Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.120 n.4 Johannesburg Apr. 2020

http://dx.doi.org/10.17159/2411-9717/952/2020

ARTICLES

Effects of mining operations on air and water quality in Mufulira district of Zambia: A case study of Kankoyo Township

D. MumaI; B. BesaII; J. ManchisiI; W. BandaII

IUniversity of Zambia, School of Mines, Department of Metallurgy and Mineral Processing, Lusaka, Zambia

IIUniversity of Zambia, School of Mines, Department of Mining Engineering, Lusaka, Zambia

SYNOPSIS

Air and water pollution are among the most significant environmental problems facing the communities living in and around the copper mining areas in Zambia. It is a complex issue, which cuts across the environmental, social, economic, and political dimensions. Despite recent investments and technological improvements to capture sulphur dioxide emissions and minimize the discharge of mine effluents into natural streams, there are still numerous reports that cite air and water pollution problems. The aim of this study was to investigate the effects of sulphur dioxide emissions and mine effluent discharge on air and water quality in Kankoyo Township of Mufulira district.

The investigation involved sampling of the ambient air, mine effluents, and domestic water and determination of sulphur dioxide and various water quality parameters. The results indicated significant improvements in sulphur dioxide capture and subsequent reductions in sulphur dioxide emissions from the copper smelter. The average sulphur capture was 48% from 2007 to 2013 and about 94% from 2014 to 2018. However, the average annual sulphur dioxide level for 2017/2018 was 144.5 ug/m3 per 24 hours, which is 15.6% above the statutory limit of 125 ug/m3 in ambient air. The general water quality meets the statutory limits, despite the fact that the water quality in this area may be affected not only by the mining activities, but also by the dilapidated water infrastructure, which may be a further source of contamination from intrusion by surface run-off and sewage leakage.

Keywords: environment, pollution, effluent, SO2 emissions.

Introduction

The problems of air and water pollution in Kankoyo Township began with the installation of two copper reverberatory smelting furnaces in 1937 (Ross and Vries, 2005). At that time there was no provision for capturing sulphur dioxide (SO2), and any SO2 emissions were vented directly into the atmosphere, resulting in many environmental and social impacts. The other contributing factor was the expansion of mining activities from the early 1940s to the present day. Thus, the current air and water pollution issues in Kankoyo Township are to some extent historical in nature, and have attracted interest from the local and international communities. However, the mining operations in this area have undergone several process and infrastructure upgrades and expansions, such as the replacement of the old electric furnace with an ISASmelt furnace and matte electric settling furnace (MSEF) which have resulted in significant operational transformations over the past decades (Alistair et al., 2012). This section gives a review of the key technological changes that have taken place, as well as challenges of the persistent air and water pollution problems that Kankoyo residents have faced over the years.

Significance of the study

The quality of air and water is at the core of the survival of human beings. The demand for clean air and water is at the top of the agenda on all governmental programmes at both national and international levels. A study of this kind is very important because it provides the most recent and relevant information on the status of air and water quality in Kankoyo Township, which can be used to assist stakeholders in making informed policy decisions to mitigate the impacts of environmental pollution arising from the mining activities. Similar studies have been done in the past by various authors (Mwaanga et al., 2019; Elisha, Clement, and Jhonnah, 2012; Chipatu, 2011), but these have not all provided updated information on the current pollution trends, including the sustainability aspect of mining and the environment.

Causes of air pollution

The gaseous fugitive emissions - mainly oxides of sulphur, acid mists, and particulate matter - from the copper smelter and sulphuric acid plants are the major cause of air pollution in Kankoyo Township (CPTD, 2010). Since the upgrade of the copper smelting process, many improvements have taken place, e.g. production of sulphuric acid from SO2 gas emissions, and also the application of more efficient pollution control technologies such as improvements in the conversion, absorption, and cleaning stages of gas emissions, which have greatly enhanced the process efficiencies leading to significant improvement in air pollution control (Ross and Vries, 2005)

Causes of water pollution

The possible sources of water contamination from the Mufulira operations include seepage and erosion from old tailings ponds, and release of process water from mining operations and metallurgical processing plants. Therefore, there is need for proper management of these point sources to minimize water contamination. Apparently, the tailing dams are approximately 10 km downstream from Kankoyo Township and discharge from the tailings dams flows outside the township into the Mufulira stream and finally into the Kafue River.

