Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of the Southern African Institute of Mining and Metallurgy

versión On-line ISSN 2411-9717

versión impresa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.116 no.9 Johannesburg sep. 2016

http://dx.doi.org/10.17159/2411-9717/2016/v116n9a1

PRESIDENTIAL ADDRESS

Presidential Address: Optimization in underground mine planning- developments and opportunities

C. Musingwini

School of Mining Engineering, University of the Witwatersrand, Johannesburg, South Africa

SYNOPSIS

The application of mining-specific and generic optimization techniques in the mining industry is deeply rooted in the discipline of operations research (OR). OR has its origins in the British Royal Air Force and Army around the early 1930s. Its development continued during and after World War II. The application of OR techniques to optimization in the mining industry started to emerge in the early 1960s. Since then, optimization techniques have been applied to solve widely different mine planning problems. Mine planning plays an important role in the mine value chain as operations are measured against planned targets in order to evaluate operational performance. An optimized mine plan is expected to be sufficiently robust to ensure that actual outcomes are close or equal to planned targets, provided that variances due to poor performance are minimal. Despite the proliferation of optimization techniques in mine planning, optimization in underground mine planning is less extensively developed and applied than in open pit mine planning. This is due to the fact that optimization in underground mine planning is far more complex than open pit optimization. Optimization in underground mine planning has been executed in four broad areas, namely: development layouts, stope envelopes, production scheduling, and equipment selection and utilization. This paper highlights commonly applied optimization techniques, explores developments and opportunities, and makes a case for integrated three-dimensional (3D) stochastic optimization, in underground mine planning.

Introduction

The late Mohandas Karamchand Gandhi, widely known as Mahatma Gandhi, lived from 1869 to 1948. He is regarded as the champion of the non-violent 1907-1914 Passive Resistance Campaign in South Africa and is also attributed with the words: 'Earth provides enough to satisfy every man's needs, but not every man's greed: These words were true back then, are true now, and will remain true into the foreseeable future as there will never be sufficient resources to satisfy human greed (or wants). This observation is a key premise in the study of economics, which recognises that humans have unlimited wants that must be satisfied from finite or scarce resources. Consequently, mankind must make choices on managing scarce resources for optimal allocation to satisfy human wants, but within limits of reasonable greed, otherwise continued survival on Earth may become impossible.

Optimal management of scarce resources is also central to the discipline of operations research (OR). OR has its origins in the United Kingdom around the early 1930s (i.e. pre-World War II era) when decision-making techniques were used by the British Royal Air Force and Army to find effective ways to kill as many enemy targets (i.e. people) as possible, using the least amount of resources (Beasley, n.d.). Accordingly, they recruited mathematicians, scientists, and engineers to solve different problems involving the allocation of scarce resources for military operations. The problems included operations such as bombing, anti-submarine strikes, the deployment of radar, and convoy management. Such work involved, for example, determining 'trade-offs' to evaluate what would be more effective: throwing one large bomb or throwing many small bombs at an enemy target, but in both cases using the same amount of bomb material, while increasing the probability of 'killing'. The application of mathematical, scientific, and engineering methods to military 'operations' led to this practice being called 'operations' research. Of course, such history inevitably bears some moral burden, but it is history.

In the post-World War II era, the exmilitary OR workers moved into peacetime disciplines, thus triggering the spread of OR to universities and different industries. This marked the emergence of systematic training of OR professionals. Since most OR work involves carrying out a large number of numerical calculations, its proliferation has to a large extent been made possible by the widespread availability of computers and their greatly improved performance and data storage capacities.

In Europe OR is generally referred to as 'operational research', while in the USA it is generally referred to as 'operations research'. Other terms that may be used synonymously with OR are: 'management science', 'managerial decision-making tools', 'industrial engineering', 'value engineering', 'decision science', 'quantitative methods', or 'quantitative techniques'. OR techniques are scientific decision-making methods that are used to solve complex management problems in systems by applying modern science (and mathematics) in order to select the 'best' or 'optimal' decision among possible alternative solutions, under conditions requiring the allocation of scarce resources and in some cases, balancing competing objectives. A system is an organization of interdependent components that work together in alignment to accomplish desired objectives. A mining production process is a system with inputs and outputs, and can be represented schematically using a systems engineering framework (Figure 1) and so, is amenable to optimization using OR.

The primary objective of optimizing a system is to minimize inputs (since they are scarce or costly) while simultaneously maximizing desirable outputs (e.g. profits) and minimizing undesirable outputs (e.g. waste). The level of outputs is fed back in order to make necessary adjustments for improving the system's performance. In a mining context, inputs (resources) are generally scarce and usually come at significant costs. For example, mineral resources and reserves are scarce and finite. So is time, since there are only 24 hours in a day.

Several techniques are available for solving different optimization problems, depending on how the problems are modelled. Modelling can be defined as the construction of a simplified representation of a system or its behaviour, using scientific and mathematical frameworks. Algorithms are used to test whether the model correctly represents the behaviour of the system in the real world, but without the model becoming a replica of the system. An algorithm is a step-by-step procedure that is executed iteratively to compare successive solutions until the process converges at an optimal solution. Due to the varied nature of problems encountered in the real world, different models have been developed to address the different types of problems that exist. The five main categories of OR models are:

1. Optimization model-a mathematical formulation that is solved using an exact algorithm to produce a single optimal solution through a process of either maximization or minimization

2. Simulation model-a model for comparing alternatives without necessarily guaranteeing an optimal solution, but is suitable for answering 'what-if?' type of questions or analysing risk in cases where decisions must deal with uncertainty

3. Network model-a model that is solved using a graphically-aided algorithm, also often producing a single optimal solution

4. Multi-criteria decision-making (MCDM) model-a model that is employed when decisions require several criteria to be considered simultaneously and generally the decision-making criteria are either competing, conflicting, or contradictory. 'Trade-offs' have to be made among the criteria in order to derive an optimal solution

5. Global optimization model-a model that uses a heuristic algorithm to find a solution to an intractable optimization problem, without necessarily guaranteeing an optimal solution. For example, the travelling salesman problem (TSP), in which a travelling salesman must visit several customers in different cities, each customer once, and use the shortest overall route, is typically solved using the nearest neighbour heuristic algorithm. Heuristic algorithms tend to be inspired by nature and are a major focus of this paper due to the complexity of optimization in underground mine planning.

