Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.119 n.7 Johannesburg Jul. 2019

http://dx.doi.org/10.17159/2411-9717/18/016/2019

PAPERS OF GENERAL INTEREST

A proposed preliminary model for monitoring hearing conservation programmes in the mining sector in South Africa

N. Moroe; K. Khoza-Shangase; M. Madahana; O. Nyandoro

University of the Witwatersrand, South Africa

SYNOPSIS

Occupational noise-induced hearing loss (ONIHL) is classified as the leading work-related disability in the mining industry. ONIHL has a negative impact, on not only the health and occupational productivity of affected individuals, but arguably also on the country's mining industry and economy. Hearing conservation programmes (HCPs) are an effective strategy in the management of ONIHL. However, current literature indicates that HCPs are not achieving the anticipated and desired outcomes in the South African mining sector despite the efforts focused on the management of ONIHL. Therefore, the purpose of this study is to propose the use of a feedback-based noise monitoring model as a tool for monitoring and managing ONIHL in the South Africa's mining sector. This model is a basic static feedback model with practical applications such as estimating, monitoring. and providing quantitative information to aid miners, mining administrators, and policy-makers in decision-making around HCPs. Additionally, the model could form part of an early intervention and management strategy for ONIHL in the workplace. The strength of this model, although currently static, is that it encompasses all the pillars of HCPs and takes into account the policies concerned with the management of ONIHL in the mining sector.

Keywords: occupational noise, hearing loss, feedback noise-monitoring model, risk management, mining sector.

Introduction

Hazardous noise levels (above 85 dBA) in the workplace place exposed employees at risk of developing a disabling occupational noise-induced hearing loss (ONIHL). ONIHL is the 'partial or complete hearing loss in one or both ears as a result of one's employment' (Nandi and Dhatrak, 2008, p. 1). This type of hearing loss develops gradually as a result of being exposed to continuous or intermittent high levels of noise over a long period of time (McBride, 2004; Patel et al., 2010; Rappaport and Provencal, 2001). A hearing threshold below 40 dBs is classified as a disabling hearing loss (Yadav et al., 2015), resulting in a hidden condition that does not readily manifest itself (Tye-Murray, 2009, p. 3). Dugan (2003) describes disabling hearing loss as the 'most prevalent, least recognized and least understood physical disability', while Copley and Frederichs (2010) and Hermanus (2007) argue that permanent disabling hearing loss is a major contributor to the global burden of disease on individuals, families, communities, and countries.

ONIHL is a prevalent condition in the mining industry and is classified as the leading work-related disability, and the second most common form of acquired hearing loss after presbycutic (age-related) hearing loss, with severe consequences for those exposed to high levels of noise (Ritzel and McCrary-Quarles, 2008). Although hearing loss is not life-threatening, the presence of a mild hearing loss (thresholds between 26-39 dBs), if unmanaged, may have a profound impact on the quality of life of the affected individual (Tye-Murray, 2009). Prolonged exposure to hazardous noise can potentially also lead to increased fatigue and decreased concentration, which ultimately increases human errors at work (Amjad-Sardrudi et al., 2012; Picard et al., 2008). ONIHL has a potential to significantly reduce workers' ability to perform or complete tasks that are dependent on auditory signals or verbal communication (Thorne, 2006). Furthermore, due to hearing loss sustained at work, which subsequently results in a communication handicap, workers may be regarded as incompetent or inactive, which ultimately, will impact on team work and group productivity (Momm and Geiecker, 2009). Moreover, hearing loss can negatively affect communication among workers, which can lead to safety concerns as workers may not be able to hear warning signals such as sirens since high-frequency sounds are the most affected. Compromised ability to communicate may lead to increased risk of accidents (Kirchner et al., 2012).

ONIHL can present a limitation on the kind of employment suitable for a person with hearing loss (Thorne, 2006), which may lead to economic burdens for developing countries in particular. Moreover, studies have shown that ONIHL contributes to occupational injuries, ill health, and absenteeism, which results in enormous social and economic implications for individuals, their families, communities, and the country at large (Amjad-Sardrudi et al., 2012; Coderio et al., 2005; Hermanus, 2007; Kramer, Kapteyn, and Houtgast, 2006).

ONIHL is a complex disease (Le et al., 2017). Regardless of the amount of noise an individual is exposed to, some people are more prone to developing hearing loss than others subjected to the same level and amount of noise (Daniel, 2007; Sliwinska-Kowalska et al., 2005). However, it is still not known why this is the case (Sliwinska-Kowalska and Davis, 2012). Individual susceptibility or risk factors associated with ONIHL can be either non-modifiable - outside one's control, or modifiable - within one's control (Daniel, 2007). Non-modifiable factors include age, race, and gender (Daniel, 2007). Modifiable factors include smoking, exposure to ototoxic agents, and ototoxic drugs (used to treat diseases like HIV/AIDS, TB, and cancer (Khoza-Shangase, 2013). These risk factors present a challenge to individuals who are exposed to occupational noise, as they undoubtedly lead to negative effects on ear care, health, and safety for individuals subjected to such excessive noise.

