Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.117 no.7 Johannesburg Jul. 2017

http://dx.doi.org/10.17159/2411-9717/2017/v117n7a10

PAPERS OF GENERAL INTEREST

Application of fuzzy linear programming for short-term planning and quality control in mine complexes

M. Rahmanpour; M. Osanloo

Amirkabir University of Technology, Tehran, Iran

SYNOPSIS

Production planning in a mine complex aims to determine the amount of material that should be mined from each site, and can be modelled as a linear programming problem. Deterministic production plans are optimized based on the estimated quantity and quality of the in-situ material. These estimations always have a level of uncertainty and impreciseness due to the insufficiency of exploration data in the planning phase. In this paper, based on the gathered data, the uncertainties of grades, recovery, and mining costs are modelled using bounded fuzzy numbers. Due to the quality variation of the material, mine planning and blending optimizations are in fact uncertainty-based optimization problems. Thus, a fuzzy linear programming model is formulated to optimize short-term production planning. The results provide a comprehensive set of solutions with a corresponding degree of membership. As an illustration, the model is applied to a limestone mine complex, and a conservative and an optimistic plan are provided.

Keywords: mine complex planning, fuzzy linear programming, blend optimization, short-term planning.

Introduction

A strategic mine plan sets the overall objectives of a mining project. Mine planning is a multidisciplinary process and its aim is to develop the life-of-mine extraction plan to meet some predefined goals (Dagdelen, 2007; Henderson and Turek, 2013). Mine plans are classified into long-, medium-, and short-term plans. Normally, these plans are organized such that the mining operations achieve the highest cash flow or net present value (Heureux, Gamache, and Soumis, 2013; Juarez et al., 2014; King, 2014). These plans should consider capacities, blending requirements, block sequencing, reclamation requirements, pit slope, and any other constraints that may exist in each particular mine site (Caccetta and Hill, 2003).However, many problems in the field of mining engineering are characterized by insufficient and incomplete data. The stochastic and uncertain nature of geological, technological, market, political, and ecological factors are inherent in the context of mining engineering. For example, the dynamic change of ore and waste material due to the presence of spatial grade uncertainty makes predictions of the optimal mining sequence a challenging task (Godoy and Dimitrakopoulos, 2004; Azimi, Osanloo, and Esfahanipour, 2013; Rahmanpour and Osanloo, 2016a). These uncertainties highlight the importance of careful and risk-based mine planning through the development of new production planning models (Osanloo, Gholamnejad, and Karimi, 2008; Newman et al., 2010).

Long-term plans outline the strategies to achieve a company's goals (the highest net present value, for instance). Short-term plans are aimed at following the strategies of the long-term plan, and the other objective of short-term plans is to minimize operating costs as much as possible. For this purpose, engineers try to find a reliable system with minimal cost (Levitin and Lisnianski, 2001; Rahmanpour and Osanloo, 2016b). Modern and successful production systems are characterized by high productivity, full utilization of resources, flexibility, and reliability. These characteristics enable an operating system to adapt to changing conditions. In any mining operation, ore is mined from different blocks and is hauled to predetermined destinations based on its chemical or mineralogical properties. Mining operations obtain the desired quality of the plant feed by blending ore of different qualities. The same practice is applied in a mine complex where the ore is sourced from different mines and has different chemical and physical characteristics (Figure 1).

Since ore properties can vary considerably, blending is a prerequisite in order to obtain a consistent feed to the processing plant. The run-of-mine quality depends on the quality and quantity of ore mined from each face. Uncertainty is the state of having limited knowledge to perform a task. During feasibility studies, the precise values of all the input parameters are not known. Normally, parameters such as the grades, operating costs, commodity prices, recoveries, and operational constraints are all estimated using the data available at the time of planning, based on the assessments of the mining engineers. Hence blending and quality control plans are determined based on some in-situ and estimated characteristics of a deposit. Therefore, the optimum blending plan is affected by the uncertainties of geological and chemical properties of the ore. Short-term planning in open pit mines has been studied by many researchers (Splaine et al., 1972; Wilke and Reimer, 1979; Zhang et al., 1992). Some researchers have incorporated the effect of uncertainties in short-term planning (Smith and Dimitrakopoulos, 1999; Kumral and Dowd, 2002; Fioroni, Bianchi, and Luiz, 2008; Gamache, Hébert, and Desaulniers, 2009; Jewbali and Dimitrakopoulos, 2009; Asad, 2010; Gholamnejad, 2008; Souza et al., 2010; Askari-Nasab et al., 2011; Eivazy and Askari-Nasab, 2012; Montiel and Dimitrakopoulos, 2015; Osanloo and Rahmanpour, 2017). They applied a variety of mixed integer linear programming models, Lagrangian parameterization, simulation, linear programming (LP), and heuristic models.

