Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.116 no.8 Johannesburg Ago. 2016

http://dx.doi.org/10.17159/2411-9717/2016/v116n8a12

PAPERS OF GENERAL INTEREST

The prediction of penetration rate for percussive drills from indirect tests using artificial neural networks

S. Kahraman

Hacettepe University, Mining Engineering Department, Ankara, Turkey

SYNOPSIS

Percussive drills are widely used in engineering projects such as mining and construction. The prediction of penetration rates of drills by indirect methods is particularly useful for feasibility studies. In this investigation, the predictability of penetration rate for percussive drills from indirect tests such as Shore hardness, P-wave velocity, density, and quartz content was investigated using firstly multiple regression analysis, then by artificial neural networks (ANNs). Operational pressure and feed pressure were also used in the analyses as independent variables. ANN analysis produced very good models for the prediction of penetration rate. The comparison of ANN models with the regression models indicates that ANN models are the more reliable. It is concluded that penetration rate for percussive drills can be reliably estimated from the Shore hardness and density using ANN analysis.

Keywords: percussive drills, penetration rate, indirect rock properties, regression analysis, artificial neural network.

Introduction

Percussive drills are extensively used in open pits, quarries, and on construction sites. The prediction of the penetration rate of drilling machines is very important for cost estimation and planning of rock excavation projects. Many researchers have investigated percussive drilling theoretically or experimentally and correlated the penetration rate with various rock properties.

Protodyakonov (1962) developed drop tests and described the coefficient of rock strength (CRS) used as a measure of the resistance of rock to impact. The Protodyakonov test was subsequently modified by Paone, Madson, and Bruce (1969), Tandanand and Unger (1975), and Rabia and Brook (1980, 1981). Paone, Madson, and Bruce (1969) conducted research work on percussion drilling in the field. They concluded that uniaxial compressive strength (UCS), tensile strength, Shore hardness, and static Young's modulus correlated tolerably well with penetration rates in nine hard and abrasive rocks. A much better correlation was obtained by using the CRS. Paone, Madson, and Bruce stated that no single property of a rock was completely satisfactory as a predictor of penetration rate. Tandanand and Unger (1975) developed an estimation equation that showed good correlation with actual penetration rates of percussive drills. They concluded that CRS was useful in predicting penetration rate and had a higher reliability than other rock properties. Rabia and Brook (1980, 1981) used a modified test apparatus to determine the rock impact hardness number and developed an empirical equation for predicting drilling rates for both down-the-hole and drifter drills. The equation relating penetration rate to drill operating pressure, Shore hardness, and rock impact hardness number was found to give excellent correlation for field data obtained from down-the-hole and drifter drills.

Selmer-Olsen and Blindheim (1970) conducted percussion drilling tests in the field using light drilling equipment with chisel bits. They established a good correlation between penetration rate and the drilling rate index (DRI) and found that rock hardness, strength, brittleness, and abrasivity were important in drilling. Selim and Bruce (1970) carried out percussive drilling experiments on nine rocks in the laboratory. They correlated the penetration rate for a specific drill rig with compressive strength, tensile strength, Shore hardness, apparent density, static and dynamic Young's modulus, shear modulus, CRS, and percentage of quartz, and established linear predictive equations. They stated that the established equations could be used for predicting the performance of percussive drills. Schmidt (1972) correlated the penetration rate with compressive strength, tensile strength, Shore hardness, density, static and dynamic Young's modulus, shear modulus, longitudinal velocity, shear velocity, and Poisson's ratio. He found that only compressive strength and those properties highly correlated with it, such as tensile strength and Young's modulus, exhibited good correlations with penetration rate. Pathinkar and Misra (1980) correlated several rock properties with the penetration rate obtained from laboratory-scale drilling in five different rock types, and concluded that conventional rock properties such as compressive strength, tensile strength, specific energy, Shore hardness, and Mohs hardness did not individually provide good correlation with penetration rate. They developed a good correlation between penetration rate and a set of rock properties, but the relationship was complex.