OR methods have their own limitations because models are a simplification of reality. Therefore, problems should not be 'forced to fit' a model in order to solve them. Most optimization problems in mine planning do not perfectly fit exact algorithms, and are therefore best solved using heuristic approaches. The following sections briefly describe some of the optimization algorithms that have been used in the mining industry, but with more emphasis on heuristic algorithms such as the genetic algorithm (GA), particle swarm optimization (PSO), ant colony optimization (ACO), and simulated annealing (SA) algorithms as these have been used to solve optimization problems in mine planning that are mentioned in later sections.

Optimization algorithms

Simplex algorithm for solving linear programming (LP) problems

In 1947 George Bernard Dantzig introduced the simplex algorithm for solving linear programming (LP) problems. The general formulation of the LP problem is as follows:

Optimize Z = cixifor i = 1,2,...,n

s.t. Ax = b

and xi>0

where, Z is the objective function to be maximized or minimized with respect to variables xi, A is the matrix of ct coefficients of x , and b is a vector of constraint limits.

Depending on the type of value that x is restricted to take, LP problems can be extended to their variants, which can be binary LP where xi є[0,1], mixed integer programming (MIP) where xican be integer or decimal, and integer programming (IP) where xiє z+. The LP variants have been applied widely for optimization in mine planning, as chronicled by Osanloo et al. (2008) for open pit optimization and Newman et al. (2010) for optimization in underground mine planning.

Dynamic programming (DP) algorithm

In 1957 Richard Ernest Bellman developed a framework based on recursion to solve DP problems. A dynamic process or system is optimally laid out when the decisions taken beginning from a given stage, n, are such that the layout of the process from stage n to the end will be optimal regardless of the decisions taken to enter n. For example, in a four-stage process to maximize output where S3> S2> S1, then state S3 in stage 4 is the optimal choice when moving from stage 3 to stage 4 (Figure 2).

DP problems are solved using forward pass and backward pass algorithms. In the forward pass a recursion formula is applied to each stage and the temporary optimum is saved in memory. At the end, a backward pass traces back the path leading to the optimal value. The general recursive formula used is ƒn= Opt {ƒn-1+ gn}, where Opt is either maximum or minimumf is the function value at point n, which is a state in a given stage,ƒn-1is the function value in a previous consecutive point n-1, and gnis the value for moving from n-1 to n. The DP algorithm has been used for open pit optimization (e.g. Lerchs and Grossmann, 1965) and optimization in underground mine planning (e.g. Dowd and Elvan, 1987) for grade control and scheduling.

Genetic algorithm (GA)

In his 1975 book titled Adaptation in Natural and Artificial Systems, John Holland presented the genetic algorithm (GA) as a method to mimic the processes of biological evolution through natural selection or the principle of 'survival of the fittest' for solving global optimization problems. Consider a normal population of rabbits, some of which are faster and smarter than others. The faster and smarter rabbits are less likely to fall prey to predators such as foxes, but some of the slower and less smart survive out of sheer luck. The larger number of the faster and smarter rabbits that survive continue to do what rabbits do best: make more rabbits amongst themselves, but also with the slower and less smart that are lucky to survive. It is expected that the resulting baby rabbits will, on average, be faster and smarter. The GA is a step-by-step procedure that mimics the rabbit story (Table I). GAs have been used to solve production scheduling optimization problems in mine planning, such as in the work reported by Kumral (2004) for production blending from different mining locations in a central processing facility to maximize net present value (NPV) over time.

Particle swarm optimization (PSO) algorithm

The particle swarm optimization (PSO) algorithm is a fairly recent method applied to solve global optimization problems. It was first proposed in 1995 by Kennedy, a social psychologist and Eberhart, an electrical engineer, who conceptualized that social behaviour can be used to solve optimization problems in engineering. It mimics the social behaviour of populations of animals, fish, and flying creatures such as bees and birds. For example, suppose that a flock of birds is randomly flying looking for food in a finite area. Initially, none of the birds has any knowledge on the exact location of the food, but any bird must have the best strategy for finding the food quickly. By frequently changing flying direction suddenly (i.e. velocity change), scattering, and then regrouping, the birds engage in social exchange of information. Individual birds are able to profit from the discoveries and previous experiences of other birds during the search for food. Since the birds (i.e. particles) change their position or state with time, the particles in a population (i.e. swarm) move around in a three-dimensional (3D) space in search of more promising regions (lower functional values for shorter distances) within the finite space than previously visited regions. The particle adjusts its flying position (i.e. vector addition) according to its own experience and position (personal best position) and that of its neighbours (global best position).

The vector addition procedure can be visually explained using the space diagram in Figure 3. Suppose at time t-1 a particle is at position O, with its personal best position as A and global best position as C. If the current velocity of the particle is B, it will have a resultant direction defined by vector OD.

Khan and Niemann-Delius (2014) provided the following two vector equations for finding better positions in the search space to describe the PSO problem formulation:

are the positions of the particle i during current and previous iterations, respectively

are the positions of the particle i during current and previous iterations, respectively

are the velocities of the particle i during current and previous iterations, respectively

are the velocities of the particle i during current and previous iterations, respectively

is the personal best position experienced by particle i during the previous iteration

is the personal best position experienced by particle i during the previous iteration

is the global best position experienced by particle i during the previous iteration

is the global best position experienced by particle i during the previous iteration

is the inertia weight used to control the contribution of the particle's previous velocity

is the inertia weight used to control the contribution of the particle's previous velocity

are the acceleration coefficients used to control the influence of cognitive and social terms on the particle's current velocity

are the acceleration coefficients used to control the influence of cognitive and social terms on the particle's current velocity

are vectors of uniform random numbers between 0 and 1.

are vectors of uniform random numbers between 0 and 1.

The velocity and position of the individual particles are iteratively adjusted using vector addition (Figure 4), which illustrates a step-by-step procedure for the PSO algorithm.

PSO is powerful in that it combines local (personal best position) with global (global best position) search methods. 'Personal best' is analogous to short-term planning or scheduling requirements in mine planning, while 'global best' is analogous to long-term scheduling requirements. PSO provides opportunities for integrating the optimization of short-term and long-term mine planning in 3D space so that the two can be executed simultaneously, such as in the work by Khan and Niemann-Delius (2014) and Goodfellow and Dimitrakopoulos (2016).

