Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.119 n.6 Johannesburg Jun. 2019

http://dx.doi.org/10.17159/2411-9717/17/409/2019

PAPERS OF GENERAL INTEREST

Release analysis of coal fines: Evolution of the methodology and critical issues involved

L. SahuI; S. BhattacharyaI; S. DeyII

IDepartment of Fuel & Mineral Engineering, Indian Institute of Technology (Indian School of Mines), India

IIMineral Processing Division, CSIR-National Metallurgical Laboratory, India

SYNOPSIS

An ideal procedure to determine the limits of flotation-based separation, as is the case with washability analysis for density separation, does not exist. Therefore, a procedure called release analysis, considered to be the counterpart of the washability process in density separation, was developed to evaluate the flotation characteristics of coal fines. Since flotation is a complex process it is necessary to know the maximum recoverable yield that could be achieved at a target ash level and what could be obtained by release analysis. Due to a number of limitations in the initial procedures, modifications were recommended by various researchers to generate an optimum separation curve. This paper presents a review of, and a discussion on, the chronological evolution of release analysis methodology over the decades. Notwithstanding the availability of a standardized release analysis procedure, such as BS 7530, the paper highlights the critical parameters involved in the procedures, such as coal type, feed characteristics, choice of reagents and dosage, operator bias, and design features of the flotation cell.

Keywords: Release analysis, ideal procedure, advanced flotation washability, impeller speed, aeration rate.

Introduction

Coal is a heterogeneous substance consisting of various combustible constituents (macerals) and associated mineral matter. The kind and abundance of the various macerals present in the coal, such as vitrinite, semivitrinite, exinite, and inertinite, determine the type of coal. As macerals are formed by biological degradation of different parts of the plant material, they have different properties based on their original composition. Coal cleaning processes are dependent on the differences in physical properties between the coal components (the macerals) and also between the macerals and the mineral matter. Thus the cleaning characteristics of the coal might vary from one type to the next. The cleaning processes influence the distribution and the concentration of macerals in the various size and density fractions of the cleaned product.

Flotation is the most commonly used method to clean and upgrade coal fines, and is typically applied in the size range of less than 500 pm. Coal being heterogeneous in nature, its composite property is dictated by its petrographic composition determined from maceral analysis, i.e. relative percentage share of macerals on a volumetric basis. Since different components, both macroscopic and microscopic, of coal have different chemical compositions, they show different degrees of floatability (Liu, Holuszko, and Mastalerz, 2017). For any coal, the macroscopic components vitrain and clarain are generally more floatable than durain and fusain (Arnold, 1986; Aplan, 1993). Analysis of microlithotypes describes the entire composition of a particulate cross-section of coal. The microlithotypes can be categorized on the basis of the number of macerals present, such as mono-, bi-, or tri-maceralic. The macerals in different proportions (at least 5% of each maceral group) within a 50 pm circle form a microlithotype (ICCP, 1963, 1971; Taylor et al., 1998). At a microscopic level, the efficiency of the flotation can be gauged from the partitioning of the microlithotype. The proportion of macerals in the microlithotype affects the floatability of the particles. Inertinite-rich coal, for example, is difficult to float. The separation of vitrinite and inertinite appears to be rank-dependent. The efficiency of any mineral response, as well as any maceral response, to flotation is dependent upon the proportion of the macerals and minerals on the surface of the particles (Hower and Parekh, 1986). Clay minerals and quartz dominate the mineral matter that is contained in typical fine coal flotation feeds.

Flotation is a complex physicochemical process in which a collector is used to impart or enhance the hydrophobicity of the contact surface of floatable particles and a frother is used to stabilize the bubbles by reducing the surface tension of the pulp so that stable bubbles can drag the floatable particles to the surface of the flotation pulp. The efficiency of separation in flotation is directly proportional to the probability of bubble-particle attachment. The probability of bubble-particle collision for coarser particles is higher than that for finer particles. Thus flotation depends upon the size of particles and distribution of different size fractions in the feed material. The rate of flotation also varies with the particle size. Those particles having a size class of 300 χ 75 μm show significant response, while 500 χ 300 μm and < 75 μm particles have a slow rate of flotation (Sukumar, 2004). Relative density (RD) of the particles is closely associated with the particle size in the assessment of flotation rate. The higher the RD of the particle the lower the flotation rate. As flotation is selective and probability-based, a number of factors affect the performance of the flotation cell. Agitation of the pulp results in dispersion of the reagents throughout the pulp and collisions between bubbles and particles. This depends on impeller design (both rotor and stator), impeller speed, cell volume, cell aspect ratio, and cell design. The size of the bubbles formed, which is a key factor in flotation performance, is influenced by the aeration rate. As cell design features such as impeller design, structure and dimension of the cell, and operating parameters such as impeller speed and aeration rate vary from cell to cell, the results obtained in different cells are not identical, even under the same experimental conditions (Gorainm Franzidis, and Manlapig, 1995a, 1995b, 1996; TTabosa, Runge, and Holtham, 2016; Anzoom, Bhattacharya, and Sahu, 2017).

As a result, process optimization is difficult where the limits of performance are unknown. To evaluate the performance of flotation the optimum boundary must be known so that an attempt to achieve the best possible separation can be made. Release analysis is considered to be an ideal separation procedure, like washability in froth flotation, and is used as the reference for batch or continuous flotation. In effect, the ideal flotation response of coal could be characterized by release analysis.

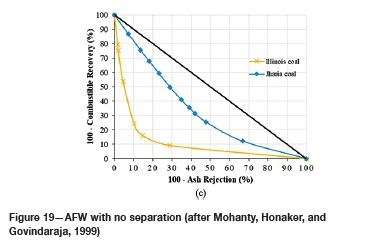

Earliest procedure of release analysis

Dell (1953) developed the first release analysis procedure as the 'counterpart in froth flotation to float and sink analysis in the gravity concentration of coal'. Dell's release analysis was trialed using copper ore, and was based on a step-by-step repeated flotation of products. Generally, the collector and frother dosages were typical for the average plant. Flotation feed was fractionated according to the time of collection and the procedure was thus called 'timed release analysis'. Four floats were collected over a range of time intervals. The first and second floats were mixed and refloated. The second and third floats were refloated separately. This procedure was repeated two more times to minimize the amount of gangue particles entrapped by bubbles and entrained in water coming off with the froth. Finally, four concentrates with different grades and four tailings were obtained. The flow diagram of Dell's original release analysis is shown in Figure 1. A release curve was prepared using a series of concentrates and tailings. The release curve showed the optimum result compared to other flotation experiments. The main drawback of this procedure was the necessity of decantating the froth every time before reintroducing to the next cell operation, to prevent pulp overflow.

