Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.121 n.7 Johannesburg Jul. 2021

http://dx.doi.org/10.17159/2411-9717/1430/2021

PROFESSIONAL TECHNICAL AND SCIENTIFIC PAPERS

Sensitivity of shotcrete Brazilian discs coated with thin spray-on liners to environmental conditions

M.J. KandaI, II; T.R. StaceyI

IUniversity of the Witwatersrand, South Africa

IIInstituto Superior Politécnico de Tete, Mozambique

SYNOPSIS

Thin spray-on liners (TSLs) have been used as sealants and rock support in tunnels for over 25 years. Laboratory tests have indicated satisfactory properties that can provide adequate strength, adhesion, toughness, and elasticity as part of rock support systems in mining excavations. These characteristics are, however, not always demonstrated in practice, when mine environmental conditions do not correspond with laboratory environmental conditions. The shortcomings of TSLs experienced in the mining industry have raised concerns, resulting in scepticism from some operators regarding their utilization. The research described in this paper aims to investigate TSL performance in environmental conditions similar to those experienced in mines. Brazilian indirect tensile (BIT) specimens were prepared from precast shotcrete and coated with TSLs. The specimens were then exposed to different environmental conditions for up to 112 days before BIT testing under various conditions: laboratory room temperature and humidity; saturated room temperature; and combined saturated and high temperature (50°C). Additional uncoated shotcrete and TSL BIT specimens were prepared for comparison purposes. The results of the BIT tests showed that environmental conditions have a significant influence on the tensile strength enhancement of shotcrete by TSLs. Water-based TSLs are most likely to be suitable for high humidity environments, although their performance decreases at higher temperatures. Numerical modelling of TSL-coated BIT samples confirms the potential limitations of designing TSL support based only on laboratory testing carried out under room conditions.

Keywords: thin spray-on liner, Brazilian indirect tensile (BIT) test, TSL performance, environmental conditions, humidity, high temperature.

Introduction

Accidents in underground mines are often rockfall related (Potvin, Stacey, and Hadjigeorgiou, 2004). To reduce accidents to a zero-harm target, various rock support techniques have been implemented and improved. Reinforcement supports such as frictional anchors, mechanically anchored rockbolts, and untensioned grouted dowels are common. Containment support such as shotcrete, wire mesh, and straps (Hoek, Kaiser, and Bawden, 2000; Stacey, 2001) has also been utilized to accommodate the rock mass displacement. These supports have shown advantages and limitations, depending on the rock mass qualities and mechanisms of rock mass failure.

An emerging areal support type is the thin spray-on liner (TSL). TSLs are also referred to as thin sprayed membranes, multi-component polymeric (based) liners, thin coating materials, or just thin liners. Suppliers have indicated, supported by laboratory results, that TSLs possess notably higher tensile strength properties than materials commonly used for rock support, such as shotcrete, and are capable of spanning cracks in the rock mass, thus limiting the movements of mobilized rocks (Tannant, 2001). Laboratory indirect tensile strength testing (Masethe, 2015; Mpunzi et al., 2015) has confirmed this, indicating that a TSL coating can increase the tensile strength of the rock and shotcrete by some 30-40%. A significant increase in the pull-off strength of TSL-coated shotcrete was reported in Canada (Simser and Pritchard, 2012; Boeg-Jensen, and Swan, 2014). With regard to practical implementation in mines, TSLs also provide rapid curing (Yilmaz, 2010) and simplicity of utilization and transportation, owing to the compact equipment size and the small volumes of TSL materials required.

All of these benefits could have been expected to lead to widespread adoption of TSLs in underground mines, but this has not transpired. The reason appears to be scepticism of mining operators regarding the actual performance of TSLs. Some mining companies are sceptical of new technology, particularly where safety is concerned, and have found that benefits claimed for TSLs were not observed in the field. Research has been carried out to understand the reasons behind these discrepancies, and possibly to find solutions for effective utilization (Kanda and Stacey, 2019; Guner and Ozturk, 2018, 2016; Boeg-Jensen and Swan, 2014). Based on industry reaction regarding TSL performance (Kanda and Stacey, 2019), it is believed that laboratory tests on TSLs should be carried out under environmental conditions similar to those in which TSL areal support is expected to be used, therefore enabling selection of the most appropriate TSL. To date, this has not been done, since laboratory tests are generally performed under room temperature and humidity conditions.

