Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.120 n.11 Johannesburg Nov. 2020

http://dx.doi.org/10.17159/2411-9717/1174/2020

PROFESSIONAL TECHINICAL AND SCIENTIFIC PAPERS

The risk-based approach to water management, and major challenges in the mining industry - ESG and the economics and ethics

S. Barry

The Advisory Group

SYNOPSIS

The risk-based approach is the only approach that views the full spectrum of risk, following transparent international guidelines (ISO 31000) which can add value. It is also the only truly holistic approach that includes all stakeholders.

Mining is now under the spotlight as never before owing to open-pit and tailings failures, and also general activist perceptions that can affect investment and operations. It must be seen to reduce the range of risks and the effects that are the consequences of its operations. The key lies in the integrated solution that includes risk management, new and resilient technology, effective procedures, the provision of real-time ground truth, and the ability to act fast. This is now possible due to advances in the IoT and automation. The display of actionable ground truth-based data that can trigger a tested and speedy response is not a luxury, but a necessity. There is now the ability to automate that response, reducing risk even further. A leading authority has recommended that the most effective approach is risk-informed safe design.

The issuing of the Global Tailings Standard in August 2020 will also exert pressure for this matter to be addressed more effectively than hitherto.

The risk-based approach is cost-effective and can deliver added value, not only for more effective operational management, but also with regard to oversight for ethical investment following IFC Guidelines and the Equator Principles, as well as any other compliance requirements.

This paper describes the methodology to be followed and the possible solutions that could result. The technical communications element was developed in conjunction with providers. It also covers the economic and ethical benefits of following this course of action, and implicitly the costs of not doing so.

Keywords: water management, tailings, open pit, risk-based approach, best practce.

Introduction

Recent disasters such as Brumadinho (Feijão Dam Expert Panel, 2019) have focused attention on the mining industry as never before. By charging the CEO of Vale with 250 counts of homicide, the Brazilian government has directly challenged mining companies both to reduce the risks from their operations, and to be seen to do so. There is also a significant effect on future investment potential.

Tailings disasters have led to the International Council on Mining and Metals (ICMM) to publish their draft Global Tailings Standard, which seeks to impose standards for compliance for their members first, but with the intention that this will spread across the industry. This is supported by the Ethical Investment Advisory Group (EIAG) of the Church of England and their Investor Mining and Tailings Safety Initiative.

This paper will explain the relevance of the application of the risk-based approach that follows the international guidelines laid down in ISO 31000, and which can also incorporate other ISO standards as appropriate (quality, HSE, environment, and infosec are other key associated areas). It will apply this approach to water management, including tailings storage facilities (TSFs), and seek to demonstrate how a combination of a clear risk management plan, supported by ground truth and effective technology, can be used to prevent disasters, rather than just give warning of them.

The requirements of environmental, social, and governance (ESG) concerns are growing relentlessly; as are the demands for compliance with standards for ethical investment, which will be crucial to raising capital in the future. Again, this can be addressed by the same provision of ground truth provided by a system that monitors and measures key indicators once they have been established.

Associated to this is insurance. Reduction of risk should so have the potential to reduce premiums, or just simply render companies more 'insurable'.

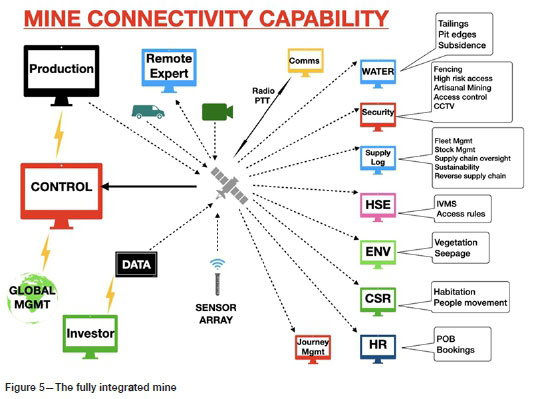

There is also a value add. This approach and the integrated solution that it will propose are scalable across the breadth of an operation to include many other key activities such as in-vehicle monitoring systems (IVMS), access control, and personnel on board (POB), as well as loss prevention to name but some; and also working across multiple operations separated geographically.

The risk-based approach

The risk-based approach as detailed in the ISO 31000 guidelines is internationally accepted best practice. It describes a very straightforward process for the management and treatment of risk which, if followed, can benefit an organization's overall management profile, increase efficiency, reduce risk significantly, add value, and provide transparency where required.

