Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.116 n.5 Johannesburg May. 2016

http://dx.doi.org/10.17159/2411-9717/2016/v116n5a12

PAPER - FURNACE TAPPING CONFERENCE

The tap-hole - key to furnace performance

L.R. NelsonI; R.J. HundermarkII

IAnglo American Platinum Ltd

IIAnglo American plc

SYNOPSIS

The critical importance of tap-hole design and management for furnace performance and longevity is explored through examining some of the specific matte, metal, and slag tapping requirements of non-ferrous copper blister and matte converting and smelting, ferroalloy smelting, and ironmaking systems. Process conditions and productivity requirements and their influence on tapping are reviewed for these different pyrometallurgical systems. Some critical aspects of the evolution of tap-hole design to meet the diverging process and tapping duties are examined. Differences and similarities in tapping practices and tap-hole management are reviewed. Finally, core aspects of tap-hole equipment and maintenance are identified -aspects that are considered important for securing improved tap-hole performance and life, so pivotal to superior furnace smelting performance.

Keywords: tapping, tap-hole, ironmaking, ferroalloy, non-ferrous, matte, slag, blister, smelting

Introduction

The sheer diversity of tapping configurations used on industrial pyrometallurgical operations is at first bewildering. They range from historical tilting furnaces without tap-holes to modern eccentric bottom tapping (EBT) tilting and/or bottom slide-gate electric arc furnaces; to classical single tap-hole multiphase tapping (e.g. metal/matte and slag); to dedicated phase tap-holes (e.g. dedicated metal/matte-only and slag-only); to dedicated phase multiple tap-hole configurations (up to eight metal/matte-only tap-holes and six slag-only tap-holes); to more esoteric metal/matte-only siphons and slag overflow skimming, e.g. Mitsubishi Continuous Process (Matsutani, n.d.). This can be further complicated by periodic batch tapping; consecutive tapping on a given tap-hole; alternating tap-hole tapping practice; near-continuous slag-only tapping, with discrete batch matte/metal tapping on higher productivity, but low metal/matte fall (<20% by mass feed) Co and Ni ferroalloy and platinum group metal (PGM) matte furnaces; near-continuous tapping through batch tapping of individual tap-holes that are opened consecutively (Tanzil et al., 2001; Post et al., 2003); to fully continuous tapping on coupled multi-furnace cascades (Matsutani, n.d.).

This is largely a consequence of differing processing conditions (process temperature, superheat (AT), Prandtl number, Pr = μCP/k, where μ = dynamic viscosity, CP= specific heat capacity and k = thermal conductivity, and resulting heat flux). But this can also be influenced strongly by industrial operating philosophy in terms of furnace design for campaign life longevity (i.e. greater capital expenditure for longer, say 20-30 years' life) versus furnace productivity (i.e. number of heats/campaigns to provide the greatest possible dilution of fixed costs per unit of commodity produced). And this may not even be consistent within a given commodity; all ironmakers (blast furnace (BF) campaign life-based) supply downstream steelmakers (who use heat/campaign-based converters and/or electric arc furnaces).

However, regardless of the specific tap-hole configuration or operating philosophy, owing to the addition of dynamic (often periodic) and more intense process conditions (exposure to higher temperatures leading to accelerated corrosion, greater turbulence, and elevated rates of mass and heat transfer) and higher concomitant thermomechanical forces (from thermal or flow shear stresses), furnace performance and longevity is intimately linked to tap-hole performance. For good reason Van Laar (2001) titled his paper 'The taphole: the heart of the blastfurnace' at the 2001 symposium entitled The taphole - the blast furnace lifeline (Irons, 2001), while the title of the 2010 Coetzee and Sylven (2010) contribution 'No taphole - no furnace' and the staging of the SAIMM Furnace Tapping conference in 2014 suggest continued criticality and relevance.

By first comparing and contrasting some of the process conditions and resulting tap-hole and tapping requirements of different commodities, we make an attempt at identifying key elements of tap-hole design, physical tapping practices, equipment, and monitoring and maintenance practices characteristic of superior tap-hole management and required to secure increased tap-hole performance and prolonged life.

Commodity-specific process and operating conditions

To provide some context to the range of tap-hole designs, and operating and maintenance practices adopted for different commodities, it is instructive to compare some key process physicochemical and operating conditions prevailing. Notable features include:

► Sheer metal fall and productivity of ironmaking BFs >10 000 t/day hot metal (HM), achieved through near-continuous tapping at more than double the rate and velocity of, but through tap-hole diameters not too dissimilar to, other commodities

► High pressure of tapping liquids of ironmaking BFs (up to 5 bar blast pressure at tuyeres, to add to already high hydrostatic pressure of comparatively thick slag and thick and dense metal)

► More limited accessibility of smaller circular blast and electric furnaces (EFs) (up to 22 m diameter) to multiple tap-holes, than larger rectangular six-in-line (6iL) furnaces (up to 36 × 12 m)

► Low comparative temperatures and superheats of (often near-autogenous) copper smelting

► Relatively low superheats of ferroalloys (FA) in DC arc and submerged-arc furnaces (SAFs)

► Higher viscosity (and Pr), but lower thermal conductivity and density of slag than metal/matte

► High thermal conductivity (k) of liquid blister Cu

► Extreme superheat (ΔT) of PGM matte (Shaw et al., 2012; Hundermark et al., 2014).

Slag freeze lining versus matte/blister copper 'hit' potentials

A striking industrial observation is the ease with which slag freeze linings can be formed and maintained (almost 'self-healing') from even superheated slag, provided cooling is adequate. It is also quite remarkable how effectively just a thin accretion layer of slag (a couple of millimetres thick) can provide a sufficient thermal resistance to appreciably lower critical lining and copper hot-face temperatures.

In stark contrast, especially in PGM matte and blister Cu processing, equivalent matte/metal accretion formation often seems near impossible to achieve, to the extent that the operation of copper coolers on blister Cu requires 'demonstrated ability to maintain a protective accretion coating' (George, 2002). Or stated in another way in the PGM matte industry: the operation of copper coolers unprotected from direct contact with superheated liquid matte is simply not tolerated.

Considering the heat transfer conditions applicable to the successful implementation of a water-cooled composite copper lining, four key criteria can be defined when considering the influence of process heat flux, q = hbΔT (where ΔT = TB- Tfand hb= convective heat transfer coefficient from bulk process liquid of temperature TB, to accretion freeze lining2 of temperature Tf), into and out through the composite cooling system. The latter is described for the simplest one-dimensional case by

qC = (Tf - TC)/(xf /kf + xR/kR + 1/hI + xC/kC + 1/hC)

where qC= composite cooler heat flux; Tf= effective accretion freeze lining temperature in contact with process liquid (whether matte or slag); TC= bulk temperature of cooling fluid; Xfand kfare, respectively, thickness and thermal conductivity of the accretion freeze lining; xRand kR are thickness and thermal conductivity of the residual refractory; hI= convective heat transfer coefficient at the cooler hot-face; xCand kCare thickness and thermal conductivity of residual refractory; and hC= convective heat transfer coefficient of the cooling medium (e.g. air or water).

Following the example of Robertson and Kang (1999), we describe some relevant limiting conditions for such a heat transfer system:

(1) For an accretion to freeze (sustainably), q must be less than qC

(2) The cooling system hot-face temperature (be it refractory or copper) must be less than Tfof the specific accretion in question (be it metal/matte or slag)

(3) The copper hot-face temperature must not exceed copper's melting point (or copper's long-term service limit of < 461°C)

(4) Usually, unless specifically designed for, the boiling point of the cooling medium should not be exceeded (as defined by the prevailing coolant operating pressure).

Somewhat paradoxically, when the thermal conductivity of matte is accounted for (kmatteapproximately 20 times that of kslag), estimates of hmatteremain approximately 20 times that of hslag. This is despite the significantly higher Pr number of slag (Robertson and Kang, 1999; Table I) and its positive contribution to both natural and forced convection heat transfer Nusselt numbers through correlations:3Nu = hL/k ∞ (GrPr)¼ and (Re½ Pr1), respectively.

So, considering the first condition, compared to slag, superheated matte of potentially four times greater superheat (ΔTmatteup to 650°C) and approximately 20 times the convective heat transfer coefficient delivers far greater incident heat flux than slag (qmatte = hmatte ΔTatte = approx. 80qslag) and so is capable of up to a couple of orders of magnitude greater thermal 'hit' of the cooling system (condition 1 above). This higher heat flux of matte compared to slag leads to higher temperatures of critical lining hot-faces (e.g. refractory and copper cooler - conditions 2 and 3), which then (condition 2) all too easily exceed the unusually low Tfof matte, due to its unusually low solidus (850°C) and even liquidus (950°C) temperatures.

In such a situation a copper cooler unprotected by any alternative thermal barrier (e.g. refractory/slag) is at significant risk from any superheated matte/blister Cu 'hit' that can rapidly lead to hot-face temperatures rising to where the cooler copper simply melts (1085°C). Yet for most slag systems these conditions are rarely violated; stable slag accretion freeze linings prevail, supported additionally by a high-viscosity slag 'mushy zone' adjacent to Tf(Guevara and Irons, 2007) to protect the composite cooling system.

