter suggests that tailings dams be classified as Category 3 structures unless there is sufficient evidence that the structure does not pose a lower risk. Classification as a Category 3 structure defines the minimum required extent of geotechnical investigation according to Eurocode EC7-1. Additional information is provided to account for tailings-specific circumstances (e.g. sampling during operational phases, location of sampling points). Detailed suggestions are provided; however, the exact geotechnical parameters that should be obtained and the tests required to establish these parameters are referenced to the relevant officially-introduced standards. As far as unusual tests are suggested, reference is made to Annex A (Non-standardized geotechnical tests on hydraulic fill). However, it must be noted that some of the parameters in Annex A are already described in other standards. For instance, the approach to determine the coefficient of consolidation (cv), the coefficient of compressibility, (mv) or the compression index (cc). Chapter 7 also deals with geochemical assessment, acid mine drainage, and sampling.

> Chapter 8: Extractive Waste Management Plan: This is the shortest chapter of EN 16907. It makes reference to a specific European Legislation (Directive 2006/21/EC, see also Chapter 6) which was officially introduced and promulgated in Germany as national law in 2006.

> Chapter 9: Mine Waste Facility (MWF) Design, Construction, Operation and Closure: Comprising 17 pages, this is the largest chapter in the Code and covers the whole life-cycle of an MWF. The chapter starts with basic comments with regard to questions such as site selection, selection of the type of embankment, or the seepage management system. It further addresses the design of the hydraulic deposition system as well as water management, and ends with a section discussing closure. In terms of slope stability, EN 16907 refers to Eurocode EC7-1, which follows the partial safety concept. Partial safety factors are introduced subject to the nature of the structure (permanent or transient). As such the values can be compared and are in the region between 1.35 and 1.50. It is important to note that in the development of EC7-1, tailings dams were not specifically considered.

> Chapter 10: Construction Quality Control:

This is a short chapter comprising two pages. It raises the need for a construction management plan and a Construction Quality Assurance (CQA) plan. For further details the Code refers to national legislation. This chapter needs to be read in conjunction with the Annexes as these contain suggestions made, for instance, regarding the frequencies of specific tests during construction.

> Chapter 11: Instrumentation and Monitoring: Similar to Chapter 10, this is a rather short chapter comprising four pages. It raises the need for an overarching monitoring plan and lists some of the principal monitoring requirements.

> Chapter 12: Inspection Regimes:

This chapter addresses technical inspections performed by the owner/operator and regulatory inspections by or on behalf of the competent authority. With regard to the minimum requirements of technical inspections; a scheme of daily, weekly, monthly, quarterly, and annual inspections is suggested, and reference is made to Annexes J to N of the document.

> Annex A: Non-Standardized Geotechnical Tests on Hydraulic Fil:

This is a very informative annex and describes geotechnical tests which are required to characterize and describe the physical and mechanical properties of tailings. These tests are in addition to the geotechnical tests described in the series EN ISO 17982. The following tests are described in detail.

o Solids content

o Particle settling velocity

o Undrained settling

o Drained settling te,

o Air drying test

o Slurry consolidation.

> Annex B: MWF Phases: This annex consists of one table (Table B.1) listing the MWF regulatory phases and comparing them to the design stage of the project. Suggested investigations and reviews for the specific design phases are listed.

> Annex C: Procedures for the Construction of a MWF Embankment: Similar to Annex B, this annex consists of a single table (Table C.1) listing required steps for the various phases (e.g. pre-deposition, operation/raises) and separately lists subjects related to the phases (e.g. design, construction, review).

> Annex D: Earth Structure Design Considerations: This annex again refers to EN 1997/EC7-1 as a design guideline (all parts) and EN 1998 with reference to seismic loading on structures (all parts) and addresses aspects such as overall stability for static and seismic conditions, hydraulic failure, and liquefaction.

> Annex E: Water Reclaim Options: Similar to Annexes B or C this annex consists of a single table (Table E.1) listing different water reclamation options.

> Annex F: Contents of Typical OMS Manual: This annex lists points that should form part of a typical OMS manual.

> Annex G: Confining Embankment CQA - Recommended Testing Frequencies: This annex tabulates the recommended testing frequencies for standard geotechnical tests (e.g. tests to determine particle size distribution, water content, Atterberg limits, in-situ density, Proctor optimum moisture content, and maximum dry density, and in-situ permeability). Tests for embankment fills and natural and engineered barriers are provided in the form of a table.

> Annex H: Confining Embankment CQA - Monitoring of Hydraulic Fill Deposits: Annex H provides a table indicating which tests should be conducted and makes reference to Annex A if the tests referred to are non-standard.