In business terms this comes down to maximizing profit and returns while keeping costs down and maintaining production within acceptable levels of risk. Added to that is the need to avoid liability and to be seen as acting ethically as well as in an environmentally responsible way. The increasing significance of the Equator Principles1 in new investment for mining, as well as activist and ethical investment bodies, marks this as an area, or indeed a risk, which can no longer be ignored. This needs to be fed with ground truth data that proves and supports compliance.

The key difference between this approach and a narrower technically based one is that the risk-based approach seeks to identify the full range of risks in detail. This enables them to be evaluated in the context of both the operation and their relationship with other risks. The best treatment can then be developed and owned by the most appropriate level of management. This solution can be technical, procedural, behavioural, or equipment-based. It is most effective when a combination of all of these. It can only succeed after proper evaluation and when subject to continuous oversight and regular review by the appropriate level of management. The integrated approach then becomes the integrated solution.

Part of the methodology is to determine what actually needs to be known - what is the 'information requirement'? Once that requirement has been defined, the best way of monitoring and measuring the item or event can be established. That method can be procedural or technical, but it should display all information outputs in one place, on a dashboard for example, enabling timely collation and evaluation, which can then trigger an action.

Water management in open pits and tailings

Water management (also referred to as 'comprehensive hydraulic solutions' in certain areas) is the most critical risk that a mining operation has to address and manage. Tailings are part of water management; however, tailings dam monitoring systems (TDMS) address only part of the water risk. This is a risk that in most cases should be addressed more comprehensively. Professor Norbert Morgenstern of the University of Alberta, a widely respected authority on water and tailings, proposed a system for performance-based risk-informed safe design (PBRISD), construction, operation, and closure of tailings storage facilities as recently as 2018 (Morgenstern, 2018). This can be scaled to include water risk; the principles are the same. It is worthy of note that a world-leading authority on the subject is recommending risk-informed design.

So often discussion of recent tailings disasters has focused on strategic planning, whereas these incidents really should be viewed in the broader context of water management. There are currently two approaches to this: warning and prevention. The first (warning) is most commonly used. Here slope stability is reactively measured by LiDAR, or proactively by piezometers positioned to warn of movement on the X, Y, or Z axes and imminent collapse. There are various steps in an integrated risk approach where there could be deficits:

> Not enough data (e.g. piezometer water levels) is obtained, or data is obtained too infrequently

> Although data is available it is not converted into information, e.g. piezometer data not used to undertake slope stability assessments or not compared against trigger levels

> There are no, or inappropriate, actions associated with trigger levels or stability assessment outcomes, e.g. inappropriate action would be to just issue a warning (sound a siren, evacuate people) and not try to lower the water level causing the trigger to be activated.

This in itself does nothing to mitigate the risk of collapse; it simply reduces some of its potential effects by issuing warnings, which if validated procedures are in place and followed, can enable an effective reaction. The collapse will still happen; and though lives may be saved, the destruction of communities and livelihoods and lost production will be major effects.

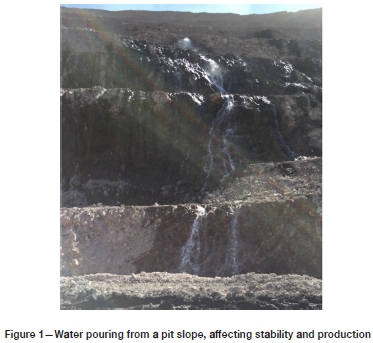

When De Beers states that it wants to manage its water as well as it manages its money it is clear that this is a serious issue. Jwaneng mine in Botswana lost almost 4 months of production due to a pit collapse in July 2012, primarily due to water pressure (Debswana, 2013). This enables an estimate of the cost of failing to prevent such an occurrence. More recently a legacy pit collapse at a Glencore mine in the DRC killed 43 artisanal miners (Financial Times, 2019). A verbal survey conducted at DRC Mining Week the month before found the two greatest concerns of mining companies in Katanga were water and artisanal mining. This event took place at a site often accessed by up to 2000 artisanal miners, in spite of security and the cooperation of Gecamines. The consequences were both financial (repair work and the fall in share price) and reputational/political, which can also affect the 'social licence' to operate. In the worst-case scenario, it can lead to the loss of the 'legal licence' to operate in that country as well, and also longer-term reaction from investors.

