Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.118 n.10 Johannesburg Oct. 2018

http://dx.doi.org/10.17159/2411-9717/2018/v118n10a2

Groundwater monitoring during underground coal gasification

J.C. van DykI, II; J. BrandI; C.A. StrydomII; F.B. WaandersIII

IAfrican Carbon Energy, South-Africa

IIChemical Resource Beneficiation, North-West University, South Africa

IIISchool of Chemical and Minerals Engineering, North-West University, South Africa

SYNOPSIS

Underground coal gasification (UCG) is a fast-emerging, in situ mining technology that provides access to low-cost energy through the utilization of coal reserves that are currently not technically or economically exploitable by conventional mining methods.

Groundwater monitoring for conventional coal mining in South Africa is well established, with SANS, ASTM, and ISO standards for the specific environment, location, and purposes. South Africa's groundwater is a critical resource that provides environmental benefits and contributes to the well-being of the citizens and economic growth. Groundwater supplies the drinking water needs of large portions of the population, and in some rural areas it represents the only source of water for domestic use. Implementation of, and adherence to, groundwater monitoring standards are thus non-negotiable.

The groundwater quality management mission, according to the Department of Water and Sanitation in South Africa, is set in the context of the water resources mission and reads as follows:

'To manage groundwater quality in an integrated and sustainable manner within the context of the NationalWater Resource Strategy and thereby to provide anadequate level of protection to groundwater resources and secure the supply of water of acceptable quality.' (SABS, 2016).

In this paper we propose fit-for-purpose groundwater monitoring standards for a commercial UCG operation. It is important to proactively prevent or minimize potential impacts on groundwater through long-term protection and monitoring plans.

Keywords: Groundwater monitoring, underground coal gasification, national standards.

Scope of study I standard proposal

The purpose of this paper is to set out a National Standard Proposal to emphasize groundwater monitoring as one of the five strategies of the 'Policy and Strategy for Groundwater Quality Management in South Africa' (Department of Water Affairs and Forestry, 2000) and to align it with the National Water Act, Act no. 36 of 1998 (Republic of South Africa, 1998).

The focus of this standard is directed solely towards groundwater monitoring during underground coal gasification (UCG). Groundwater in this context refers to water as sampled from dedicated monitoring wells around the targeted site, which will include the shallow aquifer referred to as groundwater, and water flow at the level of the underground gasifier, referred to as 'coal water'.

The period of monitoring will include:

1. Baseline monitoring before commissioning and start-up

2. Start-up and commissioning

3. Normal operation

4. Decommissioning or site closure

5. Monitoring after closure.

The proposal includes and will be limited to the following aspects:

► Groundwater

► Underground coal gasification (in situ coal mining)

► Monitoring boreholes

► Quality control,

► National standards

► Frequency of monitoring.

The proposal does not include:

► Technical specification of monitoring well design

► Monitoring well design and location (only general comments)

► Sampling methodology

► Pollution remediation

► Analytical standard per specific quality parameter

► Borehole location.

Background information

Groundwater monitoring for conventional coal mining in South Africa is well established, with specific SANS, ASTM, and ISO standards dedicated for the specific environment, location, and purposes. Coal mining can have a major impact on groundwater quantity and quality. Groundwater monitoring programmes are thus non-negotiable. The important aspect is to implement a fit-for-purpose monitoring programme for the specific technology, process, or site location. It is thus important to proactively prevent or minimize the potential impacts on groundwater through long-term protection and monitoring plans.

A successful monitoring program is one that (Barnes and Vermeulen,2007)

(1) Consists of an adequate number of wells, located at planned and strategic points

(2) Yields sufficient groundwater samples

(3) Follows a dedicated monitoring programme and quality control standard.

In order to have an efficient monitoring programme and to avoid unnecessary analysis and costs, it is also critical to determine upfront which parameters have to be monitored for the specific process and site conditions.

An overview of the coal industry in South-Africa, the future energy requirements, and a brief technical discussion on UCG, is presented to sketch the context of the proposed groundwater monitoring standard.

