Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.121 n.12 Johannesburg Dec. 2021

http://dx.doi.org/10.17159/2411-9717/1675/2021

PROFESSIONAL TECHNICAL AND SCIENTIFIC PAPERS

Risks and challenges affecting opencast pillar mining in previously mined underground bord and pillar workings

P.L. Ngwenyama; WW. de Graaf

Department of Mining Engineering, University of Pretoria, South Africa

SYNOPSIS

South Africa is one of the leading producers and exporters of coal globally. A significant amount of the country's production is obtained from previously mined underground bord and pillar workings. This coal is in the form of pillars and remnants on the roof and floor of the old workings. The good quality coal pillars were left behind as primary support during underground bord and pillar mining operations. Due to the depletion of virgin coal reserves, the pillars and remnant coal are now removed using opencast mining rather than underground methods. However, the secondary extraction of pillars and remnant coal from the old workings using opencast methods entails some serious challenges that have a negative impact on the safety and productivity of the operations, affecting both personnel and machinery. If these risk factors and challenges are managed properly, then the opencast mining operations could remove the pillars safely at recoveries competitive with those of virgin coal operations. In this study we review the recurring challenges affecting opencast pillar mining by means of field investigations and consultations with experts at five opencast pillar mining operations, and evaluate the best practices used to combat these challenges. It was found that each mine has its own unique conditions and challenges.

Keywords: opencast pillar mining, spontaneous combustion, bord collapse, bord and pillar collapse, bord voids, sinkholes.

Introduction

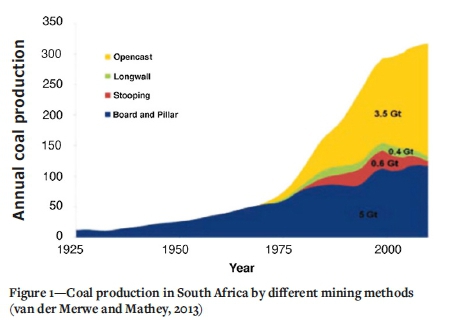

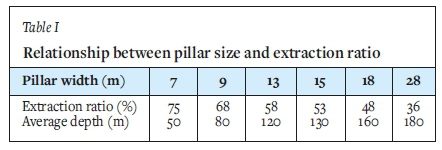

Coal was discovered and first mined in South Africa in the 1850s and continues to play a critical role in today's economy and energy supply (Hanconx and Gotz, 2014). According to the Energy Information Administration (2020) and Schernikau (2010), coal will remain a key global economic driver for some years to come. The demand for coal is expected to increase at least until the 2040s, especially in emerging economies such as India and China. During the early years of coal mining, over 90% of South Africa's coal was produced by underground bord and pillar mining (Figure 1) (Mohutsiwa and Musingwini, 2015). However, one of the biggest disadvantages of this method is its relatively low extraction ratio - an average of just less than 50% across all collieries in South Africa (Madden et al., 1995). A higher extraction ratio is possible in the case of smaller pillars, but these have a low factor of safety (Wagner, 1980). With increased pillar dimensions, the extraction ratio in bord and pillar mines can be as low as 36%, as shown in Table I.

In bord and pillar mining, a valuable amount of coal is left behind in standing pillars as primary support. According to van der Merwe and Mathey (2013), up to 9.55 Gt of coal has been mined in South Africa, of which approximately 53% came from bord and pillar mines. Moolman and Canbulat (2003) assert that approximately 1.1 Gt of potentially mineable pillar coal remains in the ground in the form of remnant pillars, mostly from mining operations dating to between 1970 and 1997. The amount of coal left behind continues to increase at a rate of 110 Mt per year. In 2003, the total number of pillars left underground was estimated to be over 1.7 million since 1970 (Moolman and Canbulat, 2003). In 1996, between 100 000 and 150 000 intact pillars were formed during bord and pillar mining operations (Madden, Canbulat, and York, 1998), and this figure has been estimated at 3 million by 2006 (van der Merwe, 2006).

