Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.122 n.5 Johannesburg May. 2022

http://dx.doi.org/10.17159/2411-9717/1728/2022

PROFESSIONAL TECHNICAL AND SCIENTIFIC PAPERS

Assessment of vibration exposure of mine machinery operators at three different open-pit coal mines

A. Tekin

Department of Machinery and Metal Technology, Soma Vocational School, Manisa Celal Bayar University, Turkey

SYNOPSIS

In almost all branches of industry, machinery and equipment in operation cause vibration. Some sources of vibration affect only the operator's hands, fingers, and arms, while others have adverse effects on the entire -body. Various types and numbers of machines are utilized in the mining sector, and operators with them are exposed to mechanical vibrations caused by the mining machinery they use. A field study was conducted to evaluate the vibration risks to the operators using mining machines in open pit mines. Vibration levels and whole-body vibration (WBV) measurements using various types brands, and models of construction equipment were evaluated in three different mines in the west of Turkey and compared to the the criteria specified in the EU 2002/44/EC directive and ISO 2631-1 (1997) standards. The results showed that operators using mining machinery for 8 hours were exposed to WBV levels below the EU limit (1.15 m/s2), while 44% of these operators were exposed to levels above the EU action limit (0.5 m/s2). Measurement data collected from the working environment and the recommended improvements that need to be made to reduce WBV exposures are presented.

Keywords: health and safety, machine operators, open-pit mines, whole-body vibration (WBV), machine vibration.

Introduction

Technological developments in recent years have led to the use of larger, more complex, and more expensive equipment in the mining sector. The constantly changing ambient conditions, as well as different geological and climatic situations during mining activities, adversely affect the employees, as well as the operators who use open-pit mine machinery, who are subjected to mechanical vibrations in the working environment. Various researches (Cann, Salmoni, and Eger, 2004; Kumar, 2004; Aye and Heyns, 2011; Mandal, Pal, and Sishodiya, 2013; Akinnuli et al., 2018) have found that high levels of whole-body vibration (WBV) exposure are experienced by workers in the mining and construction sectors (European Union 2002/44/EC, 2002). Operators exposed to vibration experience effects such as interference with activities, impaired health, and discomfort (Griffin, 1994).

Numerous standards have been introduced to provide procedures for the evaluation of WBV and shock. At the operator's seat interface, measuring and assessing the WBV of a seated driver of mobile equipment is mostly performed according to the International Organization for Standardization report (ISO 2631-1); this is also mandated for use across Europe (Directive 2002/44/EC). British Standard Institution (BS 6841, 1987) is also widely used across the world. Both ISO 2631-1 and BS 6841 use methods based on calculations of an overall dose value from measurements of acceleration at the input to the whole body. These two standards are generally applicable to and designed to be used for a wide range of environments in which people are exposed to WBV. The ISO 5805 (1997) standard is specifically designed to evaluate exposure to mechanical shock only. ISO 2631-1 (1997) describes assessments of WBV risk based on measurements of the frequency-weighted root mean square (RMS) acceleration in the most severe axis and the time of exposure (Rantaharju et al., 2015). In the ISO 2631-5 standard, exposure is determined using shocks, age, and work experience of the employee.

