Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.116 n.5 Johannesburg May. 2016

http://dx.doi.org/10.17159/2411-9717/2016/v116n5a3

PAPERS - SLOPE STABILITY CONFERENCE

An update to the strain-based approach to pit wall failure prediction, and a justification for slope monitoring

W. Newcomen; G. Dick

BGC Engineering Inc

SYNOPSIS

Effective management and mitigation of pit slope instability in open pit mines begins with a comprehensive slope monitoring programme. The ability to differentiate between non-critical pit wall movements due to rebound or relaxation of the excavated slopes and movements that may be indicative of slope failure is important for maintaining a safe working environment and maximizing production. Slope failure prediction methods using velocity, acceleration, and strain criteria have been introduced and put into practice over the past few decades. Forty-eight slope failures with surface monitoring data are presented and assessed using the strain-based failure prediction approach, with consideration of the quality of the rock mass and the potential failure mechanism. The results indicate that the strain-based approach can be used to provide general guidance regarding strain thresholds for pit walls for a variety of failure modes in diverse geological environments. The advantages and potential drawbacks of the strain-based and other slope failure prediction methods are discussed. The importance of implementing a pit slope monitoring and performance evaluation system early in mine development is also emphasized.

Keywords: open pit slopes, slope monitoring, failure prediction, pit wall strain, strain criteria, strain thresholds

Introduction

The successful prediction of the Manefay Slide pit slope failure at Bingham Canyon at 9:30 am on 10 April 2013 (Engineering and Mining Journal, 2014) highlighted the importance of having a comprehensive slope monitoring system that provides an accurate prediction of the time of failure of an open pit slope. Using most of the geotechnical monitoring tools available, the time of the failure was predicted within hours and equipment and personnel were evacuated from the pit well in advance of the failure. From a time to slope failure perspective, the monitoring system in place was a success.

There are two general groups interested in monitoring pit walls, with slightly different objectives in mind when the monitoring system is being set up. There are those at the mine site that have to implement the pit slope design, monitoring protocols, and the action response plans, and there are those designing the slopes (often consultants) who regularly visit the mine but may not be responsible for the day-to-day activities.

The 'implementers' are primarily concerned about safety. Most mining operations go to great lengths to maintain a safe working environment and generally this is a mandate of management and the mine workforce. A comprehensive slope monitoring programme will allow personnel to work more comfortably in areas within the pit that are less stable than others. The mine operation is also keenly interested in optimizing ore recovery and managing risk. Retrieving the last loads of ore often requires that mining be carried out in areas that have a higher risk associated with them, such as the last few benches of the slope in an area generally more confined than the upper portions of the pit. A slope monitoring system allows miners to work confidently below pit walls that are deforming but are not progressing towards catastrophic failure. Confidence in the pit wall behaviour allows mining to be carried out for as long as possible, resulting in optimized extraction of the mineral resources. There are significant economic benefits associated with being able to stay in an area and continue mining as long as possible. The 'mine and monitor' approach is commonly used in mature mines where slopes are in various stages of instability and where there is a comprehensive experience base in the behaviour of the pit walls.

On the other side of the team are the 'designers'. Their motivation for monitoring is often to test or confirm the pit slope design. Depending on the design approach used, performance monitoring may be a fundamental component of the design. Confirmation that the wall is stable or deforming at a manageable rate is a key aspect of providing confidence in the design process. If there is a high degree of uncertainty in the design there should be an associated requirement for more comprehensive monitoring. If a particular mode of instability is of concern or has been predicted, early implementation of a pit slope monitoring system will allow this potential to be tested. Slope deformation monitoring is important to test the design. If the design requires modifications by means of step-ins, pushbacks, or slope flattening this can be justified by the results of the monitoring data, with the ultimate goal being to keep the pit slope movement rates or total displacements within pre-defined levels estimated during the design stage.

