Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.119 n.11 Johannesburg Nov. 2019

http://dx.doi.org/10.17159/2411-9717/17/449/2019

GENERAL PAPERS

State-of-the-art of standing supports for gob-side entry retaining technology in China

H. ZhaoI, II

ISchool of Geology and Mining Engineering, Xinjiang University, Urumqi 830000, Xinjiang, China

IIThe State Key Laboratory of Coal Resources and Safe Mining, CUMT, Xuzhou 221116, Jiangsu, China

SYNOPSIS

Gob-side entry retaining technology (GERT) is a popular layout of the roadway in many modern coal mines due to its outstanding advantages in high production yield ratio and enabling the 'Y' shape ventilation configuration. During the past two decades, various standing supports, as the critical component of GERT, have been proposed and implemented. However, few systematic investigations have been conducted. This paper starts with a concise introduction of the movement of the strata overlying the standing support when the whole service period of retained gob-side entry is considered. A recently proposed new classification of standing supports based on the cross-section is then described. To obtain an in-depth comparison of each standing support, the advantages and drawbacks are investigated based on the installment procedure, economic benefits, and mechanical behaviour. Furthermore, recommendations for further research topics have been identified, such as the development of novel hybrid composite structures either in terms of the backfilling materials or the confining material. These backfill materials include coal rejects concrete, geopolymer concrete, high water-content slurry, and other environmentally friendly materials made of industry by-products. Emerging materials, including fibre-reinforced polymer (FRP) composites, high-strength steel, geosynthetic material, and combinations of these materials, should be considered. The key purpose of this review is to offer solutions for the development of easy-to-construct, cost-effective, and environmental friendly standing support for GERT.

Keywords: underground coal mining, standing support, GERT, backfill material, composite structures.

Introduction

The layout of the roadway has always been a matter of significant importance in mining engineering, for both researchers and coal operators, as the roadway is usually regarded as the 'throat' for coal mines (Li et al., 2016). Gob-side entry retaining technology (GERT), one of the most important components of an integrated pillarless retreat mining system, is normally defined as an innovative layout of roadway that leaves the tailgate close to the gob with some artificial standing supports, which will be used for the adjacent working panel (Zhang et al., 2014; Han et al., 2018). The artificial standing supports can also be set up in front of the working panel to reduce the manual risks compared to those generally constructed behind the working panel. The typical layout of the GERT is presented in Figure 1a.

Compared to traditional layouts of roadway, as shown in Figure 1b, it is believed that there are various advantages of GERT, not only in terms of technical aspects but also the economic benefits (Liu et al., 2018; Duan, Sun, and Li, 2019). It is obvious that the extra driving of roadway is not required due to the re-use of the tailgate for the next combined working panel. In other words, the tailgate with GERT can be thus shared by two working panels, which is significantly important for coal mines in hard rock where the driving of roadways is very difficult in practice. Accordingly, with the use of GERT, the coal pillar can be successfully recovered, increasing the yield of coal to some extent if appropriate standing support has been installed. Moreover, the recovery of the coal pillar can prevent load concentration, which poses a potential risk during the excavation of an adjacent coal seam. Another outstanding benefit of GERT is the constructed pathway for 'Y' shaped ventilation (see Figure 1a) in gassy coal seams. The fresh air goes through both the tailgate and the maingate to the gas drainage entry. The gas drainage boreholes can be always drilled in GERT toward a conjunct coal seam for gas pre-drainage. The most important of these benefits is that the GERT is generally located at the low-stress zone, contributing to the stability of the roadway surrounding rock. Hence, GERT has been widely accepted and used in a large number of coal mines in China, resulting in the popularity of the pillarless driving system.

The role played by standing support, the main component of GERT, is significantly important. The stability of standing support is a primary concern in the design of GERT. During the past two decades, various standing supports have been proposed and put into practical application in China based on a large amount of experimental test work and numerical analysis as well as theoretical analysis. The differences between these commercially-available standing supports are either in terms of the outer container materials (e.g. steel and fabric) or the infill backfilling materials (e.g. coal rejects, cementitious material, and concrete). As a result, GERT has been accepted by more and more coal mines in China to balance the relationship between economy, safety, and engineering requirements. Current research has revealed some critical geological factors, including the thickness of the immediate roof, the dip angle, overburden depth, mining height, lithology of the immediate roof, and the length of cantilever main roof block, that will significantly affect the stability of standing support used in GERT (Yang et al., 2016). Moreover, other mining parameters such as the properties of the main roof and the load distribution and deformation of the standing support can also affect the stability of standing support. Although a large number of investigations have been conducted to improve understanding of GERT, little attention has been paid to the systemic analysis and comparison of various standing supports under different geological conditions. There is still no standard as a reference to guide mining engineers choosing appropriate standing supports for practical application. An in-depth review of GERT as described in existing literature reports is therefore urgently required.

Against this background, we conducted a systematic review of the standing supports used in GERT and possible future developments. This paper starts with a theoretical analysis of the overall movement of the overlying strata, particularly considering the stress distribution on standing supports. Based on the roles played by the standing support at different periods during its service life, the market-available standing supports have been classified into two categories according to their cross-sections, i.e. packing wall and tubular column. The advantages and drawbacks of each typical standing support have been carefully clarified and compared. Finally, directions for further research on the infill backfilling material, the types of external confining material, and possible cross-sections are discussed to encourage the more widespread use of GERT in coal mines.

The purpose of this paper is to provide an insight into the standing support systems in GERT as a reference for the stability control of the surrounding rock. The information is expected to provide a systematic reference to assist mining engineers to better understand either the theoretical foundation or the practical application of GERT.

Theoretical foundation

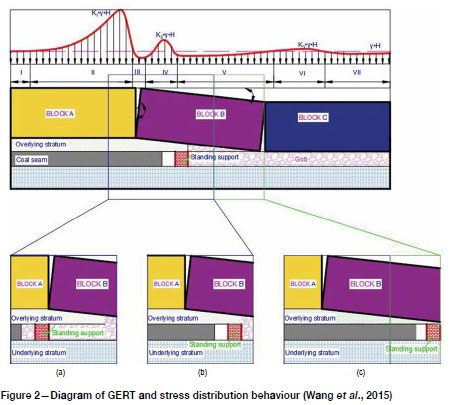

A large amount of research has been conducted to explore the deformation mechanism of the overlying strata in longwall systems by experimental investigation, theoretical analysis (Deng et al., 2010; Lu, Hua, and Zhao, 2011), numerical simulation (Zhang et al., 2018a) and field monitoring (Bai et al., 2015; Su et al., 2015). As a result, the stress distribution on standing support used for GERT is well understood (Li et al., 2016). Unlike the conventional layout of roadway, where the chain pillar is kept as a barrier to each working panel, GERT normally serves two working panels. As a result, both the deformation characteristics and the load distribution of the overlying strata will be significantly different. A diagram of the key layer and critical block for longwall operations, and sketch of the load distribution on standing support, is presented in Figure 2.

Generally, the standing support is set up along the working panel to form the new loading resistance structure for the next combined working panel. However, the breakage of the overlying stratum, in particular the failure of block B (see Figure 2), will significantly affect the loading conditions of the standing support in practice. It is apparent that (Figure 2a) the standing support will be in a situation of 'load controlling' when it is exactly under the failure line between block A and block B. That is, the main role played by the standing support is to provide a given loading resistance capacity. In other words, the deformation caused by rotation of block A can be controlled by a standing support with sufficient stiffness and strength. 'Load controlling' is also regarded as an ideal situation for the success of GERT. The other situation is termed 'displacement controlling', as shown in Figure 2c where both the strength and deformation capacity of the standing support should resist the deformation of block B. In this situation, the standing support will generally be compressed by the closure of the caving zone and thus the deformability is much more critical than stiffness. Figure 2b presents the situation, between 'load controlling' and 'displacement controlling', where the effect of standing support seems to be more complex. In this case the standing support should provide sufficient stiffness, strength, as well as deformation capacity. In fact, it is difficult to determine the most important feature of standing support that should be taken into consideration for this situation.

As mentioned earlier, the location of standing support is generally restricted by the limited space between the roadway and working panel. However, the load conditions will mainly depend on the standing support. That is, the interaction between standing support and the overlying stratum will lead to a different distribution of the failure line of key blocks such as block A and block B. The critical roles played by the standing support at different stages are therefore discussed to provide a better understanding of the effect of standing support in GERT.

