Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.120 n.6 Johannesburg Jun. 2020

http://dx.doi.org/10.17159/2411-9717/1043/2020

STUDENT PAPERS

Identification of suitable areas for multi-reef operation at Thorncliffe Chrome Mine

L.L Mthembu*; L.D. Meyer

Department of Mining Engineering, University of Pretoria, South Africa

SYNOPSIS

Thorncliffe Chrome Mine, one of Glencore's Eastern Chrome operations, is currently mining the Middle Group No.1(MG1) chromitite layer and is conducting a pre-feasibility study for an expansion project to mine the Middle Group chromitite No.2 (MG2) layer. This paper focuses on identifying viable areas within the MG2 layer that adhere to the mining, geological, and rock engineering parameters for a safe multiple-reef operation; and establishing efficient ways of accessing and extracting the MG2 chromitite layer. The findings from the multi-reef project at Samancor's Tweefontein Mine (Gouvea, 2013) and Maritz (2015) emphasized that the best layout for a safe and stable multi-reef operation is one where pillars are superimposed.

The guidelines by Salamon and Oravecz (1976) were key in the selection criteria for pillar stability.

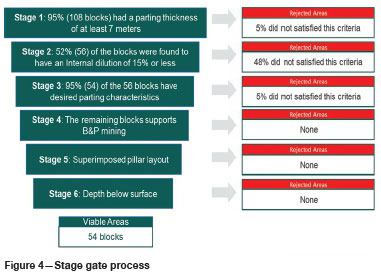

A stage gate analysis was used to identify mineable areas using the success selection criteria for mineability obtained from geotechnical and geostatistical analysis of the assay data and isopach plan. During this study, it was found that the most cost-efficient way of accessing the MG2 chromitite layer is from the MG1 mining horizon through a connecting ramp instead of sinking a shaft. Moreover, using the MG1 infrastructure during the development of the MG2 mining horizon will reduce the project development cost. A bord-and-pillar layout with superimposed pillars will assist in reducing the stress concentrations and interactions between the two mining horizons.

With all the considerations being satisfied, it can be concluded that the MG2 layer is viable to mine in a safe manner along with the MG1 layer in a multi-reef environment.

Keywords: multi-reef mining, chromite, superimpose pillars, mineable areas, Bushveld Complex, Middle Group No. 2 layer.

Introduction

This report is based on vacation work done by the author at Thorncliffe Chrome Mine during December 2018 and January 2019 to identify areas at Thorncliffe Chrome Mine that would be amenable to alternative layer mining. Thorncliffe, located in the eastern limb of the Bushveld Complex (BC), South Africa is one of Glencore's Eastern Chrome mining operations; it is a four-barrel decline system sunk on reef and produces 100 000 t/month on average from the Middle Group Chromitite No. 1 layer (MG1) using mechanized bord-and- pillar mining.

The Thorncliffe concentrator produces five main products, namely (in descending order of chromite content): foundry, metallurgical grade, low metallurgical grade, chips, and lump. The concentrates with a high chromite content are smelted to produce ferrochrome at either the Lydenburg or the Lion smelter.

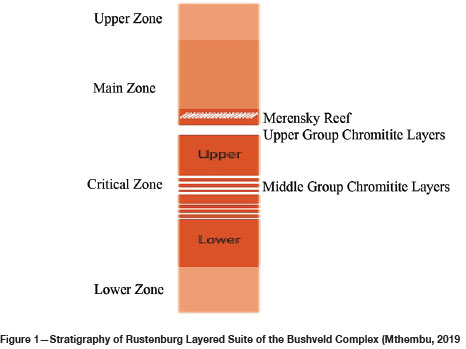

The Middle Group chromitite layers are found in the Critical Zone of the Rustenburg Layered Suite of the BC (Figure 1). The chromitite reefs are fine-grained with prominent nodules throughout; the immediate footwall and hangingwall consist of pyroxenite. It is important to note that the Middle Group No.2 chromitite layer (MG2) is situated above the MG 1 layer as seen in Figure 2. The MG1 layer has a thickness of 1.87 m and dips between 10 and 14 degrees.

Motivation for the study

The ferrochrome industry is currently facing serious challenges, due to the trade war between the USA and China, as well as production cost due to mine closures and lack of new ferrochrome capacity (Pastour, 2019). However, chrome ore production is expected to grow at a compound annual growth rate (CAGR) of 7% in the period 2019 to 2029 (Technavio, 2019).

According to Beveridge (2017), South African ore production is projected to need to increase to 2.5 Mt by 2021 in order to meet future market demands.

The projected increase in chrome ore demand affords Thorncliffe Chrome Mine the opportunity to increase output by exploiting the MG2 chromitite layer. This study was conducted to identify the viable areas within the MG2 that conform with the rock engineering, geological, and mining requirements.

The MG2 package varies from 1.85 m to 2.5 m in thickness throughout the BC, and is subdivided into the MG2a, MG2b, and MG2c (see Figure 2). For the purpose of this study these will be treated a single layer, taking into consideration the inherent dilution that would be introduced by mining the intervening pyroxenite layers.