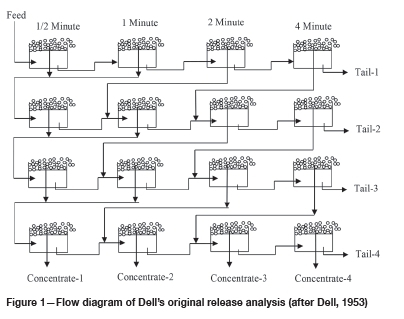

Modification of the procedure

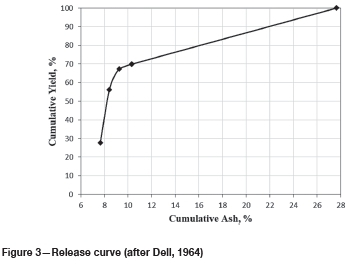

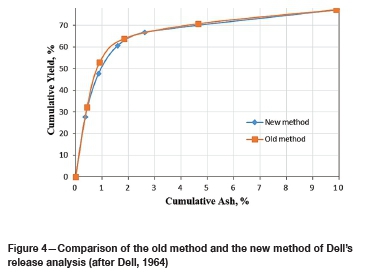

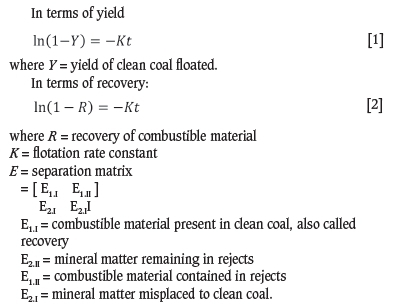

Dell (1964) modified the original procedure of release analysis by removing the time limit of froth collection. Controlled aeration rate and impeller speed were introduced in the modified version (Figure 2). The froths were fractionated by varying the impeller speed and aeration rate instead of time. Both procedures were compared and the result of the modified procedure was found to be identical to those of the original procedure. The new procedure was considered to be simpler than the original procedure and more operator-friendly. Hydrophobic and hydrophilic materials were separated in the first stage, which produced both strongly floatable and weakly floatable particles in the froth. The froths were floated and refloated three times, or more if necessary. In the final stage, a froth from the first stage was fractionated by increasing the impeller speed and aeration rate. The problem of water decantation could be eliminated to a great extent by this procedure. A set of data for the simplified release analysis of coal is reported in Table I and Figure 3. A comparison of Dell's original method and simplified release analysis is presented in Figure 4.

As a larger amount of the froth was obtained, even in the first fraction, with higher ash, a time limit was required for the froth collection so that the yield-ash locus points of the release curve could be extended to a low ash level. In order to achieve this target, Cavallaro and Deurbrouck (1965) varied the impeller speed with time as per Dell's original 1953 procedure. The rest of the conditions were kept identical, and only time was limited due to the highly floatable nature of the feed.

Since poor reproducibility was obtained in the release analysis results, possibly due to operator bias and certain other factors, an alternative method for optimum separation was developed by Nicol et al. (1983).

Classification of coal by release analysis based floatability criterion

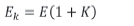

Since ash content and yield alone could not be used to assess separation efficiency, Hu (1975) introduced a floatability criterion which is comprised of separation efficiency, also called the capacity criterion, and the intensity factor or rate constant. The floatability criterion (Ek) can be calculated as:

The floatability criterion is related to the separation matrix (E), which is a function of the recovery of combustibles, rejection of mineral matter, and possible misplacement between the two. Thus the separation matrix depends upon flotation performance, which might vary between cell types because of differences in their design features (Gorain, Franzidis, and Manlapig, 1995a, 1995b, 1996; Tabosa, Runge, and Holtham, 2016; Anzoom, Bhattacharya, and Sahu, 2017). Therefore the floatability criterion appears to be cell-dependent.

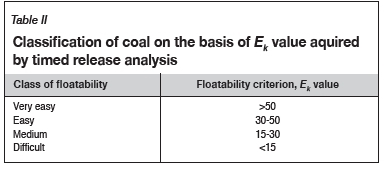

Hu, Jin, and Bodily (1987) investigated the floatability evaluation of fine coal and suggested that the coals could be categorized on the basis of their floatability criterion (Ek) value into the categories very easy, easy, medium, and difficult to clean (Table II). Ekvalue of different coal samples could be calculated as in Table III.

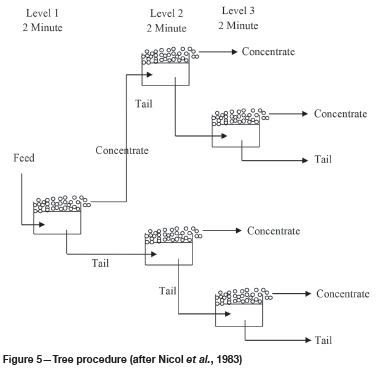

Tree analysis: an alternative method

Nicol et al. (1983) introduced a feed-independent ideal flotation response procedure called 'tree analysis', where the primary separation was followed by a number of scavenger and cleaner stages (Figure 5). Each product of flotation was subjected to repeated branching flotation. Thus the entrained and entrapped particles carried in the froth could be removed and the hydrophobic particles remaining in the tailing could be recovered by a scavenger step. In each stage, the collector was added according to requirements that are possibly dictated by feed characteristics. All the mechanical parameters were kept constant throughout the experiment.