According to Moolman and Canbulat (2003), only pillars with a safety factor of at least 1.8 can be safely extracted using underground methods. Nonetheless, greater safety risks and low recovery rates are among the disadvantage of sunderground pillar extraction methods. Furthermore, the secondary extraction of old pillars using underground mining methods can be constrained by geotechnical, geological, environmental, and economic factors. Extracting old pillars which have reduced in size due to spalling and deteriorated in strength is more difficult than the extraction of newer pillars.

Due to the safety concerns and low recovery rates associated with underground pillar extraction, opencast pillar mining became a viable option. This method has also been extensively used in countries such as India (Panigrahi, Sinha, and Singh, 2013; Mahto, 2015). In this study, it has been shown that opencast pillar mining operations can compete with virgin coal operations (Table II).

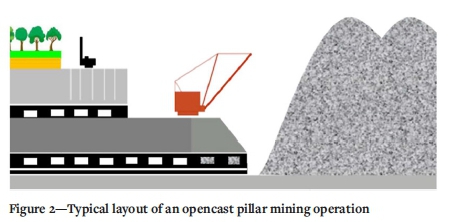

The secondary extraction of pillars from previously mined underground bord and pillar operations dates back to the early 1990s. However, opencast pillar mining is a complex method and entails multiple challenges compared to virgin coal mining, which can adversely affect the process if control measures are not properly implemented (Clough and Morris, 1985; Laybourne and Watts, 1990). Nonetheless, opencast pillar mining has been preferred over underground pillar extraction due to the safer working environment, higher extraction and recovery rates, flexibility, reduced coal losses, and increased productivity of surface methods. Figure 2 shows the layout of a typical opencast pillar mining operation:

Despite its complex challenges and difficulties, opencast pillar mining is expected to play a critical role in the supply of coal due to the good quality coal in standing pillars remaining underground (Ngwenyama, de Graaf, and Preis, 2017). This is due to the fact that virgin coal reserves in South Africa have continued to diminish and are nearing depletion (Hartnady, 2010). The effective utilization of pillar coal reserves in previously mined areas is therefore required (Schalekamp, 2006; Ngwenyama, de Graaf, and Preis, 2017). The purpose of this study was to identify the major challenges and risks associated with opencast pillar mining in order to improve the effective utilization of coal reserves remaining in pillars and remnant coal.

Field investigations

This study was conducted through field investigations and consultations with mining experts from five opencast pillar mining operations. These operations together produce an average of 60 Mt good quality coal per annum for both the export and domestic markets. Table II gives some production details for the five operations.

Risks and challenges affecting opencast pillar mining

Opencast pillar mining has been practiced since the early 1990s in South Africa, and earlier than this in other countries such as Scotland. However, despite all efforts to improve the process, this method is still experiencing continued and unresolved challenges which are detrimental to production, productivity, and health and safety. Through the field investigations, this study was able to identify the major challenges encountered during opencast pillar mining, and review the recurring challenges and best practices among the mines facing similar conditions.

Lack of information on the old workings

One of the biggest risk factors in opencast pillar mining is the paucity of information regarding the state of the old pillars and the general conditions of the workings. In some of the mines visited, it was found that information regarding the old workings is not available or only partially understood. The partially available information is extrapolated from old mine plans, which are less accurate than modern plans. This is because the old mine plans were constructed manually due to the lack of advanced survey technology at the time. The unavailable or partially known information includes the exact positions of the pillars, their centres, pillar dimensions, bord width, and roof undulation and thickness. To overcome this challenge, Govender (2018) conducted a study to evaluate techniques that can identify underground coal pillars from surface. A cavity auto-scanning laser system was found to be effective in determining sufficient information about the pillars in the old workings. The risk factors associated with old workings across the visited mines are evaluated in Table III.

