Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.120 n.3 Johannesburg Mar. 2020

http://dx.doi.org/10.17159/2411-9717/17/115/2020

PAPERS OF GENERAL INTEREST

Extending the protection range in protective seam mining under the influence of gas drainage

L. WangI, II; X. ChenII; Z. WangII; S. XuIII; Q. XuII

IKey Laboratory of Gas and Fire Control for Coal Mines, China University of Mining & Technology, Ministry of Education, China

IIHenan Polytechnic University, China

IIIGuizhou Qianxi Energy Development Limited Company, Bijie, China

SYNOPSIS

Both theoretical and field research have shown that protective layer mining with pressure-relief gas extraction in protected coal seams is an effective and economical way of controlling coal and gas outbursts in underground mines. Given the influences of coal seam angles, layer spacing, pressure-relief angles, coal pillars, and other factors in the protected areas of protected seams, the protection range is often smaller than the area of protective seam mining. This problem can be solved by using a gas drainage method based on coal seam geology and the conditions of coalbed methane (CBM) occurrence during protective layer mining. If a protective layer is prone to outbursts, crossing boreholes and bedding boreholes can be used to eliminate outburst hazards. The crossing boreholes should control the upper side of the roadway contour for at least 20 m and the lower side for at least 10 m. For other coal seams, the boreholes should control both sides of the roadway contour for at least 15 m. Crossing boreholes can not only extract CBM from the protective layer but can also extract from the protected coal seam, thus leading to a larger protection range in the protective layer than that predicted by the pressure-relief boundary, as well as expanding the protection range. The actual protection range of the protected layer was determined using an index of residual gas content. The results of the study indicate that the pressure-relief angle increased from 56° to 69° in the strike direction and from 75° to 90° in the inclination direction. The protection range was approximately equal to the mining area of the working face of the protective layer, thereby extending the protection range. One of the important reasons for protection range expansion was the influence of gas drainage via crossing boreholes. The protection range extension mitigated the outburst danger over a large area of the coal seam, thus enabling high efficiency and safe exploitation.

Keywords: protective seam mining, range extension technology, pressure-relief gas extraction, protective range, gas pre-extraction.

Introduction

China possesses abundant coal resources, and coal accounts for at least 70% of China's energy, supporting the rapid growth of the national economy. In 2015, coal production reached 3.69 Gt. The demand for energy will continue to increase with the rapid development of China's economy, and coal is projected to account for 50% of primary energy consumption through 2050.

Due to the continued exploitation of long-standing seams, coal mining depths have reached an average of 540 m and increase at an annual rate of 10-15 m, with portions of mines reaching 800 m or more (Wang et at., 2012, 2013). As mining depth has increased, conditions have become increasingly complicated. 'Four high problems and one low problem' exist in coal seams, namely, high stress, high gas pressure, high gas content, high ground temperature, and low coal seam permeability. These issues result in difficulty controlling gas. Therefore, gas control technology requires constant research and development (Zhou, Xie, and Zuo, 2005; Li et at., 2009).

Both theoretical studies and field observations have shown that protective layer mining based on pressure-relief gas extraction in protected coal seams is an effective and economical way of controlling coal and gas outbursts in underground mines. During the mining of the protective layer, stress is decreased, fractures develop, and adsorbed gas is desorbed, thus increasing coal permeability a hundredfold. Additionally, when coupled with pressure-relief gas drainage, the gas content can be effectively reduced, thus eliminating outburst hazards in protected coal seams.

Protective layer mining technology was first used in 1933 to control coal and gas outbursts in France. Since 1958, protective layer mining has been conducted in China, including field tests in the Beipiao, Tianfu, Nantong, Zhongliangshan, Songzao, Xishan, Huajin, Tiefa, Huaibei, and Huainan mining areas. These tests have yielded remarkable results and have resulted in highly efficient and safe coal exploitation. The document 'The Regulations of Coal and Gas Outburst Prevention' (State Administration of Work Safety, 2009) notes that an inspection of the effect and scope of the protective layer should first be performed when mining a protective layer. The protection range, including the protection range in the strike direction and strip direction, is the effective range in which the protective layer can be mined using pressure-relief gas extraction. Therefore, this range does not include dangerous outburst areas. The protection range is determined from the inspection results.