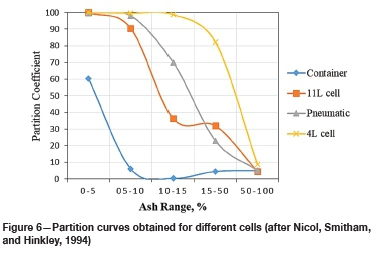

Partition curve

Considering the tree analysis as a cell-independent procedure, Nicol, Smitham, and Hinkley (1994) explored the concept of a partition coefficient to measure coal flotation efficiency (analogous to the partition coefficient determined for density separation). Ash levels were grouped by ash ranges, e.g. 0-5%, 6-10%, 10-15%, 15-50%, and 50-100% (Figure 6). The partition coefficients were calculated by the ratio of the mass percentage of the product recovered within the ash range to the mass percentage of the total feed within the same ash range. The tree curve of feed provided the mass of coal present in each ash range. The mass of clean coal in each ash range was obtained by tree analysis of froth collected from the cell. The performance of the different flotation cells was evaluated on the basis of partition curves obtained for the various types of cells, as shown in Figure 6.

Criteria for standard procedure

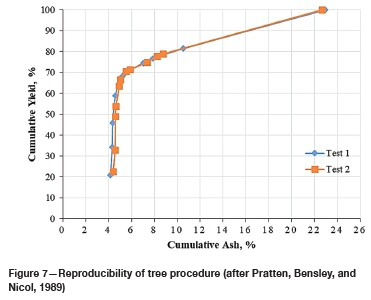

Pratten, Bensley, and Nicol (1989) specified some criteria that must be contained in the standard procedure so that it can be considered a kind of ideal response of flotation as a reference to evaluate the batch process.

> The data analysis procedure should have a set of loci (cumulative yield, cumulative ash) so that a curve made by these points can define all the results obtained by the batch flotation. If a procedure has one single locus, it can be referred to for that ash content product. For example, for a target concentrate having 62% yield at 15% ash, the analysis cannot refer to a yield at 10% ash.

> The procedure must follow the separation based on surface properties.

> Separation made through the defined procedure must describe the optimum separation.

> The locus position should not vary with reagent dosage.

> The procedure must be simple, repeatable, and reproducible.

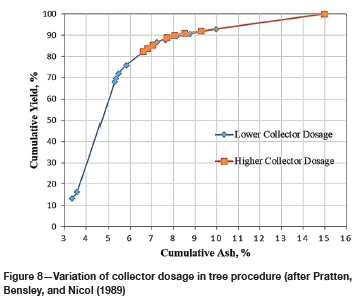

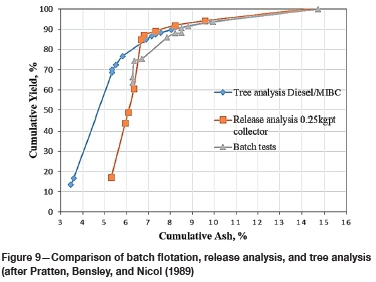

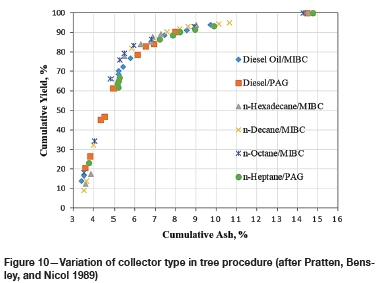

Pratten, Bensley, and Nicol (1989) tested the tree process and concluded that it was reproducible and reported a closely related yield-ash curve (Figure 7). It is important to ensure close results after variation in the parameters, otherwise it should not be acceptable as a procedure. The only curve was shifted towards the higher yield ash points when the collector dosage was increased (Figure 8), which was due to the non-floatable particles being recovered in the froth phase. They also concluded that quite close results could be obtained by tree analysis while using various types of collectors. Their comparative results showed that tree analysis is superior to batch flotation tests and release analysis. However, that superiority could be obtained only at low ash levels. At high ash levels, tree analysis was inferior to release analysis (Figure 9). It appears, therefore, that no single procedure could be recommended for reference as an ideal separation such as washability for density separation. Pratten, Bensley, and Nicol further studied the dependence of the performance of the tree procedure on collector type, and concluded that the tree curve obtained (Figure 10) using different collectors was closely located, indicating the procedure to be independent of collector type. However, that was not the case with release analysis.

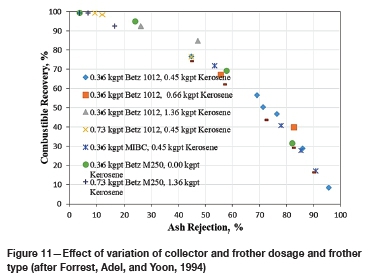

In order to verify the effect of the reagent dosage and type on Dell's procedure, Forrest, Adel, and Yoon (1994) had found that release analysis was independent of collector and frother dosage.

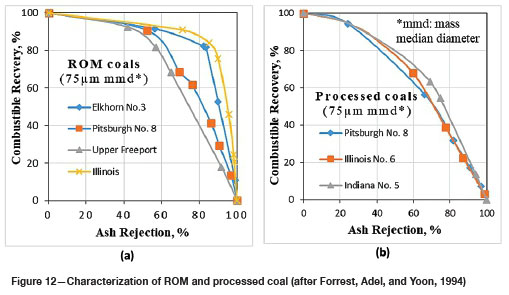

Any small variation in a release curve using different reagents at different dosage levels was found to be within experimental error due to the variation in reagent type (Figure 11). Thus a release ash curve could be used to characterize a coal sample. In Figure 12, characterization of the flotation performance of the ROM coal and processed coal shows the release analysis as a tool for indicating ultimate separation. The release curve of the ROM coal showed sharp elbows, indicating that the majority of the mineral matter present in the coal is well liberated and hence is readily removed by flotation. The release curve of processed coal has shallow elbows, indicating interlocked particles with a high proportion of mineral matter.

