Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.122 n.6 Johannesburg Jun. 2022

http://dx.doi.org/10.17159/2411-9717/1887/2022

TAILINGS EDITION

http://dx.doi.org/10.17159/2411-9717/1887/2022

Practical steps to Global Industry Standard on Tailings Management (GISTM) compliance for operational tailings storage facilities in South Africa

S.D. Dladla; S. Ramsamy

Traser Alexander, Johannesburg, South Africa

SYNOPSIS

The majority of the tailings dam operations in South Africa will be required to comply with the new Global Industry Standard on Tailings Management (GISTM) within the next one to three years, depending on the dam classification and the requirements of the respective investors and insurers. With up to 72 auditable requirements, the implementation of the Standard needs careful planning and prioritization. This paper focuses on the practical steps to GISTM compliance for tailings facilities in operation in South Africa. The discussions are based on current practices, South African regulations, and industry standards requirements. The possible changes in dam classifications and the associated requirements are presented.

Keywords: tailings management, GISTM, ICMM, SANS, standards.

Introduction

All International Council on Mining and Metals (ICMM) members have committed to implement the Global Industry Standard on Tailings Management (GISTM) on their tailings dam operations. The commitment compliance date for facilities with 'Extreme' or 'Very high' potential consequences is 5 August 2023, and all other tailings facilities in operation must be in conformance with the Standard by 5 August 2025. Given how close these dates are and considering that there are as many as 77 auditable requirements, the implementation of the Standard needs careful planning and prioritization.

In this paper we focus on the practical steps to GISTM compliance for tailings facilities in operation in South Africa, based on the current practices, South African regulations, and industry standards requirements.

In order to identify areas that are already sufficiently covered within the South African context, and areas that will need more attention during the GISTM compliance journey, we first give a high-level comparison between the requirements of the GISTM and those of the South African regulations and standards.

We also briefly look at the conformance protocol document, which gives guidance on levels of conformance with the Standard.

The proposed GISTM compliance process is presented, together with suggestions on the initial GISTM project set-up and critical appointments.

The dam classification method based on the South African Code of Practice for Mine Residue Deposits, SANS 10286 (SABS, 1998), is compared with the method described in the GISTM, and the major differences are highlighted together with the likely factors affecting the final new dam classifications.

The potential changes to the operations based on the GISTM are discussed.

Other related topics that are covered in this paper include the addressing of the brittle failure requirement, upgrading of dam monitoring instrumentation, implementation of information systems, and the required communication with interested and affected parties during the implementation process.

The Global Industry Standard on Tailings Management

Following the catastrophic tailings dam collapse at Vale's Córrego de Feijão mine in Brumadinho, Brazil on 25 January 2019, the need for a global tailings management standard to prevent similar failures in the future and to seek transparency regarding the management and executive oversight of the residue facilities was identified.

The Global Tailings Review initiative was co-convened with a multidisciplinary expert panel, which included the ICMM, the United Nations Environment Programme (UNEP), and Principles for Responsible Investment (PRI), who headed up the review. The GISTM (ICMM, 2020), which was launched in August 2020, was developed with input from a multi-stakeholder advisory group. The review involved extensive public consultation with affected communities, government representatives, investors, multilateral organizations, and mining industry stakeholders and is informed by existing best practice and findings from past tailings facility failures.

The GISTM is organized around six Topic areas and covers 15 main Principles, and has 77 auditable Requirements.

The GISTM is supported by the Conformance Protocols and Good Practice and Documents, both released by the ICMM in May 2021 (ICMM 2021a, 2021b)

The GISTM Requirements vs the South African regulations

South Africa is considered as one of the leading countries when it comes to the tailing-related regulations and standards which are aimed at preventing tailings dam failures.

SANS 10286 is based on the ISO management principles and provides a good base for tailings management in general. The mining and engineering companies were the key contributors in the establishment of these standards.

The South African legislation and standards were included in the comparative analysis of tailings-related legislation of key mining jurisdictions by Campbell et al. (2019), who looked at how various countries' regulations address the requirements of the GISTM principles. The scoring criteria are shown in Table I and the results are shown in Table II.