The protection range in the protective layer is determined from the gas content, gas drainage volume, the gas pressure, and the relative deformation of the coal seam roof and floor. Wang et al. (2014) and Hu, Wang, and Fang (2010) obtained protection ranges on the basis of gas flow theory. Tian, Sun, and Wei (2013) confirmed the protection range by comparing gas flow observations and gas contents. Wu et al. (2010) discussed a method of determining the effective pressure-relief range in protective layer mining and studied the factors that affect the scope of protection. Additionally, scholars have studied the permeability distribution, rock deformation, and stress distribution in protected layers.

The geological conditions of a coal seam significantly affect the protection range of a protective layer. Although the layout parameters of protection layers are the same, the protection range and the effect on eliminating outbursts are notably different because coal seam conditions and gas drainage methods are different in each mine. Currently, the regulations for preventing coal and gas outbursts (State Administration of Work Safety, 2009) that apply to the pressure-relief angle are conservative, and the protection border has space to be expanded. The protection range of protected coal seams can be reasonably determined and expanded by designating a wide range of coal seams for safe exploitation in order to significantly reduce outburst incidents in mines. Therefore, reasonable protection boundaries must be delineated in protection layer mining.

General situation in the Qinglong coal mine

The Qinglong mine is in Bijie, Guizhou Province, China (Figure 1). The mine includes multiple coalbed formations, and the main coal seam has exhibited an increased tendency undergo coal and gas outbursts.

The Qinglong coalfield stretches 9.0 km in the strike direction and 1.6-5.0 km in the strip direction, encompassing an area of 21.79 km2. The mine began operation in 2007, with a designed annual capacity of 1.2 Mt. The main mineable coal seams used for economic production are the no. 16 and no. 18 seams, which have an average dip of 12°.

The gas contents of the two coal seams are greater than 20 m3/t. The gas pressure and gas content of seam no. 16 are 1.73 MPa and 21.51 m3/t, respectively, and for seam no. 18, 1.5 MPa and 24.40 m3/t, respectively. Coal seams no. 16 and no. 18 are both prone to outbursts. Although seam no. 17 has exhibited no tendency for coal or gas outburst, this layer is only partially mineable. Considering its proximity to seams no. 16 and 18, mining seam no. 17 will first destroy seam no. 16. Thus, we selected seam no. 16 as a protective layer.

Gas extraction mode

Gas extraction mode in a protective coal seam

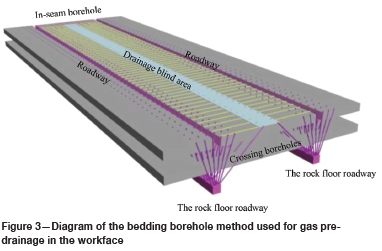

The implementation of a gas drainage mode with the crossing borehole extraction of coalbed methane (CBM) and the bedding borehole extraction of CBM comprised four steps. First, two rock floor roadways were constructed in the floor of the protected coal seam, corresponding to the protective layer roadway. The two roadways formed a negative pressure ventilation system (Figure 2).

Secondly, boreholes crossing the floor roadway were used to extract CBM from the roadway strip and eliminate outburst hazards. In the floor roadway, a drill site was excavated every 6 m with six crossing boreholes used to control both the roadway and a 15 m area outside the roadway contour line (Figure 2). The boreholes were 94 mm in diameter, and the distance between boreholes in the coal seams was 6 m. The negative pressure was greater than 25 kPa. The drainage time was longer than 10 months.

The transportation roadway and open cutting of the protective coal seam in the region eliminated the outburst hazards (Figure 3). During the third stage of implementation, a railway was constructed.

Finally, bedding boreholes within a certain distance were used to extract CBM from the workface to eliminate the outburst hazard in the protective seam. The boreholes were 108 mm in diameter, and the distance between boreholes in the coal seams was 3 m. The negative pressure was greater than 15 kPa. The drainage time was longer than six months.

A block diagram of the gas drainage pattern is shown in Figure 4.

Gas extraction mode in the protected coal seam

Mining the protective layer can relieve the stress in a protected coal seam, thereby increasing its permeability. We therefore performed pressure-relief gas extraction by using crossing boreholes (Figures 5 and 6). The boreholes were 108 mm in diameter, spaced 10 m apart. The negative pressure was greater than 25 kPa and the drainage time was longer than 10 months.

Numerical modelling

The inspection indexes used to determine the protection range include the gas pressure, gas content, and expansion deformation rate of the protected coal seam. The accuracy of these parameters is restricted by site conditions, and a full range of inspection cannot usually be achieved. Numerical simulation provides a method for determining the protection scope in protective layer mining. COMSOL Multiphysics software was used to simulate the protection range in protected layer mining to provide information for mines with similar mechanical parameters of coal and rock.