British Standard procedure (BS 7530)

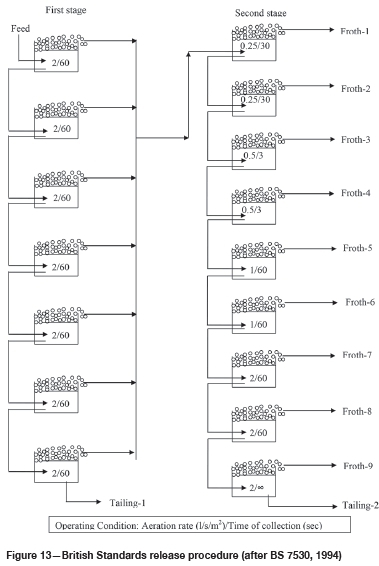

In 1994, Dell's simplified release analysis was adopted by British Standards after modifying the operational parameters for the evaluation of the flotation characteristics of coal (BS 7530, 1994). Though it is customary to report speed in revolutions per minute, BS 7530 (1994) envisaged the impeller speed to be fixed at 6 m/s throughout the experiment and the aeration rate was varied in the final stage. The reagents prescribed by the procedure are n-dodecane [CH3(CH2)10CH3] as collector and methyl isobutyl carbinol (MIBC) as frother. The procedure comprises two stages, with the first stage following an identical operational condition in each fraction of froth collection. Seven froth factions are collected, with reagent added at the stipulated dosage for each fraction. The froths collected in the first stage are mixed and reintroduced to the cell. In the second stage, the reagents are added once at the beginning of the test, and the froths are fractionated by varying the aeration time. The concentrates are obtained in a series of increasing ash. Details of the procedure are presented in the form of a flow diagram in Figure 13. Brown and Hall (1999) provided the background work for developing BS 7530 (1994) in detail.

Comparison of procedures

Despite the number of procedures (Dell, 1953, 1964; Cavallaro and Deurobrouck, 1965; Nicol et al., 1983, Nicol, and Hinkley, 1994; BS 7530 1994) that have been developed to determine the limit of the flotation-based separation, analogous to the washability analysis of the float-sink test, there appears to be no standard procedure that could precisely specify the maximum yield at any ash content. Keeping this point in mind, Brown and Hall (1999) attempted to evaluate the most preferable procedure among the methods developed earlier. They compared the results from the two most popular procedures, which are release analysis and tree analysis, using coals from three different countries -Australia, South Africa, and the UK. Release analysis (BS 7530) produced a significant result at the low-ash end (initial part) of the curve, whereas the tree analysis method indicated optimum yield in the intermediate range of ash content. They could not conclude a preference for one single procedure or method of flotation. Therefore, they advised the selection of any standard procedure on the basis of the information required.

Column release procedure

The results recorded from a flotation column were found to be superior to those found in traditional procedures, release and tree analysis. In the flotation column, selectivity is better as particles and bubbles move in opposite directions. Thus particle-bubble collision is maximized and the column height, with a greater froth height, facilitates the retention of the entrained and entrapped particles, with a longer travel time to the froth collection zone. On the basis of the separation principle of the column, McClintock, Walsh, and Rao (1995) used the column to carry out release analysis by a so-called 'column release procedure'. In the first stage, the concentrate is generated by continuous feeding of pulp. The froth is collected and kept aside and the tailings are subjected to a scavenging operation, where the froth is collected as a second concentrate and the tailings are again fed to the column. This operation is repeated until the flotation is complete.

Application of wash water reduces the misplacement of gangue material through entrapment and all floatable particles remaining in the tailings are recovered by the repeated scavenging action. This ensures that all floatable particles participate in the next and subsequent stages. After completion of the first stage, all the froths are combined and subjected to a cleaning step. In the cleaning operation a low aeration rate is provided initially before the froths are fractionated by increasing the aeration rate.

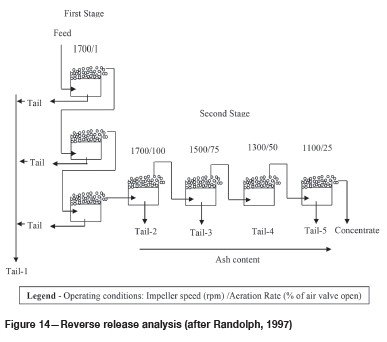

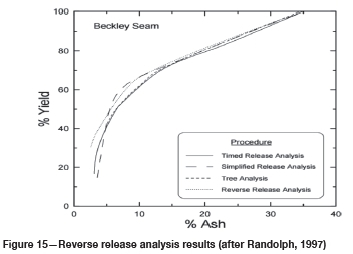

Reverse release analysis

Notwithstanding the availability of a standardized procedure such as BS 7530 (1994), it was observed by Randolph (1997) that some non-floatable particles also reported to the froth stream in release analysis. In order to minimize the misplacement of the non-floatable particles, Randolph (1997) introduced an alternative technique whereby the tailings are collected in the cleaning stage of flotation. This was named 'reverse release analysis' (Figure 14). The operating conditions followed in the cleaner stage of this procedure are in reverse of the sequence prescribed for release analysis (Dell, 1964), keeping the first stage the same. In the first stage, the floatable and non-floatable particles are separated using a high rate of air flow and high impeller speed. The tailing from this stage, designated as Tail-1, contains the highest ash of all the fractions and is positioned as the last coordinate of the curve. In the second stage, the rougher concentrate is fractionated in terms of tailing. The froth is collected until flotation is complete and an ultimate tailing is collected at each step. A high rate of aeration and agitation is maintained initially and then the operating conditions are in decreasing order, whereby a series of tailings with a decreasing level of ash is obtained. Dell's simplified release analysis was not considered to be acceptable at low ash and low yield levels. It generated a concentrate with high ash at a high yield due to the misplacement of non-floatable particles. Although the reverse release curve constituted the coordinates of mostly tailings and a single concentrate, the curve was shown to be superior to the simplified release curve, with the points extending towards the low-ash region (Figure 15).