A programme of tensile tests on TSL materials under a range of environmental conditions demonstrated that mine-like conditions could severely degrade the performance of TSLs, and therefore lead to misjudgement of their real performance (Kanda and Stacey, 2019). However, in practice, a TSL does not act as a stand-alone material, but operates as a coating on the rock mass or on shotcrete. The research described in this paper aims to assess TSL behaviour in humid and high-temperature conditions when used as a coating. To achieve this, Brazilian indirect tensile (BIT) tests were carried out using shotcrete discs as a substrate, coated with the TSL materials, thus extending the research carried out by Mpunzi et al. (2015). Another important parameter to be investigated in the trials was the period of exposure to the environmental conditions after initial specimen preparation. This period should be longer than the commonly-used curing period of 28 days. The results for different environmental conditions will be compared with those carried out under the room conditions in which TSLs have been tested to date.

Effect of atmospheric conditions on coated BIT specimens

Research published by Kanda and Stacey (2019) on this topic suggests that TSL uniaxial tensile strength (UTS) is sensitive to humidity and a combination of high humidity and temperature conditions. That research was motivated by the logical observation that the testing environment should match the field conditions in which the TSL is to be applied. One of the fundamental bases for this research relied on the suggestions from Osswald (2015) that polymeric material behaviour over time is temperature-related and could be explained through the Boltzmann superposition principle. This principle stipulates that in the linear viscoelastic regime, the strain (stress) responses to successive stress (strain) actions are cumulative. Kanda and Stacey (2020) described the results of a programme of UTS testing of TSLs in a range of environmental conditions. As in that programme, the current work will assess the effect of different environmental conditions on the tensile strength behaviour of TSL-coated shotcrete discs. In addition, the liners' adherence behaviour on the substrates will be evaluated. TSLs are expected to contribute to resisting or smoothing crack expansion through their bonding characteristics and high tensile strength properties (Boeg-Jensen and Swan, 2014).

Laboratory testing and results

TSL characteristics

Three different TSLs were assessed through the Brazilian indirect tensile (BIT) test. For reasons of confidentiality they are referred to as TSL1, TSL2, and TSL3. Their characteristics are provided in Table I.

TSL1 is a mixture of cement, polymer, and sand. The technical sheet suggests that the final product can prevent unravelling and oxidation, and can afford lateral constraint to the rock mass. This latter benefit should be an advantage regarding the mechanical properties being researched. The UTS indicated by the manufacturers is 9.7 MPa after 28 days of room curing.

TSL2 is supplied in a bag as a single component powder, to which clean tap water is added to form the mixture. This cementitious product is claimed by the manufacturer to have a compressive strength of 44.7 MPa and a tensile strength of 3.1 MPa after 28 days.

The TSL3 technical sheet presents this liner as a plasticizer-free aqueous copolymer emulsion, consisting of acrylic acid esters. It also contains wetting agents mixed with a cementitious binder. Among the claimed benefits are non-flammability and non-toxicity, and the ability to bond to dusty, wet, and fatty surfaces. The expected tensile strength after 28 days is 9.75 MPa.

Specimen preparation

The TSL materials were prepared using an electrically operated mixer under room conditions. The electric mixer is a Bosch drill driver with a rated power of 400 W and a vibration level of 13/6.

