Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.122 no.5 Johannesburg Mai. 2022

http://dx.doi.org/10.17159/2411-9717/1738/2022

PROFESSIONAL TECHNICAL AND SCIENTIFIC PAPERS

Overview of mine rescue approaches for underground coal fires: A South African perspective

M. OnifadeI, II; B. GencII; K.O. SaidIII; M. FourieIV; P.O. AkinseyeII

IDepartment of Mining and Metallurgical Engineering, University of Namibia, Namibia

IISchool of Mining Engineering, University of the Witwatersrand, Johannesburg, South Africa

IIIMining and Mineral Processing Engineering Department, Taita Taveta University, Voi, Kenya

IVMines Rescue Services - SA, Carletonville, South Africa

SYNOPSIS

Coal is mined by both surface and underground methods and its extraction is normally characterized by numerous hazards that can lead to catastrophic accidents, which result in devastating effects such as injuries or fatalities, damage to mining assets, and destruction of mineral resources. These hazards exist due to the ability of coal to support combustion and its association with toxic, flammable, and explosive gases. Underground coal mining entails higher safety risks than opencast coal mining, chiefly because of issues relating to mine ventilation and mine collapse. Furthermore, coal mine collapses mostly occur due to crumbling of mining supports, especially in room and pillar mining systems. To avoid such adverse occurrences, safety management systems need to be in place. This study reviews the various technological safety systems and principles that are used for safe-rescue and self-escape of miners in underground coal fires, particularly in South Africa, using data obtained from Mines Rescue Services in Carltonville, South Africa. The outcome of the review shows that practising safety culture has been given priority across many South African underground coal mines through setting up safety management systems and encouraging workers to stay committed to safety principles.

Keywords: mine rescue, self-escape, underground coal fires, toxic gases, coal mining.

Introduction

The success of any industry is measured not only by its production capacity, but also the ability to conduct operations in a sustainable and safe manner. The maintenance of safe operations requires continuous, accurate identification of hazards, correct evaluation of related risks, and the application of an appropriate treatment thereof in order to eliminate the chances of accidents occurring. It is generally widely accepted within industries that various risk assessment methods aid in ensuring the safety of complex operations and equipment use. There is a statutory provision in many industries for risk assessment of all dangerous structures, machinery, and facilities, considering the methods used for production, repair, supervision and management (Tripathy and Ala, 2018). This is most important in the mining industry as the operations are characterized by significant risks that can compromise the health and safety of miners. Keen attention is required from the workers as the hazards in any mining environment can be extremely harmful due to the sophisticated machinery and equipment used (Zhou et al., 2018). While external safety agents are normally used in many other industries, the coal mining industry requires in-house safety personnel, commitment, practises, and culture, which should be promoted on a daily basis by the workers.

In the mining business, safety has been a major concern for decades, especially in underground mining. Although today's mining is significantly safer than in previous decades, there are still mining accidents. Underground coal mining has traditionally posed some of the greatest risks for the health and safety of the workers (Graber et al., 2014). However, this situation has been greatly improved due to frequent safety training exercises conducted to educate the workers about the relevance of occupational health and safety. In some countries, the regulatory emphasis has followed a commitment to hazard identification, risk evaluation, treatment, and regulation, while in others a prescriptive approach prevails, and yet in other places, there is a lack of national safety and health legislation.

Ventilation is the greatest hurdle that compromises safety in underground coal mines. Poor ventilation design exposes miners to harmful gases, heat, and dust that can harm them by affecting their respiratory systems. The quantity of harmful gases and airborne contaminants in underground spaces can be reduced by diluting them, capturing them before reaching the air host stream, or by isolating the environment through seals and stoppings (National Institute for Occupational Safety and Health (NIOSH), 2015). Coal dust explosions in coal mines are normally caused by methane ignition. Mining equipment can produce sparks that are capable of igniting accumulated methane gas in coal mines.

Over time, many major incidents have been averted or ameliorated by the self-escape of miners from dangerous environments. Self-escaping has been facilitated by using various aids. Currently, the passive self-escape techniques being used comprise signs, markers for indicating primary and secondary escape routes, as well as lifelines. More safety tools to help in self-escaping in the dark, such as safety canes for locating mine ribs and handheld laser pointers, have also been examined. Lifelines are important in underground coal mines to aid self-escaping miners by directing them to the escape routes.

The physical and geological complexities of underground coal mines, together with mineworkers' poor understanding of the underground structures or workings, could damage the environmental and operational resources of the mines. Despite the accurate mineral exploration technologies that are used to locate minerals, unexpected geological structures remain a critical hazard to miners working in such underground spaces, which increase the exposure of miners to hazards. Due to the numerous hazard exposures in the underground coal mine environment, this study reviews the various technological safety systems and principles that are used for safe-rescue and self-escape of miners in underground coal fires, particularly in South Africa, and to minimize, control, or eliminate hazards in an effort to promote mine safety. The paper focuses on data obtained from Mines Rescue Services in Carltonville, South Africa, together with analyses from previous studies to investigate and evaluate the various technological safety systems and principles that are used for safe-rescue and self-escape of miners in underground coal fires. Considerations of the total number of underground fires, the number of fires dealt with by Mines Rescue Services, and the number of coal mine fire fatalities that Mines Rescue Services has dealt with over the years, were captured in this report.

Fires in underground coal mines

Fires in coal mines can be difficult, if not impossible, to extinguish as the combustion of coal itself can supply enough oxygen gas to sustain fires for years or decades, even if the mine is flooded with water or inert gases. Examples of fires that lasted for years include the incidents at Mount Wingen, Pennsylvania and Saarland. The fire at Mount Wingen in New South Wales Australia was located 30 m below the surface, and it is believed that the coal seam had been burning for 6000 years (Loughnan and Roberts, 1981). The coal fire in Pennsylvania occurred in a former open cut coal mine in 1962 after a neighbouring community accidentally ignited it, and because it has been burning ever since, the town has had to be abandoned (Pratt, 1987). Lastly, in the state of Saarland of Germany, coal spontaneous combustion started in the middle 17th century and has been burning to date (Singh, 2013).

