Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.119 n.12 Johannesburg Dec. 2019

http://dx.doi.org/10.17159/2411-9717/446/2019

GENERAL PAPERS

Effects of water content and loading rate on the mechanical properties of Berea Sandstone

E. KimI, II, III; M.A. StineIV; D.B. Martins de OliveiraIV

IUnited States Army Corps of Engineers, San Francisco, CA

IIDepartment of Mining Engineering, Colorado School of Mines, Golden, CO

IIIUnderground Construction and Tunneling Engineering, Colorado School of Mines, Golden, CO, USA

IVDepartment of Mining Engineering, University of Utah, Salt Lake City, UT, USA

SYNOPSIS

Understanding the mechanical behaviour and properties of rocks is critical for industrial operations such as blasting, fracturing, drilling, crushing, and excavating. However, the effect of water and loading rates on the mechanical properties of rocks still remains to be understood. The effects of water content on the mechanical properties of rock under different loading rates were studied. The static and dynamic mechanical behaviour of dry and saturated Berea Sandstone were examined with a quasi-static loading machine and a split Hopkinson pressure bar (SHPB). Berea Sandstone is mainly composed of quartz (87%) with about 11% porosity. Overall, static compressive strength, Young's modulus, and tensile strength were significantly greater for dry samples than for saturated ones. In the dynamic tests, tensile strength was higher in the dry samples than in the water-saturated samples, whereas water did not have a significant effect on the dynamic compressive strength. Furthermore, compared to static loading conditions, the mechanical strength and Young's modulus under dynamic loading tests were significantly higher. Our results suggest that the effect of water on mechanical properties varies with the loading rate and testing method. This provides insight into how water content and loading rate affect rock mechanical properties and behaviour.

Keywords: water content, loading rate, dynamic mechanical strength, Young's modulus, Brazilian tensile strength (BTS), uniaxial compressive strength (UCS), split Hopkinson pressure bar (SHPB).

Introduction

Many factors affect the mechanical behaviour and properties of rocks, and understanding rock mechanics is crucial for both academic research and various practical applications (Kim, Rostami, and Swope, 2012; Ramesh et at., 2015; Sieter et at., 2015). In nature, rocks typically contain various amounts of water (Live Science, 2015; Schmandt et al. 2014). Thus, an understanding of the effect of water on the mechanical behaviour of rocks is crucial for design of underground structures (Mariotti, Perlat, and Guerin, 2003; Saksala and Ibrahimbegovic, 2014; Schumacher and Kim, 2013; Wong and Baud, 2012). Additionally, loading rates or loading methods have a great impact on the behaviour of rocks during procedures such as drilling, blasting, fracturing, and grinding, as well as phenomena such as rockbursting and impact failures (Kim and Oliveira, 2015; Qian and Zhou, 2011). For example, when designing an open pit or underground mine, creating blasting patterns, or deciding which drills to use, knowledge of the rock mechanics is essential. Consequently, understanding how water content and loading rate affect the mechanical properties of rock can significantly improve the stability of underground structures and increase the productivity of excavation and energy extraction (Kim and Colvin, 2012; Schumacher and Kim, 2014).

For a long time, a number of researchers and engineers have examined the mechanical properties of rocks using several techniques. However, a limited amount of work has been conducted on rocks with varying water contents under different loading rates (Kim and Changani, 2016; Yavuz et at., 2012; Zhang and Zhao, 2013). The effects that water has on the dynamic mechanical properties of Red and Buff sandstones were previously reported (Kim and Oliveira, 2015, 2016). As our previous studies did not examine the effect of loading rate, in the present work we investigated the effect of loading rate on the mechanical properties of dry and saturated Berea Sandstone. Berea Sandstone is a useful material, as the porosity is intermediate between that of Red and Buff sandstones. Additionally, Berea Sandstone consists mainly of quartz, similar to the Red and Buff sandstones.