There are several studies available in which health hazards related to WBV are predicted in accordance with the methodologies introduced in ISO 2631-5 and ISO 2631-1. Aye (2009) attempted to identify health risks from various items of mining machinery according to ISO 2631-1 (1997) and ISO 2631-5 (2004) for determination of WBV exposure. Smets, Eger, and Grenier (2010) measured WBV induced by three different types of 35, 50, and 150 t trucks through the operator's seat during one hour according to the ISO 2631-1 and ISO 2631-5 standards. They stated that the operators are exposed to vibrations above the daily exposure value but the probable health effect is low according to the ISO 2631-1 limits, and that there is some inconsistency between the two standards. Gryllias et al. (2016) compared health effects based on ISO 5349:2001, ISO 2631-1:1997, and ISO 2631-5:2004 standards for both whole body and hand-arm vibrations. Eger et al. (2008a) compared the health risks predicted by ISO 2631-1 and ISO 2631-5 criteria on load-haul-dump (LHD) machine operators and found that ISO 2631-1 consistently predicted higher health risks. In another study, Eger et al. (2008b) measured pressure, neck loads, and joint rotations of operators performing LHD and investigated the effect of operator work postures on the musculoskeletal system during working hours when exposed to vibration. Marin et al. (2017) described WBV exposures in a series of vehicles operating in open-pit mines. Three different daily exposure parameters were compared according to the ISO 2631-1:1997 and ISO 2631-5:2004 standards. Hoz-Torres et al. (2019) analysed WBV transmitted to agricultural tractor drivers by comparing ISO 2631-1 and ISO 2631-5 standards. They emphasised that both standards provide similar assessments and stated that the probability of adverse health effects is low.

Thousands of workers in the open-pit mining sector are exposed to WBV on a daily basis (Eger et al., 2006, 2008a; Smets, Eger, and Grenier, 2010; Chaudhary, Bhattacherjee, and Patra, 2015). Factors causing WBV are vehicle activity, engine vibration, and uneven roads (McPhee, Foster, and Long, 2009). Another important factor is the frequent and intensive use of open-pit mining equipment (OPME) over a long period of time (Griffin, 1994). Kumar (2004) stated that WBV exposure levels of drivers operating different open-pit trucks, recorded along the x-, y-, and z-axes, exceeded the threshold values according to ISO 2631-1. Hagberg et al. (2006) investigated vibrations of machines operated in Sweden between 1999 and 2003, and found a strong relationship between WBV-induced back pain and spinal degeneration.

Mandal and Srivastava (2010) investigated WBV exposure among dump truck operators in a coal mine in India, and observed that the vibration value varied from 0.644 m/s2 to 1.82 m/s2 in terms of the dominant z-axis RMS acceleration value. They found that all dumper vehicles carried a high health risk according to ISO 2631-1 standards. Aye and Heyns (2011) conducted measurements using the methods and parameters given in ISO 2631-1 to determine the WBV level of operators on 34 different machines used in open-pit mines in South Africa. They foud that 95% of the machines assessed caused a vibration below the exposure limit value, and 50% caused vibration exceeding the effective value of the exposure. On the other hand, human vibration exposures were investigated for mine/quarry transport trucks during loading, handling and unloading activities (Mayton et al. (2018). Erdem, Dogan, and Duran (2020) analysed WBV exposure measurements taken from the driver's seat in 105 trucks of different types, brands, and models deployed in various open pits and an underground mining operation in Turkey. Chaudhary et al. (2019) investigated the relationship between exposure to WBV and occupational and personal factors among 39 drilling operators in Indian iron ore mines. They found that 70% of the operators were exposed to high levels of vibration, above the limit values recommended by ISO 2631-1. Sharma et al. (2020) conducted an extensive literature review and revealed the known harmful health effects of short- and long-term WBV exposure for operators of heavy earthmoving machinery (HEMM) operators in open pit mining.

In this study, we investigated vibration exposures of heavy-duty machine operators in open-pit mines and the precautions that can be taken to mitigate the severity thereof. We first present general information on the measurement methods, followed by the results of WBV exposure measurements for operators of heavy-duty machines at three different mines in the west of Turkey. Finally, directions for for further work to reduce the vibration exposures of machine operators to below the legal exposure limits are recommended.

Methods

Location of vibration measurements and features of machines

Vibration measurements were taken from three separate coal mine sites in western Turkey (Figure 1). All three mines operate with a fleet of approximately 200 and a large number of earthmovers, mobile mining equipment, and vehicles. Briefly, open-pit mining entails loosening of the overburden by drilling and blasting; extraction of coal from the seams by bulldozers, front end loaders, and wheel dozers; loading the coal with hydraulic or electric excavators; transport to the unloading area by 85 and 170 t trucks; and lightly spraying the road surfaces with water trucks to minimize dust. The machine types and operations from which WBV measurements were taken are shown in Figure 2.