It is obvious that as planning parameters change, production plans should be re-optimized using the updated data. Therefore, a simple and deterministic LP model is not an appropriate tool for these types of problem, where planning parameters are uncertain. Moreover, there is always an acceptable limit (guarantee limit) for each mining constraint. For example, a thermal power plant may require coal with a maximum sulphur limit of 0.9%. It should be noted that coal with a sulphur content of 0.91% is also acceptable for the plant (Pendharker, 1997). In typical LP models, the constraints ignore this option. In such circumstances, fuzzy linear programming (FLP) seems to be a suitable tool. An FLP model considers the possible uncertainties by using fuzzy numbers. In addition, small deviations from the acceptable limits are allowed in FLP models, which leads to the determination of practical plans. FLP has been applied in a coal mine and in a bauxite mine for production scheduling (Pendharker, 1997; Vujic et al., 2011). These studies carried out a procedure based on sensitivity analysis and shadow prices to determine a reliable production schedule.

This paper addresses short-term production planning in open pit mines in an uncertain environment. The objective is to provide a set of scenarios that represent the optimistic and the pessimistic options for short-term planning. Further, these scenarios enable the mine planner to incorporate some extra information based on his/her experiences to conduct a risk-based approach to select a suitable mining schedule. The optimized plan would present a protective strategy against unknown or highly uncertain events. For the purpose of this paper, short-term planning is investigated using a procedure based on FLP models. As an illustration, the model is applied in a limestone mine complex.

Fuzzy linear programming

An FLP model is a form of LP model where some or all of the parameters are fuzzy numbers. FLP has many applications in real-world problems, including production planning and scheduling, transportation, finance, engineering design, environmental management, and assignment (Rommelfanger, 1996; Sahinidis, 2004; Ko and Chen, 2014). This concept can be applied to optimize the mining schedule and production planning in open pit mines. Consider the general form of LP models (Equation where the objective function's coefficient  , resources (b), and coefficients of the constraints (Ã) are all fuzzy numbers (Lie and Hwang, 1992; Wang, 1997; Sakawa, Yano, and Nishizaki, 2013; Luhandjula, 2014).

, resources (b), and coefficients of the constraints (Ã) are all fuzzy numbers (Lie and Hwang, 1992; Wang, 1997; Sakawa, Yano, and Nishizaki, 2013; Luhandjula, 2014).

It should be noted that the non-fuzzy version of the model in Equation [1] should be feasible and an increasing function of the model parameters. Assume that  , and

, and  are defined as bounded fuzzy numbers (BFNs). The lower bounds of these BFNs represent the risk-free values that are conservative and implementable, and the upper bounds represent the optimistic values of the parameters Figure 2).

are defined as bounded fuzzy numbers (BFNs). The lower bounds of these BFNs represent the risk-free values that are conservative and implementable, and the upper bounds represent the optimistic values of the parameters Figure 2).

These parameters could also be represented as triangular fuzzy numbers. The fuzzy interval or the fuzzy membership function of each parameter must be specified initially. For this purpose, the decision-maker, according to his experiences and the mine conditions, specifies a membership function for each parameter. After formulating the model, a procedure similar to that presented by Carlsson and Korhonen (1986) is used to determine the optimum solution of the FLP model. This procedure is similar to a grid search algorithm. It provides a set of solutions to the decision-maker, who can select his/her preferred solution. The optimum solution of the problem is a trade-off among the degree of memberships (Lie and Hwang 1992). The full trade-off exists where the membership degrees of all the parameters in the model are equal (i.e. μ = μ0= μ λ = μb and με [0,1]). Therefore, the following equations are obtained, c = gc(μ), A = gA (μ), b = gb (μ)

where gc, gA, and gb are the inverse functions of μ ε , μ λ , and μb respectively. This converts Equation [1] into Equation [2].