In South Africa, coal spontaneous combustion has been established as the main cause of fire in coal mines (Gouws and Knoetze, 1995). It was difficult to collect data from the South African coal mines on the number of occurrences of spontaneous combustion and coal dust explosions. One reason for this could be the fact that incidents of self-heating may also be treated by loading out hot coal before a fire takes hold. Hence it is likely that reports on spontaneous combustion document only those incidents that progressed to the point that a report to the Mining Inspector was required. Statistics often represent only accidents in underground collieries and do not show the extent of the problem regarding strip mines, dumps, stocks, abandoned mines, or ships, as shown in Figures 1-3. There are also problems in isolating cases of coal-dust explosions. Data is typically available for recorded ignitions and explosions, or fires caused by flammable gases. In most situations, methane is responsible for the accident. The cause of the accident is thoroughly investigated only in the case of especially violent accidents, and in those situations a secondary coal-dust explosion is typically assumed (Gouws and Knoetze, 1995). Spontaneous combustion is the primary cause of underground fires, and a coal-dust explosion has the ability to turn an accident or explosion occurrence into a major disaster. While there have been no fatalities or recorded injuries due to spontaneous combustion for more than 20 years in South Africa, there is still a potential for serious accidents, as this phenomenon has been the main cause of fires in South African collieries over the same period (Gouws and Knoetze, 1994).

Underground fires, possibly caused by spontaneous combustion, have been burning in some abandoned coal mines for several years. Such fires cause subsidence of the surface, by the collapse of either the pillars or the bords, rendering the land unsuitable for residential or agricultural purposes (Phillips, Chabedi, and Uludag, 2011; Gouws and Knoetze, 1995). An underground fire has also recently threatened the rail link between South Africa and Mozambique. Subsidence in shallow abandoned mines also results in cracks propagating to the surface, allowing the ingress of air and water.

Mines Rescue Services provides emergency response services to the South African mining industry. The underground fire statistics shown in Figures 1-3 indicate the underground fire occurrences that Mines Emergency Services has dealt with over the years. While total number of underground fires is shown in Figure 1, Figure 2 illustrates the number of coal mine fires in South Africa.

From the statistics in Figure 3 it is evident that such fires certainly represent the single highest risk on any coal mine. Mines Rescue Services have had to deal with several fatalities during underground coal mine fires over the years.

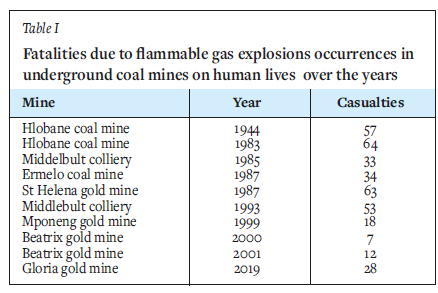

The other risk that is seen in the same light as underground coal mine fires is most certainly flammable gas explosions, which have claimed more lives over the years than any other mining-related risk (Table I). Most of these explosions result in multiple fatalities and can be regarded as disasters.

Emergency response planning for safe rescue in underground coal mines

As indicated previously, underground coal mines are characterized by numerous life-threatening hazards such as fires, explosions, toxic gases, dust, and mine collapse, but the major problem, which has the most devastating effects, is coal mine fires (Azam and Mishra, 2019; Stracher and Taylor, 2004; Wang, Yang, and Li, 2018). When such emergencies occur, it is required that miners evacuate the mine premises immediately and in a safe manner. To achieve this, this study proposes the seven steps indicated in Table II in order to achieve an optimum, safe rescue/escape operation.

Additionally, for any coal mine there should be a rescue team on standby to respond to any emergencies from hazards. However, the effectiveness of these rescue teams depends on the timely execution of self-escape procedures.

Safety measures for self-escape from underground coal mines

Coal mining is characterized by numerous hazards such as noise, dust, risk of electrocution, diesel emissions, rockfalls, explosions, and spontaneous combustion, which require adequate management to avoid devastating accidents. Fire and explosion are the leading hazards in hard coal mines, and normally lead to serious injuries and fatalities. It is worth mentioning that exogenous fires are more hazardous than coal mine fires, but they are rare with very minimal possibility of occurrence. In this vein, whenever a fire breaks out in longwall mining, miners should evacuate to the surface using escape routes are not affected by toxic gases emitted from the fires.

Over time, many major incidents in coal mines have been averted or ameliorated by the self-escape of miners from dangerous environments. Self-escaping has been facilitated by using various aids. Currently, the passive self-escape techniques being used consist of signs, markers for indicating primary and secondary escape routes, as well as lifelines. Other safety tools to help miners self-escaping in the dark, such as safety canes for locating mine ribs and handheld laser pointers, have also been considered. Lifelines are important in underground coal mines to aid self-escaping by directing miners to the escape routes. Lifelines function by providing signals using cones, spheres, and cylinders that can be felt with the hands to direct miners to escape routes in dark areas where visibility is poor. Other lifelines are used to warn of critical emergencies lying ahead of an escape route such as pitfalls and blockages (Brenkley, Lewis, and Jozefowicz, 1998; Mine Safety and Health Administration (MSHA), 1999). However, lifelines must be within the reach of the miners, which can be difficult under critical emergency situations. For example, miners can typically become disorientated due to poor visibility resulting from an explosion or fire, so they may have difficulty locating a lifeline (Gouws and Phillips, 1995).

It is important to note that the literature does not clearly state the conditions that must be complied with in designing escape routes, but only specifies that one must note the safe ways of evacuating workers from the mining zones in case of fire outbreaks that cause poor visibility. In light of this, the efficiency and effectiveness of any escape route depends on numerous human and technical factors (Badura, Grodzicka, and Musiol, 2017). The technical elements include design of the escape route heading, machinery or equipment in the route heading such as conveyors, withdrawing direction, the upwards or downwards inclination angle, the position of communication systems, marking of the escape route, and escape respirators. The human factors include the skills to use escape respirators, the knowledge of how to carry on through the escape route, resistance to stress-related conditions arising in the heading, and decision-making capabilities in the course of a staff self-rescue operation.

Despite intensive research towards improving the occupational health and safety of workers in coal mines, there is still a need to look for better solutions to improve safety, especially for miners escaping from emergencies that are life-threatening. The study by NIOSH (2016), which involved miners, rescue crews, safety officers, and researchers, indicated that escaping very early during underground mine emergencies is critical in order to survive such adverse occurrences. Thereafter, researchers at NIOSH conducted a study that considered behavioural and environmental conditions as well as miners' skills that facilitate successful escape from underground coal mines.

The study by Badura, Grodzicka, and Musiol (2017) analysed crew evacuations during fire hazards between 1990 and 2013 in Poland. The study indicated that 2574 miners were evacuated from affected headings. Out of this number, 1312 evacuations were due to coal spontaneous combustion fires and 1262 due to exogenous fires. The largest number of miners evacuated was 488 at the Bielszowice hard coal mine in 2005. The fire was caused by short-circuiting of a 6 kV cable duct on the surface connected to the downcast shaft. A huge amount of smoke occurred in the heading of escape routes and reduced visibility . This necessitated equipping escape routes with directional signage to provide guidance during escape. Mining companies utilize various techniques to mark escape routes and directions for crew evacuation, but metal signs that are well labelled according to the heading location and direction of evacuation for escape are mostly preferred. However, such methods are not effective in dense smoke, and therefore an alternative method works better in poor visibility is required.