Comparing kmatte, kFA, kHM, and kblister Cuof 17, 10, 50, and 160 W/m°C and resulting PrmattePrFA, PrHM, and Prblister Cuvalues of approximately 0.2, 0.2-0.5, 0.1, and 0.01, respectively (Table I), one can estimate ratios of convective heat transfer relative to PGM matte as hmatte:hFA:hHM:hblisterCu = 1:~1.5:~2:~5, respectively. Relative to matte, convective heat transfer coefficients of HM and blister Cu are greater. Maximum superheats ΔTPGM matte, ΔTFA, ΔThm, ΔTblister Cu of 650, 150-350, 350, and 350°C, respectively, will tend somewhat to help balance the resulting process heat fluxes, q = hAT. So it would appear that it is low Tf(listed here at its solidus lowest extreme) of Tmatte, TFA, Thm, Tblister Cuof 850, >1250, 1130, and 1065°C that most limit the ability to form a protective accretion freeze lining, and so render copper coolers ultimately more prone to thermal 'hit' by (PGM) matte/blister Cu.

Integrated tap-hole and tapping system management

Key aspects of tap-hole design and tapping operation, maintenance, and monitoring will be presented separately for convenience. However, it should be emphasized that all aspects need to be considered as part of an integral system, which must be managed as such for success. Overly focusing on one component at the expense of another (e.g. tap-hole clay optimization, without due consideration for mudgun and drill capabilities) is unlikely to yield optimal results. A 'chain being only as strong as its weakest link' adequately describes the role of integration of all aspects of the tap-hole and tapping into a comprehensive system for sound management.

Types of tapping systems

Tapping systems can be conveniently categorized according to the product phases being tapped and the process conditions prevailing: primarily temperature, ΔT (versus solidus or liquidus), k, and Pr.

Slag-only tapping

With its high Pr number and elevated melting properties (Table I), slag - provided it is kept free of metal/matte/bullion - is potentially the simplest liquid for which to design an effective tap-hole system, comprising merely a high-intensity water-cooled copper slag tap-block protected by an accretion freeze lining of product slag. A significant advantage of slag-only tapping is that it facilitates direct downstream treatment of slag by either traditional water granulation (Atland and Grabietz, 2001; Szymkowski and Bultitude-Paull, 1992), or, increasingly, 'dry' air atomization (sometimes with energy recovery) to obtain useful slag products amenable to handling and sale in ironmaking, steelmaking, and Ni and SiMn ferroalloy applications (Andō, 1985; Rodd et al., 2010).

Dedication of the tap-hole to slag is particularly effective for handling corrosive slags (especially acidic slags >50% SiO2 that are fundamentally incompatible with basic and some other refractory oxides), because there is no chemical potential for reaction with a frozen slag of essentially the same composition. Thus retention of a protective freeze lining reverts to a more predictable issue of designing for thermal equilibrium thickness, and adoption of suitable safety factors to provide some protection against deviations therefrom.

On many industrial furnaces, a combination of level measurement and phase separation is more than adequate to tap slag free of metal/matte. Nishi (2007) reports on the importance of designing the height of the slag tap-hole to avoid Mn ferroalloy discharge through it. This is also a typical requirement of more quiescent EF or slag cleaning furnace (SCF) processes of low (< 20%) metal/matte fall (effectively 'slag-making' processes, that may even be subject to near-continuous slag tapping, such as Co and Ni ferroalloy and base metal and PGM matte smelting). On other matte flash furnace (FF) to TSL converting processes (e.g. blister Cu to PGM matte, respectively), it is typically necessary to equip them with downstream FF settling and/or SCF processes for further recovery of pay metals from slag, especially oxidic losses that require recovery through reductive processes.

Theoretically, the critical height for entrainment (he) of a two-layer liquid through an orifice of diameter (d) is related to αdFr0, where α depends on the density difference and which phase is being withdrawn (typically α< 0.625 when lower viscosity phase is withdrawn; α> 0.8 when uppermost viscous layer is withdrawn), Fr = v/(dgΔρ/ρ) and v is the discharge velocity, Δρ is the density difference between heavier and lighter liquid, and ρ is the density of the lighter liquid (Liow et al., 2001, 2003). Using assumed physicochemical properties and tap-hole conditions (Table I), one can predict heof the order of 0.12 m for copper FF settler and PGM EF smelting (and theoretically even ironmaking BF conditions). Not too surprisingly, therefore, the dedicated slag tap-holes located up to 1 m above the metal/matte tap-holes, coupled with tight metal/matte level control (to a maximum height of 0.25-0.4 m above matte tap-holes on blister Cu and PGM matte furnaces - Table I), permit slag tapping substantially free of metal/matte from the interface with the bulk slag, and entrained specifically through tapping (ignoring the presence by other sources of entrained and unsettled metal/matte droplets).

Similar two-phase liquid entrainment and an initial declination of the slag interface towards the tap-hole as tapping commences followed by a switch to initial inclination and even 'pumping' out of the tap-hole later in the tap has been modelled on BFs by CFD (Shao, 2013; Shao and Saxen, 2011, 2013a, 2013b). However, in the modelling of BF tapping, He and co-authors (2012) caution that the metal should not be maintained at a depth too low above the tap-hole, as one runs a risk of entraining process gas by 'viscous fingering' during tapping, especially (1) when the slag viscosity is high, or (2) in the presence of a permeable bed of solids through tapping occurs (e.g. coke bed).

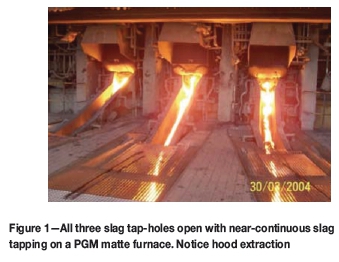

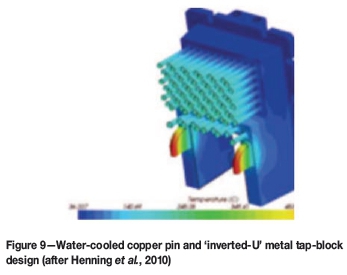

The efficacy of intense copper cooling (predominantly in a circular slag tap-block configuration) is clear (Figure 1 and Figure 2). These coolers directly impart a thicker protective freeze lining than the alternatives of just top lintel copper blocks, or 'inverted-U' square copper blocks and circular block water-cooled copper pin designs (Marx et al., 2005; Henning et al., 2010) (the latter choosing rather to try to moderate freeze lining thickness). These latter designs all avoid the presence of water below the tap-hole. It is a moot point whether this is indeed universally a safer situation, especially if control of furnace operating levels is adequate, simply because of the less desirable trade-off of imparting an inherently thinner protective freeze lining with less cooling.

Concerns frequently articulated of overly cooling copper coolers (Trapani et al., 2003; Marx et al., 2005; Henning et al., 2010) are extravagant costs, fear of preventing easy tap-hole opening, or freezing of a tapping stream. Even with the least intense top lintel or shallow-cooled (i.e. water circuits outside the furnace) copper and refractory-lined slag tap-blocks, problems associated with the latter two operational aspects can occur, and are generally coupled with undesirable increased copper slag tap-block wear rates. Szekely and DiNovo (1974), in a modelling study of the critical factors for tap-hole blockage of a molten stream (e.g. during tapping), determined that nozzle diameter was most critical, followed by metal superheat, with the extent of preheating (or in this case cooling) of the nozzle walls being less significant. Effectively, this implies that the tapping channel diameter should be enlarged if the slag tapping stream is freezing.

So again it is a moot point if reduced cooling intensity, including the removal of water circuits from beneath the tapping channel, indeed universally represents the safer option, if the consequent (sometimes inadequate) protective freeze lining thickness results in increased copper hot-face temperatures that will reduce the long-term integrity of the copper block itself (i.e. requires sustained temperatures below 461°C [Robertson and Kang, 1999]). Furthermore, if the tap-hole is still prone to 'slow tapping' even with less intense cooling, it may suggest that an alternative operational tapping strategy is appropriate.

Some of the larger ferroalloy furnaces for Mn and DC Cr alloy production also operate separate slag tap-holes, which assist greatly in separating post-tap-hole metal- and slag-handling logistics. In many instances the separate slag tap-holes are merely refractory graphite/microporous carbon/carbon tap-blocks (usually the former two owing to improved resistance to wetting and lower corrosion by slag). Increasingly, deep-cooled (i.e. water-cooled copper extending inside the furnace) copper lintel, or 'inverted-U' blocks are used to promote cooling of such refractory slag tap-holes.

Combined metal/matte and slag tapping

This is decidedly the norm, but it also often presents the greatest design challenge because of the different natures of slag and metal and their chemical incompatibility with linings selected as suitable for the other phase. Traditionally, refractory tap-blocks (refractory oxide or carbon-based) were adopted for combined metal/matte and slag tapping. With few exceptions, the refractory oxides are relatively resilient to metal- and matte-only tapping. Carbon-based tap-blocks risk carbon dissolution and/or oxidation (e.g. by dissolved oxygen) in service with carbon-unsaturated metal/matte. Corrosion of both carbon-based and oxide refractories is invariably accelerated by slag, even to the extent that corrosion becomes catastrophic, e.g. if acidic slags make contact with basic refractories (such as magnesia). Depending on the specific slag system, amphoteric (alumina) refractories can also be susceptible to both acidic (e.g. high-silica) or basic (e.g. high-lime) slags.

Refractory-lined overflow launders are used in continuous tapping of copper matte and slag from the Mitsubishi Continuous Process smelting furnace, and certain corrosion challenges are presented (addressed largely by fused cast magnesia-chrome). Somewhat remarkably, unlined water-cooled copper tap-plates are routinely fitted on to the furnace exterior for combined matte-slag tapping elsewhere in the copper industry, such as TSL furnaces. This presumably is only possible owing to the comparatively low temperature (< 1200°C, Table I) and relatively low copper matte superheat in combination, critically, with slag that has the potential to freeze (even if only as a thin layer a couple of millimetres thick) as a protective accretion on copper tapping surfaces.