Howarth, Adamson, and Brendt (1986) correlated penetration rate with rock properties and found that bulk density, saturated compressive strength, apparent porosity, and saturated P-wave velocity exhibited strong corrrelations with penetration rate. However, the correlations of penetration rate, Schmidt hammer value, and dry compressive strength were not strong. They stated that porosity could influence drillabillity, since high porosity was likely to assist the formation of fracture paths and networking of such paths. Howarth and Rowland (1987) developed a quantitative measure of rock texture - the texture coefficient - and found a close relation between the texture coefficient and percussion drill penetration rates. They found that a rock with a high texture coefficient has a low drillability and a high compressive strength. Thuro and Spaun (1996) measured drilling rates using 20 kW and 15 kW borehammers (Atlas Copco COP 1440 and COP 1238 ME) together with the geological documentation of the tunnel face. They correlated specific rock properties with the penetration rates of percussive drills and concluded that penetration rate exhibits strong logarithmic relationships with compressive and tensile strength. They also introduced a new rock property, termed 'destruction work', for toughness referring to drillability, and found a highly significant correlation between destruction work and drillability. Kahraman (1999) developed penetration rate models for down-the-hole and hydraulic top-hammer drills using multiple curvilinear regression analysis. The results showed that the parameters significantly affecting penetration rate of down-the-hole drills were operating pressure, piston diameter, and Schmidt hammer value. For hydraulic tophammer drills, the most significant parameters were blow frequency, compressive strength, and quartz content of the rock. Kahraman (2002) statistically investigated the relations between penetration rate of percussive drills and three different measures of brittleness obtained from compressive strength, tensile strength, and percentage of fines formed in the Protodyakonov test using the raw data obtained from the experimental work of different researchers. He showed that there was no correlation between penetration rate and the brittleness values derived from compressive strength and tensile strength. However, he found a strong correlation between penetration rate and the brittleness value derived from compressive strength and percentage of fines formed in the Protodyakonov test. He concluded that each method of measuring brittleness has its usage in rock drilling, depending on practical utility, i.e. one method of measuring brittleness shows good correlation with the penetration rate of percussive drills, while the other method does not. Kahraman, Bilgin, and Feridunoglu (2003) observed percussive blast-hole drills in eight rock types at open pit mines and three motorway sites and correlated penetration rates with rock properties. They found good correlations between the penetration rate and some rock properties.

Compared to the traditional expert systems, artificial neural networks (ANNs) are highly simplified models of nervous systems in the human brain and have some important features such as self-learning, adaptive recognition, and nonlinear dynamic processing. For this reason, ANNs have been used extensively in science and engineering applications in recent years. ANNs have also been applied in geotechnical engineering (Yuanyou, Yanming, and Ruigeng, 1997; Yang and Zhang, 1998; Singh, Singh, and Singh, 2001; Sonmez et al., 2006; Zorlu et al., 2008; Kahraman et al., 2005, 2009, 2010).

There are few studies in the literature on the predictability of drilling rate from ANNs. Akin and Karpuz used an ANN to estimate major drilling parameters such as weight on bit, rotational speed, and bit type for diamond drilling. They concluded that the proposed methodology provided satisfactory results both in relatively less-documented and drilled formations as well as in well-known formations. Monazami, Hashemi, and Shahbazian (2012) investigated the predictability of penetration rate in oil well rotary drilling by using an ANN. They constructed an ANN model and showed that penetration rate could be estimated by using the derived model. Aalizad and Rashidinejad (2012) studied the predictability of penetration rates of rotary-percussive drill using an ANN. Their model includes intact rock properties, rock mass characteristics, the operational variables of the drill, and some blast-hole parameters. They stated that the ANN was a suitable tool for the prediction of the penetration rate of percussive drills. Basarir, Tutluoglu, and Karpuz (2014) evaluated penetration rate prediction for diamond bit drilling by adaptive neuro-fuzzy inference system (ANFIS) and multiple regression. They found that the prediction performances of the ANFIS model were better than those derived from the traditional multiple regression model, and that the constructed models can be used for an initial estimation of the penetration rate for similar cases. Khandelwal and Armaghani (2016) investigated the predictability of drilling rate index (DRI), which is a measure of percussive drilling rate, from hybrid genetic algorithm and artificial neural network (GA-ANN) models. They reported that hybrid GA-ANN technique performed better in predicting DRI compared to other developed models such as multiple regression and ANN.