Model creation

Creation of the geometric model

COMSOL Multiphysics software was used to simulate the stress and strain characteristics of the protected coal seam on the basis of data obtained during the mining of the working face of the no. 21604 protective layer. Thereafter, the protection range of protective layer mining was determined.

The model was built according to the geological conditions in the Qinglong coal mine. The length and width of the model were 260 and 120 m, respectively. The model is shown in the strike and strip directions in Figure 7.

Boundary constraints

The left, right, and bottom boundaries were established as fixed boundaries. A compressive stress of 1.9 MPa was imposed on the top of the model according to the model size and depth of the coal seam.

Yielding criteria

The expression of the Mohr-Coulomb (M-C) yielding criterion is:

where I1is first invariant of stress, /2 is second invariant of deviator stress, and θσ is stress lode angle, -p/6 < θσ < p/6.

The Drucker-Prager (D-P) yielding criterion is based on the Mises strength criterion, considering the equilibrium stress p or I1, extending the Mises strength criterion in the following form:

where c is cohesion and φ is the internal friction angle. By transforming Equation [1], we obtain:

If θσ is constant, comparison between Equations [2] and [5] shows that:

Equations [6] and [7] are the unified expressions of the equivalent D-P transformation of the M-C criterion. They are related to θσ.

θσ can reflect the stress state of a point, that is, the proportional relationship between the main stress components.

Coal and rock mechanical parameters

The D-P failure criterion and matching M-Ccriteria were selected for the simulation. The initial properties of the rock mass are listed in Table I on the basis of the typical values in the Qinglong coal mine.

Protection range in the strike direction

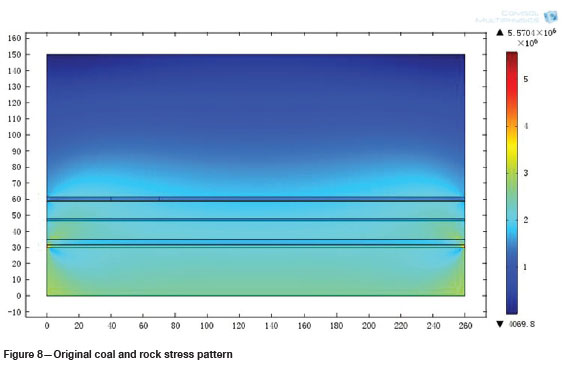

Original stress state of the rock

Figure 8 shows the coal and rock stress pattern before working face no. 21604 was mined, i.e. influenced only by gravity.

Stress and deformation associated with 100 m of protective layer mining

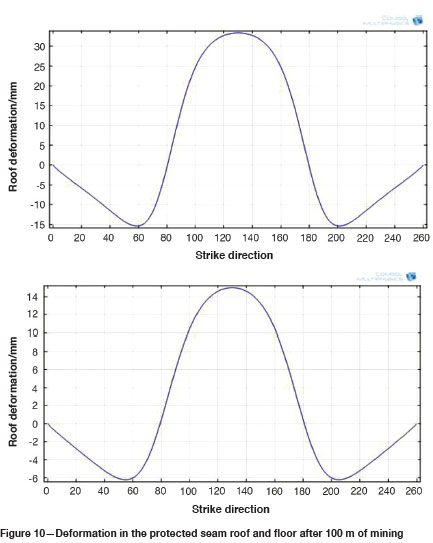

Figure 9 shows the stress changes in the surrounding rock after working face no. 21604, the protective layer, was mined to 100 m. The deformations in the roof and floor of the protected coal seam are shown in Figure 10.

Analysis of stress and deformation in the strike direction

As shown in Figures 9 and 10, stress concentrations appear at both ends of the goaf due to the mining of working face no. 21604. A stress concentration phenomenon also appears in the corresponding area of the protected coal seam, in which the roof and floor are both compressed and deformed. The roof compression/deformation in the protected layer is greater than the floor compression/deformation. Overall, the protected layer exhibits compressive deformation. Gas is more difficult to extract under this condition than in the initial state because of partial closure of fractures and a decreased permeability coefficient.

