Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.117 n.7 Johannesburg Jul. 2017

http://dx.doi.org/10.17159/2411-9717/2017/v117n7a13

PAPERS OF GENERAL INTEREST

Further development of a chemistry proxy for geometallurgical modelling at the Mogalakwena mine

R.P. SchouwstraI; D.V. de VauxII; Q. SnymanIII

IIndependent Consultant, previously Anglo American Technical Solutions Research, South Africa

IIIndependent Mineral Processor, previously Anglo American Technical Solutions Research, South Africa

IIIAnglo American Platinum, South Africa

SYNOPSIS

The Mogalakwena platinum mine is Anglo American Platinum's flagship opencast operation and has been the focus of numerous optimization studies. The initial outcomes of a geometallurgical programme were reported on in 2013. This paper further describes the development of a geochemical proxy to identify different ore types at the operation and link these with various metallurgical parameters, with the aim of optimizing the value chain. At Mogalakwena, all blast-hole samples are submitted for chemical analysis by XRF prior to blasting, thus allowing the ore to be stockpiled and treated according to grade. This paper demonstrates that it would be possible to use the chemical data to stockpile and process ores according to ore type (rock type and grade), since preliminary results indicate that the metallurgical characteristics (e.g.hardness, flotation characteristics, rheology, etc.) are linked to rock composition, which defines rock types. This investigation formed part of the geometallurgical programme at Mogalakwena. The final objective of the programme focuses on risk mitigation with improved production forecasts and full implementation of the principles of geometallurgy, resulting in the optimization of metallurgical treatment and adding value to the bottom line.

Keywords: Platreef, geometallurgy, geochemistry, domains, discriminant analyses, ore type.

Introduction

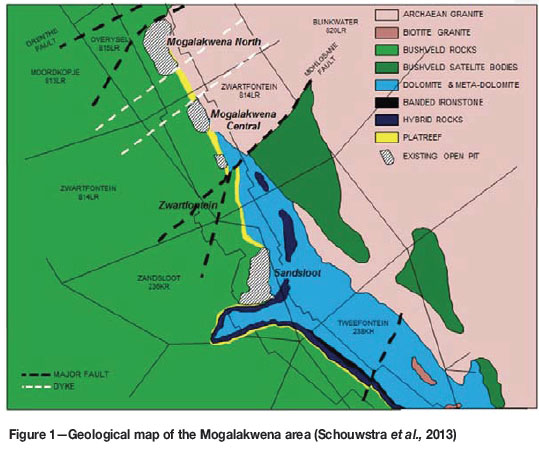

Various studies of the Platreef, in the northern limb of the Bushveld Complex, have highlighted the complexity of the reef and its mineralization (Wagner, 1926; White, 1994; Kinnaird et al., 2005; Holwell, 2006; Holwell and McDonald, 2006). Most studies have focused on the southern exposures - the major mining area during the earlier years of mining the Platreef, with a smaller number of studies undertaken on the areas to the north. In the southern area the Platreef rests on the sediments of the Transvaal Supergroup (banded iron formation and dolomites), whereas further north the footwall to the reef consists of granofels and Archaean granites (Figure 1).

As described by Schouwstra et al. (2013) the footwall to the reef has had a major impact on the Platreef composition, resulting in the presence of various ore types, each with certain metallurgical characteristics. The study by Schouwstra et al. (2013) described the dominance of four major ore types based on abundance and impact on metallurgical performance (resistance to grinding, flotation characteristics, rheology, etc.). These are:

► Pyroxenite, described by Holwell and McDonald (2006) as the best preserved 'primary' style of mineralization of the Platreef. The mine geologists use the term 'feldspathic pyroxenite' where the feldspar content is more than 10%. This definition is not internationally recognized, and Nex et al. (2006) propose to limit the use of the term to rocks in which the feldspar occurs interstitial to the pyroxene, rather than in a cumulus texture. They recommend the restriction of this term to material containing less than 20% feldspar. At higher feldspar contents, the rock should be classified as a melanorite or noriite. Pyroxenite is the dominant ore type at the Mogalakwena North operation and exhibits favourable metallurgical characteristics