The demand for water in all sectors of the economy is such that sustainable management of water resources is critical. The mining industry in Zambia consumes a lot of water for various process requirements and at the same time generates thousands of cubic litres of mine waste waters and related hazardous effluents per day. Konkola mine (though not part of this study, being located about 35 km west of Mufulira mine, upstream on the Kafue River) is one of the wettest underground mine in the world; it pumps an average of 300 000 m3/d of water into the Kafue River (Mulenga, 1993).

Effects of air and water pollution in Kankoyo

Mining activities in Zambia are a major contributor to air and water problems, especially in the copper mining region. Emissions from the copper smelting and sulphuric acid production plants are among the major sources of air pollution in Kankoyo Township. The effects of air and water pollution in Kankoyo include the degradation of roofing sheets, wall plaster, and paint on the housing structures (Stephen and Wilson, 2017). Previous studies in Zambia have shown high concentrations of sulphur dioxide emissions that are above regulatory standards. According to Simukanga et al. (2010), the SO2 concentration levels, measured as two-week means, within the copper smelter plant area were well in excess of the World Health Organization (WHO) and Zambian 24-hour guideline value (125 ug/m3). These levels give rise to concerns for the health of the communities living near the plants.

Nature of the air pollution problem

The nature of air pollution in Kankoyo Township is a historical and complex problem which can be traced back to 1937, when the first reverberatory furnaces were installed at Mufulira mine. Thus, sulphur dioxide gases have been released into the nearby Kankoyo Township, which is located on the downwind side of Mopani copper smelter, for over eight decades. According to Jones (2015), 'Mopani Copper Mines commissioned their ISASmelt plant at Mufulira mine site in Zambia's Copperbelt in 2006. It was designed to initially smelt 650 000 tonnes per annum of copper concentrate, with the potential to expand to 850 000 tonnes per annum in the future. Mopani's ISASmelt plant replaced their existing electric smelting furnace, which were introduced in 1971 to replace the original reverberatory furnaces. The plant comprised a new feed preparation system, electric settling furnace, waste heat boiler, electrostatic precipitator, gas cleaning plant, oxygen plant and acid plant. The improvements were also made to the converter aisle and anode plants'. Although the technological improvements have helped to reduce sulphur dioxide emissions by 92% by 2018, fugitive sulphur dioxide emissions still remain the major air pollution problem in Kankoyo Township. According to the World Bank (2002), the potential human health impact from the emissions of sulphur dioxide includes respiratory symptoms, increased morbidity from respiratory diseases, and increased mortality, especially from cardiopulmonary disease.

Nature of the water pollution problem

Water pollution in Kankoyo Township is mainly a result of the poor and dilapidated water infrastructural network as revealed from the field study. The township's water supply pipes are old and in poor condition, constituting a potential source of water contamination, especially when there is a massive sewer blockage and overflow, which is likely to mix with drinking water, as shown by the outbreak of typhoid fever in 2012 (Syapiila, 2018). 'The old and damaged sewer and water pipelines, which run next to each other from the main water pump to the township, were the suspected source of typhoid fever infection'. Nearly all the township houses, apart from a few housing units which receive communal supplement water supply from Mopani Copper Mines, are supplied with water from Mulonga Water and Sewerage Company (MWSC), a local water utility. The test results from the samples collected in this research indicate impurity levels in compliance with the international and statutory limits for domestic and effluent water discharges respectively, and few incidences of water pollution have been reported in Kankoyo Township.

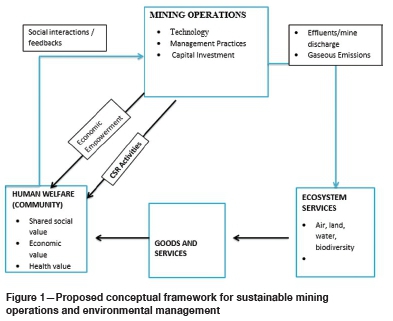

Conceptual framework

The conceptual framework given below summarizes the broad themes (social, environmental, and economic) of responsible mining that the mining companies need to focus on in order for their operations to be sustainable. It presents the interactions among the mining firms, the community, and the natural ecosystems.

Figure 1 shows the proposed conceptual framework for sustainable mining and environmental management. Sustainable development is an ongoing process, and not a temporary undertaking. It ensures the protection of natural resources and the environment. It also emphasises care for the employee at the workplace and community development in the area of the mining environment (Jozef, 2013).

