Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.116 no.4 Johannesburg Abr. 2016

http://dx.doi.org/10.17159/2411-9717/2016/v116n4a9

STUDENT EDITION - METALLURGY

The effect of particle size on the rate and depth of moisture evaporation from coal stockpiles

J. de Goede; B. Muller; Q.P. Campbell; M. le Roux; C.B. Espag de Klerk

School of Chemical and Minerals Engineering, North-West University, Potchefstroom, South Africa

SYNOPSIS

Excessive amounts of moisture in product coal can influence the efficiency of downstream utilization processes due to a decreased calorific value and handling problems. Stockpiles can be used to decrease the moisture content of coal by means of gravity drainage and evaporation. This paper is focused on the evaporation of moisture from a coal stockpile surface with the aim of investigating the effect of particle size on the rate of evaporation as well as the depth to which evaporation extends.

It was observed that moisture initially evaporates at a higher rate from a stockpile consisting of fine particles (-6.7 mm) than from coarser particles (-13.2 mm +6.7 mm). This high rate of evaporation is restricted to the outer shell of the fine coal stockpile. However, for coarse coal, the porous nature increases the depth at which evaporation occurs. Evaporation of moisture was observed up to the fourth day of each experimental run, after which steady state was obtained. It was shown the water can evaporate from the surface into the body of the stockpile, depending on the coal particle size and void spacing. An experimental reclaim depth of 0.4 m was achieved after 4 days.

Keywords: coal, stockpile, dewatering, depth of evaporation, rate of evaporation

Introduction

Coal stockpiles serve as surge capacity for downstream utilization processes and can also be used for moisture reduction by means of gravity drainage and evaporation. Excessive amounts of moisture in coal can cause handling problems and, most importantly, will decrease the calorific value, leading to inefficient combustion.

Research has shown that evaporation by means of wind and solar action is considerably more effective than gravity drainage(Williams, D.J. 2006), but the effect is limited to a restricted depth from the exterior of the stockpile (Boyapati, E. and Oates, A. 1994; CSEM-UAE, 2010). The effectiveness of wind and solar action can be improved by orienting the stockpile perpendicular to the predominant wind direction, maximizing the surface area of the pile, and reclaiming the coal from the pile gradually in shallow cuts over a large area (Williams, D.J. 2006).

The extent of evaporation is mainly influenced by the weather - in particular solar radiation, temperature, wind strength, and relative humidity (Deodhar, M.J. 2008; Fryer,

J.F. and Szladow, A.J. 1973) - as well as by the porosity, heat conductivity, and chemical nature of the coal particles (Karthikeyan, M., Zhonghua, W., and Mujumdar, A.S. 2009). Moisture from a coal stockpile surface will evaporate until equilibrium is reached between the ambient atmosphere and the coal particles. When the relative humidity increases as the temperature decreases, the coal particles can reabsorb moisture to re-establish equilibrium (de Korte, G.J. and Mangena, S.J. 2004; Karthikeyan, M., Zhonghua, W., and Mujumdar, A.S. 2009). This process of desorption and reabsorption can be repeated on a daily cycle(de Korte, G.J. and Mangena, S.J. 2004).

Sample preparation

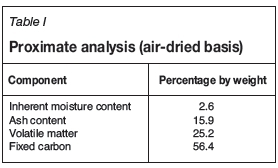

Washed South African bituminous coal from the Witbank No. 2 seam was used for the experiments. The proximate analysis of the coal can be seen in Table I.

The coal was used as received and was sieved into three size ranges: fine (-6.7 mm), total range (-13.2 mm), and coarse (-13.2 mm + 6.7 mm).

Experimental method

The objective of this investigation was to establish the effect of coal bed particle size on the rate and depth of moisture evaporation. The investigation was divided into two parts. In both cases saturated samples of the three different size ranges were prepared. The first experiment was designed to determine the depth to which evaporation extends. The samples were loaded into sectioned PVC pipes, using 12 pipes for each size range, and placed outside for 10 to 12 days and exposed to ambient conditions to facilitate the process of evaporation. In the second experiment, coal samples were placed in three shallow containers to investigate the rate at which moisture evaporates from a coal stockpile surface. These samples were exposed to ambient conditions while the masses of the containers were continuously measured. The experimental set-up included a weather station that continuously measured temperature, relative humidity, and wind speed and direction.

Apparatus

The PVC pipes for the first experiment were cut into seven 0.1 m sections and connected with duct tape as seen in Figure 1.

The shallow containers for the second experiment, with dimensions of 34 cm χ 25 cm χ 20 cm, were placed on load cells that continuously recorded the weight of the containers. This set-up can be seen in Figure 2. Both structures were covered with Perspex roofs.

Procedure

To determine the depth to which evaporation occurs, one PVC pipe containing each particle size of coal was removed on a daily basis for moisture analysis. The coal samples from each section of the three pipes were removed and weighed, then dried for 72 hours in a climate-controlled room at a constant temperature of 22°C and a constant relative humidity of 40%, and re-weighed. The samples were then placed in a vacuum oven at a constant pressure of 101.3 kPa and temperature of 105-110°C. for 6 hours. The inherent moisture content of the coal was determined by difference.

The evaporation rate (experiment 2) was determined by analysing the data from the data logger of the load cells and the weather station.

