Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.117 n.9 Johannesburg Sep. 2017

http://dx.doi.org/10.17159/2411-9717/2017/v117n9a1

PRESIDENTIAL ADDRESS

Presidential Address: Industry-academic collaborations - an opportunity for the minerals industry during the economic downturn

S. NdlovuI, II

ISchool of Chemical & Metallurgical Engineering, University of the Witwatersrand, Johannesburg, South Africa

IIDST/NRF SARChI: Hydrometallurgy and Sustainable Development, University of the Witwatersrand, Johannesburg, South Africa

SYNOPSIS

Although collaborative partnerships between universities and the minerals industry have been ongoing for ages, the potential benefits that can be realized through such partnerships have become increasingly important and are now more relevant than ever. This is because the growing complexity of problems such as the depletion of rich and easy-to-treat ore deposits, rising production costs, water issues, and stringent environmental regulations, coupled with increasing economic pressure and hence budget cuts, have made it difficult for companies to do the necessary research in-house in order to remain globally competitive. Similarly, universities are constantly faced with challenges such as lack of steady financial support for their research and training programmes, as well as the need to have their research commercialized or applied to solve existing industry problems so as to enhance their reputation.

Although industry-academic collaborations generally lay the foundations for pathways to knowledge and technology transfer from academia to industry and vice-versa, industry and universities are sometimes dissatisfied with the ability to extract value from the partnerships. For example, the research partnerships generally face various challenges such as failure to agree on intellectual property issues and confidentiality of joint projects. In addition, while industry in most cases seeks quick solutions to existing problems (corporate, profit-driven applied research), universities on the other hand may only value excellent research outputs in the form of publications (contribution to a public body of knowledge). As a result of differences in the motivations of universities and the industry, 'perceived' disappointing results can stem from the partnerships. Thus, one fundamental principle for developing an industry-academic collaboration into a successful and beneficial partnership lies in each partner's understanding of the working environment, missions, and motivations of the other.

This paper explores the benefits, the potential areas of collaboration, challenges, and the best-practice approach for successful collaborative partnership between the minerals industry and academic institutions, in order to increase the capacity for innovation and growth in the minerals sector.

Introduction

In the past, most mining and metallurgical companies had their own research and development units in-house. However, cost-cutting measures due to the economic downturn have led to these entities being closed or their capacity being significantly reduced. This does not mean that the need for innovation has abated. It is during the tough times of economic downturns that demand on productivity, process efficiency, sustainability, and quality is high in order for businesses to survive. Hard times are a catalyst for innovation. It is at such times that mining and metallurgical companies should have a relook at how innovation can impact their cost base, productivity, and longer term competitiveness. Innovation is a multidisciplinary venture driven by research and is impossible without the relevant researchers trained in the appropriate fields such as engineering, chemistry, finance, resource management, information technology, environmental management etc. who can contribute significantly across the different sectors of the mining and metallurgical industry. All these skills can be found at universities, and opportunities thus exist for universities to step in and provide the much-needed innovative ideas to keep the wheels of the minerals industry turning during the time when in-house research departments face challenges.

In view of the reasons stated, industry-academic partnerships have long been considered to be the most effective relationship due to the shared goal of advancing knowledge and innovation in order to better address the needs of industry, as well as contribute directly to economic growth and development. Universities and industry can thus link to merge the discovery-driven culture of universities with the innovation-driven environment of industry. As partners, they can plan strategically, invest in technological advancement, and deliver breakthrough discoveries that can fuel the industry and greatly improve the competitiveness of the country's economy.

The USA is a prime example of how discoveries, innovation, and global competitiveness can be greatly enhanced by the activities of research-oriented universities (Cohen, Nelson, and Walsh, 2002; Rosenberg and Nelson, 1994; Nelson et al., 2003). For example, Silicon Valley in California and Route 128 in the Boston area are made up of a combination of a large number of companies and major research universities (in California, the University of California at Berkeley, Stanford University, and the University of California at San Francisco; in Boston, Harvard University and MIT) (Mackun, 2013). The companies in Silicon Valley and Route 128 have realized that the only long-term sustainable source of competitive advantage is through intellectual capital, since only people think and invent. They have realized that universities, through their researchers, have the ability to develop problem-solving innovations that can shape the future of their companies and, in many cases, keep them at the leading edge of technical and environmental issues. These are all very good examples of how universities, through forward-looking research and development strategies, can assume a vital role in growing a country's economy

Advantages of industry-academic collaborations

There are several advantages of industry-academic collaborations, including the merging of fundamental and applied research. Whereas universities are more focused on the creation of fundamental knowledge, industry on the other hand is focused on innovation, i.e. applying fundamental knowledge for the development of products and technology. The role of the universities can thus be seen as stimulating and enhancing the power of research and development in industry (Rosenberg and Nelson, 1994). Clearly, there exists an interdependent relationship between the universities and industry; created knowledge has to be applied and companies need to apply knowledge to ensure profits and sustain growth. This interdependent relationship can be cultivated and maintained to enable both entities to sustain growth in their respective areas. This section looks at some of the benefits that can arise from a successful collaborative partnership between universities and industry.