► Parapyroxenite, compositionally a highly variable rock type, both in mineral content and appearance. This classification is also not an internationally accepted rock term. Originally the term was used to describe a hybrid pyroxenite resulting from the assimilation of copious amounts of footwall (dolomite) by the intruding Bushveld magma, but over the years the term parapyroxenite has been applied more frequently to describe rock types that are highly altered and difficult to identify. The wide variation in chemical and mineralogical composition results in significant variation in metallurgical characteristics. Schouwstra et al. (2013) proposed subdividing the group into a high- and a low-calcium component (reflected mineralogically in the abundance of diopside). The metallurgical characteristics of the parapyroxenite grouping are also highly variable, and it was postulated that by dividing the group in a highand a low-Ca subcategory the link to metallurgical characteristics could be improved

► Calc-silicate, basically a skarn rock resulting from dolomite-magma interaction. It displays typical metamorphic effects and is characterized by high contents of calcium-rich minerals (diopside, garnets, wollastonite, etc.). This rock type occurs at the footwall of the reef but is also present as rafts higher up in the reef stratigraphy. The contact with the pyroxenite is usually gradational via an intermediate zone of parapyroxenite. Both the calc-silicate and parapyroxenite are more common where the footwall consists of dolomite (the Sandsloot mining area). According to the information available, the calc-silicate has very poor metallurgical characteristics and is usually stockpiled

► Serpentinites are described as being fairly common in close proximity to major discontinuities such as the Drenthe and Mohlosane River faults. Mineralogical characterization indicated that many of the serpentinites contain less than 50% serpentine, whereas in other cases chlorite is the more abundant mineral phase (chloritization). However, there is no doubt that these rocks are highly altered and contain large amounts of hydrated magnesium silicate minerals. Available information indicates that the presence of large amounts of altered silicates adversely affects the rheology of the ore during processing.

As mentioned earlier, the footwall rocks are variable, with dolomite prominent in the southern areas of the Mogalakwena operations and granites and granofelses occurring in the north. The footwall rocks exhibit sporadic mineralization, normally associated with veining.

The hangingwall rocks consist of norites and gabbronorites and may also contain mineralization. Where mineralized, the norite is known as a hybrid norite.

Most of the mineralization can be described as disseminated sulphides with associated platinum group minerals (PGMs), although high sulphide grades do not necessarily indicate high platinum group element (PGE) values (Holwell and McDonald, 2006). There is also no clear link between rock type and PGE grade, with all rock types containing high and low grades, as well as barren areas.

More detailed descriptions of the mineralogy of the various rock types is given in Schouwstra et al. (2013).

The use of quantitative XRD to classify rock types

Given the difficulty of identifying the various rock types in hand specimen, especially the more altered or hybrid rock types, Schouwstra et al. (2013) used a combination of geochemistry and quantitative X-ray diffraction (XRD) to classify the various rock types. If it is possible to use chemistry as an indication or rock type and establish a link between rock type and metallurgical characteristics, then chemistry can be used as a direct indicator (or proxy) of metallurgical behaviour (ore type) - see Figure 2.

Quantitative XRD data was used to classify more than 200 samples into the different rock types, based on the following constraints.

► Pyroxenite group: mainly enstatite pyroxene, minor amounts of diopside, and less than 20% feldspar (higher feldspar contents would move the sample into the norite group)

► Parapyroxenite group: substantial amounts of diopside and other calcium-rich minerals (garnet, amphibole, etc.). A range of 15 to 25% diopside set the boundaries for the low-Ca parapyroxenites, whereas a diopside content of between 25 and 35% placed the sample in the high-Ca parapyroxenite class

► Calc-silicate group: samples containing in excess of 35% diopside were classified as calc-silicates

► Serpentinite: rocks containing more than 50% hydrated silicates such as serpentine and chlorite

► Granite and granofels (footwall): these rocks were easy to recognize from the high quartz and feldspar contents

► Norite (hangingwall): high plagioclase feldspar contents, with lesser amounts of pyroxene (mainly enstatite).