This model (Equation [2]) is nonlinear but can easily be converted into an LP model for any given value of membership degree (i.e. μ). Thus, for any given value of μ, an optimum solution (z*) can be determined. Finally, the pairs of solutions (i.e. (z*,μ)) provide a guide for the decision-makers to determine the suitable strategy. Each pair of solutions represents the contribution of each mine site to the run-of-mine. The procedure required to obtain the optimum solution is as follows:

Step 1: Develop a scheduling model based on FLP models

Step 2: Determine the membership function of each fuzzy parameter

Step 3: Determine a membership degree or the level of uncertainty, or start with μ = 0

Step 4: Assuming a membership degree, convert the nonlinear model into its LP equivalent, and solve the LP format of the model

Step 5: Plot the optimized solution of the model against the membership degree

Step 6: Let μ = μ + δ,δ Є [0,1] and if μ> 1 go to step 7, else go to step 4

Step 7: The plot in step 5 shows the relationship between the optimal schedule and the corresponding membership degree.

These steps are summarized in Figure 3. Considering the optimized solutions and their membership degrees, the decision-maker will select the optimal solution from among the calculated solutions. The selected solution indicates the optimum production plan.

Developing the fuzzy scheduling model

As shown in Figure 1, the aim of mine planners is to determine the optimum amount of material that should be mined from each specific mine site such that the customer (or the processing plant) is provided with a suitable and consistent quantity and quality of raw material. Therefore, the mined material is blended to provide a consistent feed with the required quality. Objectives are set at strategic and long-term planning; then the short-term objective chiefly concerns implementation to achieve those long-term goals. Short-term plans are normally optimized to achieve high productivity and full utilization of resources, which in turn minimizes operating costs. In this paper, the objective function of the short-term planning model is to minimize the total mining costs by determining the minimum amount of material that should be mined from each mine site. This is obtained through determining the optimal blending plan.

Uncertainty is a problem that all mining operations are faced with. The most important factors that affect the mining schedule and are associated with uncertainty are the in-situ quality of mineable reserves, mining and processing capacities, mining costs, and commodity price. Mining and processing recoveries are functions of the chemical, physical, and mechanical properties of the material at each mine site and the type of mining operation. To analyse the effect of ore quality, mining and processing recoveries, and mining cost uncertainties on the optimum mining schedule and blending plan, an LP model is formulated (Equation [3]). Considering the mine characteristics and the requirements of the customer or the plant, the constraints of the mine planning model are recognized (Equation [3]). The notation used in the model is as follow:

N The set of mines in the mining complex

ciThe average operating cost at site i

xiThe decision variable which is the amount of material that should be mined from site i

riThe recovery of material from site i

McThe minimum mining rate

MiThe maximum possible mining rate at site i

PC The feed rate required by the plant or the customer

gi The average grade of economic material at site i

qi,kThe average grade of penalty element of impurity k at site i

Gmin The minimum acceptable grade of economic material

Qi,maxThe maximum acceptable grade of impurity k

K The number of impurities or the penalty elements

The objective function is:

subject to:

The objective function of the model (Equation [3a]) is defined as the minimization of the total mining costs of the production system. Equation [3b] ensures that the summation of the mined material is equal to or greater than the amount required by the plant or customer. Equation [3c] restricts the mining capacity of each mine site considering a possible and implementable mining capacity. Equations [3d] and [3e] are quality control constraints. Equation [3d] ensures that the total amount of penalty elements in the feed does not exceed the prescribed upper bounds. For example, in limestone mining, the presence of dolomite and silica is not tolerated. These constituents are considered as impurities or penalty constituents and they are modelled using Equation [3d]. Equation [3e] ensures that the total amount of economic material in the feed is always greater than the prescribed lower bounds. Equation [3f] ensures that the total amount of the final product produced in the mining complex is greater than the quantity required by the plant or customers. Finally, the logical constraints are embedded into the model as represented by Equation [3g].

The FLP model defined in Equation [3] is capable of determining the optimum blending plan. The symbol ~ indicates the fuzzy parameters in the model, which are assumed to be BFNs. As stated, for each BFN the lower bounds represent a possible and risk-free value and the upper bounds represent an optimistic value. Considering the fuzzy numbers and their membership functions, the FLP model in Equation [3] is then converted into a nonlinear programming model (Equation [4]).

