Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.119 n.4 Johannesburg Apr. 2019

http://dx.doi.org/10.17159/2411-9717/565/2019

GEOMETALLURGICAL EDITION

Geometallurgical characterization of South Georgian complex copper-gold ores

J. LiipoI; M. HicksI; V-P. TakaloI; A. RemesI; M. TalikkaI; S. KhizanishviliII; M. NatsvlishviliII

IOutotec, Finland

IIJSC RMG Copper, Georgia

This paper was first presentedat the Furnace Tapping 2018 Conference, 15–16 October 2018, Nombolo Mdhluli Conference Centre, Kruger National Park, South Africa.

SYNOPSIS

The complexity of copper-gold ores leads to large variations in recoveries and concentrate grades in the processing plant. Detailed chemical and mineralogical studies revealed considerable variation in the ratios of chalcopyrite, chalcocite, and oxidized copper minerals in the ore types studied. The end-member ore types are chalcopyrite-dominated and chalcocite-dominated, while most of the ore types plot between these end-members. In addition, increasing amounts of copper oxide and sulphate minerals result in a decreased response to flotation. Good recoveries and concentrate grades can be achieved from the chalcopyrite-dominated ore type, while the more altered chalcocite-dominated ore type is more challenging to enrich.

Keywords: classification, element-to-mineral conversion, modal composition, grindability

Introduction

Rich Metals Group (RMG) Copper in Georgia (Figure 1) produces copper-gold concentrates from two open pit mines, Madneuli and Sakdrisi, both located in the Bolnisi mining district in South Georgia. RMG and Outotec began a cooperative project with the aim of improving the recoveries and metal grades in concentrate by gaining an increased understanding of the ore variability and developing more efficient procedures for ore blending, grinding, and flotation. This type of mineralogy-led approach has already been used for other complex ores such as iron oxide copper-gold ores (Hunt, Berry, and Bradshaw, 2011), for iron ores (Lund, Lamberg, and Lindberg, 2013), and for Kupferschiefer ore deposits (Rahfeld et al., 2018).

The project started with process audits and mineralogical and chemical characterization of process samples, followed by detailed chemical and mineralogical characterization of six different ore types with simultaneous flotation test work on the same samples. Since neither the recoveries nor the concentrate grades correlate with the head grades of the ores, the modal mineralogical composition, together with the ore hardness, proved to be the most promising approach in developing the geometallurgical classification of these ore types.

In order to further optimize the process design and improve the efficiency and value of production, the whole value chain was modelled, based on identified geometallurgical ore types, by the OreMet Optimizer module included in Outotec's HSC Chemistry® 9 software (Talikka et al., 2018).

Geology

The copper-gold mineralized domains at Madneuli and Sakdrisi mines are hosted by an upper Cretaceous sequence of volcanic-sedimentary rocks (RMG, 2016). The Madneuli deposit is characterized by a northeast-trending dome, with the limbs of the dome dipping between 10 and 40 degrees. A number of steeply dipping faults occur throughout the deposit. Strata are mainly composed of rhyodacitic pyroclastic rocks, with the core of the dome comprising coarse-grained and medium-grained tuffs. These rocks are overlain by alternating tuffs and tuffaceous sandstones. Hydrothermal alteration of the pyroclastic host rocks of the Madneuli deposit includes intense silicification, chloritization, sericitization, and sulphidization. Alteration is typically irregular and is strongest in the core of the dome, becoming less intense towards the marginal zones (Figure 2).

The Madneuli deposit displays three mineralization styles: vein-disseminated, breccia, and massive stockwork mineralization. The majority of the copper-gold mineralization is confined to areas of ubiquitous silica-rich alteration.

Mineralization within the Sakdrisi deposit is controlled by structure and lithology, comprising predominantly podlike bodies, sheeted vein sets, and low-grade stockwork. The primary mineralization is overprinted by surface weathering processes, resulting in zones of sporadic supergene enrichment.

The mineralization style represents a transitional type between volcanogenic massive sulphide (VMS) and epithermal gold type.

Ore samples and analytical methods

Each of the ore samples collected from the mill feed at Madneuli and Sakdrisi were divided into subsamples; one subsample was used for chemical analysis and mineralogical studies, and one for flotation test work. The chemical and mineralogical characterization tests were carried out at the Outotec Research Center in Pori, Finland and the locked cycle flotation tests were performed at RMG's Madneuli laboratory in South Georgia.