The entire service period of standing support is divided into three stages: (1) the early stage of construction; (2) the excavation of first working panel; and (3) the excavation of the second working panel.

Early stage of construction

The early stage of construction is defined as the period from the first setting up of the standing support to the regular collapse of the immediate roof behind the working panel. During this period, the purpose of standing support installed behind or ahead of the working panel is mainly to provide a suitable support stiffness to avoid the separation of the immediate roof. Early strength of the standing support is therefore desirable. With the movement of the working panel, the breakage of the overlying strata develops from block A to block B, accompanied by significant deformation, as shown in Figure 2. It is not necessary to resist the whole weight of block B in practice since that the 'big structure' consisting of block A and block B will be generated in this stage. The basic requirement for standing support is to adapt to the large deformation with a similar deformation rate to that of the immediate roof. Therefore, standing supports such as the concrete crib, which are too stiff to deform sufficiently, may fail at the beginning of this stage.

A stiff standing support will be much more suitable to generate the 'load controlling' situation once the basic requirement for deformation capacity is reached. The use of stiff standing support can accelerate the failure of the immediate roof along the working panel and block B will fail in the mode shown in Figure 2a. In this situation, the stability of both standing support and the roadway will be much easier to achieve. Generally, stiffer material will deform less. To provide the ideal standing support with sufficient stiffness together with the required deformation capacity, many technical measures have been applied, which will be discussed later.

Excavation of the first working panel

It is well known that the main consideration for standing support in the early stage of construction is to maintain the stability of the immediate roof to prevent the separation of the overlying stratum. Forming the 'load-controlling' situation is the other, but not the essential, objective in that stage. In contrast, the features of standing support, in particular, the load-carrying capacity and deformability, seem to be critical during excavation of the first working panel. During this stage, an appropriate load-carrying capacity is required to maintain the stability of the roof nearby the gob to cut off the main roof as high as possible, otherwise the load on the standing support will increase abruptly. Therefore, strength and stiffness are essential for standing support during this stage.

Figure 3 shows the distribution of stress in the surrounding rock during the entire service life of GERT, from the excavation of the roadway for the first longwall panel (Figure 3a) to the second longwall panel (Figure 3d) with three roadways. It is apparent that the stress applied to the standing support increases significantly with the excavation of a longwall panel. During this stage, the standing support should be suitable to absorb the stress without any damage to the immediate roof and floor. However, it is difficult to identify whether it is under the 'load-controlling' situation or 'displacement-controlling' situation. Accordingly, the design of standing support becomes more complex to cater for different geological conditions, exemplified by the fact that standing supports in some mines have failed early in their service life.

Excavation of the second working panel

With the caving of the second working panel (see Figure 3d), the redistribution of the stress causes a large deformation of the standing support. The main source of this stress is the adjacent pressure caused by the movement of the second working panel. It is critical to maintain the stability of the standing support during this stage, like in first stage. As shown in Figure 2, the loading concentration factor (k) will reach its peak value (k1) when the standing support is affected by the excavation of second working panel. In this stage, the deformation capacity of the standing support becomes the most important concern. High-strength standing support will lead to potential problems in roof control behind the second working panel.

From Figure 2, the following technical requirements for the standing support used in gob-side entry are indicated.

> Early strength and sufficient deformation capacity are required to prevent the separation of overlying strata in the first stage. High-strength standing support is recommended to generate the 'load-controlling' situation.

> Suitable load-carrying capacity is required to maintain the stability of the roof nearby the working face to cut off the main roof as high as possible when the first working panel has caved.

> Appropriate deformation capacity and strength are necessary for the success of the GERT in the excavation of the second working panel.

Typical standing supports used in practice

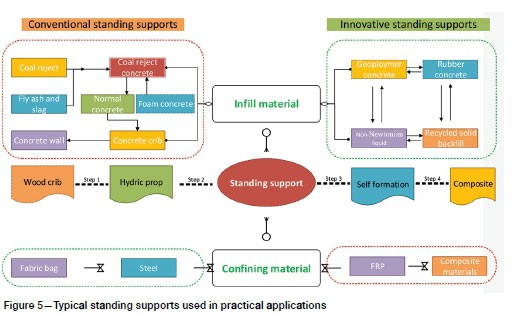

In the past few decades, a wide variety of standing supports and corresponding manufacturing procedures have been proposed and put into practical application to promote the adoption of GERT. The history of the standing supports used for GERT can be divided into the following four stages:

(1) Concept proposed and trials conducted. Wood crib was initially proposed as the standing support to maintain the stability of surrounding rock in the initial stage. During this period, the hydraulic prop was also introduced as an alternative to the wood crib due to its ease of installation. Coal rejects have been used together with the hydraulic prop to seal the gob.

(2) Rapid development of hybrid structures. Composite structures consisting of different types of infill backfilling material and external confining material have been widely accepted in this stage. Compared to standing support in the early stage, these composite structures exhibit high performance due to the composite effect.

(3) Self-formation of standing support. The new layout of roadways resulting from the use of the roof cut short-arm beam mining method (110 mining method) has been proposed recently to form the standing support from the surrounding rock itself rather than artificial supports. More detailed information can be found in following section.

(4) Novel composite structures incorporating emerging materials. Some emerging materials such as high-strength steel, fibre-reinforced polymer (FRP) composite, and geogrid have been introduced as confining materials. Meanwhile, various new-generation infill materials such as geopolymer concrete and coal rejects concrete have been proposed by the authors of this paper.

The classification of GERT is generally discussed according to infill materials and mining depth as shown in Figure 4, from a paper in which the researchers presented the statistical results from 150 case studies of GERT (Cao et al., 2016). However, due to the limitation of open literature resources, this classification may not give a critical insight into the differences between each standing support method used in GERT.

Consequently, we classify the existing standing supports into two main categories, i.e. packed wall and tubular column, according to their cross-sections, as shown in Table I. It should be noted that, except for the consideration of infill material, the confining material (which is the critical component of standing support) is discussed as well. More detailed information about the new classification can also be found in Figure 5.

The packed wall

The packed wall is an artificial wall constructed next to the gob of the first working panel to support the overlying stratum.

Having one of the most popular cross-sections widely used in practical applications, the packed wall is believed to be the most stable standing support compared to its counterparts (Cao et al., 2016). The packed wall is normally aligned along the direction of movement of the working panel to build up the continuous support structure. Details of the packed wall, including those of the initial tests (wood crib and hydraulic prop), composite structures, and self-forming structures, are discussed in the following subsections.

Wood crib and hydraulic prop

Wood crib has been introduced as a standing support at the early stage in the form of discontinuous packed wall along the gob (Bai et al., 2015). However, insufficient stiffness to resist the movement of the overlying stratum is believed to be the main drawback. As a result, the wood crib was discontinued after a few trials. However, the successful case study for the application of wood crib provides the foundation for the growing popularity of GERT, which has drawn researchers' attention to the importance of the stiffness and the effect of deformability. As an alternative to the wood crib, hydraulic props have been introduced at some mines with thin coal seams due to their high stiffness and controllable deformability. However, the high price of hydraulic props compared to wood cribs limits their wide application in GERT.

Although the wood rib and hybrid prop have not been widely used in practice, tests of these two types of standing supports have successfully illustrated the importance of the balance between stiffness and deformability. In particular, this is regarded as marking a breakthrough in GERT from concept to practice.

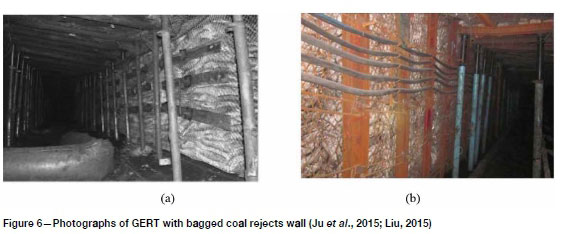

The bagged coal rejects wall

To eliminate the necessity for transport and dispoal of coal rejects i.e. the waste material from coal processing, some researchers have proposed the utilization of bagged coal rejects to form the packed wall as the standing support in GERT (Liu, 2015; Zhang et al., 2018). A large amount of research has been conducted to explore the feasibility of the use of coal rejects, both at the laboratory scale and in the field (Huang et al., 2011; Ju et al., 2015). These studies revealed that the physical properties of coal rejects, including the grain size, density, and the moisture content, will directly affect the compressive behaviour of the packed wall. Figure 6 shows two selected practical applications of GERT with the bagged coal rejects wall.