Although there are some studies in the literature on drillability prediction from ANNs, only one of these (Aalizad, and Rashidinejad, 2012) is related to percussive drilling and includes numerous direct and indirect test results. In the current study, because indirect tests are easy and economical to carry out, the predictability of penetration rate for percussive drills from indirect tests such as Shore hardness, P-wave velocity, density, and quartz content is investigated using an ANN.

Data analysis

The raw data was obtained from the study by Selim and Bruce (1970). They reported the penetration rate data for percussive drills used in the laboratory. Two drills were used for drilling nine different rocks in the experiments. The drill included in this study was a 6.67 cm bore jackleg type, which drill is a backstroke rifle-bar-rotation machine and bit diameter is confined to 3.81 cm cross-bits. Operational pressure was changed from 4.8 bar to 6.9 bar and feed pressure was changed from 4.1 bar to 6.2 bar during drilling tests for each rock type.

The descriptive statistics for the rock sample data are listed in Table I, showing minimum, maximum, and average values together with the standard deviations for each test type. The skewness values of each test are also given.

Regression analysis

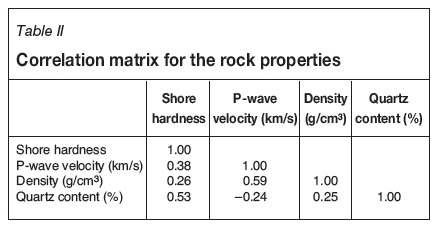

Firstly, the correlation matrix was constructed for the rock properties to determine whether high redundancies exist between these independent variables. As shown in Table II, the correlation coefficients between the rock properties are weak, indicating there is no redundancy between the parameters. However, the correlation coefficients for density and P-wave velocity, and quartz content and Shore hardness, are not very weak. This may give rise to multicollinearity. For this reason, density and Shore hardness were selected for regression analysis since it is simpler to test these variables than the others.

Multiple regression analysis was performed for the estimation of penetration rate, including the parameters operational pressure, feed pressure, and rock properties, and three models were developed. Since the operational pressure and feed pressure are intrinsic drilling parameters, they were included in all models. A total of 100 data points were used in the regression analysis. 22 data points that were used in the ANN analysis were used for the validation of the derived models. The derived models, together with the correlation coefficients (r) and standard errors (SE), are as follows:

where PR is the penetration rate (cm/dk), OP is the operational pressure (bar), FP is the feed pressure (bar), SH is the Shore hardness, and ρ is the density (g/cm3).

Equations [1] and [2] have very strong and strong correlation coefficients, respectively. However, the correlation coefficient of Equation [3] is weak. All regression equations were evaluated in the ANN analysis.