Several researchers have studied the moisture content, increases of which will cause changes of mechanical responses of rock and weaken the rock (Torok and Vasarhelyi, 2010; Vasarhelyi and Van, 2006; Yilmaz, 2010). However, the way in which water content and loading rate affect mechanical strength is not fully understood (Dyke and Dobereiner, 1991; Hobbs, 1964; Torok and Vasarhelyi, 2010; Vasarhelyi and Van, 2006). In this paper, to understand how water content affects the mechanical properties of rocks, the compressive strength, tensile strength, and Young's modulus of dry and saturated Berea Sandstone under static and dynamic loading conditions were compared. Static compressive strength, static tensile strength, and dynamic compressive and tensile strengths were measured using uniaxial compressive strength (UCS), Brazilian tensile strength (BTS), and split Hopkins pressure bar (SHPB) tests, respectively. Our data provides insightful information about the effects of water content and loading rate on the mechanical properties of rock. Also importantly, our findings suggest that rocks containing water behave differently, so new or modified equations of P- and S-wave method for calculation of saturation rock properties need to be considered.

Experimental

Sample preparation

Berea Sandstones samples were prepared with a L/D ratio of 2 (length approx 115 mm, diameter approx. 55 mm) for UCS tests, and 0.4 L/D ratio (length approx. 20 mm, diameter approx. 55 mm) for BTS and dynamic mechanical tests, using coring, cutting, and grinding machines. To produce saturated samples, each sandstone specimen was submerged in water for 48 hours inside a vacuum chamber (25 cm Hg). To make the dry samples, half of the fully saturated samples were dried in an oven at 105°C for 48 hours.

Berea Sandstone

The Berea Sandstone is a Devonian-age formation (360 to 408 Ma) occurring in eastern Ohio, western Pennsylvania, western West Virginia, and eastern Kentucky. The grain size, as measured om a thin section using a petrographic microscope, is 0.011-4.0 mm. Each graduated point or stop of the microscope stage was assigned a specific category for modal analysis to characterize the grain composition using the Folk sandstone classification (i.e., quartz/feldspar/lithic fragment) (Folk, 1965). Based on a count of 300 points, Berea Sandstone has a median grain size of 0.15 mm with a sorting coefficient of 0.74. Based on the Folk sandstone classification, Berea Sandstone is classified as a subarkose containing 72% quartz, 6% feldspar, and 4.3% other rock type fragments.

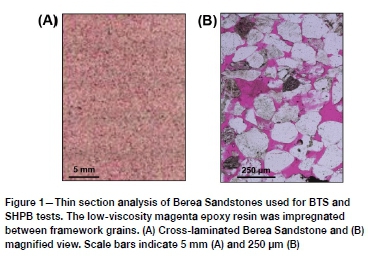

Porosity measurements

To estimate the porosity of Berea Sandstone, thin section analysis by 300-point counting was conducted at TerraTek ,as shown in Figure 1. The thin-sectioned sample was incubated in a magenta epoxy resin under vacuum to expose the porous space. The soaked sandstone specimen was removed from the resin, mounted to a standard thin section slide (24 mm x 46 mm), and ground to a thickness of 30 urn. The thin-sectioned sample was stained with an Alizarin and Red potassium ferricyanide mixture. The prepared section was photographed under plane-polarized and cross-polarized light at various magnifications using a Nikon polarizing microscope equipped with a Spot Insight digital camera. The area stained pink was used to estimate the porosity.

X-ray diffraction (XRD)

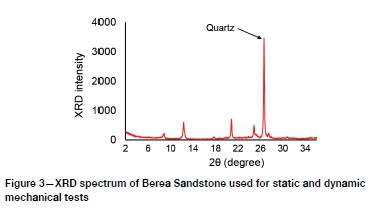

To identify and quantify the mineralogy of Berea Sandstone, a pulverized sample was subjected to X-ray diffraction (XRD) using a Rigaku Ultima III Advance X-ray diffractometer from 2° to 36° 29 using Cu K-alpha radiation and various slit and filter geometries. The raw data was analysed using JADE software based on whole-pattern fitting and Rietveld refinement methods.