The installation procedure can be summarized as follows:

> Fill the plastic bag with compacted coal rejects to reduce void

> Transport the bagged coal rejects to a site nearby the gob

> Stack the bagged coal rejects in a line to form a packing wall with the desired width and height

> Double-check the gaps between the coal rejects wall and the roof as well as the bagged coal rejects to prevent the overflowing of CH4 and water from the gob

> Repeat steps 1-3 during the movement of the working panel until the stopping line (Figure 7).

There is no doubt that the cost of this type of standing support is acceptable for coal mines due to the utilization of the industry by-product (coal rejects). However, there are also some safety and engineering concerns for practical application. As pointed out, it is difficult to prevent the overflowing of CH4 from the gob to GERT, constituting a potential risk to miners working in this roadway. The non-airtight packing wall will also result in the loss of fresh air, with consequent difficulty in ventilation management. In addition, the strenuous work of setting up the bagged coal rejects wall is counter to the trend for modern coal mines, and may result in bodily injuries. In addition, the stiffness of bagged coal rejects packing wall is another technical factor to be considered. Its compressive strength is about 3 MPa, corresponding to a peak vertical displacement of 250 mm (10% of the height). The low stiffness cannot meet the basic requirements to cut off the immediate roof. Additional strengthening methods should be carried out as well. That is the reason this type of packing wall is used only for coal seams less than 1.5 m thick.

Based on the above discussion, it can be concluded that the bagged coal rejects packing wall can be used only for certain geological conditions where the emission of CH4 is not very high and the height of roadway is restricted, despite the fact that it is still believed to be an environmentally friendly and cost-effective standing support for GERT.

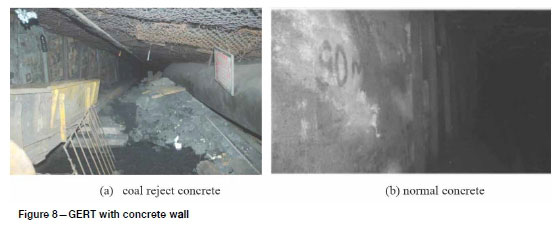

The concrete wall

Apart from bagged coal rejects, various types of concrete including standard concrete, foam concrete, and coal rejects concrete have been used to construct the packing wall in GERT in recent years (Figure 8). The high strength of concrete is believed to be the primary advantage compared with bagged coal rejects. Among these concretes, coal rejects concrete is regarded as the most cost-effective backfilling material in GERT. More detailed information is contained in the next section. Since the coal rejects concrete wall is based on the bagged coal rejects packing wall, the advantages of using coal rejects will be described as well.

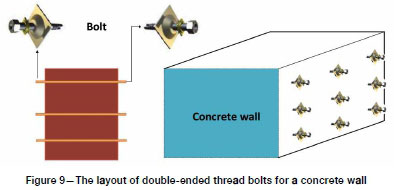

To maintain the stability of the coal rejects packing wall at the early stage of construction, high-strength structural steels and wood cribs are normally used as the permanent mould for casting coal rejects concrete in situ. Correspondingly, the manufacturing procedure has been changed to some extent. Firstly, the structural steel and the wood cribs should be set up and fixed together by double-ended thread bolts on the cleaned flat floor behind the working panel. To provide a safe working environment, hydraulic props should be set up as temporary support around the composite mould. The coal rejects concrete can then be prepared on site by mixing the required amounts of cement, fly ash, and other necessary binders together with water. The coal rejects concrete can be cast into the fixed mould to form the wall. Pre-loading can be applied by the double-ended thread bolts after the concrete has cured (Figure 9). The thread bolts are believed to provide extra lateral confinement to infill coal rejects concrete, which enhances the stiffness and the ductility. The final step is to double-check for any small cracks or gaps between the packed wall and the roof. Cement paste is usually used to fill these cracks to prevent methane overflowing from the gob.

Compared with bagged coal rejects, a coal rejects concrete wall has several advantages:

> The mixture can be poured directly into the mould by a grout system, by which means the labour required from the miners can be significantly reduced

> The stability of the standing support is enhanced due to the decreased void space, which has been filled will cementitious paste

> Quality control is much easier by referring to the mixture design code for standard concrete

> The use of structural steel is believed to provide extra support to the overlying roof before the curing of the backfilling material.

Most importantly, the width of the wall can be reduced due to the relatively high strength of coal rejects concrete. These advantages were proved by practical applications in Qishan coal mine of Jiangsu Mining Company, where the mining depth exceeds 800 m. Even though there are many examples of successful applications of coal rejects walls, the quality should be tested in the laboratory before use in the field.

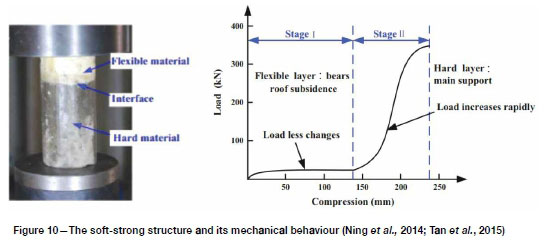

Although the performance of the coal rejects concrete wall seems to be better than that of its counterparts, it is still considered to be a brittle material. Two solutions have been proposed to improve this method - the application of double-ended thread bolts together with steel mesh to enhance the ductility of the concrete, and the use of a soft layer on the top of concrete to generate a composite structure. Similar to the coal rejects wall, the use of double-ended thread bolts with steel mesh can provide extra confinement to the concrete, enhancing the compressive strength and axial ductility. However, this increases the complexity of installing the wall compared to a standard concrete wall. Recently, Tan et al. (2015) showed that applying a soft layer on the top of the wall can significantly change the brittle behaviour of concrete.

The soft layer, as shown in Figure 10, can be made of low-strength concrete or timber, the latter of which is easy to construct. The final stiffness of the composite concrete wall is directly related to the stiffness of these two materials.

The concrete brick wall

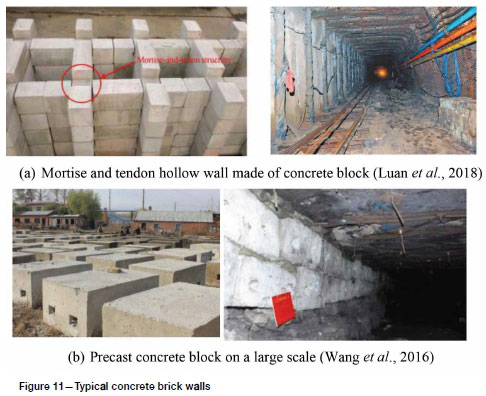

The concrete brick wall is another novel structure developed in recent years as an alternative standing support to the standard concrete wall. A concrete brick of standard size avoids the shortcomings of standard concrete in terms of the final setting time. The use of precast concrete bricks ensures a designed compressive strength (Figure 11). The special equipment designed for transportation and installation can effectively reduce the potential safety risk for miners. In addition, the use of precast concrete brick changes the building process of the packing wall from a manual basis to a much more efficient automated basis.

Considering the density of standard concrete, the foam concrete brick is recommended for the construction of concrete brick walls. From an engineering point of view, this packing wall has the same problem as mentioned for standard concrete. To modify the inherent brittle behaviour of concrete, additional strengthening methods should be considered. Furthermore, compared with the standard concrete wall, which can be cast in situ to reduce material transportation costs, a decision to utilize a concrete brick wall should take into account the extra transportation requirements.

Cementitious grout wall

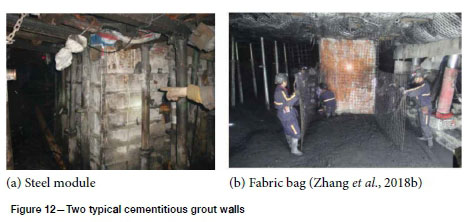

Pumpable standing support material, which is proposed based on the concrete brickwork and high-pressure pump system, has been widely used in GERT. The cementitious material is the main component of pumpable support, for which the basic requirement is fluidity. Therefore, some typical cementitious materials were developed. Foamed cement (aerated cement), Portland fly ash cement, Portland Pozzolana cement, and ettringite-based cements have been put into applications to cater for different geological conditions.