Although these constraints result in artificial boundaries and combine different rock groups (i.e. pyroxenite and feldspathic pyroxenite) into a single class, the classification is consistent and provides a framework for linking in various metallurgical characteristics. As such, the classification should not be seen as a geological tool, but rather as an initial geometallurgical domain classification.

After the rock classification by quantitative XRD, a discriminant analysis of the chemical data by X-ray fluorescence (XRF) was performed to establish whether the chemical data could explain the differences recognized by XRD.

Discriminant analysis

Discriminant analysis is a statistical technique that is used to determine which variables discriminate between two or more naturally occurring groups (Hill and Lewicki, 2006). In this case the groups were the rock types as discussed above, and the variables were the concentrations of the oxides of calcium, magnesium, and iron, and alumina and silica.

In the case of two groups and a single variable, identifying whether the variable does discriminate between the groups is relatively trivial. As the number of groups and variables increases, a single variable may not adequately discriminate between groups, but rather a combination of variables may be needed. The analysis therefore produces a new set of variables or roots, each of which is a linear function of the original variables in the analysis and has the following form:

where a is a constant, bl to bm are regression coefficients, and xl to xm are the original variable values.

If there are more than two groups, then more than one discriminant function can be estimated. The maximum number of functions is equal to the number of groups minus l, or the number of variables, whichever is smaller.

In the examples presented below, Statistica software was used for the analyses and some of the graphical presentations.

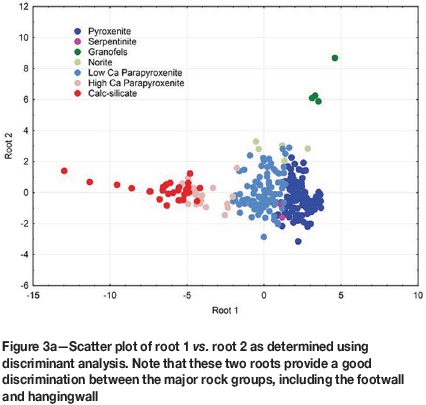

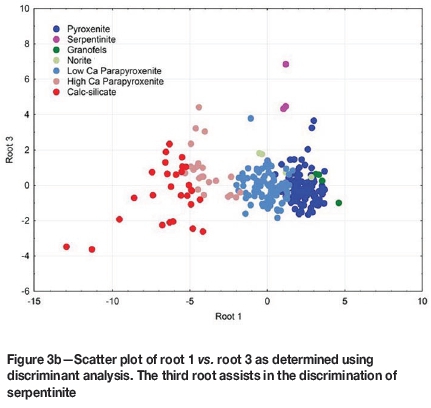

In the case of the Platreef rocks, seven classes (cf. Figure 3) and five variables (CaO, MgO, Fe2O3, Al2O3, and SiO2) were entered into the analysis and five roots were produced. Roots l, 2, and 3 are plotted against each other in Figures 3a and 3b.

From an inspection of the two figures the following is evident:

► Very distinct groups or clusters are visible in the plots, indicating the significant potential of chemistry to discriminate between the groups

► Root l provides a good discrimination between calc-silicate, high- and low-calcium parapyroxenite, and pyroxenite

► Root 2 discriminates between the above groups and granofels very well

► Root 2 discriminates between the first four groups and norite fairly well

► Root 2 does not discriminate between the pyroxenites, parapyroxenites, and calc-silicates.

► There is no discrimination of serpentinite from roots 1 or 2

► Root 3 provides discrimination for serpentinite.

As it turns out, root 1 is a strong function of CaO, as would be expected (Schouwstra et al., 2013).