The objective function becomes:

subject to:

where y(k,i) = qk,i - Qkmax and μ· = - g + Gmin are substituted in the model to simplify the formulation. The inverse membership functions of mining costs, grade of economic material, grade of penalty elements, and ore recovery are defined bygc(i) (μ),gy(j,t) (μ),gu(i) (μ), and grií) (μ), respectively. Also, the inverse membership functions of the right-hand side parameters corresponding to the quality and quantity constraints in Equations [4d], [4e], and [4f] are shown as(μ),gue (μ), andgpc(μ) , respectively. After formulating the nonlinear model in Equation [4], steps 3 to 7 described in the previous section should be carried out to convert the model into a linear one and to obtain the optimum mining schedule and blending plan.

Model verification

The model (Equation [4]) was applied to a limestone mine complex in Iran. The mine is located in Semnan province about 230 km east of Tehran (Figure 4A). There are five distinct mining areas in the complex and the quantity and quality of the mineable limestone in each mine is different. In these mines, the limestone and dolomite beds are accompanied by cherty lenses. The limestone beds are Triassic light-gray, regular bedded limestone. The limestone bed is located beneath a siliceous or cherty limestone. This formation is covered by a dark-coloured basaltic and some ferruginous layers. The beds have a dip of 50 to 65 degrees (Figure 4B) and the thickness the of limestone layers varies from 30 to 65 m.

According to the long-term plan, the amount of mineable reserve in each mine is determined. For the purpose of shortterm planning (within a one-month horizon), it is also assumed that the entire amount of materials scheduled is mineable within the short time periods. The limestone is supplied to a soda ash plant for the production of sodium carbonate, which has many uses in industrial processes. The quality control (QC) office of the plant specifies the required quality of the feed. The grade of CaCO3 in the feed should be more than 93.5%, and the grades of MgCO3 and SiO2 should be less than 3.5% and 3% respectively.

According to the data gathered from the mine sites during the year 2014, the characteristics of the limestone mined from each mine site are modelled as BFNs. As the lower bound of each BFN represents a possible and implementable value, the minimum value of the gathered data is selected as the lower bound. In case of positive parameters, such as ore grade (the percentage of CaCO3), the upper bound is selected as the expected grade of the gathered data. However, in case of negative parameters such as the grade of penalty elements (the percentage of SiO2 and MgCO3) the opposite applies (Table I).

The other parameter that governs the scheduling of the mine is the possible production capacities of each mine site. In this case, the lower bound of fuzzy representation indicates the current mining capacity of each site. These values are determined based on local factors, including pit geometry and the thickness of limestone beds. The upper bound is an optimistic possible mining rate for each site. This value is determined based on the maximum mining rate that was reported from each mine site during the year 2014, as shown in Table I.

The plant requires limestone with a size distribution of 512 mm. The overall recovery of the material in the crushing unit depends on the mining operation itself and the mechanical characteristics of the limestone from each mine. After blasting, the blasted material is moved to a loading area by dozers and then loaded onto trucks by excavators. The material is hauled from each mine site to a crushing and blending unit. The fragmentation of the limestone feed to the plant from each mine site is a function of blasting and dozing operations. The relative location of each mine site with respect to the crushing and blending unit is shown in Figure 5. According to the data and experience of the mining crew, the overall recovery of the limestone mined from each mine site is also modelled using BFNs (Table I).

The crushed material with the prescribed size distribution is fed into the soda ash plant. The current capacity of the plant is 1500 t of crushed limestone per day, and the nominal quality required by the plant is given in Table II. This data is fuzzified considering a deviation of 1% for the ore grade and 2% for the penalty elements from the nominal quality requirements.

After fuzzification of the planning parameters, the model in Equation [4] is applied to determine the mining schedule and the blending plan for the mining system. The steps described in Figure 3 are applied to solve the planning model. The procedure was programmed in MatLab and was solved using the Simplex method.

