Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.120 n.1 Johannesburg Jan. 2020

http://dx.doi.org/10.17159/2411-9717/849/2020

DEEP MINING PAPERS

The need for improved layout design criteria for deep tabular stopes

Y. JoosteI; D.F. MalanII

IHarmony Gold, South Africa

IIDepartment of Mining Engineering, University of Pretoria, South Africa

SYNOPSIS

This paper was compiled to highlight the need for additional research in the area of layout design criteria for deep gold mines. It describes aspects related to two popular design criteria used in the deep gold mines of South Africa, namely average pillar stress (APS) and energy release rate (ERR). The early layout designs in the gold mines were based on trial and error and most of the recommendations of the 1924 Witwatersrand Rock Burst Committee are still valid in modern times. The introduction of APS and ERR assisted greatly to reduce areas of high stress concentrations. Both criteria are of limited use, however, as it is not clear what the maximum value of APS for remnants should be and ERR has a significant drawback as no dissipative mechanisms are incorporated to allow for non-violent failure of the rock mass. A numerical modelling study is described that illustrates the effect of total closure on the simulated APS and ERR values of remnants. It is recommended that stress measurements be conducted below remnant areas to better calibrate the numerical models. The need for additional rock mass monitoring to supplement the design criteria is also discussed.

Keywords: stope layout, pillar stress, energy release rate, numerical model, remnants.

Introduction

The deep gold mines of South Africa are world-famous and more than 50 000 t of gold have been extracted from these mines since 1886 (Malan, 2017). Owing to the great depths of the workings, these mines are seismically active and rockbursts and falls of ground were the cause of many fatalities during the early years of mining. The fatality rate per 1000 employees per annum caused by falls of ground for the years from 1911 to 1943 varied from 0.72 to 1.2 (Jeppe, 1946). Compared to modern standards and the guidelines provided by societal risk curves (Joughin, 2011), these historical accident rates were not acceptable. The safety record of the mines has improved drastically in recent years and the additional improvement since 2007 is shown in Figure 1. Unfortunately, a number of recent rockburst accidents at various mines in 2017 and 2018 have resulted in an unacceptable loss of life. The increase in fatality rate in 2017 can be seen in Figure 1. These accidents have emphasized the need for additional research into methods to mitigate the risks of rockbursts. Production from the gold mines has now also dropped to multi-decade lows (Figure 2). Gold production in 2017 was only 137 t, whereas peak production was 1 000 t in 1970. Neingo and Tholana (2016) discussed mining depth and seismicity as a contributor to the recent decrease in production.

Surprisingly, even after a sustained production of 132 years, the Witwatersrand Basin is still the world's largest resource of gold (Minerals Council South Africa, 2018). Production can therefore continue for many years if the current poor profitability of the mines can be improved and a further improvement in safety can be achieved. Mechanization is currently being investigated by the South African Mining, Extraction, Research, Development and Innovation (SAMERDI) research programme as one possible solution. The gold industry still employs more than 100 000 workers (Minerals Council South Africa, 2018) and the social impact will be great if most of these workers lose their jobs owing to large-scale mine closures in the near future. To achieve sustainability in this sector, the development of updated design criteria for these very deep tabular mine layouts is urgently required. Remnants and pillars are mined in many of the older operations (Figure 3). Although most of these extractions are carried out without incident, there is a great need to improve the criteria used to select which remnants can be mined safely. As shown in this paper, the design criteria currently used are based on elastic theory and the failure of the rock mass is not taken into account. Total closure in some of the older mines also appears to destress some of the remnants, but there is no current methodology to objectively quantify this effect on a mine-wide scale. These aspects require urgent research, but surprisingly, there seems to be little appetite from some mining companies and the controlling bodies to fund fundamental research on design criteria and rock mass behaviour. A notable exception is Harmony Gold, which currently funds the Harmony Gold Research Chair in Rock Mechanics at the University of Pretoria. A specific aspect addressed by this research is the effect of mining rate and work was initiated to investigate the applicability of elastic design criteria when mining remnant areas.

The objective of this paper is to illustrate the shortcomings of the existing design criteria and to illustrate research areas that may lead to improvements in the layouts and better hazard identification. Van der Merwe (2006) used the Coalbrook disaster as an example of lessons not learnt from disasters and deplored the dismal state of rock engineering research in South Africa. He stated: 'Is it conceivable that the most important lessonfrom Coalbrook, namely that in order to be effective at all, knowledge has to be generated before it is needed, was not learnt?' Thirteen years after this Coalbrook paper was written, rock engineers still grapple with which are the most appropriate design criteria to use when extracting remnants, but almost no research on this topic was done during this period. This paper highlights the shortcomings of the current design criteria.