Root 1 accounts for 84.6 % of the discrimination between the rock types, root 2 a further 9.7%, and root 3 a further 4.5%. The remaining roots 4 and 5 contribute the remaining 1.2% and have not been plotted in Figure 3. These results indicate that routine XRF data can most likely be used to map the distribution of rock types in the mining area without the need for detailed mineralogical analysis. To test this approach, additional data-sets were made available by the Anglo American Platinum geology department for classification.

Classification of new data

Having performed the analysis on a set of classified data, the question then arises to what extent this technique can classify new samples based on their whole-rock chemistry. This would provide a quick computational method of classifying data robustly and consistently without any human error. Whether the classification is, strictly speaking, geologically or mineralogically correct is irrelevant if the subsequent classification can be linked to metallurgical performance in a consistent way. Initially, the scatter plots as described above were used to produce algorithms that would classify new samples based on where their calculated roots fell on these plots. This enabled a visualization of how the samples were distributed in the root 1, 2, 3 space and is useful in demonstrating the concept.

A more robust and computationally sound technique is to use the classification functions that are produced by the analysis to calculate the distances between each of the new data-sets and the arithmetic means of each of the categorized classes in the multi-dimensional space defined by the roots. It then follows that the class mean that lies closest to the new data-point defines the class of that new data-point. This is easily calculated on a spreadsheet.

The same approach can be applied to reclassify the original data-set so as to provide information on the goodness of fit of the original model. Using this approach, 89% of the samples were predicted correctly by the model. The worst classification was for norite, which had a success rate of 60%, but as there were only five data-points, one of which was identified as pyroxenite and another as low-calcium parapyroxenite, and as both of these ore types show similar metallurgical responses, this is not a cause for concern.

The other concern with the original algorithm is that when it is applied to bulk historical data obtained from operational sampling there are a significant number of datapoints whose roots plot outside of the areas defined by the original XRD data-set. These are classified as unknown when the original algorithm is applied, but if the classification function approach is used it will force a fit into a classification which might or might not be correct. For this reason it is strongly recommended that although the model is robust, more classification work should be done on these 'unknown' samples to correctly identify them and then tune the classification functions accordingly. This process would improve the accuracy of the model with time, but this does not mean that versions of the model could not be implemented immediately and useful information obtained.

Testing the results of the discriminant analysis against geological information

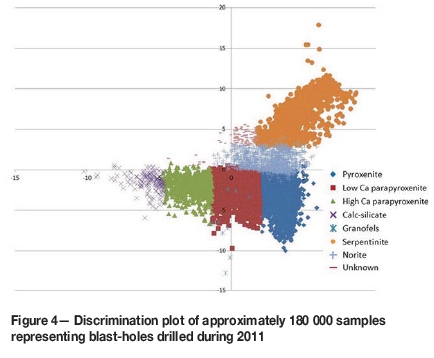

For grade control and stockpiling purposes, all blast-hole samples from the Mogalakwena mine are sent to Anglo American Platinum's Eastern Bushveld Regional Laboratory for chemical analysis. Using a sampling interval of 2.5 m, each blast-hole representing bench thickness provides six samples for PGE analysis (by Sparc), as well as Cu, Ni, and S by XRF. A full XRF scan of the samples also provides quantitative information on the silicate-type compounds. At the start of the project, XRF analyses of approximately 180 000 sample points, representing blast-holes drilled in 2011, were provided for model testing. This data was used to classify the samples into their various rock types using the scatterplot-derived algorithms described earlier (Figure 4 -Schouwstra, 2013). Note that a number of samples are classified as unknown. Many of these are close to the norite-granite/granofels classification. The unknown category is most likely a reflection of the fact that only a few hangingwall and footwall samples were available during development of the discriminate analysis.

The calculated rock type classes were then compared to the geological model based on the descriptions and logs from the mine geologists (Figure 5). Note that rock discrimination by chemistry does not take textural characteristics such as grain size, foliation, brecciation, etc.) into account, and granofels (gneiss) and granite are therefore defined as one rock type. Also note that the chemical discrimination reduces the number of rocks to seven classes compared to the 14 common rock types used by the mine geologists.