Spontaneous combustion and its control measures

Spontaneous combustion is one of the most common challenges experienced across all the opencast pillar mines visited. Although the risk may differ in magnitude from mine to mine, it is still an ongoing and unresolved problem. One of the biggest risks of spontaneous combustion is premature detonation of blasts, which can easily result in multiple fatalities and/or damage to equipment. Extensive research pertaining to spontaneous combustion has been conducted (Eroglu, 1999; Eroglu, Uludag, and Thyse, 2002; Stenzel, 2002; Eroglu and Moolman, 2003; Phillips, Uludag, and Chabedi, 2011; Genc and Cook, 2015; Gemmell, 2016). Spontaneous combustion is common not only in South African mines, but across the world in countries such as India and the USA (Panigrahi, Sinha, and Singh, 2013; Sloss, 2015). Several techniques have been developed to minimize and potentially mitigate the effects of spontaneous combustion. Some of these techniques and their advantages are described in Table IV.

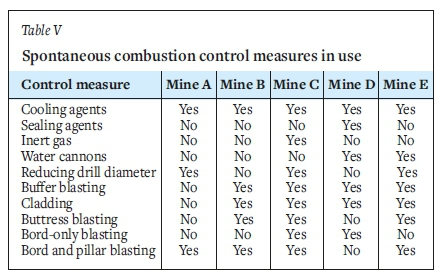

The spontaneous combustion combating techniques in Table IV have a common goal, which is to eliminate at least one of the three constituents of the 'fire triangle'; namely fuel, heat, and oxygen. Spontaneous combustion cannot occur when one (or more) of these constituents is absent. Some of the spontaneous combustion control techniques have proven to be effective and are used extensively in the mines, while some have not. Different mines have their own preferred techniques. The selection of a technique is influenced by the unique conditions of the old workings at that specific operation. Table V and Figure 3 show the usage of the spontaneous combustion combating techniques by the opencast pillar mining operations. This gives an indication of which of the techniques are more effective and practical to implement. As well as the practicality and effectiveness, the cost-effectiveness is a contributing factor to the usage of these techniques.

Cooling agents are commonly used for treating hot holes due to their practicality and cheapness. The other techniques are used selectively by specific mines. Despite all the efforts, spontaneous combustion remains an ongoing and complex problem. According to Stenzel (2002), spontaneous combustion and its mitigating measures are still poorly understood despite it being a wellknown phenomenon. Spontaneous combustion can result in the loss of coal reserves and has a negative impact on production, productivity, and health and safety (Panigrahi, Sinha, and Singh, 2013). Some of the common effects of spontaneous combustion in opencast pillar mining operations include:

➤ Devolatized coal or reduced quality of coal, and direct coal losses

➤ Decreased production rates

➤ Slope and highwall instability and sloughing

➤ Damage to property - tools, machines, and equipment

➤ Subsidence and sinkholes due to beam failure and collapse of burnt-out pillars

➤ Increased sulphur emissions

➤ Increased occurrence of hotholes

➤ Adjacent communities affected by increased emissions and dust.

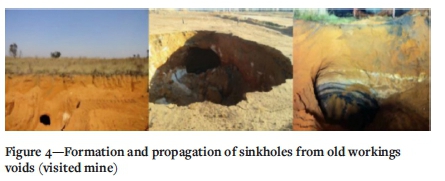

Sinkholes and surface subsidence in the old workings

Some of the mines visited were found to be severely affected by sinkholes and surface subsidence. Surface subsidence remains a concern in coal mining and has also been reported in virgin coal mining operations in South Africa and countries such as Australia, China and Indonesia (Peng, 2020; Cui et al., 2020; Han et al., 2019; van der Merwe, 2018; Sasaoka et al., 2015). The major factors contributing to surface subsidence include poor geotechnical conditions as well as the presence of voids due to mining. Sinkholes constitute a risk to people, machines, property, and the environment. Several incidents in which machines have fallen into sinkholes have been recorded. These sinkholes are initiated by the presence of voids in the old workings and propagate all the way to surface due to caving of the overlying strata into the bord voids. Sinkholes are approached and treated differently from mine to mine. Sinkholes are often invisible and may form unexpectedly while people and equipment are working directly above them.