The outer container can be made of steel or alloy formwork, fibre bags, and geogrid. If steel or alloy formwork is used (Figure 12a), the most significant problems would be the complex manufacturing process and potential risks of bodily injury, which limit widespread application. Traditionally, these formworks cannot be reused. Similar to other structures, the gap between the roof and support has not been completely eliminated. Moreover, the confinement provided by the formwork will be weakened once the formwork has yielded since the formwork cannot match the deformation of the surrounding rock. Because concrete is regarded as a brittle material, the buckling of the steel will lead to failure of the whole system.

In order to remedy this situation, plastic sheet formwork (Figure 12b) is proposed to provide confinement to backfilling material. These flame-retardant resin materials or geogrids can meet the requirements in mining engineering. A significant advantage is that these soft bags can be folded into any shape, which is convenient for transportation and can reduce the stacking space as well.

Plastic bags filled with material with a high water content, one of the most popular cementitious materials, rather than the concrete-filled steel columns, can be regarded as the breakthrough from a manufacturing perspective. The water-to-powder (w/p) ratio ranges from 1.5 to 8 according to the practical situation. The high w/p material is easy to pump and difficulties in terms of storage, transportation, and construction can be overcome. With the ancillary technique including temporary reinforcement, the stability of support structures and the upper overlying stratum can be maintained.

Moreover, pumpable concrete has also been used in pumpable standing supports. Compared with cementitious grout, the early strength of the concrete and the small axial strain are drawbacks of these structures, although there have been some successful field applications.

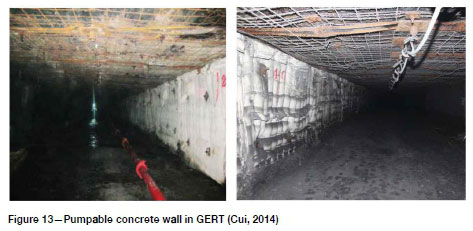

Pumpable concrete wall

Although cementitious grout has been normally accepted due to its advantageous setting time and long pumpable distance, for most of the cementitious grouts available on the market, the relatively high cost is the main concern for coal operators. Against this background, another type of pumpable concrete wall was developed recently by researcher from Xi'an University of Science and Technology (Cui, 2014).

As shown in Figure 13, geotextile has been introduced to make the rectangular module. A direct comparison can be made between geotextile and the traditional plastic bag. Unlike the plastic bag, water can pass through the geotextile, which provides the possibility to use high-water content concrete. It is well known that the strength of concrete will be significantly affected by an increase in the water-to-cement ratio. However, for this pumpable concrete wall, such influence is minor. The main role of the high water content is only to improve the pumping characteristics. With the continuous loss of water passing through the geotextile bag, an appropriate (lower) water-to-cement ratio will be reached even though the initial ratio is much higher. Due to its flowability and high strength, this pumpable concrete wall has been successfully used in more than 30 coal mines in China.

Pillarless retaining

Currently, the '110 mining method' is developed on the basis of the 'cutting cantilever beam theory', which is regarded as the third major mining science innovation for China (He, Zhu, and Guo, 2015). As opposed to existing theory, ground pressure is utilized for the purpose of advance roof caving by precutting to form a cantilever beam above the gob-side roadway. Part of the roof rock mass is driven down by the precutting methodology. As a result, only one roadway is excavated for one working panel, while the other one is retained from the last mining cycle without leaving coal pillars in the mining area. Figure 14 shows a flow chart of the entry retaining technology and a diagram of the roadway on site.

Compared with standard GERT, this method can significantly reduce the cost of artificial standing supports and ensure 100% recovery of coal pillars. The core technology for this method includes directional roof precutting, a reliable support system, and remote real-time monitoring.

Tubular columns

Recently, various cylindrical columns have been proposed and tested as the standing support used in GERT. Compared with the packing wall, the utilization of the circular columns can reduce the amount of raw material for the whole support structure while eliminating transportation difficulties. Although the concrete-filled steel tube and pumpable standing support have been widely used in tailgates for a long time, few reports can be found regarding GERT. Therefore, in this section, three typical columns are introduced in detail.

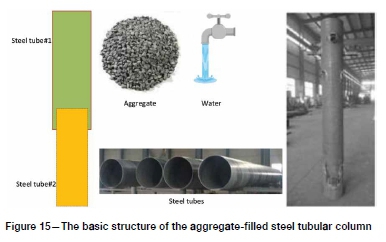

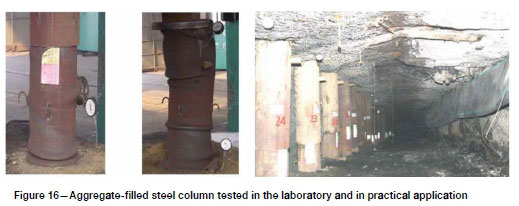

The aggregate-filled steel column

The aggregate-filled steel column was first used in Jining No. 2 mine as a type of standing support for GERT, as shown in Figure 15. The outer container of this novel structure consists of two steel tubes with different diameters. The diameter of the upper tube is slightly larger to provide the deformation capability. Due to the existence of the inner void to accommodate the aggregate, the upper steel tube cannot provide a stiff support until the aggregate is compacted. With increasing load, the steel tubes and the aggregate undergo coordinate deformation. In order to enhance the stiffness of this structure, the appropriate water content was investigated before application.

Owing to the special design of the outer steel container, this structure can be used several times as long as no significant buckling or rupture of the steel tube occurs. However, the significant shortcoming for this structure is the control of the inner space, which will affect the early strength of the aggregate column. If the outer steel tube is to be used a second time for the next roadway (Figure 16), the appropriate safety measures should be taken.

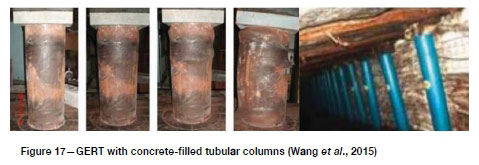

The concrete-filled steel column

The concrete-filled column, termed the Can® support, is similar to the aggregate-filled column but is filled with ordinary concrete or light concrete, with the confining pressure being provided by the outer steel tube (Figure 17). Because of the outer steel tube, the strength of the concrete is promoted and the surrounding stress is also changed from two-dimensional to three-dimensional, which will be better for the brittle concrete (Wang et al., 2015). At the same time, the buckling of the steel tube is delayed by the concrete filling, which can provide an appropriate support for the upper strata to retain the stability of the roadway.

Traditionally, the concrete was pumped by special equipment which ensures that the working panel is not too crowded for miners. With the use of the outer steel tube, the stability of the whole structure is also more reliable than those using aggregate, where the interior space is not easy to control. The application result seems to be satisfactory. The largest deformation is 50 mm in total, which can be regarded as acceptable. In order to guarantee the integrity of the ventilation, especially for gassy mines, it is necessary to use a coal gangue wall together with the concrete columns.

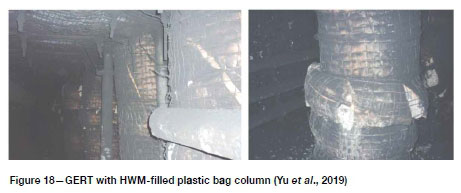

The high-water material-filled plastic bag column

This is a novel column filled with material with a high water content, which is popular in GERT. Compared with the concrete-filled column, this column is more convenient to construct and the interior void is easier to control. The filling material with high water content provides an appropriate fluidity as well as high early strength, which is important for the stability of the gob-side entry retaining.

Figure 18 shows the application of cementitious grout-filled columns in GERT. The outer tube is not made of steel but plastic, which is lighter. In order to enhance the strength of the column some other material, such as coal rejects and construction wastes, can be filled in the tube. It is evident that the strength of all three types of filled columns will be enhanced by outer confinement , and the coordinate deformation of the fill seems to be the most important factor affecting performance.

However, there are many advantages compared with the wall structure, despite the fact that the columns increase the difficulty of controlling the ventilation. The stability of the structure and the distribution of the stress are changed to some extent. Enhancing the stability of the columns and reducing the buckling of the outer tube are priority issues to be solved before this structure becomes more popular. Thus, identifying a novel outer material that can supply a reasonable confining pressure for the inner material is very urgent.