The implementers and the designers must work together during the planning, operating, and closure stages as future plans are generally influenced by previous pit wall performance. During all stages of mining there has to be a 'meeting of minds' between these two groups so that the safety, risk management, and design objectives of the operation are achieved. This is where the mine planners must balance the competing objectives of the various groups. Economics often plays a large role; for example, implementation of a comprehensive and expensive slope monitoring system may be justified if significant economic benefits from mining more aggressively in certain areas can be shown during the planning stages. Conversely, a simpler monitoring system may be appropriate during closure, as the risks may be lower at this stage of mining.

Monitoring tools

Surface and subsurface instrumentation are common in the slope monitoring programmes of most large open pit mines. Proactive mines will implement surface monitoring systems as the pit wall is developed instead of waiting until an instability occurs, recognizing that it is generally easier and more efficient to install surface instrumentation as the slope is mined. The focus of this paper is on surface displacement monitoring, as surface displacement acceleration is generally the main precursor to slope failure (Read and Stacey, 2009). Surface displacements are still the primary means by which mining operations evaluate the stability of a slope and are also generally easier to monitor than subsurface movements.

There are two main categories of pit wall surface deformation monitoring: point monitoring (prisms, extensometers, GPS) and area monitoring (laser scanning, photogrammetry, radar). Slope monitoring instrumentation can be further classified based on the time at which the monitoring data becomes available: background, extended data update times, and active, short-, or near real-time data updates. The monitoring method(s) selected by the mine should follow a risk-based approach where instrumentation is determined based on the slope risk and consequence of failure (de Graaf and Wessels, 2013).

Large open pit mines generally utilize multiple slope-monitoring instrumentation systems to manage the risk of slope instabilities. The sophisticated multi-system monitoring programme in place at Bingham Canyon (Doyle and Reese, 2011) included visual field inspections and spotters to monitor changing slope conditions, robotic total stations to survey over 200 optical prisms strategically located throughout the open pit area, and two types of ground-based slope stability radar to actively monitor specific slope instabilities. Visual inspections complemented with prism surveying, however, still appear to be the industry standard in some jurisdictions (Nunoo et al., 2015).

Area-based (radar and laser) monitoring methods are typically employed when point monitoring systems are no longer effective, i.e. when slope deformations are large and the installation of prisms is no longer safe or practical. Transition from one monitoring system to another must take into consideration the limitations of each system. It is often desirable to have multiple monitoring systems or sufficient overlap of the systems to overcome and understand their limitations.

Utilizing the monitoring data

Slope instability triggers can be identified by comparing pit slope movements (velocities, displacements, and vectors) to mining activities (blasting and excavating), precipitation events, runoff, and pore pressures. It is important to identify and understand the triggers so that appropriate movement rate thresholds can be developed that take into consideration the various factors contributing to slope movements. It also allows background movements, generally due to slope rebound, relaxation, or creep, to be quantified and filtered out of the overall movements, allowing anomalous slope movements attributed to degradation of the rock mass or the presence of an unanticipated geological feature to be better identified.

Maximum velocities, accelerations, or total movements, generally based on experience at operating mines using historical monitoring data or experience in similar geological environments, can then be used to establish trigger action response plans (TARPs) to guide mining operations during periods of increased slope displacement. The TARPs are used to guide mine operators regarding which unstable areas can be accessed, who is allowed to access these areas, and what kind of equipment can be used to work in these areas. The response plans and/or thresholds may be modified as experience is gained in mining adjacent to the area of instability.

Monitoring data can also be compared to displacements predicted by numerical models to confirm that the pit slope is performing or responding as predicted. Anomalous movements, potentially indicative of the onset of failure, may be detected that require a reassessment of the design assumptions. By monitoring the pit slopes and comparing the movements to those that would be expected for a potential mode of instability, the designers can determine if their assumptions are correct or require modification, possibly resulting in changes to the pit slope geometry.