The locked cycle flotation tests, consisting of five cycles, were carried out at a particle size of 60-62% -74 μm using from 8 to 120 g/t potassium butyl xanthate as collector and 30 to 40g/t Oxal T-92 as frother. A pH range of 12-12.3 was maintained by addition of lime to depress pyrite. The results of the locked cycle tests reflect the variation in plant performance.

The detailed chemical assays by size include complete assays, after total dissolution, by inductively coupled plasma - optical emission spectrometry (Thermo Scientific iCAP 6000), gold and silver by fire assay, and sulphur and carbon by combustion (Eltra CS-2000). In addition, the mineralogy of copper contents was determined according to the four-stage sequential copper phase assay procedure described by Young (1974) and further developed by Outotec. This procedure enables the quantification of different copper sulphates, oxides, secondary copper sulphides, and primary copper sulphides by using the element-to-mineral conversion (EMC) method available in the HSC Chemistry® 9 Geo module (Lamberg et al., 1997; Lund, Lamberg, and Lindberg, 2013).

The main minerals and their modes of occurrence were first studied per size fraction by optical microscopy (Zeiss Axioplan 2) and X-ray diffraction (Bruker D8 Focus). Scanning electron microscopy and liberation measurements were performed using a field emission scanning electron microscope (JEOL JSM-7000F) equipped with an Oxford Instruments energy-dispersive spectrometer (X-Max 80) coupled with INCAMineral liberation measurement software (Liipo et al., 2012). The hardness of each ore type was determined according to the standard Bond grindability test (Bond, 1961).

Chemical and mineral composition of the ore types

The copper and gold contents of the six samples range from 0.28 to 0.77% Cu and 0.19 to 0.75 ppm Au. The main copper minerals are chalcopyrite, and chalcocite-group minerals, which have the general formula Cu2-xS and include chalcocite, digenite, anilite, and geerite, with variable amounts of secondary copper oxides and sulphates (Table I). Gold occurs mainly as the native element, and less often alloyed with silver. In addition, a few grains of sylvanite (AuAg)2Te4 were found. The main gangue minerals are quartz, muscovite, sericite, chlorite, kaolinite, and pyrite. Minor amounts of sphalerite, barite and siderite were also encountered.

Copper sulphides appear in all ore types in a similar manner. Chalcocite is commonly associated with pyrite, rimming or filling the fractures of pyrite grains. Chalcopyrite appears as complex particles with gangue silicates and pyrite and is replaced by chalcocite along the grain boundaries. Copper sulphides form locked particles, mainly with pyrite, and the bulk liberation of copper sulphides varies from 37% up to 85%, the particle size being 60-62% -74 μηι. Gold occurs mainly as fine-grained particles less than 2 μm in diameter, and as inclusions in pyrite and gangue silicates.

The proportion of copper carried by copper sulphides, i.e., chalcopyrite and chalcocite-group minerals, is fairly constant within all the ore types and the sulphides contain anywhere from 69 to 87% of the total copper content. However, the proportion of copper carried by chalcopyrite and chalcocite varies substantially. The proportion of copper carried by chalcopyrite varies from 8% to 62%, and by chalcocite-group minerals from 25% to 67%. The proportion of copper carried by secondary copper oxides and sulphates ranges from 13% to 31% (Table II).

Since the copper oxides and sulphates are not amenable to flotation, the actual amount of copper recoverable by flotation is lower than would be estimated based on total copper assay.

The calculated sulphide fraction (SF = pyrite + chalcopyrite + chalcocite) consists mainly of pyrite (74-95%) and the chalcopyrite and chalcocite contents range from 2.3% to 14% and 2.2% to 12%, respectively (Table III). The amount of copper in the sulphide fraction varies from 2.6 to 10.8% CuSF (Table IV).