Utilization ofcoal in South Africa

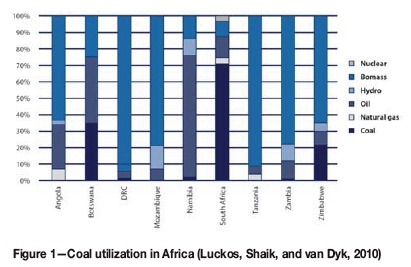

Coal is globally the most widely used primary fuel, accounting for approximately 36% of the total fuel consumption for electricity production. In South Africa, coal provides approximately 77% of the country's primary energy needs (Figure 1). This is unlikely to change significantly in the next two decades, due to the lack of suitable alternatives. Globally and in South Africa, coal will continue to be the most important fossil fuel for energy production, and with the growing energy demand the demand for coal will increase (Time for Change, n.d.).

Coal is mined in South Africa by both underground and opencast methods, with approximately 37% of production from underground and 63% from opencast mining (Time for Change, n.d.).

Many of the South-African deposits can be exploited at extremely favourable costs, and as a result, a large coalmining industry has developed (Department of Energy, 2012). The operations range from collieries that are among the largest in the world to small-scale producers. A relatively small number of large-scale producers supply coal primarily for electricity generation and synthetic fuel production. In addition to the extensive use of coal in the domestic economy, approximately 28% of South Africa's coal production is exported, mainly through the Richards Bay Coal Terminal, making South Africa the fourth-largest coal exporting country in the world.

Technologies to improve coal mining and extraction techniques have reached their peak, and according to rough predictions, there is still enough coal for the next 200 years if extraction continues at today's rate. This implies that in the near future the security of coal supplies will not be a concern. However, recovery of currently unmineable coal resources may be problematic in the long term because of the economic and ecological aspects of using this energy resource (Department of Energy, 2012). Coal utilization has always increased and forecasts indicate that in the absence of a dramatic change in policy, this trend will continue in the future. The IEA thus believes that greater efforts are needed by governments and industry to embrace cleaner and more efficient technologies to ensure that coal becomes a much cleaner source of energy in the future (YEA, 2017).

UCG is playing an increasingly important role as a cleaner and more environmentally friendly 'chemical mining' technique. This technique enables highly efficient utilization of the energy and chemical value obtained from the coal without the need for conventional mining operations, stockpiling, reclaiming, and transportation. The generation of mining wastes from overburden, discards, and ash is also avoided. Furthermore, the much-reduced underground infrastructure and elimination of the need for personnel to go underground makes UCG applicable to many deposits that would otherwise be unsafe to mine, unmineable, or sub-economic (Department of Energy, 2012). The 'UCG coal miners' are essentially 'chemical' miners, who work from the surface using drilling technology to access the coal resource and transform it into a recoverable reserve. The work environment is therefore more controllable, and safer. The shorter coal value chain from the resource in the ground to end-product enables UCG to produce lower cost energy than conventional mining.

As a practical illustration, a resource in the Free State area was reclassified from and Inferred Resource to a Measured Resource for UCG applications by Africary. An amount of 3.7 Mt (GTIS) was additionally classified as Measured, according to SAMREC (2009) and SANS 103020:2004, the South African guides to the systematic evaluation of coal resources and coal reserves. This serves as an example of utilizing a reserve that would be unmineable using conventional techniques, through applying the UCG process.