Overview of the evolution of rock engineering design criteria in the gold mining industry

Durrheim (2010) gave a comprehensive overview of the risk of rockbursts in deep hard-rock mines. The first damage on surface was reported as early as 1908 and the Ophirton Earth Tremors Committee was appointed to investigate the stress-related problems in the mines. They concluded that 'the pillars are severely strained; that they partly give way suddenly The committee recommended that the pillars be replaced by waste packs. This study was followed by the appointment of the 1915 Witwatersrand Earth Tremors Committee, which concluded that 'The removal of reef or reefs over large areas throws the weight of superincumbent mass on the unexcavated portions or pillars which, when the depth reaches 1,000feet or more, are unable to bear the weight and are crushed. When crushing takes place suddenly a rock burst occurs and causes a tremor: The committee recommended the removal of the pillars if they cannot carry the load or the use of sand filling in adjacent areas if they cannot be removed. The 1924 Witwatersrand Rock Burst Committee made several practical suggestions regarding layouts (Jeppe, 1946). The following are direct quotes of the suggestions from this source (the exact meaning is not clear in all cases).

> The ore should be extracted as completely as possible in the first working; Pillars or remnants of reef should not be left where that is avoidable.

> Efforts should be made to avoid the formation of isolated areas of reef, and to that end stoping should be kept well advanced on the mine boundaries.

> Stoping should be concentrated at the bottom of the mine so far as practicable.

> When two reefs are being mined one should be worked out as completely as possible in advance of the other.

> Large shaft pillars should be left for vertical shafts.

> Main levels should be a considerable distance in the footwall, and should be stoped over.

In terms of remnants it was suggested that:

> The working face should be advanced rapidly and continuously.

> Ample support of a character that will stand shocks should be kept close up to the working face.

> The minimum number of persons necessary should be employed near the working face.

> The direction of the working face should be carefully selected with a view to safety.

> The hanging wall portion of the face should be kept advanced.

> Stope pillars should not be cut.

Rock engineers will recognize that most of these recommendations from 1924 are still being used in industry. Close scrutiny of these empirical rules indicated that they worked in 1924 because adhering to them reduced excessive stress concentrations. None of the earlier workers described the problem in terms of quantitative values of stress, however, as no practical techniques existed to estimate stress levels in the irregular mining layouts.

To avoid the formation of remnants, the longwall stoping method was recommended by the 1924 rockburst committee. It was first introduced on Crown Mines in the 1930s where the longwall faces were carried in an overhand configuration. This consisted of a longwall covering three levels and the number of remnants was reduced to one instead of three (Jeppe, 1946). This was later changed to the 'longwall peak stoping' method where the faces were carried in underhand configuration, but this method was discontinued in 1944. In 1942 two underhand longwall stopes were successfully introduced in the Hercules section of ERPM by Hill as part of an experiment to reduce rockbursts (Hill, 1944). This layout is shown in Figure 4. It was shown that this resulted in 'A large reduction in the incidence and severity of pressure bursts.. Apparently the number of rockbursts decreased from 35 in 1941 to 14 in 1943. Longwalls were unfortunately problematic in terms of grade control and it was difficult to use this layout in areas where a large number of faults and dykes were present.

Although these empirical techniques resulted in a reduction in the number and severity of rockbursts, Cook et al. (1966) wrote that by 1950: 'It become painfully clear that that progress was reaching a standstill A more fundamental approach was required. To further mitigate the rockburst problem, the CSIR was approached and in 1953 the Chamber of Mines undertook to sponsor research in rock mechanics. A committee composed of Chamber staff, the mining groups, and the CSIR then guided research over a number of years. Assistance was also obtained from the Bernard Price Institute of Geophysical Research and the University of the Witwatersrand. The Research Advisor of the Chamber of Mines was appointed in 1962 and the Chamber of Mines Research Laboratory was established. Cook et al. (1966) summarized the progress that was made as a result of these efforts. A key breakthrough was that the far field rock mass behaviour could be approximated by elastic behaviour (Ryder and Officer, 1964). Cook et al. (1966) summarized the progress as follows: 'The paper produces evidence to show that the unfractured rock strata behave elastically, while seismic observations have confirmed the close relationship that exist between active mining operations and releases of energy. Indeed, the problem is shown by the authors to revolve around the concepts of energy release and energy dissipation and they suggest thatfurther progress in lessening the incidence and severity of bursts can best come about through either reducing the release of energy or increasing the dissipation of energy in non-violentform'. This work was indeed a major breakthrough and in the decades that followed, strategies such as the introduction of stabilizing pillars, backfill, numerical modelling of layouts to reduce the ERR, and bracket pillars to clamp geological structures were based on the foundation laid by these researchers.