Results and discussion

The membership degrees of the planning parameters are varied from risk-free or conservative values to optimistic values. Following the steps described in Figure 3, the optimum pairs of solutions are obtained. Each pair defines a scheduling scenario for the mine for each particular degree of membership. According to the results (Table III), as the membership degree of the planning parameters increases (i.e. it changes from optimistic values to risk-free values), the mines should exploit and process more material in order to fulfil the predetermined goals on limestone quality and quantity. The plant requires 45 000 t of crushed limestone monthly (equals 1500 t/d). As stated earlier, BFNs are used to represent the uncertainty of the planning parameters, where the lower and upper bounds define the conservative and optimistic values of each parameter. Considering the concept of BFNs, one could define the optimistic and conservative strategies for mine scheduling. In Table III, the schedule corresponding to a membership degree of 100% is regarded as the conservative schedule, and that with a membership degree of zero as the optimistic schedule. When the membership degree of the planning parameters decreases, it means that the optimistic values of the parameters are considered in the model and the results are optimistic as well.

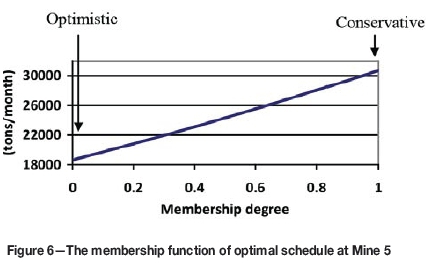

According to the results, Mine 2, Mine 3, and Mine 4 are operating at their maximum nominal production rates in all the cases. When the inherited positive error of the planning parameters increases (i.e. the membership degree of the parameters decreases), the value of these parameters tends to improve to the optimistic values, then the production rate at Mine 5 decreases as shown in Figure 6. According to the results, Mine 5 should produce 30 708 t and 18 629 t of limestone per month based on the conservative and the optimistic mining schedules, respectively. Considering the reserve characteristics at each mine site (Table I), the reserve of Mine 1 is low in quality compared to the others, and according to the results, mining should be halted at this site. However, the costs at Mine 1 and Mine 2 are low compared to the other mines and the model tends to exploit from these sites to decrease the total mining costs. The amount of material mined from these two sites is controlled by the blending requirements. In other words, the limestone available at Mine 1 and Mine 2 is a balancing reserve for the production system in order to obtain the required output and to lower the mining costs.

By analysing the results and the given scheduling scenarios, the mine planner is able to determine the best mining schedule. Based on the experiences in this mine, and considering the selected membership degree, which indicates the strategy of the decision-maker, the mining schedule is selected from among the generated scenarios. According to Table III, selection of a membership degree of 20% for the planning parameters indicates that the mine planner is somewhat optimistic (80%) about the mine condition. At 20%, the optimum mining schedule for the system is to produce 71 218 t of limestone per month. This is a decrease of 10% in the total mining rate compared with the most conservative case. This will decrease the total mining costs by 18% (Figure 7A). This is true for the rest of the cases as well.

The results show that the operation should produce less limestone when the mine planner is optimistic about the precise value of the planning parameters. This will reduce the total amount of mined material by about 12% compared to the case where the planning parameters are determined conservatively (Figure 7B). The difference in total mining costs between the optimistic and the conservative schedules is about 22% (Figure 7A). This shows that there is a chance of a considerable saving in costs.

The blending plan could be analysed based on the reliability of the production system. From a reliability point of view, as shown in Figure 7, in the conservative mining schedule the mine system must produce extra limestone in order to increase the probability of obtaining the required quality. To check the validity of this statement, a Monte Carlo simulation was conducted on the conservative and optimistic schedules. For this purpose, a beta distribution function was fitted to the data. The general form of a beta distribution function (i.e. f(x, α, β )) is as follows:

where α and β are the shape parameters of the beta distribution, and β is a normalization constant to ensure that the total probability integrates to unity.

The simulation results provide the distribution function of the conservative and the optimistic schedules with respect to CaCO3, MgCO3, and SiO2 variations. If the grade of the mined material is not within the predetermined range, it is defined as failure for the mine schedule. The distribution functions are used to predict the reliability function of the conservative and the optimistic scenarios as shown in Figure 8. Here, reliability of quality (RQ) is defined as the probability that the average grade of the mined limestone is within the range dictated by the QC as represented by Equation [5].

where g represents the minimum grade required by the quality control, G is the average grade of the mined limestone, and UB is the upper bound of the beta distribution function.

