Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.119 n.5 Johannesburg May. 2019

http://dx.doi.org/10.17159/2411-9717/194/2019

PAPERS OF GENERAL INTEREST

Performance optimization of an industrial gamma activation assay system for analysing gold and rare metal ores

A. SokolovI; V. GostiloI; M. DemskyII; E. HasikovaI

IBaltic Scientific Instruments, Latvia

IICORAD, Russia

SYNOPSIS

Previously, we upgraded and implemented two gamma activation assay (GAA) systems designed to analyse the gold content in raw ores at Zarafshan laboratory, Uzbekistan, and achieved a detection limit of less than 0.05 g/t under actual industrial conditions. Having started to design a fully modern, industrial GAA system for mining companies, this paper analyses the advantages, disadvantages, and special features of all major system components that can influence the sensitivity and accuracy of the analysis. The results of a study to optimize the detector geometry and sample size are presented and the performances of the linear electron accelerator, detector array, and sample transportation system of a modern, industrial GAA system for analysing gold, silver, and rare earth elements are considered.

Keywords: gamma activation analysis; gold ore; mining.

Introduction

Gamma activation analysis (GAA) has considerable potential as a future replacement for traditional fire assay analysis in gold mining (Hoffman, Clark, and Yeager, 1998; Morse, 1977; Bourmistenko, 1986, 1981; Sammut, 2016; Tickner etal., 2017). The essence of GAA is to irradiate ore samples with high-energy gamma quanta generated by an electron linear accelerator (LINAC) and then to use a gamma spectrometer to detect the induced activity of the excited gold nuclei. The advantages of this method are discussed in detail elsewhere (Hoffman, Clark, and Yeager, 1998; Morse, 1977; Bourmistenko, 1986, 1981; Sammut, 2016; Tickner et al., 2017), where it is shown that GAA is uniquely suited to analysing ore samples when mining for gold, other precious metals, and accompanying elements.

These advantages were realized in three industrial GAA laboratories that were commissioned in Zarafshan, Uzbekistan in 1977, in Magadan, Russia in 1979, and in Batagay, Russia in 1986 (Bourmistenko, 1986; Nii Tekhnicheskoy Fiziki I Avtomatiki, n.d). In 1989, a fourth industrial GAA laboratory was commissioned at a gold mine in Tommot, Russia. However, the project was subsequently halted due to economic reasons (Moshkov and Tjamisov, 2017). Currently, only the laboratory of the Muruntau mine in Zarafshan, Uzbekistan is in operation. The gamma activation method for gold determination is widely applicable at this mine owing to its high productivity and low cost of analysis. An outstanding aspect is the performance of more than one million analyses per year.

We have previously reported the progress in developing the GAA method for industrial gold analysis at this mine (Sokolov et al., 2018a, 2017). It involves a precision two-channel gamma spectrometer based on high-purity germanium (HPGe) three-crystal detector assemblies, providing highly efficient gamma radiation detection and high-energy resolution. The system for packaging and transporting the sample containers from the loading drum, via the irradiation and detection zones to the output drum, was not altered.

Despite the fact that in both assay systems the components from the previous system manufactured in the 1970s were used, they could be updated and modified to achieve appropriate detection limits for gold. The first commissioned gamma activation assay system provided a detection limit of 0.08-0.20 g/t gold with a 15-second measurement time, depending on the barium and hafnium contents (Sokolov et al., 2018a). With the same measurement time, the second assay system had a detection limit of less than 0.05 g/t gold (Sokolov et al., 2017. Furthermore, there is the possibility to analyse silver and rare earth elements too (Sokolov et al., 2018a, 2017). Nevertheless, the error in gold determination between the two GAA systems has remained constant at 10% (Bourmistenko, 1986). This is defined by the accuracy of the provided calibration samples and the performance of the obsolescent parts that we had to use without improvement.

Gold and rare earth elements are now mined on every continent. This has led to growing interest from mining enterprises in using GAA, as well as alternative methods (Robertson and Feather, 2004)to determine the elemental concentrations in those ores. Optimizing the GAA method further will involve developing a completely modern gamma activation assay system that incorporates up-to-date technological solutions, advanced methodical support, and contemporary computer engineering. All together, this should provide a GAA that is highly sensitive, accurate, and with increased productively.