Figure 5 visually demonstrates agreement between the reef package (pyroxenite, parapyroxenite, calc-silicate, and serpentinite), hangingwall, and footwall between the geological model and the rock type discrimination based on XRF data.

For further testing, a chemical data-set of over 50 000 samples comprising several benches was compared with geological data. Table I summarizes the data and compares the results of the chemical classification to the data from the geological model.

It is evident that there are some significant differences between the two methods. Notably, the distribution of samples classified as norite is considerably more than that identified by geologists. With the main differentiation based on the abundance of pyroxene vs. feldspar, it is quite possible that a number of high-feldspar pyroxenites (the so-called feldspathic pyroxenites) might have been classed as norites. On the other hand, the geological classification of these samples as feldspathic pyroxenites might be incorrect.

The percentage of pyroxenite classification by chemistry is considerably lower than that identified by geological means. As mentioned earlier, some of the norites might belong with this group. However, if the group classified as low-Ca parapyroxenites is added to the pyroxene group the difference from the geological distribution is reduced significantly. The chemical differentiation between pyroxenite and low-Ca parapyroxenite is based on the amount of diopside present (which is reflected in the Ca content) and is thus an artificial boundary. The visual determination of the presence of a certain percentage of diopside is difficult, especially where the texture is fine-grained. The percentage high-Ca parapyroxenite corresponds with the geological classification of parapyroxenites and perhaps indicates that this highly metasomatosed rock is easier to identify.

Calc-silicate is scarce at the Mogakwena North operation, as reflected by both the chemical classification and the geological identification of this rock group. The Mogalakwena North operation contains very little serpentinite. Many samples described as serpentinite are very fine-grained and altered pyroxenite and parapyroxenite. In most cases, the alteration to the hydrated magnesium silicates (including serpentine and chlorite) is much less than 50%, putting the classification by visual means in question.

As the Mogalakwena North operation is characterized by a high percentage of pyroxenites the exercise was repeated on the Sandsloot operation (further to the south), which contain a higher percentage of parapyroxenites and calc-silicates (Table II).

As seen in the comparison with the Mogalakwena North blast-hole samples, the visual differentiation of the pyroxenite-parapyroxenite group is challenging and the results differ from the chemical classification. The combination of the pyroxenite and low-Ca parapyroxenite groups gives a similar distribution to that of the geologically identified pyroxenite group, whereas the high-Ca parapyroxenite distribution corresponds to that of the parapyroxenite as per the geological model. The amount of calc-silicate present (as calculated from the XRF data) is significantly higher than that in the geological model. No serpentinites were identified by either means.

Although the chemical classification on the blast-hole samples from Mogalakwena North and Sandsloot differs from that supplied by the geologists (visual identification), it is difficult to assess which one better reflects the real rock type distribution. Since the primary aim was to use chemistry as a proxy for ore type, a perfect fit with the geological model is not required-the chemical classification highlights differences in the distribution of the various rock components and delineates zones that are similar in composition. The chemical classification is well-defined and will be consistent as it is based on a quantitative chemical analysis. Figure 6 demonstrates the consistency in chemical classification vs. that achieved by visual identification. The figure is a combination of two different benches (2011 and 2013 data) and clearly highlights the disparity in visual identification over time (most likely by different geologists). The chemical classification shows a continuum between the two different sets of data.

Metallurgical characterization/behaviour of various samples representing the different rock types

Preliminary metallurgical characterization test work by Schouwstra et al. (2013) allowed the authors to highlight some distinct trends for certain rock groups. Since that time, additional laboratory-scale test work has firmed up on these trends but more work is still required, particularly on those rock types for which not many samples were readily available at that time. In addition, work is required on those rock types that the algorithm classified as unknown in order to decide if they can readily be combined with one of the other geometallurgical zones or need to be placed in a class on their own. Much of the work to date has been on the flotation response of these classifications. Hardness data is available, as well as some work on rheology, as a proxy for plant operability. This data needs to be included in any geometallurgical model that is ultimately put in place in the operation.