Most combined metal-slag tap-hole processes are characterized by lower slag-metal ratios of about 0.4-1.5 t slag per ton metal (metal fall is approximately 35-60% in the case of Cr and Mn ferroalloys, Table I), or significantly lower 0.2-0.4 t slag per ton HM in ironmaking BFs (metal fall is approximately 65%, Table I), to near-slagless tapping in Si (and Si alloy) processes. A striking feature of the ironmaking BF is its sheer productivity (>10 000 t/day) coupled with complex internal process structures ('deadman' and tap-hole 'mushrooms'). Even with multiple tap-holes, these process structures would complicate attempts to control hot metal and slag levels adequately and to the extent necessary to permit effective dedicated metal- and slag-only tapping. Therefore, as with the majority of older ferroalloy SAFs and BFs, deep cooling is generally not contemplated, with limited water-cooled elements being applied more judiciously.

Dedicated metal/matte tapping

Provided that metal/matte can be tapped substantially slag-free, a configuration for dedicated metal/matte tapping is possible. Theoretically, it can be calculated that the separation of slag to at least 0.07 m above the metal/matte tap-hole should facilitate matte tapping without slag entrainment (α drops to 0.625 for tapping of the denser, less-viscous phase [Liow et al., 2003]). Efficient separation of metal/matte from slag already in the furnace decidedly simplifies post-tap-hole handling and associated logistics.

Emergency/drain tap-hole

Some furnaces are equipped with emergency/drain tap-holes (Newman and Weaver, 2002) that are used when the furnace does not drain from operating tap-holes (Cassini, 2001), or to effect bath drainage to a lower level than normal operating tap-holes for safer repairs. Some operators prefer to avoid such tap-holes for fear that they potentially increase risk by tempting non-emergency/non-drain use, and present another weakened region of furnace lining (at a higher pressure head) for unplanned drainage.

Tap-hole design

Tap-hole and tapping-channel heat transfer

On a large furnace crucible wall, bath heat transfer can reasonably be approximated as one-dimensional. In the simplest configuration of a long circular tap-hole, heat transfer from a fast-flowing hot tapped liquid is dominated by radial heat loss in the passage down the tapping channel. Even with a reasonably fast water cooling flow rate of 6 m3/h, it can readily be estimated using q = Q/A = (mCP) ΔT that for just a 1°C rise in water temperature, the equivalent tapping channel (tap-block or faceplate) heat flux (q) exceeds 0.5 MW/m2.

In a real tapping channel, in addition to the tapping channel heat transfer, heat transfer from the contained furnace bath also exists, which results in a three-dimensional heat transfer situation that is more extreme than in almost any other region of the furnace crucible. The tap-hole specifically is invariably subjected to the most arduous of conditions (Van Laar et al., 2003; Van Ikelen et al., 2000): the highest liquid (metal/matte and slag) velocities, affected by the degree of radial or peripheral flow and total flow that converge on the tap-hole to achieve the productivity set-point; the highest turbulence (increased by gas entrainment and even blowing under pressure, and associated enhanced mass and heat transfer from both stream tapping and through the action of any tap-hole clay flash devolatilization and subsequent 'boiling' at the back of the channel); wildly fluctuating and periodic thermal loads (from cool, dormant conditions, heating rapidly when the tap-hole is opened with oxygen, or hot liquid tapping, and with tap-hole clays 'boiling' and gas bubble-driven circulation upon tap-hole closure); and high dynamic loads (the action of opening and closing a tap-hole). Tap-holes are also prone to gas leakage, especially when operated under pressure in a BF, which may result (particularly in the case of ironmaking or ferroalloy processes adopting carbon-based refractories) in a continuous threat of exposure to, and reaction by, CO (the risk of carbon deposition), oxidation by injected oxygen, air, or steam (especially if water leaks), slag and maybe even SiO(g), and reaction with volatile gas species such as alkalis and zinc (which leads to refractory attack) (Van Laar, 2001; Van Laar et al., 2003; Spreij et al., 1995; Iiyama et al., 1998; Tomala and Basista, 2007).

Tap-hole 'refractory' design

Clearly, to be successful, tap-hole designs need to cater not only for average, but peak, process heat flux conditions. Van Laar (2014) suggests that in BF tap-holes, peak heat fluxes exceeding 1 MW/m2 have been detected, which is considerably in excess of the normal average heat fluxes measured (25 kW/m2, Table I). This would not be inconsistent with a 1.4 MW/m2 event involving metal encroaching on the lower zone of a copper waffle cooler recorded in Co ferroalloy production (Nelson et al., 2004).

Nearly all tap-holes are designed with a length that exceeds the adjacent sidewall thickness. Unfortunately, this provides only short-term protection against liquid breakout in the tap-hole area, because the tap-hole length will at best rapidly recede to its thermal equilibrium dimension.

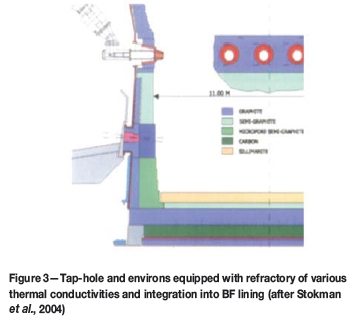

Several refractory types (Figure 3) are used in BF tapholes and their environs (Stokman et al., 2004; Jameson et al., 1999; Irons, 2001; Van Laar, 2001; Van Laar et al., 2003; Brunnbauer et al., 2001; Atland and Grabietz, 2001). They include:

► 100% alumina (the most 'insulating': k = 1-5 W/m°C)

► Pitch-impregnated carbon/alumina (Black and Bobek, 2001)

► Large carbon blocks (k approx. 14 W/m°C)

► Hot-pressed small carbon or semi-graphite bricks (a lower iron content of the latter, to reduce CO disintegration [Stokman et al., 2004; Spreij et al., 1995])

► Microporous (potential advantages of less metal infiltration if the maximum pore size is less than 1 μm [Stokman et al., 2004; Piel et al., 1998; Spreij et al., 1995; Tomala and Basista, 2007]), large carbon or semi-graphite blocks

► Thermally conductive graphite (k approx. 140 W/m°C, frequently applied as 'safety' tiles glued to the steel wall in the immediate tap-block vicinity [Van Laar et al., 2003; Edwards and Hutchinson, 2001; Atland and Grabietz, 2001])

► Sometimes graphite with high-alumina silicon carbide castable in the centre (favoured for reasons of improved tapping stream dissolution and erosion resistance over graphite in the event of the latter's loss of freeze lining or protective baked tap-hole clay inner annulus, somewhat improved tolerance to oxygen lancing over graphite, provision of some heat storage for tap-hole clay baking, and possibly some improved tolerance to microcracking induced through mudgun and drill impact forces)

► The use of higher conductivity silicon carbide (Brown and Steele, 1988) in conjunction with a carbon surround and alumina tapping channel hot-face bricks has also been reported (Yamashita et al., 1995). In some instances, heat removal is further enhanced by the addition of water-cooled iron or copper tap-hole notch channels, or even water-cooled copper inserts/plate coolers (Irons, 2001; Van Laar, 2001).

In all instances involving the use of composite refractory types (Figure 3), especially when water-cooled components are included, a critical design requirement is to cater for differential thermal expansion properties that can easily differ by an order of magnitude, with the potential to cause gaps, stresses, and strains, so raising the potential for liquid infiltration (Van Laar, 2014). An experience reported (Duncanson and Sylven, 2011) of furnace campaign life reduced from 14 to just 3 years when switching from a design where 'the original furnace had forced air cooling in the bottom, but no additional (water) cooling for the furnace walls' (and, by inference, attempt at freeze lining in, or at least near, the tap-block) may well illustrate this. Moreover, the additional requirement for effective freeze linings around thermal equilibrium has led Singh and co-authors (2007) to state: 'but in the present Indian scenario with process parameters not stable ... it is difficult to maintain the conditions inside the furnace desirable for a true freeze lining,' so failing to 'give the expected lifetime of over 25 years'.

For the adoption of any freeze lining concept, half measures are entirely unacceptable. The achievement of just a partial and/or periodic freeze lining will prove unsuccessful and present a considerably more dangerous operating condition than a traditional insulating tap-hole design concept.

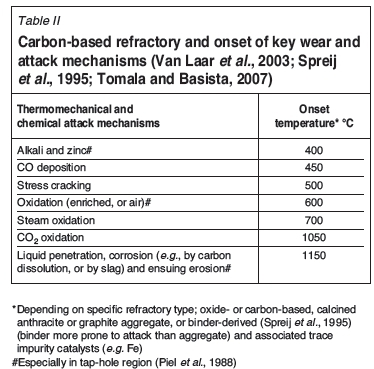

The first technique crucial to tap-hole refractory longevity is the ability to create and retain a protective accretion freeze lining or skull (Eden et al., 2001), as tap-hole performance is greatly compromised by operating in the partial or substantial absence of a stable accretion freeze- lining, which is described as a 'no-skull' condition (Stokman et al., 2004). Accretion freeze lining thickness has already been shown to be enhanced by placing refractories of higher conductivity in actively cooled furnace-lining systems, with the resulting colder refractory presenting fundamentally more resistance to attack by a number of wear mechanisms, depending on the temperature of onset of thermomechanical or chemical attack by a given mechanism (Table II).