The results showed that the current South African requirements meet or exceed the requirements of the GISTM in most areas. The two areas where the scores were low, Principle 9 (appointment and empower an EOR) and Principle 13 (prepare for emergency response of tailings facility failures), are covered in SANS 10286 and the Mine Health and Safety Act No. 29 of 1996 (MHSA).

The current scope of the MSHA Reg. 2.6.1 technical appointment has similar objectives to that of the Engineer of Record (EOR). The term EOR was coined in North America and has therefore only recently been adopted by the industry in South Africa.

The Emergency Preparedness Plan is required by the MHSA as part of the Mandatory Code of Practice (required as per Section 9(2) of the MHSA and the Chief Mine Inspector directive reference number: DME 16/3/2/5_A1). However, the GISTM requires a more comprehensive plan, including a recovery plan after failure.

Based on these results, it is therefore expected that a tailings dam that is currently fully compliant with the requirements of the South Africa regulations and standards should conform with most of the GISTM requirements by the specified deadlines.

It is worth noting that the compliance of tailings dams that currently fall under the industrial sector (e.g., Eskom, Sasol, and smelters) is not included in the discussions of this paper as they generally do not follow most of the mine-related regulations and SANS standards. Some international insurers and investors may not treat these facilities differently to mine tailings (even though they may be ash or slag facilities) and will require compliance to the GISTM.

The conformance protocols

A specific conformance protocol document was release by the ICMM in May 2021 (ICMM, 2021a). This document gives guidance on how to evaluate compliance with the Standard.

The basic principle when it comes to compliance with the GISTM requirements is that reasonable evidence must be produced to prove the level of conformance. The levels of conformance are shown in Table III (Table I, page 6 of the Protocol document).

The examples of compliance are given within the Protocol together with guidance where necessary. The good practice guidelines were also released with these protocols (ICMM, 2021b).

The mines are allowed to carry out the initial self-assessment and associated reporting as part of meeting the initial compliance dates. It is important to note that the committed compliance dates do not mean that all the requirements should be fully met by then, but it is required that at least the gaps and weaknesses in the system will have been identified and that plans will be in place to address these.

Proposed initial GISTM compliance process for existing South African operations

Different mines are likely to follow different paths to compliance based on their current level of conformance to the South African requirements, the available information, and their previous initiatives in anticipation of the new Standard. The suggested GISTM initial compliance process is as follows.

(i) Project set-up - This phase includes the appointment of the internal project team, defining roles and responsibilities within the compliance project, and the appointment of the external resources where required.

(ii) Information gathering - This phase includes gathering of the information that is required for the GISTM dam classification process.

(iii) Dam classification process.

(iv) Assessment of changes required based on the outcome of the initial dam classification process.

(v) Implementation -Involves the completion of self-assessments, creation of a strategy of closing the gaps, and documentation.

(vi) Final self-assessment and documentation, and possible third-party audit.

The rest of the paper discusses the common issues that may be encountered during the initial implementation of the GISTM compliance process and the approach that can be adopted to address some of the issues that are applicable to the majority of the tailings operations in South Africa.

Appointments and training

With the compliance dates looming, especially for the High and Extremely High classified dams as per the GISTM, it is important for mines to treat the compliance process as a project on its own, and the appointment of experienced persons is crucial for the success of this project.

Some of the mines anticipated the changes a while back, and as part of their compliance initiatives have already appointed personnel that can fulfil some of the roles as stipulated in the Standard. However, other mines are well behind in this regard.

It is important to note that most of the required skills and appointments may already exist within the mines or their external suppliers. What will need to happen in most of the cases will be to change the titles or appointments so as to be in line with those in the Standard. It will also be important to assess whether the appointed persons have the right qualifications, experience, required resources, and authority to fulfil the associated roles (refer to Annex 3, Table IV of the Standard).

A project champion must be appointed to manage and drive the GISTM compliance process. This person can be internally appointed, e.g., Responsible Tailings Facility Engineers or civil departmental engineers where available; or externally appointed, e.g., consulting engineers, independent engineers, or the technical staff of the appointed dam operator. The project champion must keep a detailed conformance table and record of the overall project timelines.