Ant colony optimization (ACO) algorithm

The ant colony optimization (ACO) algorithm was initially proposed by Marco Dorigo in 1992 to mimic the behaviour of ants in finding an optimal path in graph theory. Ants, by nature, initially wander randomly until they find food. Then they return to their colony, while releasing pheromone (a hormone that triggers a social response by members of the same species) on the food trail. When other ants find the food path by following the pheromone, they tend to stop travelling at random, by following the trail and strengthening the attractiveness of the path and popularizing it by releasing more pheromone along the path. The pheromone evaporates with the passage of time, reducing the attractiveness of the path. A short or optimal path, therefore, is travelled over more frequently, thus increasing the pheromone density compared to longer paths. Pheromone evaporation has the advantage of avoiding the convergence to a locally optimal solution. If there were no evaporation at all, the paths chosen by the first ants would tend to be excessively attractive compared with subsequent paths. In that case, the exploration of the solution space would be constrained. When an ant finds a short path from the colony to a food source, other ants are more likely to follow that path, reinforcing positive feedback and eventually leading to all the ants following that path (Figure 5). The idea of the ant colony algorithm is to mimic this behaviour with 'simulated ants' walking around the graph representing the problem to be solved. The ACO algorithm has been used for optimization of mine production scheduling by Gilani and Sattarvand (2016).

Simulated annealing (SA) algorithm

Metropolis et al. (1953) used Monte Carlo simulation to develop the simulated annealing (SA) algorithm for simulating a collection of particles in thermal equilibrium at a given temperature, T. Annealing is a heat treatment process that involves heating a metal to above its recrystallization temperature followed by gradual cooling in still air or quenching in water in order to produce a workable metal that is more ductile and less hard, as its lattice structure is altered

in the process. Rapid cooling usually results in local minima being formed (i.e. not the strongest lattice structure), while slow cooling, which takes more time, is likely to result in global minima being formed. Kirkpatrick et al. (1983) illustrated how the model for simulating the annealing of solids proposed by Metropolis et al. (1953) could be used to solve optimization problems. The Metropolis procedure starts by setting the surrounding temperature at T and then randomly selecting a state of the system of atoms or particles, si, which has a corresponding energy Ei. The system is then agitated and a new state, sj, with energy Ej is established. If the change in energy ΔΕ = Ej - Eiis negative (i.e.j is a lower energy state than i), there is a reduction in energy, so sjis accepted; otherwise the new higher energy state is accepted with probability exp (-ΔΕ /kBT). Table II gives an overview of the steps in the Metropolis algorithm.

Table III draws the analogy between simulating the annealing of a metal and solving a global optimization problem.

The Metropolis procedure has been extended for solving both discrete and continuous optimization problems. Dimitrakopoulos (2011) and Leite and Dimitrakopoulos (2014) used SA for production scheduling for an open pit mine and established that, when compared to conventional deterministic scheduling approaches, the SA schedules produced NPVs that were greater by about 25%.

Role of mine planning in a mining system under uncertainty

The entire mining system is comprised of five main stages collectively known as the mine value chain (Figure 6). These stages span from the initial discovery of a deposit from exploration activities to the final rehabilitation stage. Services such as planning, maintenance, human resources (HR), finance, engineering, and safety, health, environment, and community (SHEC) are required to support activities in each of the five main stages in the mine value chain.

Mine design and mine planning are two key supporting functions within the service area of planning. According to The South African Code for the Reporting of Exploration Results, Mineral Resources and Mineral Reserves (SAMREC Code), a mine design is 'a framework of mining components and processes taking into account such aspects as mining methods used, access to the orebody, personnel and material handling, ventilation, water, power, and other technical requirements, such that mine planning can be undertaken'. Mine planning is 'production planning and scheduling, within the mine design, taking into account such aspects as geological structures and mineralisation and associated infrastructure and other constraints (SAMREC, 2016). The key distinguishing feature between the mine design process and mine planning is that mine design describes the detailed geometries and capacities of the engineering structures, while mine planning has the added dimension of time describing when and how each structure is constructed. Mine planning, therefore, plays an important role in the mine value chain as it is the basis upon which targets are set to monitor the performance of operations and ensure that mining systems are designed to operate optimally, with each stage in the mine value chain aligning with its upstream and downstream stages. Mine planning is executed from the development to the rehabilitation stages and is done throughout the life of a mining operation. At the development stage, mine planning involves Pre-feasibility Studies with 'trade-offs' similar to that done during OR development in the pre-World War II era, but in this case to evaluate options and the optimal one taken through to Feasibility Studies. After the Feasibility Study, construction of the mine then occurs, leading into exploitation.

Mine planning should produce an optimized plan. An optimized mine plan is expected to be sufficiently robust to ensure that actual outcomes are close or equal to planned targets, provided that variances arising from poor performance are minimal. However, due to the geological, technical, and economic uncertainties inherent in mining operations, this does not always happen in practice; hence the dichotomy that mine plans tend to be based on deterministic frameworks, while actual mining operations are stochastic in nature (Magagula et al., 2015). This observation explains the emerging paradigm shift towards stochastic mine planning.

The failure to have actual outcomes close to or the same as planned targets is widely acknowledged in the mining industry due to the way the industry models its systems. For example, Gold Fields (2015) acknowledged that 'failure to achieve delivery against operational plans' was the second top risk for their Australian operations. PriceWaterhouse Coopers (2015) proposed that mining companies should develop 'adaptable mine plans' to manage the impact of uncertainties such as commodity price volatility, thus implicitly advocating stochastic mine planning.

Mine plans can incorporate uncertainty such as price volatility if a shift is made away from deterministic to stochastic optimization. For example, by recognizing that commodity prices are volatile, Sabour and Poulin (2010) showed that instead of optimization models based on a commodity price, P, it is more reliable to use stochastic models for commodity price across time periods defined by ∆t, where the price is expressed through the following stochastic differential equation (SDE):

where r is the risk-free rate of return, δis the mean convenience yield on holding one unit of that commodity, a is the standard deviation or the volatility of P, and dz are the Wiener increments of the geometric Brownian motion of P. Haque et al. (2014) used the above SDE to derive the following partial differential equation (PDE):

where V is the value of the mining project; Q is the total mineral reserve; Ac is the country risk premium; C is the total cost inclusive of capex and opex cost components; and G is the applicable tax rate. The derived PDE cannot be solved analytically. Therefore, heuristics are used to solve the PDE, thus indicating that solutions to stochastic optimisation in mine planning are computationally complex.