> Annex I: Instrumentation on a MWF:

Annex I lists various parameters such as surface movement, pore pressure, and seepage. The annex provides suggestions on what kind of instruments should be considered and partially describes these in more detail. The overview is presented in the form of a table (Table I.1)

> Annex J: Typical Inspection Frequency for a MWF:

This annex provides a table showing the phases of a dam and lists the minimum types of inspections that need to be conducted, their frequency, and which responsible parties need to carry them out (Table J.1).

> Annex K/L: Daily/Weekly Technical Inspections: This annex provides a table showing different monitoring parameters and provides comments with regard to the methods of monitoring as well as recording and assessing the monitoring data (Table K.1 and Table L.1).

> Annex M: Programme for Technical Inspection and Reporting:

Annex M lists a programme for inspections and reporting (Table M.1).

> Annex N: Content of a Technical Inspection Report: Annex N list the typical content of a technical inspection report that needs to be routinely compiled by the independent qualified engineer at intervals discussed in Chapter 12.

South African National Standard on Mine Residue (SANS 10286)

In 1994, the Merriespruit tailings dam failed and 600 000 m3 of tailings flowed into the town of Merriespruit killing 17 people (Wagener, 1997). It remains one of the worst tailings dam failures in South Africa in terms of environmental and social impact. It was also the last serious tailings incident to occur in South Africa. Following the failure, it was decided that a national standard would be developed to specify minimum requirements in terms of planning, design, operations, monitoring, review, and non-conformance follow-up in relation to mine residue facilities. In 1998, the South African National Standard on Mine Residue (later renamed SANS 10286) was published (SABS, 1998). Note that this document was developed to include all mine residue deposits, such as waste rock dumps, and is not limited to tailings dams.

Although South African National Standards by nature are not legally mandatory, they often become legally binding when referenced in legislation. This is the case for SANS 10286. Section 9 of the Mine Health and Safety Act (MHSA) specifies that a Code of Practice (CoP) must be prepared and implemented on any matter affecting the health and safety of employees and other persons who may be directly affected by activities at a mine (MHSA South Africa, 1996). It further states that the Code of Practice must comply with guidelines issued by the Chief Inspector of Mines. This guideline (the Guideline for the Compilation of a Mandatory Code of Practice on Mine Residue Deposits) was published in 2000 and states that the SANS 10286 code must generally be regarded as providing the minimum requirements for good practice on which to base the relevant sections of the CoP (DME, 2000). In this way, SANS 10286 must be legally complied with when dealing with mine residue deposits.

Although there is a design code for the basis of geotechnical design and actions (SANS 10610-5), it specifically excludes the design of geotechnical structures such as slopes, embankments, or free-standing retaining structures (SABS, 2010). Rather, the standard focuses on the determination of geotechnical actions on buildings and industrial structures, including vertical earth loading, earth pressure, groundwater and free water pressure, and actions caused by ground movement.

The management of supernatant water is generally dealt with using the SANCOLD guidelines on freeboard requirements as well as the regulations published under the National Water Act and Mineral and Petroleum Resources Development Act (South Africa, 1999, 2004; Bosman et al., 2011). This aspect is complex in itself and has been dealt with in a separate publication (Narainsamy, 2018). The stability of tailings dams is conventionally managed in accordance with the South African Institution of Civil Engineering's code of conduct on lateral support (SAICE, 1989), specifying a global factor of safety (FoS) of 1.5 and using effective stress parameters. In addition to SANS 10286 and the documents mentioned above, tailings dams in South Africa are governed by a complex combination of several pieces of legislation. These include licence requirements for water and waste usage as well as adherence to approved environmental management programmes during operation and post closure of mine residue deposits.

Global Industry Standard on Tailings Management (GISTM)

The International Council on Mining and Metals (ICMM) is an international organization dedicated to a safe, fair, and sustainable mining and metals industry. After the Feijäo tailings dam failure in 2019, the ICMM, the United Nations Environment Programme (UNEP), and the Principles for Responsible Investment (PRI) co-convened the Global Tailings Review to establish an international standard on tailings management. This initiative was led by Dr Bruno Oberle, and in 2020 the GISTM was published (Oberle, 2020). The GISTM contained 77 requirements over six categories, namely: affected communities; integrated knowledge base; design, construction, operation and monitoring of tailings facilities; management and governance; emergency response and long-term recovery; and public disclosure and access to information.