Publish or perish

University researchers know that they have to publish in order to remain relevant; the well-known 'publish or perish' mantra. Successful publication of research outcomes brings attention to academic researchers and their institutions and further ensures the researcher's progress through their field. However, just as industry needs innovative ideas in order to be dynamic, maintain competitiveness, and further sustain growth, researchers need funding to sustain knowledge creation and thus they publish. In fact, knowledge creation and technology development require considerable capital investments, which have historically been provided through government subsidies to universities in South Africa, for example. However, the decreased levels of funding, as well as increased competition for budget resource allocation with other government-funded services, has forced university researchers globally to seek alternative sources of funding. From the time of Albert Einstein to the present day, alternative/external sources of funding have been at the core of a significant level of research development. For example, funding from industry can provide much support for university research activities. Such an approach can also offer a number of benefits to the researcher; such as less time spent on writing funding proposals to research funding agencies. In addition, there would be less time spent on administrative tasks such as reporting and documentation, which is typically required by research funding agencies. Thus, sustainable funding from industry would result in more time being available for research-related activities. In addition, industry-related funding can expand the focus of a basic research programme to include thinking about new innovative and applied research that can reinvigorate the research programme itself. On the other hand, government-related funding can sometimes make researchers very comfortable in a basic research domain, whereas alternative industrial sources of funding can force researchers to venture out and look at more translational work.

Universities can also benefit through some form of inkind support from the industry, such as the exploitation of synergies and complementarities of scientific and technological capabilities, intellectual capabilities, and access to cutting-edge scientific equipment that may not be readily available in the university laboratories. All these factors can enable researchers to reduce the time needed to complete a research project, thus enabling them to explore other areas of research, which could contribute to the productivity of the university through increased publications. Other benefits of industrial-academic partnerships are the potential financial rewards of patents and licenses that result from the commercialization of academic research. Development and commercial exploitation of technologies speaks to academic entrepreneurship, which can further provide a means by which universities can also fund or support other activities such as teaching and outreach programmes.

Training and capacity building

Human resource training and transfer can be one of the significant outcomes of industry-university partnerships. Universities can collaborate with industry to help reform higher education curricula, train employees for companies, and provide in-service training to students that can translate to possible employment offers once the students have graduated. The involvement of industry in curriculum development can help university programmes to respond better to industry needs. In-service training, on the other hand, can provide a complementary practical training to theoretical education. This can greatly enhance the skills of graduates and enable them to begin their careers on a much higher industry level and better footing. This has an added advantage of potentially cutting down on some of the basic graduate training programmes currently found in most companies, and further allowing the graduates to enter the market at a more productive level, as industry-ready recruits. Secondment of university faculty and research staff to industry can also equip them with multiple skills that are usually required in the academic and/or research environment. This can be achieved by allowing faculty to spend part of their sabbatical leave in industry. Similarly, the involvement of industry personnel through the adjunct faculty route can deliver a very valuable practical component that can be used to underpin theoretical aspects typically offered at universities. In a number of countries such as Australia, India, and Indonesia, cooperative training programmes in this regard have been identified as the key to sustainable development in the mining and mineral processing industry (Mooiman, Sole, and Kinneberg, 2005; Ghandi, 2014; Rajibussalim, 2016).

Innovate or perish

Companies in the mining and minerals industry are faced with many challenges, ranging from mining at depth, the exploitation of low-grade and complex ores, generation of large quantities of mining and mineral processing waste, and environmental, water, and energy issues to name a few. Such challenges require a multidisciplinary approach, which can be found at universities. Just as companies in the minerals industry can provide universities with access to cutting-edge equipment, universities can provide companies with a first-glance access to cutting-edge research that can help them solve some of the aforementioned challenges and give them a competitive edge. Through current research, university staff can also help industrial companies identify opportunities that could prove useful for the design and development of innovative processes and technologies for the future (Edmondson et al., 2012). Such outcomes do not only benefit industry, but also promote an innovative way of thinking for university academics and researchers. Of great significance, however, is that if university researchers develop a patent through company-sponsored research the company often has the first right to license the product, and thus the potential of becoming the industry leader in that field through commercialization of the product. There are a number of examples of processes and technologies currently applied in the minerals industry that have emerged from university research laboratories or similar research organizations. Examples from academia include the high pressure grinding roll (HGPR) invented by Professor Klaus Schornet and the Jameson flotation cell invented by Professor Graeme Jameson, while research organizations like Mintek in South Africa have also played a significant role in the development of processes used in the minerals industry such as the CIP/CIL process for gold recovery.