Advanced flotation washability (AFW)

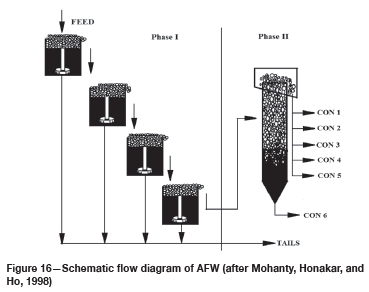

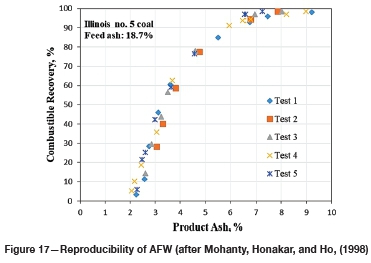

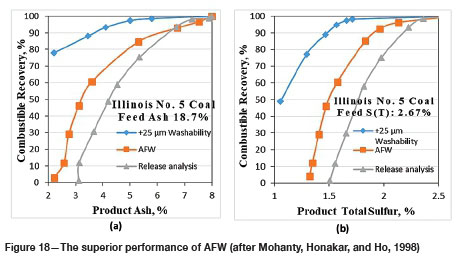

Mohanty, Honakar, and Ho (1998) investigated an alternative technique to evaluate the flotation response of a feed pulp sample. They set up a mechanical Denver cell and a packed bed flotation column. In the first phase, the hydrophobic particles were separated from hydrophilic particles by repeated flotation of the froth collected in the previous step. The final froth after repeated cleaning was fed to the flotation column, where the feed pulp was separated into six concentrates in order of their floatability by varying the aeration rate from 1.5 to 2.5 l/min. Kerosene as a collector and Dowfroth M-150 polyglycol as a frother were used in the first stage. The second stage did not need any further collector addition. The frother, at a lower dosage, was added to produce a constant froth height of 90 cm which ensured the discharge of froth to the launder. The flow diagram of the procedure, termed advanced flotation washability (AFW), is presented schematically in Figure 16. The optimum separation curve formed by AFW has been claimed to be superior to the curves from other traditional procedures presented earlier. Therefore, this procedure was believed to be preferable for any target ash level. As it was independent of operator input, with zero operator bias, the reproducibility of the procedure was found to be acceptable (Figure 17). It also showed superior performance to a multistage column flotation operation. The comparative results obtained for the ideal separation procedures are reported in Figure 18. The AFW technique also performed well for the desulphurization of coal. The same trend was observed for sulphur reduction, where AFW is superior to the release analysis (Figure 18b).

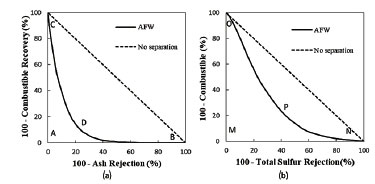

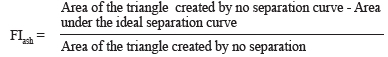

Floatability index

The floatability index (FI) is an important factor that can assist in assessing the upgrading potential of fine coal. Mohanty, Honaker, and Govindaraja (1999) developed an equation by taking the area between ideal separation and no separation. The graph in Figure 19a was plotted by taking the X-axis as (100 minus ash rejection %) and Y-axis as (100 minus combustible recovery %). A higher FI value indicates easy-to-clean characteristics, whereas a coal with a lower FI value has difficult cleaning characteristics. The floatability index is also applicable for assessing sulphur rejection (Figure. 19b), where the FI is calculated by taking (100 minus total sulphur rejection %) instead of (100 minus ash rejection %).

Area of the triangle created by no separation curve - Area under the ideal separation curve

The FI values of two samples of coal fines from different locations are shown in Figure 19c. Illinois coal, which is of in situ origin, showed a FI value of 0.77, whereas Jharia coal of drift origin had a lower FI value of 0.32. This indicated that the drift coal would be difficult to clean.

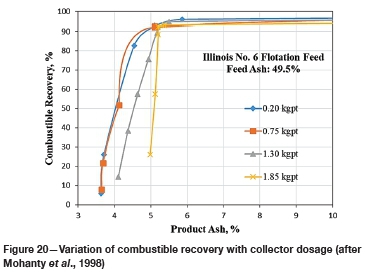

Factors affecting flotation performance by following different procedures

Mohanty et al. (1998) studied the effect of collector dosage on the performance of release analysis. Lower collector dosages of 0.20 kg/t and 0.75 kg/t showed the optimum separation over a range of dosages (Figure 20). Increasing the collector dosage resulted in the recovery of semi-hydrophobic particles in the froth, lowering the grade of the concentrate product. Thus the curve shifted towards the higher-ash side of the graph. This indicated the sensitivity of release analysis to the collector dosage. These results contradicted those of the earlier study by Forrest, Adel, and Yoon (1994), where the results of release analysis were reagent dosage-independent and any variation was taken to be due to experimental error. Since fixing the collector dosage to produce the optimum separation is the first priority before proceeding to flotation, it added an extra task, viz. optimizing the collector dosage. As had been earlier reported in the methodology and results by Pratten, Bensley, and Nicol (1989), the tree analysis carried out by Mohanty et al (1998) showed less variation in results with changes in the collector dosage rate.

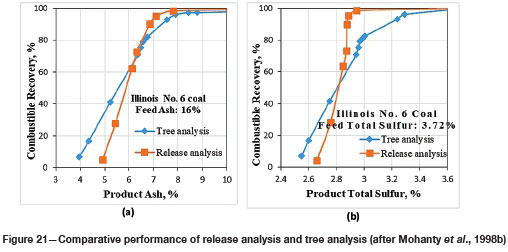

A comparison of tree analysis and release analysis showed that each procedure had individual optimum separation regions. Tree analysis would be preferable in the low-ash and -sulphur region, while the release curve defined optimum separation in the high-ash and -sulphur region (Figure 21)

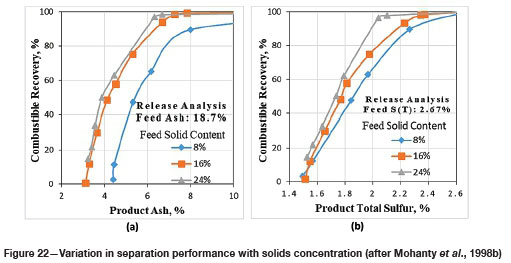

The pulp density of the feed to flotation also affects the optimum separation. The mass fraction reporting to the froth is related to the carrying capacity, i.e. maximum mass rate at which the solids can be delivered into the froth. When the initial feed solids content is high, the total bubble surface area may not be adequate to transport all the particles that have already reported to the froth zone. As a result, selective detachment of the weaker hydrophobic particles may occur, and such particles fall back into the collection zone. Re-attachment of the particles to bubbles occurs repeatedly by reflux action (Dobby and Finch, 1986). Selectivity due to detachment and reattachment improves the separation at high feed solids content. Mohanty et al. (1998) showed that an initial high solids content in flotation feed had a significant effect on the release analysis results. An increase in the initial feed solids content from 8% to 16% significantly improved the separation, with little further improvement when the solids content was raised to 24% (Figure 22a). When combustibles recovery is plotted against sulphur content (Figure 22b), it is observed that feed solids content also has a certain effect on flotation performance as measured by combustibles recovery.