The risk prevention approach for water differs in that the emphasis is on the measurement of pore pressure in sufficient time to enable effective water management measures (if put in place) to be taken to relieve that pressure (Morton, 2020). This is the critical difference for effective risk management: the ability to prevent rather than just the ability to warn - or not. It is the difference between accepting and mitigating a risk. At Brumadinho, several villages downstream received either late warning or no warning at all of the impending disaster because the processes were not in place or were not robust enough. It would be interesting to know whether they had ever been validated or recently checked, and by what level of management. These events can happen so fast that effective warning could only give a few minutes for action, but these minutes could make a difference between life and death (at Brumadinho the flow speeds would have given 3.5 to 7 minutes' warning to the first settlement downstream). That time data itself can be used as part of TARP planning. The real value of obtaining information 'in sufficient time', such as the high water levels and unwanted seepage recognized at Brumadinho for a long time (years) before the failure, would have been the ability to then take effective corrective action.

The technology is available, and the ethical requirement exists to minimize risk to life and property. In addition, the prevention of a pit collapse through proactive water management is a self-evident cost-effective method of avoiding long periods of lost production, and worse in the case of artisanal miners or anyone downstream who may be killed by such an event. Most of the fatalities at Brumadinho were Vale employees or their families.

Tailings dams can be categorized as 'active', 'dormant', or 'legacy' dams. Active dams are still being deposited on, dormant dams are no longer receiving tailings and may be part of an operating or defunct mine, and legacy dams are no longer part of an operating mine, may have little or no human presence, but may still pose a threat to their area and therefore still require monitoring. Brumadinho was not a legacy dam but an actively monitored one. The media claim that TUV SUD certified the dam as 'safe'.

'TUV-SUD said that the dam was stable, meaning the factor of safety was greater than one, within the error of their method of calculation. But the real error is the lack of complete and exact knowledge of the physical properties of the mine tailings. For that reason, the Dam Safety Guidelines of the Canadian Dam Association recommend a factor of safety of at least 1.5. Civil engineering structures are not supposed to be built or maintained at a point just slightly safer than the point of failure. In summary, TUV-SUD did not claim that the dam met generally recognized dam safety guidelines. They just said that they were certain that the factor of safety was greater than one.'(Emerman, 2019).

On the day that of the failure boreholes were being drilled on the dam to install piezometers. So, unlike many dormant dams, it cannot be said that in the case of Brumadinho there was no monitoring or human presence just because it was a dormant dam.

For a standard to be effective it has to be enforced. This concept enables a 'trust but verify' approach.

In many countries mining companies have set aside funds to cover TSF closure costs, in theory though not always in practice, as funds may have been diverted by those holding them. In Africa the most legacy tailings dams are in South Africa (252) and Ghana (45) (Grid Arendal, 2020).

Water pressure, levels, and density have all been measured by proven instrumentation for many years. Now, technology can enhance that and, when in combination with focused supporting procedures, actually provide an effective and cost-effective solution that gives actionable information in real time. There is considerable potential for artificial intelligence (AI) to enhance this, driven by data.

Figure 1 shows water flowing down the side of an open-pit in the DRC.

The technical approach

A number of possible solutions based around technology, data, and connectivity are available. They offer the ability to continue to measure those areas noted above, but also to manage the data more speedily, and therefore more effectively. However, the key question with data is: 'What does it enable me to achieve in terms of risk reduction?'. The answer is that data of itself is not a solution. Technology may provide a more efficient way of gathering the data, but there still needs to be a response that is triggered by the processing of that data, and which reduces, mitigates, or removes a risk.

For tailings and slope stability the key metric is pore pressure trend and distribution (Morton, 2020). The usual device for measuring pore pressure is a vibrating wire piezometer (Figure 2).

The other key parameters for water are movement in the X, Y, and Z axes. More inputs can also be measured but they will be surrogates. The collation, evaluation, and accurate interpretation of this data is a crucial stage in delivering the effect required.

Beyond measuring water pressure, there are ranges of sensors that can measure and report data on almost anything. Drones are being increasingly used to carry sensors to monitor environmental effects that are of interest to both communities and investors. For example, the structural integrity of some major dams is monitored by thermal imaging.

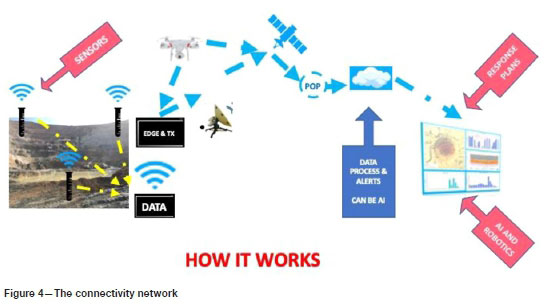

Reliable connectivity is crucial to a resilient system. Sensors can be integrated fully into the system but the technical backbone and output must be sensor-agnostic.

Figure 3 shows a sim card-enabled wireless transmitter for connection to a sensor.