In summary and from the discussion in the above sections, it is clear that the outcomes of a successful industry-academic partnership involve mainly knowledge and technology transfer. Knowledge transfer can involve research outputs, research contracts and consultations, and personnel training and mobility. The technology transfer can involve scientific publications, technological inventions, patents, and intellectual property (IP) rights. Table I summarizes the types of industry-university links and the potential outcomes.

Research areas that could benefit from minerals industry-academic collaborations

The first reaction of most companies when faced with a tough economic climate is to cut down on costs in order to improve productivity, continuously add value to operations, and hence improve profit margins. Process optimization and operational efficiency in the mineral industry thus become crucial to securing a profitable future and global competitiveness. University research sponsored by the minerals industry can play a vital role in making mining companies productive and globally competitive by developing practical solutions to the challenges which they face. Some of the areas in which industry and universities can work together are briefly discussed below. These include process optimization, processing of low-grade and complex ores, abatement of mining and metallurgical waste, energy efficiency, and water.

Process optimization and modelling

Process optimization and modelling can facilitate the evaluation of circuits in the minerals industry operations for improved overall efficiency. Process optimization is, for example, very important during economic downturns because it can help to minimize costs and maximize throughput. In fact, process optimization should be an indispensable part of any mining strategy if the company is to survive in the competitive national and international environment. In addition, the use of simulation tools can enable the analysis of different scenarios more economically than plant trials, thus cutting down on unnecessary expenditure, an important aspect during the industry tough times.

How to get more from less - processing of low-grade and complex ores

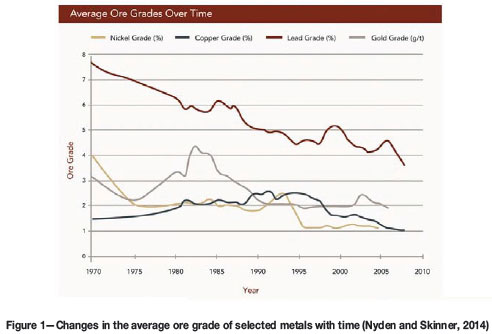

As the more accessible and high-grade mineral reserves become depleted, as shown by the trend presented in Figure 1, companies must consider processing lower grade and more complex ores in order to maintain productivity and remain competitive (Mudd 2004; International Institute for Environment and Development (IIED) and World Business Council for Sustainable Development (WBCSD), 2002). However, several factors limit the mining and extraction of metals from low-grade and complex ores. For example, extracting low-grade ore means that it takes more run-of-mine material to produce a given unit of mineral product, and this results in increased operational costs due to the mining and processing of larger volumes of ore. It also means that there is a significantly greater environmental impact due to increased land disruption, waste material, and pollution produced by mining and processing activities. Furthermore, many deposits of low-grade and complex ores are small, deep, and difficult to mine, thus entailing high extraction costs. Drilling and analytical procedures can also be very expensive. Ore 'complexity', on the other hand, has also increased in the past, with valuable components finely and sparsely distributed within the ore and often associated with a high impurities content. Due to the complex mineralogy of such ores, it is very difficult to separate each valuable component in order to produce commercially acceptable concentrates at high recovery rates. In many cases, the concentrates produced are low grade and contain high impurity levels, with a substantial proportion of the valuable components lost in the separation process.

There is, therefore, a need to either improve the efficiency of existing processes (mineral processing strategies have not changed significantly in the recent past) or develop innovative technologies that will cover the whole value chain for the processing of marginal deposits. Indeed, technological improvements that make it more economical to mine and process low-grade and complex ores can increase the global reserves of some minerals that are currently considered uneconomic due to lack of viable extraction methods. Without such an approach, limited supply of raw materials, reduced manufacturing activities, and very high prices for consumer products and technology could become a reality in the future Research areas where industry-academic partnerships can create opportunities to exploit substantial volume of complex and low-grade ores could include:

► Mining automation and control

► Cost- and energy-efficient ore extraction methods

► Improving the efficiency of existing processes and developing new processing routes

► Energy-efficient comminution

► New flotation technologies to improve selectivity and concentrate quality

► More selective reagents

► Hybrid process combining production of commercial acceptable concentrates together with low-quality concentrates

► Mitigation of environmental impacts through recovery of valuable products from mining and process wastes.

Mining and metallurgical process waste

As previously discussed, the rapid decline in high-grade and easily-processed ores has led most mining companies focusing on the extraction of metals from lower grade and more complex ores. This has subsequently been accompanied by the generation of more mining and mineral processing waste per unit of minerals extracted, as more inert materials must be physically removed, crushed, screened, processed, and residue later dumped, to yield a reasonably concentrated product. Furthermore, the waste arising from the downstream manufacturing of metallurgical products or the post-use of such metal-containing products constitutes another stream that also needs to be disposed of in a manner that does not impact adversely on the environment or on the health of local communities. This can create a significant challenge for most mining and metallurgical companies. According to Pongracz (2002): 'A thing or substance is a waste when it has no purpose [or] has fulfilled its purpose; is not used or not usable for its purpose because its performance is inadequate or its owners/ailed to use or did not intend to use it for its assigned purpose'.