Economically, ONIHL has direct and indirect costs (Hermanus, 2007). Direct costs include compensation costs, costs associated with damage in the workplace, and the cost of interruption of production; while indirect costs include the cost of livelihood lost and loss of income to dependents (Hermanus, 2007). Statistics on the burden of ONIHL in developing countries are not readily available (Nelson et al., 2005); however, Chadambuka, Mususa, and Muteti (2013) argue that 80% of individuals affected by ONIHL reside in low- and middle-income countries where ONIHL presents a 'much heavier burden than in developed regions of the world'.

In South Africa, in 2007, it was estimated that nearly half the mining industry's workforce was exposed to 'deafening noise, and of these workers more than 90% work in zones in which noise exceeds the 85 dBA time-weighted average, with 11% working in zones in which the noise levels are even higher' (Hermanus 2007, p. 534). In 2011, Edwards et al. (2011) reported that approximately 73.2% of the workforce was exposed to noise levels above the legislated occupational exposure level of 85 dBA. In 2012, the Chamber of Mines, as cited by Strauss et al. (2014), reported that 3.1 out of every 1000 workers have ONIHL.

According to Hong et al. (2013) although the impact of ONIHL on one's health and quality of life cannot be quantified in tangible measures or standards, the compensation cost for ONIHL is continually increasing. Rand Mutual Assurance (RMA) insures approximately 80% of mining industry workers. Approximately 12% of occupational injury and disease claims processed annually by RMA are due to ONIHL (Begley, 2004). In 2004, this cost was estimated at R15 000 per person (Begley, 2004), resulting to approximately R75 million paid out in compensation claims in that same year (Hermanus, 2007). Based on the analysis of the costs of NIHL claims in a study conducted by Edwards and Kritzinger (2012), RMA paid out several millions of rands in compensation for ONIHL in the period 1998-2007.

Reporting on the prevalence of ONIHL in the South African mining sector, Strauss et al. (2014) further stated that several factors, such as non-occupational noise exposure and vibration, as well as biological factors, increase the prevalence of ONIHL. These biological factors include smoking, age, gender, genetics, ototoxic drugs, and illnesses such as tuberculosis. These factors contribute to an individual's susceptibility to ONIHL.

Management of ONIHL

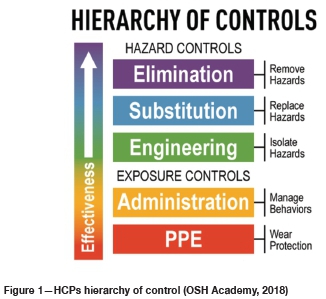

A review of literature on the management of ONIHL in the mining sector shows that hearing conservation programmes (HCPs) are the most effective way of managing excessive exposure to hazardous noise in the workplace (Amedofu, 2007; Feuerstein, 2001; Chadambuka, Mususa, and Muteti, 2013; Moroe, 2018). This is particularly so for the hierarchy of control, which if implemented correctly is reported to lead to desired outcomes that include the elimination of noise as depicted in Figure 1.

According to the hierarchy of control, engineering and administrative controls are the first line of defence in the management of hazardous noise in the workplace, after elimination and substitution of the noise source (McBride, 2004; Patel et al., 2010; Rappaport and Provencal, 2001). However, evidence suggests that in practice, engineering and administrative controls are not given first priority (Suter, 2012). Locally, there is a slow uptake in implementing engineering controls as the chief strategy in the management of ONIHL (Moroe et al., 2018). One of the main reasons for this is that machinery for engineering controls is reported to be very expensive (Rupprecht, 2017). Consequently, there is a heavy reliance on the use of hearing protection devices (HPDs), despite these being the last line of defence in the elimination of ONIHL, as indicated on the hierarchy of control.

Current international and local literature indicates that HPDs are the most widely used form of protection against high levels of noise, despite their proven inadequacy (discomfort, improper sizing, poor hygiene, and the inability to hear speech and warning signals when using them) (Bruce, 2007; Bruce and Wood, 2003; Hong et al., 2013; Suter, 2012; Ntlhakana, Kanji, Khoza-Shangase, 2015; Steenkamp, 2007). Suter (2012) argues that although there is no doubt that HPDs are helpful in reducing the impact of sound energy on the ear, they can be most effective when used in conjunction with engineering and administrative controls and other HCP pillars. Moroe et al. (2018) conducted a systematic literature review on the management of ONIHL in the mining sector in Africa. Their findings indicated that the majority of the studies conducted on the management of ONIHL focus on the use of HPDs. Furthermore, these studies were conducted in a piecemeal fashion, as specific individual pillars were targeted instead of a comprehensive, holistic HCP analysis. It is clear that ONIHL is a risk which needs to be eliminated or reduced through effective management strategies.

Risk is defined as 'the probability that a particular adverse event occurs during a stated period of time or results from a particular challenge' (Elmontsri, 2014, p. 50). Fiedler (2004) postulates that many workplaces have hazards - that is, anything presenting a threat to health and safety within an organization, which may put employees at risk of injury or harm to health, thereby necessitating systematic management such as a risk management matrix. Risk matrices have been used for years to rank various risks in the military (Donoghue, 2001). More recently, practitioners, academics, and the business community have shown an interest in risk management (Dabari and Saidin, 2014). Risk management has become a primary goal in every organization due to its ability to promote organizational outputs and create measureable value for stakeholders (Gates, Nicolas, and Walker, 2012). Specific to occupational health and safety, Hermanus (2007, p. 536) argues that 'the underlying premise of risk management is that improvements in health and safety can be made by correctly identifying and addressing hazards or factors (which may be underlying or direct) that contribute to occupational risk'. Fiedler (2004) complements this argument by stating that risk management is an integral and critical factor in the success of occupational health and safety programmes in that it serves to identify and assess risks resulting from hazards. This consequently leads to appropriate action to reduce or eliminate risk (Fiedler, 2004).