Underground coal gasification (UCG)

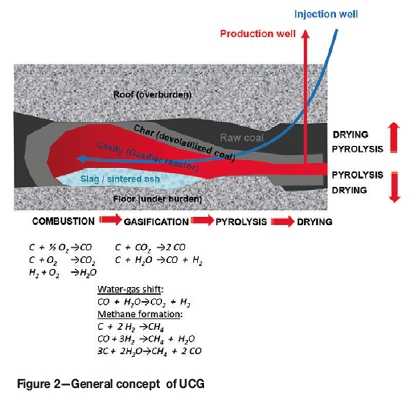

UCG is a gasification process used to produce gas from coal in situ (underground in the coal seam) by injecting air or oxygen, with or without steam, into the seam and extracting the product gas via wells drilled from the surface. UCG is a high-extraction mining method utilizing at least two boreholes (wells) that are drilled horizontally into the coal seam parallel to one another. Ambient air or air that has been enriched with oxygen is delivered to the coal seam via one or more boreholes (the injection wells) and the coal is ignited in order to start the gasification process. This may be thought of as a thermo-chemical mining process. The burning front results in high temperatures (>1000°C) that cause the coal ahead of the front to effectively reform into gas. Groundwater, augmented by water added to the injection borehole if necessary, reacts with the carbon in the coal to form a combustible gas mixture consisting mainly of carbon monoxide (CO), hydrogen (H2), and methane (CH4). The resulting synthetic gas (syngas) can be used to produce electricity, as well as chemicals, liquid fuels, hydrogen, and synthetic natural gas (Sourcewatch, n.d.). These gases are then forced out through a second borehole (the production well). Ash and other remnants of the coal remain underground in the gasifier. The gasification of coal in this manner creates a reduced coal cavity below the surface, the size of which depends on the rate of water influx from the water table, the heat content of the coal, the location and specifications of the injection and production wells, and the thickness of the coal seam.

This coal reformation takes place at high temperatures, which are created by the gasification front, and high pressure, which is caused by the build-up of hot gases in the underground gasifier. It should be noted that the pressure in the gasifier will always be lower than the hydrostatic head of the groundwater at the depth of the coal seam, which will cause the groundwater to flow slowly towards the gasifier.

UCG has lower environmental and safety impacts than traditional coal mining and power generation. The technology eliminates mine safety issues, surface damage, stockpiles of overburden and discard coal, and solid waste discharge such as ash dumps, and has lower sulphur dioxide (SO2), nitrogen oxide (NOx), and particulate (PM10) emissions.

The earliest recorded mention of the idea of underground coal gasification was in 1868. The first successful test was conducted by the Donetsk Institute of Coal Chemistry on 24 April 1934 at Lysychansk in the Soviet Union, where a local chemical plant began using the gas commercially in 1937. A number of UCG projects were established across the world after the Second World War, and UCG is now recognized globally as a technically and economically viable method of accessing deep, otherwise unrecoverable coal reserves, both on- and offshore. It has been estimated that UCG technology could effectively double the energy reserves obtained from the world's coal deposits (African Carbon Energy (Pty) Ltd , n.d.).

UCG presents certain environmental advantages over conventional coal mining. By not requiring mining, UCG can reduce the effects of issues such as acid mine runoff, mine safety, overuse of groundwater, and land reclamation. During gasification, approximately half of the sulphur, mercury, arsenic, tar, and particulates from the coal remain below surface. UGC syngas also has a higher hydrogen concentration than syngas produced on surface, giving it a potential cost advantage when used for electricity generation.

The basic UCG concept, together with the general gasification reactions (van Dyk, Keyser, and Coertzen2006; Luckos, Shaik, and van Dyk, 2010) is illustrated in Figure 2.

Groundwater monitoring at operating sites

Numerous articles on groundwater science, the impacts of industry on groundwater, and groundwater monitoring have been published and it is impossible to capture all information in this paper. However, the most critical and recent views in the literature related to groundwater and also to UCG are highlighted below.

According to Barnes and Vermeulen (2007), the coal industry impacts qualitatively and quantitatively on groundwater in two main areas:

1. Sulphur is one component in particular that contributes in a number of ways to changes in groundwater quality. When water and oxygen come into contact with a sulphide-bearing mineral such as pyrite, a reaction resulting in acid mine drainage occurs. Pyrite reacts with water and oxygen to form dissolved ferrous iron species, which with time increase the acidity of the water.