The standards are fairly new, and there are still a lot of developments taking place, therefore the appointed champion must be provided with adequate resources (support, budget, and time) to enable him or her to attend learning sessions and to consult with the field experts when required.

The next crucial internal appointment will be the Responsible Tailings Facility Engineer (RTFE), who must be well experienced and qualified for the specific classification of the dam. The current limited pool of engineers in the country may cause some delays in the appointment of the RTFE and possibly the appointment of the EOR where required. Due to the potential delays, the recruitment of potential RTFEs might have to include appointments of civil engineering graduates that can be seconded to consulting engineering companies and tailings operating companies to gain adequate technical and practical experience. The recruitment process might also include the offering of bursaries to undergraduate students. It is expected that the RTFE, with assistance from various departments and external consultants, should be able to complete the self-assessment as required by the Protocols before the compliance dates.

The current dam designers and Responsible Professional Engineer (appointment MHSA Reg, 2.6.1 - Technical) should be suitable to hold the EOR appointment, therefore the EOR appointment must be finalized in writing, and the role must include all requirements as listed in Table 4 of the GISTM.

It is important to note that the appointment of the current responsible professional engineer as an EOR does not relieve them of their duties under the MHSA, and due consideration must be given to the amendment of the letters of appointment of the professional engineers (2.6.1 Technical Appointment) to include the duties of the EOR as stated in the GISTM to streamline the process.

The field of tailings engineering is highly specialized, with only a handful of internationally recognized engineering consulting firms practicing in South Africa with sufficient expertise as envisaged in Requirement 9 in the GISTM

The current MHSA Reg 3.1 appointment (Mine Manager) can be appointed as the Accountable Executive. It is critical for the Accountable Executive to be part of the implementation team as key decisions will need to be taken at this phase of the project. Some of the current positions within the mine that can be considered for this appointment, depending on the size and organizational structure, include the Vice-President, Chief Operational Officer, General Manager, Chief Engineer, Departmental Manager etc.

Information required for dam classification purposes

Sufficient time and resources must be provided for the information gathering process. The information that is required for dam classification purposes can be obtained from the following documents, which are mandatory for all tailings operations in South Africa:

> Tailings storage facility design report (most important, often non-existent)

> The DMR Mandatory Code of Practice

> Environmental authorizations (EMPR)

> Integrated water use licence (IWUL)

> Waste management facility licence (WMFL)

> Air emissions licence (AEL)

Most of the information that is required for the consequence classification should be residing with the mine or their appointed design engineers and EORs. However, as per our recent experience, when developing our internal risk management system, which required gathering of this information from our clients, most of this information was not readily available. This can be attributed to inadequate change management processes, e.g. during changes of the operating and client personnel and/or changes of responsible engineers. As some of the operations have been continuing for extended periods of time, some of the data is stored in outdated formats and is difficult to retrieve or read.

Typical places to get the historical information include old office/drawing cabinets, storage containers, mine libraries, consultants and external operator offices or servers, and external storage warehouses.

Where insufficient information exists, 'Continuation Reports' need to be compiled as per the guidance in SANS 10286, and this might need additional investigations and test work, including some design work. This process is likely to take significant time and the reports might not be ready by the target compliance dates.

Dam classification assessment

The dam classification process should commence with the review of the current safety classification based on SANS 10286. The SANS-based classification should contain some of the information that is required for the GISTM dam classification; a quick comparison is shown in Table IV.

The dam classification is carried out by first approximating the physical area impacted by the potential failure due to flowable materials and pool water. In South Africa this is conducted based on a prescriptive method that only considers the final height of the dam, with the zone of influence determined as follows: upstream 5 χ final height, sides 10 χ final height, downstream 100 χ final height with a limit of 6500 m.

The GISTM requires that a dam breach analysis takes into consideration the actual credible failure modes and scenarios as well as site conditions. Therefore, it is possible for a dam that is operated by skilled individuals with a well-controlled pool and a phreatic surface that is kept away from the liquifiable zone to return a lower classification than a dam that is not well operated.