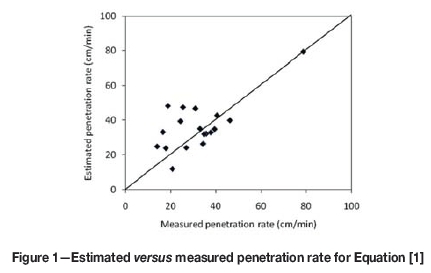

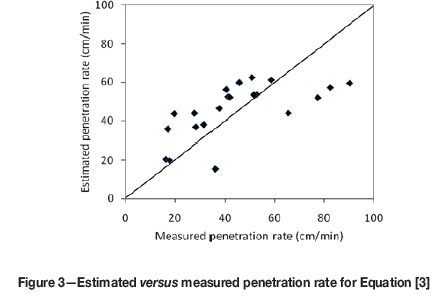

The regression models were validated by drawing scatter diagrams of the observed and estimated values. Ideally, on a plot of observed versus estimate values, the points should be scattered around the 1:1 diagonal straight line. A point lying on the line indicates an exact estimation. A systematic deviation from this line may indicate, for example, that larger errors tend to accompany larger estimations, suggesting nonlinearity in one or more variables. The plots of estimated versus observed values for the three equations are shown in Figures 1-3. For all models, although some of the data points are scattered uniformly about the diagonal line, others deviate somewhat from the line, showing that there may be some doubt about the model.

Artificial neural network (ANN) analysis

ANN models consist of an interconnected assembly of simple processing elements, neurons, which are organized in a layered fashion. Each neuron in a layer is connected to the neurons in the subsequent layer and so on, as seen in Figure 4. The interconnection between ith and jth layers is labelled as Wijand is called 'weight'. These interconnections between layers provide a powerful tool for prediction and classification. During the learning phase, these interconnections are optimized in order to minimize a predefined cost function. The weighted sum of inputs to a neuron is calculated and the output of a neuron, the activation of the neuron, is determined by an activation function, which is illustrated in Figure 4 as f ().

There are different types of neural network models. The type of neural network used in this study is the multilayered perception (MLP). A MLP neural network is shown in Figure 5. A MLP network consists of an input layer, one or more hidden layers, and an output layer. Each layer has a number of processing units (neurons) and each unit is fully interconnected with weighted connections to units in the subsequent layer. The MLP transforms i inputs into k outputs through nonlinear mapping functions.

The back-propagation algorithm (Rumelhart and McClelland, 1986) is used in this study, because it is one of the most common network types used in feed-forward multilayer neural networks, and many other types are derived from it. The Levenberg-Marquardt (LM) algorithm is the fastest training algorithm. It is a Hessian-based algorithm for nonlinear least squares optimization. Hessian-based algorithms are used to allow ANNs to learn more suitable features of a complicated mapping (Hagan and Menhaj, 1994; Suratgar et al., 2005). LM is used as the training algorithm in this study, since the training process converges quickly as the solution is approached. Regarding the number of hidden layers, there is no reason to use more than one hidden layer for many practical problems (Heaton Research, 2016). For this reason, one hidden layer is selected in this analysis. There is no strict rule for selecting the number of neurons in a hidden layer. Some rule-of-thumb methods to determine the number of neurons for the hidden layers can be found in the literature (Heaton Research, 2016).

The selected rule in this study is 'the number of hidden neurons should be between the size of the input layer and the size of the output layer'. As a transfer function, a sigmoidal function is selected because it is the most recommended activation function for back-propagation learning (Joarder and Aziz, 2002).

Some researchers (Kumar, 2005; Altun, Bilgil, and Fidan, 2007) have shown that ANN models are not consistently good in prediction in the case of highly skewed data. If the data is skewed, some transformation, such as a power transformation, can be used to reduce the skewness before performing neural network analysis. Skewness is a measure of the degree of symmetry in a normal distribution. If the skewness coefficient is zero, the distribution is symmetric (not skewed). Positive skewness indicates the distribution is skewed to the right, and negative skewness indicates the distribution is skewed to the left. As indicated in Table I, the skewness of rock parameters can be accepted as low. Therefore, the transformation or the treatment of data is not necessary.

A total of 144 data points were used in the ANN analysis. The first group, consisting of 100 data points, was used to train the network ANN models. 22 data points were used for the validation, and the remaining 22 were used for testing.