Following the publication of the GISTM, the ICMM members committed in August 2020 to implement the GISTM within three years for all facilities with an 'Extreme' or 'Very High' classification (as per Annexure 2 of the GISTM), and all other facilities within five years. To support this initiative, the ICMM published two documents in 2021. The first document, the Tailings Management Good Practice Guide (GISTM Guideline) was developed to support the interpretation of many of the requirements within the GISTM and promote good engineering practices for tailings management (ICMM, 2021a). The second document, the Conformance Protocols for the Global Industry Standard on Tailings Management (GISTM Conformance Protocols) was developed to help operators and independent third parties to assess implementation of the GISTM and to demonstrate conformance (ICMM, 2021b).

Some emphasis is given to the design of tailings dams, specifically in terms of slope stability analysis. Requirement 4.6 of the GISTM states that brittle failure modes must be identified and addressed, independent of the trigger mechanism. Interestingly, design FoS values are not prescribed. Rather it is stated that these should be determined by the Engineer of Record (EoR) and endorsed by independent review. There is an exception to Requirement 4.6 and this is detailed in Requirement 4.7 of the GISTM. This clause introduces the idea of considering not just the risk involved, but also the associated resources required to achieve that risk level.

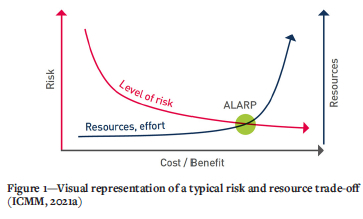

In the associated guideline, it is explained that the goal is to achieve the desired outcomes by reducing risk to levels as low as reasonable possible (ALARP). A visual representation of the ALARP concept is shown in Figure 1. In this approach, measures are taken to reduce the risk to a state where the cost and other impacts of additional risk reduction are grossly disproportionate to the benefit. As this clause could be used out of context, it is followed by a statement that this approach is acceptable only when proposed by the EoR, reviewed by the Independent Technical Review Board (ITRB), and documented and approved by the Accountable Executive. It should be noted that this approach is aimed at existing tailings dams that cannot meet the new requirements, and not for new tailings dams.

Comparison of standards

As the three different standards were developed at different points in time and for different regions, it can be expected that different terminology is used. A summary of the key terms is provided in Table I. A few key points with regard to technical aspects are discussed in Table II. A deficiency in the South African standard is that there is no mandatory requirement for an independent review of the operation. However, as discussed earlier, it is common practice for independent reviews to be conducted even though this is not mandatory. It is also interesting to note that the while the South African and European standards are applicable to all tailings storage facilities, the GISTM is applicable to only those facilities that have a wall height greater than 2.5 m and/or combined storage capacity of more than 30 000 m3. This approach is similar to that taken by the Dam Safety Office in South Africa in regard to water dams that could pose a safety risk and need to be registered. In this case, only dams with a wall height greater than 5 m and which store more than 50 000 m3 of water need to be registered. This is less conservative than the GISTM standard which, aside from the more stringent values, only requires that one of the criteria to be met.

What becomes obvious as well is that SANS 10286 explicitly introduces legally responsible persons as per the MHSA (for instance, the 2.6.1 Appointment for competent owner-managers). This explicit legal responsibility appears to be missing in the other documents or is subject to local legislation, which is not uniform within the member countries of the EU.

A summary of the technical guidance provided in the three standards is shown in Table II. For flood management, storm events up to the Probable Maximum Precipitation (PMP) are considered depending on the classification of the tailings dam. Similarly, seismic events up to the Maximum Credible Earthquake (MCE) are considered. No FoS is specified in the South African standard, although there was a locally accepted value of 1.3 using effective stress parameters until legislation under the National Environmental Management: Waste Act was promulgated in 2015 (NEMWA South Africa, 2015). This regulation specifies a minimum FoS of 1.5 but does not specify a method of determining this. Interestingly, no FoS is prescribed in the GISTM. Rather, it is recommended that the EoR proposes a FoS and that this is reviewed independently and accepted by the Accountable Executive.

An important point to note is that the GISTM clearly states that brittle failure modes must be identified and addressed, independent of trigger mechanisms. This is in line with comments by other researchers, e.g. Robertson (2021), who notes that for structures where the consequences of failure are high (e.g. loss of life and/or significant environmental and reputational damage), it is prudent to assume that strength loss will be triggered since it is often impossible to design with confidence based on an assumption that strength loss will not be triggered at some time in the life of the structure.

Discussion and conclusion

We have described and compared various standards, particularly with regard to how slope stability assessments were incorporated into these standards. EN 16907-7 is not very concise and appears to be almost a textbook. It mentions a FoS only indirectly when it remarks on the requirement to use Eurocode 7-1 for any geotechnical design. Using this document, one would expect a FoS between 1.35 and 1.50 subject to the loading conditions (permanent or transient). In this context it is, however, important to note, that EC7-1 was not developed with tailings dams in mind. A point for discussion is, for instance, the fact, that a tailings dam only reaches its final shape at the end of its life - would this indirectly allow a lower FoS during the operational phase (loading case transient)? EC7-1 also does also not specifically address the issue of liquefaction. This topic is addressed in EN 16907-7, but in a very general manner.