In the gold mines, the current rockburst mitigation strategies can be broadly classified into two categories. The first set of measures attempt to reduce the number of damaging seismic events occurring, especially during times when there are workers in the stopes. These include layouts to minimize stress concentrations, bracket pillars to prevent slip on geological structures, centralized blasting systems, and preconditioning. Secondly, measures are implemented to protect the workers during rockbursts and this involves the installation of rockburst-resistant support with energy absorbing capabilities. Malan and Napier (2018) recently explored this second aspect in more detail and highlighted some of the shortcomings of the approach currently used in the deep gold mines.

A key aspect of the first set of measures is to minimize 'excessive' stress concentrations. This is currently achieved by numerical modelling of the layouts and applying the two key design criteria, namely average pillar stress (APS) and energy release rate (ERR). It is significant that these two criteria are imperfect as they do not take into account the extensive stress-related fracturing of the rock mass that is so ubiquitous in the deep mines. Other forms of inelastic behaviour, such as total closure, cannot adequately be taken into account by these two criteria. As many of the older mines exploit remnants, the question should be asked; to what extent these criteria are valid in remnant areas, and if they are not, what alternative method should be used to estimate the stress distribution and associated hazard. This paper investigates the drawbacks of the APS and ERR criteria in areas where remnants are being mined. Modelling of a simplified remnant geometry is included to illustrate the value of stress measurements to better identify areas of high stress concentration. The third key design criterion, excess shear stress (ESS) on geological structures, is not considered in this paper.

Average pillar stress

A difficult problem faced by rock engineers is to determine if remnants can be mined safely and to estimate the stress acting on these remnants. The computation of average pillar stress (APS) is important when attempting to establish criteria for pillar design and in the analysis of the stability of tabular pillar layouts (Ryder and Jager, 2002). Pillars with a width to height ratio exceeding 10:1 are often assumed to have 'infinite strength', although this ignores possible foundation failure (Ryder and Jager, 2002). Foundation failure, which involves rupture along planes in previously intact rock, needs to be considered for highly-stressed remnants and large pillars. In the deep gold mines, foundation failure of the regional pillars is of particular concern as these can generate seismic events in excess of magnitude 3. Some of the early work on this mode of failure was conducted by Wagner and Schumann (1971). They performed laboratory tests in which the bearing strength of rock loaded with a circular stamp was investigated. For larger stamp diameters, the bearing strength of the rock was approximately four times the uniaxial compressive strength. To avoid this type of failure, an empirical rule commonly used is (Ryder and Jager, 2002):

where ocis the uniaxial compressive strength (UCS) of the foundation strata. This is the weakest of the hangingwall or footwall strata and fais an empirical factor typically taken as 2.5. This empirical factor is the controversial part of this criterion as Wagner and Schumann (1971) estimated a value as high as 4 from the laboratory testing. The value of 2.5 was suggested in the 1988 rockfalls and rockburst guide (Chamber of Mine Research Organisation, 1988). As stated in this guide: 'Laboratory tests suggest thatfoundationfailure occurs if the average pillar stress (APS) exceeds the uniaxial strength of the host rock by approximately 3.5 ümes...Thus in practice, due to the presence of rock mass weaknesses and uncertainties regarding virgin horizontal stress levels, afactor of no more than 2.5should be used.' This is unsatisfactory, as no scientific reason is given for the value of 2.5. Jager and Ryder (1999) refers to it as 'An approximate and conservative criterion In contrast, Ryder and Jager (2002) reported work by Handley et al. (1997) which indicated that back area pillar seismicity may start at values as low asf = 1.2. This was confirmed by FLAC modelling (York, 1998) with a strain softening model which indicated that the APS should be limited to 1.25 times the UCS. Based on these studies, it is clear that further modelling work and field experiments need to be conducted.

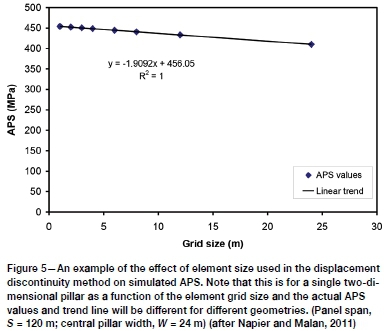

To compound the problem, a numerical modelling quirk may result in erroneous APS calculations. Although the APS can be readily estimated using tributary area theory for regular layouts, the evaluation of Equation [1] in practice requires that the pillar stress be computed for irregular layouts. One of the popular numerical methods used to determine pillar stresses is the displacement discontinuity method. In coarse element simulations, the results can depend on the chosen element mesh size. This was investigated by Napier and Malan (2011). For example, for a simple two-dimensional model, it was shown that more accurate pillar stress estimation can be obtained by calculating two APS values by using different grid sizes and then calculating the extrapolated APS value as the grid size tends to zero (Figure 5). Note that the APS values and trend line in the graph are only applicable to the specific geometry investigated by Napier and Malan (2011). Further studies of the effect of element size for actual three-dimensional pillar geometries are required.