Results and discussion

Influence ofbed depth on moisture evaporation

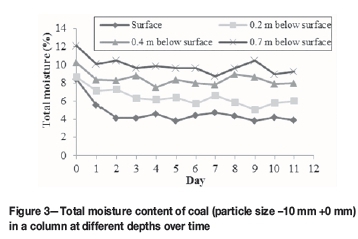

From Figure 3, a sharp decrease in total moisture content is noted from start-up to day two. This is due to drainage of moisture under gravity . From day two to day four, evaporation occurred from the top 0.2 m below the surface. From Figure 3 it can be seen that the coal samples reached steady state at day four, after which the total moisture content remained relatively constant until day twelve. This is an indication that no surface moisture is available to evaporate into the atmosphere. The void spacing of the coal bed had a major influence on the depth to which evaporation occurs. The coarse (-10 mm +6.7 mm) coal bed was more porous than the fine (-6.7 mm) coal bed. It was found that evaporation took place up to 0.4 m below the surface of the coarse coal bed, and that only the surface of the fine coal bed showed signs of evaporation.

Influence ofparticle size on moisture evaporation

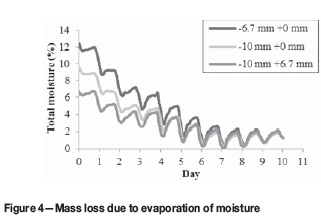

Figure 4 illustrates the cyclic behaviour in the mass loss profile of each size range. Evaporation generally occurred from 09:00 to 17:00 when the temperatures were high and the relative humidity low. As evening fell, the temperature decreased and the relative humidity increased, resulting in the reabsorption of moisture into the porous coal particles as the particles tried to stay in equilibrium with the atmosphere.

It can be seen that all coal samples reached the same moisture content by the end of the experimental run. The coarse coal sample reached the final moisture content first.

To compare the effect of particle size on the rate of evaporation, the daily rates of evaporation were calculated for each size range as shown in Figure 5. It can be seen that moisture initially evaporates faster from the fine coal sample (-6.7 mm) than from the other coal samples. After two days, the surface of the fine coal sample was dry and the rate of evaporation decreased. The same phenomenon was seen in the experiments that investigated the depth to which evaporation occurs. This is attributed to the porous structure of the coarse sample.

During the investigation, it was found that the initial moisture content had an influence on the rate of evaporation. A lower initial moisture content resulted in a lower maximum rate of evaporation.

Conclusions

This study showed that bed particle size affects the extent of moisture evaporation, and that the porous structure of a coarse coal stockpile aids the process. Experimental results indicate that moisture drainage takes place within the first two days of exposure to environmental conditions. Evaporation of moisture can be seen up to the fourth day, but this is a function of the initial moisture content of the coal. Coal with a higher initial moisture content will take a longer time to lose all surface moisture.

It was shown that water can evaporate from underneath the surface of coal stockpiles. Increased void spacing has a positive influence on the effectiveness of evaporation for coal stockpile drying. The results obtained in this study can be used to manage stockpiles efficiently. Up to 0.4 m of coal can be reclaimed from the stockpile surface and the remaining coal can be left to dry for another four days - if no rain occurs.

Acknowledgments

The authors would like to thank the following institutions for their contributions towards this project:

>Coaltech

>NRF (National Research Foundation).

This paper is based on project work carried out in partial fulfilment of a degree in Chemical Engineering at North-West University (NWU). The research was supported by the South African Research Chair's Initiative of the Department of Science and Technology and the National Research Foundation of South Africa (NRF). Any opinion, finding, or conclusion or recommendation expressed in is that of the authors and the NRF does not accept any liability in this regard.

References

Boyapati, E. and Oates, A. 1994. A mathematical model for stockpile management. 6th International Working Conference on Stored-product Protection, Canberra, Australia, 17-23 April 1994. pp. 684-688. [ Links ]

CSEM-UAE Innovation Center. 2010. Water evaporation rate at Ras-Al- Khaimah, UAE. http://www.csem-uae.com/pdfs/Water%20Evaporation%20rate%20%20in%20Ras-Al-Khaimah,%20UAE [Accessed 18 June 2014]. [ Links ]

de Korte, G.J. and Mangena, S.J. 2004. Thermal Drying of Fine and Ultra-fine Coal. CSIR.Fryer, J.F. and Szladow, A.J. 1973. Storage of coal samples. Alberta Geological Survey, Edmonton. [ Links ]

Deodhar, M.J. 2008. Elementary Engineering Hydrology. Pearson Education, India. Dorling Kindersley. [ Links ]

Karthikeyan, M., Zhonghua, W., and Mujumdar, A.S. 2009. Low-rank coal drying technologies-current status and new developments. Drying Technology, vol. 27. pp. 403-145. [ Links ]

Priyal, D. and Toerien, A. 2010. The effect of salinity on evaporation rates of brines resulting from the treatment of mine water.http://www.google.co.za/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&cad= rja&ct=8&ve d=0CCcQFjAA&url =http%3A%2F%2Fwww.ewisa.co.za %2Fliterature%2Ffiles%2F200_150%2520Dama-87Fakir.pdf&ei=7I6LU5TcFqzA7AaH6oF4&usg=AFOjCNForf8NhOQ3zVqS90GVcrPPBldPOw &bvm=bv.67720277,d.ZGU Date of access: 18 June 2014. [ Links ]

Williams, D.J. 2006. Application of Unsaturated Soil Mechanics to Product Coal Dewatering. Australian Mining Technology Conference, Hunter Valley, NSW, 26-27 September 2006. [ Links ]

Paper received Feb 2016.

Paper written on project work carried out in partial fulfilment of B.Eng. (Chemical Engineering with specialisation in mineral processing)