All factors that limit both the sensitivity and accuracy of the method for determining the gold concentration in ores have been published in detail in previous studies (Tickner et al., 2017). A three-standard-deviations detection limit between 60-75 parts per billion (ppb) has been demonstrated under laboratory conditions, with an accuracy of around 2.5% relative to a gold concentration of 3 ppm (parts per million).

Our present work involves analysing the performance of the modern components of the gamma activation system. Our aim is to identify the best design and technological solutions to optimize the process of analysing gold, other precious metals, and rare earth elements. As shown previously (Sokolov et al., 2018b), the obvious disadvantage of GAA is the high initial financial investment; commissioning a GAA laboratory (including construction) will cost between US$4-5 million. Although that cost should be recouped relatively quickly (1-2 years) (Sokolov et al., 2018b), considerable attention should be given to the economic aspects of developing and designing a GAA laboratory to provide the best technical performance for a reasonable financial investment. From a practical perspective, our goal is to develop and implement a third industrial GAA system for gold and accompanying elements for the mining industry based on modern elements, technological methods, and methodological concepts.

LINAC performance optimization

Analysing the characteristics of commercially available LINACs indicates that several companies are producing models that meet the energy and power requirements of GAA; that is MEVEX (Canada), L3 Communications (USA), Wuxi El Pont (China), Nuctech (China), and CORAD (Russia) (Mevex, n.d.; L3 Communications, n.d.; Wuxi El Pont, n.d.; Nuctech, n.d.; Corad, n.d.). However, the technical specifications of commercially available LINACs do not contain sufficient information about the temporal stabilities of the energy spectrum and beam power. These stabilities are very important in providing high accuracy in elemental analysis (Tickner et al., 2017).

For our GAA system, we provided a LINAC that, in our opinion, meets all the application requirements. It generates an electron beam with a maximum power of 10 kW and electron energy of 7-9 MeV, with the option of adjusting the electron energy in that range. The ability to adjust the electron energy during gold ore analysis affords ample possibility to optimize the sample irradiation conditions in order to suppress the lines of the associated elements that can overlap with gold in the GAA spectrum. This, in turn, affords higher accuracy at a lower detection limit.

To provide high operational stability, an additional circuit for electron beam stabilization was added to decrease the intensity spread to 2%. Constant inspection of the beam current and electron energy was introduced by displaying the parameters in the operator's software window. The safety and control of all the LINAC components were improved and the actual power consumed was decreased to 70 kW.

System for transporting samples

The ground ore samples for analysis should be packed in transportation containers and then brought to the GAA system. The sample will then be subjected to the gamma radiation and measurement process before being stocked. For a highly productive GAA system, the technological process should be automated. That will require an automatic system for sample/ container transportation.

At the GAA laboratory at the Muruntau mine, the ground ore samples are packed in plastic cylinders (100 mm diameter by 40 mm height; sample weight approx. 500 g) and placed in a loading drum which is loaded automatically into the system's transportation channel (Bourmistenko, 1986). The filled containers are moved on a transportation tray from the loading point to the irradiation site and then by gravity to the measurement zone. After leaving the transportation tray, the containers are loaded automatically into another drum.

The movement of the sample containers in the transportation channel is adjusted with a system of dampers that close or open the further movement in the channel. Such a simple gravity transportation system makes the entire system highly efficient. However, a three-storey building had to be constructed to separate the packaging and loading zones (third floor), irradiation zone (second floor), and the measurement and storage zones (first floor), which certainly increased the project cost.

The GAA laboratories constructed at mines in Magadan (1979) and Batagay (1986) in Russia rely on a single-storey variant, using pneumatic posts. Moreover, by using a linear transport channel, Batagay mine has implemented multiple irradiation of the samples to increase sensitivity. A horizontal sample-transportation system was used also by Tickner et al. (2017). To date, feeding the samples pneumatically in a horizontal single-storey transportation system has proved sufficiently simple and safe in a GAA system.

To transport samples in the current project, a linear motion system was selected. These highly automated systems appeared in industry over the past few decades. They represent a complex solution incorporating hardware and software for tasks that involve fast and precise motion and positioning (THK, n.d.; Thomson, n.d.; Bosch Rexroth, n.d.). Linear motion systems available in the market have a wide range of characteristics. For example, the step length can be specified from centimetres to tens of metres and the payload from grams to tons. The maximum carriage rate is 10 m/s, which in the GAA system minimizes the sample cooling time to between 1-2 seconds. A positioning accuracy of up to 10 μηι is acceptable if requested, but this has no practical impact on the measurement accuracy due to the precise mutual positioning of the detectors and the sample container. Another advantage of linear motion systems is the durability of the equipment in operation under the high loads associated with industrial applications, something that is very important for continuous operation of the GAA system. Additionally, it is easy to incorporate the linear motion systems into the automated sample measurement process.