Risk management is defined as 'a systematic approach that aligns strategy, people, technology, processes and knowledge with the purpose of assessing, evaluating and managing the risk that an organisation faces' (Dabari and Saidin, 2014, p. 268). Central to the current study, Elmontsri (2014, p. 49) defines risk management as the process of 'reducing the risk to a level deemed tolerable by society and to assure control, monitoring, and public communication'. This definition acknowledges that in some contexts, such as the mining industry, risk of noise as a hazard cannot be entirely eliminated, thus, this definition fits aptly with the current study.

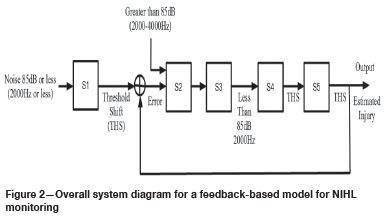

Locally, there is a dearth of studies focusing on risk management as a strategy tool in the management of ONIHL in the mining industry. Steenkamp has proposed a few models for the management of occupational noise. These models included a six sigma-based management model to eliminate noise-induced hearing loss (Steenkamp, 2007), new technology and reengineering of HCPs (Steenkamp, 2008a), and effective second-level noise control through a personal approach to hearing conservation Steenkamp, (2008b). While these studies may be effective and relevant, they seem to mostly focus on the use of HPDs, where the burden of eliminating ONIHL rests with the employee with little emphasis on the involvement of the employer and other stakeholders such as policymakers who are involved in the management of ONIHL. There is therefore a need for studies that incorporate all stakeholders and policies concerned with ONIHL in the mining sector. The purpose of this study is to introduce a feedback-based noise monitoring model (see Figure 2) as a tool for managing ONIHL in the mining sector in South Africa. This tool was conceptualized from a risk management framework as discussed below.

Conversion of the risk management framework to the feedback-based noise monitoring model (FBNMM)

This feedback-based noise management model (FBNMM, see Figure 2) is comprised of five subsystems: S1 is the baseline or reference point, S2 is the control unit, which consists of the policies and mandatory code of practice (COP), together with the milestones, S3 is the actuator, which ensures compliance, S4 is the plant, which acts as the implementation phase through an individual exposed to noise, and S5 is the evaluation or checkup point, consisting of a sensor.

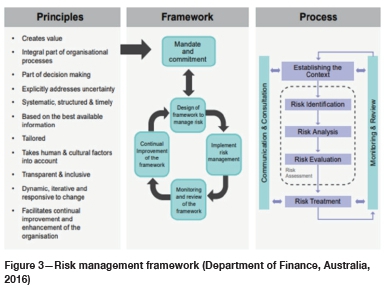

The FBNMM proposed in this paper is derived from the risk management framework (RMF) (Figure 3) adapted from ISO 31000. This RMF was further revised by the Australian Government's Department of Finance (Department of Finance, Australia, 2016) and is adopted as a conceptual framework for this paper. This framework comprises three core components which need to be implemented consistently in order to achieve a structured approach to the management of risk. These components are:

> Principles to describe the essential attributes of good risk management

> Framework providing a structure for risk management

> Process which prescribes a tailored, structured approach to understanding, communicating, and managing risk in practice.

For the purpose of this study, the focus is on the third component, the process component. Drawing from the definition of risk as discussed earlier, in order to convert this process component into a feedback-based noise monitoring model, the risk is identified as noise. In converting the risk process component, all the processes are taken into consideration as discussed below.

> Establishing the context. In this study, the context is the mining industry where the presence of excessive noise has been identified as a hazardous risk. In order to address this risk, there need to be regulations, Acts, COPs, policies etc. which give background to the context of the mine. In relating this to the proposed FBNMM, these policies represent S2.

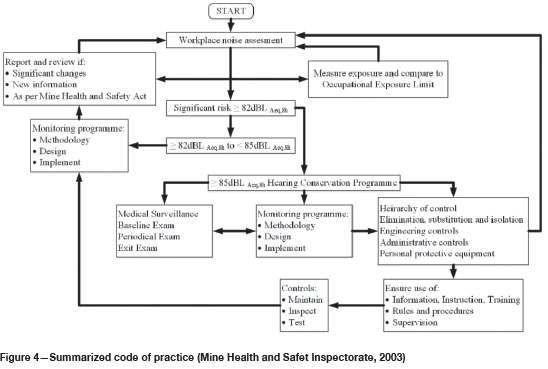

> Risk assessment, which comprises risk identification, analysis, and evaluation. This process relates to compliance with mandated policies and regulations in a given context. For this study, this applies to the COP, (Figure 4) and the 2014 Mine Health and Safety Council (MHSC) milestones (MHSC, 2014). This COP encompasses all the HCP pillars; however, it lacks a rapid monitoring system which can aid with early identification of possible ONIHL development. The COP is concerned with compliance, which is represented by S3 in the FBNMM. In order to evaluate compliance, there needs to be a checking system where the effectiveness of the implemented policies is measured. Therefore, S4 is concerned with the implementation of policies in order to check for compliance.