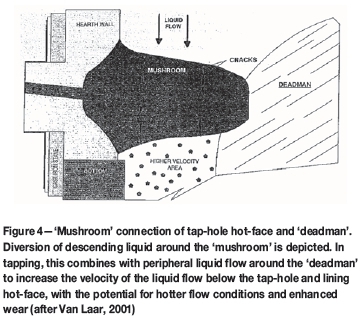

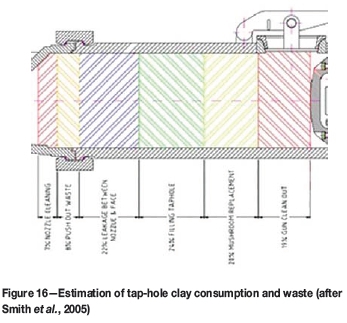

Role of the tap-hole clay 'mushroom'

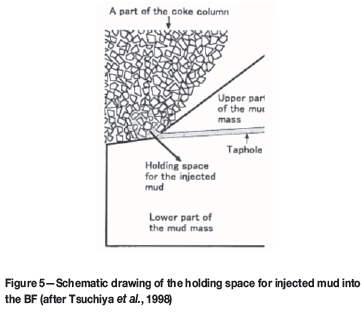

The second crucial feature, specific to ironmaking BF tap-hole design, is the active development and continuous renewal of a tap-hole clay (also described as mud) 'mushroom' to provide some hot-face protection on the back of the tapping channel (Figure 4) (Uenaka et al., 1989; Jameson et al., 1999; Eden et al., 2001; Nightingale et al., 2001, 2006; Tanzil et al., 2001; Atland and Grabietz, 2001; Cassini, 2001; Wells, 2002; Horita and Hara, 2005; Kageyama et al., 2005, 2007; Nakamura et al., 2007; Niiya et al., 2012; Kitamura, 2014). The 'mushroom' requires tap-hole clay for its development and consists additionally of incorporated slag, iron, and coke. Tsuchiya and co-workers (1998) hypothesize that a necessary condition for the development of a 'mushroom' is that the tap-hole length can be extended only when the holding space for the injected tap-hole clay is effectively realized, so that the major part of the tap-hole clay surface is covered by the coke column (Figure 5). Niiya and co-authors (2012) hypothesized further that the tap-hole clay is 'extruded in the furnace like strings' and that these 'strings accumulate in the coke-free spaces by folding together with solidified iron and/or slag'. Other conditions required for increasing the tap-hole length to develop the 'mushroom' then include there being sufficient tap-hole clay sintering time in the holding space and the specific characteristics of the clay during and after heating and sintering. 'Mushroom' stability can be adversely affected by the 'floating' of an ironmaking BF 'deadman', especially if it is physically connected to the back of the 'mushroom' (Van Laar, 2001). Water leaks are also reported to cause a 'mushroom', a frozen skull, and lining damage (Van Laar et al., 2003; Van Laar, 2001).

The necessary condition of a 'holding space covered by a coke column' may well explain why a protective tap-hole clay 'mushroom' is routinely reported only for ironmaking BFs. In non-ferrous processing coke is absent (or substantially absent), so the necessary requirement of a coke column to cover tap-hole clay in the holding space is missing. Moreover, as we describe later, certainly in electric smelting of PGM mattes, matte superheat is so high (as much as 650°C, Table I) that tap-hole clay injected into matte appears to react near-instantaneously, with the release of gas and extreme turbulence, so that a tap-hole clay-based 'mushroom' cannot be stabilized.

While a coke bed is a well-reported feature of ferroalloy smelting (Nelson, 2014), it remains local to the electrode tips. The extension of the coke bed to the furnace tap-hole - a necessary condition of the proposed mechanism of 'mushroom' development - would almost certainly result in a condition too conductive for effective electrical power input. A genuine 'mushroom', at least in the equivalent sense to that of an ironmaking BF, therefore seems improbable. At best, some extent of tap-hole clay 'self-lining', but not a 'mushroom', is depicted in ferroalloy electric SAFs (Ishitobi et al., 2010).

Ferroalloy tap-hole design

The ironmaking BF tap-hole refractory list fairly represents the experience in Cr, Mn, and Si ferroalloys, one of an increasing general trend towards the use of materials of higher thermal conductivity, and to what is colloquially known in the industry as 'freeze linings'. For traditional insulating (especially large) furnace designs, just 2-6 years of furnace lining life on Cr and Mn ferroalloys are commonly reported (De Kievit et al., 2004; Van der Walt, 1986; Coetzee and Sylven, 2010; Coetzee et al., 2010), with one slag tap-hole life reported to be as short as 2 months (Van der Walt, 1986). However, longer furnace lifetimes of 10-15 year have been achieved on traditional insulating linings in Japan. Generally, Cr and Mn ferroalloy SAFs have made use of only refractory alumina tap-blocks, silicon carbide tap-blocks surrounded by alumina, carbon, or microporous carbon blocks.

This supports a progression from more insulating refractories (refractory oxide castable and brick, carbon-based ram or SÖderberg paste), to carbon blocks of intermediate thermal conductivity and even more thermally conductive semi-graphites and graphites. The latter designs have delivered in excess of 20 years' lining life on some large Mn ferroalloys furnaces (Van der Walt, 1986; Hearn et al., 1998).

An emerging trend is of an additional composite refractory variant involving use of a thermally conductive graphite sleeve inside an insulating carbon tap-block (Figure 6). This concept, intriguingly, is the converse of placing insulating refractory oxide inside graphite, reported as a preferred option for ironmaking BFs.

Hearn and co-workers (1998) describe the reasons for this as follows: the end hot-face of the graphite insert is protected by a carbon tap-block, while the cold-face is protected by a removable carbon 'mickey' block, which can be replaced if damaged by either drilling or oxygen lancing, to secure a flat mating surface against which the mudgun can more effectively close without excessive tap-hole clay bypass. During tapping the graphite absorbs the tap heat, which the outer annulus carbon tap-block of lower thermal conductivity cannot transmit as effectively, so ensuring a hot tap-hole with improved flow rates. The heat retained in the graphite sleeve after tapping and immediately following tap-hole closure by the mudgun aids tap-hole clay baking. At the next tap, a 45 mm diameter hole is drilled through the baked taphole clay core to create a tap-hole clay annulus inside the graphite sleeve that affords some protection against its coming into direct contact with the molten tap stream. Obviously, the tap-hole clay can erode with time. With the removal of the front 'mickey' carbon block, the graphite sleeve can be core-drilled out and both items replaced to effect a taphole repair. An additional tap-hole repair design feature involves splitting in two and gluing the carbon tap-block (which contains the graphite sleeve) with carbon paste rammed to close the gap between it and the adjacent furnace sidewall lining, a measure that allows for easier removal with less peripheral lining damage during replacement in planned maintenance (Duncanson and Sylven, 2011; Coetzee and Sylven, 2010; Coetzee et al., 2010).

Some Mn (Ishitobi et al., 2010) and DC arc Cr (Sager et al., 2010) ferroalloy furnaces make use of inserted water-cooled copper components on both metal and slag tap-blocks, components that range from top lintel to 'inverted-U' designs, to cool the graphite (advantage of less wetting by slag) or microporous carbon (if dissolution and erosion of graphite by the metal tapping stream prove too aggressive) tap-blocks.

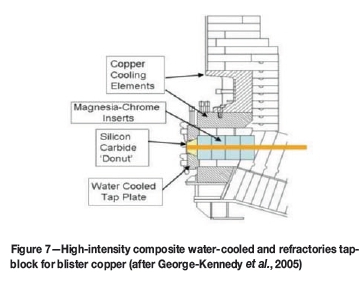

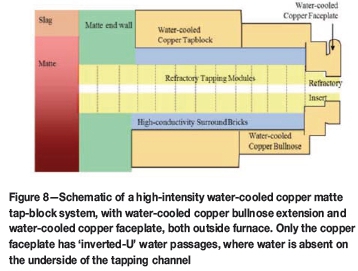

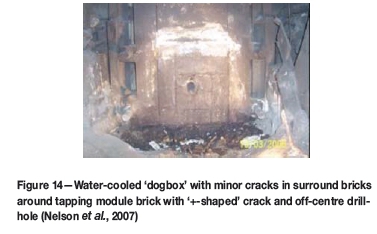

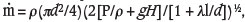

High-intensity water-cooled tap-block design

Quite different, though, are the more intensely cooled tap-block designs on blister Cu (Henning et al., 2011; Marx et al., 2005; George-Kennedy et al., 2005; George, 2002; Zhou and Sun 2013; Newman and Weaver, 2002; pers. comm. 1999, 2003) and non-autogenous processes requiring electric smelting, such as Ni and Co ferroalloy (Henning et al., 2010; Nelson et al., 2004, 2007; Walker et al., 2009; And, 1985; Voermann et al., 2010; pers. comm. 1999, 2003), base metal, and PGM matte furnaces (Cameron et al., 1995; Shaw et al., 2012; Hundermark et al., 2014; Nolet, 2014; pers. comm. 1999, 2003, 2010). These almost universally adopt water-cooled copper tap-blocks of rectangular shape: three-sided (inverted U-shape, so there is no water-cooled copper below the tapping channel), four-sided 'dogbox' (Figure 14; Nelson et al., 2007), or high-intensity one-piece waffle cooler copper tap-block designs (Figure 7 and Figure 8). Some are equipped with pin cooling (with inverted-U water passages [Henning et al., 2010]-Figure 9).