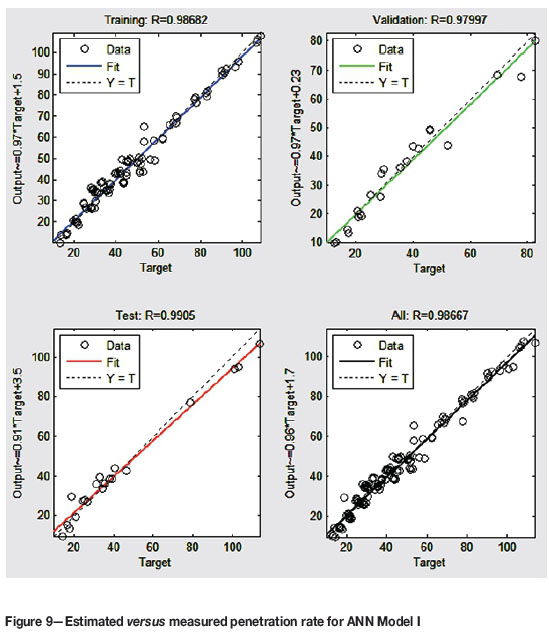

As shown in Figures 6-8, three different types of neural network structure are implemented in the MATLAB environment for the prediction of penetration rate to compare with the regression models (Equations [1]-[3]). The structures of the ANN models, namely the number of input layer neurons, the number of hidden layer neurons. and the number of output layer neurons, are given in Table III. The training parameters and the algorithm that were employed in the training phase are also shown Table III.

In the first trial, a neural network with the structure 4-31 (Model I in Table III) is employed. This structure is used to construct a model that delineates the nonlinear relation between the independent variables and the penetration rate. The model is as follows:

where PR is the penetration rate (cm/dk), OP is the operational pressure (bar), FP is the feed pressure (bar), SH is the Shore hardness, and ρ is the density (g/cm3).

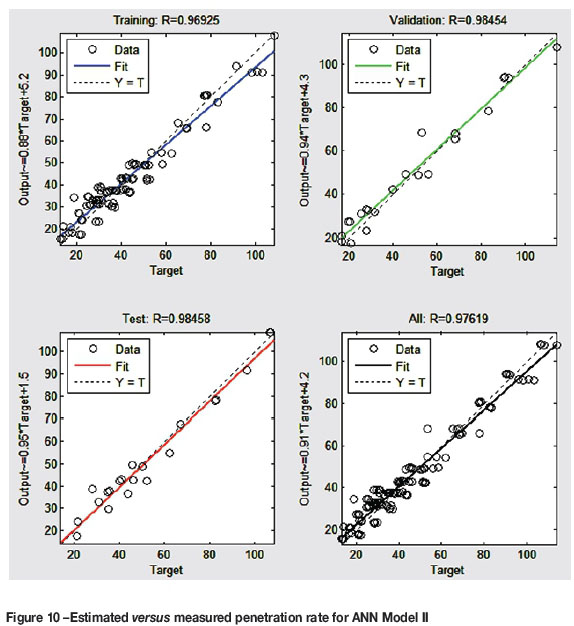

In the second trial, a neural network with the structure 32-1 (Model II in Table III) is constructed. The model is as follows:

In the third trial, a neural network with the structure 3-21 (Model III in Table III) is constructed. The model is as follows:

The estimation capability of the derived models can be shown using scatter diagrams of the observed and estimated values. Ideally, on a plot of observed versus estimated values, the points should be scattered around the 1:1 diagonal straight line. A point lying on the line indicates an exact estimation. A systematic deviation from this line may indicate, for example, that larger errors tend to accompany larger estimations, suggesting nonlinearity in one or more variables. The plots of estimated versus observed penetration rate for models I-III are shown in Figures 9-11. In the plots the points are scattered uniformly about the diagonal line, suggesting that the models are reasonable.