Seminal work on optimization in mine planning and its extensions

The starting point for optimization in mine planning is a 3D block model that contains sufficient geological, geometal-lurgical, and geotechnical spatial data that informs a mine design and mine planning process. The 3D block model is the result of extensive geological and geostatistical investigations that delineate a mineral deposit's spatial characteristics into mining blocks (Sandanayake et al., 2015) and, depending on the deposit size and granularity of available data, these blocks can be in the order of thousands, hundreds of thousands, or millions of blocks. Figure 7 schematically represents a 3D block model that is used as a key input to the mine design and mine planning processes, which include optimization as an integral component.

Optimization in the mining industry started to emerge around the early 1960s, despite OR techniques having been developed as early as the 1930s. Optimization in the mining industry can be attributed to the seminal work by Helmut Lerchs and Ingo F. Grossmann, who in the 1960s developed an algorithm to find the optimum design for an open pit mine. Their algorithm, which is known as the Lerchs-Grossmann (LG) algorithm, is an approach for solving the pit limit optimization problem, sometimes referred to as the 'ultimate pit limit' (UPL) or 'ultimate pit design' (UPD) problem. On realizing that their algorithm could not be implemented on computers due to limited computing power at that time, Lerchs and Grossmann decided to publish their findings in the Canadian Mining and Metallurgical Bulletin of January 1965. They did this with the hope of revisiting implementation of the documented LG algorithm at a later stage when computing power had improved. True to their expectations, it was in 1986 that Jeff Whittle, who had become known to them, with his team successfully developed the first computer-based application of the LG algorithm, widely known in industry as the Whittle software package.

The basic assumption of the LG algorithm is that an open pit is mined essentially in two main directions, that is, downwards and sideways, but is limited sideways by geotechnically safe slope angles. The depth is limited by the economics of mining a block of ground on the ith row andjth column that is measured using a block economic value, Bij. The block economic value is derived by subtracting the costs associated with mining and processing the block of ground from the revenue accruing from selling the recoverable mineral from that block. If Bj<0, it costs more to mine the block than the revenue obtained from it ( i.e. the block should be treated as waste). If Bj>0, then mining of the block results in a net profit (i.e. the block should be treated as ore). If Bij=0, the block of ground is a mixed or marginal block. With these assumptions, an open pit can be viewed along section lines in 2D space. Figure 8 is a 2D illustration showing that block 1 can be mined only when blocks 2, 3, and 4 have been mined, irrespective of their Bijvalues, assuming a 1:1 slope constraint.

The idea is to maximize Z =∑Bij, subject to a slope constraint, such as 1:1. It is possible to compute block column values, Mij, by summing all Bijvalues for blocks above and including the block, since a block cannot be mined until those above it have been mined. By applying dynamic programming it is possible to derive the maximum pit value by considering intermediate pit values, Pij. The mathematical calculation framework is presented below.

where mnjis the economic value of a block located in row n and column j; j is the number of columns in the section; Mijis the block column value; and the pit value, Pij, is calculated as the maximum of the preceding pit values and the current block column value as follows:

When the model is extended to cover real-world open pit optimization, the indexing of the model parameters changes from (i, j) to (i, j, k) for 3D space. Before a block (green block) can be mined in 3D, nine other blocks should have been mined previously (Figure 9). In moving from 2D to 3D the number of predecessor blocks increases from 3 to 9, hence the problem becomes computationally more difficult and requires more computational time. However, this challenge has been partly overcome through modified algorithms and the transition from 32-bit to 64-bit computers with about 24 GB RAM that are able to process computations quicker and have increased data storage capacity. With these computing developments a realistic open pit with about 5 million blocks each measuring 2 m x 2 m x 2 m can be processed in between 15 minutes and 3 hours, depending on the slope angles applied and how the LG algorithm was modified. However, 3D extensions of the LG algorithm tend to produce erratic results compared to the LG algorithm in 2D (Gholamnejad and Mojahedfar, 2010).

The inherent assumption in the LG algorithm is that block economic values are known with certainty. However, in the real mining environment, geological, technical, and economic parameters are never known with certainty, and also change over time due to improved understanding of an operation. To address uncertainty, optimization algorithms have been extended to their stochastic variants. For example, the work of Whittle et al. (2007) extended the deterministic pit optimization approach to generate probability pits with probabilities attached to each pit limit (Figure 10). In this way it is possible to proactively locate infrastructure outside limits that could eventually become part of the pit configuration should conditions change, thus improving the confidence level of the planning. A similar approach can be extended to optimization of stope envelopes in underground mine planning.

Circular logic of optimization in open pit and underground mine planning

Optimization in open pit mine planning follows a circular logic (Dagdelen, 2001; Osanloo et al., 2008; Newman et al., 2010). The objective is to maximize the NPV of the pit, but the pit outline with the maximum NPV cannot be determined until the block values are known. In turn, the block values are not known until the mining sequence is determined; and the mining sequence cannot be determined unless the pit outline and cut-off grade are known. The work by Lane (1988) is central to cut-off grade optimization, but as Alford et al. (2006) noted it has proved useful in the design of open pit mines, yet is difficult to apply to the design of underground mines. To simplify the problem so that it can be solved, the most common approach is to divide the problem into tractable sub-problems similar to that shown in Figure 11. However, by breaking down the problem into subproblems, the resultant solution will be sub-optimal because 'the sum of the parts does not equal the whole'. This realization is driving the paradigm shift from isolated optimization towards integrated optimization.

The analogy between open pit optimization and optimization in underground mine planning is proposed in Figure 12, which indicates the circular logic of optimization in underground mine planning. Again, the optimization problem in underground mine planning is divided into computationally tractable sub-problems as with the open pit optimization case.

The optimization objective is to maximize the NPV of the mine design, but the development and stope layout with the maximum NPV cannot be determined until the production costs and associated cut-off grade are known. In turn, the production costs and associated cut-off grade are not known until the mining layout and production scheduling have been determined; and the mining layout and scheduling cannot be determined unless the mining method and production capacity are available. Selection of the mining method is an MCDM optimization exercise such as in the work of Musingwini and Minnitt (2008) and Karadogan et al. (2008). Yavuz (2015) listed 15 case studies in which MCDM techniques have been used for mining method selection. However, mining method selection is dependent on prior determination of production capacity. Work on determining optimal sizing of the production of a mine was pioneered by Taylor (1986), and a historical review of work done on optimizing mine capacity was provided by Hajdasinski (1988).