Self-escape procedures/processes

Successful self-escape from emergencies in underground mines cannot be just by a personal effort but rather involves a collective effort from numerous crews and personnel. However, there is a need to emphasize self-escape in order to motivate each miner to make as much effort as possible to rescue his/ herself rather than waiting to be helped. Even though scenarios of self-escaping normally occur in operations where there is a group of workers, the ability to follow the instructions of a safety officer also requires one's initiative to survive the emergency. It is necessary that all workers in any underground mine be fully ready to respond immediately whenever an emergency occurs, either to prevent it from escalating or to escape. The main issue here is the ability to escape well in advance before an accident occurs. Therefore, every mine should ensure the best conditions possible that will aid in attaining successful self-escape. This is only possible by ensuring that all safety facilities are adequately available and installed as well as keeping workers informed and aware of these facilities. The workers should also be assisted in comprehending and complying with safety laws.

The process of self-escaping with regard to mine safety can be describer in terms of eight connected steps, which are generally divided into four phases, namely prevention or preparation, detection, assessment, and escape, as indicated in Figure 4. The first phase - prevention or preparation - is a crucial stage that constitutes the efforts to reduce the occurrence of hazards that could lead to incidents and maximize preparation against devastating effects. Performing safety drills for workers also has a positive impact in preparing workers to escape. Following the first phase are the detection and assessment phases, where all miners need to recognize and consider the available safety resources, and decide on the extent of the emergency and which escape route to use. After detecting and confirming hazardous situations, evacuation of miners must be done immediately. An important aspect of self-escape is the ability to react in a timely manner to evacuate successfully (Sultana, Anderson, and Haugen, 2019).

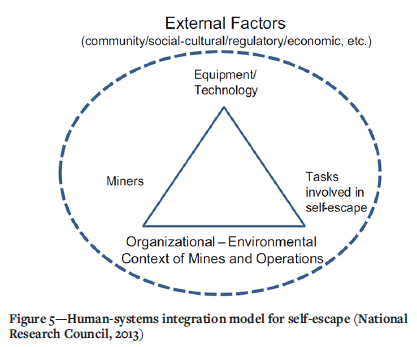

Human-systems integration approach

The process of self-escape entails teamwork either directly or indirectly, before and during the evacuation process in a dynamic environment. Achieving a successful escape depends directly on the safety resources available, the response of the rescue team, and the miners. The human-systems interaction approach evaluates the quality of interaction between people, tasks, and technology in order to attain a goal, which is a safe self-escape operation (Czaja and Nair, 2006; Booher, 2003). The most important aspect of human-systems interaction is maintaining the communication of information during the interaction, which will aid in successfully completing the mission. However, when these systems are considered individually or in isolation, messages may be lost. Hence this approach should take into account the fact that that people differ in cognitive, perceptual and physical capabilities, which affects how they engage during such missions. It is also significant to know that these interactions arise in an organization and are affected by both contextual and environmental factors that can either aid or limit the successful use of equipment and technology in facilitating the completion of tasks (Henriksen et al., 2008). Human abilities and limits exist in a dynamic system that may differ based on both external and internal factors, as indicated in Figure 5.

Mine emergencies: The human-systems aspects of self-escape

Over a long period of time, the mining industry and its workers have been keeping up with ever-evolving technology in order to prevent or respond to mining emergencies. This section focuses on describing the miners (people, individual miners, group or teams) and technologies used in responding to mining emergencies.

People

During any emergency in underground mines, the successful escape of any miner requires the cooperation of several people, which include the individual miner, the group or team, and the communication crew. This section discusses the role of the individual miner, group(s), or crew(s), and the communication centre(s) in ensuring the successful escape of an individual miner from an underground mine during emergencies. It is worth noting that several other personnel also play important roles prior to the escape of an individual miner from an underground mine, such as those involved in maintaining conducive safe working conditions and preparing the mines for rapid emergency response. This needs a continuous and dedicated effort before any emergency occurs to ensure that the mine has all the safety facilities necessary for adequate response to emergencies.

The individual miner

An individual miner entering the mining industry normally undergoes intensive training for his or her role, as well as safety induction. In some countries, like the USA, new miners are required to wear different coloured hard-hats to distinguish them for a period of six months until they understand their roles and the safety codes of conduct. An important aspect worth noting is that the health of miners is crucial in contributing towards a successful escape. For example, some miners may be suffering from chronic illnesses or lifestyle diseases. Such miners will be significantly challenged in terms of their capability to escape without being helped. Thus, this requires that assistance equipment is provided in the mines. Additionally, when creating the self-escape strategy for any mine, the safety officer needs to factor in the various physical abilities of miners, any contingencies that may occur when miners are injured in the process of escaping, and all other possible situations arising from emergencies.

Groups or teams

The solidarity of any group of coal miners in any underground mining operation contributes largely to how an individual responds when faced with an emergency (Vaught, 1991; Vaught et al., 2000). When any emergency occurs, such as a fire outbreak in an underground mine, a new group known as the escape group will be immediately formed, consisting of miners who may or may not have previously worked together to handle activities that are different from their daily work tasks. In such an emergency, miners tend not to work as a properly established team that has been trained to cooperate well. This is mainly due to the fact that the training and organization of miners are primarily geared towards the mining and production of coal, whereas that of a safety officer is to respond to emergencies. This may hinder miners from forming an effective escape group. Also, the mind-shift that occurs as a result of exposure to a hostile, hazardous, and life-threatening situation adds to the challenge of forming an effective escape group (this statement should not be construed as a criticism of the miners). However, this does not necessarily limit the ability of miners to escape safely, and historically, many miners have worked well in escape groups to achieve successful missions. This is because during such scenarios, the surrounding environment and the emergency tasks will determine the group dynamics and the decision-making process during evacuation.

With teamwork and group support being important attributes of a successful self-escape mission, miners should quickly form escape teams and delegate roles amongst the team members towards achieving the common goal of escaping. This will not only save time but also allows for effective brainstorming for all the possible solutions on how to quickly escape and pick the safest strategy.