> Risk treatment. After implementing the processes mentioned in S2, S3, and S4, an output is obtained, which is then fed back to the baseline or reference point (S1) for comparison and benchmarking. At this stage, administrators are informed regarding a suitable action plan for intervention if needed. Hence this proposed model is called a feedback noise-monitoring model. Furthermore, in line with the RMF, this proposed model can serve to monitor and review policies, thereby implementing context-specific recommendations that influence risk assessments and evaluations.

This FBNMM is a basic feedback model, and still requires further refinement. At this stage it is used to provide preliminary results to illustrate its application. The potential value of this model can be measured in terms of possible significant savings in ONIHL compensation claims and also contribute towards the quality of life of people exposed to excessive noise in the workplace.

Fundamental to any control system is the capability to measure the output of the system and to take corrective action if its value digresses from some desired value (Burns and Grove, 2009). A system may be defined as a collection of materials, parts, components, or procedures which are included within some specified boundary. A system may be open loop or closed loop. A control system may be defined as an interconnection of varying units of a system in a configuration that provides a desired response (Burns and Robinson, 1970). In this configuration, one or more output variables may be tracked (follow a certain reference over time). A control engineering approach uses engineering and mathematics to investigate and predict the performance of systems. A feedback control system is a closed-loop system whose output is controlled using its output measurements as a feedback signal. This signal is compared with a reference signal to generate an error signal which is filtered by a controller to produce the system's control input (Boulet, 2000).

The risk management matrix was developed into a basic static feedback model by identifying the inputs and the outputs of the systems, the plant, the reference, controllers, the disturbance, and sensors and actuators of the system. As a result, the ONIHL monitoring model was developed using feedback or closed-loop configuration to allow for effective monitoring of mineworkers in the presence or absence of internal or external uncertainty. Figure 2 shows the different interconnected subsystems that form the overall system. The whole system may therefore be defined as a feedback-based, single-input single-output (SISO) nonlinear stochastic system. The ISO 1999 international standard statistical equations are used for the model (ISO 1999:2013).

The practical application of this model would be to estimate, monitor, and provide quantitative information on the temporary threshold shift (TTS), which eventually leads to the permanent threshold shift (PTS). Miners and mining administrators or policy-makers use this information in decision-making with regards to noise management in the workplace that could reduce the impact of ONIHL. Monitoring employees at shorter intervals, for instance monthly, would ensure that the employers are aware of the state of hearing of their employees and will thus provide an opportunity for early intervention. The model therefore forms part of the early intervention and prevention of ONIHL in the workplace.

The input to this model is the occupational noise exposure of a 'naïve person' (S1 - reference point or baseline) (person who has not been exposed to excessive occupational noise that has caused a permanent threshold shift). The occupational noise exposure is the disturbance to the system. The estimated ONIHL is the output.

Model description

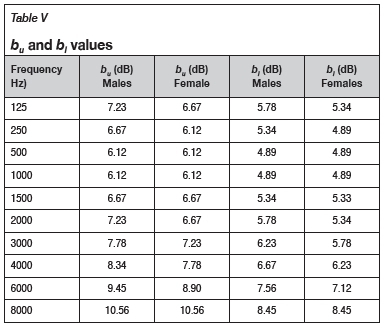

Equations to be used in calculating model parameters of the subsystem are presented below prior to model descriptions. Given the following parameters:

H The hearing threshold level for a specified fraction of a population as a function of age

Y Age in years

Q Various ranges of the percentages of the population a Coefficient used in the equation for calculation of hearing loss

SuStandard deviation of the upper half of the distribution S1 Standard deviation of the lower half of the distribution Hmd,18The median value of the hearing threshold of ontologically normal persons of the same sex aged 18 years, which for practical purposes is taken as zero, as specified in the ISO 389 series. Hence, HQis the hearing threshold level associated with age.

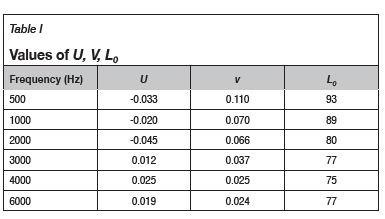

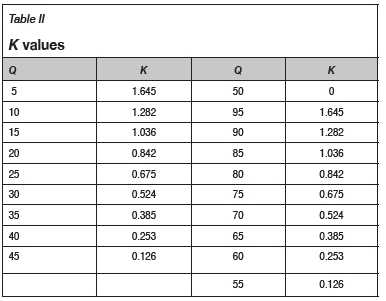

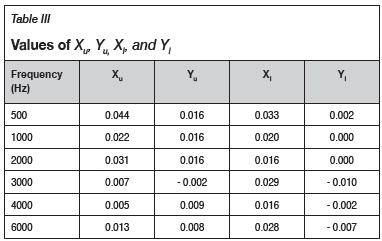

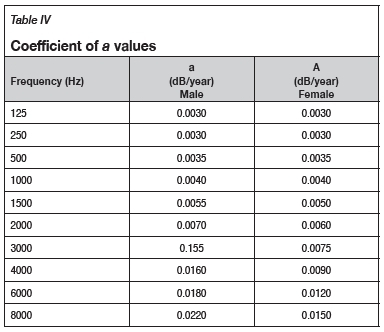

The values for the coefficient a and the multiplier are presented in Tables I and II. (ISO 1999: 2013).