Environmental sustainability

This section summarizes some important sustainability issues in the Zambian mining industry, illustrates the sector's best practices, and suggests sustainable practices for mining. Environmental stewardship is the keystone to sustainability in mining and industry (Zvarivadza, 2015).

Environmental degradation in Kankoyo Township is evident in the degraded physical structures or buildings, dust, air pollution, and surface and groundwater. This is also coupled with social and economic impacts. Therefore, mining companies must be aware of the potential impacts of their activities, and plan and execute strategies to have positive net outcomes that are sustainable in the long term. Mining companies, by virtue of their complexity, have always sought ways of improving productivity and reducing operational costs through adoption of various strategies such as reducing labour costs, and implementing austerity cost and safety measures. A mine must be profitable in order to be sustainable (IFC-World Bank, 2014).

A sustainable mining development takes cognisance of its impacts on the environment and adopts appropriate measures to address such impacts (Zvarivadza, 2015). Sustainable mining is about balancing financial, social, and environmental issues, to ensure the success of the company as well as the sustainable livelihoods of the communities. It involves community engagement and investments, respecting human rights, protecting the environment, being transparent, and acting with integrity (IFC-World Bank, 2014). It is a tool for balancing economic, social, and environmental considerations. Although the mining industry in Zambia has contributed greatly to the economic growth of the country, it has also contributed to the increase in environmental degradation. Some of the environmental hazards associated with mining activities in Kankoyo Township are listed in Table I.

Materials and methods

This study involved a combination of both qualitative and quantitative techniques. Specific techniques employed include laboratory test work and individual interviews with key informants, mainly the residents of Kankoyo Township. The study was also based on a substantive review of the publications by various scholars and researchers.

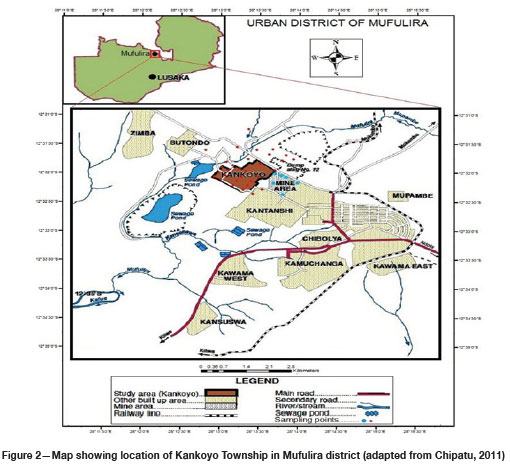

Case study location

Kankoyo Township is an old mining community located on the western side of Mufulira district near Mopani Copper Mines plc (MCM) operations. It is one of the low-cost and most densely populated areas in Mufulira district (Figure 2). The township is one of the major settlements in Kankoyo constituency with a total population of 45 258 people (22 754 males and 22 504 females) (CSO, 2013). According to Action Aid's (2015) Zambia study report, apart from a few people in Kankoyo working for the mines, the greater population is unemployed and a few people are engaged in informal trading of assorted merchandise'.

The study was focused mainly on the built-up settlement of Kankoyo Township, where most of the waters samples were collected (Figure 3).

Data collection and analysis

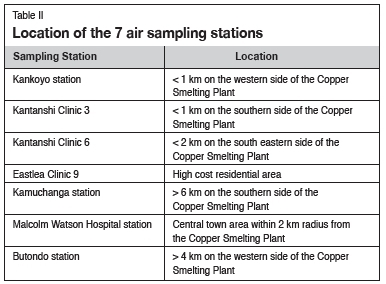

The field-based case study was both quantitative and qualitative in scope. The field work involved detailed observations of the copper smelter and acid plant emissions and mine effluent discharge, and the collection of water samples from 31 selected households. Seven weather stations for monitoring of sulphur dioxide levels (Table II) located at strategic sites in Mufulira district were used for collection of air quality data. Furthermore, mine water effluents were sampled at a few critical points within and outside the mining site to obtain additional information on the effects and extent of water pollution in Kankoyo Township. The sampling period for air quality was 18 months (i.e. from January 2017 to June 2018) at an average of 16 to 24 hours duration. and for water samples, 7 months (from January 2018 to July 2018).