Figure 4 shows the surface appearance of sinkholes of different sizes. The size and severity of a sinkhole, and the rate at which it propagates to the surface, depends on a number of factors, including:

➤ The thickness of the overlying strata: The thickness of the overburden from the old workings to the surface has an influence on the distance of propagation. Sinkholes are likely to propagate and reach surface quicker in shallower overburden.

➤ The strength and ability of the rock to resist weathering over time: Competent rocks are less affected by sinkholes than weaker rocks, especially in oxidized areas such as the upper portion of the overburden and topsoil. This is due to weaker rocks being more affected by weathering. Sinkholes propagate faster in weaker rock than in competent rock due to the faster rate of weathering.

➤ Load on the surface: The presence of heavy equipment working above a sinkhole may result in a collapse. This is also dependent on the maturity of the sinkhole.

➤ The position of the coal seam in relation to the old workings: The closer the seams are to the old workings; the quicker sinkholes can propagate to the surface.

➤The moisture content of the rock: Wet areas in oxidized rock are more prone to sinkholes. Moisture reduces the strength of the material in oxidized zones and this can result in higher propagation rates.

➤ General geology of the area: The presence of faults, sills, and dykes in the surroundings or directly above the old workings, as well as natural or mining-induced cracks, can influence the rate of propagation of sinkholes to surface.

Incompetent roof beam and highwall

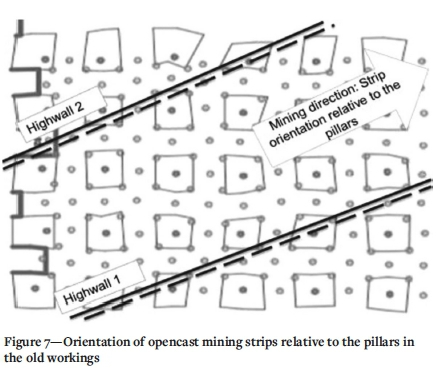

The safety of people and equipment working above the old workings depends on the conditions and competency of the overlying strata (beam layer) and highwall stability. The beam, as shown in Figure 5, is the immediate overlying stratum (layer) above the roof coal and the pillars. The competency of the beam layer is crucial for the stability of the working area. However, this is not critical in mines where buffer blasting is used. Incidents of machines falling into the bord voids have been reported. This is mainly due to the thickness and consistency of the beam being poorly understood or unknown. Furthermore, there are several restrictions regarding highwall stability, especially at shallower depths. Opencast pillar mines should be designed such that the highwall is always supported by pillars and does not hang over the bord voids, as demonstrated in Figure 6. Thompson (2005) suggested that the mining direction should be orientated at an angle relative to the pillars of the old workings, as shown in Figure 7. This is to ensure that pillars are always present at the edge of the highwall.

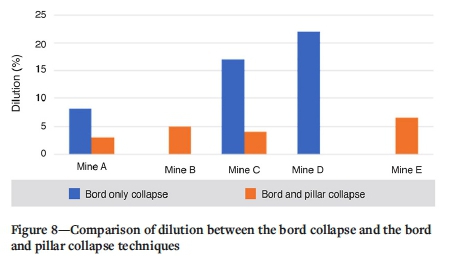

Excessive dilution

Excessive dilution is one of the major challenges in opencast pillar mining. In principle, only the bord should collapse and the bord and pillar collapse techniques are designed to prevent spontaneous combustion. However, this can result in excessive dilution. The bord-only collapse technique was designed to incur an excessive amount of dilution for the sake of avoiding or preventing spontaneous combustion. This dilution is due to the waste material (overburden) which is blasted to collapse the roof coal and fill the bord voids. The purpose of this is to prevent the ingress of air or oxygen into the old workings. This method has been effective in preventing spontaneous combustion in some of the mines where it is employed. On the other hand, the bord and pillar collapse technique is expected to incur less dilution. In this case, the pillars are collapsed first to fill in the bord voids and thus preventing the ingress of air into the old workings.