The formulae applicable for the calculation of hearing threshold (H) as a function of age Y (years), for the various ranges of the percentage (Q), having hearing threshold levels exceeding the value HQare:

For Q = 50%:

H1 = Hearing threshold level, in decibels, associated with age and noise (HTLAN)

H = Hearing threshold level, expressed in decibels, associated with age (HTLA)

N = Actual or potential noise induced permanent threshold shift (NIPTS), expressed in decibels.

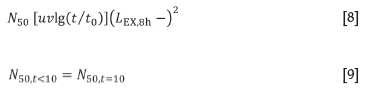

N is calculated using the following equations:

Lex,8h, is the noise exposure level normalized to a nominal 8-hour working day, expressed in decibels

L0 is the sound pressure level, defined as a function of frequency, expressed in decibels, below which the effect on hearing is negligible

t is the exposure duration, expressed in years

to is 1 year

u and v are given as a function of frequency Values of u, v, and L0used to determine the (noise-induced permanent threshold shifts) NIPTS for the median value of the population.

This formula applies to shgreater than Lo. In cases where Lex, 8his less than Lo, it shall be deemed equal to Loso that N50is zero.

Threshold shift for an individual not exposed to occupational noise

In Figure 2, S1 represents the threshold shift of an individual who has not been exposed to occupational noise. Equation [1] is used to determine the effects of age on the hearing ability of this individual. The input to this system is noise exposure which is less than 85 dB at 2000 Hz. At this level of exposure and frequency in the absence of any other factors; for instance, exposure to a sudden explosion (Burns and Robinson, 1970), then the only hearing loss that would occur is loss due to presbycusis. The output to this system is the hearing threshold shift. The hearing threshold level associated with age (HTLA) (ISO 1999: 2013) is calculated as shown in Equation [2].

Controllers (policy and intervention)

The Code of Practice (Figure 4) and the 2014 Mine Health and Safety Council (MHSC) Milestones for the elimination of ONIHL in the mining sector as published by Mine Health and Safety Inspectorate (2003) serve as policies and intervention strategies for the management of noise. Therefore, S2 is the sub-system that represents the mandatory code of conduct imposed in a mine for both surface and underground employees and anyone on site (Mine Health and Safety Inspectorate, 2003). S2 is simplified by amalgamating the policies (Code of Practice and 2014 Mine Health and Safety Milestones for the elimination of ONIHL in the mining sector) and the intervention (administrative controls and the use of hearing protection devices). Depending on the policy implemented by the mine, occupational noise is decreased. The system is therefore represented with an equation used by manufacturers in the industry in the design of noise reduction protective gear (Bannon and Kaputa, 2015), shown by Equation [6].

Sensors

S3 is the sensing unit of the model. The sensor used in this unit may be the National Institute for Occupational Safety and Health (NIOSH) Sound Level Meter mobile application tool or personal dosimeters (National Institute for Occupational Safety and Health, n.d). This sensor is used to measure sound levels in the mine and it outputs the noise intensity and the frequency.

Threshold shift for an individual exposed to occupational noise

54 is defined by Equation [7] and it represents an individual who has been exposed to occupational noise while also suffering from presbycusis.

Checkup

When the hearing threshold shifts of an employee are monitored on a daily, weekly, or monthly basis, the company will be able to assess their state of hearing. Should a worker's threshold shift significantly over a month, the mining administrator will be able to monitor and assess if the hearing protection is working properly or if there are other factors causing the shift, which will then be addressed. S5 represents the check subsystem. This can be monthly monitoring of the hearing threshold shifts. For annual and biannual checkups, an audiogram is used to establish if a temporary threshold shift has progressed into a permanent threshold shift, thus indicating damage to hearing resulting in ONIHL.