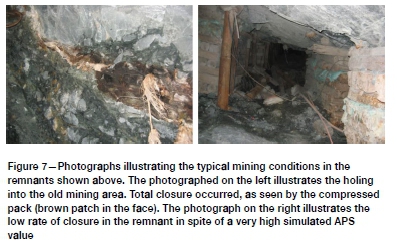

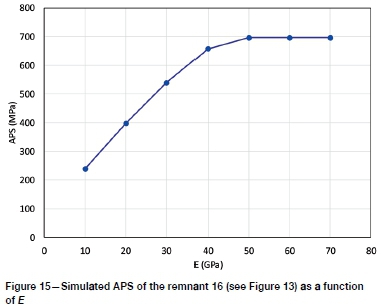

A further complication regarding APS calculations is also frequently encountered in the deep gold mines. Owing to the tabular nature of the orebody and the small mining height, total closure (contact between hangingwall and footwall) can occur in some areas (Figures 6 and 7). The resulting regeneration of stress in these old areas results in a reduction of stress on the remaining remnants. There is no reliable method to determine the extent of total closure on the reef horizon. Physical access to the old mining areas is frequently not possible and numerical modelling can only be used if it accurately reflects the inelastic rock failure and associated increase in deformation around the excavations. The modelling of off-reef failure on a mine-wide scale cannot easily be done with the existing tools. An interim solution proposed by Gurtunca and Adams (1991) was to use elastic modelling with a reduced Young's modulus (E). This is an unsatisfactory solution and one of the problems is that calibration of this 'reduced modulus' is extremely difficult. Numerical modelling of the remnant shown in Figure 6 indicated an APS value of 697 MPa when using a value of E = 70 GPa. Such a high APS did not exist in practice as the remnant was extracted safely and no large seismic events were recorded during extraction. A more practical method to determine pillar APS would be to use overcoring stress measurement techniques and these are occasionally used in the industry. The high cost and difficulty in obtaining intact cores in highly stressed pillar are as unfortunately prevent the large-scale use of this technique.

New developments in terms of energy release rate

A common criterion that is used in the design of the deep-level tabular mine layouts is the energy release rate (ERR) (Cook, 1963; Heunis, 1980). In the definition of this criterion, the energy release increment, ΔWA, represents the difference between the incremental work done by gravity forces acting on the rock mass, ΔW, and the incremental change in the strain energy, ΔU, that is stored in or released from the rock mass when mining an increment (Napier and Malan, 2014). This is given by:

For tabular excavations, the mining increment is typically expressed in terms of the area mined with respect to the plan view of the stope. If the incremental area mined is designated by AA, then the energy release rate is given as

For practical ERR calculations, stress analysis programs based on the displacement discontinuity boundary element method are typically used (Plewman, Deist, and Ortlepp, 1969; Deist, Georgiadis, and Moris, 1972; Ryder and Napier, 1985). The excavation is approximated as a narrow slit and in many applications, the reef material is assumed to be rigid and to have infinite strength. The use of ERR as a criterion for layout design has been extensively discussed. It has a number of practical shortcomings as a measure of the rockburst hazard (Salamon, 1984; Napier, 1991). The most significant drawback of the ERR criterion when used with the elastic models is that no dissipative mechanisms are incorporated to allow for local on-reef failure. Equation [3] represents the local value of the energy release at each point of the tabular excavation boundary and can be used as a measure of the local stress concentration at the stope face. An improved measure of stability can be obtained by modifying Equation [2] to include an energy dissipation term, ΔWD. This is the same component of energy referred to by Cook et al. (1966) who stated that the severity of rockbursts can be reduced by: increasing the dissipation of energy in a non-violentform: It would therefore be advantageous for the value of ΔWD to be as large as possible. A general measure of incremental mining stability, designated as ΔWR, can be defined as:

The incremental stability measure, defined by Equation [4], is associated with each incremental change to the excavation shape. It can also include released energy from explicitly modelled faults or other discontinuities. Napier and Malan (2018) proposed that a simple time-dependent limit equilibrium model could represent the fracture zone adjacent to the edges of tabular excavations. In this case, the energy dissipation term AWD can be computed explicitly in a series of discrete time-steps with imposed face advance increments corresponding to a given mining schedule. This approach allows parameters such as the size of mining increment and overall mining rate to be investigated.