The South African Standard, does not specify a FoS. There is, however, a locally accepted value of 1.5 using effective stress parameters, although the method of establishing this is not specified.

Interestingly, no FoS is prescribed in the GISTM either. Rather, it is recommended that the EoR proposes a FoS and that this is reviewed independently and accepted by the Accountable Executive. The initial rigorous striving for safety at all costs ('zero harm') committed to after the recent catastrophic failures is already softened by an approach called ALARP (see Figure 1).

The intent of national codes and standards in the context of tailings dams is to promote good engineering practice to ensure the safe planning, design, construction, operation, and closure of tailings dams with the ultimate goal of zero harm to people and the environment. The three standards described make great strides towards achieving this goal. However, during the review, several areas for potential improvement were noted, specifically in terms of technical aspects and clear guidance required for the slope stability assessment of tailings dams. These can broadly be described as follows.

1. Standards should be as short and concise as possible and written in plain, simple terms.

2. Guideline documents should be developed to assist in the interpretation of the standards. These guideline documents should clearly and objectively describe how compliance to the standard can be achieved and verified.

3. This clarity is especially important with respect to methods of assessing the stability of tailings dam. As the intent is to provide minimum standards, the authors are of the opinion that minimum FoS values and minimum scenarios should be specified. For example, a standard or guideline could state that limit equilibrium slope stability analysis must be conducted using effective strength parameters and a minimum FoS of 1.5 must be achieved. In addition, limit equilibrium slope stability analysis must be conducted using peak undrained strength parameter and a minimum FoS of 1.3 must be achieved.

It is suggested that in the future, standards for the planning, design, construction, operation, and closure of tailings dams provide clear, concise requirements for slope stability assessment. Standards should also make reference to scientifically well-researched design approaches which can be introduced in daily engineering by all stakeholders involved, such as designers, operators, and regulators. An example is the topic of 'liquefaction'. Even EN 16907-7 acknowledges that this topic is the 'subject of advanced geotechnical research' (EN 16907-7, D.2.3.5). Also, the authors are of the opinion that there is currently uncertainty regarding generally accepted methods on how to test for liquefaction or how to incorporate this into a design with confidence. Until a clear approach on how to incorporate this aspect is available, one would have to make extremely conservative assumption to achieve the goal of 'zero harm'. This, however, leads to a very expensive design solution. With reference to Figure 1 the authors fear that this noble goal will be bypassed due to economic considerations.

Significant resources are currently being spent on enhancing the safety of tailings dams as regards liquefaction. As indicated above, the question must be raised if this is not premature in some cases. We hope that some of these resources can be made available for research purposes as this will allow the topic of liquefaction to be addressed and incorporated into design approaches with confidence.

References

Anglo American. 2019. Mineral residue facilities and water management structures standard and technical specifications (AA TS 602). Version 5.2, Bosman, D.E., Basson, J.R., Tente, T., and Basson, G.R. 2011. South African Committee on Large Dams (SANCOLD)-Volume II. Guidelines on freeboard for dams. SANCOLD, Pretoria. [ Links ]

Department: of Minerals and Energy (DME). 2000. Guideline for the compilation of a mandatory code of practice on mine residue deposits. Reference no.: 16/3/2/2-A1. Pretoria. [ Links ]

Do Carmo, F.F., Kamino, L.H.Y., Junior, R.T., de Campos, I.C., do Carmo, FFS.G., and Mauro, M.L. 2017. Fundäo tailings dam failures: The environment tragedy of the largest technological disaster of Brazilian mining in global context. Perspectives in Ecology and Conservation, vol. 15, no 3. pp. 145-151. [ Links ]

Ecojustice. 2021. De Beers pleads guilty to failing to report mercury pollution at Canadian diamond mine.https://ecojustice.ca/pressrelease/de-beers-pleads-guilty-to-failing-to-report-mercury-pollution-at-canadian-diamond-mine/ [Accessed 13 July 2021]. [ Links ]

European Committee for Standardization (CEN) 2021. European Standard EN16907 - Earthworks - Part 7: Hydraulic placement of extractive waste - final draft. ICS 93.020. Brussels. [ Links ]

International Council on Mining and Metals (ICMM). 2021a. Tailings management: Good practice guide. London. [ Links ]