Illustration of the model - preliminary results

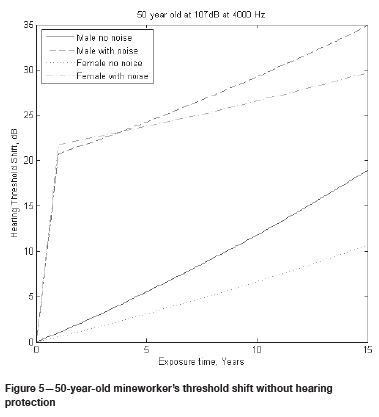

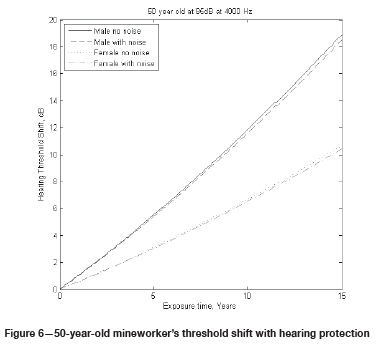

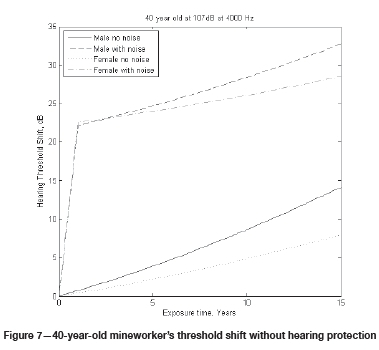

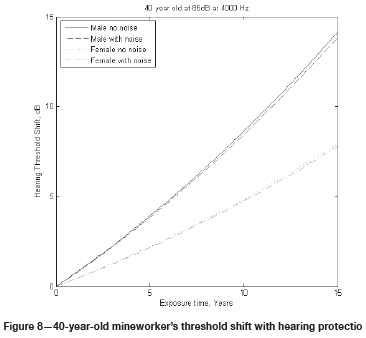

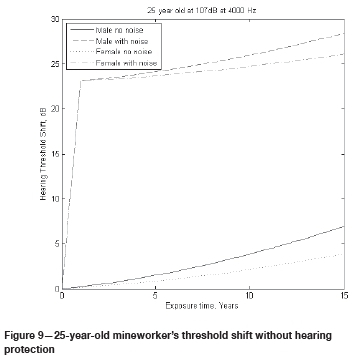

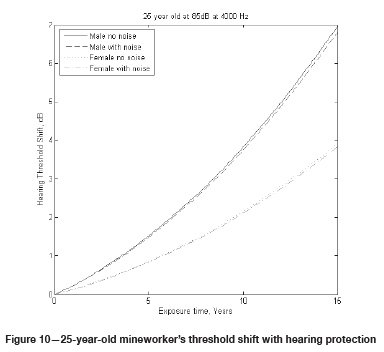

To demonstrate the use of the feedback model, the following fictitious scenario was created. Six mineworkers, comprising three females and three males, who started employment at the ages of 50, 40, and 25 years respectively are used as case studies (Figures 5-10). It is assumed that all subjects have hearing within normal limits, with no previous history of exposure to occupational noise, thus the baseline is not taken into account. They work in a deep mine with a maximum noise intensity of 107 dB at a frequency of 4000 Hz. The results show the pattern of threshold shift if the workers were without hearing protection for 15 years. This illustration demonstrates the significant shift in hearing threshold, thus highlighting the importance of the use of hearing protection devices in noisy environments. Furthermore, research indicates that most workers, although provided with HPDs, sometimes do not use them correctly or the HPD may be faulty.

From the graphs, it is observed that if left unprotected and unmonitored, all mineworkers, irrespective of their age, will have experienced a threshold shift of more than 25 dB from their given baseline in less than 10 years. The designed system currently offers a predictive model for the mine administrators, who should now take steps to monitor the mineworkers frequently to ensure that significant threshold shift does not occur, as stipulated by the Mine Health and Safety Council (MHSC, 2014).

Limitations of the model

> The presented model is a static model and currently excludes the dynamic aspects. Future refinements will include the dynamic aspects, thus enabling the mine administrators to access the real-time hearing status of workers while at work.

> The current model does not include a controller. Future versions will include design of linear and nonlinear controllers for the system, thus allowing for interpretation of policies using control law.

> Model validation with real audiological patient data has not been performed. Therefore, the model will be validated using real data from the mines, and the results presented in a subsequent paper.

> The success of this model relies on the active involvement of different stakeholders. This may present complexities as multiple departments may have to work together. Current studies have indicated a lack of involvement of all stakeholders, which impacts on the success of any implemented programme.

> This model does not take into consideration non-modifiable factors when inputting data

Recommendations

> Model validation with real audiological patient data has not been performed. Therefore, the model needs to be validated using real data from the mines. This will be covered in a subsequent paper.

> Conversion of the current model from a static to a dynamic model by incorporating the model of the human ear as part of the plant.

> Interpretation of policy as a control law, hence the use of both basic and robust appropriate controllers for the system.

Conclusion

Successful elimination of ONIHL is the goal of any HCP. Efforts towards enhancing strategies to achieve this goal should be increased. Research into HCPs and their effectiveness with tangible recommendations on how to manage this occupational health risk should be prioritized. The model introduced in this paper aims to achieve this. This proposed model should be interpreted taking cognisance of the five identified limitations, which will be addressed in a subsequent paper.

References

Airmic. 2010. A structured approach to Enterprise Risk Management (ERM) and the requirements of ISO 31000. https://wiww.theirm.org/media/886062/ISO3100_doc.pdf [ Links ]

Amedofu. 2007. Effectiveness of hearing conservation program at a large surface gold mining company in Ghana. African Journal of Health Science, vol. 14. pp. 49-53. [ Links ]

Amjad-sardrudi, h., Dormohammadi, a., Golmohammadi, a. , and Poorolajal, J. 2012. Effect of noise exposure on occupational injuries: A cross-sectional study. Journal of Research in Health Sciences, vol. 12. pp. 101-104. [ Links ]

Bannon, M. and Kaputa, F. 2015. Decibel drop and noise reduction coefficients for material combinations. Thermaxx Noise Insulation Jackets. https://www.thermaxxjackets.com/noise-reduction-coefficients-and-decibel-drop/ [ Links ]

Boulet, Β. 2000. Introducction to feedback control system. Coronado Systems. http://www.cim.mcgill.ca/~ialab/ev/Intro_control1.pdf [ Links ]

Bruce, R.D. 2007. Engineering controls for reducing workplace noise. Noise Engineering, vol. 37, no. 3. pp. 33-39. [ Links ]