In South Africa, dam breach assessments have been conducted primarily on water dams, therefore these skills reside predominantly with water dam engineers. However, a tailings dam breach analysis requires additional understanding of the behaviour of the tailings material, therefore the need for the reskilling and integration of water and tailings dam engineers with evolving software is required.

The GISTM dam classification has five classes of potential consequences (Low, Significant, High, Very High, and Extreme) while SANS 10286 has three classes (Low, Medium, and High).

SANS 10286 requires significant input and involvement from the Professional Engineer for dams with Medium and High hazard classifications. Therefore, there is a strong likelihood that if the current facilities are classified as either Medium or High they will satisfy most of the GISTM requirements.

It should be noted that most of the dams currently classified as Medium to High hazard (based on SANS 10286) will mostly likely fall within the High to Very High classification based on the GISTM. The significant contributors are noted in Table IV.

Investigations are ongoing around the world on tailings dam breach analysis, for example the work by Martin, Al-Mamun, and Small (2019), which might be adopted widely in the future.

One of the main contributors to the final dam classification is the number of people residing within the zone of influence. The illegal and sometimes legal occupation of the land within the zone of influence is a common occurrence in South Africa, and it is not always easy to execute eviction orders even on land owned by the mines themselves. The classification of the dam is likely to change with time if the influx of residents within the zone of influence is not controlled.

A high influx of people may also complicate the implementation of the Emergency Preparedness and Response plans, as per Requirement 13.2.

The mines will have to find creative ways of addressing this issue and must engage the services of experienced social specialists.

The mines, regulators, communities, and all other affected and interested parties must agree on acceptable levels of compliance on requirements related to the communities.

The zone of influence must be frequently monitored using technology and regular patrols to ensure that the mine is able to act in time to prevent the influx of people within the zone of influence.

Operational changes based on the GISTM consequence classification

The two design criteria affected by the GISTM consequence classification are:

> The flood design criteria

> The seismic design criteria.

The changes in the two design criteria have the potential to change the current freeboard requirements and may have other implications for the general factors of safety. These are discussed below.

Freeboard compliance

The current value used for flood design in South Africa is a 150-year, 24-hour storm event (2% annual exceedance probability) for all dam classifications. This storm event plus 800 mm of freeboard is used to determine the ongoing freeboard requirements during operations. The freeboard requirements are normally revised by the consulting engineers on a quarterly to yearly basis on most of the operations and are tracked monthly by the dam operator.

The GISTM requirements are shown in Table V. They are significantly stricter than the South African requirements and are based on the consequence classification of the individual dams.

On a few of our operations where the new requirements have been adopted, the general freeboard requirements as provided by the EORs have increased typically by 150 mm to 300 mm above the South African legal requirements. Although marginal, this has resulted in non-compliance on some facilities that are borderline with respect to freeboard.

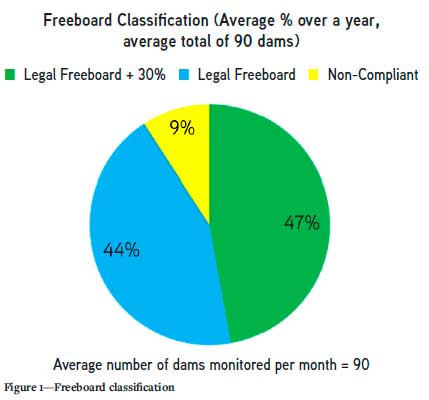

Figure 1 shows the distribution of the classification of the freeboard over the past year for the operations we are currently monitoring (90 dams) using our internal risk monitoring system (TORAS). Approximately 47% of the dams, which comply with the legal requirement plus our own additional 30% requirement, are not expected to experience any operational challenges with the new requirements.

However, it is expected that for some of the dams that fall within the TORAS legal freeboard status, the original deposition method may have to be revised in order to accommodate the new freeboard requirements, and this will affect most of the dams with the current low freeboard requirement, between 1 m and 1.5 m. On most of our cyclone operations, no changes will be required as they normally have a high freeboard.