International Council on Mining and Metals (ICMM). 2021b. Conformance protocols: Global industry standard on tailings management. London. [ Links ]

International Commission on Large Dams (ICOLD). 2016. Selecting seismic parameters for large dams - Guidelines. ICOLD Bulletin 148 (Revision of Bulletin 72). Paris. [ Links ]

Morgenstern, N.R. 2018. Geotechnical risk, regulation, and public policy. Soils and Rocks, vol. 41, no. 2. pp. 107-129. [ Links ]

Morgenstern, N.R., Vick, S.G., Viotti, C.B., and Watts, B.D. 2016. Fundão Tailings Dam Review Panel Report on the Immediate Causes of the Failure of the Fundäo Dam. SAMARCO, SA, Vale, SA, Eds, 76. https://www.resolutionmineeis.us/documents/fundao-2016 [ Links ]

Narainsamy, Y. 2018. A review of freeboard criteria for tailings dams. Proceedings of the 6th International Mining and Industrial Waste Management Conference. Polokwane, South Africa. South African Institution of Civil Engineering. [ Links ]

Oberle, B. 2020. Global Industry Standard on Tailings Management (GISTM). https://globaltailingsreview.org/wp-content/uploads/2020/08/global-industry-standard_EN.pdf [ Links ]

Olson, S.M., and Stark, T.D. 2003. Use of laboratory data to confirm yield and liquefied strength ratio concepts. Canadian Geotechnical Journal, vol. 40, no. 6. pp. 1164-1184. [ Links ]

Poswa, T.T. and Davies, T.C. 2017. The nature and articulation of ethical codes on tailings management in South Africa. Geosciences, vol .7, no. 4. https://doi.org/10.3390/geosciences7040101 [ Links ]

Rio Tinto. 2020. Group standard - D5 - management of tailings and water storage facilities. London. [ Links ]

Robertson, P. 2021. Evaluation of flow liquefaction and liquefied strength using the cone penetration test: An update. Canadian Geotechnical Journal. https://doi.org/10.1139/cgj-2020-0657 [ Links ]

Robertson, P.K., de Melo, L., Williams, D.J., and Wilson, G.W. 2019. Report of the expert panel on the technical causes of the failure of the Feijäo dam 1. https://bdrb1investigationstacc.z15.web.core.windows.net/assets/Feijao-Dam-I-Expert-Panel-Report-ENG.pdf [ Links ]

South Africa. 1996. Mine Health and Safety Act. Government Gazette 17242, vol 584, no 967, 14 June 1996, as amended. [ Links ]

South Africa. 1999. National Water Act Regulations. Government Gazette 20119, Government Notice R704, 4 June 1999, as amended. [ Links ]

South AAfrica. 2004. Mineral and Petroleum Resources Act Regulations. Government Gazette 26275, Government Notice R527, 23 April 2004, as amended. [ Links ]

South AAfrica Bureau of Standards (SAABS) 1998. SAANS 10286: Code of practice for mine residue. Pretoria. [ Links ]

South AAfrica Bureau of Standards (SAABS). 2010. SAANS 10160-5: Basis of structural design and actions for buildings and industrial actions. Part 5: Basis of geotechnical design and actions. Pretoria. [ Links ]

South AAfrican Institution of Civil Engineering (SAAICE). 1989. Lateral support in surface excavations - Code of practice. Midrand, South AAfrica. [ Links ]

Vale. 2019. List of contactless people and identified bodies resulting from the breaking of dam 1 in Brumadinho on 01/25/2019. http://www.vale.com/EN/aboutvale/reports/atualizacoes_brumadinho/Pages/updated-lists.aspx [Accessed 12 July 12 2021]. [ Links ]

Vardanega, P.J. and Bolton, M.D. 2016. Design of geostructural systems. ASCE-ASME Journal of Risk and Uncertainty in Engineering Systems, Part A: Civil Engineering, vol. 2, no. 1. doi: 10.1061/AJRUA6.0000849 [ Links ]

Wagener, F. 1997. The Merriespruit slimes dam failure: Overview and lessons learnt. Journal of the South African Institution of Civil Engineering, vol. .39, no. 3. pp. 11-15. [ Links ]

Wates, J. and Lyell, K. 2018. A review of the evolution of tailings management and the impact on improved safety in South AAfrica. Proceedings of the 6th International Mining and Industrial Waste Management Conference, Polokwane. pp. 109-116. [ Links ]

Correspondence:

Correspondence:

Y. Narainsamy

Email: yashay.narainsamy@tuks.co.za

Received: 29 Oct. 2021

Revised: 8 Mar. 2022

Accepted: 8 Mar. 2022

Published: June 2022