Bruce, R.D. and wood, E.w. 2003. The USA needs a new national policy for occupational noise. Noise Control Engineering, vol. 51. pp. 162-165. [ Links ]

Burns, Ν. and Grove, S.K. 2009. The Practice of Nursing Research : Appraisal, Synthesis, and Generation of Evidencei. Elsevier Saunders. [ Links ]

Burns, W. and Robinson, D.w. 1970. Hearing and noise in industry. Her Majesty's Stationery Office, London. [ Links ]

Chadambuka, a., Mususa, f., and Muteti, S. 2013. Prevalence of noise induced hearing loss among employees at a mining industry in Zimbabwe. African Health Science, vol. 13. pp. 899-906. [ Links ]

Coderio, R., Clementa, A.p., Diniz, C.s., and Dias, a. 2005. Occupational noise as a risk factor for work-related injuries. Rev Saude Publica, vol. 39. pp. 1-5. [ Links ]

Department of Finance, Australia. 2016. An overview of the risk management process. COMCOVER Information sheet. https://www.finance.gov.au/sites/default/files/Risk-Management-Process.pdf [ Links ]

Copley, G.J. and Frederichs, N.B. 2010. An approach to hearing loss in children. South African Family Practice, vol. 52. pp. 34-39. [ Links ]

Dabari, I.J. and Saidin, S.Z. 2014. A theoratical framework on the level of risk management implemenattion in the Nigerian banking sector: The moderating effect of top management support. Social and Behavioral Sciences, vol. 164. pp. 627-634. [ Links ]

Donoghue, A.M. 2001. The design of hazard risk assessment matraces for ranking occupational health risks and thier application in mining and mineral processing. Occupational Medicine, vol. 51. pp. 118-123. [ Links ]

Dugan, M.B. 2003. Living with Hearing Loss. Gallaudet Press, Washington. [ Links ]

Edwards, A.L. and Kritzinger, D. 2012. Noise-induced hearing loss milestones: past and future. Journal of the Southern African Institute of Mining and Metallurgy, vol. 112. pp. 865-869. [ Links ]

Elmontsri, M. 2014. Review of the strengths and waeknesses of risk matrices. Journal of Risk Analysis and Crisis Response, vol. 4. pp. 49-57. [ Links ]

Feuerstein, J.F. 2001. Occupational hearing conservation. Handbook of Clinical Audiology.. 5th edn Katz, J. (ed.). Lippincott Williams & Wilkins, Philadelphia, PA. [ Links ]

Fiedler, A.e. 2004. The role of risk management for occupational health and safety: Benefiting from effective risk assessment. Northwest Controlling Corporation Ltd. https://www.noweco.com/download/wp_ohse.pdf [ Links ]

Gates, S., Nicolas, J.L., and Walker, P.L. 2012. Enterprise risk management: A process for enhanced management and improved performance. Management Accounting Quarterly, vol. 13. pp. 28-38. [ Links ]

Hermanus, M.a. 2007. Occupational health and safety in mining-status, new developments, and concerns. Journal of the Southern African Institute of Mining and Metallurgy, vol. 107. pp. 531-537. [ Links ]

Hong, o., Kerr, M.J., Poling, G.L., and Dhar, S. 2013. Understanding and preventing noise-induced hearing loss. Disease-a-Month, vol. 59. pp. 110-118. [ Links ]

ISO 1999. 2013. Acoustics - Estimation of noise induced hearing loss. [ Links ]

International Organization for Standardization, ISO 389 series. https://wwww.iso.org/search.html?q=ISO%20389%20series [ accessed 20 January 2019]. [ Links ]

Khoza-Shangase, K. 2013. Ototoxicity in tuberculosis treatment in South Africa: Views from healthcare workers involved in the management of TB. African Journal of Pharmacy and Pharmacology, vol. 7. pp. 2141-2145. [ Links ]

Kirchner, D.B., Evenson, Ε., Dobie, R.A., Rabinowitz, p., Crawford, J.,Kopke, R., and Hudson, T.W. 2012. Occupational noise-induced hearing loss. Journal of Occupational and Environmental Medicine, vol. 54. pp. 106-108. [ Links ]

Kramer, S.E., Kapteyn, T.S., and Houtgast, T. 2006. Occupational performance: Comparing normally-hearing and hearing-impaired employees using the Amsterdam Checklist for Hearing and Work. International Journal of Audiology, vol. 45. pp. 503-512. [ Links ]

Le, T.N., Straatman, L.V., Lea, J., and Westerberg, B. 2017. Current insights in noise-induced hearing loss: a literature review of the underlying mechanism, pathophysiology, asymmetry, and management options. Journal of Otolaryngology - Head and Neck Surgery, vol. 46. pp. 1-15. [ Links ]

Mcbride, D.I. 2004. Noise-induced hearing loss and hearing conservation in mining. Occupational Medicine (London), vol. 54. pp. 290-296. [ Links ]

MHSC 2014. The road to zero harm - New milestones: Proceedings of the 10th Anniversary of the2003 Occupational Health and Safety. Mine Health and Satety Council, Johannesburg. [ Links ]

Mine Health and Safety Inspectorate. 2003. Guideline for the compilation of a mandatory code of practice for an occupational health programme (occupational hygiene and medical surveillance) for noise. Department of Minerals and Energy, Pretoria. [ Links ]