Comparison of regression and ANN models

The models produced from ANN and regression analysis were compared using the correlation coefficients, the estimation capabilities, and the standard errors of estimates. The correlation coefficients of Equations [1] and [2] are strong, as shown in Table IV. However, the estimation capabilities of these equations are not good, as shown in Figures 1 and 2. Nevertheless, the corresponding ANN models (Model I and II) have much stronger correlation coefficients than those of the regression models and their estimation capabilities are very good, as shown in Figures 9 and 10. Although the correlation coefficient and the estimation capability of Equation [3] are not good, the corresponding ANN model (Model III) has a very strong correlation coefficient and its estimation capability is good, as shown in Figure 11.

The standard errors of estimates, which are the other criteria for the comparison, are also indicated in Table IV. The values of standard error of estimates for the ANN models are much lower than those of the regression models.

The comparison of the models produced from ANN and regression analysis using the correlation coefficients and the standard error of estimates indicates that ANN models for the prediction of penetration rate are more reliable than the regression models.

Comparison of derived models and previous models

Most of the previous regression models were derived for specific cases. For example, while some of them are valid for pneumatic drills, others are valid for hydraulic drills. The rock bit type may also change from one study to another. On the other hand, some previous models were derived for constant operational variables and only include rock properties. The examples of specific cases can be increased. For this reason, a direct comparison between the models derived in this study and the models suggested by other authors is difficult - only a general comparison can be made. Compared to the some previous models, the derived models include operational variables such as operational pressure and feed pressure. This makes the models more generalized. Another advantage of the derived models is that they include indirect test values, which can be easily determined.

Regarding the studies on the predictability of drilling rate from ANN, making a direct comparison between the ANN models constructed in this study and the models suggested by other authors is also difficult. As stated above, there are very limited studies on this subject. Some of the derived models are valid for diamond drilling (Akin and Karpuz, 2008; Basarir, Tutluoglu, and Karpuz, 2014) or oil well rotary drilling (Monazami, Hashemi, and Shahbazian, 2012). There is another available model (Khandelwal and Armaghani, 2016) which is related to DRI, and is an indirect measure of penetration rate. The ANN model constructed in this study can only be compared to the ANN model suggested by Aalizad and Rashidinejad (2012). The strength of the Aalizad and Rashidinejad model is that it includes rock mass and hole properties together with operational variables. However, because the model includes seven intact rock properties, it is too complex and not practical. Determining seven rock properties is time-consuming and expensive. On the other hand, it is known from the literature that there are generally strong correlations among some of these seven rock properties, such as uniaxial compressive strength, Brazilian tensile strength, and P-wave velocity. As a result, it can be said that because the ANN model constructed in this study includes one or two indirect test values, it is more practical than Aalizad and Rashidinejad's model.

Conclusion

The predictability of penetration rate for percussive drills from indirect tests such as Shore hardness, P-wave velocity, density, and quartz content was investigated using ANNs and the results were compared with the derived regression models. Very good models were derived from ANN analysis for the prediction of penetration rate. The comparison of ANN models with the regression models showed that ANN models are more reliable than the derived regression models. This is because the drillability of rock is a nonlinear multivariable problem and ANNs show good performance in the solving such problems.

This research has shown that the penetration rate for percussive drills can be reliably estimated from the operational pressure, feed pressure, Shore hardness, and density by using ANN analysis. Three ANN models that are reliable were derived. One of these models can be alternatively used for the estimation purpose. Because the constructed ANN models have little input, they can be used practically. On the other hand, the rock properties included in the ANN models are indirect test values which are easy and cheap to obtain. Therefore, it can be said that the derived ANN models will be useful for practitioners and researchers studying rock drilling.

In conclusion, the ANN is a useful method for the estimation of the penetration rate for percussive drills. Further research should be carried out for different drilling machines and different cases.