The coal and rock mass stress decreases in the upper and lower parts of the mining area. Additionally, a pressure-relief zone appears, and the roof stress in the protected layer decreases considerably. With continued mining of working face no. 21604, the stress decreases and eventually stabilizes. Correspondingly, expansion deformation occurs in the roof and floor. The roof expansion deformation in the protected layer is greater than the floor expansion deformation. Overall, the protected layer exhibits expansive deformation. Gas extraction in this state is easier than in the initial state because of the development of fractures and increased permeability.

Confirmation of the protection range

By using a protective layer mining length of 100 m as an example, we found that the maximum compression deformation in the protected layer was 9 mm, and the maximum relative compression deformation was 2.8%. Additionally, the maximum swelling deformation was 18 mm, and the maximum relative expansion deformation was 5.6%.

Combining these results with the protection criteria for seam deformation relief shows that if the relative expansive deformation in the protected layer is greater than 3%, then the protective effect is satisfactory. Therefore, 3% was considered the critical value in the delineation of the protection scope. The relative expansion deformation reached 3% in 14 m of working face along the protected layer. Furthermore, the relative expansion deformation was greater than 3% along 14 m in the region. Combined with 24 m spacing between coal seams no. 16 and 18, the pressure-relief angle was approximately 60° in the strike direction.

Protection range in the strip direction

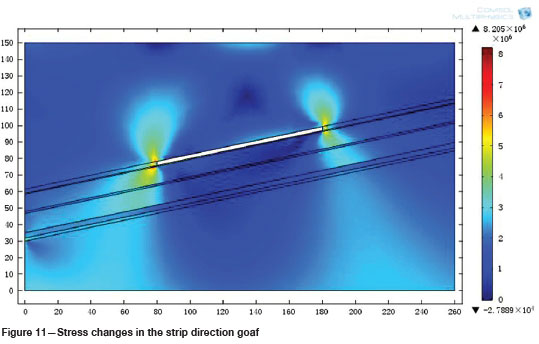

Stress and deformation in the protected layer in the strip direction

The stress changes in the strip direction in the rock surrounding working face no. 21604 after mining began are shown in Figure 11. The roof and floor deformation in the protected coal seam are shown in Figure 12.

Confirmation of the protection range in the strip direction

Figure 12 illustrates that the maximum compression deformation in the protected layer was 15 mm. The maximum relative compression deformation was therefore 4.7%. The maximum swelling deformation was 18 mm, and the maximum relative expansion deformation was 6.3%.

Combining these results with the protection criteria for seam deformation relief shows that if the relative expansive deformation in the protected layer is greater than 3%, the protective effect is satisfactory. Therefore, 3% was considered the critical value in the delineation of the protection scope. The relative expansion deformation reached 3% along 13 m of the working face in the strip direction. Furthermore, the relative expansion deformation was greater than 3% along 13 m in the region in the strip direction. Combined with 24 m spacing between coal seams no. 16 and 18, the pressure-relief angle was approximately 62° in the strike direction.

Field measurements of protection scopes

Arrangement of drill-holes

If a protective layer is prone to outbursts, crossing boreholes and bedding boreholes can be used to eliminate outburst hazards. The crossing boreholes are used to extract CBM from the protective layer and protected coal seam. The yellow area in Figure 13 represents the area affected by gas extraction.

In designing the drilling locations and number of drill-holes, two boreholes were drilled in the area affected by gas extraction to determine whether the residual gas content was below 8 m3/t. Within the boundaries of the affected area, the unloading pressure was sufficient. Therefore, coupled with gas drainage, the residual gas content should have dropped below 8 m3/t. Two drill-holes were established to verify these expectations. Outside the affected area, the residual gas content may be high, therefore three drill-holes were established for further investigation.

The boreholes used to investigate the protection range were divided into six groups, each group consisting of seven holes, totalling 42 boreholes (Figures 13 and 14).

Analysis of the test results

The residual gas content test results are shown in Figure 15. The gas contents of boreholes no. 8 and 9 were 11.37 and 9.60 m3/t, respectively, which are both greater than 8 m3/t. However, the residual gas contents measured at the remaining points were less than 8 m3/t. By performing calculations that included a safety factor, the pressure-relief angle in the strike direction was determined to be 69° (Figure 16). The residual gas contents in the drill-holes in the strip direction were less than 8 m3/t. Furthermore, calculations suggested that the pressure-relief angle was greater than 90°. For safety, we confirmed that the pressure-relief angle was 90°. The pressure-relief angle increased from 56° or 60° to 69° in the strike direction and from 75° or 62° to 90° in the strip direction; this finding illustrates the potential extension of the protection range.