This definition by Pongracz (2002) implies that waste is a temporary state (Rankin 2011) and allows for the possibility of the waste to be turned into something of value and of use. According to Lottermoser (2011) and Rankin (2011), there are a number of benefits associated with integrating techniques that utilize all streams of waste generated during the mining-to metal-production cycle. These include:

► Savings in basic raw materials, water, and energy

► Efficiency and reduction in intensive use of virgin resources

► Increased profitability through a secondary income stream

► Reduced disposal costs; the value of the recovered byproduct can offset the cost of the waste management and disposal

► Improved sustainability for the local communities.

However, in order for these waste streams to be put to good use so that the abovementioned benefits can be realized, economic technologies and processes have to be developed or existing ones re-engineered. Countries in Europe have realized the value that can result from utilizing these materials as a resource rather than just regarding them as waste. These countries have, through the European Union, invested significant funding in research on strategies for the reduction, reuse, or recycling of waste (Rankin, 2011). The research projects mainly involve a strong level of industry-academic partnership, in addition to the government involvement. The motivation for these investments of significant funds into this secondary metals industry is largely the lack of the primary raw materials. Africa, however, does not suffer from such concerns. Africa still hosts considerable unexploited mineral resources, and thus production remains largely focused on virgin material. Although no strong economic case has as yet been established for such strategies in Africa, the processing of waste to recover metals can add a complementary stream to the current primary production processes and further extend the lifespan of the natural reserves (Ndlovu, Simate, and Matinde, 2017). For example, recycling of autocatalytic converters for the recovery of platinum group metals (PGMs) can add to the large stream of PGMs currently being produced in South Africa. Research into the utilization of such metal-bearing streams, as well as integrating these materials into the primary production streams, remains largely untapped in Africa. There is, therefore, vast potential for sustainable industry-academic collaborative research and development on how to extract more value from these waste materials in order to meet future metals and materials needs.

Energy efficiency

Energy is a significant input across the whole mining value chain, and therefore energy efficiency can have a major impact on the success of any operation. This becomes increasingly the case as mining becomes more mechanized, ores more complex and of lower grade, electricity prices increase, and energy supplies become erratic, especially in most developing countries. Like any consumable commodity, energy needs to be of a set quality, at a fair market price, and the supply needs to be continuous, otherwise production is curtailed when unpredictable supply failures occur.

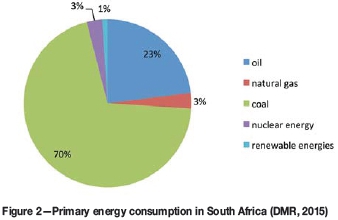

Mining and minerals processing now consumes 15% of South Africa's total electricity supply. The South African Department of Energy introduced the Energy Efficiency Strategy in 2005 (DMR, 2015). This is an energy efficiency programme targeted at reducing national energy demands. Efforts to lower energy usage and intensity across the mining value chain have thus become very important, and innovative ideas in this regard have to be continuously investigated. In addition, energy consumption and greenhouse gas emissions are closely related, since much energy is based on fossil fuel (70% of South Africa's energy supply is derived from coal (see Figure 2) (DMR, 2015). Reduction in energy consumption will not only lower the operating costs of metal production, but will also bring substantial environmental and sustainability benefits.

Many opportunities exist for research that will lead to improved energy efficiency in mining and minerals operations through better innovative, diversification (reducing the heavy dependence on coal-based supply), recycling, reuse, and substitution. Research should also focus on broadening energy supply through a mixture of sources such as biomass, biofuel, natural gas, and renewable energy technologies such as solar, wind, and hydrothermal power. Success in this area is critical, and academic-industry collaboration aimed at improving energy and process efficiencies in the minerals industries should be a key strategy for sustainable economic progress.

Water

Water is an important input to the mining and minerals industry. Large quantities are used to in exploration, drilling, mineral processing, chemical reactions, slurry transportation, cooling etc. Given the many activity streams in mining and mineral processing operations, it is vitally important for mines to first have a proper understanding of their water needs and water footprint. It is therefore crucial for any mining operation to have effective water accounting systems in place in order to identify, characterize, and quantify the available water supply, consumption, and discharge, i.e. conduct a water balance. A water balance that is integrated with appropriate operating tools or models can help a company towards a more effective utilization of water.