King (2011) noted the complexity around the interpretation of the 'optimal' concept by mining engineers, especially when optimization is done in isolation as some form of technical or financial optimization. However, it is always important to understand the general optimization process in mine planning in order to meaningfully interpret the results obtained. Education and training in optimization in mine planning are essential to realize this objective.

Developments in optimization in underground mine planning

As stated earlier, optimization in open pit mine planning is well developed and widely applied because for an open pit mine, the direction of mining is essentially down and outward to the pit limits. However, optimization in underground mine planning is intrinsically more complex, because there are numerous permutations of the direction of mining, such as advance or retreat mining, depending on the mining method chosen (Alford et al., 2006; Musingwini 2009, 2010; Topal and Sens, 2010; Sandanayake, 2014). In addition, individual underground mines have unique designs and operations to suit the specific characteristics of each mineral deposit, thus making generic optimization difficult (Newman et al., 2010; Alford et al., 2006). It has also been observed that most of the optimization algorithms in underground mine planning fail to guarantee true optimality in a 3D space (Ataee-Pour, 2000; Sandanayake, 2014). These are the main reasons why there is a lack of extensive optimization algorithms and commercial software packages for underground mining, and why most of the work on optimization in underground mine planning is largely academic. There are a few practical applications, such as that of Alford (1995), which is embedded in Datamine, Snowden's Stopesizor mining software package, used internally by Snowden Consultants to produce a single mining outline for a selected cut-off grade, and the Anglo Platinum Optimisation Tool (APMOT) (Smit and Lane, 2010).

Optimization in underground mine planning has therefore been focused on three main areas, namely: development infrastructure layout; stope boundaries or envelopes; and production scheduling (Sens and Topal, 2009; Topal and Sens, 2010; Sandanayake, 2014). Optimizing equipment selection and deployment is also part of underground mine planning. Selection and deployment of equipment is important because ignoring it can result in operational inefficiency, with operational symptoms such as low equipment productivity. With proper mine planning, equipment utilization can also be improved through optimization processes such as the Theory of Constraints (TOC). Most of the developments in optimization in mine planning have been made possible through the greatly improved computing power and capacity and increased exposure to OR techniques by the mining industry.

Developments in optimization of development layout

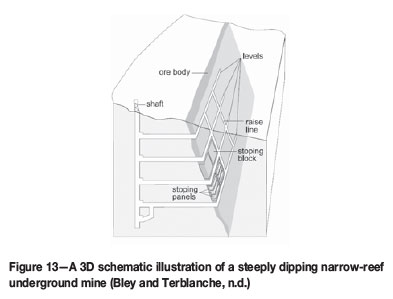

Figure 13 is a schematic layout of a steeply dipping, narrow-reef underground mine, showing stopes that are demarcated by main development such as levels and raises. The challenge with underground mining is that unlike open pit mining, it is very unforgiving because once the development infrastructure has been laid out, the operation is 'locked-in' to the layout and any future layout changes can be very capital-intensive. Therefore, optimization of the development layout is critical for the future operation of an underground mine.

Optimization of the development layout must consider financial, technical, and safety requirements (Musingwini, 2009, 2010). The financial requirements include minimizing operating costs by spacing out development, minimizing capital costs, and maximizing NPV. The technical requirements include maximizing shaft head grade through selective mining, which is possible if development spacing is reduced; maximizing extraction ratio, and maximizing productivity by reducing development spacing. The safety requirements include concentrating production in areas close to each other to improve supervision and minimizing unsupported spans to achieve better geotechnical stability, which can be achieved by reducing development spacing. When spacing of development is increased, some of the associated desirable and undesirable impacts that occur concomitantly, resulting in conflicting objectives are (Musingwini, 2009, 2010):

► The stope size increases, resulting in a decrease in the number of stopes per unit area of the orebody. When the number of stopes per unit area decreases, the number of points of attack for production decreases, making it more difficult to relocate production teams should a stope area become unsafe. This is an undesirable outcome

►Operating flexibility decreases as a result of reduced points of attack caused by fewer stopes per unit area. This is an undesirable outcome

►Ore reserve replacement ratio increases since more reserves are created with less development. This is a desirable outcome

►Productivity decreases due to reduced flexibility and points of attack. This is an undesirable outcome, even though the decrease in productivity may be offset by potential savings in development costs

►An increase in development spacing reduces the number of areas and hence the density of sampling of stopes. This is undesirable because a decrease in sampling density compromises the quality of ore reserve estimation, although multiple point statistics (MPS) can now be applied to improve grade estimation for sparsely distributed samples

►By increasing development spacing, production stopes become more spread out, making concentrated mining difficult to achieve, leading to reduced productivity. In addition, supervision becomes increasingly difficult because working places are further apart, impacting both productivity and safety. Musingwini (2009, 2010) noted that increasing development spacing potentially leads to undesirable productivity and safety outcomes.

These observations indicate that the layout of development infrastructure has conflicting requirements and so should be optimized using MCDM techniques. Several case studies have been reported on the application of MCDM techniques for optimal layout of development, such as the work by Musingwini (2009, 2010).

Developments in optimal sizing of stope envelopes

In order to generate an optimal stope layout it is necessary to combine several contiguous mining blocks, each with an economic value Bij, into a set of stopes, while satisfying the physical mining and geotechnical requirements in order to produce a layout with maximum value. However, the decision on whether or not a mining block is included in a stope requires that all possible combinations from thousands of mining blocks are evaluated for variable stope sizes and pillars to obtain the maximum value stopes. This introduces computational complexity in the stope optimization problem. Exact algorithms for such a problem are intractable, and heuristic algorithms are therefore used. Figure 14 illustrates the computational complexity in a simple 2D hypothetical orebody model containing just 64 mining blocks. These would be stopes as seen along a longitudinal section taken along strike in Figure 13.