Artificial intelligence, machine learning, and robotics

AI and robotics have the ability both to enhance resilience and to manage and act upon data more efficiently than humans.

This is a great opportunity for digitalization, which could culminate in digitalizing the whole project from end to end. Digital workers can automate many of the tasks and activities, including making decisions and escalating issues where these are rules-based - 'if the data says this, then do that'. The bots can send alerts to the human operators for them to action. AI means many things. In the case of mines AI (machine learning) can process data to learn things, make predictions, spot trends, and tell whoever needs to know details that may not be apparent based on their experience / intuition alone.

The robotics/AI opportunities make most sense when implemented at scale (which allows for redundancy). For example, a single digital operations room, as an outsourced utility, can monitor activities at any number of mines, providing a totally reliable, resilient, and low-cost service (the bots will always turn up, work 24x7, do not get tired or sloppy, are totally accurate, do not act malevolently) working remotely and cost effectively to support any mining operation, anywhere on the globe.

This can make the system as close to 100% reliable as it gets, and therefore constitutes a very effective and transparent risk treatment measure. It also provides strong evidence of effective governance. Security from vandalism and theft is an issue, but work is being done to 'harden' possible vulnerable parts of the system.

Procedure

Data is only as good as the effect it can deliver or prevent. Effective and validated procedures based around the risk management process are a key element of the system. It was a failure of procedures that resulted in the consequences of Brumadinho being worse than they should have been. The primary cause of the failure was poor design (too steep). The secondary cause was not implementing sufficient corrective actions when high water levels were observed. As the Expert Report states: 'Thefailure is also unique in that it occurred with no apparent signs of distress prior to failure. High quality video from a drone flown over Dam I only seven days prior to the failure also showed no signs of distress. The dam was extensively monitored using a combination of survey monuments along the crest of the dam, inclinometers to measure internal deformations, ground-based radar to monitor surface deformations of the face of the dam, and piezometers to measure changes in internal water levels, among other instruments. None of these methods detected any significant deformations or changes prior to failure.

'That such a catastrophic failure can develop with no signs of distress, and no indication that stability was being compromised, is a great surprise. It implies that thefailure was extremely brittle. The Expert Panel looked in detail at all of the monitoring data, and undertook a back analysis of historical InSAR data. They conclude that the dam was settling at rates of up to 30 mm per year, but this was expected and could not be used to infer that stability was compromised (Feijão Dam Expert Panel, 2019).

This shows clearly the need to validate the applicability of various data to a specific site, and to have procedures in place to ensure that no gaps exist in the data cover or processing. When the human interface is part of any risk treatment process, that process can be complete only when properly validated procedures are in place and universally practiced and understood.

Connectivity and system resilience

Connectivity can be based on the GSM network where available and switch to satellite when GSM is no longer available. It is not satellite-reliant; satellite connectivity just gives full resilience. The system on site will be connected through a long-range wide area network (LoraWAN) network, which operates via GSM or satellite as necessary. In fact, integration with legacy communications and IT systems on site can now be part of the solution. The remote sensors can be monitored for serviceability and resilience on an hourly basis, or even less, using remote AI. This has been proven in field tests with 'management by exception reporting', which also provides a verifiable systems resilience audit trail.

Figure 4 shows a possible connectivity network. The acronyms are explained in the glossary at the end of this paper.

Ethical conduct and investment

There has been an increase in the demand for ethical investment oversight, and also environmental, social, and governance (ESG) compliance. Here the stakeholders are from a broad range and can be as diverse geographically as they are by discipline and organization. Their influence is increasing to the extent that they form a key element of the investment due-diligence process. Their demand accurate information and transparency, in near-real time, will only increase.

The effects on communities and the environment are now identified as critical risks by investors. Addressing these risks and concerns, openly and efficiently, may be crucial to securing investment; being able to assure investors of continued compliance may also be the key to subsequent investment. This technology can support a variety of relatively cheap sensors that monitor and measure those environmental effects that are now the cause of such concern (for example, area water and air quality supported by sampling and testing). Just as importantly, they can continue to do so through the life of a project and beyond. This is one of the areas where the integration of drones with the appropriate sensors has significant potential.

The Church of England's EIAG has growing influence with multi-billion dollar funds, investment from which is key to the raising of capital. It is no coincidence that the cover of their most recent report was a picture of a mine pit in Africa. Investors want to be able to monitor compliance with set environmental and ethical standards, not just when raising capital, but throughout the life of the project. This is part of the overall risk management process and is a realistic by-product of this proposed system.