Discussion

Table II shows the pressure-relief angles in the protection range based on the provisions of the prevention of coal and gas outbursts (China State Administration of Work Safety, 2019), the numerical simulation results, and the field measurements.

As shown in Table II, the pressure-relief angles in the strike and strip directions are 69° and 90°, respectively, which are greater than the angles noted in the outburst prevention regulations and those determined by numerical simulations. The protection range of the protective layer is approximately equal to the mining area of the working face of the protective layer; this result illustrates the potential extension of the protection range. One of the important reasons for the expansion observed in the protection range is the influence of gas drainage via crossing boreholes.

If a protective layer is prone to outbursts, crossing boreholes and bedding boreholes can eliminate outburst hazards. Crossing boreholes can extract CBM from the protective layer and protected coal seam.

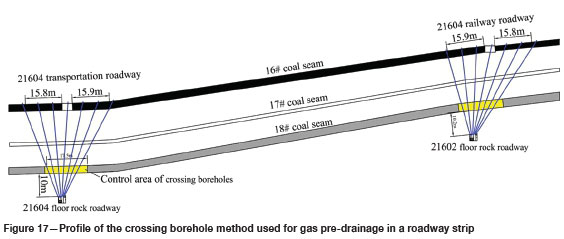

China State Administration of Work Safety (2019) states that the outburst hazards in the roadway and within a certain range on both sides of the roadway must be eliminated before mining the roadway. The specific requirements are as follows. For inclined and steeply inclined coal seams, the borehole should control the upper and lower sides of the roadway contour for at least 20 and 10 m, respectively. For other coal seams, the borehole should control both sides of the roadway contour for at least 15 m. The dip angle of the coal seam in the Qinglong coal mine is 12°, thus suggesting that it belongs to the coal seam group with shallow inclines. According to the stated requirements, the pre-drainage boreholes control both sides of the roadway contour for at least 15 m, as shown in Figure 17.

As shown in Figure 17, the crossing boreholes extract CBM from the protective layer and the protected coal seam, thus leading to a larger protection range in the protective layer than that predicted by the pressure-relief boundary, as well as expanding the protection range. To obtain similar extensions of protection ranges in other working faces in the Qinglong coal mine or other coal mines, the boreholes should control the yellow area highlighted in Figure. 18.

Conclusions

Numerical simulations and field measurements were used to determine the actual protective range of the protected layer, with the goal of improving mining technology associated with the protective layer.

1. The stress and strain changes associated with 100 m of mining were simulated and analysed using COMSOL Multiphysics software. Given the exploitation of the working face of the protective layer, the protective layer covers a certain range. In this range, the stress in the protective layer decreases and the roof and floor expand. The combination of these results with the protection criteria for seam deformation relief shows that the pressure-relief angles in the strike and strip directions were 60° and 62°, respectively.

2. The actual protective range of the protected layer was determined on the basis of residual gas content. The pressure-relief angles in the strike and strip directions were 69° and 90°, respectively. The protection range was approximately equal to the mining area of the working face of the protective layer, thereby extending the protection range. One of the important reasons for protection range expansion was the influence of gas drainage via crossing boreholes.

3. Technology that is used for protection range expansion can be used in other working faces in the Qinglong coal mine or other coal mines by controlling the extension area with boreholes.

Acknowledgments

The authors are grateful for the financial support from the Natural Science Foundation for the Youth of China (No. 51404091), the China Postdoctoral Science Foundation (2014M561990) and the PhD Foundation of Henan Polytechnic University (B2015-08).

References

Chen, H.D., Cheng, Y.P., Ren, T.X., Zhou, H.X., and Liu, Q.Q. 20104. Permeability distribution characteristics of protected coal seams during unloading of the coal body. International Journal of Rock Mechanics and Mining Sciences, vol. 71. pp. 105-116. [ Links ]

Cheng, Y.P. and Yu, Q.X. 2003. Application of safe and high-efficient exploitation system of coal and gas in coal seams. Journal of China University of Mining Technology, vol. 32. pp. 471-476. [ Links ]

China State Administration of Work Safety. 2019. Detailed Rules for Prevention and Control of Coal and Gas Outburst. China Coal Industry Press, Beijing, China. [ Links ]

DIaz Aguado, M.B. and González Nicieza, C. 2007. Control and prevention of gas outbursts in coal mines, Riosa-Olloniego coalfield, Spain. International Journal of Coal Geology, vol. 69. pp. 253-266. [ Links ]