The amounts of dilution incurred by each mine with the different blasting techniques employed are depicted in Figure 8. It is clear that the bord-only collapse method incurs higher dilution than bord and pillar collapse. In Mine A, the amount of dilution is relatively low even with the bord-only collapse technique because the waste material around the pillars is loaded separately from pillar material. For example, an excavator would be used to clean waste material around the pillars. In Mine C and Mine D, the pillars are loaded together with the waste material, hence resulting in higher dilution. Mine B and Mine E have always employed the bord and pillar collapse technique, while Mine D utilizes the bord-only collapse technique. Figure 9 illustrates how the bord-only collapse technique incurs higher dilution than bord and pillar collapse.

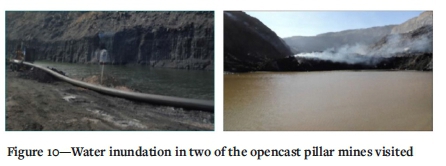

Pit flooding

Opencast pillar mining operations are also heavily affected by large quantities of water, which result in the pit being flooded as can be seen in Figure 10. According to the experts in this field, the flooding is caused by water that was pumped back into the old mines when they ceased operation. This water needs to be pumped out before the pillar coal can be extracted. However, it was observed that spontaneous combustion starts to occur after pit dewatering. This was also noted by Philip, Uludag, and Chabedi (2011).

Highly undulating coal seams

One of the operations visited was found to be severely affected by excessively undulating coal seams. These undulating coal seams also contain some old workings. This makes the opencast pillar mining process even more complex. Figure 11 shows a stratigraphic section of the undulations.

Drilling and blasting technique

There are two main types of drilling and blasting techniques in opencast pillar mining; bord-only collapse and bord and pillar collapse. These drilling and blasting techniques are aimed at preventing the ingress of air into the old workings, stabilizing the beam, and eliminating the occurrence of sinkholes. During the field investigations it became apparent that opencast pillar mining operations often struggle to identify the most suitable technique. The mines visited were found to have switched between the two blasting techniques as shown in Table VI.

The changes in Table VI are a result of several factors such as dilution, coal losses, and health and safety. For example, Laybourne and Watts (1990) conducted a study in which a mine switched from the bord-only collapse to the bord and pillar collapse technique with the aim of minimizing excessive dilution.

However, converting from one technique to the other has an effect on the drilling and blasting processes. The changes that can be expected when converting from the bord-only to the bord and pillar collapse technique are shown in Figure 12 and Table VII.

With the bord-only collapse technique, the pillars remain intact (standing) or semi-collapsed after blasting. This results in waste material (blasted overburden) falling and filling the bord voids around the standing pillars. This technique may result in excessive dilution and minimal coal losses due to top-ofcoal scalping. On the other hand, the bord and pillar collapse technique results in good segregation between the pillar coal and waste material. This is due to the simultaneous blasting of the pillars and the overburden. Although dilution is significantly reduced, this technique may result in an interlock of roof coal and waste. Minimal dilution may still be experienced on the borderline of the roof coal and the overburden. The expected outcomes of the two blasting techniques are shown in Figure 13.

Deciding between the bord-only collapse and the bord and pillar collapse blasting techniques can be difficult, not only for new mines but also existing mines that seek to convert. In general, the major challenges expected were identified as spontaneous combustion, sinkholes, incompetent roof strata, excessive dilution, pit flooding, and tramp material. Any opencast pillar mining operation can expect to encounter one or more of these challenges. These challenges were found to originate from risk factors associated with the old workings. The three main risk factors are (1) unknown conditions of the old workings, (2) partially known conditions of the old workings, and (3) inaccurate information on the pillars in the old workings. When the conditions of the old workings are unknown or only partially known, detailed information such as pillar dimensions, pillar centres, roof thickness, and coal seam undulation are unavailable.