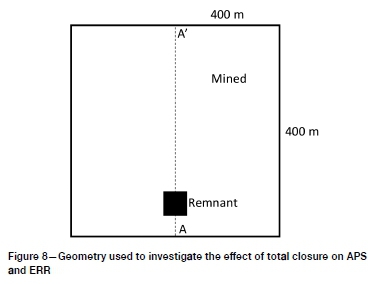

The effect of total closure on ERR and APS

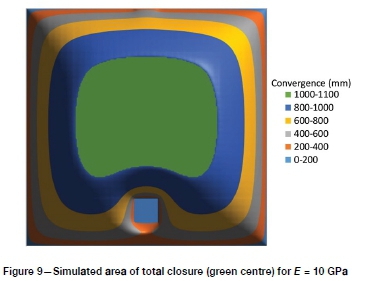

As a simple illustration of the effect of total closure on ERR and APS, a remnant geometry was simulated with the TEXAN code (Napier and Malan, 2007). The geometry consisted of a single remnant of size 40 m χ 40 m in a mined area of 400 m χ 400 m (Figure 8). The remnant was offset to the left to allow a larger area of total closure on the right. This remnant was simulated at a depth of a 1000 m with various values of Young's modulus to simulate different areas of total closure. The Poisson's ratio in all cases was 0.2, the stoping width was 1 m, and the dip was assumed to be zero. A 'stope' constitutive model in TEXAN allows for the correct calculation of stress generated in areas subjected to total closure. When the closure becomes equal to the stoping width (1000 mm in this case), stress is regenerated in the area where total closure occurred. The displacement discontinuity elements used were 2 m square elements.

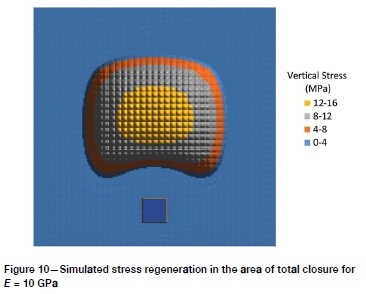

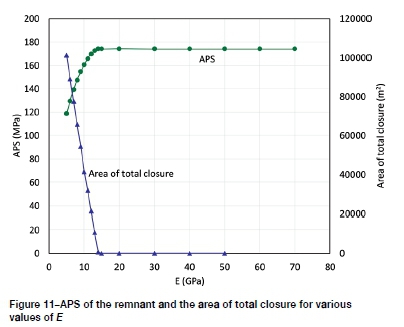

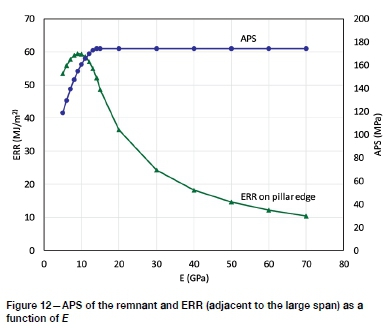

Figure 9 illustrates the area of total closure for the specific case of E = 10 GPa. This results in the regeneration of stress of more than 12 MPa in the centre portion of the mined stope (Figure 10). Figure 11 illustrates the decrease in APS on the remnant for an increase in the area of total closure. Note that the APS on the remnant decreases from 174 MPa for no total closure to 119 MPa at the lowest value of E. Based on these elementary results, it is clear that elastic modelling may overestimate the stress acting on remnants in old mining areas with large mining spans if inappropriate values of E are used. Figure 12 illustrates the corresponding decrease in average ERR values for the remnant (calculated for the remnant face adjacent to the large area of total closure) once total closure occurs at low values of E.

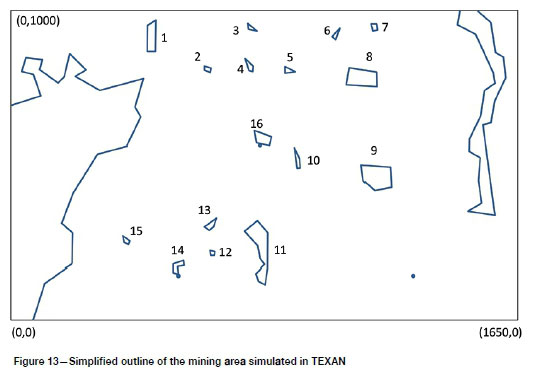

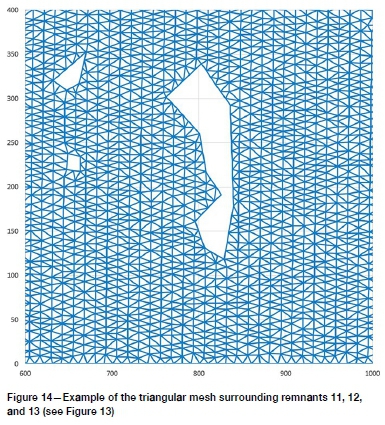

As a second modelling step using TEXAN, the actual layout in Figure 6 was simulated using different values of Young's modulus. The layout outline was approximated using straight-line segments to simply the generation of the triangular element mesh that was used for the simulation. The layout outline is shown in Figure 13 and the area simulated was approximately a 1000 m χ 1650 m. An example of the triangular mesh is shown in Figure 14. The simulated APS results for remnant 16 (also shown inside the circle in Figure 6) are shown in Figure 15. Note that total closure for this simulated geometry occurs for values of E < 50 GPa. The simulated APS value on the pillar is substantially reduced for low values of E because of the total closure.