According to the results, the likelihood of attaining the required quality by implementing the optimistic and the conservative schedules is about 88%, and the probability of failure is 12% in both cases. This means that there is no bottleneck on attaining the required quality. In the next step, the plans are analysed to evaluate the overall tonnage of material produced by the plant. The reliability of tonnage (RT) is defined as the probability that the tonnage of the crushed and sized limestone is within the range dictated by the quality control as represented by Equation [6].

where t represents the tonnage required by the plant (in this case t is equal to 45 000 t/month), T is the tonnage of mined limestone, and UB is the upper bound of the beta distribution function.

The reliability in this case is a function of recovery in the plant. The result shows that the reliability of the conservative schedule is 100% and the reliability of the optimistic schedule is almost zero, as shown in Figure 9. Based on the results, the conservative option is the most reliable schedule. However, decision-making about the scheduling option depends on the utility function of the decision-maker and his/her knowledge and experience at the mine site.

Conclusions

A mine production-scheduling model based on fuzzy linear programming has been developed and applied to optimize the mining schedule and blending plan in the presence of uncertainty. Fuzzy linear programming is a useful tool for modelling and optimizing mine production planning. Due to the fact that at the time of mine planning the precise values of all input data are not known in advance, the uncertainty of the input parameters (or simply planning parameters) should be considered in any mine planning optimization. The input data was fuzzified (into bounded fuzzy numbers) according to the data gathered from the mine during the year 2014. In addition, the 'right-hand side' values of the constraints were fuzzified with a deviation of 2% from the nominal values.

The procedure presented is capable of determining variable scenarios for the mining schedule. Therefore the mine planner, considering a degree of preciseness and optimism about the planning parameters, will be able to select the optimum mining schedule from among the presented options. Introducing uncertainty into the production planning model has increased the total amount of material that should be mined. This means that the mining operation pays for the cost of uncertainty by excess production. Mining and processing extra material would increase the reliability of the mining operation (Figure 9). In case of full uncertainty (the conservative option), the mine system should produce about 78 708 t of limestone in each month in order to satisfy the quality and quantity requirements of the blending plant. In the optimistic case, however, the operation should be producing about 69 629 t/month, which is 12% less than the conservative option.

References

Asad, M.W.A. 2010. Implementing a blending optimization model for short- range production planning of cement quarry operation. Journal of Mining Science, vol. 46, no. 5. pp. 525-535. DOI: 10.1007/s10913-010-0066-x [ Links ]

Askari-Nasab, H., Eivazy, H., Tabesh, M., and Badiozamani, M.M. 2011. A mathematical programming model for open pit short-term production scheduling. Proceedings of the SME Annual Meeting, Denver, Colorado, USA, 28 February - 2 March. pp. 1-8 [ Links ]

Azimi, Y., Osanloo, M., and Esfahanipour, A. 2013. An uncertainty based multi- criteria ranking system for open pit mining cut-off grade strategy selection. Resources Policy, vol. 38. pp. 212-223. DOI:10.1016/j.resourpol.2013.01.004 [ Links ]

Caccetta, L, and Hill, S.P. 2003. An application of branch and cut to open pit mine scheduling. Journal of Global Optimization, vol. 27. pp. 349-365. DOI: 10.1023/A:1024835022186 [ Links ]

Carlsson, C. and Korhonen, P. 1986. A parametric approach to fuzzy linear programming, Fuzzy Sets and Systems, vol. 20. pp. 17-30. DOI: 10.1016/S0165-0114(86)80028-8 [ Links ]

Dagdelen, K. 2007. Open pit optimization - strategies for improving economics of mining projects through mine planning. Orebody Modeling and Stochastic Mine Planning. 2nd edn. Dimitrakopoulos R. (ed.). Spectrum Series no. 14. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 145-148. [ Links ]

Eivazy, H. and Askari-Nasab, H. 2012. A mixed integer linear programming model for short-term open pit mine production scheduling. Mining Technology, vol. 121, no. 2. pp. 97-108. DOI: 10.1179/1743286312Y.0000000006 [ Links ]