Communication centres and responsible persons

Communication centres are important support systems in the decision-making procedure for miners escaping during emergencies. Such centres can be positioned immediately within the surface infrastructure of the mine or far from the site, where reception is good. Despite their location, they are important in relaying and processing information during emergencies. These centres must be installed at all underground mines in order to pass information to escaping miners so as to guide them during that process. The most important person in any of these centres is the 'responsible person' at the surface, who can clearly decipher information and can communicate clearly with the miners to update them about the rescue operation. Such people require extensive training, especially in decision-making and other nontechnical skills.

Technologies

Emergency scenarios normally tend to stress miners and this may adversely affect their basic reasoning abilities. Despite this fact, miners working in underground coal mines must understand well enough how to correctly use various items of safety equipment such the self-contained self-rescuer (SCSR) and compressed air breathing apparatus (CABA) in harsh conditions - for example, in complete darkness and smoky environments, even when they cannot think rationally or clearly. This is achievable through ensuring that workers undergo extensive training so that the safety response becomes habitual. Beilock and Carr (2011) reported that an individual's ability to acquire skills increases through various stages, which are characterized by the differences in the operations of the memory. During the initial stages of learning, skills and execution are normally supported by functional memory, which is monitored in a stepwise manner (Fitts and Posner, 1967). Procedural awareness unique to the assignment, however, evolves with practice. Procedural awareness primarily functions outside of working memory and needs no continuous control (Beilock et al., 2002; Beilock and Gonso, 2008). Thus, unlike the earlier stages, once a skill is reasonably well learned the step-by-step regulation of execution may not require attention.

Another technique to classify the various types of thinking that occur at different skills levels is the 'skill, rule, knowledge' approach (Rasmussen, 1983; Reason, 1990). The terms skill, rule, and knowledge generally define the degree of a person's conscious control over their actions. Therefore, it is advisable to train miners how to use various items of safety equipment frequently, so that they form a habit of automatically using them when the need arises. For example, miners need to be properly trained on how to use breathing systems automatically, so that when working memory has been affected by stress, the miner does not make poor decisions. In order to build up habitual responses, the miner needs to know what is to be expected from using various safety gadgets. In addition, it is important that miners are trained to solve problems on the spot so that they get used to finding solutions when faced with unexpected events. Beilock et al. (2002) reported that when procedures are clearly stipulated for every task, humans are left with some cognitive resources to deal with other problems. Therefore, the usage of every item of safety equipment needs to be clearly stipulated in a procedure, so that miners have the reasoning capacity to deal with other problems while in self-escape situations.

Various technologies assist miners when escaping during emergencies. Some of these include the technologies for daily mining but some are intended for occupational safety purposes such as self-escape. A few examples of these are briefly described below with their limitations, to allow for improvement.

Sources of oxygen

To survive any underground mine emergency, it is important to have access to breathable air. Most mining emergencies normally result in the production of toxic gases and lack of ample breathable air, which leads the miners to suffocate. To overcome this hazard, technologies have been developed to provide miners with ample amount of breathable air in any emergency. Bollinger and Schutz (1987) classified types of respiratory escape equipment as indicated in Figure 6. The systems can be classified as either those operating in a closed circuit or those operating in an open circuit. The closed-circuit systems are known as SCSR systems and function by providing oxygen to miners while removing moisture and carbon dioxide produced during exhalation. These include the long-duration self-contained self-rescuer (LDSCSR), which has a 60-minute operational time and the SCSR, which has a 30-minute operational time. Weighing between three to six pounds, a SCSR begins functioning after the miner inserts a mouthpiece into the mouth. This exposes the SCSR to moisture, which then triggers a chemical reaction that produces oxygen. When using these systems, breathing resistance increases with time and heat is generated due to the production of oxygen. The mouthpiece also hinders talking, thereby hampering communication. Open-circuit systems, on the other hand, normally supply oxygen from a compressed gas cylinder. This type of system is also known as a CABA (compressed air breathing apparatuses). These systems have a full-face mask, unlike the SCSR, which only has a mouthpiece. CABAs are gaining popularity in many countries such as Australia. Whereas the open systems last for only 30 minutes, the closed systems can last up to 4 hours. CABAs are open air systems. They supply compressed air to the user, and the exhaled air is dispersed into the atmosphere. This is the reason why the duration of the cylinder is only 30 minutes as the cylinder size restricts the amount of compressed air that the user can carry on his back. The long-duration breathing apparatus (LDBA) is a closed loop system, hence it can last for 4 hours. It incorporates a soda-lime canister that filters the air exhaled by the user, removing all the carbon dioxide and other impurities. The system also has an oxygen cylinder that through a pressure reducer and flow sensor, adds pure oxygen into the circuit, which improves the purity of breathable air for the user.

Gas monitoring

Real-time gas measurement is important in underground mines to alert the miners when threshold limits are almost reached or to guide miners during escape or evacuation (Brady, 2008). It is important for every miner to know the air quality at every point in the underground mine, especially at escape routes. The air quality is determined with the help of personal gas monitors, which can quantify the main gases of concern such as methane, CO, CO2, and O2. Where possible, such devices should be issued to all underground miners and if only a limited number are available, then the senior workers in various areas should have these devices readily at hand. Fixed air quality monitors should also be installed at various points. For example, in the USA, such fixed gas monitors are normally installed on conveyor belts to enable detection of CO generated by conveyor belt heating. Also in the USA, coal mines have methane monitors on longwalls as well as on all machines such as shearers, at midfaces, and in tailgate drives. Stationary CO detectors are also installed in battery-charging stations and fuel storage areas, and more gas information can be obtained from fan charts found in air shafts and mine seals. Similarly, Australian safety regulations require the installation of gas detection systems in all operating parts of mines and at unsealed goaf areas in return airways (Queensland Parliamentary Counsel, 2001). These systems consist of a series of sensors or tubes that extract the air from the mine and transport it to the surface for analysis. This enables continuous monitoring of mine gases such as methane, CO, CO2, and O2.

Refuge stationslsafe havens

When wearing a self-rescuer of any sort, the distance that can be covered depends more on a miner's physiological abilities (fitness, breathing rate, stress level, body posture etc.) and the terrain to be crossed (visibility, footing) than on the efficiency of the self-rescuer. In mines where the places of safety are far apart, self-rescuers need to have longer lifespans. Due to the limited timespans of self-rescuers, there is a growing tendency for Emergency Escape Plans (EEPs) not to rely on the use of these devices. The provision of refuge stations is very important as distance limits the escape of employees all the way to the surface, especially in older and more mined-out workings. The workforce shelters in sealed, fireproof structures that provide safe havens for evacuating personnel to rest in and change. Caution should be applied in the selection of conventional refuge bays or new movable ones. Refuge stations have been installed in South African and Canadian mines.