The machines that regularly move on unpaved and uneven surfaces consist of 41 different brands and models, including earthmoving trucks, hydraulic excavators, crawler dozers, graders, and hydraulic hammer drills. The distribution and technical specifications of the machines from which measurements were taken in this study are given in Table I.

WBV measurements

Before any WBV exposure measurements were made, information such as the duration of the work, the sources causing the exposure, action steps affecting the work done, the exposure time, and the status of the workstation were recorded. Machine operators work 6 days a week, 8 hours a day. Before the operators start work, they first undergo an entrance examination. A health file is prepared for each employee, and employees undergo a health screening every year. In addition, 16 hours of occupational health and safety trainings are given to the operators every year. During this training, the subject of vibration is explained.

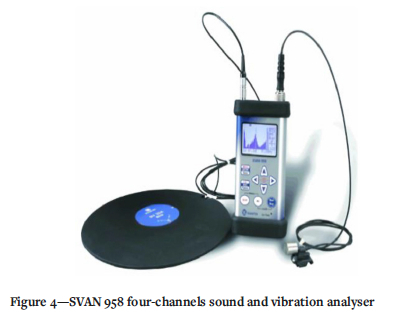

An accelerometer attached to an electronic instrument is used to detect and measure vibrations, and to analyse and store vibration data. For this purpose, a SVAN 958 model triaxial noise-vibration measuring device was used for WBV measurements on operators using trucks, dozers, drills, graders and excavators (Figure 3). Records of vibration measurements were easily downloaded to a PC with SvanPC++ software via USB port. In addition, with the SvanPC++_RC remote communication software, device settings and data are easily accessed remotely from the internet (Figure 4).

Direction of vibration measurements

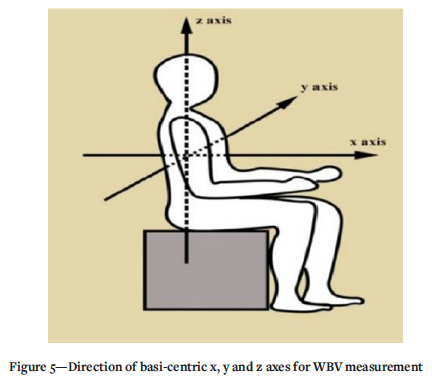

There are many sources of vibration in the mining industry that are encountered all phases of a mining operation. The impact on human health depends on the transmission characteristics of the vibration from the movement of the various parts of the machinery to the operator's seat, and depends on the working time, sitting position, seating arrangement, and road conditions. The vibration value in each of these stages is different. Also, depending on whether the operators are standing or sitting, vibration can act on the body along the x-, y-, or z-axis. Vibration on employees was measured in all three axes (WBV measurements) in accordance with the principles specified in the TS ISO 2631-1 standard. The measurement device was fixed to the operator's seat cushion and each operator was briefed about the purpose of the measurement. The transducer was positioned so as to point in the x-dimension (back to chest), y-transverse (left to right), and z-vertical (seat to head position) (Figure 5).

Evaluation of WBV exposure

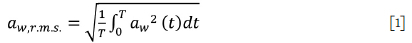

Vibration analysis for WBV is calculated according to the formulae in the ISO 2631-1 (1997) standard. For each of these measurements, all frequency-weighted root mean square (WRMS) values in the x-, y-, and z-axes were calculated separately for each vehicle using Equation [1].

where

aw (t) = WRMS acceleration at a particular time

t (m/s2) T = Duration of measurement (seconds)

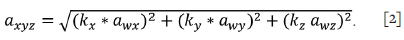

The individual RMS values of the accelerations measured along the x, y, and z directions by the precision vibration meter are represented by awx, awy, and awz, respectively. For triaxial measurements (Figure 5), the peak accelerations (maximum instantaneous acceleration during the measurement period) are also calculated together with the WRMS vector sum value (Equation [2]).