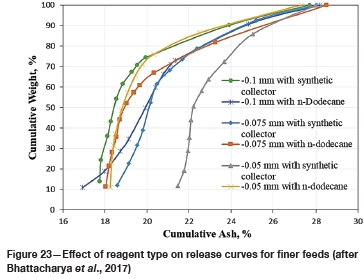

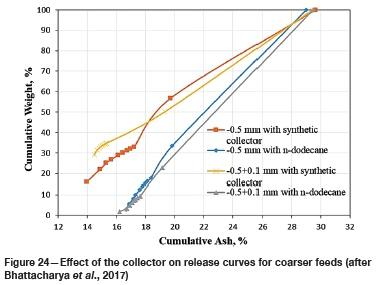

According to Bhattacharya et al. (2017), the release analysis results are sensitive to particle size and collector type. If a size fraction responds well to a reagent, that does not necessarily mean that the same reagent will deliver good results on any other size fractions of the same coal. Bhattacharya et al. (2017) studied the effect of feed size by treating coarse to ultrafine fractions with different collectors. They found that n-dodecane was significantly more effective on ultrafine size fractions of < 75 μm (Figure 23), where most coal particles were found to be liberated. However for the particles of size greater than 100 μιη a synthetic collector of NALCO chemicals played a significant role in floating both liberated and unliberated particles (Figure 24). The combined effect of two different types of collectors might improve the flotation performance of the entire feed material. Bhattacharya et al. (2017) suggested the use of a blend of collectors on the basis of the response of different size fractions to the respective collectors and the mass proportions of those size fractions. It is postulated that an improvement in the release analysis results and flotation can possibly be brought about by the synergy between a collector effective for unliberated and partially liberated coarser particles and a collector effective for finer liberated particles.

Evolution of the procedures

The evolution of the different versions of release analysis procedures over the last seven decades, beginning in 1953, and their modifications along with their attributes are highlighted in Table IV.

The first ideal flotation-based separation procedure (Dell, 1953) was developed to evaluate copper flotation, and was later extended to coal flotation. A major difficulty encountered in the experimental work was the repeated decantation of water, which was partially resolved by varying operational parameters such as aeration rate and impeller speed in order to control the pulp volume generated in the previous stages. Thus a simplified release analysis partially resolved the decantation problem (Dell, 1964). In an attempt to completely solve the decantation problem, Cavallaro and Deurobrouck (1965) varied the impeller speed with time with the aeration rate set to maximum. In view of the experimental bias in all these three procedures, perceived or real, an alternative method, tree analysis (Nicol et al., 1983), was developed in which roughing was followed by branching through the cleaning and scavenging stages. This route cleans the material thoroughly and the release curve generated covers all the points on a graph starting from a low ash-yield coordinate to a high ash-yield coordinate, indicating optimum yield. Tree analysis particularly showed superiority at the low-ash end of the curve. Its limitation was, however, the large number of products that were generated. Hu (1975) did not suggest any new procedure to evaluate the flotation response of coal. Hu, Jin, and Bodily (1987), however, proposed a methodology, called floatability criterion, to classify coal for flotation purposes, based on release analysis data, in a four-point scale from very easy to difficult to clean. The decantation problem in the timed-release analysis appears to have been completely solved by British Standards (BS 7530, 1994) by dividing the pulp into froths by varying the impeller speed and aeration rate with time instead of varying only the time. A flotation column instead of a mechanical cell was used for the release analysis procedure known as column release (McClintock, Walsh, and Rao, 1995), which is similar to the simplified release analysis of Dell (1964). Because of repeated scavenging of the tailings to recover all the floatable particles, the procedure is time-consuming. Randolph (1997) therefore proposed a reverse release analysis in which the tailings were collected by repeated cleaning of froths, minimizing the misplacement of gangue particles. Advanced flotation washability (AFW), proposed by Mohanty, Honakar, and Ho (1998), comprised the use of a mechanical cell followed by column flotation. In this procedure the final froth obtained by repeated cleaning in the mechanical cell is fractionated into six froths in the flotation column by varying the aeration rate. Since an automated packed-bed flotation column is used, the procedure appears to be independent of the operator. Hence reproducibility of results is high, though the operation is time-consuming.

Considerations

The discussion presented so far, in particular the one around Table IV, indicates that there remain a number of considerations, summarized below, which make the selection of a release analysis procedure very challenging.

> Feed characteristics-Results of release analysis vary with feed characteristics, raw coal versus cleaned coal (Forrest, Adel, and Yoon, 1994), and with feed particle size. Different size fractions show different flotation responses. This is particularly true for drift coal (Bhattacharya et al., 2017).

> Pulp density-Higher pulp density results in better separation (Mohanty et al., 1998). Pulp density is usually affected by the feed size, in particular, the mass percentages of < 75 μm and < 50 μm particles. Finding, the optimum pulp density, whatever is to be the procedure of release analysis, is therefore not an easy task.

> Reagent type-Release analysis results have shown frother dependency (Forrest, Adel, and Yoon, 1994) and collector dependency for the entire feed of < 500 μm (Pratten, Bensley, and Nicol, 1989) and for the constituent size fractions of the same feed, say 500 χ 100 μm, < 1 00 μm, < 75 μm (Bhattacharya et al., 2017).

> Reagent dosage-Release analysis results have also shown dependency on dosage, in particular, that of the collector (Pratten, Bensley, and Nicol, 1989; Forrest, Adel, and Yoon, 1994; Mohanty et al., 1998).

> Operating conditions-Different experimental conditions, such as aeration rate, impeller speed, flotation time, froth cleaning methodology, and scavenging operations, all affect the results, whether the method be release analysis (Dell, 1964; Cavallaro and Deurbrouck, 1965; BS 7530 1994), reverse release analysis (Randolph, 1997), tree analysis (Nicol et al., 1983), or AFW (Mohanty et al., 1998).