Routefinding

Efficient route finding out of an underground mine relies heavily on whether the miners know their location, as well as the safest routes to take to self-escape. As mentioned earlier, technologies that assist with this process include signs, lifelines, headlamps, and communication systems. However, such technologies are liable to be affected by smoke, fire, and other harsh conditions. For instance, headlamps have a limited battery life, signs can be blown off during an explosion, and lifelines can be destroyed.

To overcome such problems, these technologies can be complemented with the use of chemical glow- sticks that can last up to 12 hours. Metal configurations can be used to show signage riveted on the doors. Canes can also be used to assist miners in comprehending what structures are around them, such as crushers and conveyor belts, when in total darkness.

The common practice in numerous mines of marking escape routes with reflective signs and symbols has disadvantages. It is important to keep the signs clean, in good shape, and up to date, because mine personnel often pay little attention to reflective route/way markings and reflective markings are of little use in low-visibility environments. To overcome these disadvantages, passive lifeline technologies and active electronic audiovisual guidance systems have been used (Thyer and Weyman, 1997). Whichever method is considered, it must achieve the following to the greatest extent possible:

➤ Significantly increase the speed of egress

➤ Be useful in extremely low-visibikity conditions >- Provide precise directional information

➤ Provide audible, visual, and tactile signals

➤ Be inexpensive, with minimum requirements for maintenance

➤ Accommodate differences in mine layout, working practices, culture, and language.

➤ Offer a high-integrity and preferably fail-safe operation

➤ Not depend on background lighting [idem]

➤ All employees familiar with and trained on these devices.

Other guidance systems for route finding in low-visibility conditions have been developed, including passive and active guidance systems and instrument meteorological conditions (IMC) egress beacon systems.

Lifelines

Lifelines are common safety aids used for guiding miners to designated escape ways using directional cones to show the correct travelling direction. These cones can be seen in dim light or can be felt by hand in darkness. Safety regulations for every country normally stipulate the minimum distance between cones. Lifelines may also be used to indicate other safety facilities such as personnel doors and refuge chambers, as illustrated in Figure 7.

Vision aids

Inadequate visibility due to power outages or dense smoke from fire is a common hazard during mining emergencies. This necessitates appropriate lighting technologies and equipment to be installed to provide lighting needed for vision during such emergencies. Currently, miners use cap lamps. The latest lamps require frequent charging, but those using older technology can last for more than 20 hours, but they are heavier due to the bigger batteries (Lewis, 1986). Other types of vision-aiding equipment include goggles and eyeglasses that protect miners from eye irritation, especially in dusty, smoky, or polluted underground spaces. However, these do not aid vision in extreme darkness. A worthwhile technological invention would be goggles that incorporate thermal imaging to assist miners with vision in dark spaces.

Communication and tracking equipment

The maintenance of communication inside the mine and to the surface during operations is usually a tough task. Due to the continuous mining operations advancing daily, communication systems need to progress together with the mining crew. Communication systems therefore need to be robust enough to withstand harsh environments such as extreme humidity, corrosive water, and electrical characteristics of coal that can hamper communication signals and cause interference (Schiffbauer and Brune, 2006). These systems should also be safe for use in underground mines and not pose any hazards. To overcome all such limitations, a combination of both wired and wireless connections is needed to create a robust communication system. Personnel detection devices (RFD tags, high or low frequency) fitted to the cap lamps are becoming more common and can assist greatly.

Functional design of technologies

Technology is crucial in ensuring efficient self-escape from any underground mine emergency. A human-systems integration approach places primary importance on the person operating the system by placing the use of these technologies as the centre of the design process (Norman, 1993; Wickens, Gordon, and Liu, 2004). Despite the advent of new technological trends in mine safety, complete reliance on these technologies may not be the best choice for the miner involved. For example, a miner being limited in space and strength cannot monitor, comprehend, and synthesise information from numerous safety devices delivered in many formats. Therefore, when considering the design of technological systems for safety in underground mines, the user should be placed at the centre and the human behaviour factor should be fully taken into consideration. Examples of such factors include the human aspect in decision-making, comprehending, and assimilating information as well as responding in the required manner. However, safety technologies must meet several requirements, including size and weight, before they can be considered suitable for underground mines. A miner can only carry a limited amount of equipment during an emergency. This equipment must be easy to deploy and easy to use. If miners cannot understand how to use these technologies they will not use them.

South Africa has advanced systems for rescue from underground refuge chambers. Mines in some cases predrill 660 mm rescue boreholes from the surface into these chambers to speed up the process of rescue should there be an emergency.

Should such holes not be available they would call upon Mines Rescue Services, who will then deploy their rescue drill unit, supply winder, colliery rescue winder with rescue capsule, and specialized rescue teams.

Safety training requirements for safe rescue operations in underground coal fires

The process of mine rescue and recovery is normally complex and involves numerous interconnected activities.

Rescue teams

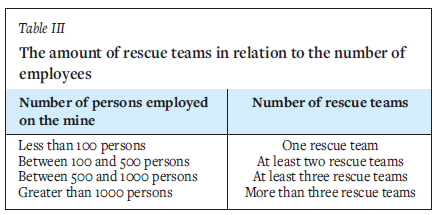

During any emergency, the rescue of persons is the highest priority and therefore the provision of rescue teams is the most urgent requirement. Depending on the size of the operation, the rescue teams can be voluntary employees or dedicated rescue personnel/teams from either a neighbouring mine or a centralized rescue provider. Since each mine emergency is different and the number of suitable rescue teams is contingent on the type of emergency, a formal reciprocal aid agreement between either neighbouring mines or with a centralized rescue organization, is hugely beneficial to provide all mines with access to more rescue teams they would otherwise be able to access. It is an accepted rule-of-thumb that a correlation exists between the number of persons employed underground and the number of rescue teams available as per the guidelines in Table III.

In further determining the number of rescue teams, cognisance must be taken of the fact that when a rescue team is working in a non-respirable atmosphere, there must always be a secondary backup team available. Where rescue teams from neighbouring mines or centralized rescue providers are used, the availability of these teams will depend on location, occurrence of other emergencies nearby, travelling distance, and response time. Where a secondary backup rescue team is not available, the original rescue team has limited capabilities, and these mines are advised to remedy this deficit. Furthermore, any rescue team is limited by the time for which they can be deployed, as this depends on the capability of the breathing apparatus (no more than 4 hours) together with a period of rest between deployments (minimum 12 hours).