This paper outlines the process followed to ascertain the feasibility of mining the MG2, but does not include the financial implications of the expansion nor does it consider downstream smelting as the project is still in feasibility stage.

Method

The methodology used in this study is outlined in Table I.

Literature survey

Multi-reef mining in a hard-rock environment is an established practice as shown by the following case studies of similar projects.

Case study 1: Tweefontein Chrome Mine

Samancor's Tweefontein Mine is situated in close proximity to Thorncliffe Chrome Mine, and is thus benchmark for multi-reef mining due to the stratigraphy being similar to that at Eastern Chrome Mines. Tweefontein is currently mining the MG2 layer above the mined-out MG1 horizon. Multi-reef mining started in 2008.

Pillar stability and the influence of the MG2 horrizon on the stability of the pyroxenite middling were assessed using numerical modelling to determine the best pillar layout, on the basis of induced tensile stress and excess shear stress, for a safe and stable operation (Gouvea, 2013).

The results conclusively indicated that the best layout was one with superimposed pillars. The stress due to the overburden on the MG2 mining horizon and the stress interactions between the MG2 and MG1 horizons were found to be insignificant and did not affect the overall stability of the operation. Due to the low average pillar stress, determined using the methodology proposed by Malan and Napier (2011), footwall punching was not expected

Case study 2: The effects of vertical stresses on pillar strength

The study (Maritz, 2015) focused on a mine situated in the eastern limb of the BC with a similar stratigraphy to Thorncliffe Chrome Mine. The mine's bord-and-pillar layout was simulated using Tabular Excavation Analysis (TEXAN) code. The author hypothesised a scenario for one section in which the pillars in the MG2 horizon and those in the MG1 mining horizon were superimposed (situated directly above each other), while in the other section the pillars not superimposed.

The effect of possible shear stresses on the pillar strength was evaluated.

The author argues that shear stress can be induced in pillars that are superimposed, while on the other hand, if pillars are not superimposed less stress is transferred to the MG2 pillars and the stresses on the MG1 pillars increase, as expected. However, the author emphasises that this scenario applied when the mining spans in the MG2 horizon were small and the factor of safety of pillars was high. As mining progresses, pillar and beam failure might occur due to the difficulty in transferring stress because of the longer spans. Hence, it is vital that MG2 regional pillars are superimposed with MG1 regional pillars to assist with the transfer of stresses.

Maritz (2015) concluded, based on this specific study, that when identical pillars are perfectly superimposed in a multi-reef layout, shear stresses are induced. This is due to the slight reduction in the normal stress acting on pillars. However, he emphasised that the effects of shear stress on the stability of pillars was not quantified and requires further research.

Summary

The findings from these two case studies can be utilized by Thorncliffe Chrome Mine to understand the factors influencing the positioning of pillars. Moreover, they emphasise the importance of a superimposed pillar layout in a hard-rock multi-reef environment for a safe and stable operation.

Multi-reef mining

Zipf (1900) and Hill (2014) investigated the factors that control interactions in multi-seam mining including vertical stress concentration, stress re-direction, bedding plane slip bands, and horizontal stress concentrations. Other factors to be considered are mining geometry, mine design, mining sequence, and geology. Although these factors were established in a coal mining environment, they can be applicable in a hard-rock mining environment with the same mining layout. However, it is important to note how these factors will differ in a hard-rock environment.

The industry guidelines for superimposition (Salamon and Oravecz 1976) were instrumental in the evaluation of mineable areas at Thorncliffe.

Results

Geostatistical and geotechnical analysis

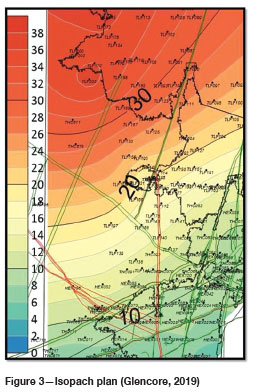

The isopach chart illustrated in Figure 3, together with the assay data, was used to assess mineable areas. The isopach chart was compiled from borehole data and indicates the parting thickness between the MG1 and MG2.

During the evaluation of mineability, the MG2 was divided into 114 geological blocks.

The criteria used to assess the mineability of the blocks are detailed in Table II.

Analysis of the selection criteria

Geostatistical and geotechnical analysis were conducted using the borehole data.

> The parting thickness between the MG1 and MG2 averaged 10 m over 95% of the production sections.

> The internal dilution due to the partings in the MG2 chromitite layer was less than the threshold of 15%, thus making 52% of the geological blocks economical for exploitation.

> 95% of working area had favourable parting characteristics.

> The case studies from the literature showed that bord-and-pillar mining will reduce the stress interactions in the MG2 mining horizons.

> The 54 geological blocks that can be mined economically allow for bord-and-pillar mining with a superimposed pillar layout, which does not influence the alternative mining horizons. There is a slight reduction in the normal stress concentration due to the generation of shear stress, which reduces the stress transfer between the pillars.