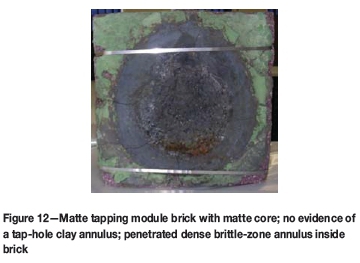

These copper coolers are lined internally with a square configuration of surround bricks, usually made of magnesia (graphite was apparently also trialed successfully in nickel matte smelting [Cameron et al., 1995], but was reported to have been discontinued), containing internal tapping module refractory bricks through which the tapping channel runs (Figure 7, Figure 8, Figure 12 and Figure 14). The latter comprises refractories that vary with commodity: almost exclusively pitch-impregnated magnesia in Ni ferroalloys (Nelson et al., 2007; pers. comm. 1999, 2003), magnesia-chrome in blister Cu or matte (Cameron et al., 1995; Nolet, 2014; George- Kennedy et al., 2005; pers. comm. 1999, 2003), or alumina-chrome in PGM mattes (Nolet, 2014; pers. comm. 1999, 2003). Both graphite and silicon carbide have been trialed in matte smelting (Cameron et al., 1995; pers. comm. 1999, 2003).

For Pb bullion (temperatures of 800-1100°C tapping, with 700°C drossing) (Veenstra et al., 1997; pers. comm. 1999, 2003) and PGM matte processes (Shaw et al., 2012; Hundermark et al., 2014; Nolet, 2014; pers. comm. 1999, 2003), process superheats are high (Table I). Specifically for the latter, process temperatures are elevated to the extent that the potential for corrosion of magnesia chrome refractory by PGM matte above 1500°C has recently been investigated (Lange et al., 2014). Good evidence of expected significant matte penetration and signs of FeO and MgO corrosion products have been found, but not as yet a CrS product suggested by any proposed mechanism. This suggests a potential for high refractory wear rates with exceptionally high matte superheats (approaching 650°C, Table I).

In Pb bullion smelting (Veenstra et al., 1997; pers. comm. 1999, 2003), blister copper (Henning et al., 2011; pers. comm. 1999), and PGM matte ACP top submerged-lance converting (Nelson et al., 2006; pers. comm. 2003), circular copper tap-blocks have also been used, with both annular graphite and silicon carbide inserts, or silicon carbide, high alumina, or graphite tapping module bricks.

So whereas ironmaking BF superheats of 350°C may seem challenging to copper-cooled operations, they are only half the matte superheats experienced on the highest intensity non-ferrous operations. Consider also the significantly lower melting temperatures of many mattes (<950°C, Table I) and this effectively makes it impossible to develop any protective matte freeze lining, even when using higher cooling water flow rates (but still short of those legislated for designation as pressure vessels). Notwithstanding this limitation, Ni and PGM mattes also have a greater solubility for copper than do iron and steel, blister copper, and copper mattes; so additionally they have a greater driving force for the chemical dissolution, not merely melting, of copper.

As we have described earlier, in such a harsh pyrometallurgical processing environment the consequence of a superheated matte/blister Cu 'hit', or lancing a water-cooled tap-block (George-Kennedy et al., 2005) and tap-hole failure is extreme. It can occur rapidly with a near-identical sequence of events, regardless of furnace size (Nelson et al., 2006). The potential for catastrophic cooler failure and/or furnace refractory breakout (Zhou and Sun, 2013; Newman and Weaver, 2002) within, most commonly, a few minutes of mudgun closure, is high (Hundermark et al., 2014). A breakout following mudgun closure has even prompted one PGM producer to resort to drilling and lancing, but to closing tap-holes with clay manually using stopper rods rather than mudguns (Coetzee, 2006).

Faceplate and refractory insert design

External faceplates are important for providing a 'perfectly' flat vertical mating face for the mudgun to engage the tapping channel (for accuracy of tap-hole clay quantity injected into the tapping channel, so ensuring minimal bypass), coupled with the refractory insert, for providing a mechanism to help secure tight joints along the length of the tapping channel to minimize infiltration and gas leakage (Eden et al., 2001), and to help prevent the entire tapping channel lining from dislodging and 'tapping' out of the furnace lining owing to internal furnace pressure (comprising both internal operating pressure and any blast pressure and hydrostatic head). The last of these incidents has apparently been experienced in the past on a Ni matte EF.

Thermal fatigue cracking or direct matte attack of water-cooled copper faceplates, typically associated with matte splashing during tap-hole plugging, presents a risk of water leaks. Sacrificial refractory or metallic cover plates have been used to address this risk (Cameron et al., 1995), with the introduction of inverted-U water-cooled pipe arrangements to secure the absence of water-cooling directly below the tapping channel, a measure that better mitigates the risk of matte making contact with water.

Tap-hole inclination and active hearth sump design

Tap-holes are normally designed with a horizontal or vertical ( e.g. EBT) orientation. The notable exception is the near-universal implementation of inclined tap-holes (approx. 10°) on ironmaking BFs. Modelling has shown that inclined tap-holes, coupled with longer tapping channels and deeper hearth sumps (the minimum sump depth is 20% of the hearth diameter [Jameson et al., 1999; Gudenau et al., 1988]) that drain liquid deeper in the furnace (further from the sidewalls), lower liquid velocities (and resultant wall shear stress and wear) both below the tap-hole and at the wall periphery (that otherwise lead to undercutting and so-called 'elephant's foot' wear) (Stokman et al., 2004; Eden et al., 2001; Smith et al., 2005; Dash et al., 2004; Jameson et al., 1999; Post et al., 2003). The localized higher velocities below the tap-hole are attributed to the draining of liquid down past the 'mushroom' (Figure 4, Van Laar, 2001). The higher peripheral velocities at the wall periphery are more a function of draining through and around a 'deadman' (Dash et al., 2004; Jameson et al., 1999; Tanzil et al., 2001). Optimum tap-hole inclination was modelled as 15° (Dash et al., 2004). Tapping conditions are further noted to distort fluid flow to the extent that, towards the end of tapping, the slag is lowest in the vicinity of the draining tap-hole, inclined to its highest at the opposite side of the BF (Post et al., 2003; Tanzil et al., 2001). We are aware of at least one high-carbon (HC) Cr ferroalloy furnace equipped with a declined tap-hole.

Modelling has similarly motivated the deepening of the metal bath of a circular HC Mn ferroalloy SAF (but still with a horizontal tapping channel, presumably in part because of the absence of anything equivalent to a 'sitting deadman') by removing a full course of carbon blocks to reduce the peripheral liquid flow velocity along the wall to a draining tap-hole (Ishitobi et al., 2010). The reduced peripheral flow induced by the deepening of the hearth reduced metal tapping temperatures by an average of 40°C (to 1350°C), despite the uprating of the transformer capacity to permit a simultaneous increase of the electrode current by 25 kA to raise the average power load at night by 2.3 MW, combined with operation at a higher coke loading to allow approach to metal carbon saturation (so limiting wear by dissolution of the carbon lining). Deepening of another Japanese HC Mn ferroalloy furnace gave benefits of marginally increased power input, faster tapping, and increased productivity (Nishi, 2007). On Si ferroalloy SAFs (Kadkhodabeigi et al., 2011), where metal drains through a porous bed of solids to the tap-hole, crater pressure and bed permeability significantly influence the rate of drainage of metals to and through the tap-hole.

In the largest rectangular six-in-line PGM matte smelting furnace, the matte inventory can exceed 600 t, with contained metal value exceeding US$50 million. Furnace deepening will come at a greater cost. Fortunately, with a combination of periodic and low-volume matte tapping (< 20% matte fall) through an end-wall of an inverted arch hearth design, in a rectangular furnace configuration, tap-hole wear has recently been predictable even at operations exceeding 60 MW power input (Hundermark et al., 2014). With a circular furnace configuration more conducive to the development of circumferential flow along the sidewall to a draining matte tap-hole, especially when the matte tap-hole is located almost on the top of the skew line of the hearth invert, it is not inconceivable that conditions for accelerated matte tap-hole wear could develop, even at far lower inputs of power.

Tap sequencing

A variety of strategies are adopted, depending largely on productivity requirements, number and layout of tap-holes, and process conditions. For single tap-holes processing dual metal-slag mixtures, total reliance is placed on the availability of the sole tap-hole. Such tapping systems are especially common in Cr and Mn ferroalloy SAFs, which may emphasize the importance of the tapping stream superheat (average-to-maximum heat flux 1-10 kW/m2 [De Kievit et al., 2004; Table I]) over absolute temperature in describing an onerous process condition.

That said, a still impressive 5 700 t/d HM in a campaign life of 13 years at the time of reporting was achieved from a single taphole BF operation (Ballewski et al., 2001). Similarly the Mitsubishi Continuous Process for copper relies on continuous liquid flow down heated launders from smelting, to slag cleaning, to converting, and to anode refining furnaces, this being effected through a combination of furnace overflow, skimming, and siphon tapping arrangements, at overall availabilities exceeding 92% (Matsutani, n.d.). These examples illustrate what is possible with superior tap-hole management and tapping practices.