Hu, G.Z., Wang, H.T., and Fang, x.G. 2010. The law of methane gas leak flow in adjacent layer and its relief-pressure protection region. Journal of China Coal Society, vol. 35, no. 10. pp. 654-1659 [in Chinese]. [ Links ]

Li, D.q. 2014. Underground hydraulic mining of thin sub-layer as protective coal seam in coal mines. International Journal of Rock Mechanics and Mining Sciences, vol. 67. pp. 145-154. [ Links ]

Li, M., Zhang, X.P., Mao, S.J., and Liu, Q.S. 2009. Study on deep mining safety control decision making system. Procedia Earth and Planetary Science, vol. 1. pp. 377-383. [ Links ]

Liu, H.B., Cheng, Y.P., Song, J.C., Shang, Z.J., and Wang, L. 2009. Pressure relief, gas drainage and deformation effects on an overlying coal seam induced by drilling an extra-thin protective coal seam. Mining Science and Technology, vol. 19. pp. 724-729. [ Links ]

Liu, Y.K., Zhou, F.B., Liu, Y., Liu, C., and Hu, S.Y. 2011. Experimental and numerical investigation on the deformation of overlying coal seams above double-seam extraction for controlling coal mine methane emissions. International Journal of Coal Geology, vol. 87. pp. 139-149. [ Links ]

Noack, K. 1998. Control of gas emissions in underground coal mines. International Journal of Coal Geology, vol. 35. pp. 57-82. [ Links ]

State Administration of Work Safety. 2009. The Regulations of Coal and Gas Outburst Prevention. Coal Industry Press, Beijing. [ Links ]

Tian, K.Y., Sun, W.B., and Wei, E.J. 2013. Determination of protection range for mining upper protective layers and its numerical simulation. Journal of Liaoning Technical University (NaturalScience), vol. 32, no. 1. pp. 7-13. [ Links ]

Wang, H.T., Huang, H.L., Yuan, Z.G., Shu, C., and Hu, G.Z. 2014. Model of gas leak flow coupled solid and gas for exploiting of steep-inclined upper-protective layer and its protection scope. Rock and Soil Mechanics, vol. 35, no. 5. pp. 1377-1383 [in Chinese]. [ Links ]

Wang, L., Cheng, Y.P., Ge, CG., Chen, J.X., Li, W., Zhou, H.X., and Wang, H.F. 2013. Safety technologies for the excavation of coal and gas outburst-prone coal seams in deep shafts. International Journal of Rock Mechanics and Mining Sciences, vol. 57. pp. 24-33. [ Links ]

Wang, L., Cheng, Y.P., Wang, L., Guo, P.K., and Li, W. 2012. Safety line method for the prediction of deep coal-seam gas pressure and its application in coal mines. Safety Science, vol. 50. pp. 523-529. [ Links ]

Wu, J., Sang, S.X., Fang, L.C., Huang, H.Z., Wu, D.G., and Yang, X.C. 2010. Protective seam mining released range and the site deployment of the released methane draining surface well in Huainan mine area. Coal Geology & Exploration, vol. 38, no. 3. pp. 10-14 [in Chinese]. [ Links ]

Yang, W., Lin, B.Q., Qu, Y.A., Zhao, S., Zhai, C., Jia, L.L., and Zhao, W.Q. 2011a. Mechanism of strata deformation under protective seam and its application for relieved methane control. International Journal of Coal Geology, vol. 85. pp. 300-306. [ Links ]

Yang, W., Lin, B.Q., Qu, Y.A., Zhao, S., Zhai, C., Jia, L.L., and Zhao, W.Q. 2011b. Stress evolution with time and space during mining of a coal seam. International Journal of Rock Mechanics and Mining Sciences, vol. 48. pp.1145-1152. [ Links ]

Yuan, L. and Xue, S. 2014. Defining outburst-free zones in protective mining with seam gas content-method and application. Journal of China Coal Society, vol. 39, no. 9. pp. 1786-1791 [in Chinese]. [ Links ]

Zhou, H.W., Xie, H.P., and Zuo, J.P. 2005. Developments in researches on mechanical behaviors of rocks under the condition of high ground pressure in the depths. Advances in Mechanics, vol. 35, no. 1. pp. 91-99 [in Chinese]. [ Links ]

Correspondence:

Correspondence:

X. Chen

cxjhpu@163.com

Received: 4 Jul. 2017

Revised: 12 Jun. 2019

Accepted: 5 Nov. 2019

Published: March 2020