Stress measurements to calibrate numerical models

It appears from the modelling in the previous section that it will be difficult to accurately model pillar or remnant stresses in areas where total closure has occurred. The proposal by Gurtunca and Adams (1991) to use elastic modelling with a reduced Young's modulus may be one approach to estimate APS values in remnant areas. In the short term, this may perhaps be more feasible than modelling attempts using complex inelastic codes to simulate fracturing, bed separation, and bulking of the rock mass. Calibration of these complex inelastic codes and forward modelling may possibly never be feasible owing to the large number of constitutive model parameters and the difficulty of characterizing the underground rock mass (Jing, 2003; Bahrani and Hadjigeorgiou, 2018). Further research is nevertheless required to investigate whether the gross simplification of a stiffness reduction will lead to a better estimation of stress concentrations in remnant areas. Reducing the value of E has been discussed for many years as a method of reducing the disparity between underground closure and simulated closure, but the concept has also been widely criticized.

Owing to the difficulty in accessing old mining areas, an estimate of the area of total closure from visual observations may not be possible. A possible solution would be to do stress measurements in the footwall haulages below these areas and then use this data to calibrate the numerical models. Figures 16 and 17 illustrate the vertical stress along line AA' (see the geometry in Figure 8) at depths of 50 m and 100 m below the reef. Note that the effect of the remnant is clearly visible at 50 m below the reef, but not at 100 m. The vertical stress in the middle of the mined span increases substantially as the amount of total closure increases. In actual underground mines, stress measurements in the remnant areas will be important to verify the results obtained from numerical models. If there are areas of total closure, the measured vertical stress below these areas will typically be higher than the simulated values and the stress on nearby remnants on the reef plane will be lower. Both numerical modelling and actual stress measurements are required to quantify this effect.

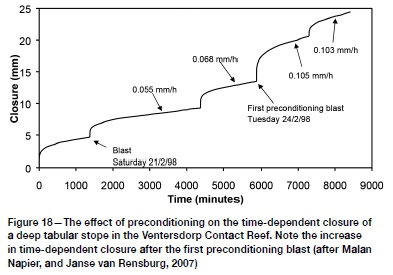

The Fourth Industrial Revolution and rock engineering design criteria

A further aspect to highlight is that, apart from seismic data, only limited data on the rock mass behaviour is currently collected in deep gold mines. It is hypothesised that the next major breakthrough in improved design criteria may be to combine the classical design criteria and in-situ rock mass data collected on a routine basis in the areas surrounding the active stopes. Surprisingly, very little laboratory testing of rock properties is conducted for rock engineering purposes compared to, for example, the number of tests conducted during civil engineering construction. The so-called Fourth Industrial Revolution (4IR) and its effect on mining technology is discussed in recent popular articles (Odendaal, 2019). Four aspects may impact the mines of the future, namely automation, robotics, a digitally enabled workforce, and next-generation analytics and decision support. A key building block of these technologies is new developments in sensor technology. The use of wireless sensor technology in rock engineering applications is an important development in this regard (Zhu and Zhuang, 2011) and large-scale application of this technology may significantly assist in the design of deep layouts. To illustrate the value of measurements other than seismic data, Figures 18 and 19 illustrates historical closure data that was collected in a deep gold mine in the Carletonville area (Malan, Napier, and Janse van Rensburg, 2007). The effect of preconditioning on the rock mass behaviour is clearly visible. Routine rock mass behaviour data, such as this closure data collected on a mine-wide scale, would give managers and rock engineers a much improved understanding of aspects such as the effectiveness of preconditioning. This information cannot be obtained from the seismic networks and new developments in terms of wireless sensor technology may make this possible. It is recommended that research in this area be initiated.