As such, a process flow chart for selecting the most suitable blasting technique based on the availability of information is proposed. The flow chart (Figure 14) consolidates the findings from the mine visits and provides a guideline for the selection of the most appropriate blasting technique. This flow chart takes into consideration the risk factors and the possible challenges that can be experienced during operation, which are influenced by the availability of information regarding the old workings. Based on this information, the appropriate blasting technique can be selected.

Health and safety

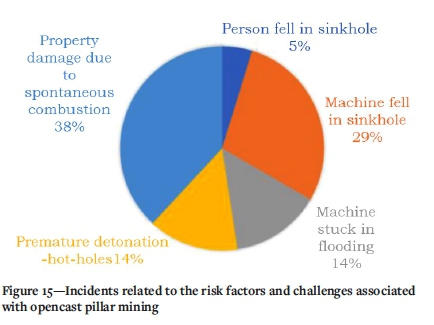

As opencast pillar mining is a complex and challenging undertaking, health, safety, and the environment are other major aspects for consideration. A number of unique incidents and accidents have been reported from the opencast pillar mines which were visited. These incidents were found to be directly related to the risk factors and challenges associated with the old workings. A total of 21 incidents were identified. These incidents include first aid cases, lost time injuries, recordable injuries, and fatalities, and involved both machines and persons. The major and frequently occurring incidents are summarized in Figure 15. All these incidents can be seen to be directly associated with the challenges and risk factors identified. Examples of these accidents include premature detonation of explosives due to hot holes, damage to trucks loading and transporting burning coal, and machines falling into sinkholes.

Conclusion

The extraction of pillars and remnant coal in previously mined underground bord and pillar operations using opencast mining methods involves some serious challenges. These challenges are mainly due to risk factors associated with the absence or partial availability of information pertaining to the old workings. The major challenges affecting opencast pillar mining were investigated. These challenges and risk factors need to be managed very well as they can have an adverse impact on productivity and safety.

A significant and valuable amount of coal can be effectively extracted from pillars in old workings. This requires the risk factors and challenges associated with opencast pillar mining to be managed properly. These challenges are managed differently by each mine as the conditions differ depending the way in which the underground mines operated. This requires a good understanding and management plan to deal with the challenges and risk factors. Drilling and blasting techniques and can be selected based on the conditions of the old workings.

Suggestions for further studies

➤ A significant amount of coal continues to be lost due to spontaneous combustion. However, no study has been able to quantify the amount of coal lost due to spontaneous combustion in opencast pillar mining operations. Therefore, some method of quantifying thee losses needs to be developed.

➤The biggest risk factor in opencast pillar mining is the paucity of information regarding the old workings. Therefore, a study of the feasibility of locating and assessing the condition of pillars in the old workings should be conducted to obtain the essential information required. This information can be used to extrapolate the parameters of the pillars and bords.

➤ The amount of water being pumped out from the old workings is still unknown. A study should be conducted to quantify the amount of water present in the old workings.

➤ An investigation into the effects of spontaneous combustion on the health and safety of employees and the nearby communities. This can be conducted through measuring the amount of emissions due to spontaneous combustion.

Acknowledgements

The authors would like to thank the mines that were visited and the personnel who facilitated the visits and contributed to the discussions by sharing their experience and expertise.