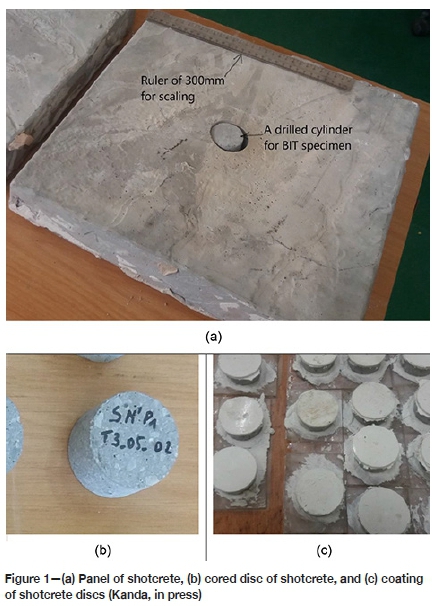

Discs of shotcrete were prepared for use as substrates in conformance with International Society of Rock Mechanics and Rock Engineering (ISRM) recommendations (Ulusay and Hudson, 2007). They were cored from fibre-reinforced shotcrete (Wetcrete) panels 45 χ 45 cm2 and 55 mm thick (see Figure 1a) provided by Concrete Lining Products (CLP), Carltonville, South Africa. These panels were cured in water containers for at least 30 days before supply, and had a characteristic strength of 40 MPa after 28 curing days. All cored discs were 42 mm in diameter and were trimmed to a length of 21 mm using a diamond saw, resulting in a length to diameter ratio of approximatively 0.5, as illustrated in Figure 1b. The coating of the shotcrete discs is illustrated in Figure 1c, the TSL thickness being 4 to 5 mm, as adopted by Mpunzi et al. (2015).

The BIT specimens were prepared as follows:

➤ A thin film of release agent was applied on all the circumferential parts of the mould pieces to avoid the formation of air bubbles.

➤ The mould pieces were placed on a flat working surface, previously covered with a plastic film to avoid direct contact between the liner material and the working surface, to avoid damaging the liner during specimen removal.

➤ The TSL materials were mixed as recommended in the manufacturers' technical specifications.

➤ The mixture was poured into the moulds, and spread using a spatula to ensure that it filled the moulds.

➤ A small quantity of the mixed TSL was applied to the cleaned shotcrete disc surface to ensure subsequent TSL adherence.

➤ The shotcrete disc was placed on the TSL in the mould and gently levelled.

➤ One day of setting time was allowed before removing the coated shotcrete.

➤ The procedure was repeated for the other surface of the shotcrete disc.

➤ Using a diamond saw, the TSL coating diameter was reduced to about a millimetre smaller than the shotcrete disc diameter, to ensure full contact between the steel platens and the disc during BIT testing.

A total of 300 BIT specimenswere prepared: 50 shotcrete discs were coated for each of the three TSLs; and 50 other discs were prepared from each of the TSLs. In addition, 40 uncoated shotcrete discs were also prepared. From the 50 coated shotcrete discs and 50 TSL discs obtained from each TSL, three groups of 16 to 17 specimens were allocated to three environmental conditions. These were: room conditions (R), the humid condition, defined as storage in a container full of tap water at room temperature (H); and the humid and high-temperature condition, involving storage of specimens in a container of water which was placed in an oven at 50°C (HT). The uncoated shotcrete discs were split into three groups of 13 to 14 specimens each and allocated to each of the three environmental conditions. BIT testing was planned after exposure to these conditions for periods of 15, 28, 56, and 112 days. The focus was, however, on the periods longer that the usual TSL 28-day curing time.

Test set-up

The BIT tests were performed on specimens coated with TSL1, TSL2, and TSL3. The aim was to assess the influence of environmental conditions on the indirect tensile strength of coated BIT shotcrete. TSL discs and uncoated shotcrete discs were also tested separately, in all cases following the ISRM suggested methods (Ulusay and Hudson 2007) The specimens were exposed to R, H, and HT conditions for periods up to 112 days, before testing in a MTS testing machine, shown in Figures 2a and 2b. An example of the output BIT test graphs is shown in Figure 2c.

The tensile strength was calculated as follows:

where

F is the compressive force applied along the disc diameter (N)

t is the disc thickness (mm)

d is the disc diameter (mm).

In determining the disc thickness, the TSL thickness was not taken into account, since its effect has been shown to be negligible (Mpunzi et al., 2015). The TSL helps to strengthen the substrate by its resistance to tensile failure.

Laboratory results

After testing, only the specimens that failed along the loaded diameter were considered. Those that had circumferential failures were discarded. A sample of the tested BIT specimens is presented in Figure 3.

Uncoated shotcrete discs, cored from the supplied panels of reinforced shotcrete, exhibited a near-constant BIT strength of about 5.2 MPa under room conditions. These results, and those for discs exposed to the different environmental conditions, are shown in Figure 4.