Since the risk of damage differs along the three axes, WRMS accelerations (aw;, a; aw) are calculated using appropriate weighting factors defined in ISO 2631-1 (k = 1.4 for x-axis and y-axis, k = 1.0 for z-axis).

The value of A(8) is found using Equation [3].

The A(8) value is calculated using the daily exposure times (ζ) of each phase, the WRMS vibration associated with each phase (awn), the N number , and the estimated daily exposure equivalent to an 8-hour continuous exposure level. The calculated values were used to ascertain the potential health risk to workers using the health guidance caution zone (HGCZ) consistent with Annex B of the ISO 2631-1 standard (ISO 2631,1-1997).

Results

Effects of vibration on the human body

Vibration affects the human body in many ways. The response to vibration exposure depends primarily on the frequency, amplitude, and duration of exposure. Other factors include the direction of vibration input, body mass, level of fatigue, and ground conditions. Humans can respond both mechanically and physiologically to vibration.

The measured vibration values are compared with the ISO 2631-1 HGCZ to determine the recommended exposure times (Figure 6).

The frequency-weighted acceleration values corresponding to the 8 hours exposure time HGCZ low (attention) and high (risk) limits are 0.45 m/s2 and 0.90 m/s2 respectively according to ISO 2631-1 (Table II). On the other hand, A(8) daily exposure action and the daily exposure threshold values of ISO 2631-1 are 0.5 m/s2 and 1.15 m/s2 respectively.

Vibration analysis

WRMS acceleration values of the data along three vibration axes of each operator group of the mining machines at mines A, B, and C are presented in Table III. At every stage of the work cycle (dozing or digging, loading, hauling, and unloading) the working machines transmit vibrations to the operators continuously. Operators were regularly exposed to WBV levels that exceed safety limits as dictated by the ISO 2631-1 standard. The highest WBV exposure levels were found among dozer operators, because they work on the roughest surfaces in the open-pit mine. Excavator operators were exposed the lowest vibration levels. Operators of different brands, models and capacity mine machinery were exposed to changing WBV levels between 0.11 and 1.24 m/s2 in terms of RMS. Variations in measurement amplitudes were recorded for the same type of mining machine operating at the same environment. The daily WBV exposures of operators were recorded over periods ranging from 1 to 5 hours. As can be seen in Table III, operatore are mostly exposed to WBV in vertical direction (z).

As it can be seen in Figure 6, the prediction of health risk from exposure to vibration generated with equipment primarily depends on two factors: vibration magnitude along the dominant axis and duration of exposure in a day.

The average values (A(8)) and standard deviation of minimum and maximum daily WBV exposures of mining operators are summarized in Table IV. In addition, the health risks based on precaution and risk thresholds are specified as percentages for all machines according to the ISO 2631-1 standard and the EU 2002/44 / EC directive. It can be seen in Table IV and Figure 7 that all machine operators are exposed to WBV under the daily exposure limit value of 1.15 m/s2, predominantly.

The measured WBV values were compared with the HGCZ to determine the recommended exposure times for operators using the mining machines. Of the 41 machines, 20 caused vibration below the caution zone, 20 of them were within the HGCZ, and one was above the threshold value. On the other hand, when the results were compared with of the European directive were evaluated ; 23 operators' WBV values were below the effective exposure value and 18 operators were exposed to vibration between the effective exposure value and the limit value. Since the excavators and the drills mostly generate vibration accelerations below the exposure action value (0.5 m/s2) the risk can be tolerated except for hypersensitive operators. Trucks, dozers, and graders produce vibrations somewhere between the exposure action and the threshold value and extra efforts should be made to reduce the risk for these machines. According to Figure 7, the dozer operators at the B open-pit area were exposed to higher WBV levels, while the excavator operators working at the C open-pit area were exposed to the lowest WBV levels. Since the terrain in open-pit mining locations changes constantly, factors such as operator experience, irregular and/or rough terrain, intensity of work, exposure time, and even tyre pressure of mining machinery affect WBV levels.