References

Clough W.D. and Morris, R. 1985. The opencast mining of previously undergroundmined coal seams. Journal of the South African Institute of Mining and Metallurgy, vol. 85, no. 12. pp. 435-439, [ Links ]

Cui, X., Zhao, Y., Wang, G., Zhang, B., and Li, C. 2020. Calculation of residual surface subsidence above abandoned longwall coal mining. Journal of Sustainability, vol. 12. p. 1528. [ Links ]

Eroglu, N. 1999. A literature survey of methods to prevent and control spontaneous combustion associated with mining and subsidence. Coaltech 2020, Project 3.4.1. Division of Mining Technology, CSIR, Johannesburg. [ Links ]

Eroglu, N. and Moolman, C. 2003. Develop methods to prevent and control spontaneous combustion associated with mining and subsidence. Coaltech 2020, Division of Mining Technology, CSIR, Johannesburg. https://coaltech.co.za/wp-content/uploads/2019/10/Task-3.4.1-The-Prevention-and-Controlof-Spontaneous-Combustion-associated-with-mining-and-subsidence-2003.pdf [ Links ]

Eroglu, N., Uludag, S., and Thyse, E. 2002. Develop methods to prevent and control spontaneous combustion associated with mining and subsidence. Coaltech 2020, Interim Report, Task 3. CSIR Mining Technology, Johannesburg. [ Links ]

Gemmel, G.B. 2016. Estimation of the propensity of remnant underground coal pillars to spontaneous combust during opencast mining at a colliery in the Witbank coalfield. MSc dissertation, University of the Witwatersrand. [ Links ]

Genc, B. and Cook, A. 2015. Spontaneous combustion risk in South African coalfields. Journal of the Southern African Institute of Mining and Metallurgy, vol. 115, no. 7. pp. 563-569. [ Links ]

Govender, G.L. 2018. Review of techniques for identification of underground bord and pillar workings. MSc dissertation, University of the Witwatersrand. [ Links ]

Han, H., Xu, J., Wang, X., Xie, J., and Xing, Y. 2019. Surface subsidence prediction method for coal mines with ultrathick and hard stratum. Advances in Civil Engineering. https://www.hindawi.com/journals/ace/2019/3714381/ [ Links ]

Hancox, P.J. and Gotz, A.E. 2014. South Africa's coalfields - A 2014 perspective. International Journal of Coal Geology, vol. 132. pp. 170-254. http://www.sciencedirect.com/science/article/pii/S0166516214001438 [ Links ]

Hartnady, C. 2010. South Africa's diminishing coal reserves. South African Journal of Science, vol. 106, no. 9/10. doi: 10.4102/sajs.v106i9/10.369 [ Links ]

Laybourne, R.A. and Watts, R. 1990. The development and application of strip mining to previously mined underground coal workings. Journal of the South African Institute of Mining and Metallurgy, vol. 90, no. 8. pp. 187-197. [ Links ]

Madden, B.J., Canbulat, I., Jack, B.W., and Prohaska, G.D. 1995. A reassessment of coal pillar design procedures. SIMRAC Final Project Report - COL021. Division of Mining Technology, CSIR, Johannesburg. [ Links ]

Madden, B.J., Canbulat, I., and York, G. 1998. Current South African coal pillar research. Journal of the South African Institute of Mining and Metallurgy, vol. 11. pp. 7-10. [ Links ]

Mahto, T. 2015. Safe extraction of developed pillars by opencast method - A challenge for mining engineers: A case study. https://www.slideshare.net/tikeshwarmahto5/extraction-of-developed-pillars-by-opencast-mine-acasestudy [ Links ]

Mohutsiwa, M. and Musingwini, C. 2015. Estimation of capital costs for establishing coal mines in South Africa. Journal of the Southern African Institute of Mining and Metallurgy, vol. 115, no. 8. pp. 789-797. [ Links ]

Moolman, C. and Canbulat, I. 2003. Economic and safe extraction of pillars and associated reserves. Coaltech 2020. Division of Mining technology, CSIR, Johannesburg. [ Links ]