Consecutive individual tapping practice

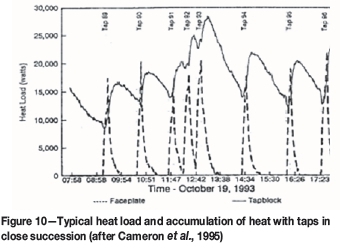

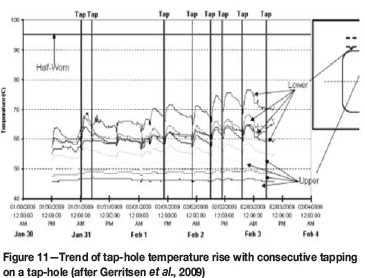

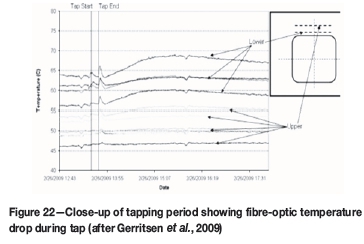

Consecutive tapping on an individual tap-hole is a common traditional practice on several ironmaking BFs (Rüther, 1988; Cassini, 2001), ferroalloy, and matte-smelting operations. Even on two-tap-hole BFs, tapping campaigns of 4 days to 3 weeks are reported (Rüther, 1988). Matte tap-hole temperature trends in Ni matte smelting clearly demonstrate the accumulation of heat in the tap-hole refractory when taps are in close succession (Cameron et al., 1995; Figure 10). Similar rising temperature trends with tapping have been observed in PGM matte smelting (Gerritsen et al., 2009; Figure 11). With an ironmaking BF interpretation this could possibly be considered desirable for promoting tap-hole clay baking and sintering. However, in the more intensely superheated matte-only tap-hole environment this is rather interpreted to imply that a resting or recovery period of no tapping is called for, to help lower refractory temperatures and re-establish improved accretion, as evidently occurred on the tap-hole on the furnace in Figure 10.

Alternating tap-hole practice

This variant, also described as 'side-to-side' casting (Petruccelli et al., 2003), is certainly the norm for achieving the highest of productivities through optimal tap-hole condition, consistent operability, and reliable availabilities; it also best supports preventative tap-hole maintenance. This is true of two tap-holes (Petruccelli et al., 2003) and tap-hole pairs on four-tap-hole ironmaking BFs (Rüther, 1988; Steigauf and Storm, 2001); 2-8 metal-only and 2-6 slag-only tap-holes on blister Cu and ferroalloy furnaces (George, 2002; Zhou and Sun, 2003; Newman and Weaver, 2002; George- Kennedy et al., 2005; Nelson et al., 2004, 2007; Walker et al., 2009; pers. comm. 1999, 2003); and up to three matte- and three slag-only tap-holes on base metal and PGM matte EFs (Nolet, 2014; Nelson et al., 2006; pers. comm. 1999, 2003). It includes ironmaking BF variants described as 'back-to-back' or 'mother-daughter' tapping (Irons, 2001; Cassini, 2001), where a pair of taps is made before alternating tap-holes. In the case of the ironmaking BF, this practice of a pair of taps is usually in response to suboptimal conditions, such as inadequate draining or persistent taps of short duration.

A detrimental feature reported for alternating tapping on BFs, where a zone of low permeability exists between tap-holes, is the potential for the slag level to rise due to excessive pressure loss, which disrupts bosh gas flow (Iida et al., 2009; Shao, 2013; Shao and Saxen, 2011, 2013a, 2013b). Slag levels could conceivably fluctuate on SAFs similarly, owing to the presence of less permeable zones. Iida and co-workers (2009) recommend enlarging the tap-hole diameter (by approx. 10%) as the best remedy to alleviating this issue.

While operating at a still impressive HM superheat, ΔT approx. 350°C, the focus on the BF is largely HM productivity-driven, with up to 75% metal fall and daily targets exceeding 10 000 t HM, thus demanding the most effective and efficient tapping with reliable operability. Most operators appear to seek to operate somewhere close to a 'dry' hearth condition (De Pagter and Molenaar, 2001), in which hot metal and slag levels in the hearth are kept as low as possible (Van Laar et al., 2003), but without escape of hot gas (Nightingale et al., 2001; Tanzil et al., 2001). In contrast, the requirement on the multiple tap-hole, lower metal/matte fall (<20%) Ni ferroalloy and matte furnaces is primarily to secure maximum tap-hole and furnace reliability. This is especially true of high-intensity PGM matte furnaces, with their onerous matte superheat, ΔT approx. 650°C, that imposes integrity challenges on even the most intensely water-cooled, refractory-lined copper tap-hole.

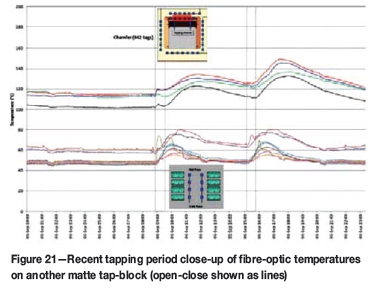

On the highest intensity of these operations, even with less frequent matte tapping events, the practice generally is to alternate tapping between the available tap-holes in order to give the tap-holes maximum 'recovery' time to lower tap-hole temperatures between taps. This is reported (Eden et al., 2001; Mitsui et al., 1988; Entwistle, 2001; Cameron et al., 1995; Gerritsen et al., 2009) and has been modelled in the BF (Ko et al., 2008). The merits of such an approach, originally diagnosed from scrutinizing well-instrumented copper tap-block and cooling water temperature tapping trends, are presented using the latest fibre-optic temperature measurement trends available in PGM matte smelting (see section on Advanced tap-hole monitoring).

At first glance an alternating tap-hole practice would appear to complicate the timing of minor routine, monthly planned tap-hole maintenance activities (Nolet, 2014). However, it should be appreciated that, despite such diligent monthly repairs and essentially slag-free tapping, process conditions remain so onerous that all but the hot-face matte tapping module bricks have to be replaced roughly every quarter to secure incident-free tapping, good tap-hole condition, and ultimately furnace integrity and longevity. To undertake such a deep tap-hole repair, tap-hole temperatures and safety dictate that the furnace power needs to be lowered for the duration of the repair. So in fact a simultaneous repair of all matte tap-holes by a team of masons on a furnace at lowered furnace power actually minimizes the impact on overall furnace utilization.

Also, it should be clarified that in high-intensity PGM matte smelting the 'as-low-as-possible' liquid matte and slag levels of the BF 'dry hearth' operation are definitely not sought, nor considered desirable. Considering first the overall liquid level, one finds that generally too high a pressure head is not sought, because it promotes an increased rate of tapping and increases the potential for matte infiltration of the furnace lining. Specifically, one also does not seek too high a matte level, for fear of exposing the effective slag-line, water-cooled copper waffle coolers to a greater risk of making contact with superheated matte. While the waffle cooler design reportedly (Trapani et al., 2002; Merry et al., 2000) caters for metal contact of copper waffle coolers in Ni (Nelson et al., 2007) and Co (Nelson et al., 2004) ferroalloy processing, contact by matte, especially superheated matte, can rapidly lead to catastrophic failure.

However, this still does not warrant seeking the lowest possible matte level. This is because the matte-only tap-hole is especially configured to be refractory oxide-lined, with generally good corrosion resistance to matte, but with decidedly poor corrosion resistance to acidic slags (> 50% SiO2 content). Indiscriminate lowering of the matte level would therefore not only expose the tap-hole to the risk of 'slagging' by the hotter slag, but would accelerate corrosion, and ultimately wear, of the refractory lining. A target minimum matte level is therefore simultaneously sought with matte operated below the maximum matte level permissible.

In respect of the slag level, the absolute minimum furnace slag level is controlled by its interface with matte. Operation around the slag tap-hole, located typically approximately 1 m above the matte tap-hole (Table I), represents the lowest overall pressure head condition on the matte, which is beneficial. However, at the highest smelting rates with < 20% matte fall, slag make becomes significant, which requires near-continuous tapping in contrast to periodic batch matte tapping. With the slag level only at the level of the slag tap-hole, the pressure head is simply inadequate for slag tapping rates to be acceptable. So a practical minimum operating slag level exists, above which slag tapping rates are adequate for achieving an efficient rate of slag drainage (even if multiple slag tap-holes are open).

Finally, the maximum permissible top of slag level is designed relative to the slag tap-hole. This measure primarily ensures that superheated slag does not rise above the zone of sound crucible containment below the top of the copper coolers, but also limits excess pressure head at both the slag tap-hole and the underlying matte tap-hole.

Slag tapping

Where consecutive tapping practice has indeed found nonferrous application is during 'slow' slag tapping on both Ni ferroalloy and PGM matte smelters. The slag tap-hole has a tendency to open fast and then the tapping rate declines with time. In situations where the number of slag tap-holes available is limited (e.g. owing to planned maintenance), an effective solution involves closing on lazy-flowing slag with the mudgun, and shortly thereafter re-drilling the slag tap-hole open again (exposure of drill bits to slag only is far less aggressive than exposure to metal or matte). This can easily double the initial tapping rate on a 'slow' slag tap-hole.

Closure on flowing slag is crucial to this operation, because it ensures easy re-drilling of tap-hole clay only to open the slag-tapping channel. In the event where the flow from a slag tap-hole has been allowed to stop, even with an attempted mudgun closure, an adequate plug of tap-hole clay to the inner hot-face cannot be secured. When re-drilling is attempted, solidified slag is quickly encountered, which impedes the drill and can cause skew drilling - potentially towards a water-cooled copper cooler! So somewhat paradoxically, to be safer, oxygen lancing with its ability to 'cut' open, and so straighten, the solidified slag tapping channel then becomes necessary to re-open the slag tap-hole.

Tap-hole opening

It is essential to be able to 'quickly and certainly open the tap-hole whenever required' (Tanzil et al., 2001).