Strain-based approach to failure prediction

The use of strain measurements to predict the onset of failure of a geological material is not a new concept. This approach has been used in underground applications by means of measuring convergence, and is also routinely measured during testing of geological materials to understand the conditions leading to failure. Pit slope design practitioners have proposed strain limits to define the onset of tension cracking, steady-state movement, and the onset of progressive slope failure (Zavodni, 2001). Building on that initial work, using a relatively small data-set of twelve slope failures collected from various sources, the proposed strain limits were tested and compared to the quality of the rock mass (the rock mass rating (RMR), as defined by Bieniawski, 1976) to see if a correlation could be developed between RMR and strain thresholds (Brox and Newcomen, 2003). Due to the limited size of the database, pit slopes experiencing a variety of failure mechanisms and in different stages of instability ( e.g. initial cracking, steady state, and progressive) were grouped together.

The key conclusion of that work was that the strain at 'failure' is generally influenced by the quality of the rock and that, in general, the lower the rock quality the higher the potential strain at failure. The results of that study suggested that the deformability of the rock mass, which can be estimated from the RMR, plays a primary role in the amount of strain a pit wall can accommodate prior to failing. However, those assessments also indicated that the failure mode must be considered when assigning the allowable strain in a pit slope. For example, much smaller movements are tolerable in a pit wall susceptible to planar failure than one susceptible to toppling. In other words, different strain threshold values are appropriate for different failure modes when defining allowable 'strain at failure'. An extensive evaluation of a toppling and a planar failure in the north wall of the Nchanga pit (Wessels et al., 2009) was conducted to test the slope collapse strain criteria originally proposed by Brox and Newcomen (2003). That evaluation concluded that there was not a significant difference between the strain at the onset of tension cracking, progressive failure, or collapse for the two failure mechanisms at that site. That work highlighted the potential complexity of trying to apply strain thresholds to the various stages of slope instability, which may be poorly defined in some cases. However, due to the limited data-set, it cannot definitively be concluded that different strain thresholds should not be applied to different failure mechanisms.

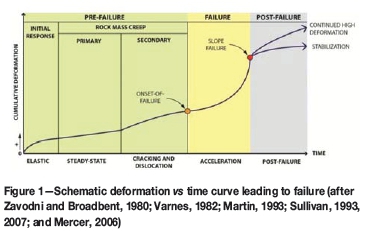

Other pertinent conclusions from the original work (Brox and Newcomen, 2003) included the need for a clearer definition of 'failure' of a pit wall, as steady-state movements due to primary rock mass creep, for example, are not as critical as secondary creep leading to the onset of failure and collapse of the pit wall (Figure 1). For the purpose of this paper, failure was more precisely defined as 'complete collapse of the pit wall', which differs from the original work where the case histories presented included some failures that did not progress to complete collapse. As a result, those case histories were taken out of the database, which was then updated to include slope collapses documented by Whittall et al. (2015) as part of a pit wall failure runout prediction study. Thus, the database presented is more rigorous in its definition of failure and also contains a larger number of failures for the four failure modes presented.

Consistent with the previous work by Brox and Newcomen (2003), the 'strain' in the pit slope was defined as the total movement measured at the surface divided by the height of the slope below the prism. This is an approximation of strain and does not represent the actual strain at surface or in the pit wall. This approach probably underestimates the actual strain; however, it is simple to calculate and considered accurate enough to approximate the surface strain, as long as the surface slope monitoring system was implemented relatively soon after mining was started.

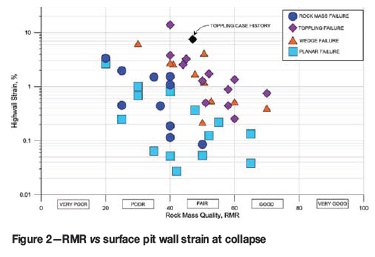

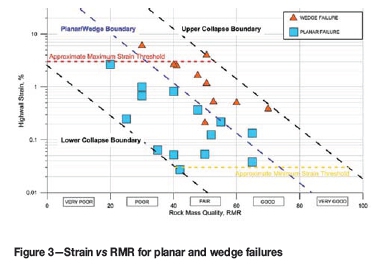

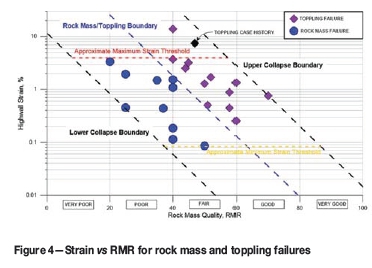

Using these definitions, a revised RMR vs strain plot was developed from the updated database using only slope instabilities with well-defined failure mechanisms that resulted in complete collapse of the pit wall (Figure 2). To further explore the relationship between RMR and strain at collapse, the data was divided into two groups:

► Planar and wedge failures

► Rock mass and toppling failures.