The target population was specifically Kankoyo Township, including other strategic sites (i.e. the market and police post) around and within the township. Thus, the target population tended to be randomly selected based on the settlement plan. Structured questionnaires were also administered to 31 households/residents of Kankoyo to collecting additional information for research use.

Air quality samples

The air samples considered in this study were taken from the ambient air in Kankoyo Township and other selected parts of the Mufulira district. The locations of the seven air-sampling stations are given in Table II. These air sampling and monitoring stations have state-of-the-art equipment, which uses the S5001 SO2 analyser series to perform sulphur dioxide measurements over a range of 0-2 ppm with a lower detection limit (LDL) of 0.5 ppb. The measurement of sulphur dioxide is based on X-ray fluorescence spectroscopy (XRF) principles. Sulphur dioxide (SO2) exhibits a strong ultraviolet (UV) absorption spectrum between 200 and 240 nm, and so when SO2 absorbs UV from this range, emission of photons occurs at 300-400 nm. The amount of fluorescence emitted is directly proportional to the SO2 concentration (Ecotech, (2011).

Results

Water samples

The water samples referred to in this study are of two types: mine effluents and domestic water. These were all analysed by wet chemistry methods using an ICP-OES finish.

Industrial/mine effluents

Eleven mine effluent samples were collected from the existing mine effluent discharge points, eight of which were located within the mine site and three outside the mine site. The reason for sampling these points was to find out the levels of pollutants (sulphates, copper, cobalt, iron, manganese etc.) from the mine source and also to track them downstream before finally discharging into the main natural drainage (Kafue River). The results are shown in Tables III and IV.

Domestic water

Twenty-nine sampling points located in the core of Kankoyo Township were strategically defined for collection of domestic water samples to determine the water quality of Kankoyo community with respect to pH, TSS, Pb, Cd, TDS, Fe, Co, Cu, Mn, SO42-, and conductivity (see Table V). Domestic household water from Mulonga Water and Sewerage Company (MWSC) water network system was collected from household taps.

The chemical test results were within the ZEMA statutory limits for industrial mine effluent.

The general physical and chemical characteristics of drinking water with respect to non-toxic constituents are shown in Tables VI and VII.

Air samples

The air samples referred to in this study are from the ambient air in Kankoyo Township plus six other selected areas outside the township that were used as a reference for comparison (see Table II for locations of the sampling points). The average SO2 concentrations measured are shown in Table VIII.

SO2 emission trends

Figures 4-9 show the SO2 emission trends at the seven weather stations from January 2017 to May 2018.

The 18-month average trends indicate that the SO2 levels recorded at all the stations were below the ZEMA statutory limit, apart from Kantanshi Clinic 3 and Kankoyo Clinic 5, which had levels of 28% and 44% above the ZEMA statutory limit respectively.

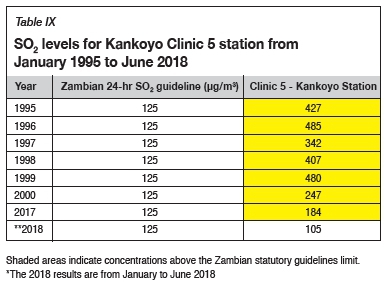

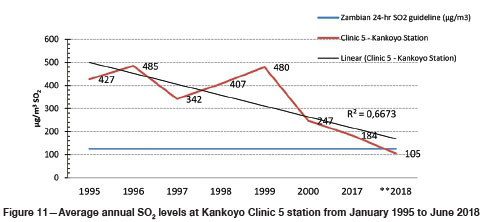

Average sulphur dioxide levels for Kankoyo Township in the last two decades

The available information for sulphur dioxide levels for the last two decades for Kankoyo (see Table IX and Figure 11) shows a significant decrease from over 400 ug/m3/24h in 1995 to less than 110 ug/m3/24h in June 2018. The results reflect the massive investments in technology for sulphur dioxide capture in the copper smelting plants after the year 2010, which have improveed sulphur dioxide capture by over 90% (Ross and Vries, 2005; Alistair et al., 2012).

The coefficient of determination (R2) of 0.6673 means that about 67% of the variation in the SO2 emission data is due to variation with time. There has been a significant decrease in SO2 emissions (v64 = 0.817 = 82%) with time in the last two decades.