As can be seen from Figure 4, H and HT conditions adversely influence shotcrete BIT strength, contrary to the expectation that the H condition would strengthen the shotcrete, since it was cured in saturated conditions. A possible explanation is that the discs were prepared using a diamond coring machine that employs water for lubrication and cooling during cutting, producing a signiicant quantity of ines. This could be one of the reasons for the subsequent strength loss.

The BIT strength trends for the discs coated with TSL1, TSL2, and TSL3, and exposed to various environmental conditions are shown in Figure 5.

The graphs in Figure 5 show that TSL1 and TSL3 are the best-performing coatings under room conditions, while water-based TSL2 performs better under saturated conditions, retaining the BIT strength just below the room strength. In HT conditions, none of the three TSLs was able to improve the overall BIT strengths over time. TSL3 showed the greatest strengthening capability in HT conditions. This TSL has better combined bonding and tensile characteristics than TSL1 and TSL2 in HT conditions. However, the evaluation of strengthening capability must take into consideration the substrate's loss of strength under the same environmental conditions. To do this, representative strength curves of specimens were chosen based on their average strengths. Table II displays a sample of these averages and the corresponding coefficients of variation (CoV) after exposure for 15 and 112 days.

The TSL strengthening results obtained are summarized in Figure 6.

Figures 6 shows the strengthening trends of TSLs under room conditions. All three TSLs enhanced the strength of the discs, thus demonstrating their potential to improve the resistance of shotcrete to crack expansion. In saturated conditions, the TSLs imparted a somewhat smaller strength improvement, and under HT conditions, the effect of all three TSLs was reduced. These results complement those from Figure 5, which displays the overall strength trends for coated discs without considering the influence of environmental conditions on substrate behaviour. Therefore, for shotcreted walls that are susceptible to tensile cracks, TSL1 would be recommended when the environment is close to room conditions. In saturated conditions, TSL2 should be recommended, while TSL3 would be the most appropriate of the three for walls in environments that combine both high humidity and temperature conditions.

Since a TSL coating is expected to enhance the BIT strength of the substrate, the elongation of TSLs and uncoated shotcrete under BIT loadings was assessed. Elongation is proportional to the vertical displacement recorded at the BIT strength. Referring to the two cited properties, the behaviours of BIT discs of the TSLs and the uncoated shotcrete were compared. The results are displayed in Figures 9, 10, and 11. These results support resorting to TSL1 under room conditions, while TSL2 should be used in saturated conditions, although having slightly lower elongation capabilities than shotcrete over longer periods of exposure. TSL3 has almost the same elongation ability with shotcrete in HT conditions and should be used in such conditions.

Modelling of a shotcrete disc coated with TSL under R and HT conditions

The influence of a TSL coating on the tensile strength of rock and shotcrete was evaluated by Mpunzi et al. (2015) by means of BIT testing in the laboratory. This work indicated that the tensile strength of the shotcrete disc was increased by some 30 to 40% when coated with a TSL. As part of this evaluation, they carried out numerical modelling of a shotcrete disc coated with TSL, but that investigation was limited to TSL properties under room environmental conditions. To extend this work in the current research, and with the aim of simulating TSL performances when coated on underground walls subject to extension cracks, modelling of coated discs was carried out for two environmental conditions, R and HT. In these analyses, to focus on the impact of the coating on the substrate BIT strength, the material properties of the substrate in HT conditions were maintained constant and equal to those for room conditions. Input strength and deformation parameters for the analyses were adopted from the laboratory results, and TSL1 properties were used.

The numerical modelling was carried out using the Rocscience RS3 three-dimensional finite element stress analysis package. The factor of safety (FoS) was assessed for BIT coated specimens exposed to varied atmospheric conditions for 112 days. To evaluate risk associated with the adoption of TSL properties, it is necessary to determine the probability of failure (PoF). Since a probabilistic analysis is not incorporated in RS3, the response surface methodology (RSM) (Chiwaye and Stacey, 2010;

Kanda and Stacey, 2016) was used to assist in generating FoS probability distributions with the help of an Excel spreadsheet add-in simulation package, Oracle Crystal Ball. From the distribution of FoS, the PoF can be obtained and the associated risk determined. In this analysis, only two strength properties of the TSL were considered, namely the uniaxial compressive strength (UCS) and the uniaxial tensile strength (UTS).