2. Deterioration of groundwater quantity is caused by the removal of water that has entered the mining operations. This result in a depression cone (decrease in hydraulic head) surrounding the gasification zone, causing dewatering of surrounding aquifers. The depression cone alters the natural flow of groundwater through the creation of paths of less resistance, which results in water entering the mining area.

In developing an analyses list, it is necessary to establish and define the objectives of the monitoring activity (i.e. baseline, construction, operational, closure, and post-closure monitoring). Conventional and UCG process-specific analyses techniques should be selected. The general chemistry of an aquifer may be used to monitor changes in the hydrogeological system surrounding a UCG plant. The monitoring of the mobility of chemical species, correlating recharge and flow zones with water quality, assessing the chemical equilibrium and kinetics of groundwater reactions, and developing contour maps and graphical plots are thus all needed to understand the flow and quality of the groundwater system. Monitoring programmes should include basic chemistry species analyses (especially important for ambient and compliance monitoring at larger sites that have the potential to be influenced by other contaminants), neighbouring facilities, and groundwater flow paths (Commonwealth of Pennsylvania, 2001).

Ahern and Frazier (1982) investigated changes in groundwater quality at various field test sites and in laboratory experiments. Their report summarizes more than 300 articles and 19 UCG field tests that were in operation or completed in the 1980s. The most significant findings and summaries related to UCG groundwater are highlighted.

1. At the Hoe Creek I monitoring network, in the Powder River Basin, Wyoming, 11 wells were drilled into the coal aquifer. Water quality samples were taken during the burn, and 3 days, 83 days, 183 days and randomly over a 25-month period after the burn. Analyses for more than 70 inorganic and organic species were carried out. The following most significant changes were observed:

a. Ammonium, boron, calcium, bromide, lithium, cyanide, magnesium, sulphate, potassium, and phenols showed at least a five-fold increase in the water in comparison to the baseline case, both within the burn zone and outside the zone.

b. Other species reported to have increased in the water samples were barium, lead, organic carbon, and volatile organics.

Most of the changes occurred within 10 ft (3 m) of the burn zone and independent of direction. Concentrations of several species increased over time at a monitoring well located 10 ft (3 m) from the burn zone, due to movement of contaminated groundwater out of the burn zone.

2. The Hoe Creek II monitoring network consisted of 14 wells drilled into the gasified coal cavity and overlying aquifer. Water quality samples were taken before the burn, during the burn, and at least five times up to 9 months after completion of the burn (Ahern and Frazier, 1982). The list of species at Hoe Creek II which increased in concentration in the groundwater closely parallels those measured at Hoe Creek I. The differences in concentration levels between the two sites can be attributed to differences in coal quality and rates of gasification.

3. Water quality data from the Hanna sites was obtained from the Hanna III test, which consisted of 12 wells drilled into the coal seam and overlying aquifer. Water quality was monitored before, during, and after operation (Ahern and Frazier,(982), and the main findings were summarized as follows:

a. Conductivity and temperature increased over baseline values in both the coal aquifer and overlying water aquifer.

b. Sodium and dissolved solids increased in all wells up to a period of 1 year after gasification.

c. Sulphate and chloride ionic concentrations decreased in all wells.

d. Aluminium concentrations increased to almost 100 times over the baseline values during the UCG operation, but rapidly decreased to the baseline values afterwards.

e. Other elements and compounds that increased during gasification were boron, copper, iron, lead, zinc, calcium, ammonia, and sulphate compounds, in agreement with both Hoe Creek I and II findings.

4. Water quality tests were also reported for the UCG tests in Fairland, Tennessee Colony, and the Big Brown sites in Texas (Ahern and Frazier, 1982). At the Fairland monitoring network four wells were drilled into the coal seam, six close-in wells to the other aquifers and 40 wells at greater distances from the burn. The water quality was monitored before the experiment, at the end of gasification, and also one year after gasification. The main findings were:

a. Concentrations of all monitored inorganic species increased during gasification, especially calcium, zinc, iron, hydrogen, magnesium, ammonium, manganese, sulphate, mercury, and boron.

b. Phenols were the principal organic species produced, but high amounts of two- and three-ring polynuclear aromatic hydrocarbons were also observed, especially during gasification.