Discussion

Kankoyo residents' perceptions on the effects of mining on air and water quality

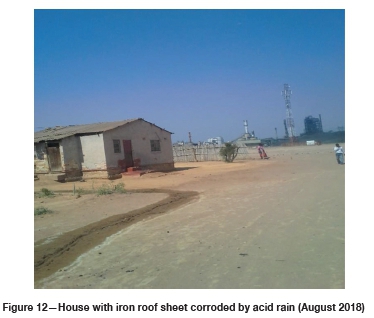

According to residents' perceptions, the adversity caused by copper smelting has reached an extent where it is a danger to the natural and physical environment in Kankoyo Township. The damage caused by excessive SO2 levels is depicted in Figures 12 and 13. The mining industry needs to formulate clear strategies to address these misconceptions, and to engage the local community of Kankoyo, if it is to survive. Despite the significant reduction in air pollution that has been achieved in the last decade, residents of Kankoyo Township still believe that very little has been done in addressing the air and water quality issues. The community blames the mining industry for the economic hardships, unemployment, and air and water pollution. This may be attributed to the historical background -the previous mine owners used to clean up the mine townships and provided social amenities in addition to employment opportunities, but this is no longer the case (World Bank, 2002).

Causes of air pollution

Air pollution in Kankoyo Township is perceived to be due entirely to mining operations, and this is a strong belief among the residents of this old mining township. Perhaps this has been an inherited problem for the current generation in the township. Clean air is a basic requirement of human health and wellbeing (WHO, 2006). Air pollution has continued to be perceived as a serious environmental problem in Kankoyo Township. The main causes of air pollution are the sulphur dioxide gas and particulate matter emitted from the copper smelting plant. The extent of air pollution is quite devastating, as can be seen from the destructive effects on the physical and natural environment (Figures 11 and 12), and requires sustainable and responsible solutions to minimize its impact on the environment..

Causes of water pollution

The cause of water pollution in Kankoyo Township is perceived to be negligence by the water utility and lack of concern from the mining company. The erratic extent of water pollution is cause for concern and requires sustainable and responsible solutions to mitigate its impact on the health and social wellbeing of people in the township. Although there is limited information on public perceptions of water supply in Kankoyo, the available evidence focuses on perceptions of water quality. Even though previous reports show instances of acid contamination in Mufulira's water network (CTPD, 2010), this study found that about 80% of the population in Kankoyo have the misconception that MCM has permanently polluted the water supply to the township.

Comparison of SO2 levels at different sampling points

The air quality was evaluated by comparing SO2 levels from seven weather stations. As shown in Table VIII, the highest average SO2 concentration was 159.73 ug/m3/24h at Kankoyo Clinic 5, and the lowest was 9.49 ug/m3/24h at Butondo Clinic 7. The average levels of SO2 from the seven weather-sampling stations for a period of 18 months from January 2017 to June 2018 are compared to the Zambia Environmental Management Agency (ZEMA) emission limits in Figures 3 to 9. The 18-month average trends show that the emissions recorded at all the weather monitoring stations were below the ZEMA statutory limit, apart from Kantanshi Clinic 3 and Kankoyo Clinic 5, at which the SO2 levels were 28% and 44% above the ZEMA statutory limit respectively.

Sulphur dioxide capture

The capture of sulphur dioxide from the copper smelting plant has greatly improved due to the new and improved technologies, which reduce or even eliminate air and water pollution. The traditional smelters used to emit most of the sulphur dioxide generated, but now almost all of it is captured prior to emission using new technologies, such as the complex gas absorption towers in the sulphuric acid plants and electrostatic precipitators, which capture dust particles and return them to the process.

The results indicate a significant reduction in sulphur dioxide emissions from the copper smelter. As shown in Figure 13, the average sulphur dioxide capture was 48% from 2007 to 2013 and about 94% from 2014 to 2018. However, the average annual sulphur dioxide levels for 2017/2018 were 144.5 ug/m3 in Kankoyo Township, which is 15.6% above the statutory limit of 125 ug/m3 in ambient air (per 24 hours). Figure 13 shows the smelter sulphur dioxide capture trends for the period March 2007 to March 2018.