Ngwenyama, P.L., de Graaf, W.W., and Preis, E.P. 2017. Factors and challenges affecting coal recovery by opencast pillar mining in the Witbank coalfield. Journal of the Southern African Institute of Mining and Metallurgy, vol. 117, no. 3. pp. 215-222 [ Links ]

Panigrahi, D., Sinha, S.K., and Singh, G.N. 2013. A study into occurrence of fire in opencast workings over developed coal pillars and evolving control parameters for its safe extraction. Archives of Mining Sciences, vol. 58, no. 4. pp. 1145-1162. [ Links ]

Peng, S.S. 2020. Surface Subsidence Engineering: Theory and Practice. Routledge, Abingdon-on-Thames, Oxfordshire, UK. [ Links ]

Phillips, H., Uludag, S., and Chabedi, K. 2011. Prevention and control of spontaneous combustion. Best practice guidelines for surface coal mines in South Africa. Coaltech 2020. Division of Mining Technology, CSIR, Johannesburg. https://coaltech.co.za/wp-content/uploads/2019/10/prevention-and-controlof- spontaneous-combustion-best-practice-guidelines-for-surface-coalmines-2011.pdf [ Links ]

Sasaoka, T., Takamoto, H., Shimada, H., Oya, J., Hamanaka, A., and Matsui, K. 2015. Surface subsidence due to underground mining operation under weak geological condition in Indonesia. Journal of Rock Mechanics and Geotechnical Engineering. https://www.sciencedirect.com/science/article/pii/S1674775515000438 [ Links ]

Schalekamp, E.E. 2006. The financial viability of coal reserves within previously mined areas of the Witbank coalfield. MSc dissertation, University of Pretoria. https://repository.up.ac.za/bitstream/handle/2263/26138/dissertation.pdf?sequence=1&isAllowed=y [ Links ]

Schernikau, L. 2010. Economics of the International Coal Trade. Springer, London. [ Links ]

Sloss, L.L. 2015. Assessing and managing spontaneous combustion of coal. IEA Clean Coal Centre. https://usea.org/sites/default/files/media/Assessing%20and%20managing %20spontaneous%20combustion%20of%20coal%20-%20ccc259_new.pdf [ Links ]

Stenzel, G.J. 2002. The effects of spontaneous combustion on safety, health and the environment of New Vaal Colliery. South African Collieries Managers Association. http://www.sacollierymanagers.org.za/docs/sacma9.pdf [ Links ]

Thompson, R.J. 2005. Surface strip coal mining. South African Colliery Managers Association. [ Links ]

US Energy Information ADMiNiSTRATion (EIA). 2020. Coal. http://www.eia.gov/todayinenergy/archive.php?my=all [ Links ]

Van der Merwe, J.N. and Mathey, M. 2013. Probability of failure of South African coal pillars. Journal of the Southern African Institute of Mining and Metallurgy, vol. 113, no. 11. pp. 849-857. [ Links ]

Van der Merwe, J.N. 2006. South African coal pillar database. Journal of the Southern African Institute of Mining and Metallurgy, vol. 106, no. 2. pp. 115-128. [ Links ]

Van der Merwe, J.N. 2018. Effects of coal mining on surface topography in South Africa - Updates and extensions. Journal of the Southern African Institute of Mining and Metallurgy, vol. 118, no. 7. pp. 777-786. [ Links ]

Wagner, H. 1980. Pillar design in coal mines. Journal of the South African Institute of Mining and Metallurgy, vol. 8. pp. 37-45. [ Links ] ♦

Correspondence:

Correspondence:

P.L. Ngwenyama W.W. de Graaf

Email: ngwenyama.pl@gmail.com wolter.degraaf@up.ac.za

Received: 9 Jul. 2021

Revised: 31 Oct. 2021

Accepted: 15 Nov. 2021

Published: December 2021

ORCID:

P.L. Ngwenyama https://orcid.org/0000-0002-9568-4964

W.W. de Graaf https://orcid.org/0000-0003-0169-4721