Fioroni, M.M., Bianchi, T.J., and Luiz, R.P. 2008. Concurrent simulation and optimization models for mining planning. Proceedings of the 2008 Winter Simulation Conference, Miami, Florida, USA, 7-10 December. IEEE. pp. 759-767. [ Links ]

Gamache, M., Hébert, D.L., and Desaulniers, G. 2009. A generic linear program for an optimal mine production plan. Proceedings of the 18th International Symposium on Mine Planning and Equipment Selection (MPES), Banff, Alberta, Canada, 16-19 November. Singhal, R.K. (ed.). The Reading Matrix. pp. 326-334. [ Links ]

Gholamnejad, J. 2008. A zero-one integer programming model for open pit mining sequences. Journal of the Southern African Institute of Mining and Metallurgy, vol. 108. pp. 759-762. [ Links ]

Gholamnejad, J. and Osanloo, M. 2007. Incorporation of ore grade uncertainty into the push back design process. Journal of the Southern African Institute of Mining and Metallurgy, vol. 107, March. pp. 177-185. [ Links ]

Godoy, M. and Dimitrakopoulos, R. 2004. Managing risk and waste mining in long-term production scheduling of open-pit mines. SME Transactions, vol. 316. pp. 43-50. [ Links ]

Henderson, R. and Turek, C. 2013. Mine planning best practice at Kinross Gold. Mining Technology, vol. 122, no. 2. pp. 86-93. DOI: 10.1179/1743286313Y.0000000041 [ Links ]

Heureux, G.L., Gamache, M., and Soumis, F. 2013. Mixed integer programming model for short term planning in open-pit mines. Mining Technology, vol. 122, no. 2. pp. 101-109. DOI: 10.1179/1743286313Y.0000000037 [ Links ]

Jewbali, A. and Dimitrakopoulos, R. 2009. Stochastic mine planning - example and value from integrating long and short-term mine planning through simulated grade control. Proceedings of Orebody Modelling and Stochastic Mine Planning. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 16-8. [ Links ]

Juarez, G., Dodds, R., Echeverria, A., Guzman, J.I., Recabarren, M., Ronda, J., and Vila-Echague, E. 2014. Open pit strategic mine planning with automatic phase generation. Proceedings of the Orebody Modeling and Strategic Mine Planning Symposium, Perth, WA, 24-26 November. Dimitrakopoulos, R. (ed.). Australasian Institute of Mining and Metallurgy, Melbourne. pp. 147-153. [ Links ]

King, B. 2014. Modelling open pit and underground production scheduling in concert. Proceedings of the Orebody Modeling and Strategic Mine Planning Symposium, Perth, WA, 24-26 November. Dimitrakopoulos, R. (ed.). Australasian Institute of Mining and Metallurgy, Melbourne. pp. 369-373. [ Links ]

Ko, W.C. and Chen, L.H. 2014. An approach of new product planning using quality function deployment and fuzzy linear programming model. International Journal of Production Research, vol. 52, no. 6. pp. 1728-1743. [ Links ]

Kumral, M. and Dowd, P.A. 2002. Short term mine production scheduling for industrial mineral using multi objective simulated annealing. Proceedings of the 30th International Symposium on the Application of Computers and Operations Research in the Mineral Industry (APCOM), University of Alaska. Society for Mining, Metallurgy, and Exploration, Littleton, CO. pp. 731-737. [ Links ]

Levitin, G. and Lisnianski, A. 2001. A new approach to solving problems of multi-state system reliability optimization. Quality and Reliability Engineering International, vol. 17. pp. 93-104. DOI: 10.1002/qre.388 [ Links ]

Lie, Y.J. and Hwang, CL. 1992. Fuzzy Mathematical Programming, Methods and Applications. Springer-Verlag. pp. 74-127. DOI: 10.1080/00207543.2013.848479 [ Links ]

Luhandjula, M.K. 2014. Fuzzy optimization: milestones and perspectives. Fuzzy Sets and Systems, vol. 274. pp. 4-11. DOI:10.1016/j.fss.2014.01.004 [ Links ]

Montiel, L. and Dimitrakopoulos, R. 2015. Optimizing mining complexes with multiple processing and transportation alternatives - an uncertainty-based approach. European Journal of Operational Research, vol. 247, no. 1. pp. 166-178. DOI: doi:10.1016/j.ejor.2015.05.002 [ Links ]