Discounting the most primitive past practices of 'pricking' or 'excavating' the tap-hole open, a wide range of tap-hole opening methods are adopted (Ballewski et al., 2001), including:

► Manual oxygen lancing, suggested near universally to be minimized to < 1% of taps (Jameson et al., 1999), or for 'emergency only' on ironmaking BFs (Ballewski et al., 2001). This practice has led directly to a reported blister tap-hole failure and resulting explosion on at least one site (George-Kennedy et al., 2005), and yet is still adopted as the primary means of tap-hole opening on 36% of PGM matte furnaces (Nolet, 2014)

► Automated or robotic oxygen lancing (pers. comm., 2010)4

► A soaking bar technique5

► Conventional pneumatic drilling (air)

► Improved pneumatic drilling (nitrogen and/or watermist-bit cooling)

► Hydraulic drilling (nitrogen and/or water-mist-bit cooling)

► Combination pneumatic drilling (without opening) and deliberate lancing of the last remaining metal/matte plug.

It is worth noting that to avoid contamination by iron or other elements, metallurgical-grade silicon tapping requires a variety of alternative tools to open a tap-hole and maintain the flow of metal. These alternatives include an electric stinger (connected to a busbar system from the furnace transformers), a kiln gun (Guthrie, 1992)6, steel and graphite lances, wooden poles, and graphite bott tools (Szymkowski and Bultitude-Paull, 1992).

Tapping rate

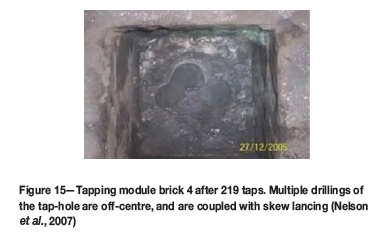

A primary requirement of tapping is to reliably secure the desired rate of furnace products. Thus, it is important to establish the factors influencing tapping rate. Guthrie (1992), applying Bernoulli's equation, provides a useful estimate of tapping rate,  through a tap-hole of diameter d, where, CDis a discharge coefficient (approx. 0.9), g is the gravitational acceleration constant, and H is the effective liquid head of the phase being tapped, with a phase of density p.

through a tap-hole of diameter d, where, CDis a discharge coefficient (approx. 0.9), g is the gravitational acceleration constant, and H is the effective liquid head of the phase being tapped, with a phase of density p.

Mitsui and co-workers (1988), combining Bernoulli's and Darcy- Weisbach's equations, estimated the iron BF tapping rates as  , thereby including a correction for the tapping-channel length (l). This yields typical iron BF tapping rates of 7 t/min (approx. 10 000 t/day on a near-continuous tapping basis) and liquid tapping velocities of 5 m/s in tap-holes of 70 mm diameter by 3.5 m length. Both approaches show that tap-hole geometry strongly influences tapping rate (with velocities of up to 8 m/s recorded [He et al., 2001; Atland and Grabietz, 2001]), primarily through the tap-hole diameter. The second equation suggests tap-hole length as the next most significant influence.

, thereby including a correction for the tapping-channel length (l). This yields typical iron BF tapping rates of 7 t/min (approx. 10 000 t/day on a near-continuous tapping basis) and liquid tapping velocities of 5 m/s in tap-holes of 70 mm diameter by 3.5 m length. Both approaches show that tap-hole geometry strongly influences tapping rate (with velocities of up to 8 m/s recorded [He et al., 2001; Atland and Grabietz, 2001]), primarily through the tap-hole diameter. The second equation suggests tap-hole length as the next most significant influence.

In the case of Si ferroalloy SAFs (Kadkhodabeigi et al., 2011), where metal must drain through a permeable bed of solids to the tap-hole, the height of liquid metal influences the onset of gas breakthrough to the tap-hole and the concomitant sudden drop in tapping rate, but exerts less influence than crater pressure and bed permeability on the initial tapping flow rate.

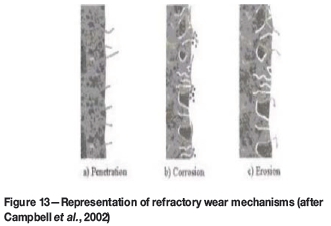

Tap-hole wear mechanisms

Given a dominant influence of tap-hole dimensions on tapping rate, it is instructive to consider factors contributing to tap-hole wear (Figure 12), which are elegantly summarized by three sequential steps: penetration, corrosion, and erosion (Figure 13; Campbell et al., 2002).

The first step in refractory wear involves the penetration of refractory, the rate of which, upen, can be described by a capillary-force-driven flow according to rγcose/4μlp, where r is the capillary (pore) radius, γ is surface tension, θ is the contact angle, lpis penetration depth, and μ is liquid viscosity. The last property (viscosity) is related inversely to process temperature.

Once a liquid has penetrated a refractory, corrosion by the infiltrating liquid becomes possible. Campbell and co-workers (2002) describe corrosion as a 'cooking time' to illustrate that its rate relates to how long a penetrated refractory has been at a temperature that supports reaction. Furthermore, as corrosion rate conforms to Arrhenius's Law, an exponential (as opposed to linear) scale of temperature is required to predict the increase in the rate of corrosion with temperature.

Once a refractory has been penetrated and further weakened by corrosion, erosion becomes possible if the shear stress, τ = μ(dv/dy) induced by the liquid flow through the tap-hole is sufficient to remove refractory. Once again, temperature affects liquid viscosity, whereas the rate of tapping affects the velocity gradient (dv/dy). Estimated tapping velocities of 1-5 m/s suggest that the applied shear force is a few orders of magnitude lower than the hot modulus of rupture of most refractories. So it is well-argued that tap-hole refractory erosion cannot occur until the refractory structure has somehow first been weakened by liquid penetration and corrosion (Campbell et al., 2002).

In PGM matte tap-holes an annulus of tap-hole clay does not appear to persist in lining the tapping module refractories (Figure 12). However, the same (low) velocities may possibly provide a shear force that is in excess of the hot modulus of rupture of poorly baked/sintered tap-hole clay. So in operations that critically depend on a 'maintainable' baked and sintered annulus of tap-hole clay to line the tapping channel to protect the tap-hole refractory (e.g. especially when combined tapping of more corrosive slag, as in ironmaking BFs), far more attention should be paid to the issue of tap-hole clay sintering and erosion-resistance properties (Mitsui et al., 1988).

Generally, the potential adverse influences of suboptimal tapping velocities are:

► Too slow tapping-limits tapped production; delays liquid drainage, which may potentially be unsafe if critical furnace levels are threatened (e.g. matte encroachment to near the vicinity of copper coolers, or slag overflow over the design maximum crucible containment height)

► Too fast tapping-induces loss of control, thereby creating unsafe tapping and post-tap-hole conditions; in the extreme, and only then, promotes tapping channel and furnace lining erosion.

These influences may have more adverse consequences than erosion does.

Drilling practices

Owing to the potential for oxygen-induced lancing damage to tap-holes, the vast majority of operations seek to practise drilling the tap-hole open. This typically includes sacrificing the drill bit and, potentially, the drill rod. In at least one Japanese Mn ferroalloy operation, to conserve costly drill bits, the operator withdraws the drill as soon as metal is expected to be encountered, places a sacrificial crimped steel pipe over the drill bit, and then drills the hole open. This protects the drill bit enough to permit re-use.

Combination drilling and 'plug' oxygen lancing practice

On most alloy-only and matte-only tap-holes operated in the substantial absence of any tap-hole hot-face 'mushroom', a combination of deep drilling followed by 'plug' oxygen lancing is practised deliberately. The aim is to drill through the tap-hole clay as (consistently) deep as possible (700-1200 mm, depending on tap-hole design length), until the drill encounters resistance from a 'plug' of metal/matte/ residual entrained slag. Experience indicates that attempts to drill further through this 'plug' often lead to unintended skew drilling. This measure is particularly hazardous in a water-cooled copper tap-block configuration, and often results in the drill simply getting stuck in the tapping channel. Even with reverse percussion hammering (Bell et al., 2004), it may become impossible to free a stuck drill bit and rod, an outcome that requires the tapper to resort to oxygen lancing to remove the obstruction.

In combination practice, the drill is then withdrawn, and the drill length measured accurately (but manually) with a gradated drill-T, which simultaneously verifies that the drilling was not off-centre. Once the drill-hole is confirmed as being straight, oxygen lancing of the short remaining tapping channel 'plug' is then undertaken to open the tap-hole. This usually requires a minimum of lancing (less than one lance pipe). In this way there is also a lower risk of tappers losing the skill of using oxygen lances safely owing to infrequent practice.

The rationale behind this practice is driven by a decided requirement not to overfill tap-hole clay, through the addition of a metered amount of tap-hole clay, which permits operation with a consistent short (as possible) tapping-channel 'plug' to lance.

Tap-hole drilling requirements

The requirements to control and optimize the rate of drainage to the tap-hole (to reduce liquid velocities and wear of the furnace lining) and the associated tapping rate through it (a controlled liquid tap with stable post-tap-hole conditions) impose a need to maintain a constant and optimal tap-hole length and smooth shape (Van Ikelen et al., 2000). The length is usually as long as is practicably achievable, while one maintains a near-cylindrical channel shape of defined diameter. In reality, some extent of fluting towards the hot-face (conveniently modelled as a cone [Van Ikelen et al., 2000; Nightingale et al., 2001]) with erosion at the hot-face (conveniently modelled as a paraboloid to represent a zone for 'mushroom' development [Van Ikelen et al., 2000; Nightingale et al., 2001]) has been inferred from tapping channel temperatures, drill depths, and their distributions (Mitsui et al. 1988; Van Ikelen et al., 2000; Nightingale et al. 2001).