Protective bunker

In the GAA system, the LINAC and irradiation area should be isolated from other premises by a concrete layer of biological shielding. Using a horizontal system to transport samples with linear motion systems allows us to construct a rather simple single-storey protective bunker, thereby reducing the construction cost considerably. The entire GAA system can be accommodated in this relatively small and inexpensive concrete building (see Figure 1). The protective bunker (height approx. 2.3 m) containing the 3 MeV LINAC is built directly in an existing production hangar. The bunker for the LINAC with energy of 8 MeV and a power of 10 kW will have a footprint of 7.5 χ 8 m and a height between 3-4 m, depending on the materials used.

Detection system

The characteristics of the detection system largely determine both the minimum detectable concentration and the accuracy for the measured elements. The background count rate 5(ε), together with other basic parameters of the detector (i.e. the relative registration efficiency £(ε) and the energy resolution Λ(ε)), forms a complex spectrometer parameter called the figure of merit (FoM) (Gilmore, 2008). This parameter is inversely proportional to the minimum detectable isomeric concentration at a given energy and is expressed as

where t is the live measurement time.

Equation [1] shows that the better the detector resolution and the higher the registration efficiency, the lower the minimum detectable concentration. In the spectrometer set for GAA, these two detector parameters, being in contradiction, should be optimized. The need for background reduction is especially crucial in scientific experiments (e.g. double beta decay, searching for dark matter). However, in GAA, reducing the background level in the registered spectrum decreases the minimum detectable concentration of elements and makes the measurements more accurate. The background level in the registered GAA spectrum could also be lowered by the obligatory use of passive and (sometimes) active detector shielding; however, the technical and commercial expediency of such use should be evaluated in each case.

As specified by Equation [1], the detector efficiency and energy resolution have a significant effect on the detection limit and the measurement accuracy. Over the past decades, the most precise instruments for detecting nuclear radiation in nuclear and elementary particle physics have been PGe spectrometers (Gilmore, 2008). The technology for manufacturing HPGe single-and multi-crystal detectors is mature and highly flexible, enabling detectors to be manufactured with specific energy resolutions and various registration efficiencies, thereby offering a range of registered energies (Baltic Scientific Instruments, n.d. (a)). In any configuration of HPGe detector assemblies, the crystal sizes and quantity should be defined by the optimum compromise between (i) the energy resolution, (ii) the registration sum efficiency, and (iii) the instrumental background level. This is why the design and sizes of the detector multi-crystal assemblies in GAA spectrometers should always be optimized under the sizes and shape of the sample container.

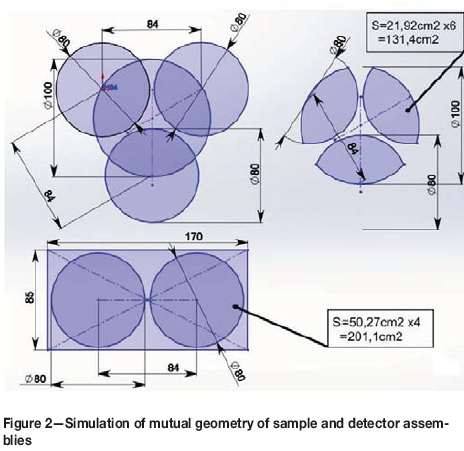

Simulation of mutual geometry of detector and sample

In previous work (Sokolov et al., (2018a, 2017) we analysed 500-g gold ore samples that were packed in plastic cylinders (100 mm diameter χ 40 mm height). The mutual geometry of the detectors and the plastic sample container is simulated in Figure 2a. To provide the maximum registration efficiency of the gamma radiation from the sample, a two-channel spectrometer was used and each of the two detector assemblies comprised three HPGe crystals of size 80 mm diameter χ 30 mm height. Despite the effective overlapping of the sample area by the two three-crystal assemblies (six crystals from both sides of the container; the total sensitive area is 6 χ 21.90 cm2 = 131.4 cm2), the redundant sizes of the crystals themselves provides the surplus capacity of the detector assembly and therefore the energy resolution is poorer than what could ideally be achieved.