From Table III and Figure 8, it is evident that Mines Rescue Services needs to cater for all types of mines in relation to the number of employees working in mines. Mines Rescue Services have two methodologies of service delivery namely 'A' and 'B' class member mines. 'B' class members have less than 100 employees, and such mines are not required to have their own rescue teams and rescue equipment on site, but they have the option to call for assistance from 'A' class member mines, with Mines Rescue Services acting as the liaison. 'A' class member mines employ more than 100 employees and are therefore required to have their own trained rescue team members on site in relation to the number of employees, as stipulated in Table III with their relevant specialized rescue equipment.

The way mine rescue teams respond to any situation depends on the type of emergency and the kind of mine being accessed. The condition inside an underground mine will dictate what the emergency crew should do to rescue miners and control hazards, where possible. Rescue teams are tasked with numerous roles such as exploring the affected mine areas, searching for and rescuing survivors, administering first aid, and firefighting, among other things.

Requirements to become a rescue team member Physical requirements

Ideally, a rescue team member must not be younger than 21 or older than 45 years. The minimal age is to ensure that the person has obtained some experience and simple life-skills and is mature and responsible enough to be placed in a position of responsibility. The maximum age has been scientifically determined as it is accepted that generally, persons above this age begin to deteriorate physically, and more importantly, their oxygen consumption (VO2max) increases, thus reducing the period for which they can benefit from an oxygen breathing apparatus. The potential member will be subjected to a full medical examination, but the initial requirement is that they be physically fit, have no obvious disabilities, and are not obese. The person must have a reasonable level of intellectual capability and sufficient numeric and literacy skills in order to communicate effectively.

Pre-assessment of the individual

Before a rescue team member begins training, they will be required to undergo a full medical examination and be tested for heat tolerance. The medical examination must be conducted by a professional medical examiner and the following minimum tests should be carried out:

➤ Not suffering from diabetes mellitus, any form of seizures, or hypertension

➤ Not receiving any drug treatment (or if so, this must be specified)

➤ Not receiving regularly prescribed medication

➤ Within height/mass nomogram limit (BMI between 25 and 35)

➤ No abnormalities detected from an X-ray

➤ Blood pressure (systolic 90-145 mm and diastolic 5090 mm)

➤ Physical screening of temperature, mouth, lips, throat, abdomen, herniation, defect of limbs etc.

➤Urine analysis (normality and drug dependency)

➤ Spirometry

➤ Optometry (minimum 6/9 both left and right eyes)

➤ Audiology (reject if greater than 40 dB average loss).

The purpose of the heat tolerance test, which in cooler regions may appear to be superfluous, is because rescue teams can be exposed to excessive heat, especially during fires. This test will be conducted in a climatic chamber, where the environment is saturated (high humidity with a wet bulb temperature of 31.7°C and dry bulb temperature of 33.2°C), and the person is subjected to 60 minutes of physical work (bench stepping to obtain a work rate of 54 W), after which the core body temperature is measured. The candidate will be rejected if the core body temperature is greater than 39.0°C.

Initial training

The primary purpose of the initial training is to ensure that a rescue team member is fully competent in the use of a breathing apparatus. This should take at least five days of both theoretical and practical training. During this period, other relevant core competencies are dealt with, including fire chemistry, firefighting techniques, gases, communications, rescue, and recovery. The competencies and a brief description of the training are listed below.

➤ Long-duration closed-circuit breathing apparatus

➤ Fresh air base (FAB) for the backup rescue team should the operational rescue team proceed beyond the last point of fresh air

➤ Known modus operandi that was briefed to the rescuer by the manager in the control/ emergency management room

➤ Hazard identification risk assessment

➤ Rescue protocols, policies, procedures, special instructions, and systems of works.

➤ Gas measurements and understandings

➤ Communication between rescue teams, rescuers, and management in control/emergency centre

➤ Firefighting methods.

➤ Accident scene management

➤ Specialised rescue and/or recovery equipment

➤ First aid.

Physical capacity test

After completing the pre-selection, medical examination, and the training course, the member is subjected to a physical capacity test. This will determine the individual's ability to perform physical work in the arduous conditions normally encountered during deployment. Typically, this test will include stoop walking, carrying of 25 kg items, crawling in confined spaces, and climbing. The test must be completed in a pre-determined time while wearing a breathing apparatus.

Quarterly refresher training

All rescue team members must undergo a refresher training every three months, preferably in a simulated mine that has been filled with smoke. The members are required to wear their breathing apparatus during this training, which can also serve to familiarize them with any new technologies or developments. Similarly, routine planned maintenance can be performed on equipment during this training.

Specialized skills

While the core competencies of the rescue team have traditionally been firefighting, entering non-respirable atmospheres, and search and rescue, there are circumstances that require additional skills that have subsequently been included in the proficiency requirements. These additional skills include emergency medical care (paramedic or medical first responder) and rope rescue skills for working at depths and heights. Ideally, each member of the rescue team should have some basic life-support skills and, where possible, certain members could have either intermediate or advanced life-support skills. The latter two are, however, to be possessed by highly skilled and trained personnel. It is likely and more reasonably accepted that a skilled person (with advanced life support) be trained as a member to be used only in cases involving a medical emergency.

Depending on the type of operation (deep-level mines or shaft structures), certain members can be skilled in rope access or rope rescue techniques, and be able to ascend or descend shafts, buildings, orepasses, silos, or any structure in which the height can become a concern, in order to perform a rescue. Mine rescuers can also be assigned as surface fire responders to cater for all surface-related emergencies and/or incidents. The number of rescue team members in South Africa to cover underground mines is shown in Figure 9.

Composition of a mine rescue team

An operating rescue team cannot consist of less than five members, but in order to ensure readiness of a team, there should be at least seven members to allow for leave of absence, sickness, non-availability, non-conformance to operational requirements, etc. The team should also consist of a mix of production, engineering, and health, safety, and environmental personnel. This will ensure that all relevant disciplines (mining issues, engineering installations, or ventilation control) or problems that could be encountered during an incident are catered for. Furthermore, the team will include a captain and vice-captain. These positions are normally permanent as these members have specific duties. During deployment, an additional sixth or seventh member can be included, either due to the requirements of the operation or simply to improve the experience of newer members. The appointment of a rescue team manager or liaison officer is considered beneficial as this person can manage the team, prepare and submit budgets, liaise with executive management, or assist with emergency preparedness. Figure 10 shows the number of active rescue teams available to cover underground mines in South Africa.