Discussion

Numerous studies are under way to ensure that open-pit mining machinery is operated with the highest possible efficiency and performance. Operators using these machines may be exposed to long-term high WBV levels that can affect their health. The operator's vibration exposure level depends on several factors, such as the magnitude of the vibration, the duration of exposure, total working hours, terrain conditions, mobility, and machine type and maintenance. Therefore, when a machine is classified as safe as regards WBV levels under certain operating conditions, it can pose a threat to human health in different operating conditions. This study reveals the role of WBV in the analysis of such problems.

For this purpose, WBV levels generated by various types and models of 41 heavy mining machines located at three different open-pit mines in the west of Turkey were studied in accordance with the criteria of ISO 2631-1 standards and EU directive 2002/44/ EC. The mining machines are mainly trucks, dozers, drills, graders, and excavators. The following results were obtained from the study.

According to the ISO 2631-1 standards, all operators using open-pit mine working machines are exposed to vibrations below the EU exposure limit of 1.15 m/s2, while 44% of these operators are exposed to WBV levels exceeding the threshold value. Forty-nine per cent of the operators are exposed to WBV levels in the range of 0.45-0.90 m/s2, which is within the HGCZ of the vibration levels, apart from a dozer operator at mine B, who was exposed to WBV levels above the acceptable limits.

The results are supported by previous studies. In a study of six different track loaders at four different workplaces (Newell, Mansfield and Notini, 2006), it was observed that the most severe general frequency-weighted RMS vibration magnitude, that is, the emission value, was 1.12 m/s2. Burström et al. (2016) studied 95 mining vehicles of different models and capacities, and showed that the daily average vibration exposure was between 1.9 and 6.7 hours, and the average A(8) value was between 0.2 and 1.0 m/s2. Mandal, Pal, and Sishodiya (2013) observed that the daily vibration exposure times (2-7.5 hours) and vibration levels of 157 items of mining equipment in ten open pit mines varied between 0.21 and 1.82 m/s2.

High levels of vibration exposure may result from the operation of such machines on uneven floors. However, environmental conditions such as cold and snow in winter and heat in summer affect road and surface conditions in open pit mines, which are known to be critical for WBV exposure (Wolfgang, 2014). So vibration from rough roads and bad roads can be alleviated by implementing a good road maintenance plan, and can also be reduced by providing suspension cabins, and ensuring that tyre are inflated to the correct pressures and shock absorbers are in good condition. Many researchers on this subject have made similar suggestions (Chaudhary et al, 2019; Marin et al, 2017).

Conclusions and recommendations

This study was conducted to examine the exposure of operators of various types and models of construction equipment at open pit mining sites to whole-body vibration (WBV). The results indicate that operators are frequently exposed to WBV levels in the vertical direction that are within or above the HGCZ as defined by ISO 2631-1 standards and EU directive 2002/44/EC. Therefore, it is important to examine the impact of vibration on operators in open pit mine sites, and to collect information that will help design better working conditions that will improve the health of the operators and the efficiency of their work.

The following actions are recommended to avoid vibrations above allowable levels for operators.

Terrain conditions, speed, seat status, vehicle maintenance, etc. Many factors can affect the vibration of work machines. Therefore, a machine classified as safe in one working environment may pose a threat to human health in another. Since mining is characteristically a constantly changing process, periodic maintenance plans for all these machines, regular checking of tyre pressures and moving parts of the machine, and good maintenance of haul roads can contribute to reducing the health risk caused by vibration.

Since the effect of RMS acceleration values on the z-axis is greater than the x-longitudinal and y-transverse axes, risk assessments should be done especially by measuring vertical vibration values in order to prevent adverse effects on health and work performance. Previous studies confirm that Aw WBV exposures are dominant (z-axis) (Kumar, 2004; Eger et al., 2006, 2008; Smets et al., 2010; Chaudhary, 2015; Burgess-Limerick and Lynas, 2016). Vibration in the z-axis direction is accepted as the most critical aspect for low back pain in drivers (Rehn et al., 2005).