Failures with complex or poorly defined failure modes were generally eliminated from the data; however, rock mass failures were included, which still tend to be used as a catch-all phrase for failures that are poorly defined. Nonetheless, the divisions noted above were used to produce Figures 3 and 4. Although there is a large amount of scatter in the plots, there also appears to be some trends, as discussed below.

Figure 3 indicates that planar failure generally occurs at the lowest strains and can occur over a relatively wide range - up to 1.5 orders of magnitude for a given RMR. Several slopes that experienced planar failure collapsed at strains of between 0.03% and 0.06%. The maximum strain measured for a planar failure was about 3%. The data for the wedge failures indicates a minimum strain of 0.2% and a maximum strain of 6%; two cases observed had strains greater than 3%. The range of strain for a given RMR is smaller for wedge failures than for planar failures, with only about one order of magnitude between the upper collapse and the planar/wedge boundary. The results suggest that 3% may be a reasonable maximum threshold to use for prediction of planar and wedge failures in poor- to fair-quality rocks.

Figure 4 indicates that rock mass failures can occur over a relatively wide range - up to 1.5 orders of magnitude for a given RMR. One pit wall experiencing rock mass failure collapsed with a strain of less than 0.1%. The maximum strain measured for a rock mass failure was about 3%. The highest strain was observed for a toppling failure, with almost 15% strain measured at failure; however, the strain was less than 4% for most failures. The minimum strain for the toppling failures was between 0.2% and 0.3%. The range of strain for a given RMR appears to be smaller for toppling than for rock mass failure, with only about one order of magnitude between the upper collapse and the rock mass/toppling boundary. The results for the rock mass and toppling failures suggest that 4% may be a reasonable maximum strain threshold to use for prediction of non-kinematic failures in poor- to fair- quality rocks.

Surprisingly, the results presented indicate that strain to collapse for the rock mass failures documented is lower than the strain for wedge-type failures for a particular RMR value, and is within similar ranges to those measured for planar failures. It would generally be expected that rock mass failures would occur in weak and deformable rock masses, resulting in higher strains leading up to collapse of a slope. This may simply be due to the limited data-set used in this study or to the use of 'rock mass failure' terminology as a catch-all for otherwise undefined failures. There is also a possibility that rock mass failure involves more internal strain that is not captured by measuring surface deformations. Further review of the database and/or additional data is required to evaluate this apparent inconsistency.

The results suggest that if the RMR of a pit slope can be estimated it can be used to define a range of strains that could typically be expected at collapse for a particular failure mechanism. The plots in Figures 3 and 4 indicate that there is a relatively well-defined boundary between the planar and wedge failures, and between the toppling and rock mass failures. Based on the data evaluated for this study, it is reasonable starting point to assume that 4% could be used as the maximum strain at which a pit slope failure could occur, regardless of the failure mode. It is noteworthy that this is twice the maximum strain value of 2% previously suggested by Brox and Newcomen (2003) and four times the strain value of 1% originally proposed by Zavodni (2001).

Assuming that pit wall movements can be projected forward and used to estimate the strain in the slope at some future point in time, the maximum strain thresholds proposed could be used for contingency planning. However, since the minimum strain at failure varies substantially and also appears to be sensitive to the failure mode, slope designers, and those responsible for implementing the designs, must have an understanding of the potential failure mode early on so that proper protocols are in place in the event that a slope progresses to complete collapse closer to the minimum strain threshold. This highlights the importance of establishing a reliable geotechnical data acquisition programme early on in the mine life.