Conclusions

This paper was compiled to highlight the need for additional research in the area of layout design criteria for deep gold mines. In a recent article, Stacey (2019) wrote: 'How is it possible that the mining industry would regard the research as too costly? And thus, how can rock engineering research capacity in South Africa have been allowed to dissipate completely from the research powerhouse that it once was?' To further emphasise the need for additional research, this paper investigated problematic aspects related to two popular design criteria used in the deep gold mines of South Africa, namely average pillar stress (APS) and energy release rate (ERR). The early layout designs in the gold mines were based on trial and error and most of the recommendations of the 1924 Witwatersrand Rock Burst Committee are still valid in modern times. The introduction of APS and ERR assisted greatly in reducing areas of high stress concentrations. Both criteria are of limited use, however, as it is not clear what the maximum value of APS on remnants and pillars should be and ERR has a significant drawback as no dissipative mechanisms are incorporated to allow for on-reef failure. A numerical modelling study has been described that illustrate the effect of total closure on the simulated APS and ERR values of remnants. As an interim solution, it is recommended that many more actual stress measurements be conducted below remnant areas to supplement the numerical models. This may be a useful interim measure until more complex numerical models can be developed and calibrated to simulate inelastic rock mass behaviour on a mine-wide scale. Further research is also required to investigate whether the gross simplification of a stiffness reduction in elastic models will lead to a better estimation of stress concentrations in remnant areas. Reducing Young's modulus has been discussed for many years in order to reduce the disparity between underground closure and simulated closure, but the concept has also been widely criticized. As a further important recommendation, routine rock mass behaviour data, such as closure data collected on a mine-wide scale, would give managers and rock engineers a much improved understanding of aspects such as the effectiveness of preconditioning. This information cannot be obtained from the seismic networks and new developments in terms of wireless sensor technology may make these large-scale measurements possible.

Acknowledgments

This work forms part of a PhD study by Yolande Jooste at the University of Pretoria. This work was undertaken under the auspices of the Harmony Gold Chair of Rock Engineering, and the authors would like to thank Harmony Gold for permission to publish this paper. Professor John Napier is thanked for the assistance with the TEXAN code.

References

Bahrani, N. and Hadjigeorgiou J. 2018. Influence of stope excavation of drift convergence and support behavior: insights from 3D continuum and discontinuum models. Rock Mechanics and Rock Engineering, vol. 51, no. 8. pp. 2395-2413. [ Links ]

Chamber of Mines Research Organisation. 1988. An industry guide to methods of ameliorating the hazards of rockfalls and rockbursts. Johannesburg. [ Links ]

Cook, N.G.W. 1963. The basic mechanics of rockbursts. Journal of the South African Institute of Mining and Metallurgy, vol. 64, no. 3. pp. 71-81. [ Links ]

Cook, N.G.W., Hoek, E., Pretorius, j.P.G., Ortlepp, W.D., and Salamon, M.D.G. 1966. Rock mechanics applied to the study of rockbursts. Journal of the South African Institute of Mining and Metallurgy, vol. 66. pp. 435-528. [ Links ]

Deist, F.H., Georgiadis, E., and Moris, J.P.E. 1972. Computer applications in rock mechanics. Journal of the South African Institute of Mining and Metallurgy, vol. 72. pp. 265-272. [ Links ]

Gürtunca, R.G. and Adams, D.J. 1991. Determination of the in-situ modulus of the rock mass by the use of backfill measurements. Journal of the South African Institute of Mining and Metallurgy, vol. 91, no. 3. pp. 81-88. [ Links ]

Handley, M.F., Selfe, D.A., vieira, F.M.C.C., Maccelari, M.J., and Dede, T. 1997. Current position of strike stabilizing and bracket pillar design-Guidelines for deep level tabular orebodies. Journal of the Southern African Institute of Mining and Metallurgy, vol. 97, no. 3. pp. 103-117. [ Links ]

Heunis, R. 1980. The development of rock-burst control strategies for South African gold mines. Journal of the South African Institute of Mining and Metallurgy, vol. 80. pp. 139-150. [ Links ]

Hill, F.G. 1944. A system of longwall stoping in a deep level mine with special reference to its bearing on pressure bursts and ventilation problems. Association of Mine Managers of South Africa - Papers and discussions 19421945, vol. 1. Johannesburg. pp. 257-276. [ Links ]

Hinds, CG. 1963. The extraction of a remnant using mechanical props as a means of support. Association of Mine Managers of South Africa - Papers and discussions 1962-1963, vol. 1. pp. 497-510. [ Links ]

Jager, J.A. and Ryder, A.J. 1999. A Handbook on Rock Engineering Practice for Tabular Hard Rock Mines. Safety in Mines Research Advisory Committee, Johannesburg. [ Links ]

Jeppe, C.B. 1946. Gold Mining on the Witwatersrand. Transvaal Chamber of Mines. vol. I. pp. 805-806. [ Links ]

Jing, L. 2003. A review of techniques, advances and outstanding issues in numerical modelling for rock mechanics and rock engineering. International Journal of Rock Mechanics and Mining Sciences, vol. 40, no. 3. pp. 283-353. [ Links ]

Joughin, N.C. 2011. Engineering considerations in the tolerability of risk. Journal of the Southern African Institute of Mining and Metallurgy, vol. 111. pp. 535-540. [ Links ]