In ironmaking operations with lower metal fall (a high slag ratio of lower density) it is argued that 'the decision for diameter and tapping practice must be focused on slag' (Brunnbauer et al., 2001). This highlights the role of reliable drilling, as it represents the primary means for controlling tap-hole diameter.

Tap-hole drilling equipment and control

Owing to the excessive risk of skew drilling (directly contributing to similarly skew oxygen lancing in combination drilling and 'plug'-lancing practice), especially to operations with water-cooled copper tap-blocks, practice typically requires that the accurate alignment (to surveyed tap-hole centre/s [Estrabillo, 2001]) of mudgun/s and drill/s be checked and, if necessary, recalibrated at the start of each shift (Irons, 2001). Tap-hole-centering notches are also reported; they locate and indent the tap-hole clay to help keep the drill from 'walking off from the centre of the tap-hole (Estrabillo, 2001).

In addition, guided and stiff drill rods are essential to reducing excessive drill flex and securing a straight, centred tap-hole. Guide systems include automatic travel to within limits, followed by a hydraulic pin, sometimes colloquially called 'antlers' (Black and Bobek, 2001), being physically positioned down into latch hooks. For drilling 4 m long ironmaking BF tap-holes (requiring 6 m drill rods), additional hydraulic rod devices are fixed to the drills to prevent bending of the drill rods and drilling off the tap-hole axis (Ballewski et al., 2001). The undesirable consequence of using a less precise suspended rock drill for tap-hole drilling has been reported previously in a four-piece, water-cooled copper Ni ferroalloy tap-block operation (Nelson et al., 2007; Figure 14 and Figure 15).

An encoder that measures the drill position can be correlated with drill torque (in hydraulic systems - Jameson et al., 1999; Atland and Grabietz, 2001) or drill air-pressure forward drive (in pneumatic systems - Van Ikelen et al., 2000) and drill speed to determine automatically the start and end of the tapping channel and hence the all-important tap-hole length (Jameson et al., 1999; Van Ikelen et al., 2000; Eden et al., 2001; Tanzil et al., 2001; Edwards and Hutchinson, 2001; Smith et al., 2005). Drill-time sigma (Black and Bobek, 2001) and tap-hole length (Jameson et al., 1999) are regarded as benchmark statistics and, with the application of statistical process control (SPC), measures with which to quantify and effect tap-hole improvements.

Drill rod and bits

Drill-bit shape and material - carbide (Black and Bobek, 2001; Tanzil et al., 2001; Entwistle, 2001) or heat-resistant Cr-Ni alloy (Atland and Grabietz, 2001) tips are preferred -has been the subject of intense investigation, especially in the ironmaking BF application (Van Ikelen et al., 2000; Ballewski et al., 2001; Black and Bobek, 2001; Brunnbauer et al., 2001; Estrabillo, 2001; Entwistle, 2001; Atland and Grabietz, 2001). The ability to retain a sharp cutting edge so as to cut, rather than hammer, through the tap-hole clay 'plug', with the bit cutting face presented to a debris- and dust-free face to drill, is essential (Estrabillo, 2001). Drill-bit diameter is controlled usually within the range of 33 mm (Tanzil et al., 2001) to 45-65 mm (Steigauf and Storm, 2001; Atland and Grabietz, 2001). Where hammering is considered important, an inside bit face that is totally flat (to maximize transmission of impact energy) is reported (Tanzil et al., 2001), coupled with transition from spherical to semi-spherical carbide shapes.

Air scavenging is typically used to clear the hole, providing additionally some cooling of the drill bit to help prolong its life (Van Ikelen et al., 2000). Further improvement has involved progressively improving drill-bit cooling (from air, to nitrogen, to water mist) on ironmaking BFs (Eden et al., 2001; Petruccelli et al., 2003; Van Ikelen et al., 2000; Smith et al., 2005; Irons, 2001; Steigauf and Storm, 2001; Ballewski et al., 2001; De Pagter and Molenaar, 2001; Black and Bobek, 2001; Edwards and Hutchinson, 2001), where water-mist cooling rates are in the range of 2-5 L/min and typically 4 L/min (Tanzil et al., 2001). Water-mist cooling systems are reported to have undergone still further development to overcome disadvantages of increased risk of drill equipment corrosion (Van Ikelen et al., 2000).

In ferroalloy and matte operations, especially those equipped with any potentially hydratable magnesia-based refractory, use of any water would be taboo (in fact even to the extent that dew-point condensation associated with liquid-nitrogen cooling to accelerate tapping channel repair is sometimes a concern). The short drill-bit life is largely overcome when drilling only tap-hole clay (i.e. deliberately not drilling metal/matte/slag) in both metal/matte-only combination drilling and slag-only drilling open tapping practices.

Two opposing effects of drilling on the control of tapping channel diameter are reported. With premature bit wear, negative fluting of the tapping channel (diameter decreasing evenly down to the drill rod diameter towards the hot-face) has been reported (Van Ikelen et al., 2000). Side-cutting designs capable of cutting during both forward and reverse drilling have been developed to limit the influence of drill-bit wear on the resulting drilled diameter (Van Ikelen et al., 2000). More frequently, though, a bit that fails to retain its cutting edge tends to wander, which causes positive fluting to the hot-face (Nightingale et al., 2001; Mitsui et al., 1988; Tanzil et al., 2001), or a 'mushrooming' effect (Estrabillo, 2001; Edwards and Hutchinson, 2001). Traditional rock drill-bit designs provide some increased resistance to this, and are often preferred (Estrabillo, 2001), despite still requiring drill-bit replacement every tap on an ironmaking BF. This warrants further clarification: on ironmaking BF tap-holes the ability to open with 'one drill-bit for every attempt' is regarded as an achievement (Estrabillo, 2001), with only a 50% success rate reported at one site (Nakamura et al., 2007), or an average of 1.2 drill bits per tap reported (Atland and Grabietz, 2001). Progression from threaded to bayonet drill-rod couplings is reported (Estrabillo, 2001) to limit the incidence of drill rods jammed tightly in couplings.

The direct consequence of a smooth, straight tapping channel is a consistent smooth tapping stream and controlled post-tap-hole logistics. In contrast, a tapping channel that has an inner corkscrew shape is reported to induce a rotating and spraying tapping stream (Van Ikelen et al., 2000), an outcome exacerbated by any gas-tracking on a pressurized BF operation. 'Softer drilling' (feed-forward pressure < 3 bar) together with instructions to the operator to 'let the drill do the work' and so not try to force the tap-hole open using maximum force, which can bend the drill rod and promote a corkscrew channel, is reported to lower the incidence of rotating and spraying tapping streams (Van Ikelen et al., 2000).

This is remarkably akin to the requirements of successful oxygen lancing: a good tapper tends to use the hot burning lance tip (> 2000°C) to progressively cut the tap-hole open in a series of small precessing actions to guide the lance ever deeper to make a straight tapping channel. An inexperienced tapper, on the other hand, tends to try to force-burn the tap-hole open by pushing hard on the thin, long and flexible lance pipe, which readily causes it to deflect off-course and cause damage.

Finally, it is said that 'a rotating drilling method for opening the tap-hole, without hammering ... is expected to give an improvement of the tapping process' (Van Ikelen et al., 2000). Similarly, many local ferroalloy and PGM matte tap-holes are indeed opened by drill rotating action alone without hammer action, despite the latter's usual availability. Even on ironmaking BFs it is suggested that 'future advancements will be directed toward drilling the tap-hole without the need for hammering' (Estrabillo, 2001).

Tap-hole closure

It is essential to be able to 'close the tap-hole with a high degree of certainty that the desired volume of tap-hole clay has in fact been installed' (Tanzil et al., 2001), and additionally ensure that mudgun retraction does not result in an unplanned tap-hole re-opening. Total elimination of reopening events remains important, even given reported improvement from 10 to just one such event per annum by 2000 on one site (Black and Bobek, 2001).

Especially on slag-only closure, stopper bars, water-cooled 'rosebuds', and manual stopper tap-hole clay 'plugs' remain common in the ferroalloy and non-ferrous industry. Slightly more sophisticated variants are used on some of the lower temperature and lower superheat mattes and blister Cu operations, e.g. 'Polish plug', comprising ceramic surrounding a cone-shaped tap-hole clay 'plug' (George-Kennedy et al., 2005). Over 25% of PGM and local Ni matte operations still practise manual plugging of tap-holes (Nolet, 2014; Coetzee, 2006).

However, by far the majority of ferroalloy furnaces, 70% of PGM and local Ni matte operations (Nolet, 2014), and all ironmaking BFs have increasingly adopted sophisticated and powerful mudguns to effect tap-hole closure. Again, the importance of considering mudgun, tap-hole clay, and tap-hole operating practice holistically as a fully integrated system cannot be understated - coupling a hard new-generation tap-hole clay with an old weak mudgun incapable of properly delivering the clay into the tap-hole is bound to fail. Smith, Franklin, and Fonseca (2005) describe this well: the 'design of tap-hole clay is usually a compromise between "equipment capability" and "process" requirements.'

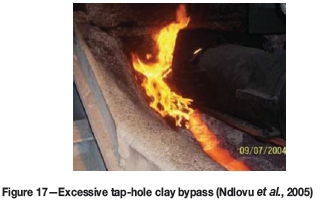

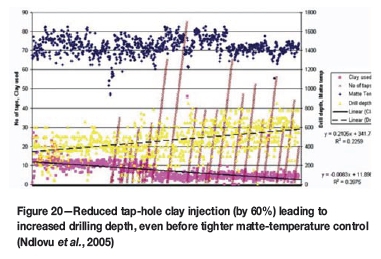

Mudgun equipment and operation