The results given in Figure 13 show a significant reduction in sulphur dioxide emissions from the copper smelter. The average sulphur dioxide capture was 48% from 2007 to 2013 and about 94% from 2014 to 2018. The 46% improvement in sulphur dioxide capture in the four years from 2014 to 2018 is attributed to technological upgrades and good operating practices implemented at the Mopani Mufulira copper smelter. According to Ross and Vries (2005), from the inception of the Mufulira copper smelter in 1937 there was no sulphur dioxide abatement facility. However, the current ISASmelt technology is designed to capture sulphur dioxide in a separate plant and convert it into sulphuric acid, which is sold to other mines. The average annual atmospheric sulphur dioxide level for 2017/2018 was 144.5 ug/m3 in Kankoyo Township, which is 15.6% above the statutory limit of 125 ug/m3 per 24 hours in ambient air. This is not an acceptable level of exposure as it may have adverse environmental and health implications for the community.

Water quality

The results from the five critical sampling points are given in Tables III, IV, and V. These results are the arithmetic averages of the analyses obtained for each parameter for the period January to July 2018, except for household or domestic water from taps, which was sampled between March and August 2018. The prefixes 'T' and 'D' for Cu, Co, Fe, and Mn stand for total and dissolved species respectively.

Kafue River water

The Kafue River water is the source of water supply for both domestic and industrial use. The average water quality parameters were all within the statutory limits (Table V).

Tap water (domestic water from underground)

Drinking water for the people of Mufulira is supplied from three main sources. The municipal residential area has piped water from the Kafue River. The mine townships are supplied by the network that delivers water partly from the dewatering operations in the underground mine and partly from the Kafue River. The local water utility, Mulonga Water and Sewerage Company (MWSC), solely manages the water supply. The third source of water is the boreholes and shallow wells for those people who are not connected to the piped network. Kankoyo Township is a mine residential area, which is exclusively supplied with treated water from the underground network. The average water quality parameters were all within the statutory limits (Table V). The relatively high levels of turbidity, iron, and sulphates (see Table III) can be attributed to the heavily dilapidated water network infrastructure, since these are not lower than those from the mine effluents, which are the possible sources of contamination. The tap water in most households was collected from dilapidated water connections, which are much more prone to contamination.

Air quality

Ambient air quality is defined by the physical and chemical measure of pollutant concentrations in the ambient atmosphere to which the general population will be exposed. In most developing countries, ambient air quality is reported to have deteriorated seriously, especially in urban areas, exposing populations to pollutant levels above the recommended limits (UNEP, 1998).

Although there are seasonal and operational variations in sulphur dioxide levels as shown in Table VIII, the general trend still shows that Kankoyo Township is more affected than other townships. Out of the 48 times that Mufulira recorded SO2 levels above the 125 ug/m3 per 24 hours ZEMA maximum allowable limit in the period January 2017 to June 2018, Kankoyo township alone recorded 23 instances representing 48% of the total counts. Kantanshi Clinic 3 and Clinic 6 stations recorded excessive levels thirteen and six times, representing 27% and 13% respectively. Butondo and Eastlea stations recorded no incidences of excessive SO2 levels during the same period. Kamuchanga Station and Malcolm Hospital Station recorded four and two incidences representing 8% and 4% respectively.

Water quality

The chemical composition of water and effluent samples from the Kafue River, industrial water (from underground), domestic water (from underground), household water (from the taps), and mine effluents is given in Table V. These results are the averages of the analyses obtained for each parameter in the period March to August 2018. Table V shows that the values of all parameters were within the ZABS allowable limits for drinking water (see Tables VI and VII). The pH values were within ZEMA statutory limits of 6.5-9 in all water samples tested.

The domestic water from underground shows relatively high conductivity levels, including total iron (TFe) (0.01-1.11 mg/l) and sulphates (214-577 mg/L. The relatively high level of copper at 3.62 mg/l in the month of July 2018 in the mining effluent samples can, however, be attributed to direct contamination from the runoff waters (see Table V) accounted for by experimental error.

The impact of air and water pollution on the local environment

The environmental impacts of mining operations are significant and quite often severe, especially in Kankoyo Township. The buildings and the surrounding environment have been degraded due to the corrosive effects of acid rain. Residents complain of headaches, coughing, itching eyes and ears, and bronchitis. The mining operations in the Mufulira district are within the catchment area of the Kafue River and other natural water bodies such as the Mufulira and Kansuswa streams. Several studies have shown that concentrations of many dissolved elements are elevated in the Kafue River and its tributaries within the Copperbelt (Lindahl, 2014). The contaminants are mainly from the run-of-mine (ROM) ore and untreated effluent such as the domestic and industrial water from underground and processing plants.