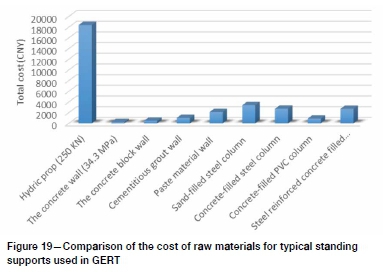

Economic benefits evaluation

Figure 19 shows the costs of the different types of standing support, based on the data presented in Wang et al. (2015). The cost of raw materials for the concrete-filled steel tubular (CFST) column and hydraulic prop has been compared. To provide 5000 kN axial load, the cost of the CFST is 2726 Chinese Yuan (CNY), approximately equivalent to 390 US dollar, 15% of that of the hydraulic prop. More detailed information used for the calculation based on an assumed load-bearing capacity of 5000 kN can be found in the original paper (Wang et al., 2015).

It has been noted that the economic benefits of the application of GERT are directly relevant to the revenue from the additional coal extracted and the total cost of the standing support. Although the additional revenue is not difficult to calculate, obtaining an accurate cost for the standing support including installation, transportation, and other costs over the whole life of the support is a complex exercise. As a result, the data presented in Figure 19 will vary for each coal mine with different depths and transportation systems.

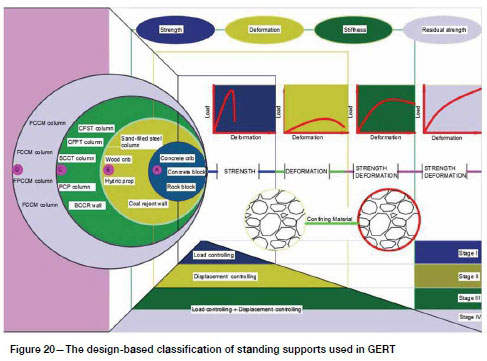

Design-based classification

The above sections have systematically presented detailed information on the typical standing support methods used in GERT according to their structural shape. Design-based classification illustrates the development of standing supports and provides the foundation for recommendations for further research. As described in Figure 20, standing supports are initially classified into three types according to design criteria -load controlling, displacement controlling, and load controlling plus displacement controlling.

For the load-controlling situation, strength and stiffness are the two main factors to be considered in the design. Stiff standing supports such as the concrete crib, concrete block, and rock block are generally used to achieve the successful application of GERT. As mentioned earlier, it is difficult to make sure the standing support is exactly under a load-controlling situation. Some additional soft materials with 'non-yielding ' characteristics, such as timber, will be placed on the top of these stiff standing supports, although the stiffness will be affected.

In the case of displacement controlling, standing supports with a large deformation capacity are highly recommended. Compared to the requirements of stiffness and strength, the deformation is much more critical so as to adapt to the rotation of the key block. As a result, standing supports with loadshedding behaviour, such as the aggregate-filled steel column, wood crib, hydraulic prop, and bagged coal rejects wall, can be successfully applied in GERT for some coal mines. It should be noted that these structures are not used alone in practice. To provide sufficient load-bearing capacity, cable bolts and some other strengthening methods are usually applied. That is, the successful use of soft standing support does not indicate that this is the ideal choice for GERT.

The most common situation is the combination of load controlling and displacement controlling, where both the load-bearing capacity and deformation capacity should be well designed. Since stiffer materials always have a smaller deformation capacity, the effective method of balancing these two parameters is the use of confining material. The brittleness of stiff material can be successfully changed by an exterior confining material. One good example is the concrete-filled steel tubular (CFST) column, where the stiff concrete core is in a state of triaxial compression. In addition, some other standing support including the concrete-filled PVC tubular (CFPT) column, steel-confined concrete tubular (SCCT) column, PVC confined paste material (PCP) column, and bagged confined coal rejects (BCCR) wall, are used as well.

Although the confining material can change the state of infill material, the majority of existing standing supports are associated with load-shedding behaviour and are therefore not ideal choices for GERT. Based on the analysis of the movement of the overlying stratum on standing supports, it is critical to develop a novel 'strain-hardening' standing support by introducing some innovative materials. These novel hybrid structures, illustrated in Figure 20, will be discussed in the following section.

Further research and directions

Although various standing supports have been proposed and used in gob-side entry technology, further research in this area, especially in terms of the support structure, is required.

Backfilling materials

As discussed above, normal concrete and CSA cement-based backfilling material have been widely used in gob-side entry for different mine conditions. However, more investigations should be carried out to identify economical and environmentally-friendly backfilling materials to reduce the use of Portland cement and emissions of CO2. Here, some potential developments in backfilling material are discussed.

Modified cementitious material

Based on the successful use of Portland cement as a bonding agent in underground mines (Patchet, 1977), different types of cementitious materials, including gypsum-lime mortar, fly ash-slag mortar, and silica-active geopolymer mortar, have been investigated as alternatives to conventional construction and building materials in civil engineering (Davidovits, 2002; Hardjito and Rangan, 2005; Shen, Zhou, and Zhao, 2007; Liu, Zhang, and Tan 2015). However, previous research focused mainly on the compressive strength rather than the high water-to-powder ratio and setting time, the latter of which is the primary concern for use underground. Therefore, the development of innovative cementitious material by adding some chemical components to enhance the water-to-powder ratio becomes very important (Komnitsas and Zaharaki, 2007; Kong, Sanjayan, and Sagoe-Crentsil, 2007). These chemical activators normally include NaOH and CaO (Yang, Qian, and Pang, 2008; Rattanasak and Chindaprasirt, 2009; Zhou, 2009; Somna et al., 2011). Industry by-products such as slag, lime, and fly ash should also be considered (Erdem and Ölmez, 1993; Degirmenci, 2008; Huang and Lin, 2010).

As discussed earlier, the compressive strength required for cementitious material is not critical. It is possible to use coal washing rejects with an appropriate particle size to partially replace cementitious material (Yu et al., 2019). As well as fine coal washing rejects, there are some other ideal materials like red mud, coarse sand, and rubber particles for possible application. Even though there are many choices for the development of cementitious products, the key point is that these innovative materials should have good pumpability and a suitable setting time compared to existing available cementitious materials.

Precast environmental concrete

The application of premixed concrete used in construction and building is believed to be an ideal solution for GERT underground in a confined working space. A change of the manufacturing order can successfully reduce the hazards of manual operation. With the setting up of the coal washing system underground (Cao, Shang, and Zhang, 2018), it becomes much easier to collect coal rejects in situ. Therefore, much attention should be paid to the use of coal rejects as an alternative to normal aggregate. In addition, the potential pozzolanic properties of coal rejects should be improved to generate geopolymer concrete (Li et al., 2013). Aside from coal rejects-based geopolymer concrete, some other typical concretes can be also introduced to GERT underground. Recycled aggregate concrete (Etxeberria et al., 2007) and rubber concrete (Sukontasukkul, 2009) show outstanding advantages not only in terms of their light weight, but also cost-effectiveness.

Solid backfill materials

Apart from coal rejects, which have been widely accepted as a backfilling material, there are some other potential backfilling materials (Li et al., 2019). Recycled concrete lumps, coarse sand, soil lumps, and waste bricks are not only expected to play the same role as coal rejects, but their use will have environmental benefits (Sun, Zhang, and Zhou, 2018; Sun et al., 2018; Zhang et al., 2018c). The use of foldable rubber bricks or rubber columns will present advantages as well. However, a critical environmental evaluation should be carefully conducted before practical application, due to the existence of harmful elements in these recycled materials.

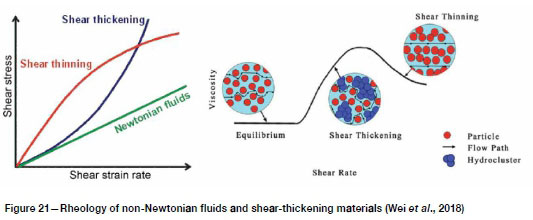

Other concepts

Some new concepts proposed during the past decades should be progressed to practical application. High-strength rubber containers filled with compressed air or water would constitute a novel standing support. In addition, some non-Newtonian fluids can be considered to replace water in waterproof containers. The obvious advantage of non-Newtonian fluids is their load-bearing capacity under dynamic loading caused by mining activities. Figure 21 presents the rheology and the effect of non-Newtonian fluids. Since there are no reports of non-Newtonian fluids used in underground supports, much more attention should be paid to these, from the initial selection to practical application. Non-Newtonian fluids have been suggested as an infill material for rapid-yield props with a similar structure to hydraulic props (Roberts and Brummer 1988).