Deployment of rescue teams

When an emergency call is initiated, a sense of urgency, anxiety and possible apprehension are normal emotions experienced by rescue team members. A team's state of emergency preparedness and readiness has a direct bearing on their ability to control these emotions. A rescue team manager/designated officer must provide the team captain with the following information:

➤ Type of emergency e.g., fire, rescue etc.

➤ Possible number of persons involved and (if known) their condition

➤ Time to report to the mine and time to go underground e.g., 06:00 for 07:00

➤ Place to report to (the rescue room)

➤ Transport arrangements

➤ Plan for pre-operational medical examination, or in the case of an emergency ASAP callout, the rules applicable to the use of declaration of fitness.

Mines should be able to call upon multiple rescue teams and have enough rescue teams available as many underground fires can grow in extent over time. This will have a direct effect on the rescue teams' performance and efficiency, because after a few callouts, rescue teams may be affected by fatigue and this can have adverse safety implications for both rescuers and employees requiring rescue. From Figure 11, it is evident that during fires, multiple rescue teams would be required. The complexity of underground fires can also have a direct bearing on the number of rescue teams that a mine would deploy.

Summary

Coal mining is characterized by numerous hazardous activities that require proper safety management systems to be set in all coal mining companies. Coal mining accidents have long-lasting, devastating effects on all stakeholders as poor mining practises can not only damage the equipment and machinery but can also lead to loss of human life. This demands that adequate safety management systems that are effective and prepared to handle emergencies be put in place in a timely manner to avoid devastating accidents. Old technologies should be replaced with modern ones in order to ensure efficient and effective management of mine safety.

With stringent safety measures adopted to eliminate the possibility of catastrophic accidents, the safe mining environment that is created will not only save miners' lives but will also protect the main mining assets from being ravaged. To this end, miners should be provided with adequate personal protective equipment (helmets, safety boots, gloves, dust masks, glasses, and breathing aids) that will safeguard them from injury. Appropriate safety facilities should be installed in all mines (fire alarms, gas monitoring devices, and mine ventilation. Where blasting is required, water-based emulsions and electronic detonators should be used due to their advantage of allowing the miners to verify the blasting system before firing.

Mines should have clear signs that can guide their workers during situations that require evacuation via the nearest escape routes. All working areas and any other areas where employees may travel should have lifelines installed. Where visibility is poor, lifelines should be used to direct miners for self-escape. Lifelines should be placed within the miners' reach and they must be able to understand their indicative directional signals. Miners should also be trained on how to communicate clearly with the central communication centre in case of an emergency to enable the rescue crew to evacuate trapped miners. All miners should be well conversant with the various safety gadgets such as SCSR and CABA, so that they can promptly put them on if they encounter toxic gases.

Any development in the underground spaces should be updated on the mine plans and shared among all miners so they know about hazardous areas to avoid, escape routes, and the locations of refuge chambers. Communication systems should always be kept running to allow miners to seek help from the response centres in case of emergencies. Above all, it is important that all miners promote a safety culture within the mines to create a safe and conducive working environment.

Concluding remarks

Coal mining companies should continue to promote a safety culture within the mines, right from top management down to the casual workers. This will encourage miners to abide by the safety rules and suggest any measures that can be implemented to improve safety in the mining environment. In many activities or operations in coal mines, it might not be feasible to completely remove some inherent hazards or avoid exposure to such hazards, and therefore some risks may never be completely eliminated. However, it is necessary for the employer to manage and control such hazards so as to minimize the consequences for the health and safety of all affected stakeholders. All miners should be trained regularly on safety practices so that they are continuously equipped with the necessary skills to maintain safety in underground spaces. They also need regular training on how to employ self-escape techniques during emergencies.

Acknowledgments

The authors wish to express their gratitude to Coaltech for their financial support for this study.

The portion of the work presented here was part of a Coaltech 2020/2021 annual report.

References

Azam, S. and Mishra, D.P. 2019. Effects of particle size, dust concentration and dust-dispersion-air pressure on rock dust inertant requirement for coal dust explosion suppression in underground coal mines. Process Safety and Environmental Protection, vol. 126. pp. 35-43. [ Links ]

Australian Building Codes Board. 2005. International Fire Engineering Guidelines. Canberra, Australia. [ Links ]

Badura, H., Grodzicka, A, and Musiol, D. 2017. Study of the "lifeline' as the measure allowing for safe self-rescue of miners in conditions of lack of visibility caused by underground fire. IOP Conference Series: Materials Science and Engineering, vol. 268, no. 1. doi: 10.1088/1757-899X/268/1/012015 [ Links ]

Beilock, S.L. and Carr, T.H. 2011. On the fragility of skilled performance: What governs choking under pressure? Journal of Experimental Psychology: General, vol. 130, no. 4. pp. 701-725. [ Links ]

Beilock, S., Carr, T., MacMahon, C., and Starkes, J. 2002. When paying attention becomes counterproductive: Impact of divided versus skill-focused attention on novice and experienced performance of sensorimotor skills. Journal of Experimental Psychology: Applied, vol. 8, no. 1. pp. 6-16. [ Links ]

Beilock, S. and Gonso, S. 2008. Putting in the mind versus putting on the green: Expertise, performance time, and the linking of imagery and action. Journal of Experimental Psychology, vol. 1, no. 6. pp. 920-932. [ Links ]

Bennet, J.D. 1982. Relationship between workplace and worker characteristics and severity of injuries in USA underground bituminous coal mines. PhD thesis, Pennsylvania State University. [ Links ]

Booher, H.R. 2003. Human systems integration. Handbook of Human Systems Integration. Wiley, Hoboken, NJ. pp. 1-30. [ Links ]

Bollinger, N.J. and Schutz, R.H. 1987. NIOSH Guide to Industrial Respiratory Protection, A NIOSH Technical Guide. Department of Health and Human Services, Centres for Disease Control, Pittsburgh, PA. [ Links ]

Brady, D. 2008. The role of gas monitoring in the prevention and treatment of mine fires. Proceedings of the Coal Operators' Conference. University of Wollongong, New South Wales, Australia. Australasian Institute of Mining and Metallurgy. pp. 202-208. [ Links ]

Brenkley, D., Lewis, D., and Jozefowicz, R. 1998. Assisting evacuation from underground mine workings under conditions of poor visibility. United Kingdom Health and Safety Executive, London. [ Links ]

Czaja, S.J. and Nair, S.N. 2006. Human factors engineering and systems design. Handbook of Human Factors and Ergonomics. Wiley, New York. [ Links ]

Fitts, P.M. and Posner, M.I. 1967. Human Performance. Brooks/Cole, Belmont, CA. [ Links ]