MCM has shown commitment to pollution control and environmental management, as evidenced by environmental monitoring and investments in technological upgrades in order to improve process efficiency and minimize pollution. However, the results from this study show that the general dilapidation of the water pipeline and network system is another potential source of water pollution.

Conclusions

The study found that there has been a significant reduction in sulphur dioxide emissions from the copper smelter since the implementation of the smelter technological upgrades in 2014. The average sulphur dioxide capture was 48% from 2007 to 2013 but improved to about 94% from 2014 to 2018. The average annual sulphur dioxide level for 2017/2018 was 144.5 ug/m3 in Kankoyo Township which is 15.6% above the statutory limit of 125 ug/m3 .The occurrence of periodic fugitive emissions (due to technical or operational failure) may cause air pollution, but not to significant or alarming levels. This is evidenced by some high spikes in the SO2 level on certain days of the month, as is the case for Kantanshi Clinic 3 and Kankoyo Clinic 5 air monitoring stations. It was also observed that air pollution has adversely affected the physical environment, as evidenced by excessive corrosion of iron roofing sheets, wall plaster, and paint degradation, as well as serious deterioration of the soils due to acid rain.

The general water quality meets the ZEMA and ZABS statutory limits for effluent discharge and domestic drinking water quality, respectively. It is worth noting that the water quality in this area may not only be attributed to the mining activities, but also to the dilapidated water infrastructure and pipe network, which may be another source of water contamination.

However, the negative effects of air and water pollution that has prevailed for the past six decades are still noticeable and give rise to serious environmental concerns among Kankoyo residents and other interested parties. It is for these reasons that this study sought to fill this knowledge gap by investigating the effects of sulphur dioxide emissions and mine effluent discharge on air and water quality respectively in Kankoyo township of Mufulira district.

Recommendations

It is recommended that other researchers take this research further and look at the aspects of soil quality and rehabilitation of the degraded environment in Kankoyo Township.

Furthermore, the mining company should seriously consider investing in environmental protection programmes and projects, such as reclamation of mine tailings, revegetation of degraded mine land, and investing in research and development on green mining technology, that will help mitigate some of the environmental concerns raised by the communities around the mine site and various other stakeholders. It should also consider ongoing technological improvements to maximize sulphur dioxide capture. The captured sulphur dioxide could be used not only for sulphuric acid production, but also for other value-added byproducts such as phosphoric acid and sulphate- and phosphate-containing fertilizers.

To ascertain the effectiveness of its air and water pollution control, MCM should ensure robust equipment maintenance and strict routine environmental monitoring of all pollution control points. ZEMA and the local authority should have adequate resources to provide the various stakeholders with information on the state of the environment and various sources of pollution that the community may be experiencing.

Acknowledgement

> D.M. engaged in data collection, analysis and development of the manuscript.

> J.M. and W.B. made major contributions to the critical review of the manuscript.

> B.B. provided overall supervision and project administration.

> Funding: This research received some funding for data collection from Education for Sustainable Development (ESDA) at the University of Zambia (UNZA)

> Conflicts of interest: The authors declare no conflict of interest.

References

Action Aid. 2015. Study on impacts of mining and other extractive industries on women in Zambia. [ Links ]

Alistair, B., Phil, P., John, S., and Paul, H. 2012. ISASMELT at Mufulira - Increased flexibility on the Zambian Copperbelt. Proceedings of the Fray International Symposium. Cancun, Mexico. Paper 6-528, Flogen Star OUTREACH. http://flogen.com/FraySymposium/paper-6-528.html [ Links ]

Chipatu, I. 2011. Environmental education to address negative impacts of copper mining in Kankoyo township of Zambia's Copperbelt. University of Zambia, Lusaka. [ Links ]

CTPD. 2010. The Mopani Mine, Zambia. How the European development money has fed a mining scandal. Centre for Policy Trade and Development, Lusaka, Zambia. [ Links ]

CSO. 2013. 2010 Census of population and housing descriptive tables. Vol. 2. GRZ-Central Statistical Office, Lusaka. [ Links ]

Ecotech. 2011. Serinus 51 SO2/H2S analyser. user manual version 1.0. Ecotech, Victoria, Australia. [ Links ]

EEA. 2005. Market-Based Instruments for Environment Policy in Europe. EEA, Copenhagen. [ Links ]