Due to improvements in grinding technology and the reprocessing of tailings, most of the deposited tailings material is now finer and uniformly graded (i.e. comprises mainly particles of one size, as opposed to the original design assumption of 'well graded' with an even proportion of all size particles) This will result in flatter beaches, which affects the available freeboard.

The conversion of the deposition method will be required on some of the facilities. A few operations have already been converted from spigot dams to hybrid systems. The common hybrid system consists of mechanically built paddocks on the outside, which are filled with the tailings material using spigots. These operations are similar to a 'daywall' system. Deposition trials must be conducted before the conversion to determine feasibility, drying times, and deposition cycles.

Seismic loading

In South Africa there is no legislated minimum Operating Basis Earthquake (OBE) for tailings dam design because of the low seismic activity in the region. Most of the tailings dams in South Africa are located within the regions with a peak ground acceleration (PGA) of between 0.2 and 0.4 m2/s with a 10% chance of exceedance in 50 years (1 in 475 years return period). A PGA value of 0.05 χ gravitational acceleration, as proposed in the Chamber of Mines of Guidelines (1996), is often adopted for earthquake loading analysis. The application of the full PGA when conducting pseudo-static stability analysis often returns acceptable factors of safety.

With the new higher values stipulated by the GISTM, also shown in Table V, it is likely that when more detailed slope stability analyses are conducted (e.g., coupled stress-deformation stability analysis), some materials that are currently assumed to have drained shear strength may show weaker undrained shear strengths or potential liquefaction behaviour. The results of such analyses may require the mines to construct large buttresses around their tailings dams, which is extremely expensive. Therefore, it is important for the industry to understand how the new values are derived and what the impact of these values will have on the tailings dams. Detailed earthquake analyses for the tailings dams in South Africa have not been widely undertaken, and thus upskilling of the current consultants will be required in order to fulfil the Standard requirements.

It is important to note that with regard to existing tailings facilities, the Standard allows for the review of the applicability of these requirements. This review is to be completed by the EOR and the independent technical reviewers. The Accountable Executive must understand and accept the risks, if any, associated with not implementing or delaying the required changes.

It will be critical for the tailings industry to hold frequent workshops to share knowledge and tips with regard to handling and implementing these design criteria as these will be fairly new to most players. Knowledge must also be obtained from the mines and consulting engineers who have already implemented some of these criteria on their operations.

Addressing the GISTM brittle failure mode requirements

The GISTM requires that brittle failure modes be identified and addressed with conservative design criteria during the design phase of the tailings dam (Requirements 4.6. and 7.2; refer also to the definition of 'Robust design' in Annex 1 of the Standard).

For most of the operational dams in South Africa, the site and tailings characterization undertaken during the design did not include the identification of brittle materials within the foundation materials and the dam. There is little or no reference to potential liquefiable materials in the reports. This is changing rapidly as cone penetration testing with pore pressure dissipation (CPTu) testing is being carried out more often.

Although brittle failure is not explicitly addressed in most of the design reports, the generally conservative design approach adopted by South African engineers limits the rate of rise (ROR) of the daywall and spigot tailings dams to around 2 m/a, which ensures sufficient compaction and drying, thus increasing the strength of the outer wall.

The cyclone dams are able to accommodate a higher ROR as the consolidation of the underflow material takes place rapidly, provided the correct grading is achieved. The maximum ROR for these dams is limited to between 4 and 6 m/a.

This low ROR affords sufficient time for the tailings material to desiccate, consolidate, and remain at a dense state, which allows for dilation during shear, which in turn reduces pore pressures. Importantly this allows more material to be placed while still achieving the required factor of safety (FOS).

In addition to the low ROR, the designs include careful sizing and placing of the underdrains, especially the blanket and the toe drain, with the optimal positions and sizes generally 'understood' by the engineers. This, in combination with keeping the operational pool relatively small (usually less than 30% of the top surface), has ensured that the outer zone of the tailings dam remains in a drained state .