Static compressive and indirect tensile strengths

Static compressive strength was measured by applying a uniaxial load to the cylindrical specimen under standard conditions. In this study, two different diameters, AX and NX, of sandstone specimens were cored and cut in accordance with ASTM to a length-to-diameter (L/D) ratio of 2:1. The ends of the samples were ground until they were flat and parallel in accordance with ASTM D7012-14 (2014). These sample diameters were at least 10 times larger than the maximum grain size, as recommended by the standard. Small-diameter specimens with similar L/D ratios were used to compare the static compressive strength to the dynamic strength. All static unconfined strength measurements were performed using a load frame equipped with an MTS Teststar IIM control system and Multipurpose Testware. The loading rate in the static compressive tests was 1.3 kNs-1.

The indirect tensile strength of the rock samples was determined by the split tensile method. The indirect tensile tests were conducted according to the procedure described in ASTM D3967-08 (2008). In this case, the vertically applied compressive load on a disk-shaped sample induced a horizontal tensile stress, and the sample broke while under tension. The disk specimens had a thickness-to-diameter ratio of 0.3-0.4. The indirect tensile strength of rock in this test was calculated using the following equation:

where P is the maximum load at failure, D is the diameter of the specimen, and t is the thickness of the specimen. The loading rate in static indirect tensile tests was approximately 0.06-0.08 kNs-1.

Dynamic loading compression and indirect tensile tests by split Hopkinson pressure bar (SHBP)

Dynamic loading compression and indirect tensile tests were conducted with a split Hopkinson pressure bar. Samples were prepared according to ASTM recommendations. Dynamic compression and tensile strengths of the samples were calculated using the same equations used to determine the static condition strengths (Kim and Oliveira, 2015). The SHPB basically consists of two long steel rods (bars) with strain gauges, a projectile (striker), a gas gun, and data acquisition system as described in Figure 2. When the striker, shot by the gas gun, hits the first rod (incident bar) it generates waveform energy, which is transmitted through the incident bar (incident wave). The rest of the energy is expected to propagate through the rock sample. However, after the wave reaches the rock sample, part of the wave is reflected (reflected wave) at the interface between the sample and the incident bar (Changani, Young, and Kim, 2013; Kim and Changani, 2015). Then, the rest of the energy is transmitted to the second rod (transmitted bar). After the stress reaches the second (transmitted) rod, then for safety reasons, the remaining energy is captured by the absorber. The data was recorded at a 10 MHz sampling rate using the data acquisition system (Kim and Changani, 2015). Dynamic testing methods were carefully examined to satisfy the fundamentals of dynamic stress curves and stress equilibrium.

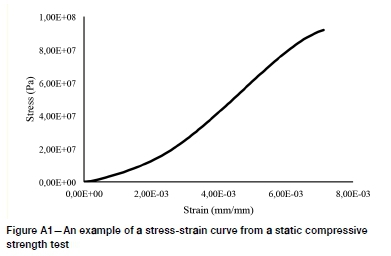

The Young's modulus, a stress-strain ratio, was evaluated to understand the trend of rock deformation under different loading conditions. In a typical stress-strain curve, the modulus, which is the slope of the curve, was analysed in the linear part of the curve as the slope at the beginning of the loading cycle fluctuated a little due to crack closure and seating of the platens (see Appendix, Figure A1). Thus, Young's moduli of the dry and saturated sandstone samples were calculated from the linear portion of the curve.

P- and S-wave velocity measurements

For a preliminary estimation of the rock properties, a nondestructive method, ultrasonic testing using compressive (P-wave) and shear (S-wave) wave velocities, was used. The P-and S-waves were generated with a frequency of 1.0 MHz in the ultrasonic testing apparatus to measure P- and S-wave velocities in the cylindrical rock samples (3.175 and 5.46 cm diameters with an L/D ratio of 2.0).