At the same time, mining operations are often located in areas where there are municipal, agricultural, and industrial water demands. Mining operations can, therefore, have an impact on water use at local levels. Communities close to mine sites might have concerns about availability of water -especially in dry and arid regions, security of their access to it, and the potential for water contamination. Mine-impacted water (acid mine drainage) may be discharged from mine sites and enter the groundwater or run into streams used by local communities. Acid mine drainage is of special concern in South Africa.

A reduction in water usage across an operation can immensely benefit the local community, as well as the mine, through reduced operational costs and improved efficiencies. There is, therefore, a need to identify options for life-of-mine strategies and smart water management initiatives that not only minimize the environmental impact of mining operations but also promote the steady supply of water to the mining and mineral processing operations and surrounding communities. Responsible utilization and management of water by mining companies is crucial for ensuring that their contribution to sustainable development is positive over the long term. Therefore, technology needs to be developed to find solutions to the challenges of water supply, reducing demand, and designing more efficient and effective means of water management. All these areas can benefit from industry and university collaboration.

In South Africa, there are a significant number of university-based entities that have a strong focus on water research. Most of these also work closely with the Water Research Commission and the Department of Water Affairs and Forestry. However, more funding and support from both the government and the mining industry is needed to solve the current and future challenges related to water in the industry.

Challenges to a successful partnership

Although industry-academic partnerships can lay the foundations for the building of pathways to knowledge and technology transfer, industry and universities are sometimes dissatisfied with the value obtained from these partnerships. This is because the benefits that can be realized from such a relationship are not always fully maximized. The challenges to the success of these partnerships are discussed in the next section.

The threat to blue-sky research

The biggest fear with most university researchers is that obtaining funding from industry sources sometimes diverts attention away from fundamental research. This is mainly due to the fact that industry usually does not offer funding for research that has no direct application to its own operations. Funding is usually made available to research that is relevant to the industry's priorities and goals, which can change over time. Research topics are consequently directed by the funder, and thus researchers have to adjust their thematic research areas accordingly. This type of corporate-driven applied research can drastically undermine the researchers' capacity to conduct unfettered, fundamental, curiosity-driven, long-term research with the potential to make genuine scientific leaps that can lead to technological evolution and process re-engineering.

Companies, on the other hand, feel that innovations that do not integrate seamlessly with their goals are valueless, as they require cost and effort to implement and can also result in complexity and unintended consequences further downstream. Because of the inherently uncertain return on investment, blue-sky projects are commercially unpopular and tend to be passed over in favour of potentially more profitable or practical research. In addition, companies generally prefer not to take unnecessary risks and would rather stick to proven and tested technology instead of new untested technologies, especially during tough times. On the other hand, continued investment in basic research is essential to make the necessary scientific progress if both immediate and long-term problems are to be addressed. Clearly, there needs to be a balance. Research should not focus only on the day-to-day 'bread and butter' operational issues, but must also have a vision for the future. For companies to be sustainable and globally competitive, new ways of thinking should be accommodated. The doorway to blue-sky and potential transformative technology should thus be always kept open, as answers to previously known (and even unknown) questions can lead to the scientific breakthroughs that will shape the future of technological development and advancement.

Publishing versus IP

The traditional norm for an academic researcher is to conduct research without any boundaries, for the advancement and spread of knowledge and without any necessary focus on the commercial application of the outcome. The results are then subsequently shared with peers on the relevant platforms on a wide scale for validation, recognition, and to generate research income. The information can be further used to train students, who are the future leaders of the universities and industry. This, however, is in direct contrast to the industry agenda which is more concerned with the protection of intellectual property and commercialization in order to secure its niche with a new product and increase its competitiveness. As a result, companies tend to stipulate that the research outcomes cannot be shared or published on public platforms, as they are considered to be proprietary information that needs to be protected through patents. These different mindsets can lead to high-level disagreements and legal disputes, and ultimately to a breakdown in the collaborative partnership.

Best-practice approach to a successful partnership

The challenges outlined in the preceding section clearly underline the need for both parties to understand the nature and purpose of the partnership from the outset, in order for it to be successful. Developing a framework to support the collaborative effort would go a long way towards alleviating some of the pitfalls and conflict that could potentially arise once the partnership has commenced. The next section discusses some of the approaches that can lead to a successful and sustainable industry-academic relationship.

Agree on the nature and purpose of the partnership

There are three major areas that can form the basis of industry-university partnership: strategic, operational, or transactional, and these can be related to entrepreneurial, research, and student training activities. According to Guimon, 2013), the scope and priorities of the partnership can vary according to the level of economic development of a country. In developing countries such as those found in Southern Africa, the biggest concern is a lack of capacity and limited funding available to universities. A collaborative partnership is, therefore, most likely to focus on research and student training rather than on entrepreneurial activities. This would help to build adsorptive capacity to adopt and diffuse existing technologies as well as focus on technologies that respond to local needs (Guimon 2013).