The strain-based approach to failure prediction provides a reasonable 'first check' in the evaluation of the stability of a pit slope, and can be used to determine if further attention regarding monitoring is necessary. It could also be incorporated into the TARP for a particular slope instability, for example by specifying a maximum displacement of the slope at which further evaluations or more detailed stability assessments are required.

Other approaches to failure prediction

Inverse velocity

The Fukuzono (1985) inverse velocity method for predicting the time of pit slope failure has become a widely applied failure prediction method in the mining industry. One of the most notable applications of the inverse velocity method for failure prediction is by Rose and Hungr (2007), where the time of slope failure was successfully predicted in three open pit mines by linearly extrapolating the inverse velocity versus time trend to zero. The power of the inverse velocity method lies in its simplicity; however, care must be taken when applying this method as it is highly dependent on the user's understanding of the data source. Successive progressive-regressive phases of pit slope movement also complicate the use of this method.

One limitation of the inverse velocity method is the linear extrapolation of the inverse velocity versus time trend to zero. In reality, the inverse velocity is never zero since the velocity at failure is not infinite. In addition, the velocity at failure varies with the geological environment, failure mechanism, instability size, and slope angle. Depending on their understanding and experience at a particular site, those trying to predict when the failure is going to occur may have confidence in establishing a non-zero inverse velocity as the point of failure to ensure a more conservative time-of-failure prediction.

When conducting inverse velocity analysis, those analysing the monitoring data must also consider what data to include and exclude in their analysis and what data smoothing is required, especially when using ground-based radar measurements. Dick et al. (2015) provide recommendations on the application of the inverse velocity method in real time, based on the back-analysis of several slope failures monitored using ground-based radar. To improve the reliability of the inverse velocity analysis, they recommend including only data following the estimated onset of progressive deformation (Zavodni and Broadbent, 1980) and updating the analyses if a change in the accelerating deformation trend is observed. This is a significant limitation to the approach, as the onset of progressive deformation is not always obvious until failure is well underway.

Acceleration and velocity

Catastrophic pit wall failures are generally preceded by a significant increase in displacement rates; thus, accelerating pit slope displacements should be considered as an indication that failure is underway (Figure 1). Federico et al. (2012) present a collection of 38 case studies where the velocity and acceleration of a rock slope trending towards failure were measured, and proposed that there is a relationship between acceleration and velocity just prior to failure. The slope failures presented in the assessment range from natural slopes in clay shales to limestone quarry slopes and highly altered pit slopes in intrusive rocks. A wide range of failure mechanisms were included in the variety of cases presented, including one waste rock dump failure.

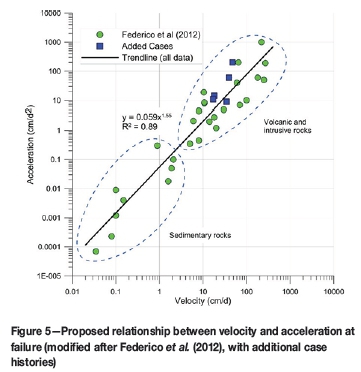

The proposed relationship between acceleration and velocity appears to be reasonable and therefore was further investigated. A modified version of the Federico et al. (2012) relationship between velocity and acceleration during slope failure is shown in Figure 5. Five case histories from the pit slope failure strain database (indicated by blue squares) were added and the waste dump failure was removed from the data-set. The additional case histories fall within reasonable proximity to the best fit trend line shown.

The ability of point-based monitoring systems to measure slope displacements, and thus calculate velocities and accelerations up to the point of failure, however, requires further scrutiny. For example, during pit wall failure it is unlikely that slope monitoring prisms could be accurately surveyed. However, area-based radar monitoring systems are able to collect data within seconds of slope collapse and should yield more insight to the validity of this approach to failure prediction, as long as the radar data can be corrected for the difference between the line of sight and the failure movement direction.