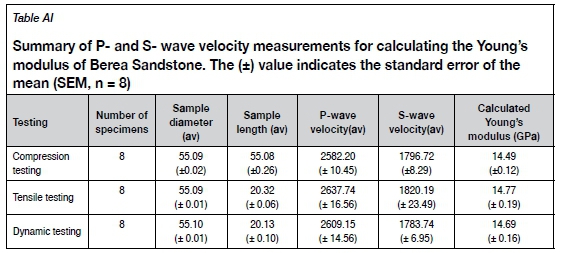

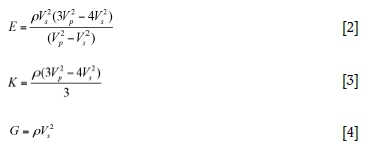

All samples used in this study were prepared according to the ASTM D2845 standard, as the minimum lateral dimension of the specimen was at least five times longer than the compressive pulse wavelength, and the wavelength was at least three times longer than the average grain size of the samples (ASTM D2845-08, 2008). To calculate the compression and shear wave velocities, the distance between two opposite transducers (the sample's length) was divided by the travel or arrival time, which was measured by an ultrasonic instrument. The preliminary elastic properties of the sandstone such as Young's modulus (E), the bulk modulus (K), shear modulus (G) as a function of P-wave velocity (Vp), the S-wave velocity (Vs), and the density (p), were calculated using the following equations:

The obtained P- and S-wave values and calculated Young's modulus are presented later in this paper (see Appendix, Table A1).

Results and discussion

In this study, Berea Sandstone was used because sandstones appear to have a relatively homogeneous grain and pore size, which is relevant when investigating the effects of loading rate and water content on the mechanical properties. The porosity value of Berea Sandstone was 11.0%. The mineral composition of Berea Sandstone, as obtained by XRD, is shown in Figure 3.

Effects of water on static mechanical properties of Berea Sandstone

First, the effects of water content on static compressive strength were examined using UCS tests. The maximum strength (MPa) was greater when dry than when saturated, as illustrated in Figure 4, supporting the conclusion that water can decrease the cohesion of geomaterials, which results in a reduction of the compressive strength (approx. 10.5% in this case). Furthermore, the compressive Young's modulus was approximately 5.0% higher for the dry samples than the saturated samples.

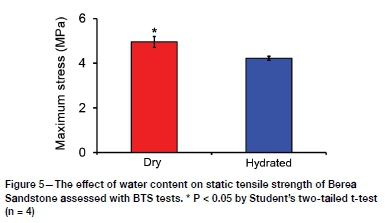

Consistent with the results obtained from compressive strength tests, tensile strength was approximately 17.2% greater for the dry samples than for the saturated samples, as illustrated in Figure 5. These results indicate that the effect of water on the reduction of static compressive and tensile strengths is significant, suggesting that the decrease of mechanical strength with increasing water content should be considered when designing and constructing geostructures, especially around sandstone areas.

Effects of water on dynamic mechanical properties

The effect of water on the dynamic compressive Young's modulus and strength in Berea sandstone samples was examined using the SHPB. In contrast to the static compressive Young's modulus and strength, the effect of water on the dynamic mechanical properties was not substantial, and the overlap range in dynamic compressive strengths between saturated and unsaturated is large, as shown in Figure 6. This data suggests that the effect of water content on rock mechanical properties can be significantly influenced by loading rates. Especially, the effect of water on the mechanical behaviour under compression was more apparent when the loading rate was lower. The porosity of Berea Sandstone obtained with 300-point count measurement was 11.0%. This suggests that different porosities affect the compressive mechanical stress with loading rates.