Momm, W. and Geiecker, O. 2009. Disability and work. Encyclopaedia of Occupational Health and Safety. International Labour Office. http://www.ilocis.org/documents/chpt17e.htm [ Links ]

Moroe, N.f. 2018. Occupational noise-induced hearing loss in South African large-scale mines: Exploring hearing conservation programmes as complex interventions embedded in a realist approach. International Journal of Occupational Safety and Ergonomics. pp. 1-9. [ Links ]

Moroe, N.f., Khoza-Shangase, Κ., Kanji, Α., and Ntlhakana, L. 2018. The management of occupational noise induced hearing loss in the mining sector in Africa: A systematic review- 1994-2016. Noise and Vibration Worlwide, vol. 49. pp. 181-190. [ Links ]

Nandi, s.S. and Dhatrak, S.v. 2008. Occupational noise-induced hearing loss in India. Indian Journal of Occupational Environmental Medicine, vol. 12. pp. 53-56. [ Links ]

National Institute for Occupational Safety and Health. Not dated. Noise and hearing loss prevention: NIOSH Sound Level Meter App. https://www.cdc.gov/niosh/topics/noise/app.html [ Links ]

Nelson, D.i., Nelson, R.Y., Concha-Barrientos, M., and Fingerhut, M. 2005. The global burden of occupational noise-induced hearing loss. American Journal of Industrial Medicine, vol. 48. pp. 446-58. [ Links ]

Ntlhakana, L., Kanji, Α., and Khoza-Shangase, Κ. 2015. The use of hearing protection devices in South Africa: Exploring the current status in a gold and a non-ferrous mine. Occupational Health Southern Africa, vol. 21. pp. 10-15. [ Links ]

Patel, D.s., Witte, Κ., Zuckerman, C., Murray-Johnson, L., Orrego, v., Maxfield, A.m., Meadows-Hogan, S., Tisdale, J., and Thimons, E.D. 2010. Understanding barriers to preventive health actions for occupational noise-induced hearing loss. Journal of Health Communication, vol. 6. pp. 155-68. [ Links ]

Picard, M., Girard, S.a., Simard, M., Larocque, R., Leroux, T., and Turcotte, F. 2008. Association of work-related accidents with noise exposure in the workplace and noise-induced hearing loss based on the experience of some 240,000 person-years of observation. Accident Analysis & Prevention, vol. 40. pp. 1644-1652. [ Links ]

Rappaport, J.M. and Provencal, C. 2001. Neurotology for audiologists. Handbook of Clinical Audiology. 5th edn. Katz, J. (ed.). Lippincott Williams & Wilkins, Philadelphia, PA. [ Links ]

Ritzel, D.O. and Mccrary-Quarles, A.R. 2008. Hearing loss prevention and noise control. Umwelt und Gesundheit, vol. 1. pp. 22-29. [ Links ]

Rupprecht, S.m. 2017. Bench mining utilizing manual labour and mechanized equipment - a proposed mining method for artisanal small-scale mining in Central Africa. Journal of the Southern African Institute of Mining and Metallurgy, vol. 117. pp. 25-31 [ Links ]

Sliwinska-Kowalska, M., Zamyslowska-Szmytke, Ε., Szymczak, W., Kotylo, p., Fiszer, M., Wesolowski, W., and Pawlaczyk-Luszczynska, M. 2005. Exacerbation of noise induced hearing loss by co-exposure to workplace chemicals. Environmental Toxicology and Pharmacology, vol. 19, no. 3. pp . 547-553. [ Links ]

Sliwinski-Kowalska, M. and Davis, Α. 2012. Noise induced hearing loss. Noise and Health, vol. 14. pp. 274-280. [ Links ]

Steenkamp, R.J. 2007. A six sigma-based management model to eliminate the noise-induced hearing loss pandemic in South African mines. Southern African Business Review, vol. 11, no. 1. pp. 104-124. [ Links ]

Steenkamp, R.J. 2008a. Effectve hearing conservation demands new technology and re-engineering. South African Journal of Industrial Engineering, vol. 19. pp. 215-229. [ Links ]

Steenkamp, R.J. 2008b. A personal approach to hearing conservation: the key to effective second-level noise control. South African Journal of Industrial Engineering, vol. 19. pp. 215-229. [ Links ]

Suter, A.H. 2012. Engineering controls for occupational noise exposure: The best way to save hearing. Sound and Vibrations, vol. 45. pp. 21-31. [ Links ]

Thorne, P. 2006. Best practice in noise-induced hearing loss management and prevention: A review of literature, practices and policies for the New Zealand context. Accident Compensation Corporation, New Zealand. [ Links ]

Tye-Murray, N. 2009. Foundations of Aural Rehabilitation: Children, Adults, and their Family Members. Delmar Cengage Learning, Clifton Park, NY. [ Links ]

Yadav, M., Yadav, K.s., Netterwala, Α., Khan, B., and Desai, N.S. 2015. Noise induced hearing loss (nihl) and its correlation with audiometric observations in heavy vehicle operators suffering with metabolic disorders. International Journal of Medical and Clinical Research, vol. 6. pp. 315-320. [ Links ]

Correspondence:

Correspondence:

N. Moroe

Nomfundo.Moroe@wits.ac.za

Received: 3 May 2018

Revised: 28 Jan. 2019

Accepted: 14 Mar. 2019

Published: July 2019