Insurance

Insurance is a significant operating cost to most mining companies. An effective system to prevent or mitigate the major risks associated with water can affect a company's 'insurability' and could even lead to a reduction in premiums once the effectiveness of the system has been proven. This could add to the business case for implementing such a system. This area is being developed with the insurance industry, insurance being a widely used risk treatment option (ISO 31000).

Value addition

The ability to access real-time ground truth has a significant operational value. The integration of legacy systems is now a reality, enabling the display of all information deemed important at multiple locations across operations and continents in real time. Investment in the mitigation of key risks can bring with it increased operational efficiency at little extra cost.

Figure 5 shows the range of additional functions that can be integrated to maximize the potential of the technology and deliver a fully integrated mine.

Conclusion

The risk-based approach is feasible and can be implemented now.

Getting water management wrong will cost money and possibly worse, as in the case of Vale. The risk management-based approach to this and associated elements is a proven methodology that can deliver a comprehensive and integrated solution, which can provide confidence, though an element of risk will always remain. The purpose of risk management as defined in ISO 31000 is the creation and protection of value. This concept aligns with that principle. A leading authority has recommended (Morgenstern, 2018) that the most effective approach is risk-informed safe design.

The difference between receiving warning of an event that is inevitable and being able to prevent that event by sound planning is enormous, as are the effects. It requires investment, but by making a risk preventable, has a value. This value is more than monetary, it is also ethical and reputational. The ability to prove to investors that the organization is, and will remain, compliant will be a key factor in securing investment. Proof that ESG principles are being followed will also be increasingly important for future investment.

The technology is proven, cost-effective, resilient, and now has the added advantage of being able to integrate legacy systems and is sensor-agnostic. This can deliver a more integrated management system across the board, as well as ensuring that all those who need to know ground truth can do so, wherever they may be. Beyond this is the ability to automate risk mitigation to deliver enhanced resilience and risk reduction. Most importantly, this offers a cost-effective and transparent approach to increasing value and reducing risk across the full spectrum of operations.

References

Church of England. 2020. Investor Mining and Tailings Safety Initiative. Ethical Investment Advisory Group. https://wwww.churchofengland.org/eiag [ Links ]

Debswana. 2013. Report to Shareholders. Gaborone. [ Links ]

Emerman, S.H. 2019. Safety audit of the failed dam at the Córrego Feijão Mine. Summary [in English]: https://worldminetailingsfailures.org/wp-content/uploads/2019/02/Corrego_Feijao_Safety_Audit_Summary.pdf [ Links ]

Equator Principles. 2020. https://equator-principles.com/about [ Links ]

Feijão Dam Expert Panel. 2019. Report of the expert panel on the technical causes of the failure of Feijão Dam. http://www.b1technicalinvestigation.com/report.html [ Links ]

Financial Times. Report on Glencore pit collapse DRC. 4 July 2019. [ Links ]

Grid Arendal. 2020. Global tailings dam portal. Global Industry Standard on Tailings Management, https://www.grida.no/news/8 [ Links ]

International Finance Corporation. 2020. Performance standards. https://www.ifc.org/wps/wcm/connect/Topics_Ext_Content/IFC_External_Corporate_Site/Sustainability-At-IFC/Policies-Standards/Performance-Standards [ Links ]

International Council on Mining and Metals. 2020. Global Industry Standard on Tailings Management. https://globaltailingsreview.org/wp-content/uploads/2020/08/global-industry-standard_EN.pdf [ Links ]

ISO. International Organization for Standardization. 2018. ISO 31000. Risk Management Principles and Guidelines. Geneva. [ Links ]

Morgenstern, N. 2018. Geotechnical risk, regulation and public policy. 6th Victor de Mello Lecture. http://www.victorfbdemello.com.br/arquivos/Lectures/6TH_VICTOR_DE_MELLO_LECTURE.pdf [ Links ]

Morton, K. 2020. Tailings dam risk reduction using accurate pore pressure monitoring. Proceedings of the Tailings Storage Conference, Johannesburg, South Africa, 10-13 February 2020. https://globaltailingsreview.org/wp-content/uploads/2020/07/Dr-Kym-L-Morton-response-combined.pdf [ Links ]

United Nations. 2007. Principles for responsible investment. https://www.unpri.org/pri/what-are-the-principles-for-responsible-investment [ Links ]

Correspondence:

Correspondence:

S. Barry

Email: simon@theadvisorygroup.org.za

Received: 8 Apr. 2020

Revised: 1 Oct. 2020

Accepted: 5 Oct. 2020

Published: November 2020

1 The Equator Principles is a risk management framework, adopted by financial institutions, for determining, assessing and managing environmental and social risk in project finance.