The dynamic compressive strength results did differed significantly between dry and saturated specimens (Figure 6). However, in dynamic tensile tests, the effect of water on the maximum stress level was significantly greater for the dry sample than the saturated sample, as shown in Figure 7. The dynamic tensile strength of dry Berea Sandstone was approximately 36% higher than when saturated. These results suggest that the effect of water could be more marked in dynamic tensile tests than in dynamic compressive tests. In addition, the dynamic tensile Young's modulus was approximaely 42.4% greater in the dry sample compared with the saturated sample, although the difference was not statistically significant due to the variation. Thus, our data can provide insight into how water content and different testing methods affect the mechanical behaviour of rocks.

In particular, it should be noted that the effect of loading rate on mechanical strength was much greater in tensile tests than in compressive tests, as shown in Table I. The difference between static and dynamic compressive tests was 114.0% for the dry sample and 168.0% in the saturated sample, whereas the difference between static and dynamic tensile tests was 811.7% for the dry sample and 686.5% for the saturated sample. These results are consistent with our previous work (Kim and, Changani 2016), which showed that the more drastic increase in the maximum strength of Red and Buff sandstones was exhibited in tensile tests. Currently, it is not fully understood why the effect of loading rate on maximum strength is more pronounced in tensile tests than in compressive tests, and further investigation is needed.

The static Young's modulus of Berea Sandstone was similar to that of Red sandstone approx. 5% porosity), while the dynamic Young's modulus of Berea Sandstone was close to that of Buff sandstone (approx.18% porosity) (Kim and Oliveira, 2015, 2016). These results suggest that the effect of porosity on the mechanical properties of Berea Sandstone is between that for Red and Buff sandstones.

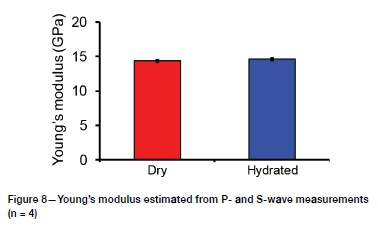

Young's modulus estimated with ultrasonic wave measurements and SHPB tests

P- and S-wave velocity measurements were used to estimate the Young's modulus of dry and saturated Berea Sandstone samples. Overall, the effect of water on the Young's modulus when measured by the ultrasonic velocity method was not significant, as illustrated in Figure 8. Noticeably, the Young's modulus (approx. 15 GPa) estimated from ultrasonic velocity tests was close to the value (approx. 12 GPa) obtained from static loading tests, but was much smaller than the dynamic compressive Young's modulus (approx. 199 271 GPa), measured with the SHPB. These results suggest that the effect of loading rate on the Young's modulus is much more extreme when tested mechanically than when estimated from P- and S-wave velocity measurements.

Additionally, it was apparent that the dynamic compressive Young's modulus was about 32 times greater than the dynamic tensile Young's modulus as determined for dry samples with the SHPB, and 62 time greater for saturated samples (Table I). This suggests that the effect of water on Young's modulus is more drastic in dynamic compressive tests.

Another interesting finding is that the Young's modului of dry and saturated Berea Sandstone, estimated from P- and S-wave measurements, did not show any significant difference. However, some researchers have discovered no difference in P-wave velocity measurements between saturated and dry limestone and volcanic rocks, although there were differences in S-wave velocity measurements (Karaman, Kaya, and Kesimal, 2015).

It is still not fully understood why water and loading rate have different influences on rock mechanical behaviour, especially under dynamic conditions. The apparent physical rate-dependent constitutive model for estimating effects of loading rate and water on experimental data and physical mechanisms should be studied. Some energy or stress-based dynamic fracture criteria for brittle materials can be considered with various failure criteris, including the Mohr-Coulomb criterion.

Conclusions

The effects of water content and loading rate on changes in the mechanical responses in Berea Sandstone were examined. The compressive and tensile strengths of dry and saturated samples were examined under static and dynamic loading conditions. The main findings of this study are as follows.