Selected slope failure case histories used to develop Figure 5 were reviewed in terms of the geology and potential failure modes. Pit wall failures in claystone, limestone, shale, and sandstone (sedimentary rocks), which are likely to be more prone to kinematically possible failures, appear to have generally lower velocities and lower associated accelerations. Failures in rock masses with less predictable or more complex geological structure (e.g. porphyry copper deposits) appear to have significantly higher velocities and accelerations. This may be a function of the failure mode and could possibly be related to the amount of strain at failure or strain build-up; however, the ability of the failure to deform internally also probably plays a role in the mobility and speed of the failure. The failures presented in Figure 5 may need to be further divided into brittle and ductile rock types, possibly using RMR to guide these divisions, to see if certain groupings become apparent and to determine if separate best fit trend lines are needed for these two groupings.

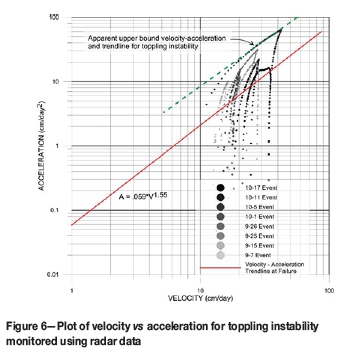

Velocity and acceleration data from area-based radar monitoring of a toppling instability in a pit wall excavated in deformable granitic rocks that appeared to be trending towards failure was used to test the relationship proposed by Federico et al. (2012), as illustrated on Figure 6. For reference, this toppling instability case has been plotted on Figures 2 and 4. The maximum strain measured for this pit wall was about 8%, which is twice as high as the recommended maximum strain of 4% for this failure mode, but less than half the strain of 15% measured for another toppling failure in the database.

The velocity and acceleration data (Figure 6) recorded by radar for this instability were smoothed using a 12-hour moving average to reduce the 'noise' in the radar measurements. As a result of the data smoothing technique, the velocity and acceleration values are lower than what was recorded incrementally. However, the smoother trend allows the important patterns in the data to be captured and results in less ambiguity when identifying the curve transition at the maximum recorded values.

It can be seen in Figure 6 that the pit slope of interest experienced eight periods of accelerating movements, with peak velocities of over 40 cm/d and accelerations in excess of 60 cm/d2. Higher velocities were measured during each subsequent movement event, confirming that the pit wall was accelerating as the pit was mined and suggesting that progressive failure might be underway. The velocity vs acceleration curves were plotted for each movement event and compared with the 'failure trend line' from Figure 5. The velocity-acceleration curves from the radar monitoring data crossed the trend line on all occasions; however, the toppling slope did not collapse as predicted, in spite of apparent progressive slope deformations.

Our assessment of this case history suggests that additional work is required to confirm the usefulness of this failure prediction tool, or that possibly the failure trend line needs additional calibration with monitoring data from more case histories. Figure 4 also indicates that the strain estimated for the toppling failure far exceeded the maximum strain threshold value for the toppling failures in the database and was close to the upper collapse boundary for that failure mode. Thus, collapse of the slope was anticipated for this particular pit slope using the strain-based approach to failure prediction.

Of potential significance is that the velocity-acceleration curves for the movement events of the toppling failure case history (Figure 6) appear to asymptotically approach a line that is parallel to the failure trend line developed from the modified database. It is unclear if this is a result of the data smoothing techniques applied to the radar data, or an indication that the slope of the failure trend line is accurate but modifications are required to the intercept on the acceleration axis. Alternatively, the data used in Figure 5 may need to be sorted by failure mode or rock type to develop failure trend lines for smaller data subsets (e.g. planar and wedge vs rock mass and toppling failures, or brittle vs ductile failures). With further sorting of this data it is possible that the velocity-acceleration approach to failure prediction could be used in conjunction with the strain-based approach to failure prediction presented in this paper.

Conclusions

The strain-based approach to failure prediction shows promise as a tool for developing a range of strain thresholds that could be experienced prior to slope collapse for various failure modes based on the quality of the rock mass. Planar slope failures generally experienced the lowest strain prior to collapse, and toppling failures generally experienced the highest strain. Surprisingly, the strain to collapse for the documented rock mass failures is lower than the strain for wedge-type failures for a particular RMR value; however, this may simply be due to the limited data-set used in this study.

