Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.119 n.8 Johannesburg Aug./Jul. 2019

SAMMRI: Working towards the sustainability of the South African mineral processing industry

Cyril O'Connor (co-authors - V. Ross and J.R. Mann)

A 2009 survey of the South African mining industry indicated that

major challenges facing the industry were a shortage of skilled people in the industry and in SA universities in the area of mineral processing to enable the sustained development of a strong technological base.

On the basis of these findings, the South African Minerals to Metals Research Institute (SAMMRI) was established as a national initiative to promote sustainable development of the SA mineral processing industry through the development of globally competitive technology, driven by people with world-class skills. This Institute is funded jointly by the industry and the Department of Science and Technology (DST).

South Africa features prominently in terms of the world's reserves and producers of many mineral commodities. A recent report stated that South Africa is the world's richest country in terms of its mineral reserves, which are estimated be worth US$2.5 trillion. As in the case of most countries endowed with abundant natural resources, South Africa has relied immensely on its primary minerals sector as a source of wealth and economic growth in the past and continues to do so today. According to the Minerals Council South Africa's annual reports the mining sector employs almost 500 000 people and contributes about 8% to South Africa's GDP - about 18% if the multiplier effect is taken into account.

On the basis of concerns at the time that most of the South African mining industry's investment in research was being directed offshore, a study was carried out in 2009 by SAMMRI, funded by the DST, to identify the reasons and to propose a strategy to address this challenge. The major weaknesses and threats were identified as a shortage of skilled people both in the industry and at SA universities as well as inefficiencies of many of the existing processes .

Recent economic pressures have led to a reduction by local companies of investment in longer-term research and development, both internally and through external investments in universities. If these technical challenges are to be addressed the country needs to ensure ongoing significant investment in research and development. To address this situation, in 2009 five mining companies - Anglo American, Impala, Lonmin, Exxaro, and AngloGold Ashanti - collaborated to establish a national initiative to promote mineral processing research investment and this gave birth to SAMMRI, a virtual institute intended to involve all of the higher education institutions. This was to be achieved through the development and support of research capacity at South African universities, through developing researchers and students with world-class skills that would create a platform from which globally competitive technology would emanate.

The SAMMRI model

In the context of R&D being carried out by industry and supplier laboratories, including organizations such as Mintek and the CSIR, SAMMRI identified its role to be to one of expanding research capacity by involving universities in a national programme aimed at developing human capital in the form of an increased number of highly skilled people with postgraduate degrees to take up employment in industry and academia. At the same time, it is focused on developing a strong cohort of younger researchers at universities capable of driving this programme, thus promoting sustainable development of the South African minerals processing industry through globally competitive, innovative technology. This would be achieved by supporting emerging academics and researchers at South African universities by funding industry approved research projects. After its establishment, the DST approached SAMMRI with a view to entering into a joint venture and this led to an injection of funds from DST to complement industry's contributions. Since 2015, SAMMRI has become the beneficiary of more significant funding from the government through the Sector Specific Innovation Fund (SSIF).

From the outset SAMMRI has defined its scope as all aspects of the processing and extraction of minerals from the point of delivery of the mined ore to the production of the final refined and saleable metal or mineral product. Currently it exists as an association of member companies whose representatives constitute a Board. Assessor members, who are appointed on the basis of their influence and strategic roles as key players in the industry, include DST, DTI, Mintek, the Council for GeoScience, and Coaltech. In order to minimize administrative costs, the management and administration of SAMMRI has since the outset been entrusted to the University of Cape Town which is a public institution subject to all the usual financial regulations governing any such institution. The CEO is appointed by the Board and reports directly to the Chair of the Board.

Roadmap

From the outset, SAMMRI established a template against which it could measure its long-term success and inform the SAMMRI Board in its decisions on which projects to fund. To this end a roadmap for the South African minerals processing industry was developed, defining the main drivers that would shape the future of the industry. Based on extensive input of senior technical staff from industry stakeholders, government departments, research institutions, and other similar roadmaps these factors were distilled into four strategic focus areas:

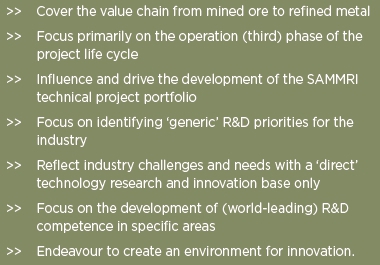

The roadmap is generic in nature, identifying gaps and defining initiatives specific to key strategic / economic commodities. The development of human capital is the key focus of SAMMRI activities and therefore was not included as a separate driver. The scope of the SAMMRI technology roadmap was hence to:

Outputs

Since its inception in 2011 (which was a 2-year pilot programme to develop appropriate processes to manage this Institute) SAMMRI has co-funded 66 projects at seven Universities viz. North West, Stellenbosch, Cape Town, Limpopo, Pretoria, Witwatersrand, and KwaZulu Natal. These projects have addressed major technical challenges (decided upon by the industry sponsors) in 11 different technology themes of critical importance to the minerals industry. These interventions have led to 22 Masters and 8 PhD completed degrees, with 21 and 15, respectively, in progress at the time of writing. In terms of demographics, more than 63% of the students have been black and 28% women. A total of almost 80 publications have been produced to date. At the same time, 28 young research supervisors have been groomed at these universities, of whom 12 are women and 9 black. These are the future research leaders of the academic departments where they are located. Of importance is the spin-off which the outcomes of these projects have had either directly or indirectly on the local minerals industry, and these are elaborated on below.

The projects SAMMRI supports are typically in the development of fundamental science and knowledge, protocols, and procedures, rather than fully implementable processes and process technologies, i.e. knowledge products that can be transferred into the industry via their use by SAMMRI members. Using this approach, and together with the additional industry funding procured by the principal investigators (PIs), SAMMRI has facilitated the development of several sustainable Centres of Technical Competence. A number of them are now internationally acknowledged and are research partners in bilateral and multilateral research consortia and collaborative platforms.

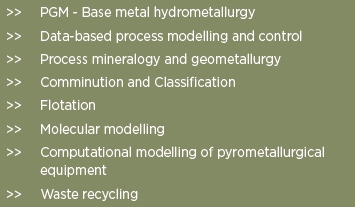

There is now significant local capability and capacity to conduct research and development at South African HEIs to address most of the sector's mineral processing technology development and efficiency improvement needs. This includes inter alia research in the fields of:

Project-specific mentorship is provided by appointing Board members to the students and PIs for each allocated project. This is to meet the SAMMRI aspiration of developing world-class researchers, who through mentorship are assisted in not only producing research outputs that are of scientific and academic value but knowledge products that can be transferred into value-added usage within the industry. This intervention has arguably been considered by the PIs as the most valuable contributions by SAMMRI to their research development.

One of the major challenges which SAMMRI has faced has been to ensure that there is appropriate transfer of the research outputs to industry. This is self-evidently greatly facilitated by the close working collaboration between the industry sponsors and the PIs and their students through the industry mentoring programme. Hence there are now many examples of research which appeared at face value to be fundamental in nature but being transferred with great success into company operations. Examples of these include the following.

>> Bench-scale test procedures developed during the research being used by industry to optimize their process performance, leading to real benefit in financial returns. There are also now case studies that demonstrate the progress from project conceptualization through fundamental research, piloting, demonstration, techno-economic assessment, construction and commissioning, to full-scale implementation. One example is the development of the use of reflux classifiers for chromite recovery Similarly, the development of a strong area of expertise in geometallurgy using technologies such as XCT microtomography has the potential to have a major positive impact in the industry.

>> Knowledge transfer impact occurring via involvement of final-year students carrying out projects associated with the sponsored projects.

>> Industry members using the universities to deliver curriculum-specific training in these knowledge products for their graduate engineer employees.

>> The establishing of Centres of Technical Competence which now deliver key research and consulting services to the industry to help improve production performance. Examples include applications in flotation, fault detection through process monitoring, and assessing the impact of process water quality on the efficiency of flotation.

In the above regard it is worth noting that SAMMRI is endeavouring to move its focus into more applied areas of technology (e.g. TRL> 4). There is abundant literature on this topic, much of it emphasizing that the best way to achieve this is for university-based research to partner with industry rather than to try to mimic what industry does so much better. Besides, the cost ramifications of moving into TRL> 4 areas significantly greater than that to which SAMMRI has access. SAMMRI's view therefore continues to be that its primary role is to strengthen the availability of highly skilled engineers and scientists to the industry so that the challenges can be addressed in the best manner.

Conclusions

The intervention by SAMMRI has enjoyed considerable international attention and is seen to be unique in terms of the close collaboration between industry, the higher education sector and the state in promoting the development of the minerals processing industry. The programme clearly requires a long-term commitment by both the industry and the government if it is to ultimately achieve its objective of ensuring South Africa is a global leader in terms of the high quality of its technology and its human capital, and so enable the minerals industry to play an ever-greater role in the economic growth of the country. *