Figure 14(a) illustrates a stope layout for a 3 x 3 stope size in which a candidate mining block, b, may become part of 1 out of 9 possible stope combinations such as stopes 1 and 2. Avoiding of stope overlaps, as these are not practical, requires that only 1 out of the 9 stopes be selected, and the selected stope must result in an optimal value. Figure 14(b) shows that as the stope size increases, the candidate mining block, b, becomes part of 1 out of 16 possible stope combinations, indicating that as stope size increases the number of stope combinations escalates exponentially, thus making the problem more complex to solve. The complexity of the underground stope optimization problem necessitates solution by heuristic approaches. Consequently, few algorithms have been developed for optimizing underground mining stope envelopes and none of these approaches can guarantee an optimum solution in 3D space (Little, 2012). One of the earliest attempts at solving this problem was the work by Alford (1995), who developed the heuristic floating stope algorithm to define the optimum stope envelopes, analogous to the floating cone algorithm used in open pit optimization. The floating stope algorithm assumes that, given a cut-off grade and a minimum mining width, economic stopes can be defined. A stope shape of the minimum stope dimension is floated around the block model to locate the position of the stope with the highest grade. The main limitation of this algorithm is that stopes overlap, making it difficult to define optimum stope layouts and requiring manual interventions (Little, 2012). The multiple pass floating stope process and the Vulcan stope optimizer are some of the extensions of the floating stope algorithm embedded in the Datamine and Maptek mining software packages, respectively.

Ataee-Pour (2006) presented an application of the maximum value neighbourhood (MVN) heuristic algorithm to determine optimal stope envelopes. He ran a multiple pass of the algorithm to remove waste blocks from the final stope envelope and add other ore blocks to it, since a single-pass MVN stope envelope may contain waste blocks or exclude ore blocks.

Topal and Sens (2010) developed an algorithm to find an optimum stope layout for a given resource model in 3D for different stope sizes and stope selection strategies. Little (2012) developed an algorithm that simultaneously optimizes stope layouts and production schedules for sublevel stoping operations. The algorithm was developed using the integer programming (IP) technique. Previously, most underground optimization techniques focused on optimizing stope layouts and production schedules separately. The idea behind Little's algorithm was to integrate the two and optimize them simultaneously.

Sandanayake et al. (2015) developed a heuristic algorithm to find a 3D optimal stope layout for an orebody by maximizing economic value while satisfying mining and geotechnical constraints. When tested against the maximum value neighbourhood (MVN) algorithm and the Sens and Topal (2010) heuristic algorithm, the algorithm generated higher value solutions than these two existing algorithms.

Developments in optimization of underground production scheduling

Production scheduling specifies the mining sequence for economic stopes and the associated mine development required to bring the stopes into production. The optimization decision hinges on variables that represent the time at which to mine each stope in order to maximize NPV subject to operational constraints such as mining infrastructure production capacity constraints, milling capacity constraints, grade and geometallurgical constraints, and rules on precedence relationships between stopes. Production scheduling can be executed for both short-term and longterm planning. Short-term and long-term production scheduling optimization for mines has received a lot of attention through the application of LP variants such as IP and MIP (Alford et al., 2006; Newman et al., 2010). Integrated LP and MIP modules, also called large-scale linear programming solutions (LSPS), have also been used for production scheduling. For example, Guest et al. (n.d.) reported on the application of integrated LP for short-term production scheduling and MIP for long-term production scheduling for underground block cave operations.

Smit and Lane (2010) presented an application of the Anglo Platinum Mine Optimisation Tool (APMOT), which is a form of an enterprise-wide optimization tool for optimizing the scheduling of a mine production system for conventional or mechanized underground platinum mining by taking into account all geological, mine design, and mining method parameters. Their work was based on experience-based rules to constrain the system, but did not mention the application of any specific OR techniques.

Developments in optimization of underground equipment selection and utilization

Geotechnical constraints dictate the size of excavations and hence the dimensions of equipment that can fit into those excavations, while complying with legal requirements for safety. Once the maximum equipment dimensions are known, the equipment optimization problem becomes a two-stage problem as described by Krause and Musingwini (2007) and Newman et al. (2010). The first stage focuses on fleet size estimation and the second on equipment deployment using computerized dispatch systems such as Dispatch®. For the first stage, MCDM techniques have generally been used to optimize the selection of underground mining equipment fleets. In order to estimate the production rates and productivity of the equipment fleets, simulation studies have been done using such software as variants of the General Purpose Simulation System (GPSS) and Arena. In some cases models based on LP variants have been used for optimal equipment deployment, backed up by simulation analyses. In order to optimize equipment utilization, TOC has often been used, for example in the study by Andrews and Pickering (2010), who reported about 32% improvement in machine cycle time for an underground mechanized platinum mining operation.

Opportunities in optimization in underground mine planning

The proliferation of commercially available optimization algorithms and software has been made possible by the greatly improved computing power and data storage capacity that has become available over the past decades. There is sometimes a tendency to accept whatever solution the computer or software package generates as 'true' or 'correct'. McCarthy (2010) also observed that many commercially available optimizers are presented as 'black boxes' that produce solutions which clients cannot verify as they are not privy to the optimizer methodology. Therefore, it is always important to understand the optimization processes in mine planning in order to meaningfully interpret and communicate results for decision-making. These and other challenges mentioned earlier create the following opportunities for optimization in underground mine planning:

► Offering mine planning and optimization specializations in university master's degree programmes such as the MSc in Mine Planning and Optimisation that was introduced in 2014 by Wits Mining (Musingwini, 2014). In addition, Wits Mining also established a small Mine Planning Optimisation and Valuation (MPOV) group that is researching various optimization algorithms for underground mining. Such programmes will develop better-equipped professionals who can contribute to solving mine planning optimization problems in the mining industry

► Developing more robust mine planning through stochastic optimization by extending the work of Whittle et al. (2007) on probability pit design to probability underground excavation design of stopes and development in order to improve confidence in the placement and sizing of excavations

► Integrating stochastic optimization within the four broad areas in underground mine planning -development layout, sizing stope envelopes, production scheduling, and equipment selection and utilization -so that these can be executed simultaneously and enable planning of just-in-time development as described by Musingwini (2004, 2009) and Musingwini et al. (2003). In addition, the integrated optimization should guarantee true optimality in 3D space and incorporate uncertainty, thus making a case for integrated 3D stochastic optimization

► Crafting simple, effective, and meaningful ways of communicating stochastic information for decision-making, which often requires some kind of 'crisp' values rather than a range of values as depicted in Figure 15. A possible way is to use an acceptable confidence level, Cplan, to plan production targets(e.g. C80, C85, C90, etc.). Cplan is selected such that the variance between historical data (where it exists) and the planned target is at a minimum. Where historical data is not available, data from a reasonably similar operation can be used.