The advantages of the strain-based failure prediction approach are:

► It is simple to use

► It can be used as a planning tool and to guide instrumentation selection

► It can be used as a first check to evaluate the slope risk level and to guide instrumentation

► Potential minimum strain thresholds can be assigned according to the anticipated failure mechanism

► Maximum strain thresholds appear to apply to most failure mechanisms.

The disadvantages of this approach are:

► Slope monitoring must be initiated early on in the development of the pit to accurately estimate the strain

► The strain at depth or along the failure plane are not captured

► If there are changes to the rock mass strength/quality over time due to deformation or to changes in the geology as the pit wall gets higher, this method of failure prediction requires caution, particularly if the RMR decreases at depth

► Predicting the strain to collapse for a particular rock mass requires an understanding of the potential failure mode of the pit slope.

The strain-based approach to failure prediction needs to be further tested by adding more data to the plots to further calibrate the strains for different failure mechanisms and a wider range of rock qualities. Comparison with other methods of rock mass classification may also yield further insight.

The inverse velocity method is useful as a failure prediction tool and is still the industry standard; however, the data requires a considerable amount of smoothing to get the inverse velocity plots to converge. Higher confidence in the failure prediction time is attained the closer the pit wall is to actual collapse. Displacement vs time plots can also be used to predict the time to failure and should still be reviewed as part of evaluations to identify when the pit wall is accelerating and trending towards collapse. The displacement vs time plots are also helpful to define the onset of failure (Figure 1).

The velocity-acceleration failure prediction method proposed by Federico et al. (2012) appears to have some limitations and requires more case histories to refine the currently proposed trend line. Further sorting of the data by failure mode, and possibly differentiating between brittle and ductile rock masses, may provide additional insight. If information on the failure mode and rock quality can be determined for those case histories, the velocity-acceleration method of failure prediction could possibly be used in conjunction with the strain-based approach presented in this paper.

Although the definition of 'collapse' of a pit slope is relatively straightforward, this still may not accurately reflect the behaviour of toppling or rock mass failures and may explain why there is still a significant amount of scatter in this data-set. Thus, further review of the failure case histories is required to determine if the term 'collapse' is appropriate for these failure modes.

The methods of predicting when a pit slope is going to collapse, as discussed here, require that accurate pit slope monitoring information be collected. The use of multiple methods of slope monitoring data collection and assessment is encouraged to test the usefulness of the various methods. Thus, it is proposed that all of the methods presented in this paper be used to assess failures so that decisions made regarding mitigation and risk management are well informed, increasing the confidence of the mine operators that have to work in close proximity to unstable pit slopes.

References

Bieniawski, Z.T. 1976. Rock mass classification in rock engineering. Exploration for Rock Engineering. vol. 1. Bieniawski, Z.T. (ed.). Balkema, Cape Town. pp. 97-106. [ Links ]

Brox, D. and Newcomen, W. 2003. Utilizing strain criteria to predict highwall stability performance. Proceedings of ISRM 2003 -Technology Roadmap for Rock Mechanics, Sandton, South Africa. 8-12 September. South African Institute of Mining and Metallurgy, Johannesburg. [ Links ]

Carter, R.A. 2014. Recovering from Bingham Canyon's record-setting 2013 slide. Engineering and Mining Journal, 6 May 2014. pp 46-47. [ Links ]

De Graaf, P. and Wessels, S. 2013. Slope monitoring and data visualization state-of-the-art - advancing to Rio Tinto Iron Ore's Mine of the Future. International Symposium on Slope Stability in Open Pit Mining and Civil Engineering, Brisbane. Australian Centre for Geomechanics, Perth. pp. 803-814. [ Links ]

Dick, G.J., Eberhardt, E., Cabrejo-Lievano, A.G., Stead, D., and Rose, N.D. 2015. Development of an early-warning time-of-failure analysis methodology for open pit mine slopes utilizing ground-based slope stability radar. Canadian Geotechnical Journal, vol. 52, no. 4. pp. 515-529. [ Links ]