5. In the Huntley UCG pilot operations, New Zealand, the first and most important conclusion was that there were no detrimental effects on the groundwater in the Tauranga Group aquifer by either contamination or depletion. A spike in the dissolved organic carbon (DOC) was observed at the coal seam in one well during a period of high pressure, which reverted to background levels once the pressure was reduced. Monitoring wells further away showed no response. Although a wide range of chemical components were monitored, changes in DOC proved to be the most responsive indicator of the effects of gasification (Dobbs et al., 2014). Despite similar results from the different sites at which groundwater has been monitored and specific species showing general trends, it has to be stressed that a number of factors can influence these results. The following information on the specific site has to be taken into account regarding the effect of groundwater changes.

► Coal type-the coal rank may determine the type and relative amounts of chemical species produced during a UCG process; for example, liquid hydrocarbons, phenols, etc.

► Amount of coal gasified-this may be related to the amount of chemical species generated.

► Injection agent-the chemical composition of the atmosphere in which the coal is pyrolised may influence the types of chemical species formed.

► System pressure-this factor influences the distances which volatile species can move from the burn cavity during UCG operation.

► Burn cavity temperature-the temperature affects the mineralogy of the coal ash in the burn cavity and the leachability of constituents within the ash.

► Product gas composition-the composition, together with the cavity temperature, provides a measure of the ash leachability.

► Gas losses-gases produced by UCG cause changes in the chemical equilibrium and dissolution of certain species in the surrounding water.

► Roof collapse-a collapse of overburden into the cavity can introduce material of different chemical composition into the gasification hot zone and affect movement of chemical species.

► Interconnection of aquifers-interconnection through fracturing, roof collapse, ruptured borehole casing, or by other means can change groundwater movement and the movement of chemical species.

The water quality information gathered at UCG sites is not abundant, but appears to be adequate for developing a theory that explains similarities and differences in water quality at various UCG sites. Some of the similarities and differences in water quality may be real, while others are only apparent. Real differences may result from different gasification techniques, different coal ranks, different hydrogeologies, or different baseline water quality.

Well location (not discussed in this paper) is site-specific and will differ for projects with different aims.

Proposed groundwater monitoring standard for UCG sites

Groundwater or borehole water is used without treatment for human and livestock consumption and other agricultural activities. Groundwater, as a natural source of water, cannot be directly required to adhere to the specifications of SANS 241-1, but it is recommended that any changes in water quality due to UCG activities must not decrease the quality to below the minimum standard stipulated in SANS 241-1 standard. The SANS standard is specifically cited to incorporate a standard with tighter restrictions. In summary, it is proposed that

► Baseline groundwater quality to be measured and monitored on a continuous basis

► SANS 241-1 to be used as standard to compare to the baseline quantity

► Minimum limits to be determined between a combination of (1) and (2) and the specification to be set at the determined quality values. Thus, if the baseline value for a specific property is higher compared to the baseline for drinking water as specified in SANS 241-1, then the baseline value will be set as standard; otherwise the standard stipulated in SANS 241-1 will be used.

The drinking water parameters according to SANS 241-1 shall comply with the physical, aesthetic, and chemical limits for lifetime consumption, as specified in Table I.

There are only a few chemical species in water that can lead to health problems as a result of a single exposure, except through massive accidental contamination of a drinking water supply. Moreover, experience shows that in many, but not all single exposures, the water becomes undrinkable due to unacceptable taste, odour, and appearance. Chemicals that cause adverse health effects include fluoride, arsenic, phenols, benzenes, and nitrate compounds. Human health effects have also been demonstrated in the case of lead (from domestic plumbing), while there is also concern regarding the potential extent of exposure to iron, manganese, selenium, and uranium. . These species should be taken into consideration as part of any risk assessment process (SABS, 2016).