> Cell type-Flotation performance is dependent upon cell design features such as tank geometry, impeller design, structure, and associated operational features (Gorain, Franzidis, and Manlapig, 1995a, 1995b, 1996; Tabosa, Runge, and Holtham 2016; Anzoom, Bhattacharya, and Sahu, 2017).).

Effect of petrographic composition on flotation of coal

All the investigations on release analysis referred to in this study, except those carried out by Bhattacharya et al. (2017) and in an isolated case by Brown and Hall (1999), have used in situ coal a: feed material. All the samples used in the investigations appear to be vitrinite-, and possibly liptinite-rich, coals. The effect of maceral composition and the degree of oxidation of the coal do not appear to have been investigated, though these factors might affect coal flotation and therefore the release analysis.

It is important to note in this context that Arnold and Aplan (1989) studied the response of coal components, both petrographic and chemical, to flotation. They used contact angle measurement techniques to assess the hydrophobicity of coal macerals. Generally, the rank of coal is determined by the percentages of C and O and vitrinite reflectance. These three factors provide a reasonable estimate of the flotation characteristics of the coal. The components containing carbon are mostly hydrophobic in nature. The hydrophobicity can be estimated from the contact angle of the particle. The contact angle increases with an increase in carbon content up to 88%, and after that point it decreases, as is the case with anthracite coal (Horsley, 1951; Gutierrez-Rodriguez, Purcell, and Aplan, 1984). This was verified using the sessile drop and captive bubble technique for measuring the contact angle of coal particles (Arnold and Aplan, 1989). The contact angle increased with an increase in oxygen content up to 5%, at which point a contact angle of 60-70° was observed. Thereafter the contact angle decreased rapidly to zero as the oxygen content increased to 20-25%. The contact angle was at a maximum at a vitrinite reflectance of around 1.0. For high-volatile bituminous coal, the hydrophobicity of coal macerals thus follows the order liptinite > vitrinite > inertinite (Arnold and Aplan, 1986; Aplan, 1993).

The nature of the hydrocarbon chain and oxygen functional group dictates the hydrophobicity of macerals. The oxygen functional group allows water to adsorb on the coal surface due to the formation of strong hydrogen bonding between the water molecule and oxygen functional group. For higher rank coals, an increase in aromaticity results in a reduction in hydrophobicity, while an increase in the aliphatic group improves the hydrophobicity. Collector adsorption changes the surface chemistry of coal and thus its hydrophobicity. Selective adsorption of collectors on macerals with specific chemical composition influences the flotation performance (Wang et al., 2017; Holuszko and Mastalerz, 2015). Thus maceral concentration and maceral chemistry play an important role in recovery of froth. Characteristics of collectors such as their chemical composition, selectivity, and reactivity with the coal surface determine the performance of coal flotation (Holuszko and Mastalerz, 2015). Collectors should be such that they are able to increase the aliphatic group with minimization of aromaticity after adsorption so that hydrophobicity can be increased.

Summary and conclusions

The first release analysis, also known as timed release analysis, was developed by Dell (1953) using copper ore. Dell (1964) subsequently simplified the procedure and used coal fines. Since then a number of researchers have suggested various modifications to the procedure. A British Standard (BS 7530, 1994) was developed for this purpose. To overcome the inadequacies of the release analysis procedures, alternative methods such as tree analysis, reverse release analysis, column release procedure, and advanced flotation washability (AFW) have been developed by other researchers.

All the procedures mentioned show some dependence on factors such as feed characteristics, pulp density, collector and frother type and dosage, and experimental conditions such as aeration rate, impeller speed, flotation time, froth cleaning methodology, scavenging operations, and on cell type due to design features such as tank geometry, impeller design and structure, and associated operational features. Practically every study has been carried out using a different type of cell.

Nearly all the investigations have been carried out using in situ coal as feed material. All the samples used in the experimental work appear to be vitrinite-, and possibly liptinite-rich, coals. The effect of maceral composition and the degree of oxidation of the coal do not appear to have been investigated, though these features might affect the coal flotation and therefore the release analysis. This is particularly true for the inertinite-rich coals, typically of drift origin, because the hydrophobicity of coal macerals follows the order: liptinite > vitrinite > inertinite.

References

Anzoom, S.J., Bhattacharya, S., and Sahü, L. 2017. Dependency of batch coal flotation on cell types. NexGen Technologiesjor Mining and Fuel industries. Allied Publishers, Delhi. Vol. 2. pp. 1489-1494. [ Links ]

Aplan, F.F. 1993. Coal properties dictate coal flotation strategies. Mining Engineering, vol. 45. pp. 83-96. [ Links ]

Arnold, B.J and Apian, F.F. 1986. Coal froth flotation: the response of coal and mineral particles to reagent and circuit variations. Advances in Mineral Processing. Society of Mining Engineers. pp. 351. [ Links ]

Arnold, B.J. and Aplan, F.F. 1989. The hydrophobicity of coal macerals. Fuel, vol. 68. pp. 651-658. [ Links ]

Bhattacharya, S., Jyoti, D., Sahu, L., Dey, S., and Singh, H. 2017. Flotation of low volatile coking coal fines. Transactions of the Indian Institute of Metals, vol. 70, no. 2. pp. 421-432. doi: 10.1007/s12666-016-0996-3 [ Links ]

Brown, D.W. and Hall, S.T. 1999. Froth flotation: Preparation of a laboratory standard. Fuel, vol. 78. pp. 1621-1629. [ Links ]

BS 7530. 1994, Methods for froth flotation testing of hard coal. Part 2. Evaluation of flotation characteristics. British Standards Institution, London. [ Links ]

Cavallaro, J.A. and Deurbrouck, A.W. 1965. Froth flotation washability data of various Appalachian coals using the timed release analysis technique. Report of Investigation no. 6652. US Bureau of Mines. [ Links ]

Dell, Ce. 1953. Release analysis - A new tool for ore dressing research. Recent Developments in Mineral Dressing. Institute of Mining and Metallurgy, London. pp. 75-84. [ Links ]

Dell, Ce. 1964. An improved release analysis procedure for determining coal washability. Journal of the Institute of Fuel, vol. 37. pp. 149-150. [ Links ]