> The static compressive and tensile strengths were greater for dry samples than for saturated samples.

> The effect of water on the compressive dynamic mechanical strength was not significant in Berea Sandstone, suggesting that the effect of water on the mechanical behaviour of rock under compression is more apparent at lower loading rates.

> In contrast to the dynamic compressive test, in dynamic tensile tests, the effect of water on the maximum stress was greater for the dry sample than for the saturated sample, supporting the evidence that the effect of water could be more obvious in dynamic tensile tests than with dynamic compressive measurements.

> The effect of water on the Young's modulus was much more drastic in dynamic tensile tests than in dynamic compressive tests.

The results of our study provide insight into how the water content of rock can affect mechanical behaviour, depending on the stress loading rates, and contribute to the improvement of safety and cost-effectiveness in geotechnical applications.

ORCiD ID:

E. Kim: https://orcid.org/0000-0002-3373-6642

References

AsTM D2845-08. 2008. Standard test method for laboratory determination of pulse velocities and ultrasonic elastic constants of rock. West Conshohocken, PA. [ Links ]

AsTM D3967-08. 2008. Standard test method for splitting tensile strength of intact rock core specimens. West Conshohocken, PA . [ Links ]

AsTM D7012-14. 2014. Standard test methods for compressive strength and elastic moduli of intact rock core specimens under varying states of stress and temperatures. West Conshohocken, PA. [ Links ]

Changani, H, Young, A., and Kim, E. 2013. Effect of L/D ratio on dynamic response of aluminum 7076 and the natural Motoqua quartzite sandstone in Saint George, UT using Split Hopkinson Pressure Bar (SHPB). Proceedings of the 47th US Rock Mechanics/ Geomechanics Symposium, San Francisco, CA. American Rock Mechanics Association, Alexandria, VA. [ Links ]

Dyke, C.G. and Dobereiner, L. 1991. Evaluating the strength and deformability of sandstones. Quarterly Journal of Engineering Geology and Hydrogeology, vol. 24. pp. 123-134 [ Links ]

Folk, R.L 1965. Petrology of Sedimentary Rocks. Hemphill. [ Links ]

Hobbs, D.W. 1964. The tensile strength of rocks. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, vol. 1. pp. 385-396. [ Links ]

Karaman, K., Kaya, A., and Kesimal, A. 2015. Effect of the specimen length on ultrasonic P-wave velocity in some volcanic rocks and limestones. Journal of African Earth Sciences, vol. 112, Part A. pp. 142-149. [ Links ]

Kim, E. and Changani, H. 2015. Study of dynamic mechanical behavior of aluminum 7075-T6 with respect to diameters and L/D ratios using Split Hopkinson Pressure Bar (SHPB). Structural Engineering and Mechanics, vol. 55. pp. 857-869. [ Links ]

Kim, E. and Changani, H. 2016. Effect of water saturation and loading rate on the mechanical properties of Red and Buff Sandstones. International Journal of Rock Mechanics and Mining Sciences, vol. 88. pp. 23-28 [ Links ]

Kim, E. and Colvin, s. 2012. A preliminary full scale cutting test to find pre-cursor parameters of frictional ignition. Proceedings of the 14th US Mine Ventilation Symposium, University of Utah, Salt Lake City, UT. [ Links ]

Kim, E. and Martins de Oliveira, D.B. 2015. The effects of water saturation on dynamic mechanical properties in red and buff sandstones having different porosities studied with Split Hopkinson Pressure Bar (SHPB). Applied Mechanics and Materials, vol. 752-753. pp. 784-789. [ Links ]

Kim, E. and Martins de Oliveira, D.B. 2016. The water saturation effects on dynamic tensile strength in red and buff sandstones studied with Split Hopkinson Pressure Bar (SHPB). Proceedings of the International Conference on Advanced Materials, Structures and Mechanical Engineering, Incheon, South Korea. Kaloop, M. (ed.). Taylor & Francis. [ Links ]