Although it is important to select the area(s) that would be of benefit to both parties in the early stages of the relationship, the purpose and nature of the relationship can evolve with time to encompass all three major areas if the partnership is successful. This is possible only if there is a shared vision on how the collaborative partnership can enable each partner to achieve what it cannot on its own. The roles and needs of each partner should, therefore, be clearly defined and understood; industry executives and university experts should meet and highlight the key questions and challenges that are of high priority to both. In addition to the clear agendas outlined above, the partnership should also be based on mutual understanding, cultural compatibility, qualified personnel, and complementary competencies and resources. The idea is to strive for a long-term partnership of equals with shared decision-making.

Establish strong communication linkages

Strong communication and engagement between the two parties can lead to a most creative and successful collaborative partnership. Giving the researchers relevant information so that they are able to appreciate the project's strategic context within the company is essential in order to produce work of significance and impact. Hence, regular meetings can lead to a better understanding of the company's needs. These regular meetings and/or informal exchanges over lectures or seminars create opportunities for dialogue, encouraging sufficient high-level exchange of information that can further stimulate other common areas of interest and thus accelerate the innovation process. In addition, ideas that might have looked unpromising in the past could trigger new insights when discussed among experts in high-level workshops or meetings. This engagement further allows for the shared agenda, vision, and expectations from the collaboration to be kept at the forefront. Furthermore, any changes or potential conflicts can be quickly noted and addressed before they cause major damage to the relationship. This approach should be considered as a journey and not a once-off approach. With such an approach, all parties can gain a tremendous amount of knowledge along the way.

Provide strong and relevant leadership

With the need for strong communication linkages in the partnership, as already indicated, it stands to reason that there should be a champion from each party to allow strategic issues to emerge and to be addressed. The collaboration can be successful only if it is managed by people who can cross the industry-university boundaries, can communicate easily, are multidisciplinary, and have a strong understanding of the university and industry working environments so as to bridge the culture gap (Edmondson et al., 2012). These individuals can easily acquire information from the other partner and disseminate it within their organization. Therefore, university staff that have some form of industrial experience and understand the business world would be better equipped to take this role from the university side. Universities in South Africa can develop a pool of academics that have worked in industry and have quick access to the top executives in industry and thus be the bridge-builders. These are traditional known as adjunct professors or lecturers. However, as part of a long-term strategy, a two-way exchange of personnel from company to university and from university to company should be encouraged to allow for a deeper understanding of the activities, culture, and strategies of both parties. The significant advantage of this is that academics who understand the industry not only enhance the research agenda of the company, but also help to produce a graduate student cohort that has a better understanding of the industry they will serve.

Invest in a long-term relationship

Industry and academia usually have different mindsets when it comes to establishing timelines for undertaking projects. This can create unrealistic expectations from both parties. Industry is driven by economic and product cycles (Pertuze et al., 2010) and thus requires the work to be undertaken at a fast pace. On the other hand, the duration an academic research project depends largely on the time period required for a graduate degree programme, i.e. a degree programme is focused on training and ensuring that the graduate acquires a certain set of skills over a specific time period. For a successful partnership, both parties need to have an understanding of the environment in which the other operates and strive to come up with a programme outline with a timeframe that will satisfy both parties.

The creation of a multilayered and long-term, flexible collaborative programme would go a long way towards addressing such issues and improving the chances of a successful collaborative outcome. In such cases, short-term and urgent research as well as operational-based projects could be undertaken by postdoctoral or tenured research fellows, while long-term projects could be undertaken on a continuous and rolling basis by graduate students at Masters and PhD levels. Student support through some form of internship programme, where the Masters and PhD students undertake part of their research at the company under joint industry and university supervision, can also improve employment possibilities and broaden the students' career paths. Such an approach would also cater for multilayered projects that not only offer solutions to day-to-day operational problems but also look at long-term strategies and further allow for blue-sky projects to be undertaken. From the above discussion, it is clear that a well-managed partnership can, over time, impact positively on teaching and learning, produce a growing number of professors, researchers, and graduate students who can think and act across the cultural divide, connect with the key research interests of a company, and work harmoniously to define big and common strategic goals (Edmondson et al., 2012). A long-term investment can also allow non-strategic partnerships to evolve into long-term strategic partnerships.

Such an approach can centre the university's creativity and talent, allow the companies to solve their current problems but at the same time give them an opportunity to glimpse into the future, and thus enable strategic decisions to be made and the development of stronger innovative capacity for long-term growth.

Build broad awareness of the partnership and give support

Generally, the strength of universities lies in proof-of-concept and early stage innovative research. There is, however, a lot of work that needs to be to be done afterwards to bring the final product to market. The industry or company partner can provide the much-needed support for the research team during this time until the research product can be exploited. The industrial partner has extended market knowledge and as a result, can help widen networks as well as grow a pool of relevant partners and sponsors so that the idea or technology can move from research scale to commercial application.

