Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of the Southern African Institute of Mining and Metallurgy

versión On-line ISSN 2411-9717

versión impresa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.117 no.12 Johannesburg dic. 2017

Mining research and development reborn - the Mining Precinct

History tells us that, during the 1970s and 1980s, mining research and development in South Africa was at the global forefront, driven by the need to continue and grow mining, and gold in particular, at depths 'way beyond where other mining countries dared to go'.

South Africa, through the Chamber of Mines Research Organisation (COMRO) and other initiatives, became the leader in mining research in deep level, narrow-reef mining, as well as block caving mining in the diamond and copper industries. This was as a result of co-investment by Chamber of Mines member companies which, in today's money terms, amounted to some R400 million a year.

Unfortunately, during the 1990s and beyond, R&D funding reduced significantly, to the extent that, by 2014, only some R5 million was allocated by government to mining R&D. Part of the reason for this was that mining companies decided to 'go it alone', and set up their own R&D capacity and projects. Whilst this was in many cases successful, these initiatives inevitably became the victims of fluctuating price cycles, and budgetary constraints.

The world is moving forward at an alarming pace. The term Industry 4.0 is a name for the current trend of automation and data exchange, particularly in the manufacturing industries. It includes the Internet of Things, which focusses on the integration of all data into platforms that allow real time decision making. Industry 4.0 is now upon us, and our mining industry, and if our industry does not join this innovation curve, it will be left behind. Our industry is faced not only with technological and economic challenges, but also challenges of the requisite skills, water supply, depleting reserves and environmental, health and safety issues.

Nevertheless, we have opportunities, if R&D can find the answers, of mining the extensive resources that still exist unmined, either in deep operations, or in lower grades. These challenges can only be met if we establish a collaborative and enabling environment for mining R&D, innovation and the development of world-class manufacturing in the mining and beneficiation space.

The Mining Phakisa was held in 2015, as a multi-stakeholder engagement that spanned some five weeks of intensive work and debate, aimed at finding ways to re-establish the mining industry in a sustainable manner as a significant contributor to GDP.

The broad aim of Mining Phakisa was to foster growth, transformation, investment and employment preservation and creation along the entire mining value chain, in relevant input sectors and within communities affected by mining activities. This was to be achieved by conducting innovative research and development initiatives in collaboration with industry, the original equipment manufacturers (OEMs) within the mining supply chain, tertiary education institutions, government departments such as the Department of Science and Technology (DST) and Department of Trade and Industry (DTI), as well as other stakeholders in the industry.

Prior to the Phakisa, the Council for Scientific and Industrial Research (CSIR) with the support of the DST developed the South African Mining Extraction Research, Development & Innovation (SAMERDI) Strategy. In parallel, following extensive discussions between Chamber of Mines members, through the Chamber Council, there resulted a breakthrough in terms of establishing an industry open innovation platform. A forum was established that identified the main research areas or programmes, and these were then meshed into the SAMERDI strategy,

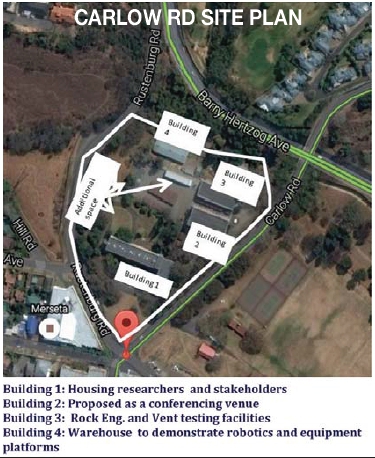

Thus, the SAMERDI strategy was adopted post-Phakisa as the mining R&D strategy that would achieve the outcomes of the Phakisa. The Mining Precinct@Carlow Road was established as the physical location from where R&D activities would be co-ordinated along with the Mining Hub to provide management oversight in the implementation of the SAMERDI strategy.

The aims of the strategy is:

'To maximize the returns from South Africa's mineral wealth through collaborative, sustainable research, development, innovation and implementation of mining technologies in a socially, environmentally and financially responsible manner that is rooted in the wellbeing of local communities and the national economy'.

Of great significance in these developments has been the financial commitment to the R&D programmes by the following:

1. The DST made the Carlow Road facility available which is now known as the Mining Precinct@Carlow Road for the coordination and facilitation of Mining R&D;

2. The DST granted, through National Treasury, an amount of R150 million over a three- year period, and which may be increased and certainly continued;

3. The DTI granted an amount of R8 million for the establishment of MEMSA (Mining Equipment Manufacturers of South Africa) as a development cluster to increase the capacity and capability of local mining equipment manufacturing, both for the local and export markets. MEMSA is housed within the Mining Precinct@Carlow Road;

4. The Chamber of Mines, in addition to initial seed funding in 2016 of some R10 million, has pledged support of R33 million for 2018.