Kim, E., Rostami, J., and swope, C. 2012. Full scale linear cutting experiment to examine conical bit rotation. Journal of Mining Science, vol. 48. pp. 882-895. [ Links ]

Live science. 2015. What is groundwater? https://www.livescience.com/39579-groundwater.html [accessed 30 June 2019]. [ Links ]

Mariotti, C., Perlat, J.P, and Gu6rin, J.M. 2003. A numerical approach for partially saturated geomaterials under shock. International Journal of Impact Engineering, vol. 28. pp. 717-741. [ Links ]

Qian, Q. and Zhou, X. 2011. Quantitative analysis of rockburst for surrounding rocks and zonal disintegration mechanism in deep tunnels. Journal of Rock Mechanics and Geotechnical Engineering, vol. 3. pp. 1-9 . [ Links ]

Ramesh, K.T., Hogan, J.D., Kimberley, J., and stickle, A. 2015. A review of mechanisms and models for dynamic failure, strength, and fragmentation. Planetary and Space Science, vol. 107. pp. 10-23 [ Links ]

saksala, T. and Ibrahimbegovic, A. 2014. Anisotropic viscodamage-viscoplastic consistency constitutive model with a parabolic cap for rocks with brittle and ductile behaviour. International Journal of Rock Mechanics and Mining Sciences, vol. 70. pp. 460-473. [ Links ]

schmandt, B., Jacobsen, s.D., Becker, T.W., Liu, Z., and Dueker, K.G. 2014. Dehydration melting at the top of the lower mantle. Science, vol. 344, no. 6189: pp. 1265-1268. [ Links ]

schumacher, F.P. and Kim, E. 2013. Modeling the pipe umbrella roof support system in a western US underground coal mine. International Journal of Rock Mechanics and Mining Sciences, vol. 60. pp. 114-124. [ Links ]

schumacher, F.P. and Kim, E. 2014. Evaluation of directional drilling implication of double layered pipe umbrella system for the coal mine roof support with composite material and beam element methods using FLAC3D. Journal of Mining Science, vol. 50. pp. 336-349. [ Links ]

sieter, J., smith, M., Kim, E., and Cox, s. 2015. Dust and noise hazard exposure: Comparison of PDC vs.WC roof bolt bits in laboratory. Mining Engineering, vol. 67. pp. 28-33. [ Links ]

Torok, A. and Vasarhelyi, B. 2010. The influence of fabric and water content on selected rock mechanical parameters of travertine, examples from Hungary. Engineering Geology, vol. 115. pp. 237-245 [ Links ]

Vasarhelyi, B. and Van, P. 2006. Influence of water content on the strength of rock. Engineering Geology, vol. 84. pp. 70-74. [ Links ]

Wong, T-f. and Baud, P. 2012. The brittle-ductile transition in porous rock: A review. Journal of Structural Geology, vol. 44. pp. 25-53. [ Links ]

Yavuz, H., Tufekci, K., Kayacan, R., and Cevizci, H. 2012. Predicting the dynamic compressive strength of carbonate rocks from quasi-static properties. Experimental Mechanics, vol. 53. pp. 367-376. [ Links ]

Yilmaz, I. 2010. Influence of water content on the strength and deformability of gypsum. International Journal of Rock Mechanics and Mining Sciences, vol. 47. pp. 342-347. [ Links ]

Zhang, Q.B. and Zhao, J. 2013. A review of dynamic experimental techniques and mechanical behaviour of rock materials. Rock Mechanics and Rock Engineering, vol. 47. pp. 1-68. [ Links ]

Correspondence:

Correspondence:

E. Kim

Email: eunhye.kim@usace.army.mil

Received: 18 Nov. 2018

Revised: 20 Jul. 2019

Accepted: 11 Oct. 2019

Published: December 2019

Appendix: Supplementary information