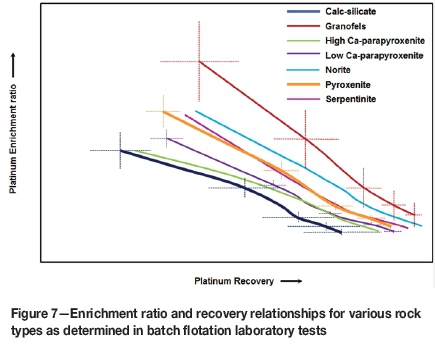

All the batch flotation test results on samples from the identified rock types were averaged, and their enrichment ratios (concentrate grade divided by feed grade) versus recovery responses are plotted in Figure 7. Seeing that the relationship between recovery and enrichment ratio is essentially a trade-off, it is important to look at the relationship between the two, and not one or the other in isolation. A particular sample might well produce a good recovery but at a sub-economic concentrate grade, for example. Figure 7 also displays the confidence limits. It is clear from these results that there are definite differences between the rock types. The granofels samples had the best flotation response, whereas calc-silicates and high-calcium parapyroxenites were the worst. This is in line with previous experience and was expected. The serpentinites constitute a small data-set, but were also consistently poor.

This data facilitates the fitting of a mathematical model to each rock type as described by Schouwstra et al (2013). The model defines the relationship between enrichment ratio and metal recovery, depending on the ore type. It thus becomes theoretically possible to predict, for a given ore classification and head grade, the recovery for a given concentrate grade, or the concentrate grade at a given recovery. This type of model can then be integrated into a geometallurgical simulator that provides expected plant performance, depending on the feedstock.

It must be emphasized that the data is from batch flotation tests carried out in ideal laboratory conditions and may be a poor predictor of plant performance. Pilot plant tests in a continuous operation are required to determine firstly, whether the trends identified manifest in a large-scale operation; and secondly, if so, what is the magnitude of the effects. Once this has been established a realistic geometallurgical model may be put in place. In addition, the synergistic or antagonistic effects of ore blending need to be established with confidence so that any decisions emanating from such a model are well-informed.

Combining metallurgical outcomes with chemical classification to define geometallurgical zones

The rock type characterization using XRF data differentiated between seven different rock types-these included the hangingwall and footwall rocks, which are infrequently mineralized.

Metallurgical test work highlighted that the low Ca-parapyroxenite is metallurgically compatible with the pyroxenite, and these two types can thus be combined into one geometallurgical zone. This geometallurgical zone comprises most of the current Mogalakwena North operation.

Where mineralized, the norite (limited data) and granite-granofels exhibit better metallurgical characteristics than the pyroxenites and can also be grouped together.

In terms of flotation characteristics, the high-Ca parapyroxenites behave similarly to samples from the serpentine group. However, with only a few samples belonging to the serpentine group available for testing, as well as some anecdotal evidence of this material having previously caused rheology issues in the operation, it is recommended that these two groups are regarded as two distinctive geometallurgical zones.

Test work has confirmed the poor recoveries previously obtained on calc-silicates, and rocks belonging to that group should be part of a separate geometallurgical domain.

Conclusion

Many reports on processing difficulties at Mogalakwena provided anecdotal evidence that there existed a link between rock type and metallurgical behaviour. This led to the working hypothesis that mine planning and ore processing based on rock type classification should improve production and assist with optimizing the milling and flotation regime.

Geological characterization and metal recovery potential are an integral part of a value-based spatial resource model that incorporates estimates of various aspects of the mining value chain into each of the smallest mining units, and ultimately leads to optimized mining decisions.

Using a geological rock type classification (using visual classification or X-ray diffractometry) would most likely lead to a rock model incorporating more than 15 rock types. Some of these rock types would have a very small volumetric distribution, complicating the mining process. Keeping the number of geometallurgical zones small-even though that might slightly increase the variation-makes the process more viable.