Graber, J.M., Stayner, L.T., Cohen, R.A., Conroy, L.M., and Attfield, M.D. 2014. Respiratory disease mortality among US coal miners; Results after 37 years of follow-up. Occupational and Environmental Medicine, vol. 1, no. 71. pp. 30-39. [ Links ]

Gouws, M. J. and Knoetzef, T.P. 1995. Coal self-heating and explosibility. Journal of the South 4frican Institute of Mining and Metallurgy, vol. 95, no. 1. pp. 37-43.94. [ Links ]

Gouws, M.J. and Phillips, H.R. 1995. Post-explosion guidance systems. Proceedings of the 26th International Conference on Safety in Mines Research Institute, Katowice, Poland. Central Mining Institute, Katowice. [ Links ]

Henriksen, K., Dayton, E., Keyes, M., Carayon, P., and Hughes, R. 2008. Understanding adverse events: A human factors framework. Patient Safety and Quality: An Evidence-based Handbook for Nurses. Agency for Healthcare Quality and Research, Rockville, MD. [ Links ]

Lewis, W. 1986. Underground Coal Mine Lighting Handbook. Information Circular 9073. US Bureau of Mines. [ Links ]

Loughnan, F.C. and Roberts, F.I. 1981. The natural conversion of ordered kaolinite to halloysite (10Å) at Burning Mountain near Wingen, New South Wales. American Mineralogist, vol. 66. pp. 997-1005. [ Links ]

Mine Safety and Health Administration (MSHA). 1999. Accident investigation. Safety Manual no. 10. Arlington, VA. [ Links ].

National Institute for Occupational Safety and Health (NIOSH). 2015. Improve drill dust collector capture through better shroud and inlet configurations. Department of Health and Human Services, Center for Disease Control and Prevention, DHHS 2015 No. 2006-108. [ Links ]

National Institute for Occupational Safety and Health (NIOSH). 2016. Occupational exposure to respirable crystalline silica. Occupational Health and Safety Administrationm 81(04800). Occupational Safety and Health Administration (OSHA), Department of Labor. Fed. Regist. 2016 Mar 25; 81(58):16285-890. PMID: 27017634. [ Links ]

Norman, D. 1993. Things That Make Us Smart: Defending Human Attributes in the Age of the Machine. Perseus, Cambridge, MA. [ Links ]

Phillips, H., Chabedi, K., and Ulüdag S. 2011. Best practice guidelines for South African Collieries. Coaltech, Johannesburg. 129 pp. [ Links ]

Pratt, J.A. 1987. Unseen Danger: A Tragedy of People, Government, and the Centralia Mine Fire. University of Pennsylvania Press, Philadelphia. 299 pp. https://doi.org/10.2307/3115362 [ Links ]

Queensland Parliamentary Counsel. 2001. Queensland Consolidated Regulations. 2001. Coal Mining Safety and Health Regulation. Section 222. https://www.legislation.qld.gov.au/view/pdf/repealed/2017-07-01/sl-2001-0015 [ Links ]

Reason, J. 1990. Human Error. Cambridge University Press, Cambridge, UK. [ Links ]

Rasmussen, J. 1983. Skills, rules, and knowledge; Signals, signs, and symbols, and other distinctions in human performance models. IEEE Transactions on Systems, Man, and Cybernetics, SMC, vol. 13, no. 3. pp. 257-266. [ Links ]

Schiffbauer, W.H. and Brune, J.F. 2006. Underground coal mine communications for emergencies and everyday operation. Presentation at the Energy Forum: A Discussion of West Virginia's New Mine Safety Rules, Charleston, WV, 1 March 2006. Department of Health and Human Services, Centers for Disease Control and Prevention, Pittsburgh, PA. [ Links ]

Singh, R.V.K. 2013. Spontaneous heating and fire in coal mines. Procedia Engineering, vol. 62, pp. 78-90, https://doi.org/10.1016/j.proeng.2013.08.046 [ Links ]

Stracher, G.B. and Taylor, T. P. 2004. Coal fires burning out of control around the world: Thermodynamic recipe for environmental catastrophe. International Journal of Coal Geology, vol. 59, no. 1. pp. 7-17. [ Links ]

Sultana, S., Anderson, B.S., and Haugen, S. 2019. Identifying safety indicators for safety performance measurement using a system engineering approach. Process Safety and Environmental Protection, vol. 128. pp. 107-120. [ Links ]

Thyer, A. and Weyman, A. 1997. Investigating the scope for improvements in navigational aids to assist evacuation from underground mine workings under poor visibility conditions. Mine Safety. Proceedings of 27th International Conference of Safety in Mines Research Institutes, New Delhi, India, 20-22 February 1997, vol. 1. Oxford & IBH, New Delhi. pp. 947-953. [ Links ]

Tripathy, D.P. and Ala, C.K. 2018. Identification of safety hazards in Indian underground coal mines. Journal of Sustainable Mining, vol. 17, no. 4. pp. 175-183. [ Links ]

Vaught, C., Brnich, M., Mallett, L., Cole, H., Wiehagen, W., Conti, R., Kowalski, K., and Litton, C. 2000. Behavioral and organizational dimensions of underground mine fires. Information Circular 9450. Department of Health and Human Services, Center for Disease Control and Prevention, Pittsburgh, PA. [ Links ]

Vaught, C. 1991. Patterns of solidarity: A case study of self-organization in underground mining. PhD thesis, Department of Sociology, University of Kentucky, Lexington, KY. [ Links ]

Wang, C., Yang, S., and Li, X. 2018. Simulation of the hazard arising from the coupling of gas explosions and spontaneously combustible coal due to the gas drainage of a gob. Process Safety and Environmental Protection, vol. 118. pp. 296-306. [ Links ]

Wickens, C., Gordon, S., and Liu, Y. 2004. An Introduction to Human Factors Engineering. Pearson Prentice-Hall Upper Saddle River, NJ. [ Links ],

Zhou, L., Cao, Q., Yu, K., Wang, L., and Wang, H. 2018. Research on occupational safety, health management and risk control technology in coal mines. International Journal of Environmental Research and Public Health, vol. 15, no. 5. pp. 868. [ Links ] ♦

Correspondence:

Correspondence:

B. Genc

Email: Bekir.genc@wits.ac.za

Received: 10 Sep. 2021

Revised: 17 Jan. 2022

Accepted: 17 Mar 2022

Published: May 2022

ORCID: B. Genc https://orcid.org/0000-0002-3943-5103

P.O. Akinseye https://orcid.org/0000-0002-0519-5957