IP should not be the core focus

The biggest stumbling block to industry-academic partnership is intellectual property (IP) issues. It is very common to come across very passionate but frustrated researchers who, because of the stringent IP terms developed by their universities, have lost potential ground-breaking collaborative research work with an interested company. This is largely because some universities seem to have unrealistic expectations as to how much licensing income can be generated from patents. This can hinder the trust-building process. It is vital for universities to avoid becoming too 'corporate' as they can lose their very essence; that boundless and unfettered knowledge that companies seek from them in the first place. The role of the universities is to generate knowledge and be a source of competence and problem-solving for society, and hence the university systems should foster rather than hamper that knowledge generation process. Universities need to take note that the true value of the collaboration lies in knowledge generation and relationship building. Once trust has been built between the two parties and a long-term relationship established, commitment of greater amounts and quality of resources and responsibilities to the relationship, leading to benefits beyond patents and licensing, can be realized. However, that said, the most realistic approach to the IP issues is to have a framework agreement from the outset to avert the need for ongoing contract negotiations. Addendums can then be attached to the agreement as the partnership evolves.

From the discussion in this section, it is clear that a partnership can be described as successful if it promotes innovation, entails strong commitment from both parties through a shared strategic vision, and enhances the impact and effectiveness of action through combined and efficient use of resources (Buckley-Golder et al., 2017). The next section looks at some of the initiatives to foster industry-academic partnerships in South Africa.

Initiatives to foster industry-academic partnerships in South Africa

South Africa has embarked on a number of initiatives to increase research capacity in the minerals industry and at universities. These include the creation of centres of excellence, research chairs, and research groups. The centers of excellence mostly comprise dedicated teams of specialists with comprehensive competencies. They are designed to integrate knowledge produced by universities with industry expertise, thus stimulating the emergence of an innovative culture and, utilizing government support, to create strategic synergies that boost economic growth. The research chairs and research groups are designed to build human and research capacity for industry. All these initiatives obtain their base funding mainly through the Department of Science and Technology (DST) and the National Research Foundation (NRF). However, as they grow, they can leverage funding through other sources.

It is important to note, however, that it is not only the government that has been at the forefront in promoting strategies for innovation and growth in the minerals industry. The minerals industry in South Africa has also established the South African Minerals to Metals Research Institute (SAMMRI). This is a group of mining-related companies that, through a collaborative partnership with the DST, have come together and raised funding for research projects in areas believed to be of key importance to the South African minerals industry. These projects are carried out at South African universities. SAMMRI offers universities the prospect of research funding over a longer term than is normally expected for short-term industry projects. This is essential for establishing viable centres of expertise and for funding postgraduates over the full terms of their projects. Research can also be focused on pre-competitive areas that would minimize the problems of IP that plague current industry-university research contracts. All these efforts should intensify technology transfer and commercialization as well as attract venture capital and other sources of private investment.

Conclusion

The key to success during an economic downturn is the development and application of innovative, cost-effective exploration, mining, and mineral processing technologies that can ensure sustainability and return on investment. This paper has highlighted the fact that industry- academic partnerships can go a long way towards facilitating such achievements during these periods. The major benefits that can be gained from such a partnership are in three distinct areas; student training, research, and entrepreneurial activities, which can lead to the transfer of both technology and knowledge. These various activities can, through successful and credible industry-university interaction, intensify the relevance of research and education programmes, advance the scientific knowledge base, facilitate research discoveries and accelerate the application of new discoveries, and achieve beneficial results for society more readily than when the two sectors work in isolation.

A successful and long-term partnership can be established if certain basic principles are adhered to. These include establishing and understanding the nature of collaboration and respecting each other's work environments, culture, goals, and objectives. In this regard, the use of the right people at the right level, and those who have worked in both industry and academia, can help build bridges between the two environments. Communication between the two parties in each other's language is also essential, and continuous dialogue between academia and industry needs to be promoted in order to build the trust that is essential for a long-term relationship. At the same time, a more sustainable relationship is fostered by enabling students and academics to gain experience in business settings and industrial professionals to work in academic settings in order to build intercultural understanding and promote the crosspollination of ideas.

Legal issues should not stand in the way of the success of the partnership, and legal agreements that are acceptable to both parties should be defined from the outset. The partnership must understand that academia's primary function is education, learning, research, and knowledge generation, while that of business is to supply products and services for societal needs with an economic return. These two primary functions need not be mutually exclusive or incompatible.

All these abovementioned strategies can go a long way towards ensuring that industry and academics work together to help the minerals industry continue to function profitably, even during tough economic times.