Confining material

Steel and polymer have been considered as two typical materials for the outer container to provide sufficient confinement. However, they are not perfect materials from a design aspect. Therefore, some novel materials, including fibre-reinforced polymer (FRP), ultra-high molecular weight polyethylene (UHMWPE), and other composite materials can be considered as alternatives to steel and polymer (Teng et al., 2002, 2003).

High-strength steel

There are many reports concerning high-strength steel-confined concrete columns, which have smaller cross sections than conventional columns. With the use of high-strength steel, the mass of steel will be significantly reduced for the same confinement, which will help relieve the transportation tasks and facilitate the construction procedure. Recently, a high-strength steel with a yield strength of over 1100 MPa has become available (Jiang et al., 2017). This steel should be investigated further to better understand its applicability as a confining material. The other potential application of high-strength steel is to manufacture new-generation circular steel sets for use in deep underground mines (Beus and Chan, 1980; Chang et al., 2014).

Fibre-reinforced polymer (FRP)

Fibre-reinforced polymer (FRP) composite material has been widely used in civil engineering during the past two decades. Compared to steel, FRP possess several advantages, including its high strength-to-weight ratio and good corrosion resistance. Considering the short-time service requirement of standing support in GERT, FRP is believed to be one of the best choices as a confining material. Figure 22 shows the tensile stress-strain curves of typical FRP composites (Wu, Wang, and Iwashita, 2007).

It is clear that the liner behaviour of FRP is superior compared to that of normal steel. However, it should be noted that the ultimate strain of FRP is much less than that of steel. To maintain the stability of standing support under large deformations, a combination of steel and FRP is regarded as a better choice.

Composite materials

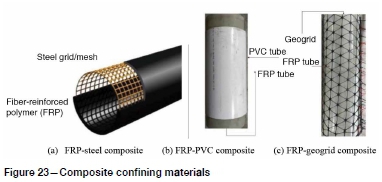

Compared with high-strength steel and FRP materials, the emerging composite materials shown outstanding combination effects and eliminate the defects when each the material is used alone. A good example of a composite confining material is the FRP-confined steel tubular column, where the outer buckling of the steel tube will be effectively restrained (Hu, Yu, Teng, 2011). The other type of FRP-steel composite consists of a steel grid or mesh cylinder with an FRP jacket covering both sides of the mesh, as shown in Figure 23a. As mentioned earlier, the main role of the outer container used in standing support is to provide confinement rather than to resist axial loading, therefore the novel FRP-steel mesh composite is believed to be much more cost-effective for the same confinement. Most importantly, the steel mesh will provide sufficient residual loading resistance after the rupture strain of FRP is reached.

The PVC tube and biaxial geogrid (Figures 23b and 23c) have been recently introduced in underground mining as novel confining materials. It should be noted that either the biaxial geogrid or the PVC tube will be generally placed in an axial direction to restrict the movement of infill material, which helps enhance the strength. Due to the light weight and large deformation capacity of the geogrid and PVC, these are believed to be among the most the effective confining materials for standing support.

Cross-sections

Telescopic circular column

The cross-section of the standing support will have a significant effect on the confining action on the infill material. These standing supports with circular cross-section are believed to be the ideal choice from a design aspect. Due to the variable height of the roadway where the standing support is generally installed, the telescopic circular column should be investigated further. The manufacturing and installation processes should be kept as simple as possible.

Oval-shaped columns

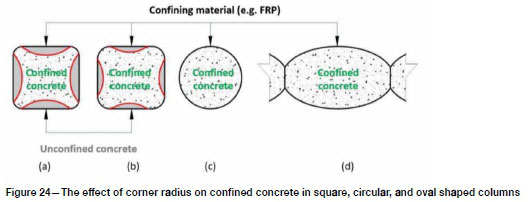

The confinement provided by an exterior container with either square or rectangular cross-section is believed to be inferior to that of a circular column. Taking FRP-confined concrete as an example, when the same amount of FRP composite is used, the extent of enhancement is directly related to the corner radius (Al-Salloum, 2007). As shown in Figure 24, with increasing corner radius, the effect of force concentration in the corners of a square column will be reduced, resulting in a relatively uniform distribution of the confining pressure.

As an alternative to the existing packed wall where the cross-section of the columns is generally rectangular, the author proposed the oval shaped cross-section to enhance the confining action of the exterior container. Here it should be noted that the loading condition of an oval column is different from that of the conventional rectangular columns used in construction and building. Each column in the row is restricted by the two columns on either side (see Figure 24d). The confining action and the mechanical behaviour of this wall of oval-shaped columns should be thoroughly investigated as well.

Concluding remarks

After several decades of sustainable development, gob-side entry retaining technology is widely used in China as a main component of 'green' mining systems. The author has presented a systematic analysis and summary of the standing supports currently in use. According to the cross-section, these standing supports were divided into two categories, the packed wall and the tubular column. To identify direction for further research, the detailed preparation and installation procedure for each type of support were discussed and compared.

> GERT is an innovative layout of roadway for underground coal mines. As one of its essential components, the stability of standing support is vital to the success of GERT compared to traditional support technology using wide coal pillars. Due to the existence of the 'key layer' and 'critical block' over these artificial standing supports, a large deformation capacity seems to be much more critical for standing support than strength and stiffness.

> Standing support in the form of wood cribs and hydraulic props made GERT possible. Since then, different types of standing support have been developed and put into practices in coal mines with various geological conditions and mining methods. The most popular standing supports are the packed wall made of wood cribs, hydraulic props, bagged coal rejects, concrete, concrete brick, foam concrete, rock blocks, and cementitious material. The other type of standing support is the tubular column, and includes the aggregate-filled steel column, concrete-filled steel column, and plastic bag column filled with high-water content material.

> Further research into backfilling materials for standing support should be conducted. Based on the analysis of existing materials, the modified cementitious material containing industry by-products, precast environmental concrete using coal rejects, solid backfill materials such as recycled concrete, and other emerging materials can be investigated as possible alternative to current backfilling materials.

> Combinations of steel and FRP, as well as biaxial geogrid, can be considered as alternatives to steel and fabric for exterior containers to improve the confinement on infill material. A change of cross-section is the other effective method to improve the confining action of the exterior container. For standing support used in GERT, the oval-shaped rectangle is proposed as a promising choice for the next generation of standing support.

The main aim of this paper is to provide a systematic overview of the standing support used in GERT and to point out areas for further research to progress the technological development of the next-generation standing support. Therefore, the author only focuses on the description of the backfill material, confining material, and cross-section rather than the combination of these three components. A large variety of innovative standing supports will become available when these components are properly selected to meet the requirements for service under different geological conditions and loading states.

Acknowledgements

The author would like to acknowledge the financial support provided by the State Key Laboratory of Coal Resources and Safe Mining, CUMT (SKLCRSM18KF004).

References

Al-Salloum, Y.A. 2007. Influence of edge sharpness on the strength of square concrete columns confined with FRP composite laminates. Composites Part B: Engineering, vol. 38, no. 5-6. pp. 640-650. [ Links ]

Bai, J., Shen, W., Guo, G., Wang, X., and Yu, Y. 2015. Roof deformation, failure characteristics, and preventive techniques of gob-side entry driving heading adjacent to the advancing working face. Rock Mechanics and Rock Engineering, vol. 48, no. 6. pp. 2447-2458. [ Links ]

Beus, M.J. and Chan, s.S. 1980. A structural approach to shaft design for deep mines in hard rock. Proceedings of the 21st US Symposium on Rock Mechanics (USRMS), American Rock Mechanics Association, Alexandria, VA. [ Links ]

Cao, S., Chen, X., Yang, Y., Wang, S., and Zou, D. 2016. 2016. Analysis on roadside control technology of gob-side entry retaining and applicable conditions. Coal Science and Technology, vol. 44, no. 4. pp. 27-33. [ Links ]

Cao,W., Shang,D., and Zhang, B. 2018. Underground Coal Preparation System and Applications. IOP Conference Series: Earth and Environmental Science, vol. 28, no. 1. IOP Publishing. doi: 10.1088/1755-1315/128/1/012019 [ Links ]