Doyle, J.B. and Reese, J.D. 2011. Slope monitoring and back analysis of the east fault failure, Bingham Canyon Mine, Utah. Proceedings of Slope Stability 2011: International Symposium on Rock Slope Stability in Open Pit Mining and Civil Engineering, 18-21 September. Vancouver, Canada. Canadian Rock Mechanics Association. [ Links ]

Federico, A., Popescu, M., Elia, G., Fidelibus, C., Interno, G., and Murianni, A. 2012. Prediction of time to slope failure: a general framework. Environmental Earth Science, vol. 66, no. 1. pp. 245-256. [ Links ]

Fukuzono, T. 1985. A new method for predicting the failure time of a slope. Proceedings of the Fourth International Conference and Field Workshop on Landslides. Japan Landslide Society, Tokyo. pp. 145-150. [ Links ]

Martin, D.C. 1993. Time dependent deformation of rock slopes. PhD thesis, University of London. [ Links ]

Mercer, K.G. 2006. Investigation into the time dependent deformation behaviour and failure mechanisms of unsupported rock slopes based on the interpretation of observed deformation behaviour. PhD thesis, University of the Witwatersrand, Johannesburg, South Africa. [ Links ]

Nunoo, S., Tannant, D.D., and Newcomen, H.W. 2015. Slope monitoring practices at open pit porphyry mines in British Columbia, Canada. International Journal of Mining, Reclamation and Environment, vol. 30, no. 3. pp. 245-256. [ Links ]

Read, J. and Stacey, P. 2009. Guidelines for Open Pit Slope Design. CSIRO Publishing, Collingwood, Victoria, Australia. [ Links ]

Rose, N. D. and Hungr, O. 2007. Forecasting potential rock slope failure in open pit mines using the Inverse-velocity method. International Journal of Rock Mechanics and Mining Sciences, vol. 44. pp. 308-320. [ Links ]

Sullivan, T.D. 1993. Understanding pit slope movements. Proceedings of the Conference on Geotechnical Instrumentation and Monitoring in Open Pit and Underground Mining, Kalgoorlie, Western Australia, 21-23 June. Szwedzicki, T. (ed.). Balkema, Rotterdam. pp. 435-445. [ Links ]

Sullivan, T.D. 2007. Hydromechanical coupling and pit slope movements. Proceedings of Slope Stability 2007, Perth, WA, 12-14 September. Australian Centre for Geomechanics, Perth. pp. 3-43. [ Links ]

Varnes, D.J. 1982. Time-deformation relations in creep to failure of earth materials. Proceedings of the Seventh Southeast Asian Geotechnical Conference, Hong Kong, 22-26 November. McFeat-Smith, I. and Lumb, P. (eds.). Southeast Asian Geotechnical Society, Bangkok, Thailand. pp. 107-130. [ Links ]

Wessels, S. 2009. Monitoring and Management of a Large Open Pit Failure. MSc thesis, University of the Witswatersrand, Johannesburg. [ Links ]

Whittal, J., Eberhardt, E., Hungr, O., and Stead, D. 2015. Runout of open pit slope failures using and abusing the Fahrböschung angle. Proceedings of Slope Stability 2015: International Symposium on Slope Stability in Open Pit Mining and Civil Engineering, Cape Town, South Africa, 12-14 October. Southern African Institute of Mining and Metallurgy, Johannesburg. [ Links ]

Zavodni, Z.M. and Broadbent, C.D. 1980. Slope failure kinematics. CIM Bulletin, vol. 73, no. 816. pp. 69-74. [ Links ]

Zavodni, Z.M. 2001. Time-dependent movements of open pit slopes. Proceedings of Slope Stability in Surface Mining, Denver, Colorado. Hustrulid, W.A., McCarter, M.K., and Van Zyl, D.J.A. (eds.), SME, Littleton, CO. pp. 81-87. [ Links ]

© The Southern African Institute of Mining and Metallurgy, 2016. ISSN 2225-6253.

This paper was first presented at the, International Symposium on Slope Stability in Open Pit Mining and Civil Engineering 2015, 12-14 October 2015, Cape Town Convention Centre, Cape Town.