Model discretization

A disc of 42 mm diameter, 21 mm thick and coated with a 5 mm TSL was modelled, as illustrated in Figure 7. The circular section was subdivided into 40 equal parts. Loading was applied to four of these parts, and the four diametrically opposite parts were restrained; these represented the platen conditions. Loading of the model was chosen to produce an FoS between 1.50 and 2 in R condition, an assumption made to create stability.

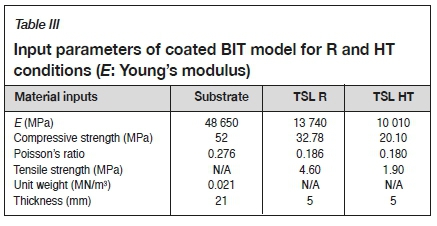

Table III shows the input parameters for shotcrete, and the TSL room and HT conditions.

Modelling results

The base cases of the FoS obtained from modelling of the coated BIT disc from BIT models related to R and HT conditions were 1.61 and 1.15, respectively. The RSM dictated the determination of a total of 2n+1 FoS values, corresponding with five values for each model type, as illustrated in Tables IV.

The FoS distributions generated through RSM are presented in Figures 8a and 8b for R and HT conditions, respectively. The base cases represent the averages of the FoS, while the PoF values are presented as the certainty percentages of the FoS that are less or equal to unity. These PoFs are 14.98% and 36.44% for R and HT, respectively.

Risk is defined by the relationship:

Risk = PoF *Consequence

The consequence was assumed to be identical in R and HT conditions. Therefore, the comparative study of the risks of using

TSLs in R and HT conditions relied solely on a comparison of the PoFs. Based on the coated BIT results from room and HT conditions, the risk of employing TSL1 in HT conditions is more than twice that for R conditions. It may therefore be concluded that it is inappropriate to design TSL rock support for deep underground HT conditions using parameters determined in normal room conditions in the laboratory.

Discussion

Laboratory tests

The choice of 50°C for high-temperature conditions was motivated by the fact that, although rock temperatures in deep and ultra-deep mines range between 50 and 140°C (Oniyide, 2015), TSLs will usually be applied in openings that are ventilated. Therefore, the interface between the liner and the rock mass is assumed to be at temperatures between the high rock temperature and the cool ventilation temperature.

H and HT BIT specimens were coated one face after the other, under room conditions. This process required three to four days for a secure setting of the coatings before the specimens were exposed to H and HT conditions for the required periods. In practice, however, there is no 'waiting time' between the application of liners and their exposure to the environmental conditions; and TSLs may be applied directly onto hot and moist or wet rock. Additional studies on less brittle TSLs that can soon be handled are therefore encouraged, to obtain possibly more representative strength enhancement behaviour in various environmental conditions. Other factors such as the type of tests used to assess TSL performance, ground preparation, and scale effect. may be investigated in the suggested studies.

In the assessment of coated BIT strength enhancement, the decline in substrate strength that occurs in H and HT conditions was taken into account. This decline may be due to the friability of the substrate's surface when exposed to those environmental conditions. Therefore, a coated shotcrete disc should not be fully affected by the weakening effect of H and HT conditions. This assumption is supported by the fact that the shotcrete surface is covered with TSL before it is exposed to more aggressive environmental conditions. However, the strengths of the coated BIT specimens tested after long exposures in H and HT conditions could decline to the extent of becoming lower than the uncoated substrate strengths. This proves that there has been a loss of the substrate strength. Otherwise, if the substrate did not lose strength, the recorded BIT strength could have remained, in the worst scenario, not less than that of the uncoated shotcrete. Thus, the shotcrete worst case was preferred for analyses.

Although wallrock deformation behaviour in underground conditions may be more complex than in the BIT specimens, the BIT tests have provided a reasonable basis for the evaluation of TSL comparative performance under room and HT conditions. A testing method that could better simulate the wallrock deformation than the BIT tests might bring more understanding and knowledge in the consideration of rock support using TSLs.