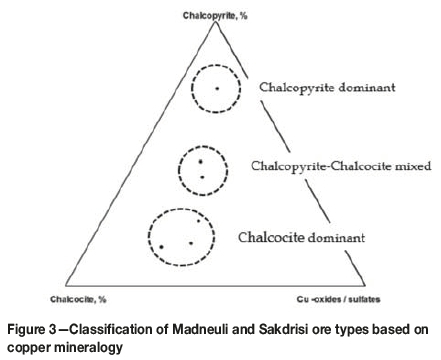

Based on their copper mineralogy, the ore types are classified into three groups: chalcopyrite-dominated, chalcocite-dominated, and mixed chalcopyrite-chalcocite (Figure 3). The chalcopyrite-dominated ore type represents less altered primary zones, and with increasing alteration, the amounts of chalcocite and secondary copper oxides increase (Figure 4).

Ore types and geometallurgical classification

The results of mineralogical characterization, ore grindability, Bond Wi, and the locked cycle flotation tests were reprocessed with HSC Chemistry® 9 Data module utilizing linear regression analysis and principal component analysis. The analysed total copper content does not have any correlation with recovery of copper, while the amount of chalcopyrite correlates positively with recovery of copper (Figure 5). The highest concentrate grades and recoveries for both copper and gold were achieved from the chalcopyrite-dominated ore type, and an increasing degree of alteration decreases both grades and recoveries (Figure 5 and Table V), as shown also by principal component analysis.

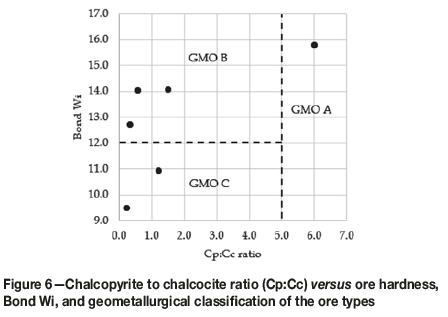

Based on this and previous studies (e.g. Hunt, Berry, and Bradshaw, 2011; Lund, Lamberg, and Lindberg, 2013; Rahfeld et al., 2018), the modal mineralogical composition, and in this case especially the modal mineralogy of copper, has been shown to be the main factor in geometallurgical characterization of complex copper-gold ores. However, based on the grindability tests, copper mineralogy alone is not adequate for geometallurgical classification and the ore hardness needs to be taken into account. Based on the mineralogy and the hardness of these ore types, three geometallurgical ore types (GMO A, GMO B, and GMO C) can be defined (Figure 6). The main characteristics of these three ore types and the test work results are presented in Table V.

Based on the HSC Chemistry® 9 process simulations and estimation of economic revenue by OreMet Optimizer simulation of these geometallurgical ore types (Talikka et al., 2018), the chalcopyrite-dominated ore type GMO A yields by far the highest net smelter return (NSR) and operating profit, despite incurring the highest operating costs. The chalcocite-dominated ore type GMO C yields the second highest NSR and operating profit, and the intermediate chalcopyrite-chalcocite mixed ore type GMO B the lowest NSR and operating profit. The simulation results clearly demonstrate that the variability in the mill feed has significant impact on the processing performance and economics of the operations.

Discussion

This study is the first attempt to develop a geometallurgical classification for the complex copper-gold ores of Madneuli and Sakdrisi. The established geometallurgical ore types, GMO A, B, and C illustrate the variation in copper mineralogy as well as variations in ore hardness and explain the metallurgical response obtained both in locked cycle tests and at the concentration plants.

Element-to-mineral conversion is a practical and inexpensive technique to calculate the modal mineralogical composition, and especially the modal mineralogy of copper of the Madneuli and Sakdrisi ore types. In this study, a large range of chemical assay data was used to establish the modal mineralogical composition of different ore types, but in practice, for geometallurgical classification purposes, only the sequential copper phase assays are required in addition to the plant's routine analyses.

The ore grindability was determined by Bond grindability tests, which can require up to 10 kg of material and are, in the authors' opinion, not as practical as the methods and quantities used in this investigation. Geometallurgical testing should be viable at a small scale and with only relatively small amounts of sample material. In addition, there should also be the possibility of using the corresponding sample for mineralogical characterization and beneficiation test work such as flotation tests.