Malan, D.F., Napier, J.A.L., and Janse van Rensburg, A.L. 2007. Stope deformation measurements as a diagnostic measure of rock behaviour: a decade of research. Journal of the Southern African Institute of Mining and Metallurgy, vol. 107. pp. 743-765. [ Links ]

Malan, D.F. 2016. Krugerrand - Golden Jubilee. Prestige Bullion. South African Mint and Rand Refinery, Johannesburg. [ Links ]

Malan, D.F. and Napier, J.A.L. 2018. Rockburst support in shallow-dipping tabular stopes at great depth. International Journal of Rock Mechanics and Mining Sciences, vol. 112. pp. 302-312. [ Links ]

Minerals Council South Africa. 2018. Facts and Figures 2017. Johannesburg. [ Links ]

Napier, J.A.L. 1991. Energy changes in a rock mass containing multiple discontinuities. Journal of the South African Institute of Mining and Metallurgy, vol. 91. pp. 145-157. [ Links ]

Napier, J.A.L and Malan, D.F. 2007. The computational analysis of shallow depth tabular mining problems. Journal of the Southern African Institute of Mining and Metallurgy, vol. 107. pp. 725-742. [ Links ]

Napier, J.A.L. and Malan, D.F. 2011. Numerical computation of average pillar stress and implications for pillar design. Journal of the Southern African Institute of Mining and Metallurgy, vol. 111. pp. 837-846. [ Links ]

Napier, J.A.L. and Malan, D.F. 2014. A simplified model of local fracture processes to investigate the structural stability and design of large-scale tabular mine layouts. Proceedings of the 48th US Rock Mechanics / Geomechanics Symposium, Minneapolis, MN. American Rock Mechanics Association, Alexandria, VA. [ Links ]

Napier, J.A.L. and Malan, D.F. 2018. Simulation of tabular mine face advance rates using a simplified fracture zone model. International Journal of Rock Mechanics and Mining Sciences, vol. 109. pp. 105-114. [ Links ]

Neingo, P.N. and Tholana, T. 2016. Trends in productivity in the South African gold mining industry. Journal of the Southern African Institute of Mining and Metallurgy, vol. 116. pp. 283-290. [ Links ]

Odendaal, N. 2019. SA mining adopting, driving 4IR as its transformation journey continues. Engineering News, 21 June 2019: [ Links ]

Plewman, R.P., Deist, F.H., and Ortlepp, W.D. 1969. The development and application of a digital computer method for the solution of strata control problems. Journal of the South African Institute of Mining and Metallurgy, vol. 70. pp. 33-44. [ Links ]

Ryder, J.A. and Jaeger, A.J. 2002. A Textbook on Rock Mechanics for Tabular Hard Rock Mines. Safety in Mines Research Advisory Committee, Johannesburg. [ Links ]

Ryder, J.A. and Napier, J.A.L. 1985. Error analysis and design of a large-scale tabular mining stress analyser. Proceedings of the 5th International Conference on Numerical Methods in Geomechanics, Nagoya, Japan, 1-5 April 1985. Balkema, Rotterdam. pp. 1549-1555. [ Links ]

Ryder, J.A. and Officer, N.C. 1964. An elastic analysis of strata movement observed in the vicinity of inclined excavations. Journal of the South African Institute of Mining and Metallurgy, vol. 64, no. 6. pp. 219-244. [ Links ]

Salamon, M.D.G. 1984. Energy considerations in rock mechanics: fundamental results. Journal of the South African Institute of Mining and Metallurgy, vol. 84. pp. 233-246. [ Links ]

Stacey, T.R. 2019. What happened to rock engineering research in South Africa? Journal of the Southern African Institute of Mining and Metallurgy, vol. 119, no. 8. pp. 60-61. [ Links ]

Wagner, H. and Schumann, E.H.R. 1971. The stamp-load bearing strength of rock -An experimental and theoretical investigation. Rock Mechanics, vol. 3. pp. 185-207. [ Links ]

York, G. 1998. Numerical modelling of the yielding of a stabilizing pillar/foundation system and a new design consideration for stabilizing pillar foundations. Journal of the South African Institute of Mining and Metallurgy, vol. 98, no. 6. pp. 281-297. [ Links ]

Zhu, H. and Zhuang, X. 2011. Recent advances of digitization in rock mechanics and rock engineering. Journal of Rock Mechanics and Geotechnical Engineering, vol. 3, no. 3. pp. 220-233. [ Links ] ♦

Correspondence:

Correspondence:

D.F. Malan

francois.malan@up.ac.za

Received: 27 Jun. 2019

Revised: 25 Sep. 2019

Accepted: 22 Oct. 2019

Published: January 2020