To optimize the mutual geometry of the samples and detector assemblies in the developed GAA system, we use rectangular plastic containers of size 170 χ 90 χ 40 mm (Figure 2b). This enables us to increase the mass of the sample from 500 g to 1000 g. That provides a larger flux of exciting gamma radiation and in turn makes the analysis more representative. Besides, to overlap the area of that sample, it is more effective to use the two-crystal detector assembly with crystals of the former size. The total sensitive area from both sides is now 4 χ 50.265 cm2 = 201.1 cm2, i.e. an increase of 1.5 times. Using a two-crystal detector assembly instead of a three-crystal has reduced the price of the registration system by about 30%.

Ore analysis technique development in laboratory conditions

Experience gained in manufacturing and applying online XRF conveyor-belt analysers for the mining industry (Baltic Scientific Instruments, n.d. (b)) confirms the need to develop a specific technique that can provide low detection limits with high accuracy for analysis in industrial conditions. To develop the method for analysing different elements in various ores using GAA, we conducted research to simulate analysis conditions for ores from different mines. The research is based on an accelerator with energy of 8 MeV and power of 2 kW. Ore samples were crushed and packed manually in the laboratory in rectangular containers 170 χ 80 χ 35 mm in size. The operator fixes the sample manually on the carriage of the linear motion system against the accelerator target. The operator exits the radiation zone and starts the accelerator beam for the specified irradiation time (10-20 seconds). Immediately after irradiation, the sample is relocated to the detectors to register the isomeric radiation. Then, if required, the sample can again be moved to the accelerator target for multiple irradiations. The distance between the radiation and detection zones is 4 m. After the required number of irradiation measurement cycles, the operator replaces the sample manually. The time required for replacement is 5 minutes, and the total time to analyse one sample is 10 minutes. That means that during an eight-hour working shift, 48 samples can be measured.

The gold calibration samples (Sokolov et al., (2018a, 2017) were prepared in the 1970s with a certified accuracy of approximately 10%. This defined the accuracy of gold analysis under industrial conditions. Currently, calibration samples with a certified accuracy of 1% in the ppm concentration range can be prepared (Fluxana, n.d.; Scott Automation., n.d.). These calibration standards improved the accuracy considerably, and in turn the total accuracy of the developed GAA system. The measurement accuracy was evaluated on a calibration sample with a certified gold concentration of 1.08 ppm and a certified accuracy of 1% (Scott Automation, n.d.), measuring 12 spectra for that sample. The irradiation time was 10 seconds, the measurement time 15 seconds, and the time between the end of irradiation and the beginning of measurement 2.7 seconds. The region of the spectrum containing the gold line at 279 keV is shown in Figure. 3. All measurements were made using local GAA software, details of which are presented in Sokolov et al. (2018b). All calculations were performed using the measured spectral parameters in accordance to methodology (Iskroline, n.d.). The calculations provided a minimum detectable concentration of 42 ppb and an accuracy of measurement of 3.9% for 1.08 ppm gold concentration.

Conclusions

The results obtained using industrial samples show that GAA systems can provide a detection limit of less than 0.05 g/t gold with an analysis accuracy of approximately 10% and a maximum production rate of one million analyses per year (Sokolov et al., 2018a, 2017). The investigation of various modern technological solutions and the characteristics of various components of a GAA system presented here demonstrates that the sensitivity and accuracy of the GAA method could be improved further while maintaining high productivity. Errors introduced by the excitation, transportation, and registration systems, as well as the accuracy of the certified reference material, provide an overall GAA accuracy of 3.9%. By using a linear motion system and modern software, a fully automated GAA system for analysing precious metals and rare-earth elements was developed. The return on investment is within 1-2 years (Sokolov et al., (2018b).

Acknowledgements

The authors are extremely grateful to V. A. Moshkov (Atomredmetzoloto) for discussions regarding the practicalities of implementing the GAA method for ores in mining and other useful practical information.