Chang, X., Luo, X., Zhu, C., and Tang, C. 2014. Analysis of circular concrete-filled steel tube (CFT) support in high ground stress conditions. Tunnelling and Underground Space Technology, vol. 43. pp. 41-48. [ Links ]

Chen, Y., Bai, J.-B., Wang, X.-Y., Ma, S.-Q., Xu, Y., Bi, T.-F., and Yang, H.-Q. 2012. Support technology research and application inside roadway of gob side entry retaining. Journal of China Coal Society, vol. 37, no. 6. pp. 903-910. [ Links ]

Cui, Y. 2014. Application and technology research on rapid gob-side entry retaining in Shendong mining area. Coal Science and Technology, vol. 42, no. 1. pp. 129-135. [ Links ]

Davidovits, J. 2002. 30 years of successes and failures in geopolymer applications. Market trends and potential breakthroughs. Keynote Address, Geopolymer 2002 Conference, Melbourne, Australia, 28-29 October 2002. https://www.geopolymer.org/fichiers_pdf/30YearsGEOP.pdf [ Links ]

Degirmenci, N. 2008. The using of waste phosphogypsum and natural gypsum in adobe stabilization. Construction and Building Materials, vol. 22, no. 6. pp. 1220-1224. [ Links ]

Deng,Y., TangJ., Zhu, X., Fu, Y., and Dai, Z. 2010. Analysis and application in controlling surrounding rock of support reinforced roadway in gob-side entry with fully mechanized mining. Mining Science and Technology (China), vol. 20, no. 6. pp. 839-845. [ Links ]

Duan, H., Sun, M., and Li, Q. 2019. A new gob-side entry retaining approach with reinforced filling gangue wall in thin coal seam. Geotechnical and Geological Engineering, March 2019. pp. 1357-1529. [ Links ]

Erdem, E. and Ölmez, H. 1993. The mechanical properties of supersulphated cement containing phosphogypsum. Cement and Concrete Research, vol. 23, no. 1. pp. 115-121. [ Links ]

Etxeberria, M., Vazquez, E., Marí Α., and Barra, M. 2007. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cement and Concrete Research, vol. 37, no. 5. pp. 735-742. [ Links ]

Guo Dongming, F.L., Gao, J., Zhao, P., Liu. C., and Wang, H. 2018. Study on sidewall support technology of pier pillar type gateway retained along goaf in Wutongzhuang mine. Coal Science and Technology, vol. 46, no. 1. pp. 81-87. [ Links ]

Han, C., Zhang, N., Xue, J., Kan, J., and Zhao, Y. 2018. Multiple and long-term disturbance of gob-side entry retaining by grouped roof collapse and an innovative adaptive technology. Rock Mechanics and Rock Engineering, October 2018. pp. 1-13. [ Links ]

Hardjito, D. and Rangan, B.V. 2005. Development and properties of low-calcium fly ash-based geopolymer concrete. Curtin University of Technology, Perth, Australia. [ Links ]

He, M.-C., Gao, Y.-B., Yang, J., Wang, J.-W., Wang, Y.-J., and Zhu, Z. 2018. Engineering experimentation of gob-side entry retaining formed by roof cutting and pressure release in a thick-seam fast-extracted mining face. Rock and Soil Mechanics, vol. 39, no. 1. pp. 254-264. [ Links ]

He, M., Zhu, G., and Guo, Z. 2015. Longwall mining cutting cantilever beam theory and 110 mining method in China-The third mining science innovation. Journal of Rock Mechanics and Geotechnical Engineering, vol. 7, no. 5. pp. 483-492. [ Links ]

Hu, Y., Yu, T., and Teng, J. 2011. FRP-confined circular concrete-filled thin steel tubes under axial compression. Journal of Composites/or Construction, vol. 15, no. 5. pp. 850-860. [ Links ]

Huang, Y.-L., Zhang, J.-X., Zhang, J., and Zan, D.-F. 2011. Technology of gob-side entry retaining on its original position in fully mechanized coalface with solid material backfilling. Journal of China Coal Society, vol. 36, no. 10. pp. 1624-1628. [ Links ]

Huang, Y. and Lin, Z. 2010. Investigation on phosphogypsum-steel slag-granulated blast-furnace slag-limestone cement. Construction and Building Materials, vol. 24, no. 7. pp. 1296-1301. [ Links ]

Jiang, S., Wang, H., Wu, Y., Liu, X., Chen, H., Yao, M., Gault, B., Ponge, D., Raabe, D., and Hirata, A. 2017. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature, vol. 544, no. 7651. pp. 460-464. [ Links ]

Ju, F., Chen, Z., Zhang, Q., Huang, P., Tai, Y., and Lan, L. 2015. Surrounding rock stability control in gob-side entry retaining with solid backfilling in coal mining technology. Journal of Mining and Safety Engineering, vol. 32, no. 6. pp. 936-942. [ Links ]

Komnitsas, K. and Zaharaki, D. 2007. Geopolymerisation: A review and prospects for the minerals industry. Minerals Engineering, vol. 20, no. 14. pp. 1261-1277. [ Links ]

Kong, D.L.Y., Sanjayan, J.G., and Sagoe-Crentsil, K. 2007. Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cement and Concrete Research, vol. 37, no. 12. pp. 1583-1589. [ Links ]

Li, L. and Yang, P. 2015. A numerical evaluation of continuous backfilling in cemented paste backfilled stope through an application of wick drains. International Journal of Mining Science and Technology, vol. 25, no. 6. pp. 897-904. [ Links ]

Li, M., Zhang, J., Song, W., and Germain, D.M. 2019. Recycling of crushed waste rock as backfilling material in coal mine: effects of particle size on compaction behaviours. Environmental Science and Pollution Research, vol. 26, no. 1. pp. 1-9. doi: 10.1007/s11356-019-04379-9 [ Links ]

Li, X., Ju, M., Yao, Q., Zhou, J., and Chong, Z. 2016. Numerical investigation of the effect of the location of critical rock block fracture on crack evolution in a gob-side filling wall. Rock Mechanics and Rock Engineering, vol. 49, no. 3. pp. 1041-1058. [ Links ]

Li, Y., Yao, Y., Liu, X., Sun, H., and Ni, W., 2013. Improvement on pozzolanic reactivity of coal gangue by integrated thermal and chemical activation. Fuel, vol. 109. pp. 527-533. [ Links ]

Li, Z., Dou, L., Cai, W., Wang, G., Ding, Y., and Kong, Y. 2016. Roadway stagger layout for effective control of gob-side rock bursts in the longwall mining of a thick coal seam. Rock Mechanics and Rock Engineering, vol. 49, no. 2. pp. 621-629. [ Links ]

Liu, H. and Zhao, H. 2017. Analysis of stress evolution law and large deformation mechanism in surrounding rock of gob-side entry retaining. China Mining Magazine, vol. 26, no. 2. pp. 122-128. [ Links ]

Liu, L. 2015. Technology of gob-side entry retaining based on flexible filling wall with bagged gangue. Coal Engineering, vol. 47, no. 3. pp. 47-49. [ Links ]

Liu, L., Zhang, Y., and Tan, K. 2015. Cementitious binder of phosphogypsum and other materials. Advances in Cement Research, vol. 27, no. 10. pp. 567-570. [ Links ]

Liu, X., Ning, J., Tan, Y., Xu, Q., and Fan, D. 2018. Coordinated supporting method of gob-side entry retaining in coal mines and a case study with hard roof. Geomechanics and Engineering, vol. 15, no. 6. pp. 1173-1182. [ Links ]

Lu, X., Hua, X., and Zhao, M. 2011. Calculation and analysis of immediate roof subsidence in gob-side entry retaining. Journal of Mining and Safety Engineering, vol. 8, no. 1. pp. 34-38. [ Links ]

Luan, H., Jiang, Y., Lin, H., and Li, G. 2018. Development of a new gob-side entry-retaining approach and its application. Sustainability, vol. 10, no. 2. pp. 470. [ Links ]

Ning, J., Wang, J., Liu, X., Qian, K., and Sun, B. 2014. Soft-strong supporting mechanism of gob-side entry retaining in deep coal seams threatened by rockburst. International Journal of Mining Science and Technology, vol. 24, no. 6. pp. 805-810. [ Links ]

Patchet, S. 1977. Fill support systems for deep-level gold mines. Journal of the South African Institute of Mining and Metallurgy, vol. 78, no. 2. pp. 34-46. [ Links ]