Mwanga, Rosenkranz, and Lamberg (2015) give a short review of existing comminution test methods suitable for geometallurgical investigations. One of the methods is the Outotec Mergan mill, developed originally by Niitti (1970), and its usability as a part of a geometallurgical testing procedure was confirmed recently by Heiskari (2017) and Heiskari et al. (2018). Mergan grinding tests enable prediction of the Bond work index quickly while using only a small (2-3 kg) sample. Furthermore, the ground sample material is available for analysis of the chemical and mineral composition, and for metallurgical test work.

Conclusions

Identifying the variability within an ore deposit, and understanding the mineralogical composition and the metallurgical performance of the various ore types, are key requirements for efficient mining and minerals processing.

In this study a useful and viable method for mineralogy-led geometallurgical characterization of the Madneuli and Sakdrisi copper-gold ores was developed. Practical geometallurgy requires fast and inexpensive modal mineralogical analyses and a suitable method for determination of the ore hardness.

In this case, the element-to-mineral conversion method can provide the required modal mineral compositions which, combined with a suitable grindability testing method such as the Mergan test, enable the geometallurgical classification of individual ore samples/domains and the prediction of their metallurgical response to be developed.

Acknowledgements

We thank two anonymous referees for their valuable comments and suggestions. We would also like to thank the laboratory technicians at Outotec Research Center, Pori, for their skilful assistance in the experimental and analytical work.

References

Bond, F.C. 1961. Crushing and grinding calculations, part 1. British Chemical Engineering, vol. 6, no. 6. pp. 378-385. [ Links ]

Heiskari, H. 2017. Development of comminution test method for small ore samples. MSc thesis, Faculty of Technology, University of Oulu, Finland. [ Links ]

Heiskari, h., Kurki, P., Luukkanen, S., Sinche- Gonzalez, M., Lehto, h., and Liipo, J. 2018. Development of comminution test method for small ore samples. Minerals Engineering, vol. 130. pp. 5-11. [ Links ]

Hunt, J., Berry, R., and Bradshaw, D. 2011. Characterising chalcopyrite liberation and flotation potential: Examples from an IOCG deposit. Minerals Engineering, vol. 24. pp. 1271-1276. [ Links ]

JSC RMG. 2016. Technical report on the JSC RMG copper mine operations: Madneuli & Sakdrisi in Georgia. Unpublished report. [ Links ]

Lamberg, P., Hautala, P., Sotka, P., and Saavalainen, S. 1997. Mineralogical balances by dissolution methodology. Proceedings of Short Course on Crystal Growth in Earth Sciences, Mamede de Infesta, Portugal, 8-10 September. International Mineralogical Association. pp. 1-29. [ Links ]

Liipo, J., Lang, C., Burgess, S., Otterström, h., Person, h., and Lamberg, P. 2012. Automated mineral liberation analysis using INCAMineral. Proceedings of Process Mineralogy '12, Cape Town, South Africa, Minerals Engineering International, Falmouth, UK. pp. 1-7. [ Links ]

Lund, C., Lamberg, P., and Lindberg, T. 2013. Practical way to quantify minerals from chemical assays at Malmberget iron ore operations - an important tool for the geometallurgical program. Minerals Engineering, vol. 49. pp. 7-16. [ Links ]

Mwanga, A., Rosenkranz, J., and Lamberg, P. 2015. Testing of ore comminution behavior in the geometallurgical context-a review. Minerals, vol. 5. pp. 276-297 [ Links ]

Rahfeld, A., Kleeberg, R., Möckel, R., and Gutzmer, J. 2018. Quantitative mineralogical analysis of European Kupferschiefer ore. Minerals Engineering, vol. 115. pp. 21-32. [ Links ]

Talikka, M., Remes, A., Hicks, M., Liipo, J., Takalo, V-P., Khizanishvili, S., and Natsvlishvili, M. 2018. Copper ore variability - benefits of advanced simulation. Proceedings of Copper Cobalt Africa Conference, Livingstone, Zambia, 9-13 July 2018. Southern African Institute of Mining and Metallurgy, Johannesburg. [ Links ]

Young, R.S. 1974. Chemical Phase Analysis. Charles Griffin and Company, London. [ Links ]

Correspondence:

Correspondence:

J. Liipo

jussi.liipo@outotec.com

Received: 7 Jan. 2019

Revised: 14 Mar. 2019

Accepted: 26 Mar. 2019

Published: April 2019