The methods of analysis should be chosen to apply the necessary limit of quantification of SANS 241 and to be of the required accuracy and precision (SABS, 2016).

It is proposed that sampling of groundwater be conducted according to current SANS or ISO standards (Table II).

Laboratory quality control may be conducted according to the ISO 17025:2005 standard.

Table III summarizes the groundwater monitoring properties to be measured on each monitoring well (sentinel and compliance wells) on both the groundwater and coal water, as well as the measuring frequency.

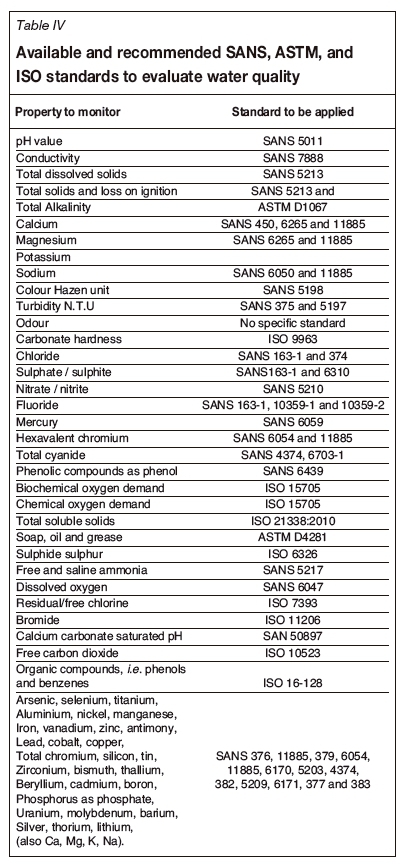

The SANS, ASTM, or ISO standards listed in Table IV are recommended for the analyses as specified in Table III and serve as a guide, but overall laboratory quality control based on ISO 17025:2005 should be adhered to.

Conclusions

The importance of water and the environmental impact that specific operations may have on groundwater necessitate that standardized monitoring and rehabilitation programmes be adopted.

UCG is a fast-emerging in situ mining technology that can be used to exploit coal resources that are currently not technically or economically viable by conventional mining methods. As such it offers significant potential to increase the world's recoverable coal resources. The UCG plant operation, however, has to be performed in an environmentally responsible manner.

Numerous studies have been published on groundwater science, the impact of industries on groundwater quality, and groundwater monitoring. Using some of these findings, it is important to develop a groundwater monitoring programme for UCG sites before the start-up of such an operation.

Groundwater monitoring in the South African mining industry for conventional coal mining is well established, with specific SANS, ASTM, and ISO standards dedicated for the specific environment, location, and purposes. The South African UCG and gas industries, however, are relatively unregulated at this stage. South Africa's groundwater is a critical resource. Utilization and implementation of groundwater monitoring standards are thus non-negotiable.

A National Standard has been proposed in this paper as a fit-for-purpose groundwater monitoring programme for commercial UCG operations.

Acknowledgements

Part of the research presented in this paper was hosted by the South African Research Chairs Initiative (SARChI) of the Department of Science and Technology and National Research Foundation of South Africa (Coal Research Chair Grant No. 86880).

Any opinion, finding or conclusion or recommendation expressed in this material is that of the author(s) and the NRF does not accept any liability in this regard.

In addition to the co-authors of this study, the following people and institutions are acknowledged for their inputs to this study.