Regular health monitoring is recommended for all operators exposed to vibration in mines. Occupational exposure to WBV from operating these vehicles is a significant risk for vehicle drivers' low back pain (Burström et al, 2016). Musculoskeletal pain is more pronounced in groups of miners exposed to WBV compared to unexposed groups (Mandal et al, 2010; Skandfer et al, 2014).

Operator competence also affects WBV acceleration levels due to the use of operating machines. For that reason, operators should be trained on a regular basis by expert trainers on how to minimize vibration levels during operations, especially on uneven ground.

As a result, vibration risk assessment is necessary in open-pit mining operations and more focus must be addressed to implementing preventive measures to reduce vibration risks significantly.

References

Akinnüli, B.O., Dahünsi, O.A., Ayödeji, S.P., and Bödünde, O.P. 2018. Whole-body vibration exposure on earthmoving equipment operators in construction industries. Cogent Engineering, vol. 5, no. 1. pp. 1-14. https://www.tandfonline.com/loi/oaen20 [ Links ]

Aye, S.A. 2009. Evaluation of operator whole-body vibration and shock exposure in a South African open cast mine. MSc thesis. Faculty of Engineering, Built Environment and Information Technology, University of Pretoria. 140 pp. [ Links ]

Aye, S.A. and Heyns, P.S. 2011. The evaluation of whole-body vibration in a South African opencast mine. Journal of the Southern African Institute of Mining and Metallurgy, vol. 111, no. 11. pp. 751-757. https://repository.up.ac.za/bitstream/handle/2263/18670/Aye_Evaluation%2820 11%29.pdf?sequence=1&isAllowed=y [ Links ]

British Standards. 1987. Measurement and evaluation of human exposure to whole-body mechanical vibration and repeated shock. BS 6841. British Standards Institution, London. [ Links ]

Burgess-Limerick, R. and Lynas, D. 2016. Long duration measurements of whole-body vibration exposures associated with surface coal mining equipment compared to previous short-duration measurements. Journal of Occupational and Environmental Hygiene, vol. 13, no. 5. pp. 339-345. https://www.tandfonline.com/loi/uoeh20 [ Links ]

Burström, L., Hyvarinen, V., Johnsen, M., and Pettersson, H. 2016. Exposure to whole-body vibration in open-cast mines in the Barents region. International Journal of Circumpolar Health, vol. 75, no: 29373. https://dx.doi.org/10.3402%2Fijch.v75.29373 [ Links ]

Cann, A., Salmoni, A., and Eger, T. 2004. Predictors of whole body vibration exposure in transport truck operators. Ergonomics, vol. 47, no. 13. pp. 1432-1453. https://doi.org/10.1080/00140130410001712618 [ Links ]

Chaudhary, D.K., Bhattacherjee, A., Patra, A.K. and Chau, N. 2015. Whole-body vibration exposure of drill operators in iron ore mines ,and role of machine-related, individual, and rock-related factors. Safety and Health at Work, vol. 6. pp. 268-278. [ Links ]

Chaudhary, D.K., Bhattacherjee, A., and Patra, A. 2015. Analysis of whole-body vibration exposure of drill machine operators in open pit iron ore mines. Procedia Earth and Planetary Science, vol. 11. pp. 524-530. https://doi.org/10.1016/j.proeps.2015.06.054 [ Links ]

Chaudhary, D.K., Bhattacherjee, A., Patra, A.K., Upadhyay, R., and Chau, N. 2019. Associations between whole-body vibration exposure and occupational and personal factors in drill operators in indian iron ore mines. Mining, Metallurgy & Exploration, vol. 36. pp. 495-511. https://doi.org/10.1007/s42461-019-0061-y [ Links ]

Eger, T., Salmoni, A., Cann, A., and Jack, R. 2006. Whole-body vibration exposure experienced by mining equipment operators. Occupational Ergonomics, vol. 6, no. 3-4. pp. 121-27. [ Links ]