The introduction of stricter barrier system requirements in 2013 has meant that, for the newer dams, the brittle failure mode must be carefully considered, as the drainage regime is significantly different to the older dams. The regulation that required plastic lining of almost all tailings dams was withdrawn in 2018, and a risk-based approach was adopted instead.

In the context of South African operational facilities, it is possible to prove compliance to the GISTM requirement for reducing the probability of brittle failure by presenting evidence of the following:

> The low ROR, within the design limits, and the deposition plans that show sufficient time for material drying and consolidation

> Pool location, depth, and size

> The original design or as-built drawings showing the positions of the drains

> The drain flow readings, and associated maintenance (jet-rodding).

> Piezometer readings and associated maintenance (upset tests). Installation of the more accurate vibrating wire piezometers may be required for some facilities where issues already exist

> The tailings material testing results (CPTu testing is highly recommended), which indicate a dilatant rather than contractive response during shearing

> Installation of an appropriately designed buttress, where the FOS is below the new requirements

> The annual slope stability analysis, which takes into consideration all of the available information. These analyses require specialized skills, therefore third-party review (ITRB or a Senior Technical Reviewer) is required.

It is then critical for the operations to be run as per the design intent, and the documentation of the operations and associated investigations must be accurate and up to date. The critical elements from this report must be included into a Trigger Action Response Plan (TARP) and any deviation fromthe requirements must be attended to as soon as practically possible.

Updating of dam monitoring instrumentation

The monitoring instrumentation on most of the dams in South Africa is limited to standpipe piezometers, with the freeboard monitoring conducted using freeboard poles and occasional aerial survey, and drain flows measured manually once a month. The current dam instrumentation is not robust enough to satisfy the requirement of the Standard. With the new classifications and the need to increase transparency, it will be necessary to install electronic monitoring systems and, in some cases, real-time monitoring. It must be noted that with generally low RORs, the changes in the measurements do not vary rapidly, therefore the frequency of readings will have to be adjusted accordingly.

The general challenge globally is the availability of integrated platforms that are able to accommodate various instrument types, makes, and models. The selection of the platform must take this into consideration, and also the potential for integration with other systems at the mine.

There is a drive internationally to develop and introduce these systems specifically to the mining industry. Prices are expected to decrease as more mines adopt these systems, and the ICMM is looking at common systems that can be used by their member companies, as mentioned during the launch of the Protocols in May 21.

The integration of the various instruments is important to enable quicker analysis and correlations, to make decision-making quicker, and enable potential issues to be identified much earlier and more efficiently.

The instrumentation installation needs may differ from mine to mine, and the most practical implementation strategy must include the following:

> Completion of slope stability assessment to identify critical sections that will need immediate attention

> Installation of vibrating wire piezometers at critical areas, possibly followed by retrofitted piezometer probes (pressure transducers) on the rest of the standpipes (the annual upset tests will still be required to ensure continued satisfactory performance)

> The use of suitable slope movement technology, with InSAR used to track the movements for at least the previous two years.

Theft and vandalism is one of the biggest challenges on the tailings sites, therefore the design and installation must take this into consideration.

On most of the dams the information is currently dispersed, and environmental monitoring information has mostly been left out of the annual audits and quarterly reports. With the introduction of the GISTM this should form part of the normal reporting.

Information system implementation

The collection, storage, and transparency of information is critical and as such, information should be stored in a central database, which is easily accessible. This information should include life of facility documentation, records of meetings, policies, dam safety reports, ITRB reports, deviations reports, and emergency and preparedness plans. The transparency of information, to all key stakeholder and affected persons, is a fundamental process. Regular engagement must be conducted with parties that are impacted by the tailings facility and recorded. In the case of Very High or Extreme consequence facilities it is suggested that a representative of the relevant regulatory authority attends these engagements.

The information must be dealt with in accordance with the Protection of Personal Information Act (POPIA) or General Data Protection Act (GDPA).

The systems must be flexible to cater for the requirements of other standards and regulations that the facility still needs to comply with, e.g., the Cyanide Code.

Communication with interested and affected parties

It is unlikely that tailings facilities will be able to satisfy all the GISTM requirements within a short space of time, therefore it is important to prioritize the most important criteria, especially those related directly to the stability of the dam. The ultimate strategy and timelines for full compliance must be communicated to all interested and affected parties, e.g., insurers, financiers, and the local communities.