5. Additionally, commitments have been made by the mining departments at Universities and the CSIR to participate in these programmes in a fully collaborative manner.

As a result of these developments, mining R&D has been restarted, and the Mining Precinct@Carlow Road now has some 55 occupants, ranging from interns to researchers, principal investigators, programme managers and a Mining Hub directorate. Governance has been addressed through the establishment of a steering committee, with representation from key stakeholders, operating similar to that of a board.

The R&D programmes listed below are currently funded by the DST and participating mining companies and are co-managed by the CSIR and the Chamber of Mines. The CSIR is contracted by the DST to serve as an incubator of the Mining Hub and the lead implementer of SAMERDI. This is part of a strategic journey that aims to re-establish a world-class organization as a public-private partnership that will support the industry from now until 2030, and beyond.

The SAMERDI Steering Committee is co-chaired by representatives from the DST and the Chamber of Mines, and includes the following programmes (each of which has many sub-projects):

1. Longevity of Current Mining operations (LoCM)-The focus is to increase the efficiency of extraction, improvement in occupational health and safety and reduction in costs in current mining operations.

2. Mechanized Drill and Blasting (MD&B)-To develop fully mechanized mining systems that will allow for remote drilling and blasting of narrow hard rock mines (in particular the gold and platinum mines).

3. 24/7 Non-Explosive Rock breaking (NERB)-To develop complete mining systems for continuous mining, allowing for ore extraction that is completely independent of the use of explosives.

4. Advanced Orebody Knowledge (AOK) -Mechanization and modernization of mining requires better knowledge of the orebody ahead of the mining face. This project aims to make 'glass rock' so that, instead of mining blind, an accurate 3-D real time model can be used for safety and planning.

5. Real Time Information Management Systems (RTIMS)-The inability to accurately monitor issues in real time poses a significant challenge across the entire mining process, even more so when using mechanized mining methods. Production-related issues have a direct impact on the efficiency of the mines. Using real time information for monitoring and control allows pro-active intervention that can correct deviations and unsafe conditions as they arise. Thus, the 'Internet of Things' becomes a mining imperative for the future.

6. Successful Applications of Technology MAP (SATMAP)-Modernization via automation and mechanization of South African mining processes will have significant implications on the number of people employed in the industry as well as the required skills level. This will also require significant attention to change management issues. The requirements for the upstream and downstream processes associated with mechanisation will have to be understood.

These programmes extend well beyond pure technology implementation. They obviously include many people issues, and mining process and system issues, where radical, modern ideas are required. As such, the programmes focus on people-centric solutions, that will allow mining to be conducted in a safe, healthy and ergonomically friendly environment, whereby lower grade orebodies can be mined with minimal dilution, with order of magnitude improvements in efficiency and cost effectiveness.

Less obvious, but equally important, is the need to engage with communities and other stakeholders, on issues of local industrialization, the establishment of local agri-business, and skills development. Skills development requires that not only are direct skills identified for the future, but also supervisory and management skills, as well as community skills development, and skills development within OEMs and small, medium and micro enterprises (SMMEs) are identified.

The Southern African Institute of Mining and Metallurgy (SAIMM) has been kept abreast of the developments post-Phakisa, and has organized events that support elements of the R&D programmes. It now needs to become more involved in terms of providing platforms for dissemination of research and development information, in helping to develop new R&D skills and competencies, and in supporting R&D initiatives.

A direct result of the demise of R&D over the last 20 years has been the loss of key research capacity and experience. Now that this new initiative is underway, there is a need to develop a new breed and critical mass of researchers, to take the programmes forward. These researchers are being drawn from research organisations, Universities, industry and interns. In the case of interns, these are being sourced through the databases of the Young Professionals Council, thus further increasing the support of the SAIMM.

Here, the SAIMM can also assist through its members. Members who may wish to become involved in the activities at the Mining Precinct are encouraged to support the activities of the researchers and interns in an advisory, or mentorship role, so as to rebuild much-needed capacity and capability. These people will require guidance in how to conduct their research, as well as assistance in terms of linkages to industry and its needs, while at the same time being encouraged to engage in disruptive thinking and ideas

Anyone who would like to pursue such an interest is encouraged to contact the Directors of the Mining Precinct@Carlow Road-Alastair Macfarlane (Amacfarlane@chamberofmines.org.za) or Navin Singh (NSingh1@csir.co.za) or telephonically via 011 358 0004.