Eger, T., Stevenson, J., Boileau, P-E., Salmoni, A., and VibRG. 2008 . Predictions of health risks associated with the operation of load-haul-dump mining vehicles: Part 1 - Analysis of Whole-Body Vibration Exposure Using ISO 2631-1 and ISO 2631-5 Standards. International Journal of Industrial Ergonomics, vol. 38, no. 9-10. pp. 726-738. https://doi.org/10.1016/j.ergon.2007.08.012 [ Links ]

Eger, T., Stevenson, J., Callaghan, J.P., Grenier, S., and VibRG1. 2008 . Predictions of health risks associated with the operation of load-haul-dump mining vehicles: Part 2-Evaluation of operator driving postures and associated postural loading. International Journal of Industrial Ergonomics, vol. 38, no. 9-10. pp. 801-815. https://doi.org/10.1016/j.ergon.2007.08.012 [ Links ]

Erdem, B., Dogan, T., and Duran, Z. 2020. Assessment of whole-body vibration exposure of mining truck drivers. Journal of the Southern African Institute of Mining and Metallurgy. vol. 120, no. 9. pp. 547-559. http://dx.doi.org/10.17159/2411-9717/1146/2020, [ Links ]

EU. 2002. European Parliament and Council Directive, 2002/44/EC on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (vibration) (sixteenth individual Directive within the meaning of Article 16(1) of Directive 89/391/EEC. Official Journal of the European Communities. 177 pp. [ Links ]

Griffin, M.J. 1990. Handbook of Human Vibration. Academic Press, San Diego, CA. [ Links ]

Gryllias, K., Yiakopoulos, C., Karamolegkou, S., and Antoniadis, I. 2016. Human-body vibration exposure experienced by tram drivers - An evaluation according to ISO standards & European directives. Proceedings of the 23rd International Congress on Sound & Vibration, Athens, Greece, 10-14 July. International Institute of Acoustics, Aiburn, AL. [ Links ]

Hagberg, M., Burström, L., Ekman, A., and Vilhelmsson, R. 2006. The association between whole body vibration exposure and musculoskeletal disorders in the Swedish work force is confounded by lifting and posture. Journal of Sound and Vibration, vol. 298, no. 3. pp. 492-498. [ Links ]

Hoz-Torres, M.L., Aguilar-Aguilera, A.J., Martínez-Aires, M.D., and Ruiz, D.P. 2019. A Comparison of ISO 2631-5:2004 and ISO 2631-5:2018. Standards for whole-body vibrations exposure: A case study. Occupational and Environmental Safety and Health. https://doi.org/10.1007/978-3-030-14730-3. [ Links ]

ISO 2631-1. 1997. Evaluation of Human Exposure to Whole-Body Vibration - Part 1: General Requirements, ISO Standard Handbook (1995): Mechanical Vibration and Shock, Volume 2: Human Exposure to Vibration and shock; Vibration in Relation to Vehicle, Specific Equipment and Machines, Buildings. 2nd edn. International Organization for Standardization, Geneva. pp. 1-31. [ Links ]

ISO 5805. 1997. Mechanical Vibration and Shock - Human Exposure - Vocabulary. International Organization for Standardization, Geneva. [ Links ]

Kumar, S. 2004. Vibration in operating heavy haul trucks in overburden mining. Applied Ergonomics, vol. 35, no. 6. pp. 509-520. https://doi.org/10.1016/j.apergo.2004.06.009 [ Links ]

Mandal, B.B. and Srivastava, A.K. 2010. Musculoskeletal disorders in dumper operators exposed to whole body vibration at Indian mines. International Journal of Mining, Reclamation and Environment, vol. 24, no. 3. pp. 233-243. [ Links ]

Mandal, B.B., Pal, A.K., and Sishodiya, P.K. 2013. Vibration characteristics of mining equipment used in Indian mines and their vibration hazard potential. International Journal of Environmental Health Engineering, vol. 2, no. 4. pp. 1-10. [ Links ]