Conclusion

It is expected that most of the dams that currently comply with the South African regulations and standards will likely comply or partially comply with most of the GISTM requirements. In instances where they do not comply, with minimum FOS requirements, the construction of an appropriately designed buttress may be needed.

To ensure the success of the compliance process it is critical that a project be set up and appropriately qualified people be appointed. The Accountable Executive must be part of this team. The Accountable Executive is responsible for ensuring that the operations and designs conform to the principles of As Low As Responsibly Practicable (ALARP)

One of the main challenges in the South African context is the encroachment of residents within the zone of influence. Mines need to understand the impact of this on the overall consequence classification and need to carefully manage it.

Furthermore, the site laydown areas and offices are usually within the zone of influence, and the relocation of these facilities should be considered in order to lower the consequence classification and to minimize the number of potential casualties in the event of a failure.

The necessary EOR skills are available within South Africa, although due to the limited number of engineers they may be fulfilling the role of third-party reviewers. Additional training and upskilling might be needed for engineers to take on the role of RTFE.

There is sufficient technology available, although the gap between tailings engineers and software developers must still be bridged to enable the development of suitable tailings monitoring software. Relevant training must be obtained, or a co-creation methodology should be adopted.

We believe the new GISTM standards will greatly improve accountability and transparency between all key stakeholders and further minimize risk, although funds, resources, training, and software development must be considered.

Nomenclature

ALARP - As Low As Reasonably Practicable

CPTu - Cone penetrometer test (with pore pressure measurement)

DSR - Dam Safety Report

EOR - Engineer of Record

FOS - Factor of safety

GDPA - General Data Protection Act

GISTM - Global Industry Standard on Tailings Management

ICMM - International Council on Mining and Metals

InSAR - Interferometric synthetic aperture radar

ITRB - Independent Technical Review Board

MHSA - Mine Health and Safety Act

POPI - Protection of Personal Information Act

PRI - Principles for Responsible Investment

ROR - Rate of rise

RTFE - Responsible Tailings Facility Engineer

TARP - Trigger Action Response Plan

TMS - Total Management System

TORAS - Technical and Operations Risk Assessment System

UNEP - United Nations Environment Programme

References

Campbell, R., Hussain, T., Wright, O., Voulaz, S., and Infante, F. 2019, Comparative analysis of tailings-related legislation in key mining jurisdictions. Towards Zero Harm - A Compendium of Papers Prepared for the Global Tailings Review. https://globaltailingsreview.org/wp-content/uploads/2020/09/Ch-XXIII-Comparative-Analysis-of-Tailings-related-Legislation-in-Key-Mining-Jurisdictions.pdf [accessed: 13 June 2021]. [ Links ]

Chamber of Mines of South Africa. 1996. Guidelines for environmental protection, the engineering design, operation and closure of metalliferous, diamond and coal residue deposits. Johannesburg. [ Links ]

ICMM. 2020. Global industry Standard on Tailings Management. International Council on Mining and Metals, London. [ Links ]

ICMM. 2021a. Global Conformance Protocols: Global Standards on Tailings Management. International Council on Mining and Metals, London. [ Links ]

ICMM. 2021b. Tailings Management, Good Practice Guidelines. International Council on Mining and Metals, London. [ Links ]

Martin, V., Al-Mamun, M., and Small, A. 2019. CDA technical bulletin on tailings dam breach analyses. https://knightpiesold.com/sites/en/assets/File/ICOLD%202019%20-%20CDA%20Tailings%20Dam%20Breach.pdf [accessed 10 June 2021]. [ Links ]

SABS. 1998. SANS 10286. Code of Practice for Mine Residue Deposits. South African Bureau of Standards, Pretoria. [ Links ]

Correspondence:

Correspondence:

S. Ramsamy

Email: shaunr@fraseralexander.co.za

Received: 2 Nov. 2022

Revised: 19 May 2022

Accepted: 19 May 2022

Published: June 2022