Dobby, G.S. and Finch, J.A 1986. Flotation column scale-up and modelling. CIM Bulletin, vol. 79, no. 889. pp. 89-96. [ Links ]

Forrest, W.R., Adel, G.T., and Yoon, R.H. 1994. Characterizing coal flotation performance using release analysis. Coal Preparation, vol. 14. pp. 13-27. [ Links ]

Gorain, B.K., Franzidis, J.P., and Manlapig, E.V. 1995a. Studies on impeller type, impeller speed and air flow rate in an industrial scale flotation cell - Part 1: Effect on bubble size distribution. Minerals Engineering, vol. 8, no. 6. pp. 615-635. [ Links ]

Gorain, B.K., Franzidis, J.P., and Manlapig, E.V. 1995b. Studies on impeller type, impeller speed and air flow rate in an industrial scale flotation cell - part 2: Effect on gas holdup. Minerals Engineering, vol. 8, no. 12. pp. 1557-1570. [ Links ]

Gorain, B.K., Franzidis, J.P., and Manlapig, E.V. 1996. Studies on impeller type, impeller speed and air flow rate in an industrial scale flotation cell. Part 3: Effect on superficial gas velocity. Minerals Engineering, vol. 9, no. 6. pp. 639-654 [ Links ]

Gutierrez-Rodriguez, J.A., Purcell, R.J. and Aplan, F.F. 1984. Estimating the hydrophobicity of coal. Colloids and Surfaces, vol. 12. pp. 1-25. [ Links ]

Holuszko, M.E. and Mastalerz, M.D. 2015, Coal macerals chemistry and its implications for selectivity in coal floatability. International Journal of Coal Preparation and Utilization, vol. 35. pp. 99-110. [ Links ]

Horsley, R.M. and Smith, H.G. 1951. Principles of coal flotation. Fuel, vol. 30. p. 54. [ Links ]

Hower, J.e. and Parekh, B.K. 1986. Chemical/physical properties and marketing. Coal Preparation. Leonard, J.W. (ed.). 5th edn. AIME, Englewood, CO. pp. 16-19. [ Links ]

Hu, W.B. 1975. Separation efficiency. Journal of Non-Ferrous Metals, vol. 6. pp. 40-51 [ Links ]

Hu, W.B., Jin, R., and Bodily, D.M. 1987. Floatability evaluation of fine coal, Transactions of the AIME, vol. 282. pp. 1910-1915. [ Links ]

International Committee for Coal Petrology (ICCP). 1963. International Handbook of Coal Petrography. 2nd edn. Centre National de la Recherche Scientifique and Academy of Sciences of the USSR, Paris/Moscow. [ Links ]

International Committee for Coal Petrology, (ICCP). 1971. International Handbook of Coal Petrography. 1st Supplement to 2nd Edition. CNRS, Paris. [ Links ]

Liu, J., Holuszko, Μ., and Mastalerz, M. 2017. Applications of micro-FTIR technique in studying hydrophobicity of coal. International Journal of Coal Geology, vol. 178. pp. 74-83 [ Links ]

McClintock, W.W., Walsh, D.E., and Rao, P.D. 1995. Release analysis of a stratiform copper sulfide ore using column flotation. Minerals and Metallurgical Processing, vol. 12. pp. 112-117. [ Links ]

Mohanty, M.K., Honaker, R.Q., and Ho, K. 1998. Coal flotation washability: Development of an advanced procedure. Coal Preparation, vol. 19, no. 1. pp. 51-67 [ Links ]

Mohanty, M.K., Honaker, R.Q., and Govindaraja, B. 1999. Development of a characteristic flotation cleaning index for fine coal. International Journal of Mineral Processing, vol. 55, no 3. pp. 231-243. [ Links ]

Mohanty, M.K., Honaker, R.Q., Patwardhan, Α., and Ho, K. 1998. Coal flotation washability: An evaluation of the traditional procedures, Coal Preparation, vol. 19, no. 1-2. pp. 33-49. [ Links ]

Nicol, S.K., Bensley, C.N., Teh, K.C., and Firth, B.A. 1983. The estimation of coal flotation response. Proceedings of the Congressfor Improving Froth Flotation of Coal. Membrey, W. (ed.).Australian Coal Industry Research Laboratories. p. 116. [ Links ]

Nicol, S.K., Smitham, J.B., and Hinkley, J.T. 1994. Measurement of coal flotation efficiency using the tree flotation technique. Proceedings. of the XII International Coal Preparation Congress, Krakow, Poland. pp. 741-746. [ Links ]

Pratten, S.J., Bensley, C.N., and Nicol, S.K. 1989. An evaluation of the flotation response of coals. International Journal of Mineral Processing, vol. 27. pp. 243-262. [ Links ]

Randolph, J.M. 1997. Characterizing flotation response: A theoretical and experimental comparison of techniques. M.S. thesis, Department of Mining and Minerals Engineering, Virginia Polytechnic Institute and State University, Blacksburg, VA. [ Links ]

Sukumar, 2004. Size-density analysis of coal flotation process, M.Tech thesis, Indian School of Mines, Dhanbad, India [ Links ]

Tabosa, E., Runge, K., and Holtham, P. 2016. The effect of cell hydrodynamics on flotation performance. International Journal of Mineral Processing, vol. 156. pp. 99-107. [ Links ]

Taylor, G.H., Teichmuller, Μ., Davis, Α., Diessel, C.F.K., Littke R., and Robert, P. 1998. Organic Petrology. Gebrüder Borntraeger, Berlin. 704 pp. [ Links ]

Wang, W., Kumar, Α., Holuszko, M.E., and Mastalerz, M.D. 2017. Selection of reagents based on surface chemistry as derived from micro-FTIR mapping of coal surface to facilitate selectivity in coal flotation. International Journal of Mineral Processing/Minerals Engineering - Special Issue after COM2017. https://open.library.ubc.ca/cIRcle/collections/facultyresearchandpublications/52383/items/1.0347213 [ Links ]

Correspondence:

Correspondence:

L. Sahu

Email: lksmineral@gmail.com

Received: 25 Jan. 2018

Revised: 8 Jan. 2019

Accepted: 9 Jan. 2019

Published: June 2019