The initial study used CaO as an indicator of rock type, but using a more comprehensive set of chemistry data and a principal component analysis approach made it possible to subdivide the rocks in the Mogalakwena mine into seven different classes. Focusing on the mineralized rocks (i.e. ignoring the footwall and hangingwall) further reduces this to five for the whole mining operation or four for the Mogalakwena North pit, where the highly altered calc-silicate rock is poorly developed. Limiting the number of geometallurgical zones will obviously simplify the mining and process schedules.

The link between these different rock classes and metallurgical behaviour is tentative at the moment. Although our preliminary data corroborates some of the anecdotal evidence (i.e. calc-silicate has always been regarded as a problematic ore and is typically stockpiled for future processing), the data is limited, especially on the scarcer rock types. The data is also currently based on standard laboratory tests, using a standard grind, flotation times, and reagents.

It is therefore imperative to continue with the metallurgical characterization of the different ore types and link these to the proxy-based geometallurgical model. This should include test work on several blends of poor and good ores to determine the impact of blends on metallurgical throughput and recovery, as well as pilot plant confirmation and qualification of the trends observed. The impact of variable grade on recovery also needs to be better quantified.

It is further recommended that XRF characterization and modelling of proxies be continued. The models should be revised and improved as new information becomes available and as knowledge on the interaction between geological and metallurgical parameters improves.

The study thus far has shown that there is not much value in changing the mining method at Mogalakwena North (where only 10% of the rock types will have a deleterious effect on processing), but it is believed that selective mining by rock type will have a pronounced effect as mining moves towards areas where the rock type distribution is more variable and where the mining area contains a larger percentage of mineralization with detrimental metallurgical characteristics.

References

Hill, T. and Lewicki, P. 2006. Statitistics: Methods and Applications - A Comprehensive Reference for Science, Industry and Data Mining. 1st edn. Statsoft. pp.155-162. [ Links ]

Holwell, D.A. 2006. The roles of magmatism, contamination and hydrothermal processes in the development of Platreef mineralization, Bushveld Complex, South Africa, PhD thesis, Cardiff University. [ Links ]

Holwell, D.A. and McDonald, I. 2006. Petrology, geochemistry and the mechanisms determining the distribution of platinum-group element and base metal sulfide mineralization in the Platreef at Overysel, northern Bushveld Complex, South Africa. Mineralium Deposita, vol 41. pp. 575-598. [ Links ]

Kinnaird, J.D., Hurchinson, D., Schurmann, L., Nex, P., and De Lange, R. 2005. Petrology and mineralisation of the southern Platreef: northern limb of the Bushveld Complex, South Africa. Mineralium Deposita, vol 40. pp 576-597. [ Links ]

Nex, P., Kinnaird, J.D., Jones, B., and Colloty, A. 2006. Platreef rock type definitions and descriptions. Economic Geology Research Institute, University of the Witwatersrand, Johannesburg. [ Links ]

Schouwstra, R.P., De Vaux, D., Muzondo, T., and Prins, C. 2013. A geometallurgical approach at Anglo American Platinum's Mogalakwena operation. Proceedings of the Second AusIMM International Geometallurgy Conference (Geomet2013), Brisbane, Queensland, 30 September - 2 October 2013. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 85-92. https://www.researchgate.net/publication/262973972_A_geometallurgical_approach_at _Anglo_American_Platinum%27s_Mogalakwena_operation [ Links ]

White J.A. 1994. The Potgietersrust prospect - Geology and exploration history. Proceedings of the XVth CMMI Congress, Johannesburg, South Africa. Glen, H.W. (ed.). vol. 3. Symposium Series no. 14. South African Institute for Mining and Metallurgy, Johannesburg. pp. 173-181 [ Links ]

Wagner, A. 1929. The Platinum Deposits and Mines of South Africa, Oliver and Boyd, Edinburgh. [ Links ]

Paper received May 2016

Revised paper received May 2017