Numerical modelling

In the modelling, it was assumed that the material properties of the shotcrete substrate in HT conditions are equivalent to those under R conditions. This assumption is not borne out by the results of the laboratory tests, which showed that HT conditions affected the tensile strength of the shotcrete. However, the assumption was incorporated in the modelling to focus attention on the enhancement effect of TSLs in varied environmental conditions. Moreover, the declining strength of the substrate followed a negative logarithmic curve, indicating that the strength remained constant after a longer exposure period. In practice, the rock mass with shotcrete surface support in deep mines will have been subjected to such environmental conditions, and thus have already reached its long-term strength.

Only TSL1 properties were modelled and the resulting risk in using this TSL in room and HT conditions applies only for this liner. Further analyses need to be undertaken for other TSL types - for example, TSL3 showed better strength resistance in HT conditions. In addition, single values of the TSLs' UCS and UTS were adopted, whereas the laboratory tests showed that these properties were normally distributed, and this variability needs to be taken into account. Furthermore, the bonding properties of TSL should also be included in such studies. However, the omission of these parameters in the current study is justified by the assumption of their constancy and the fact that the analysis has been a comparative one.

The sensitivity of the FoS evaluations to the change in TSL material properties due to the environmental effects suggests that the combined numerical analysis/FoS approach could have potential for design calculations. However, further research will be required to confirm this.

Conclusions

Previous publications have indicated that TSLs can provide significant benefit in the support of underground excavations in rock masses. Laboratory testing of TSL materials and indirect tensile testing of TSL-coated rock and shotcrete discs have confirmed this supposition. However, the implementation of TSLs as support in mines has been limited, possibly due to scepticism from mining operators regarding their effectiveness in the mining environment. Most TSL test data reported in the literature has been obtained in 'standard' room temperature and humidity environments, which are not typical of conditions in deep mines. In the research described in this paper, results of intensive and reproducible tests carried out on TSL materials exposed to high humidity and 50°C conditions have been described. Indirect tensile testing of TSL-coated shotcrete discs was carried out to determine whether TSL performance under deep mine conditions matched that in normal laboratory conditions. The results showed that a TSL coating can enhance the tensile strength of the shotcrete under the deep mine conditions, but not to the same extent as indicated for normal laboratory conditions. Whereas in the laboratory the tensile strength of the tested TSLs was enhanced by between 9% and 21%, in the deep mine conditions the improvement varied between 4% and 18%. The degree of enhancement depends on the duration of exposure to the more severe conditions, and on the type of TSL.

In addition to the laboratory testing, numerical modelling of coated BIT test specimens was carried out. These tests showed that, based on the input parameters from laboratory testing, the factor of safety could be as high as 1.61 after 112 days of exposure to room (R) conditions. However, when exposed for the same time to high temperature and humidity (HT) conditions, the factor of safety may be closer to unity. Extending these studies to probabilistic analyses showed that the resulting probabilities of failure of the coated BIT specimens for R and HT conditions would be about 15% and 36%, respectively. This indicates that to ensure that the rock support will provide a safe and stable working environment, it is essential to determine the properties and performance of TSLs under environmental conditions that are typical of the mining environments in which they will be applied.

Acknowledgements

The first author would like to thank the High Polytechnic Institute of Tete, Instituto Superior Politécnico de Tete (ISPT), Mozambique, for financial support.

References

Boeg-Jensen, P. and Swan, G. 2014. The operational and laboratory aspects of a thin spray-on liner. Proceedings of the 7th International Conference on Deep and High Stress Mining. Australian Centre for Geomechanics, Perth. pp. 241-251. [ Links ]

Chiwaye, Η. and Stacey, T.R. 2010. A comparison of limit equilibrium and numerical modelling approaches to risk analysis for open pit mining. Journal of the Southern African Institute of Mining and Metallurgy, vol. 110. pp. 571-580. [ Links ]

Güner, D. and Ozturk, Η. 2018. Creep behaviour investigation of a thin spray-on liner. International Journal of Rock Mechanics and Mining Sciences, vol. 108. pp. 58-66. [ Links ]

Guner, D. and Ozturk, Η. 2016. Experimental and numerical analysis of the effects of curing time on tensile mechanical properties of thin spray-on liners. Rock Mechanics and Rock Engineering, vol. 49. pp. 3205-3222. [ Links ]