► Dr Jennifer Pretorius, Senior Hydrologist, Golder Associates Africa (Pty) Ltd

► Michael Barnes, Hydrogeologist, Cabanga

► C. Bosman, Director CBSS Consulting

► Concepts, www.cabangaconcepts.co.za

► Sonia Maritz, Geologist, Shanduka Coal

► Johan de Korte, CSIR Consulting

► Lerato Mahalo, Standards SA

► R.J. Vreeswijk, Laboratory Manager, Buckman Africa

► J.F. Brand, CEO, African Carbon Energy

► Frikkie van Heerden, Buckman Africa

► Professor F.B. Waanders, North-West University

► Gerhard van der Linde, Associate, Divisional Leader -Groundwater, Golder Associates Africa (Pty) Ltd

► Dr Wietsche Roets, Department of Water and Sanitation

► Professor C, Strydom, North-West University

► Professor I. Dennis, North-West University

References

African Carbon Energy (Pty) Ltd. Draft EIA Report: underground coal gasification and power generation project near Theunissen. DEA Reference number: 14/12/16/3/3/2/558, EMS-9,22,23,3,4,5,26/13/11 [ Links ]

Ahern, J.J. and Frazier, J.A. 1982. Water quality changes at underground coal gasification sites - A literature review'. Water Resources Research Institute University of Wyoming, Laramie, Wyoming. [ Links ]

Barnes, M.R. and Vermeulen, P.D. 2007. Guide to groundwater monitoring for the coal industry. Institute of Groundwater Studies, University of the Free State, Bloemfontein, South Africa. [ Links ]

Commonwealth of Pennsylvania, Department of Environmental Protection. 2001. Groundwater monitoring guidance manual. http://www.depgreenport.state.pa.us/elibrary/GetDocument?docId=7616&DocNam e=GROUNDWATER%20MONITORING%20GUIDANCE%20MANUAL.PDF%20 [ Links ]

Department of Energy. 2012. Coal resources overview. Pretoria. http://wíww.energy.gov.za/fíles/coal_frame.html [ Links ]

Department of Water Affairs and Forestry. 2000. Policy and Strategy for Groundwater Quality Management in South-Africa. 1st edn. Pretoria. [ Links ]

Department of Water Affairs and Forestry. 2007. Best Practice Guideline G3. Water, Monitoring Systems, July 2007. http://www.dwaf.gov.za/Groundwater/Documents.aspx [ Links ]

Dobbs, R.M., Pearce, S.M., Gillard, G.R., Crampton, N.A., and Pattle, A.D. 2014. Deep groundwater characterisation and monitoring of a UCG pilot plant. Pattle Delamore and Partners, Christchurch, New zealand. [ Links ]

IEA. 2017. International Atomic Energy, Paris. http://www.iea.org/topics/coal/ [ Links ]

Luckos, A., Shaik, M.N., and van Dyk, J.C. 2010. Gasification and pyrolysis of coal. Handbook of Combustion. Vol. 4: Solid Fuels. Lackner, M., Winter, F., and Agarwal, A.K. (eds.). Wiley-VCH, Weinheim. pp. 325-364. [ Links ]

Republic of South Africa. 1998. National Water Act, Act No. 36 of 1998, 20 August 1998. [ Links ]

SABS. 2016. SANS 241-1:2011, Edition 1. South African National Standard, Drinking water, Part 1: Microbiological, physical, aesthetic, and chemical determinants. SABS Standards Division, Pretoria. [ Links ]

SAMREC. 2009. South African Mineral Resource Committee. The South African Code for Reporting of Exploration Results, Mineral Resources and Mineral Reserves (the SAMREC Code). 2007 Edition as amendedJuly 2009. http://www.samcode.co.za/downloads/SAMREC2009.pdf [ Links ]

Sourcewatch. Not dated. http://www.sourcewatch.org/index.php/Underground_Coal_Gasification#Recent_UCG_Projects [ Links ]

Time for Change. (Not dated). http://timeforchange.org/prediction-of-energy-consumption [ Links ]

Van Dyk, J.C., Keyser, M.J., and Coertzen, M. 2006. Syngas production from South African coal sources using Sasol-Lurgi gasifiers. International Journal of Coal Geology, vol. 65. pp. 243-253. [ Links ]

Van Wyk, D. 2014. Competent Person's geological report including the recent drilling of the defined target area of Theunissen underground gasification project. African Carbon Energy, June 2014. [ Links ] ♦

Paper received Mar. 2018

Revised paper received Jun. 2018