In all these opportunities, it is important to always ask questions such as: How do we know we are getting it right? Is it through obtaining higher NPVs? Is it because the optimized plans are robust enough for operations to survive tough economic times?

Conclusions

Optimization in mine planning developed from the application of OR techniques to solve optimization problems in mining. Its growth has relied heavily on the greatly improved computing power and data storage capacity that has become available over the past decades. Consequently, well-developed optimization algorithms and software are now routinely applied to solve optimization problems in open pit mines. Open pit optimization developed extensively because the direction of mining in open pit mines is essentially down and outward to the pit limits, making the problem easy to model. However, optimization in underground mine planning remains largely fertile ground for new developments because the direction of mining in underground mines has numerous permutations, depending on the mining method used, making the underground mining optimization problem intrinsically more complex to solve. This complexity explains the isolated piecemeal developments for solving parts of the overall optimization problem in underground mine planning in four key interdependent areas, namely: development layout, sizing stope envelopes, production scheduling, and equipment selection and deployment. Many opportunities therefore, exist for the development of integrated 3D stochastic optimization models for underground mine planning.

References

Alford, C. 1995. Optimisation in underground mine design. Proceedings of APCOM XXV: Application of Computers and Operations Research in the Minerals Industries, Brisbane, Australia, 9-14 July 1995. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 213-218. [ Links ]

Alford, C., Brazil, M., and Lee, D.H. 2006. Optimisation in Underground Mining. https://www.researchgate.net/publication/227033781 DOI: 10.1007/978-0-387-71815-6_30 [Accessed 6 June 2016]. [ Links ] Chapter 30.

Andrews, M. and Pickering, R.G.B. 2010. A systematic approach to the optimization of extra low profile (XLP) mine productivity for narrow reef platinum mines. Proceedings of the 4th International Platinum Conference: Platinum in Transition 'Boom or Bust', Sun City, South Africa. 11-14 October, 2010. Southern African Institute of Mining and Metallurgy, Johannesburg. pp. 267-276. [ Links ]

Ataee-pour, M. 2000. A heuristic algorithm to optimise stope boundaries. PhD thesis, Faculty of Engineering, University of Wollongong. http://ro.uow.edu.au/cgi/viewcontent.cgi?article=3923&context=theses [Accessed 15 February 2016]. [ Links ]

Ataee-pour, M. 2006. The MVN multiple pass algorithm for optimisation of stope boundaries. Iranian Journal of Mining Engineering, vol. 1, no. 2. pp. 7-20. [ Links ]

Beasely, J.E. Not dated. OR-Notes. http://people.brunel.ac.uk/~mastjjb/jeb/or/intro.html [Accessed 14 February 2015]. [ Links ]

Bley, A. and Terblanche, S.E. Not dated. An improved formulation of the underground mine scheduling optimization problem when considering selective mining. http://www.optimization-online.org/DB_FILE/2012/11/3687.pdf [Accessed 15 June 2016]. [ Links ]

Dagdelen, K. 2001. Open pit optimization - strategies for improving economics of mining projects through mine planning. Proceedings of the 17th International Mining Congress and Exhibition of Turkey (IMCET). Chamber of Mining Engineers of Turkey. pp. 117-121. [ Links ]

Dimitrakopoulos, R. 2011. Stochatsic optimization for strategic mine planning: A decade of developments. Journal of Mining Science, vol. 47, no. 2. pp. 138-150. [ Links ]

Dowd, P.A. and Elvan, A. 1987. Dynamic programming applied to grade control in sub-level open stoping. Transactions of the Institution of Mining and Metallurgy: Section A (Mining Technology), vol. 96. pp. A171-A178. [ Links ]

Gholamnejad, J. and Mojahedfar, A.R. 2010. Determination of the largest pit with the non-negative net profit in the open pit mines. International Journal of Mining and Environment, vol. 1, no. 2. pp. 45-52. [ Links ]

Gilani, A. and Sattarvand, J. 2016. Integrating geological uncertainty in longterm open pit mine production planning by ant colony optimization. Computers and Geosciences, vol. 87. pp. 31-40. [ Links ]

Gold Fields Limited. 2015. Integrated Annual Report. Johannesburg. [ Links ]

Goodfellow, R.C. and Dimitrakopoulos, R. 2016. Global optimization of open pit mining complexes with uncertainty. Applied Soft Computing, vol. 40. pp. 292-304. [ Links ]

Guest, A.R., van Hout, G.J., von Johannides, A., and Scheepers, L.F. Not dated. An application of linear programming for block cave draw control. http://lslps.com/blockcave/index.htm [Accessed 14 February 2015]. [ Links ]

Hajdasinski, M.M. 1988. Optimization of mine size and mine life in a historical perspective. Mining Science and Technology, vol. 7. pp. 305-310. [ Links ]

Haque, Md. A., Topal, E., and Lilford, E. 2014. A numerical study for a mining project using real options valuation under commodity price uncertainty. Resources Policy, vol. 39. pp. 115-123. [ Links ]

Karadogan, A., Karhiman, A., and Ozer, U. 2008. Application of fuzzy set theory in the selection of an underground mining method. Journal of the Southern African Institute of Mining and Metallurgy, vol. 108, no. 2. pp. 73-79. [ Links ]

Khan, A. and Niemann-Delius, C. 2014. Production scheduling of open pit mines using particle swarm optimization algorithm. Advances in Operations Research, vol. 2014. pp. 1-9. [ Links ]

King, B. 2011. Optimal mining practice in strategic planning. Journal of Mining Science, vol. 47, no. 2. pp. 247-253. [ Links ]

Kirkpatrick, S., Gelatt C.D., and Vecchi, M.P. 1983. Optimization by simulated annealing. Science, vol. 220, no. 4598. pp. 671-680. [ Links ]

Krause, A. and Musingwini, C. 2007. Modelling open pit shovel-truck systems using the Machine Repair Model. Journal of the Southern African Institute of Mining and Metallurgy, vol. 107, no. 8. pp. 469-476. [ Links ]

Kumral, M. 2004. Genetic algorithms for optimization of a mine system under uncertainty. Production Planning and Control, vol. 15, no. 1. pp. 34-41. [ Links ]

Lane, K.F. 1988. The Economic Definition of Ore: Cut-off Grade in Theory and Practice. Mining Journal Books, London. [ Links ]