Hoek, E., Kaiser, P.K., and Bawden, W.F. 2000. Support of Underground Excavations in Hard Rock. CRC Press, Boca Raton, FL. [ Links ]

Kanda, M.J. (In press). Long term performance of thin spray-on liners for permanent support in underground mines. PhD thesis, University of the Witwatersrand. 359 pp. [ Links ]

Kanda, M.J. and Stacey, T.R. 2020. Tensile strength sensitivity of thin spray-on liners to changes in environmental conditions. Journal of the Southern African Institute of Mining and Metallurgy, vol. 120, no. 4. pp. 251-259. [ Links ]

Kanda, M.J. and Stacey, T.R. 2019. Review of the practical effectiveness of thin spray-on liners based on information from suppliers and observations from the mining industry. Proceedings of the First International Conference on Mining Geomechanical Risk. Australian Centre for Geomechanics, Perth. pp. 443-458. [ Links ]

Kanda, M.J. and Stacey, T.R. 2016. The influence of various factors on the results of stability analysis of rock slopes and on the evaluation of risk. Journal of the Southern African Institute of Mining and Metallurgy, vol. 116. pp. 1075-1081. [ Links ]

Masethe, R. 2015. Quantification of the effects of thin spray-on liner application on shotcrete tensile strength. MSc dissertation, University of the Witwatersrand. [ Links ]

Mpunzi, p., Masethe, R., Rizwan, M., and Stacey, T.R. 2015. Enhancement of the tensile strengths of rock and shotcrete by thin spray-on liners. Tunnelling and Underground Space Technology, vol. 49. pp. 369-375. [ Links ]

Oniyide, G. 2015. Thermo-mechanical behaviour of rocks from the Bushveld Igneous Complex with relevance to deeper mining. PhD thesis, University of the Witwatersrand. 363 pp. [ Links ]

Osswald, T.A. 2015. Understanding polymer processing: processes and governing equations. Carl Hanser Verlag GmbH Co KG, Munich. [ Links ]

Potvin, Y., Stacey, T.R., and Hadjigeorgiou, J. (eds). 2004. Surface Support in Mining. Australian Centre for Geomechanics, Perth. [ Links ]

Simser, B. and Pritchard, C. 2012. Innovative ground control at Xstrata's Nickel Rim South Mine, Sudbury, Ontario. Presentation: Work Place Safety North, Sudbury, April 2012. https://www.workplacesafetynorth.ca/sites/default/files/resources/Innovative%2 0Ground%20Control%20at%20Xstrata.pdf [ Links ]

Stacey, T.R. 2001. Review of membrane support mechanisms, loading mechanisms, desired membrane performance, and appropriate test methods. Journal of the South African Institute of Mining and Metallurgy, vol. 101. pp. 343-351. [ Links ]

Tannant, D. 2001. Thin spray-on liners for underground rock support-Testing and design issues. Proceeding of the International Seminar and Field Trials on Surface Support Liners: membrane, shotcrete and mesh. Australian Centre for Geomechanics, Perth. pp. 1-18. [ Links ]

Ulusay, R. and Hudson, J.A.(eds). 2007. The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974-2006, Compilation arranged by the ISRM. Turkish National Group, Ankara, Turkey. 628 pp. [ Links ]

Yilmaz, Η. 2010. Tensile strength testing of thin spray-on liner products (TSLs) and shotcrete. Journal of the Southern African Institute of Mining and Metallurgy, vol. 110. pp. 559-569. [ Links ]

Correspondence:

Correspondence:

M.J. Kanda

Email: jacquesmpoyi@gmail.com

Received: 26 Nov. 2020

Revised: 11 Apr. 2021

Accepted: 26 May 2021

Published: July 2021

ORCID:

M.J. Kanda https://orcid.org/0000-0002-1220-855X

Appendix

Declarations

Financial support: The research was supported by the University of the Witwatersrand, which availed both logistics and financial support whenever needed. The High Polytechnic Institute of Tete (Instituto Superior Politécnico de Tete (ISPT)) also contributed through financial support to the first author to complete his studies.

Conflicts of interest/Competing interests: The authors declare that they have no conflict of interest