References

Aalizad, S.A. and Rashidinejad, F. 2012. Prediction of penetration rate of rotary-percussive drilling using artificial neural networks - a case study. Archives of Mining Science, vol. 57. pp. 715-728. [ Links ]

Akin, S. and Karpuz, C. 2008. Estimating drilling parameters for diamond bit drilling operations using artificial neural networks. International Journal of Geomechanics, vol. 8. pp. 68-73. [ Links ]

Altun, H., Bilgil, A., and Fidan, B.C. 2007. Treatment of skewed multidimensional training data to facilitate the task of engineering neural models. Expert Systems with Applications, vol. 33. pp. 978-983. [ Links ]

Basarir, H., Tutluoglu, L., and Karpuz, C. 2014. Penetration rate prediction for diamond bit drilling by adaptive neuro-fuzzy inference system and multiple regressions. Engineering Geology, vol. 173. pp. 1-9. [ Links ]

Hagan, M.T. and Menhaj, M.B. 1994. Training feed forward networks with the Marquardt algorithm. IEEE Transaction on Neural Network, vol. 5. pp. 989-993. [ Links ]

Heaton Research. 2016. https://web.archive.org/web/20140721050413/ http:/www.heatonresearch.com/node/707 May 2016. [ Links ]

Howarth, D.F. and Rowland, J.C. 1987. Quantitative assessment of rock texture and correlation with drillability and strength properties. Rock Mechanics and Rock Engineering, vol. 20. pp. 57-85. [ Links ]

Howarth, D.F., Adamson, W.R., and Brendt, J.R. 1986. Correlation of model tunnel boring and drilling machine performances with rock properties. International Journal of Rock Mechanics and Mining Sciences, vol. 23. pp. 171-175. [ Links ]

Joarder, K. and Aziz, S.M. 2002. A note on activation function in multilayer feed forward learning. Proceedings of the International Joint Conference on Neural Networks: IJCNN '02, vol. 1. IEEE, New York. pp. 519-523. [ Links ]

Kahraman, S. 1999. Rotary and percussive drilling prediction using regression analysis. International Journal of Rock Mechanics and Mining Sciences, vol. 36. pp. 981-989. [ Links ]

Kahraman, S. 2002. Correlation of TBM and drilling machine performances with rock brittleness. Engineering Geology, vol. 65. pp. 269-283. [ Links ]

Kahraman, S., Altun, H., Tezekici, B.S., and Fener, M. 2005. Sawability prediction of carbonate rocks from shear strength parameters using artificial neural networks. International Journal of Rock Mechanics and Mining Sciences, vol. 43. pp. 157-164. [ Links ]

Kahraman, S., Alber, M., Fener, M., and Gunaydin, O. 2010. The usability of Cerchar abrasivity index for the prediction of UCS and E of Misis Fault breccia: regression and artificial neural networks analysis. Expert Systems with Applications, vol. 37. pp. 8750-8756. [ Links ]

Kahraman, S., Bilgin, N., and Feridunoglu, C. 2003. Dominant rock properties affecting the penetration rate of percussive drills. International Journal of Rock Mechanics and Mining Sciences, vol. 40. pp. 711-723. [ Links ]

Kahraman, S., Gunaydin, O., Alber, M., and Fener, M. 2009. Evaluating the strength and deformability properties of Misis Fault Breccia using artificial neural networks. Expert Systems with Applications, vol. 36. pp. 6874-6878. [ Links ]

Khandelwal, M. and Armaghani, D.J. 2016. Prediction of drillability of rocks with strength properties using a hybrid GA-ANN technique. Geotechnical and Geological Engineering, vol. 34. pp. 605-620. [ Links ]

Kumar, U.A. 2005. Comparison of neural networks and regression analysis: a new insight. Expert System with Applications, vol. 29. pp. 424-430. [ Links ]

Monazami, M., Hashemi, A., and Shahbazian, M. 2012. Drilling rate of penetration prediction using artificial neural network: a case study of one of Iranian southern oil fields. Oil and Gas Business, no. 6. pp. 21-31. [ Links ]