References

Baltic Scientific Instruments. Not dated (a). http://bsi.lv/en/products/hpge-detectors-spectrometers/ [accessed 25 June 2018]. [ Links ]

Baltic Scientific Instruments. Not dated (b). http://bsi.lv/en/products/xrf-analyzers/-line-xrf-conveyor-analyzer-con-x/ [accessed 25 June 2018]. [ Links ]

Bosch Rexroth. Not dated. https://www.boschrexroth.com [accessed 25 June 2018]. [ Links ]

Bourmistenko, Y.N. 1981. Gamma activation installation for fast determination of gold and its accompanying elements in ore sample. Izotopenpraxis, vol. 17, no. 6. pp.2 41-243. [ Links ]

Bourmistenko, Y.N. 1986. Photonuclear analysis of materials composition. Energoatomizdat, Moscow. 200 pp. [in Russian]. [ Links ]

Corad Ltd. Not dated. Linear electron accelerator (LINAC) for radiation sterilization, food irradiation, shrinkable tubes irradiation and other radiation processing. http://www.corad.pro/linacs.aspx [accessed 25 June 2018]. [ Links ]

Fluxana GmbH. Not dated. https://www.fluxana.com/ [accessed 25 June 2018]. [ Links ]

Gilmore, G. 2008. Practical Gamma-Ray Spectrometry. 2nd edition. Wiley. [ Links ]

Hoffman, E.L., Clark, J.R., and Yeager, J.R. 1998. Gold analysis - fire assaying and alternative methods. Exploration and Mining Geology, vol. 7, no 1-2. pp.155-160. [ Links ]

Iskroline Inc. Not dated. https://iskroline.com/ [accessed 25 June 2018]. [ Links ]

L3 Communications (USA). Not dated. https://www.l3t.com/ [accessed 25 June 2018]. [ Links ]

Mevex (Canada). Not dated. 10 MeV system. http://mevex.com/products/10mev-system/ [accessed 25 June 2018]. [ Links ]

Morse, J.G. 1977. Nuclear Methods in Mineral Exploration and Production. Elsevier. [ Links ]

Moshkov V.A. and Tjamisov N.E. 2017. Gamma-activation analysis for gold and silver- an effective development of Soviet physicists. Zolotodobicha (Gold Mining), no. 225, August. [ Links ]

Nii Tekhnicheskoy Fiziki I Avtomatiki. Not dated. http://wvww.niitfa.ru [accessed 25 June 2018]. [ Links ]

Nuctech (China). Not dated. http://www.nuctech.com/en [accessed 25 June 2018]. [ Links ]

Robertson M.E.A and Feather C.E. 2004. Determination of gold, platinum and uranium in South African ores by high energy XRF spectrometry. X-ray Spectrometry, vol. 33. pp. 164-173. [ Links ]

Sammut, D. 2016. Gamma activation analysis. A new gold standard? Chemistry in Australia, February. pp.18-21. [ Links ]

Scott Automation. Not dated. https://www.scottautomation.com/rocklabs/products/reference-materials [accessed 25 June 2018]. [ Links ]

Sokolov, A.D., Burmistenko, Y.N., Gostilo, V.V., and Titov, V.L. 2018a. Industrial gamma-activation assay system for gold ore analysis. Minerals Engineering, vol.117, 15 January. pp 179-181. [ Links ]

Sokolov, A., Gostilo, V., Demsky, M., and Hasikova, E. 2018b. Optimization of industrial gamma-activation assay system for analysis of gold and rare metals ores. Proceedings of ALTA Gold 2018. ALTA Metallurgical Services, Perth. pp. 61-71. [ Links ]

Sokolov A.D., Demsky M.I., Gostilo V.V., Hasikova E.I., and Titov V.L. 2017. Gold ore analysis using industrial gamma-activation assay system. Proceedings of ALTA Au 2017, Perth, WA, 20-27 May. ALTA Metallurgical Services, Perth. pp.146-153. [ Links ]

THK. Not dated. http://www.thk.com [accessed 25 June 2018]. [ Links ].

Thomson. Not dated. http://www.thomsonlinear.com [accessed 25 June 2018]. [ Links ]

Tickner, J., Ganly, B. Lovric, B., and O'Dwyer, J. 2017. Improving the sensitivity and accuracy of gamma activation analysis for the rapid determination of gold in mineral ores. Applied Radiation and Isotopes: Including Data, Instrumentation and Methodsfor use in Agriculture, Industry and Medicine, vol. 122. pp. 28-36. [ Links ]

Wuxi El Pont (China). Not dated. http://www.elpont.net/en/ [accessed 25 June 2018]. [ Links ] ♦

Correspondence:

Correspondence:

A. Sokolov

Email: a.sokolov@bsi.lv

Received: 26 Jun. 2018

Revised: 30 Jan. 2019

Accepted: 15 Feb. 2019

Published: May 2019

ORCiD ID: V. Gostilo. https://orchid.org/0000-0003-0411-1309