Marin, L.S., Andres, C.R., Estefany, R., Hugo, P., Lope, H.B., Jack, T.D., and Peter, W.J. 2017. Assessment of whole-body vibration exposure in mining earth-moving equipment and other vehicles used in surface mining. Annals of Work Exposures and Health, vol. 61, no. 6. pp. 669-680. [ Links ]

Mayton, A.G., Porter, W.L., Xueyan, S.X., Weston, E.B., and Rubenstein, E.N. 2018. Investigation of human body vibration exposures on haul trucks operating at U.S. surface mines/quarries relative to haul truck activity. International Journal of Industrial Ergonomics, vol. 64. pp. 188-198. https://doi.org/10.1016/j.ergon.2017.05.007 [ Links ]

McPhee, B., Foster, G., and Long, A. 2009. Bad Vibrations: A Handbook on Whole-Body Vibration Exposure in Mining: The Joint Coal Board Health and Safety Trust, Sydney, Australia. [ Links ]

Newell, G.S., Mansfield, N.J., and Notini, L. 2006. Inter-cycle variation in whole-body vibration exposures of operators driving track-type loader machines. Journal of Sound and Vibration, vol. 298, no. 3. pp. 563-579. https://doi.org/10.1016/j.jsv.2006.06.015 [ Links ]

Rantaharju, T., Mansfield, N.J., Ala-Hiiro, J.M., and Gunston, T.P. 2015. Predicting the health risks related to whole-body vibration and shock: A comparison of alternative assessment methods for high-acceleration events in vehicles. Ergonomics, vol. 58, no. 7. pp. 1071-1087. [ Links ]

Rehn, B., Nilsson, T., Olofsson, B., and Lundstrom, R. 2005. Whole-body vibration exposure and non-neutral neck postures during occupational use of all-terrain vehicles. Annals of Occupational Hygiene, vol. 49, no. 3. pp. 267-75. doi:10.1093/annhyg/meh077 [ Links ]

Sharma, A.S., Mandal, S.K., Suresh, G., Oraon, S., and Kumbhakar, D. 2020. Whole body vibration exposure and its effects on heavy earthmoving machinery (HEMM) operators of opencast mines - A review. Journal of Mines, Metals and Fuels, vol. 68, no. 7. pp. 221-228. [ Links ]

Skandfer, M., Talykova, L., Brenn, T., Nilsson, T., and Vaktskjold, A. 2014. Low back pain among mineworkers in relation to driving, cold environment and ergonomics. Ergonomics, vol. 57. pp. 1541-8. https://www.tandfonline.com/loi/terg20 [ Links ]

Smets, M.P.H., Eger, T.R., and Grenier, S.G. 2010. Whole-body vibration experienced by haulage truck operators in surface mining operations: A comparison of various analysis methods utilized in the prediction of health risks. Applied Ergonomics, vol. 41, no. 6. pp. 763-770. https://doi.org/10.1016/j.apergo.2010.01.002 [ Links ]

Tekin, A. 2020. Noise exposure estimation of surface-mine - Heavy equipment operators using artificial neural networks. Celal Bayar University Journal of Science, vol. 16, no. 4. pp. 429-436. [ Links ]

Turkish Standard - International Organization for Standardization [TS-ISO]. Mechanical vibration and shock - Assessment of exposure to whole body vibration - Part 1: General rules. TS ISO 2631-1:2013. Ankara. 37 pp. [ Links ]

Wolfgang, R. and Burgess-Limerick, R. 2014. Whole-body vibration exposure of haul truck drivers at a surface coalmine. Applied Ergonomics, vol. 45. pp. 1700-1704. [ Links ] ♦

Correspondence:

Correspondence:

A. Tekin

Email: ayla.tekin@cbu.edu.tr

Received: 2 Jul. 2021

Revised: 5 Jan. 2022

Accepted: 24 Jan. 2022

Published: May 2022

ORCID: A. Tekin https://orcid.org/0000-0002-2547-0872

1 'Vibration Research Group, Laurentian University, IRSST, Queen's University, University of Western Ontario, MASHA and CSAO, Canada