Paone, J., Madson, D., and Bruce, W.E. 1969. Drillability studies - laboratory percussive drilling. Report of Investigation RI 7300. US Bureau of Mines. [ Links ]

Pathinkar, A.G. and Misra, G.B. 1980. Drillability of rocks in percussive drilling from energy per unit volume as determined with a microbit. Mining Engineering, vol. 32. pp. 1407-1410. [ Links ]

Protodyakonov, M.M. 1962. Mechanical properties and drillability of rocks. Proceedings of the 5th Symposium on Rock Mechanics, University of Minnesota. pp. 103-118. [ Links ]

Rabia, H. and Brook, N. 1980. An empirical equation for drill performance prediction. The State of The Art in Rock Mechanics. Proceeding of the 21st US Symposium on Rock Mechanics, University of of Missouri-Rolla. pp. 103-111. [ Links ]

Rabia, H. and Brook, N. 1981. The effects of apparatus size and surface area of charge on the impact strength of rock. International Journal of Rock Mechanics and Mining Sciences, vol. 18. pp. 211-220. [ Links ]

Rumelhart, D. and McClelland, J. 1986. Parallel distributed processing. MIT Press, Cambridge, Mass. [ Links ]

Schmidt, R.L. 1972. Drillability studies - percussive drilling in the field. Report of Investigation RI 7684, US Bureau of Mines. [ Links ]

Selim, A.A. and Bruce, W.E. 1970. Prediction of penetration rate for percussive drilling. Report of Investigation RI 7396, US Bureau of Mines. [ Links ]

Selmer-Olsen, R. and Blindheim, O.T. 1970. On the drillability of rock by percussive drilling. Proceeding of the 2nd Congress of the International Society for Rock Mechanics. pp. 65-70. [ Links ]

Singh, V.K., Singh, D., and Singh, T.N. 2001. Prediction of strength properties of some schistose rocks from petrographic properties using artificial neural networks. International Journal of Rock Mechanics and Mining Sciences, vol. 38. pp. 269-824. [ Links ]

Sonmez, H., Gokceoglu, C., Nefeslioglu, H.A., and Kayabasi, A. 2006. Estimation of rock modulus: for intact rocks with an artificial neural network and for rock masses with a new empirical equation. International Journal of Rock Mechanics and Mining Sciences, vol. 43. pp. 224-235. [ Links ]

Suratgar, A.A., Tavakoli, M.B., and Hoseinabadi, A. 2005. Modified Levenberg-Marquardt method for neural networks training. Proceedings of the World Academy of Science, Engineering and Technology. pp. 46-48. [ Links ]

Tandanand, S. and Unger, H.F. 1975. Drillability determination - a drillability index of percussive drills. Report of Investigation RI 8073. US Bureau of Mines. [ Links ]

Thuro, K. and Spaun, G. 1996. Introducing the 'destruction work' as a new rock property of toughness referring to drillability in conventional drill and blast tunnelling. Proceedings of Eurock'96: Prediction and Performance in Rock Mechanics and Rock Engineering, vol. 2. pp. 707-713. [ Links ]

Yang, Y. and Zhang, Q. 1998. The applications of neural networks to rock engineering systems (RES). International Journal of Rock Mechanics and Mining Sciences, vol. 35. pp. 727-745. [ Links ]

Yuanyou, X., Yanming, X., and Ruigeng, Z. 1997. An engineering geology evaluation method based on an artificial neural network and its application. Engineering Geology, vol. 47. pp. 149-156. [ Links ]

Zorlu, K., Gokceoglu, C., Ocakoglu, F., Nefeslioglu, H.A., and Acikalin, S. 2008. Prediction of uniaxial compressive strength of sandstones using petrography-based models. Engineering Geology, vol. 96. pp. 141-158. [ Links ]

Paper received Aug. 2015

Revised paper received May 2016