A stage gate process (Figure 4) was used to evaluate mineable blocks.

Mapping of the mineable area

MicroStation (3D CAD) was used to map the mineable area illustrated in Figure 5 that conforms to the selection criteria in Table II) within Thorncliffe Chrome Mine. The precise layout of the mineable area is withheld due to confidentiality reasons.

Summary

From the above evaluation criteria, it can be seen that approximately 47% of the potentially mineable MG2 reef is actually viable for extraction. This means that 53% of the geological block is not viable for extraction.

However, there are working areas that are borderline between viability and non-viability. Minimal changes can be made to make these areas viable for extraction. The characteristic that makes these areas nonviable is the parting thickness. By installing additional support and using relief mining, 16% of the borderline areas may be rendered viable. This would increase the area that can be exploited to 63% of the original block area, accounting for 72 of the original 114 blocks. Applying the mining method suggested and the appropriate method of access can increase the mine's reserves by 16.9 M reserves, and increase production by 50 kt/month.

Conclusion

A stage gate approach was used to evaluate criteria for the mineable areas. The criteria used the inherent geology required and the mining requirements for multi-reef operations as per operational standards. Fifty-four out of 114 geological blocks were found to be mineable.

The geological factors that were considered in the evaluation include depth of cover, rock characteristics, parting characteristics, and parting thickness. These were ranked from highest to lowest priority.

The production capacity of the current infrastructure was reviewed, and it was found that an additional production of 50 kt per month from the MG2 could be sustained.

Due to the fact that the infrastructure capacity supports mining from the main shaft, a secondary access will be used to access the reef as oppose to a new shaft being sunk from surface. This helps to improve the profitability, as the costs of sinking a new shaft clearly outweigh the revenue of mining the MG1.

With all the considerations being satisfied, it can be concluded that the MG2 layer is viable to mine in a safe manner together with the MG1 layer in a multiple reef environment.

Acknowledgements

I wish to extend my gratitude and appreciation to the following organizations and persons for their guidance and assistance during the course of the study.

Dr L.D. Meyer of the University of Pretoria (supervisor) Mr W. du Preez of Glencore (Chief Geologist)

References

Beveridge, M. 2019. Ferrochrome Market Overview.2017. Merafe Resources. https://www.meraferesources.co.za/pdf/presentations/2017/cru-market-overview.pdf. [accessed 10 October 2019]. [ Links ]

Edwards, A.C. 2001. Mineral Resource and Ore Reserve Estimation - The AusIMM Guide to Good Practice: (Monograph 23) - 36.2.2 Underground Mining. Ausralasian Institute of Mining and Metallurgy, Melbourne. 325 pp. [ Links ]

Glencore. 2017. Mandatory Code of Practice. Thorncliffe Chrome Mine. DMR Number: 3057. Unpublished internal report. [ Links ]

Glencore. 2018. Support Procedure. Thorncliffe Chrome Mine. DMR Number: 2595. Unpublished internal report. [ Links ]

Gouvea, J.P. 2013. Numerical modelling and analysis of the multi-reef mining layout at Tweenfontein Mine. Open House Management Solution (Pty) Ltd. Unpublished internal report. [ Links ]

Hill, R.W. 1994. Multiseam design procedures. CSIR: Division of Mining Technology. Safety in Mines Research Advisory Committee, Johannesburg. pp. 4-5. [ Links ]

Maritz, J.A. 2015. The effect of shear stresses on pillar strength. MEng thesis, Department of Mining Engineering, University of Pretoria. pp. 40-50. [ Links ]

Martin, C. and W. Maybee, W. 2000. The strength of hard-rock pillars. International Journal of Rock Mechanics and Mining Sciences, vol. 37, no. 8. pp. 1239-1246. [ Links ]

Pastour, D. 2019. Chrome alloy global markets - challenges and prospects. https://www.unichrome.ch/storage/20092019.pdf [accessed 10 October 2019]. [ Links ]

Technavio. 2019. Global ferrochrome market analysis - size, growth, trends, and forecast 2019 -2023. https://www.technavio.com/report/global-ferrochrome-market-industry-analysis?utm_source=t10discount&utm_medium=bw_wk50&utm_campaign=businesswire [accssessed 25 February 2019]. [ Links ]

Australasian Institute of Mining and Metallurgy. https://app.knovel.com/hotlink/pdf/id:kt008VMPW2/mineral-resource-ore/underground-mining [ Links ]

Zipf, R.K. 1900. Failure mechanics of multiple seam mining interactions. NIOSH-Pittsburgh Research Laboratory. pp. 93-94. [ Links ]

Correspondence:

Correspondence:

L.L Mthembu

Email: u15360319@tuks.co.za

Received: 30 Nov. 2019

Revised: 4 Jun. 2020

Accepted: 7 Jul. 2020

Published: June 2020

* Paper written on project work carried out in partial fulfilment of B.Eng (Mining Engineering) degree