References

Buckley-Golder, D., Way, D., Glover, M., Lindsay, C., Coates, I., Maughan, R., Robertson, D., Mitchell, T., Davies, J., and Hand, J. 2017. Best practice strategies for successful innovation through university-business collaboration. National Centre for Universities and Business. http://www.innovationalliance.eu/en/wp-content/uploads/2017/02/01-bps-successful-innovation.pdf [accessed July 2017]. [ Links ]

Cohen, W.M., Nelson, R.R., and Walsh, J.P. 2002. Links and impacts: The influence of public research on industrial R&D. Management Science, vol. 48, no. 1 pp. 1-23. [ Links ]

Department of Mineral Resources. 2015. South Africa's Mineral Industry 2013/2014. Pretoria. [ Links ]

Edmondson, G., Valigra, L., Kenward, M., Hudson, R.L., and Belfield, H. 2012. Making university-industry partnerships work: lessons from successful collaborators. Science Business Innovation Board AISBL. http://www.sciencebusiness.net/assets/94fe6d15-5432-4cf9-a656-633248e63541.pdf [accessed July 2017]. [ Links ]

Gandhi, M.M 2014. Industry-academia collaboration in India: Recent initiatives, issues, challenges, opportunities and strategies. The Business & Management Review, vol. 5, no. 2. pp. 45-67. [ Links ]

Guimon, J. 2013. Promoting university-industry collaboration in developing countries. Innovation Policy Platform (Policy Brief), 111. World Bank. http://innovationpolicyplatform.org/sites/default/files/rdf_imported_documents/Promoting_UniversityIndustryCollaborationInDevelopingCountries.pdf [accessed July 2017]. [ Links ]

IIED and WBCSD. 2002. Breaking new ground: mining, minerals and sustainable development. Earthscan, London, UK. [ Links ]

Lottermoser, B.G. 2011. Recycling, reuse and rehabilitation of mine wastes. Elements, vol. 7. pp. 405-410. [ Links ]

Mooimana, M.B., Sole, K.C., and Kinneberg, D.J. 2005. Challenging the traditional hydrometallurgy curriculum-an industry perspective. Hydrometallurgy, vol. 79. pp. 80-88. [ Links ]

Mudd, G.M. 2004. Sustainable mining: an evaluation of changing ore grades and waste volumes. Proceedings of the First International Conference on Sustainability Engineering & Science, Auckland, New Zealand, 6-9 July 2004. Institution of Professional Engineers of New Zealand. pp. 1-13. [ Links ]

Mackun, P. 2013. Silicon Valley and Route 128: Two faces of the American technopolis. http://www.netvalley.com/silicon_valley/Silicon_Valley_and_Route_128.html [accessed July 2017]. [ Links ]

Ndlovu, S., Simate, G.S., and Matinde, E. 2017. Waste Production and Utilization in the Metal Extraction Industry. CRC Press, Taylor and Francis Group, Boca Raton, FL. [ Links ]

Nelson, R., Mowery, D.C., Sampat B., and Ziedonis, A. 2003. The ivory tower and industrial innovation: university-industry technology transfer before and after the Bayh-Dole Act. Stanford University Press. [ Links ]

Nyden, M. and Skinner, B. 2014. New thinking needed on costly mining as ores get less rich. http://theconversation.com/new-thinking-needed-on-costly-mining-as-ores-get-less-rich-21888 [accessed July 2017]. [ Links ]

Pertuze, J.A., Calde, E.S. Greitzer, E.M., and Lucas. W.A. 2010. Best practices for industry-university collaboration. Sloan Management Review, vol. 51, no. 4. pp. 83-90. [ Links ]

Panarina, E. 2015. University-industry partnership as a key strategy for innovative sustainable economic growth. Journal of International Business Research and Marketing, vol. 1, no. 1. pp. 24-27. [ Links ]

Potočnik, J. and Verheugen, G. 2007. Improving knowledge transfer between research institutions and industry across Europe. European Commission. http://ec.europa.eu/invest-inresearch/pdf/download_en/knowledge_transfe_07.pdf [accessed July 2017]. [ Links ]

Pongracz, E. 2002. Redefining the concept of waste and waste management: evolving the theory of waste management. http://herkules.oulu.fi/isbn9514268210 [accessed July 2017]. [ Links ]

Rajibussalim, S.T. and Pillay, H. 2016. Realisation of university-industry collaboration through industry-based learning at Indonesian higher education. INTED2016. Proceedings of the 10th International Technology, Education and Development Conference, Valencia, Spain, 7-9 March 2016. International Academy of Technology, Education and Development, Valencia. pp. 3853-3863. [ Links ]

Rankin, W.J. 2011. Minerals, Metals and Sustainability: Meeting the Future Materials Needs. CSIRO Publishing, Australia. [ Links ]

Rosenberg, N. and Nelson, R.R. 1994. American universities and technical advances in industry. Research Policy, vol. 23, no. 3. pp. 323-348. [ Links ]