Elisha, N., Clement, B., and Jhonnah, M. 2012. Air pollution on the CopperbeltProvince of Zambia: Effects of sulphur dioxide on vegetation and humans. Journal of Natural & Environmental Sciences, vol. 3, no. 1. pp. 34-41. [ Links ]

IFC-World Bank. 2014. Sustainable and responsible mining in Africa - A getting statrted guide. World Bank, Delter Centre, Nairobi, Kenya. [ Links ]

Jones, R.T. 2015. An overview of copper smelting in Southern Africa. Proceedings of Copper Cobalt Africa Conference, incorporating the 8th Southern African Base Metals Conference, Livingstone, Zambia. Southern African Institute of Mining and Metallurgy, Johannesburgy. pp. 499-504. [ Links ]

Jozef, D. 2013. Sustainable deveopment of mining mineral resources. Journal of Sustainable Mining, vol. 7, no. 1. pp. 1-6. [ Links ]

Lindahl, J. 2014. Environmental impacts of mining in Zambia. Towards better environmental management and sustainable exploitation of mineral resources. Geological Survey of Sweden. [ Links ]

Lins, C. and Horwitz, E. 2007. Sustainability in the Mining Sector. Fundacao Brasileira O Desenvolyimento Sustentavel, Rio de Janeiro. [ Links ]

Michaels, D. 2008. Doubt is their product: How industry's assault on science threatens your health. Oxford University Press, New York. [ Links ]

Mulenga, S.C. 1993. Solution to Konkola mine water inflow problem. Proceedings of the International Mine Water Association Symposium, Sydney, Nova Scotia. B1P 6L2 Canada: International Mine Water Association. [ Links ]

Mwaanga, P., Silondwe, M., Kasali, G., and Manda, P. 2019. Preliminary review of mine air pollution in Zambia www.heliyon.com.cdoi:10.1016/j.heliyon.2019.e02485 [accessed 20 December 2019]. [ Links ]

OECD. 1991. Environmental Policy: How to Apply Economic Instruments. Organisation for Economic Co-operation and Development, Paris, France. [ Links ]

Ross, J. and vries, D. 2005. Mufulira smelter upgrade project - Industry smelting on the Zambian Copperbelt. Mopani Copper Mines, Kitwe, Zambia. [ Links ]

Simukanga, S., Hicks, W., Feresu, S., and Kuylenstierna, J. 2010. Proceedings of a Regional Policy Dialogue in Southern Africa. Air Pollution Information Network for Africa (APINA). [ Links ]

Stavins, R. 2004. Environmental Economics. Resources for the Future Discussion. Resources For the Future (RFF). pp. 4-54. [ Links ]

Stephen, C. and Wilson, M. 2017. The effect of mining on the environment: A case study of Kankoyo Township of Mufulira District of the Republic of Zambia. Bodrum, Turkey. https://www.researchgate.net/publication/320540234 [ Links ]

Syapiila, P. 2018. Factors associated with the 2012 typhoid fever outbreak in Mufulira district, Zambia. Zambia's Journal on Public Health, Disease Surveillance, Prevention and Control, vol. 2, no. 2. pp. 8-16. [ Links ]

UNEP. 1998. Environmental effects of ozone depletion:1998 assessment.: United Nations Environmental Program, Nairobi, Kenya. [ Links ]

WHO. 2006. WHO air quality guidelines for particulate matter, ozone, nitrogen,dioxide and sulfur dioxide; Global Update, 2005. Summary of Risk Assessment. World Health Organisation, Geneva. [ Links ]

World Bank. 2000. Beyond Economic Growth. World Bank Group, Washington DC: [ Links ]

World Bank. 2002. Environmental Assessment of the World Bank Copperbelt Environmental Project. Komex International Limited, Calgary. [ Links ]

ZABS. 2010. Drinking water quality - Specification. Zambian Standard-ZS190:2010. Zambia Bureau of Standards, Lusaka. [ Links ]

Zvarivadza, T. 2015. Sustainability in the mining industry: An evaluation of the National Planning Commission's diagnostic overview. Proceedings of the Mining, Environment and Society Conference, 12-13 May 2015. Southern African Institute of Mining and Metallurgy, Johannesburg. [ Links ]

Correspondence:

Correspondence:

D. Muma

Darius.muma@mopani.com.zm

Received: 2 Oct. 2019

Revised: 11 Feb. 2020

Accepted: 9 Mar. 2020

Published: April 2020