Leite, A. and Dimitrakopoulos, R. 2014. Stochastic optimization of mine production scheduling with uncertain ore/metal/waste supply. International Journal of Mining Science and Technology, vol. 24. pp. 755-762. [ Links ]

Little, L. 2012. Simultaneous optimisation of stope layouts and production schedules for long-term underground mine planning. PhD thesis, University of Queensland. [ Links ]

Magagula, N.S., Musingwini, C., and Ali, M.M. 2015. Multinomial logistic regression analysis of a stochastic mine production system. Proceedings of the 23rd International Symposium on Mine Planning and Equipment Selection (MPES2015): Smart Innovation in Mining, Johannesburg, South Africa, 9-11 November 2015. Southern African Institute of Mining and Metallurgy, Johannesburg. pp. 331-339. [ Links ]

McCarthy, P.L. 2010. Beyond the feasibility study - Mine optimisation in the real world. Proceedings of the 2nd International Seminar on Strategic versus Tactical Approaches in Mining, Perth, Western Australia, 8-10 March 2006. Australian Centre for Geomechanics (ACG), university of Western Australia. pp.1-8. [ Links ]

Metropolis, N., Rosenbluth, A.W., Rosenbluth, M.N., Teller, A.H., and Teller, E. 1953. Equation of state calculation by fast computing machines. Journal of Chemical Physics, vol. 2, no. 6. pp. 1087-1091. [ Links ]

Musingwini, C. 2004. Some thoughts on strategic development planning for 'no-surprises-mining'. Proceedings of the International Symposium on Orebody Modelling and Strategic Mine Planning: Uncertainty and Risk Management, Perth, Australia, 22-24 November 2004. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 59-62. [ Links ]

Musingwini, C. 2009. Techno-economic optimisation of level and raise spacing range in planning a Bushveld Complex platinum reef conventional breast mining layout. PhD thesis, university of the Witwatersrand. http://wiredspace.wits.ac.za/handle/10539/8291 [Accessed 11 February 2016]. [ Links ]

Musingwini, C. 2010. Techno-economic optimization of level and raise spacing in Bushveld Complex platinum reef conventional breast mining. Journal of the Southern African Institute of Mining and Metallurgy, vol.110, no. 8. pp. 425-436. [ Links ]

Musingwini, C. 2014. Introduction of specialization in Mine Planning and Optimisation within the Master's degree (MSc) programme at the University of Witwatersrand. Proceedings of the 6th International Platinum Conference, 'Platinum-Metalfor the Future', 20-22 October 2014. Southern African Institute of Mining and Metallurgy, Johannesburg. pp. 23-27. [ Links ]

Musingwini, C. and Minnitt, R.A. 2008. Ranking the efficiency of selected platinum mining methods using the analytical hierarchy process (AHP). Proceedings of the Third International Platinum Conference, 'Platinum in Transformation', Sun City, South Africa, 5-9 October 2008. Southern African Institute of Mining and Metallurgy, Johannesburg. pp. 319-326. [ Links ]

Musingwini, C., Minnitt, R.C.A., Phuti, D., and Makwara, F. 2003. Just-in-time development model for a sub-level caving underground mine in Zimbabwe. Journal of the South African Institute of Mining and Metallurgy, vol. 103, April 2003. pp. 187-191. [ Links ]

Newman, A.M., Rubio, E., Caro, R., Weintraub, A., and Eurek, K. 2010. A review of operations research in mine planning. Interfaces, vol. 40, no. 3. pp. 222-245. [ Links ]

Osanloo, M., Gholamnejad, J., and Karimi, B. 2008. Long-term open pit mine production planning: a review of models and algorithms. International Journal of Mining, Reclamation and Environment, vol. 22, no. 1. pp. 3-35. [ Links ]

PriceWaterhouseCoopers. 2015. Mine 2015 - The gloves are off. http://www.pwc.com/gx/en/mining/publications/assets/pwc-e-and-m-mining-report.pdf [Accessed 31 May 2016]. [ Links ]

Sabour, S.A.A. and Poulin, R. 2010. Mine expansion decisions under uncertainty. International Journal of Mining, Reclamation and Environment, vol. 24, no. 4. pp. 340-349. [ Links ]

SAMREC. 2016. South African Mineral Resource Committee. The South African Code for the Reporting of Exploration Results, Mineral Resources and Mineral Reserves (the SAMREC Code) 2016. The Southern African Institute for Mining and Metallurgy (SAIMM) and the Geological Society of South Africa (GSSA). [ Links ]

Sandanayake, D.S.S. 2014 Stope boundary optimisation in underground mining based on a heuristic approach. PhD thesis, Western Australian School of Mines, Curtin university, Queensland. [ Links ]

Sandanayake, D.S.S., Topal, E., and Asad, M.W.A. 2015. Designing an optimal stope layout for underground mining based on a heuristic algorithm. International Journal of Mining Science and Technology, vol. 25. pp. 767-772. [ Links ]

Sens, J. and Topal, E. 2009. A new algorithm for stope boundary optimisation, Proceedings of New Leaders 2009. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 25-28. [ Links ]

Smit, A. and Lane, G. 2010. Mine optimization and its application using the Anglo Platinum Mine Optimisation Tool (APMOT). Proceedings of the 4th International Platinum Conference, Platinum in Transition 'Boom or Bust', Sun City, South Africa. 11-14 October, 2010. Southern African institute of Mining and Metallurgy, Johannesburg. pp. 317-328. [ Links ]

Taylor, H.K. 1986. Rates of working of mines - a simple rule of thumb, Transactions of the Institution of Mining and Metallurgy, Section A: Mining Industry, October 1986. pp. A203-A204. [ Links ]

Topal, E. and Sens, J. 2010. A new algorithm for stope boundary optimisation. Journal of Coal Science and Engineering, vol.16, no. 2. pp. 113-119. [ Links ]

Whittle, G., Stange, W., and Hanson, N. 2007. Optimising project value and robustness. Proceedings of the Project Evaluation Conference, Melbourne, Australia, 19-20 June 2007. Australasian Institute of Mining and Metallurgy, Melbourne. pp.147-155. [ Links ]

Yavuz, M. 2015. The application of the analytic hierarchy process (AHP) and Yager's method in underground mining method selection problem. International Journal of Mining, Reclamation and Environment, vol. 29, no. 6. pp. 453-475. [ Links ]