Newman, A.M., Rubio, E., Caro, R., Weintraub, A., and Eurek, K. 2010. A review of operations research in mine planning. Interfaces, vol. 40, no. 3. pp. 222-245. DOI: 10.1287/inte.1090.0492 [ Links ]

Osanloo, M., Gholamnejad, J., and Karimi, B. 2008. Long-term open pit mine production planning: a review of models and algorithms. International Journal of Mining, Reclamation, and Environment, vol. 22, no. 1. pp. 3-35. [ Links ]

Osanloo, M. and Rahmanpour, M. 2017. Optimizing short-term production plan using a portfolio optimization model. Revista Escola de Minas, vol. 70, no.1. pp. 109-116. DOI: 10.1590/0370-44672016700071 [ Links ]

Pendharker, P.C. 1997. A fuzzy linear programming model for production planning in coal mines. Computers and Operations Research, vol. 24, no. 12. pp. 1141-1149. DOI: 10.1016/S0305-0548(97)00024-5 [ Links ]

Rahmanpour, M. and Osanloo, M. 2016a. Determination of value at risk for long-term production planning in open pit mines in the presence of price uncertainty. Journal of the Southern African Institute of Mining and Metallurgy, vol. 116, no. 3. pp. 229-236. [ Links ]

Rahmanpour, M. and Osanloo, M. 2016b. Resilient decision making in open pit short-term production planning in presence of geologic uncertainty. JE Transactions A: Basics, vol. 29, no. 7. pp. 1022-1028. DOI: 10.5829/idosi.ije.2016.29.07a.00 [ Links ]

Rommelfanger, H. 1996. Fuzzy linear programming and applications. European Journal of Operational Research, vol. 92. pp. 512-527. [ Links ]

Sahinidis, N.V. 2004. Optimization under uncertainty: state-of-the-art and opportunities. Computers and Chemical Engineering, vol. 28. pp. 971-983. DOI:10.1016/j.compchemeng.2003.09.017 [ Links ]

Sakawa, M., Yano, H., and Nishizaki, I. 2013. Linear and Multi-Objective Programming with Fuzzy Stochastic Extensions. Springer. pp. 104-148. [ Links ]

Smith, M.L., and Dimitrakopoulos, R. 1999. The influence of deposit uncertainty on mine production scheduling. International Journal of Surface Mining, Reclamation and Environment, vol. 13. pp. 173-178. DOI: 10.1080/09208119908944244 [ Links ]

Souza, M.J.F., Coelho, I.M., Ribas, S., Santos, H.G., and Merschmann, L.H.C. 2010. A hybrid heuristic algorithm for the open-pit-mining operational planning problem. European Journal of Operational Research, vol. 207, no. 2. pp. 1041-1051. DOI: 10.1016/j.ejor.2010.05.031 [ Links ]

Splaine, M. Atklnson, D.C., Davidson, W., and Smith, M.L. 1972. Optimizing medium-term operational plans for a group of copper mines. Journal of the South African Institute of Mining and Metallurgy, vol. 72. pp. 225-230. [ Links ]

Vujic, S., Benovic, T., Miljanovic, I., Hudej, M., Milutinovic, A., and Pavlovic, P. 2011. Fuzzy linear model for production optimization of mining systems with multiple entities. International Journal of Minerals, Metallurgy, and Materials, vol. 18, no. 6. pp. 633-637. [ Links ]

Wang, L.X. 1997. Fuzzy linear programming. A Course in Fuzzy Systems and Control. Prentice Hall chapter 30. pp. 381-392. [ Links ]

Wilke, F.L., and Reimer, T. 1979. Optimizing the short term production schedule for an open pit iron ore mining operation. Computer Methodsfor the 80's in the Mineral Industry. Society of Mining Engineers of the American Institute of Mining, Metallurgical, and Petroleum Engineers, New York. pp. 642-646 [ Links ]

Zhang, Y., Cai, Q., Wu, L., and Zhang, D. 1992. Combined approach for surface mine short term planning optimization. Proceedings of the 23rd APCOM Symposium, Tucson, AZ. Kim, Y.C. (ed.). SME, Littleton, CO. pp. 499-506. [ Links ]

Paper received Sept. 2015

Revised paper received Jan. 2017