Rattanasak, U. and Chindaprasirt, P. 2009. Influence of NaOH solution on the synthesis of fly ash geopolymer. Minerals Engineering, vol. 22, no. 12. pp. 1073-1078. [ Links ]

Roberts, M. and Brummer, R. 1988. Support requirements in rockburst conditions. Journal of the South African Institute of Mining and Metallurgy, vol. 88, no. 3. pp. 97-104. [ Links ]

Shen, W., Zhou, M., and Zhao, Q. 2007. Study on lime-fly ash-phosphogypsum binder. Construction and Building Materials, vol. 21, no. 7. pp. 1480-1485. [ Links ]

Somna, K., Jaturapitakkul, C., Kajitvichy\nukul, P., and Chindaprasirt, P. 2011. NaOH- activated ground fly ash geopolymer cured at ambient temperature. Fuel, vol. 90, no. 6. pp. 2118-2124. [ Links ]

Su, H., Bai, J., Yan, S., Chen, Y., and Zhang, Z. 2015. Study on gob-side entry retaining in fully-mechanized longwall with top-coal caving and its application. International Journal of Mining Science and Technology, vol. 25, no. 3. pp. 503-510. [ Links ]

Sukontasukkul, P. 2009. Use of crumb rubber to improve thermal and sound properties of pre-cast concrete panel. Construction and Building Materials, vol. 23, no. 2. pp. 1084-1092. [ Links ]

Sun, Q., Zhang, J., and Zhou, N. 2018. Study and discussion of short-strip coal pillar recovery with cemented paste backfill. International Journal of Rock Mechanics and Mining Sciences, vol. 104. pp. 147-155. [ Links ]

Sun, Q., Zhang, J., Zhou, N., and Qi, W. 2018. Roadway backfill coal mining to preserve surface water in western China. Mine Water and the Environment, vol. 37, no. 2. pp. 366-375. [ Links ]

Sun, X., Li, G,. Song, P., Miao, C., Zhao, C., Li, Q., and Xia, X. 2019. Application research on gob-side entry retaining methods in no. 1200 working face in Zhongxing mine. Geotechnical and Geological Engineering, no. 1. pp. 1-16. [ Links ]

Tan, Y., Yu, F., Ning, J., and Zhao, T. 2015. Design and construction of entry retaining wall along a gob side under hard roof stratum. International Journal of Rock Mechanics and Mining Sciences, vol. 100, no. 77. pp. 115-121. [ Links ]

Tang, J., Hu, H., Tu, X., and Deng, Y. 2010. Experimental on roadside packing gob-side entry retaining for ordinary concrete. Journal of China Coal Society, vol. 35. pp.1426-1429. [ Links ]

Tang, Z.-B., Zhao, Y.-L., Kong, D.-S., and Kan, D. 2013. Study and application of a new type of foamed concrete wall in coal mines. Journal of Coal Science and Engineering (China), vol. 19, no. 3. pp. 345-352. [ Links ]

Teng, J., Chen, J.-F., Smith, S.T., and Lam, L. 2002. FRP: strengthened RC structures. Frontiers in Physics, vol. 1. p. 266. [ Links ]

Teng, J.G., Chen, J.F., Smith, S.T., and Lam, L. 2003. Behaviour and strength of FRP-strengthened RC structures: a state-of-the-art review. Proceedings of the Institution of Civil Engineers - Structures and Buildings, vol. 156, no. 1. pp. 51-62. [ Links ]

Wang, H., Zhang, D., and Fan, G. 2011. Structural effect of a soft-hard backfill wall in a gob-side roadway. Mining Science and Technology (China), vol. 21, no. 3. pp. 313-318. [ Links ]

Wang, H., Zhang, D., Liu, L., Guo, W., Fan, G., and Wang, X.-F. 2016. Stabilization of gob-side entry with an artificial side for sustaining mining work. Sustainability, vol. 8, no. 7. pp. 627. [ Links ]

Wang, J., Gao, Y., He, X., Huang, W., Gao, K., Yang, L,. and Fang, S. 2015. The analysis of roadside supporting parameters and the support technology in the concrete filled steel tubular column in goaf-side entry retaining. Journal of Mining and Safety Engineering, vol. 32, no. 6. doi: 10.13545/j.cnki.jmse.2015.06.012. [ Links ]

Wang, Q., He, M., Yang, J., Gao, H., Jiang. B., and Yu, H. 2018. Study of a no-pillar mining technique with automatically formed gob-side entry retaining for longwall mining in coal mines. International Journal of Rock Mechanics and Mining Sciences, vol. 110. pp. 1-8. [ Links ]

Wang, X., Zhao, B., Zhang, C., and Zhang, Q. 2009. Paste-like self-flowing transportation backfilling technology based on coal gangue. Mining Science and Technology (China), vol. 19, no. 2. pp. 137-143. [ Links ]

Wang, Z. and Zhao, N. 2015. Influence of coal gangue aggregate grading on strength properties of concrete. Wuhan University Journal of Natural Sciences, vol. 20, no. 1. pp. 66-72. [ Links ]

Wei, M., Sun, L., Qi, P., Chang, C., and Zhu, C. 2018. Continuous phenomenological modeling for the viscosity of shear thickening fluids. Nanomaterials and Nanotechnology, vol. 8. https://journals.sagepub.com/doi/pdf/10.1177/1847980418786551 [ Links ]

Wu, Z., Wang, X., and Iwashita, K. 2007. State-of-the-art of advanced FRP applications in civil infrastructure in Japan. Proceedings of Composites and Polycon 2007, Tampa, FL. American Composites Manufacturers Association, Arlington, VA. pp. 1-17. [ Links ]

Yang, H., Cao, S., Wang, S., Fan, Y., Wang, S., and Chen, X. 2016. Adaptation assessment of gob-side entry retaining based on geological factors. Engineering Geology, vol. 209. pp. 143-151. [ Links ]

Yang, J., He, M., and Cao, C. 2019. Design principles and key technologies of gob side entry retaining by roof pre-fracturing. Tunnelling and Underground Space Technology, vol. 90. pp. 309-318. [ Links ]

Yang, M., Qian, J., and Pang, Y. 2008. Activation of fly ash-lime systems using calcined phosphogypsum. Construction and Building Materials, vol. 22, no. 5. pp. 1004-1008. [ Links ]

Yu, T., Zhao, H., Ren, T., and Remennikov, A. 2019. Novel hybrid FRP tubular columns with large deformation capacity: Concept and behaviour. Composite Structures, vol. 212. pp. 500-512. [ Links ]

Zhang, G.-C., Tan, Y.-L., Liang, S.-J., and Jia, H.-G. 2018a. Numerical estimation of suitable gob-side filling wall width in a highly gassy longwall mining panel. International Journal of Geomechanics, vol. 18, no. 8. doi: 10.1061/(ASCE) GM.1943-5622.0001217 [ Links ]

Zhang, J., Jiang, H., Miu, X., Zhou, N., and Zan, D. 2013. The rational width of the support body of gob-side entry in fully mechanized backfill mining. Journal of Mining and Safety Engineering, vol. 30, no. 2. pp. 159-164. [ Links ]

Zhang, J., Zhou, N., Yin, W., and Li, M. 2018c. Solid-filling coal mining feeding and conveying monitoring system. US patent 9988905. China University of Mining and Technology. [ Links ]

Zhang, N., Han, C.-L., Han, J.-G., and Zheng, X.-G. 2014. Theory and practice of surrounding rock control for pillarless gob-side entry retaining. Journal of China Coal Society, vol. 39, no. 8. pp. 1635-1641. [ Links ]

Zhang, Z., Wang, W., Li, S., and Yu, X. 2018b. Analysis on rockbolt support interaction with roof dilatancy above roadside backfill area in gob-side entry retaining. Geotechnical and Geological Engineering, vol. 36, no. 4. pp. 2577-2591. [ Links ]

Zhou, S. 2009. Study on the reaction degree of calcined coal gangue powder in blended cement by selective solution method. Procedia Earth and Planetary Science, vol. 1, no. 1. pp. 634-639. [ Links ]

Correspondence:

Correspondence:

H.Zhao

Email: xjuzhc@163.com

Received: 2 Oct. 2017

Revised: 17 Jun. 2019

Accepted: 2 Jul. 2019

Published: November 2019